1. Introduction

The nano-patterning techniques for nano-imprint lithography (NIL) have attracted many research groups due to its practical implication on an industrial scale. Ahn et al. [

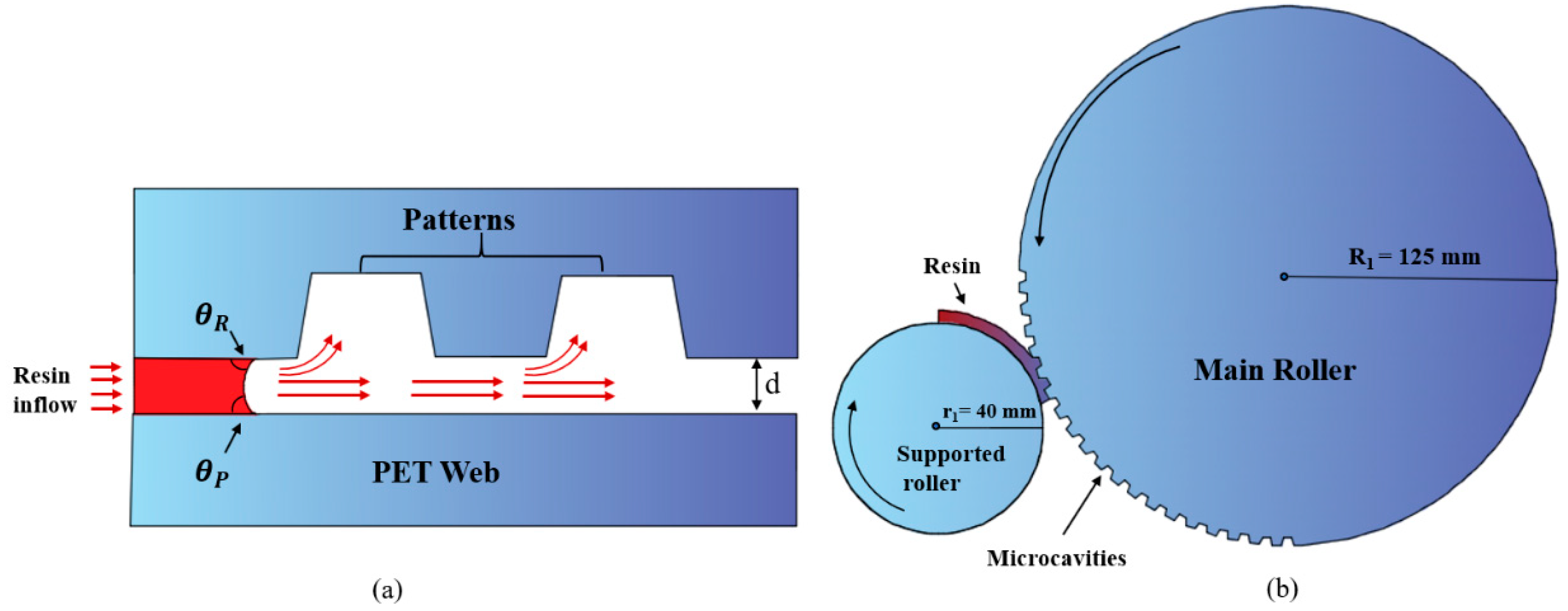

1] were the pioneers who introduced roll-to-roll ultraviolet nano-imprint lithography (R2R-UV-NIL) by replicating lenticular lens patterns on polyethylene terephthalate (PET) substrate. R2R-UV-NIL is one of the most promising technologies that fabricate low-cost, high-throughput, and large-area micro/nano features on functional films. R2R-UV-NIL is a process-based batch NIL used to replicate nano/micro-scale patterns from a surface of the patterned mold to a large area of the flexible or rigid substrate. Due to wide applications of R2R-UV-NIL in several fields, it has been studied broadly by numerous researchers working in the area of electronic devices [

2], polarizers [

3], transistors [

4], and solar cells [

5], etc. On the commercial scale, productivity in the development of flat display panels [

6], biotechnological applications [

7], and optoelectronic devices [

8] is yet to meet with standards. High fidelity and productivity in NIL represent the complete filling of resin in nano/microcavities or exact replication of imprint patterns from the imprinting mold on a PET or polydimethylsiloxane (PDMS) substrate.

Due to the complex setup and fluid flow into the microcavities, R2R-UV-NIL is rarely studied by the research community. The mathematical models are the comprehensive way to explore the R2R-UV-NIL process. Numerous researchers [

9,

10,

11,

12,

13] studied the R2R system through different numerical models and they suggested varied solutions to achieve high fidelity during the imprinting process. Jain et al. [

9] derived a mathematical model for droplet dispensing of UV resin on the substrate. For imprint material, they used the Maxwell model due to the material’s viscoelastic nature and discussed different processing parameters such as the merging of droplets on the substrate, the peeling off of the resist layer, the exposure time, and the pressure profile of the imprint layer by using lubrication theory [

14,

15]. Ye et al. [

12,

13] categorized numerical models for bubble entrapment with regular bubbles and irregular bubbles during the R2R imprinting process. They discussed the point that the resin’s viscosity, contact angles, and aspect ratios play a great role in the quality of the final product. They also discussed the fact that, by varying the imprint velocity beyond a certain value for a particular experimental setup, bubble entrapment occurs. They suggested that low aspect ratio, low viscosity, and small contact angle are the key parameters for complete filling of resin into the microcavities. Song et al. [

11] employed a coupled Eulerian-Lagrangian algorithm and considered the effect of solid backing film and UV resin flow during R2R imprinting. They conducted numerical simulations for UV resin filling into rectangular patterns at different PET web speeds without considering the air into their model. The implication of air in R2R-UV-NIL cannot be ignored at the industrial level. Peng et al. [

10] used two-phase fluid flow by considering the air in their three-dimensional numerical model and discussed the resin flow behavior in pyramid-shaped microcavities. They also considered the effect of processing parameters like viscosity, pressure, inlet speed, and pyramidal structure direction. All of the above discussed numerical studies only consider the small part of the imprinting system, which is most similar to plate-to-plate imprinting and cannot define the whole physics of the problem. Most recently, Zhou et al. [

16] used a two-phase flow model and discussed UV resin filling into the microcavities only at the preceding end of the imprinting mold. In their numerical model, they used a two-body system with an interface between the mold region and outer region. However, UV resin filling at both (preceding and succeeding) ends of the imprinting mold is yet to be addressed by considering the whole physics of the problem through numerical simulations.

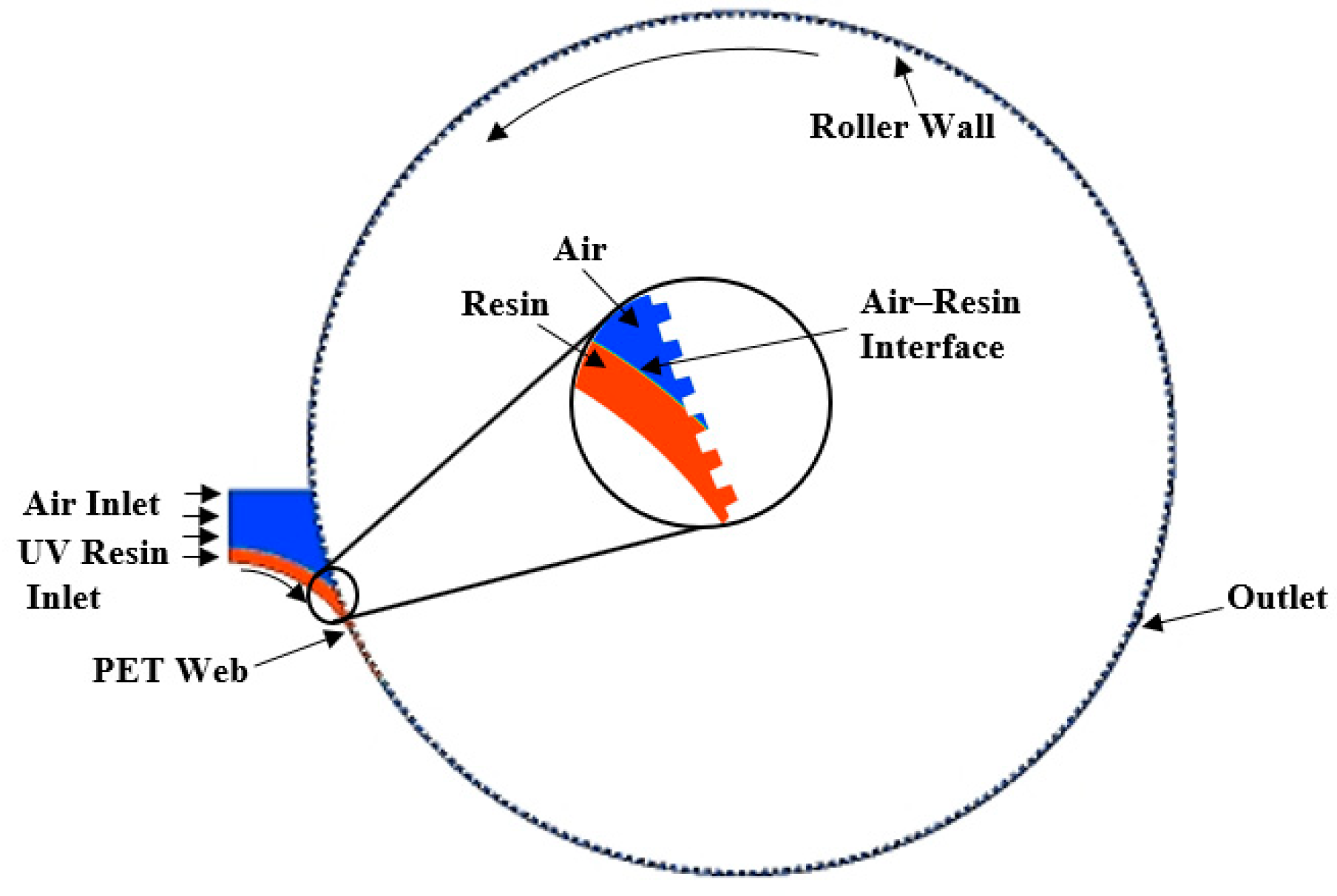

The objective of the current work was to optimize the filling process during R2R imprinting with a modified numerical model that was based on a single zone with no interface between the mold and outer regions. This model simulated the direct contact of UV resin with mold during the imprinting process. In addition, the model simulated UV resin filling into the microcavities at both ends (i.e., preceding and succeeding) with more accuracy. The optimization of important parameters such as PET web speed, contact angles, and pattern shape for complete filling was also studied through the proposed numerical model. Experiments were conducted by considering the optimized parameters using the numerical model and they resulted in successful imprinted patterns without bubble entrapment. Experimental results validated the successful imprinted patterns without bubble entrapment using optimized parameters.

Section 2 presents the numerical model and open-channel boundary conditions.

Section 3 presents the experimental setup regarding the numerical model and results are discussed in

Section 4. Finally,

Section 5 concludes this study.

3. Experimental Setup

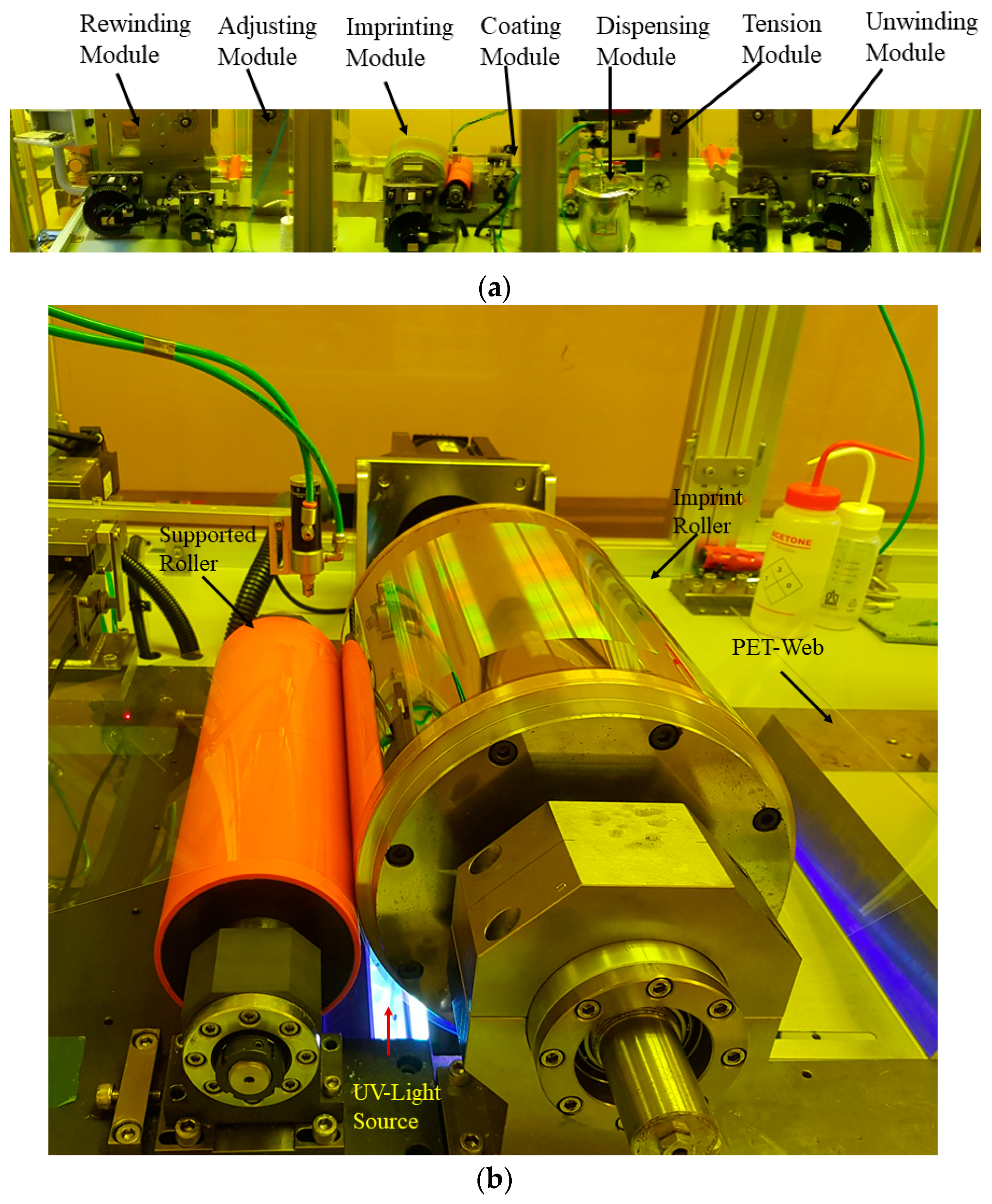

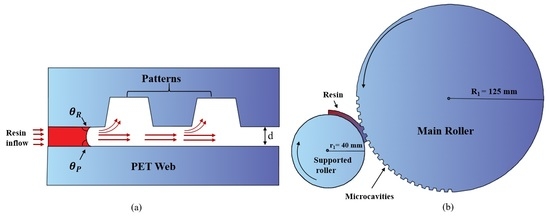

The R2R-UV imprinting system is shown in

Figure 4a. The experimental system consists of different modules other than the imprinting module. These modules provide support for the imprinting module to conduct the imprinting process properly. The device contains seven modules, namely, unwinding module, tension module, dispensing module, coating module, imprinting module, adjusting module, and rewinding module. The unwinding module supplies the PET film without coating. The thickness of the PET film (Kolon polyester film, Daegu, Korea) used as a substrate was 125 μm. The tension module is responsible for creating tension at the two ends of the PET film so that the film moves properly into the imprinting process. The dispensing module consists of a resin cylinder that can possibly evacuate the bubbles from the resin and drop-casting unit [

15]. The adjusting module adjusts the wrap angle between the stamp roller and the PET substrate.

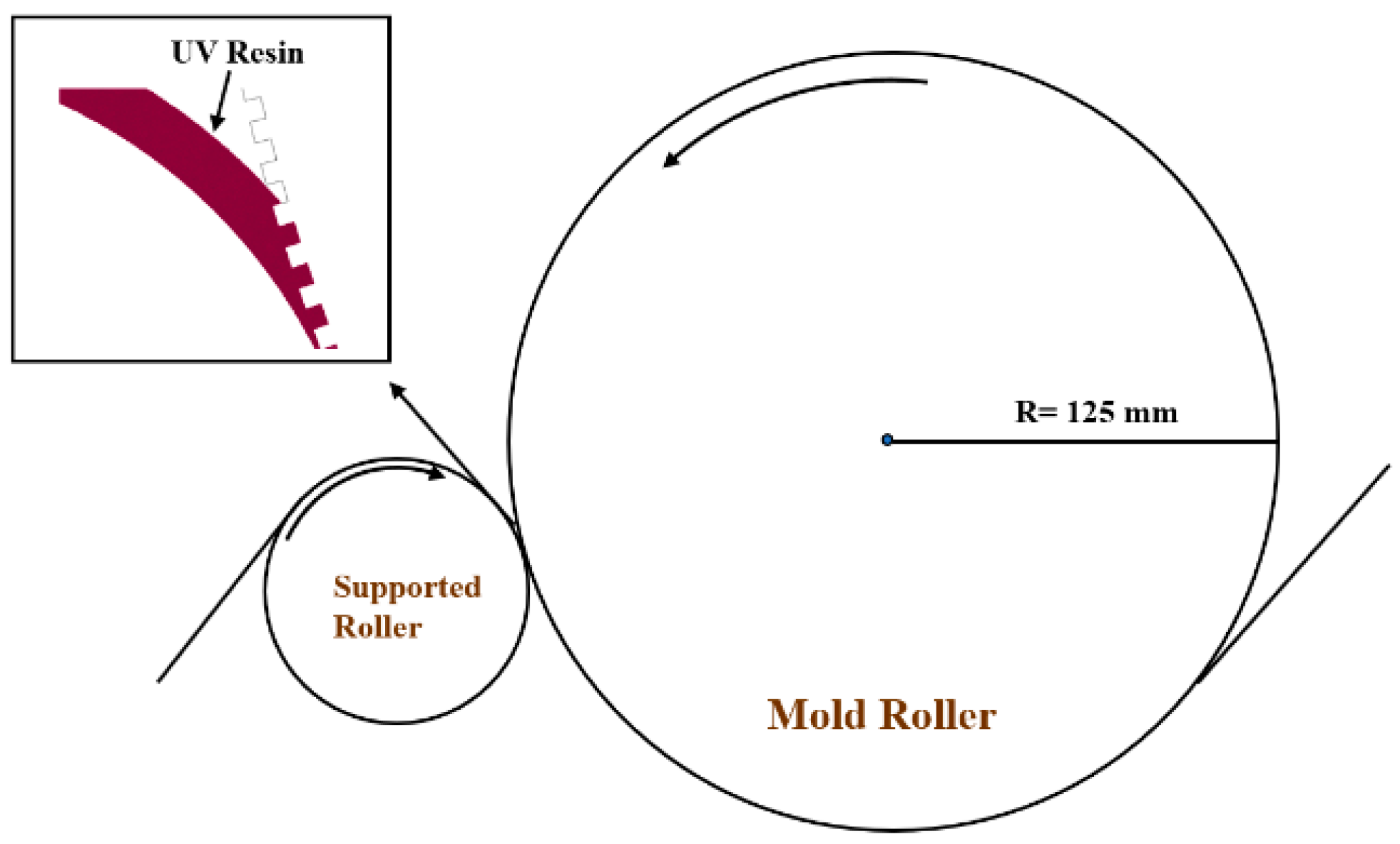

The main module of the device is the imprinting module that consists of a supported roller with a diameter of 80 mm, a stamp roller with a diameter of 250 mm having a rectangular pattern with a tapering angle 5° and a UV light underneath the rollers that cures the resin. The magnified view of the imprinting process is shown in

Figure 4b.

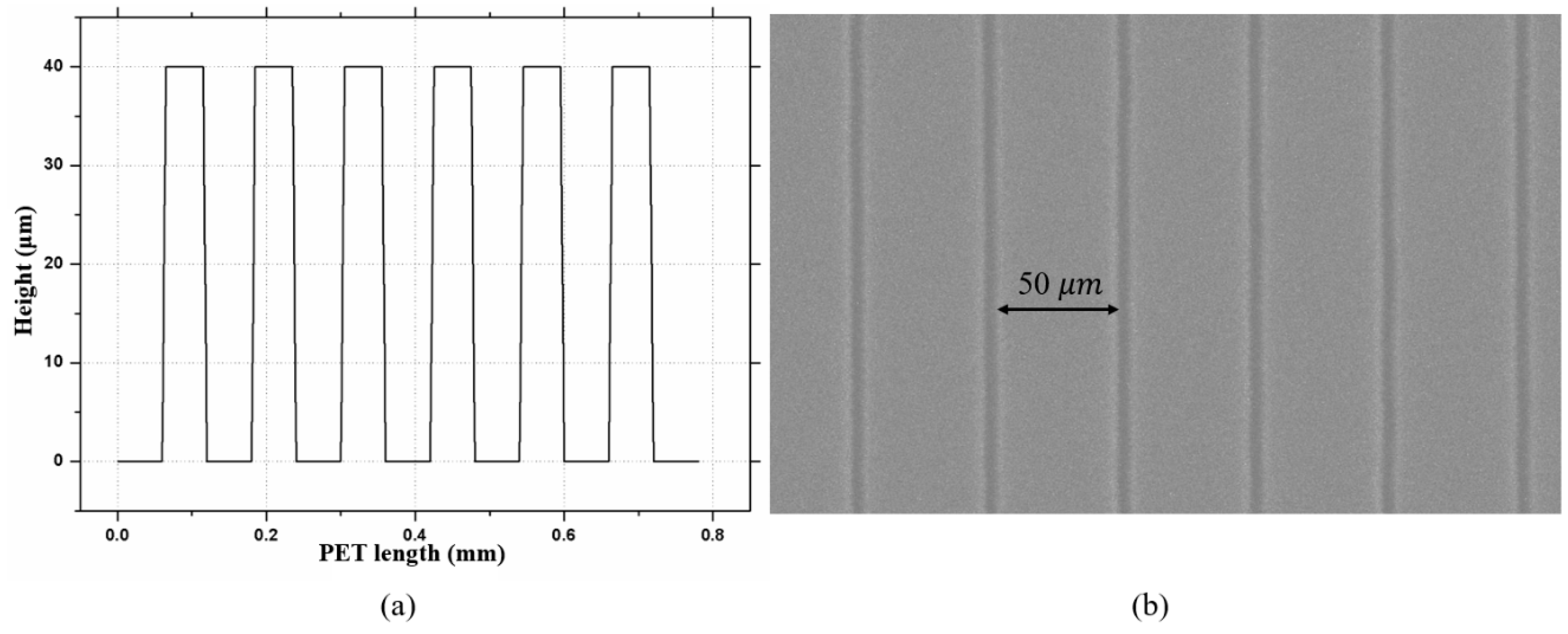

The height and width of the line patterns were 40 and 50 μm, respectively. In the imprinting module, the imprinting force was applied between the stamp roller and the supported roller to fill the resin into the microcavities and, after filling, the UV- light cured and solidified the resin. The rewinding module pulled back the imprinted pattern onto the PET substrate. Further, these patterns were analyzed by scanning electron microscopy (SEM, SNE-3200M, SEC Co., Ltd., Suwon, Gyeonggi, Korea) to check the pattern shape and size on the PET substrate. During the experiments, the resin was dispensed by drop-casting unit evenly onto the PET web film and this method made the coating more uniform than the original coating method (roll coating method). The UV light was a light-emitting diode (LICHTZEN, Gunpo, Korea) used to cure the resin under the imprinted module. The UV lamp threw the light at the focus point with an intensity of 800 mW/cm2 and cured the resin at a wavelength of 365 ± 5 nm. The resin used in the experiments was produced by Minuta Technology Co., Ltd. (MINS-311R, Osan, Korea; viscosity: 0.1 Pas at 25 °C).

4. Results and Discussion

R2R-UV imprint model simulations for optimal filling depend on different parameters such as contact angles, pattern shape, speed of the filling, aspect ratios, and viscosity. To optimize the filling process, different simulations were performed in this study considering different parameters; also, in addition, the experiments were conducted considering the numerical simulations. A complete setup was studied during the numerical simulations. An imprint mold with rectangular patterns and rectangular patterns with a tapering angle and V-shape patterns with different aspect ratios (i.e., 0.75, 0.8) were thoroughly studied with this numerical model.

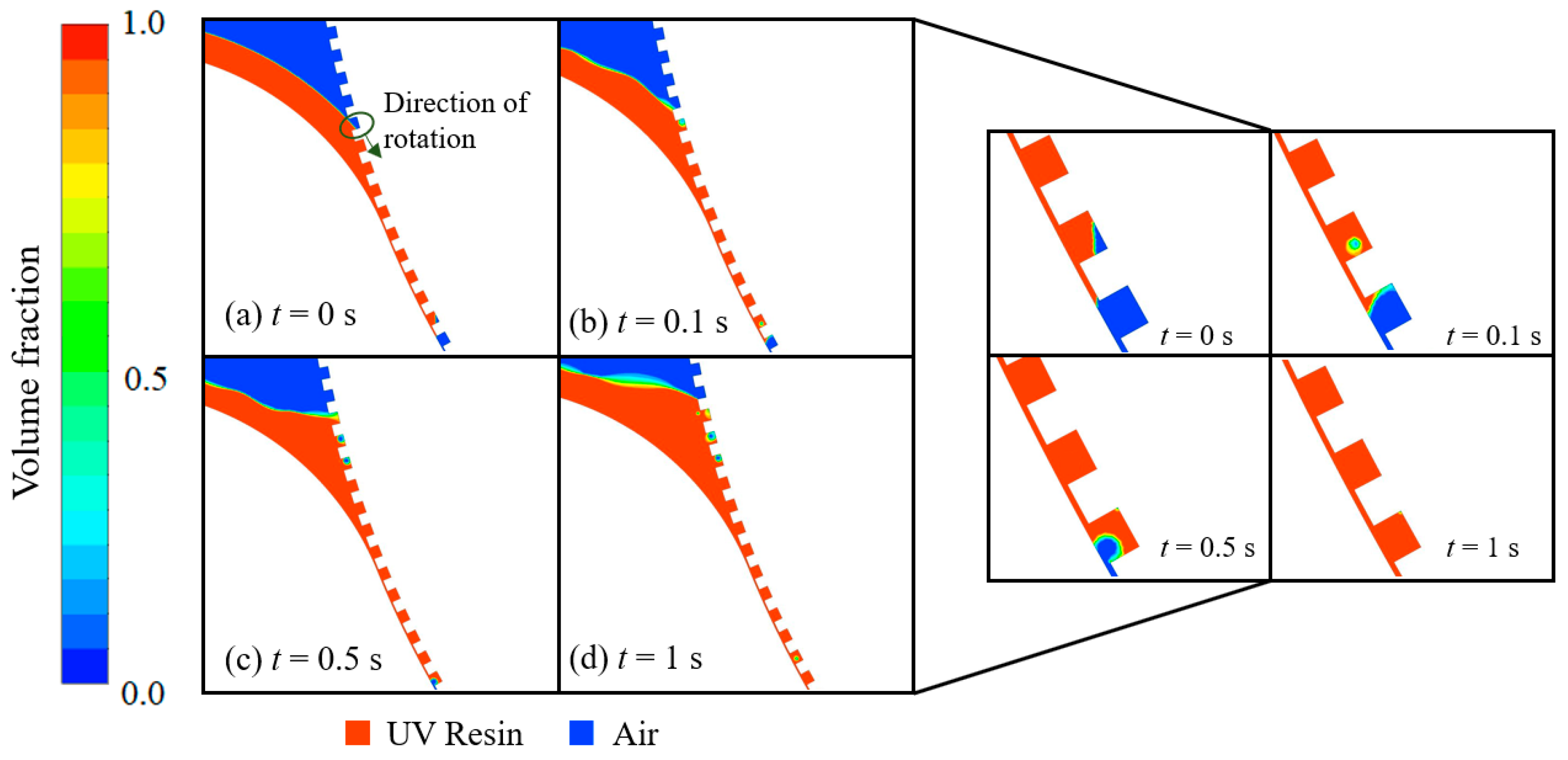

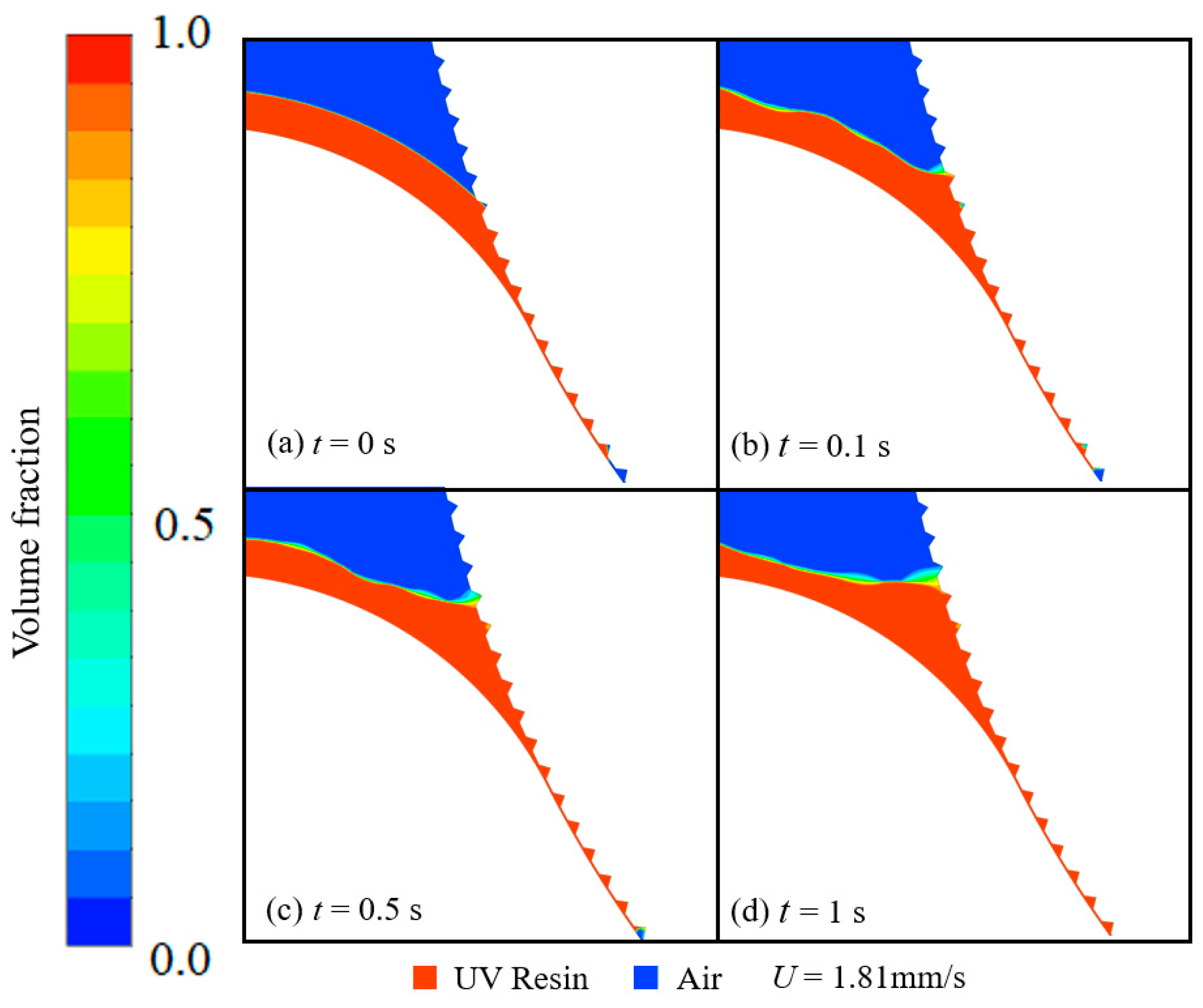

Figure 5 shows the filling process into rectangular microcavities at different time-steps.

Figure 5a shows the UV resin flow field and the air above the UV resin at time

t = 0 s. When the imprint mold starts to rotate, the PET web delivers the resin into the microcavities at the same time. At a specific rotational velocity of the imprint mold, the air starts to escape into the microcavities, which are filled by UV resin. The UV resin flows into the microcavities from the two ends of the imprinting mold, called the preceding end and the succeeding end. When UV resin starts to fill the microcavities, some backflow of UV resin occurs at the preceding end of the imprint mold. The UV resin filling at the succeeding end is shown in magnified view in

Figure 5b–d. At time

t = 0.1 s, UV resin fills the first microcavity and leaves the microcavity with incomplete filling as shown in

Figure 5b. Over time, UV resin fills the first microcavity completely and starts filling the second microcavity at

t = 0.5 s, as shown in

Figure 5c. The second microcavity is completely filled with UV resin at time

t = 1 s, as shown in

Figure 5d. In

Figure 5b–d, it can be seen at the preceding end that the backflow of UV resin does not fill the rectangular microcavities, which can cause bubble defects at any stage of the imprinting process. In our numerical model, the microcavities on the imprint mold change their reference position with respect to time, so these bubble defects can be ignored, but at any stage of the imprinting process these bubble defects may affect the quality of the final product. Therefore, we tried to resolve this issue by using a tapering angle for the rectangular microcavities.

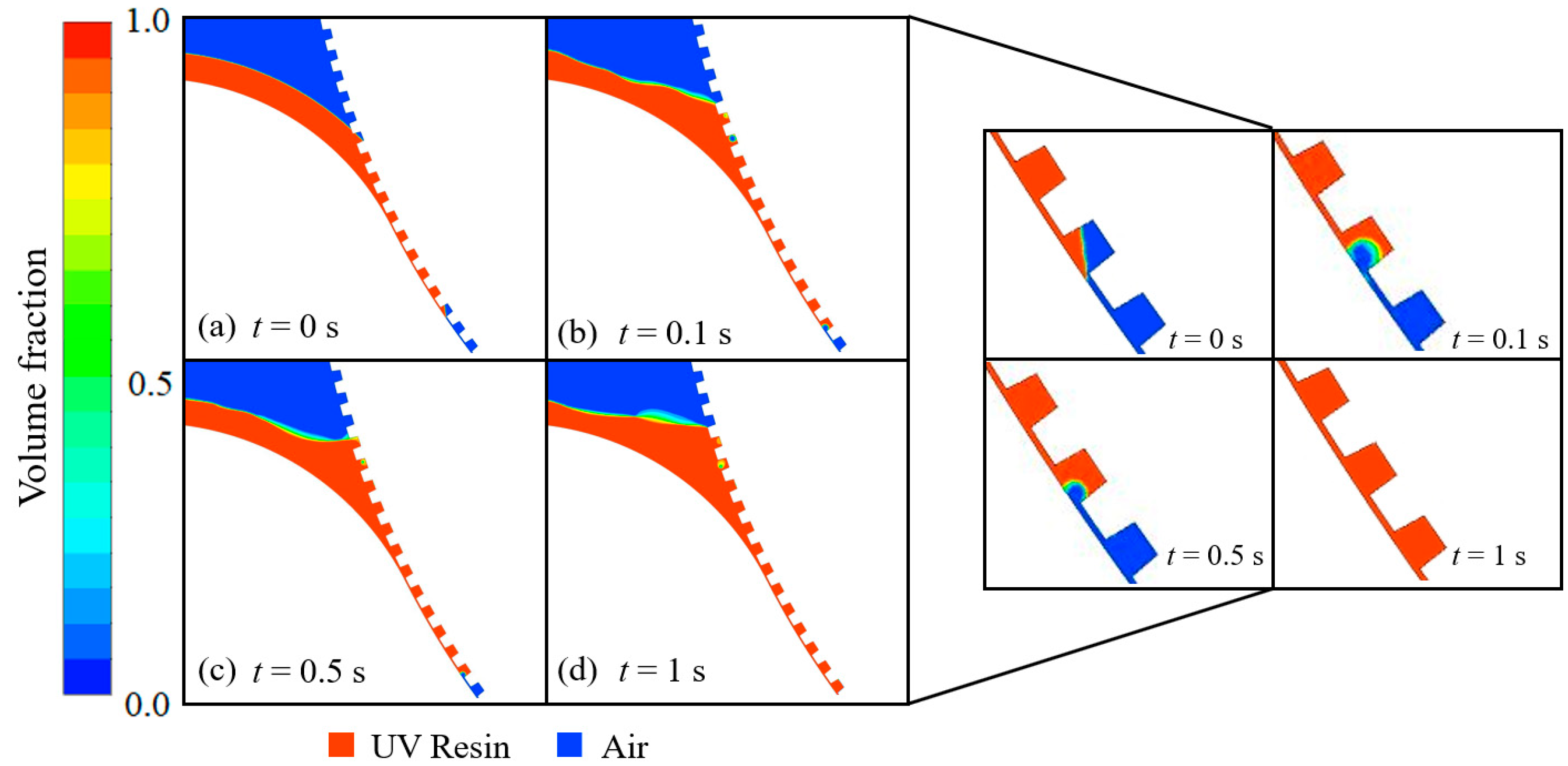

Figure 6 shows the filling process into rectangular microcavities with a tapering angle of

at different time-steps.

Figure 6a shows the UV resin flow field at time

t = 0 s.

Figure 6b–d represents the UV resin filling into microcavities at the preceding and succeeding ends of the imprint mold at time

t = 0.1 s,

t = 0.5 s, and

t = 1 s, respectively. It can be seen that UV resin fills the microcavities successfully at the preceding and succeeding ends. The contact angles and PET web speed for rectangular patterns, with a tapering angle of 5°, were kept the same as for the rectangular pattern’s simulations as displayed in

Figure 5. The suitable contact angles measured for the filling process are

and

, where

and

represent the contact angle of resin to the imprint roller and the contact angle of resin to the PET web, respectively. The contact angle between the resin and imprint roller is very important during the filling process in numerical simulations and its values differ with respect to pattern shape; therefore, we keep both contact angles within a feasible range to obtain the complete filling into microcavities. It is also noted that the contact angle between the resin and the roller should be in a specific range to optimize the filling process rather than the contact angle between the resin and the PET web. The PET web speed noted in this study for successful filling into microcavities is 24.2 mm/s.

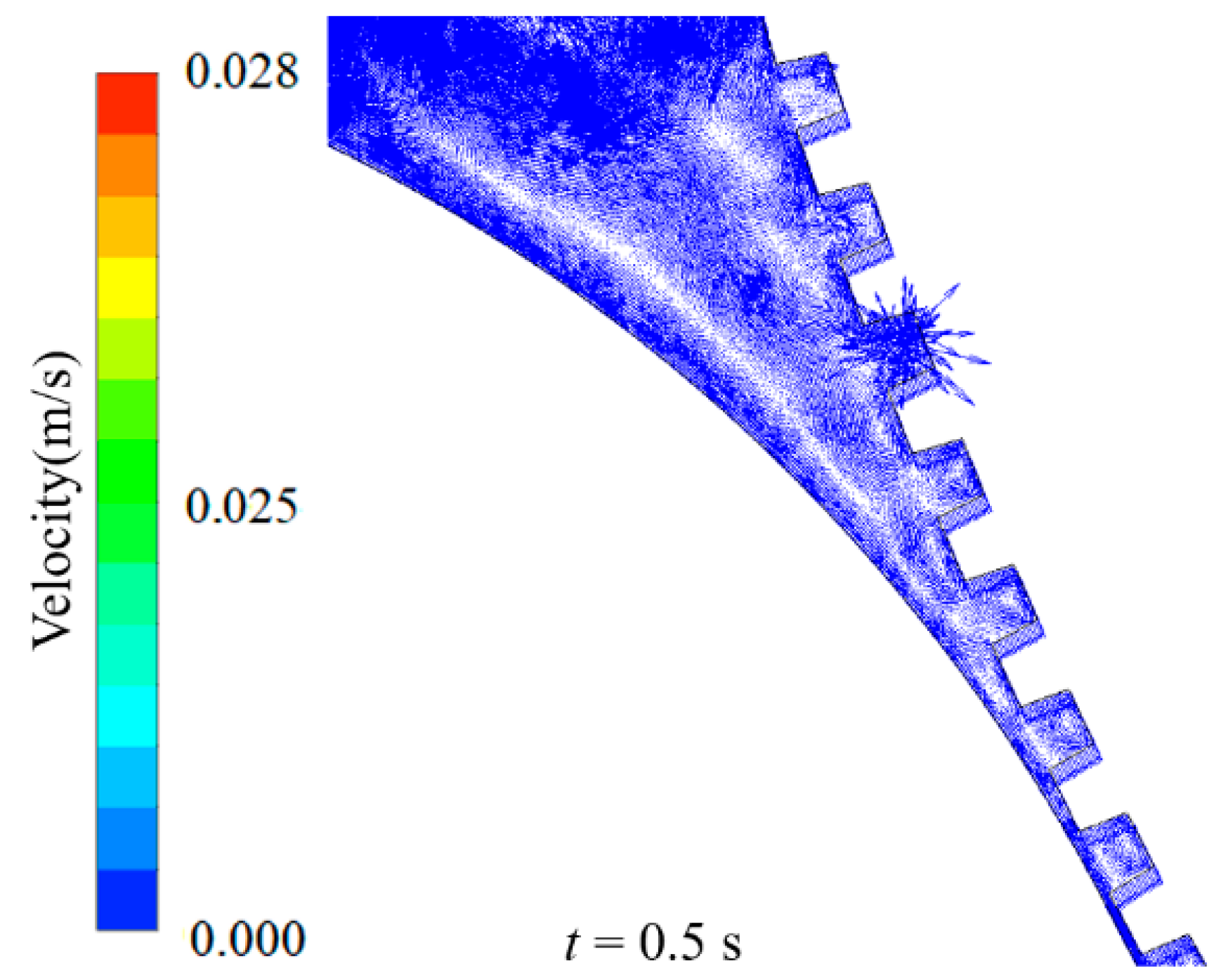

Figure 7 shows the contours for the velocity vector distribution in the flow field of resin–air phases, the rotational movement of the roller, and the successful filling of backflow into the microcavities. It can be seen from the velocity vectors that resin flows from the two ends of the imprint roller. The vortices [

22,

23] show that resin slows down for some time and waits for the air to escape into the microcavities and, after escaping, the resin fills the microcavities.

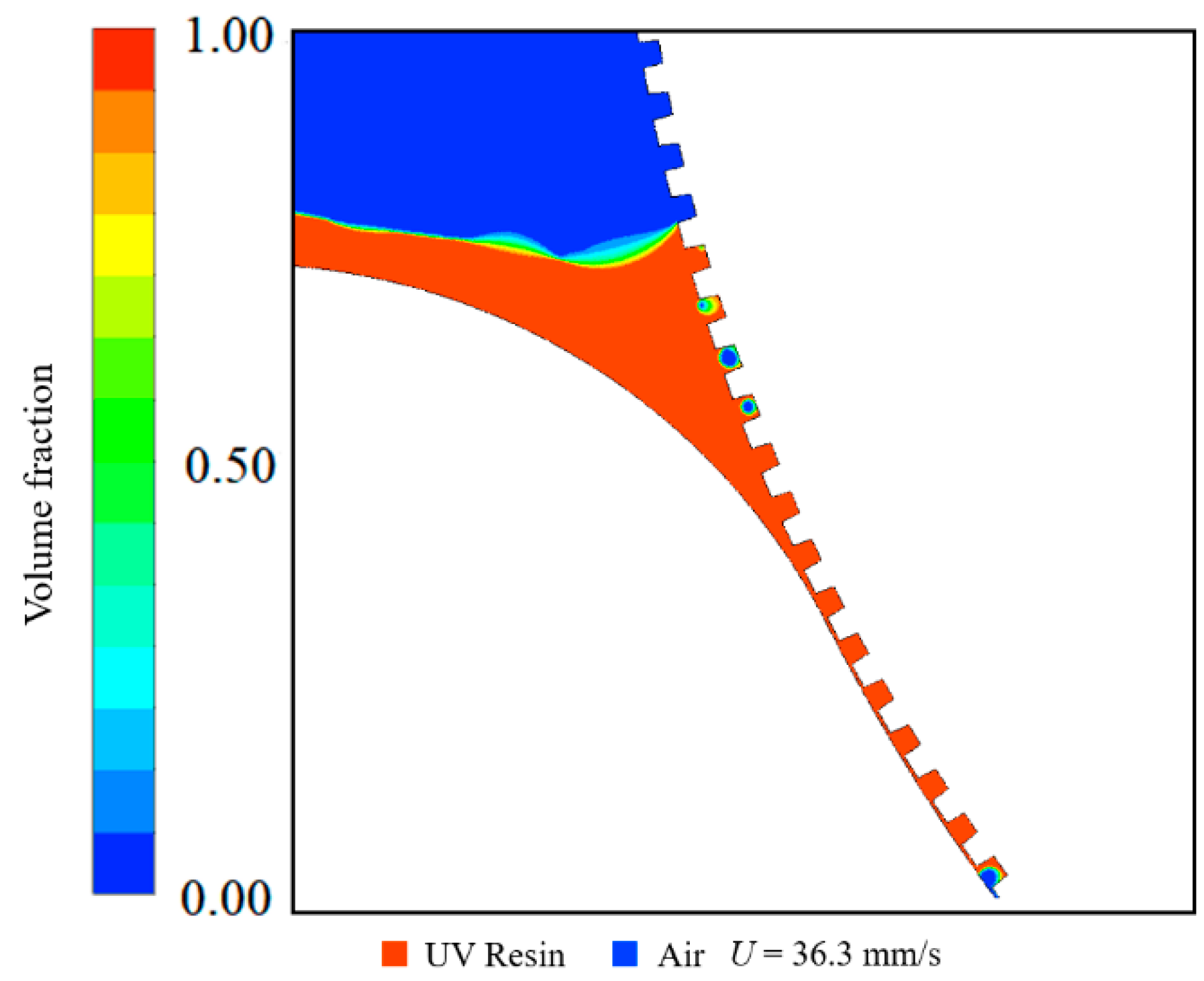

Figure 8 shows the incomplete filling at the rotating mold’s high speed. When UV resin enters into the microcavities at high speed, it leaves the microcavities with incomplete filling. It can be seen from

Figure 8 that the UV resin fails to fill the cavities from both sides of the imprint mold.

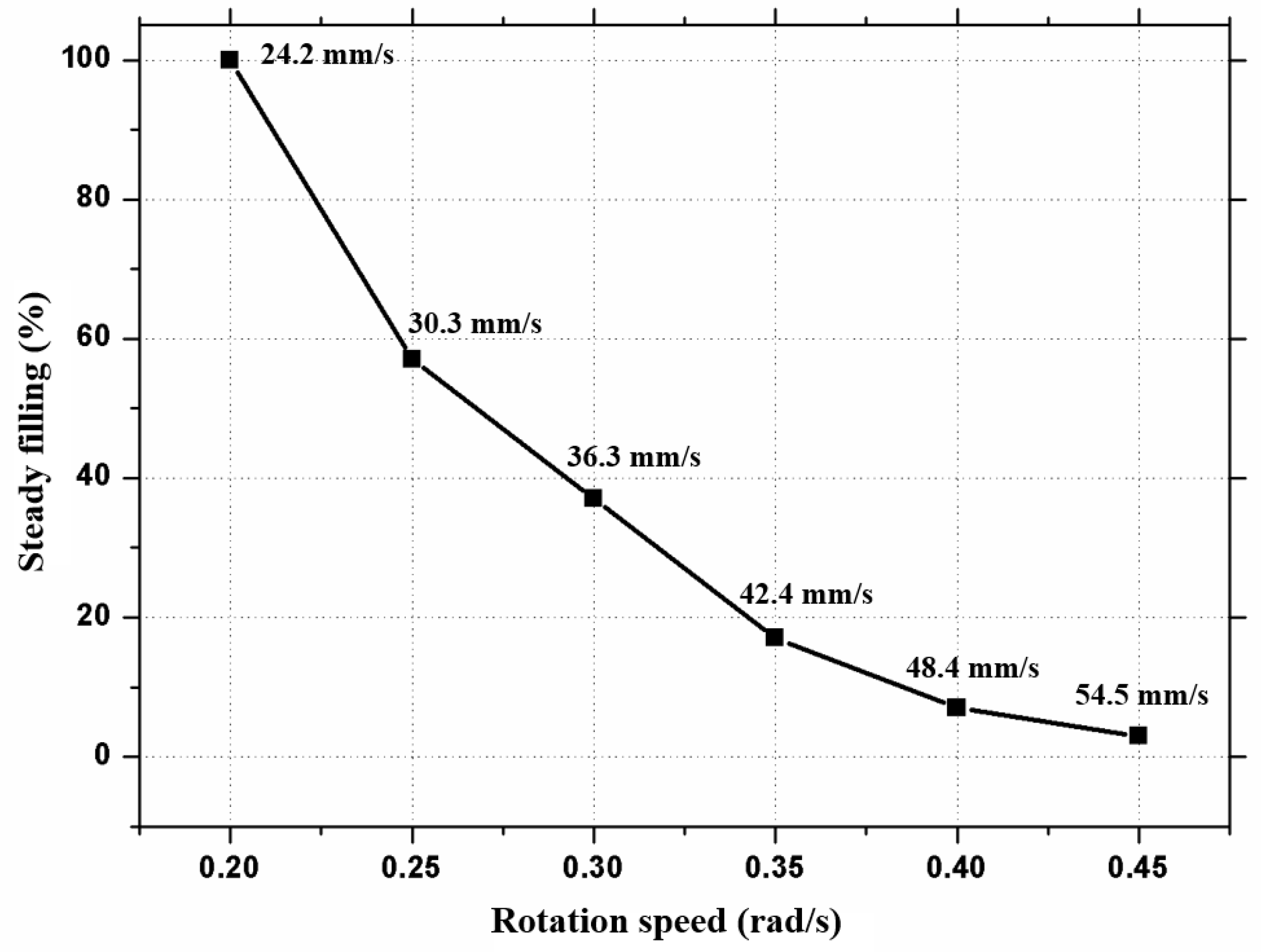

Figure 9 represents the steady filling at different rotation speeds or PET web speeds. Different numerical simulations were conducted at high speed and it was observed that, above a specific speed, the UV resin left the microcavities with incomplete filling.

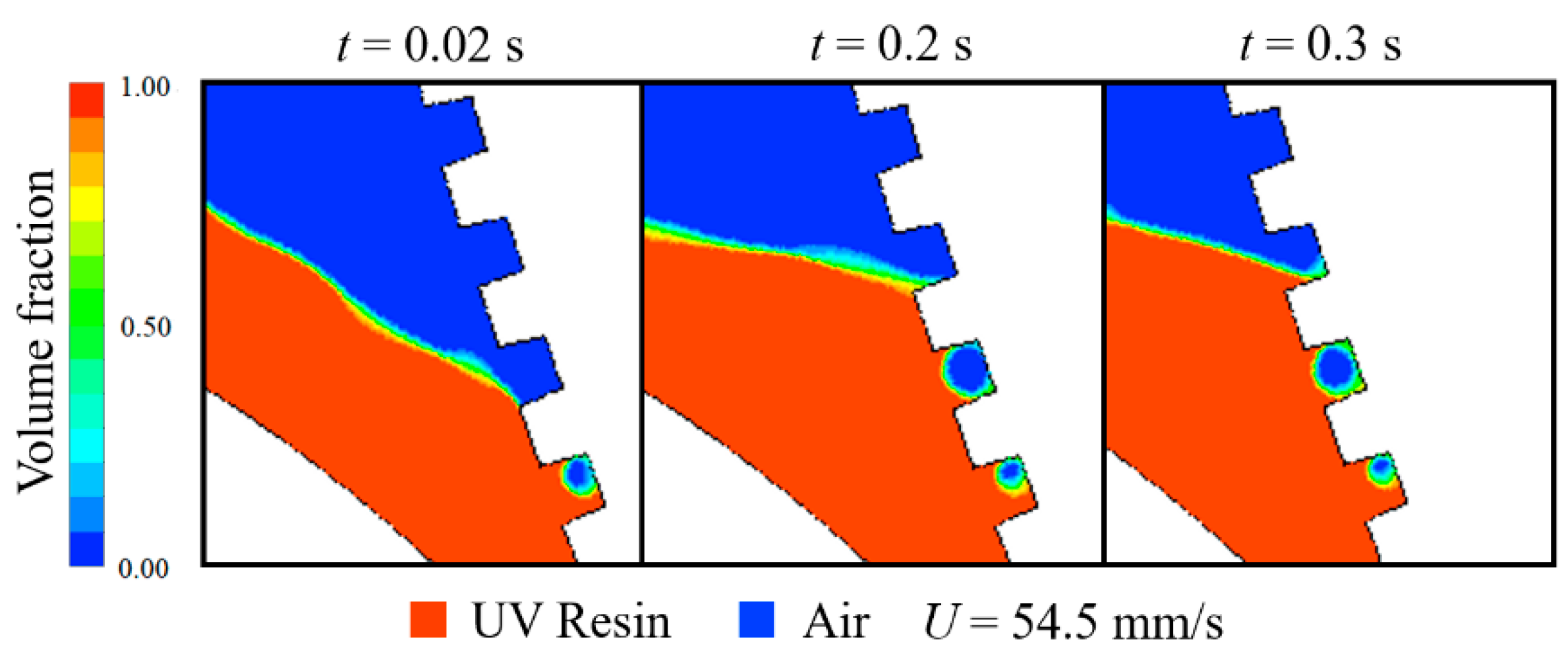

Figure 10 represents the backflow incomplete filling of cavities from time

t = 0.02 to 0.3 s at a PET web speed of 54.5 mm/s. It is evident that the air cannot escape at that speed and that bubbles formed into the cavities. It can be concluded that air entrapment occurs if the system’s speed increases beyond a barrier speed.

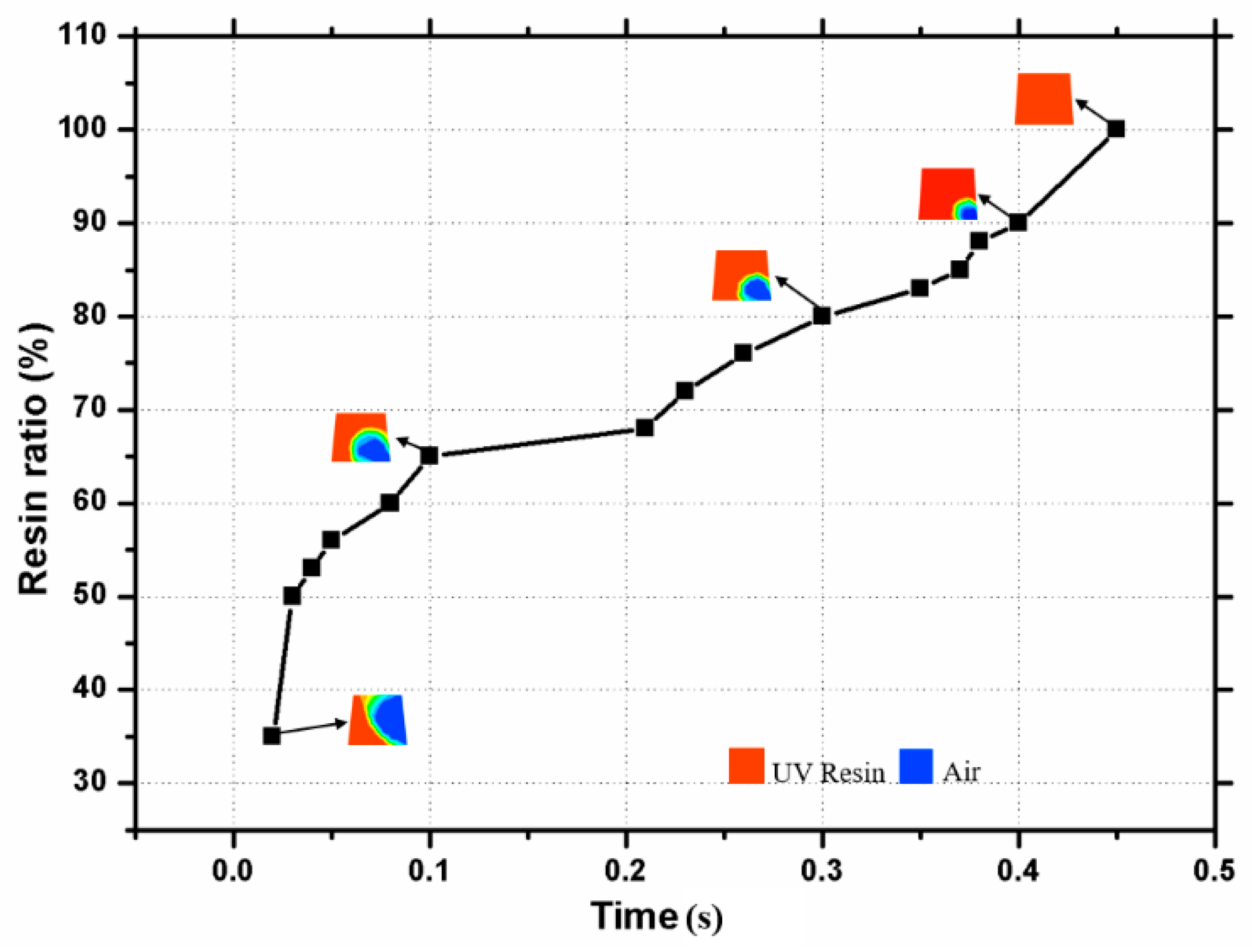

Figure 11 presents the resin percentage with time at a PET web speed of 24.2 mm/s. UV resin starts to move into the microcavity at

t = 0 s. It can be seen at

t = 0.1 s that the resin fills the cavity to approximately 65%. With a continuous supply of the UV resin with time, this air entrapment starts decreasing, and it vanishes at

t = 0.45 s.

Figure 12a–d represents the numerical simulation results for V-shape patterns with an aspect ratio of 0.75 at different time-steps and considering the previously studied numerical simulation parameters. The resin fills the V-shape microcavities at the optimal speed discussed in a previous study [

16]. These results validate our numerical model based on a single zone with a rotating imprinting wall as shown in

Figure 3. Furthermore, by removing the interface between the outer part and the mold cavities, resin filling behavior can be observed more realistically. The numerical simulations also show that, by increasing the tapering angle, the air easily escapes from the microcavities and they fill easily with resin. Therefore, it is evident that pattern shape is also responsible for cavities filling during the R2R-UV imprinting process. The V-shape patterns with an aspect ratio of 0.75 have a tapering angle of 35°.

Figure 13a shows the filling profiles for rectangular patterns with a tapering angle of 5°. No bubbles were found for this type of pattern during the R2R-UV imprinting process.

Figure 13b shows the SEM image of bubble-free imprinted microcavities at a PET web speed of 24.2 mm/s.