1. Introduction

Laser engineered net shaping (LENS) is an additive manufacturing technology that is used to manufacture parts with enhanced property by melting a powder and depositing onto substrate with high energy laser beam [

1,

2,

3]. This technology has become an academic and industrial focus because of the exceptional physical property, high density, and low pore rate of the finished product [

4,

5].

Beyond tradition materials, the materials used in additive manufacturing have expanded to composite materials [

6]. Stainless steel has been widely used in industrial applications because of its plasticity, toughness, and corrosion resistance [

7]. Among different types of stainless steel, AISI 316L draws the attention of researchers due to its well formability, outstanding oxidation, and corrosion resistance. However, its industrial application is limited due to its insufficient hardness and wear resistance [

8]. This deficiency can be improved by adding a reinforcement material [

9]. For instance, Lyu et al. used selective laser melting deposited multilayer of TiAlN/TiN coating on the substrate. By conducting orthogonal experiments they found the optimal coating with the best comprehensive property was made with a 170 W laser power, 110 mm/s scanning speed, and 0.08 mm scanning space [

10]. Wu et al. deposited gradient SiC reinforced 316L metal matrix composite, and found that the micro-hardness and wear resistance were improved by increasing the SiC percentage [

11]. Wang et al. applied laser melting deposition to fabricate 316L stainless steel with different levels of Cr

3C

2 content. They found the highest wear resistance was obtained with 15 wt.% Cr

3C

2 content [

9]. Titanium carbide (TiC) is a favorable reinforcement material because of its outstanding wear resistance, corrosion resistance, and hardness [

12]. In the past there have been numerous research work focused on TiC powder reinforcement coating. Obadele et al. [

13] used the laser particle injection technique, deposited titanium carbide (TiC) and tungsten carbide (WC) composite coating, and investigated the relationship between laser process parameters and the composite coating. They found the micro-hardness was improved by hard ceramic particles, which provided an effective bonding with the substrate [

13]. Liu and Shin studied TiC-reinforced Ti6Al4V-TiC composites and found carbon induced solid solution strengthening enhanced the composite microstructure [

14]. Zhou et al. applied selective laser melting (SLM) in fabricating Al–15Si alloy and TiC composite. They found the TiC significantly improved the micro-hardness and wear resistance of the alloy [

15].

Research on 316L stainless steel reinforcement primarily added Ti, SiC, or other ceramic powder and investigated the related mechanical properties. However, prediction and control of micro-hardness, wear resistance as well as defect diminishing was not thoroughly investigated in reinforced coating made by LENS. The value of the additive manufactured part was determined by its properties [

16]. The micro-hardness and wear resistance affects the service life of parts. Therefore, improving micro-hardness and wear resistance is a goal for the additive manufactured part. Additionally, the parts’ performance are also affected by their defects (pores and cracks), which are influenced by the proportion of TiC during manufacturing [

12]. Thus, the quality control regarding this defect is also a goal to guarantee the performance. This research aims to produce an outstanding 316L stainless steel and TiC-reinforced composite coating, which can be used to manufacture high performance parts. Mathematical models were developed by response surface methodology to optimize and predict the micro-hardness, wear resistance, and defect area by manipulating the LENS processing parameters.

2. Materials and Methods

AISI/SAE 1045 steel was selected as the substrate with a size of 40 mm × 20 mm × 10 mm. The powder used in the LENS process was a composite of 316L stainless steel powder and titanium carbide (TiC) powder. Both types of powder had a particle size ~100 μm to meet the requirement of powder feeding system specification. The elemental composition of the cladding powders and the substrate is shown in

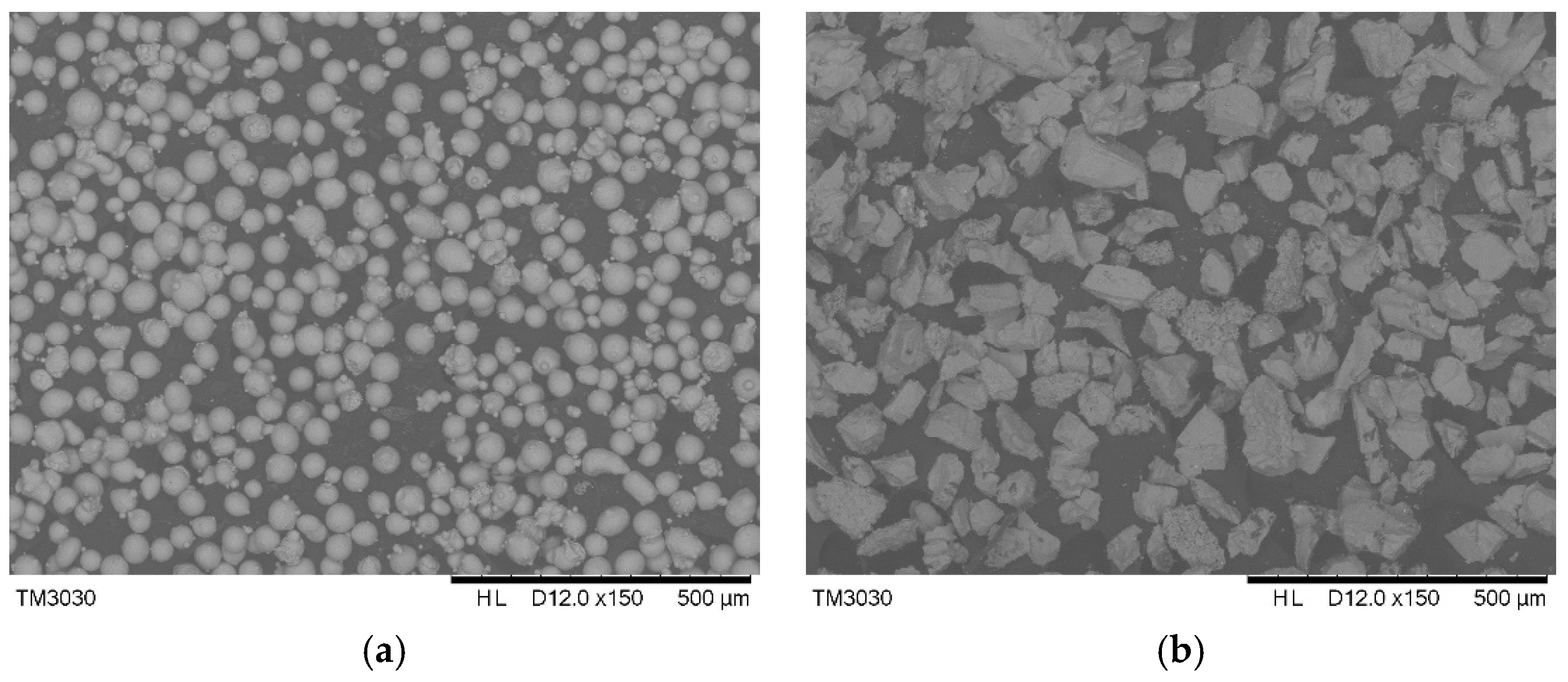

Table 1. The morphology of 316L and TiC powder are shown in

Figure 1.

Before conducting the LENS process, the 1045 steel substrate surface was cleaned by ethanol. The 316L and TiC powder was mixed at a speed of 400 rpm in a MITR–YXQM–2L ball mill machine (MITR, Changsha, China) for 30 min [

17]. Then, the powder mixture was dried in a vacuum dryer for another 30 min at a temperature of 100 °C.

Figure 2a illustrates the LENS 450 system (Optomec, Albuquerque, NM, USA) utilized in this study, consisting of a 400 W maximum output IPG fiber laser system (IPG Photonics, Oxford, MA, USA), a chamber system, a powder and gas delivery system, and a computer–controlled motion system. The powder was injected onto the substrate by the powder and gas delivery system, equipped with coaxial nozzles on a four–jet deposition head. Argon was used as a protective and carrier gas during the process. Gas flow in this study was kept at 5 L/min. The delivered powder was melted under the laser power, and the 3–axes numeric controlled motion workstation was moved to fabricate the coating, layer by layer, following the track of movement shown in

Figure 2b. A 5 mm × 5 mm × 5 mm cubic size 316L/TiC composite coating was obtained on top of the substrate.

After the completion of LENS process, the samples were preceded by cutting, setting, and polishing. Next the samples were immersed in aqua regia for 10 s, and cleaned by alcohol and water afterwards. Then, the samples were dried by cold air gun. Afterwards, the microstructure and elemental analysis was examined by a scanning electron microscope (SEM) TM3030Plus (Hitachi, Tokyo, Japan) equipped with an energy-dispersive X–ray spectroscopy (EDS) A550I (IXRF, Austin, TX, USA). The micro-hardness was measured using a MVA–402TS micro-hardness tester, with 22° slant angle quadrangular pyramid diamond indenter (HDNS, Shanghai, China) by applying a 500 g force on the surface of the specimen with a 30 s duration. Then the diagonal length of the indentation was measured, and the measured length was used to check the corresponding micro-hardness with the micro-hardness table (

Figure 3a). The average value was acquired by measurements that were repeated five times, to reduce errors. The complete diamond shape indentation in

Figure 3a had a clear boundary, no obvious cracks and a minor pile-up effect was observed. A minor discontinuity (pop-in phenomenon) on the load–displacement curve was observed in

Figure 3b, but the slight pop-in phenomenon did not imply a significant impact on the measurement of the micro-hardness [

18].

The setup for the scratch test parameters are shown in

Table 2. Then, the wear resistance was evaluated by a UMT-2 high load scratch tester (Bruker, Billerica, MA, USA). Additionally, the 3D morphology of the wear surface was obtained through white light interferometry, and the width and depth of the worn area was measured. Repeating the measurement of the width and depth in five different locations enabled to obtain the average wear-off area. Then, the wear volume was calculated by multiplying the average wear-off area with the scratching distance [

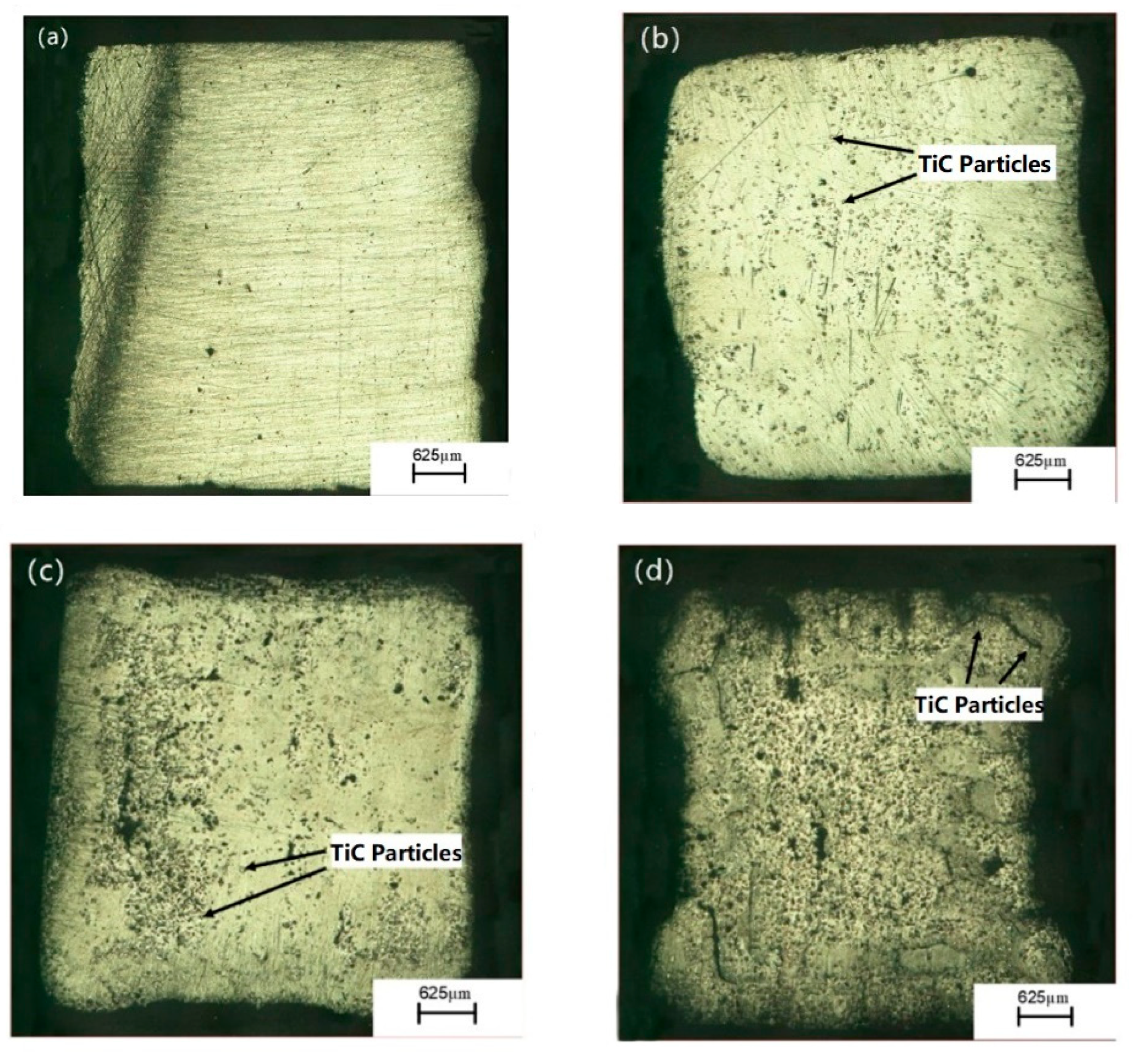

17]. In the end, the defect area was measured by using a KH–1300 3D microscope (Hirox Co., Ltd., Tokyo, Japan).

Respond surface methodology (RSM) is an integrated method that combines experimental design, data processing, and optimization. RSM is used to build a mathematic model between input and output variables. The central composite design (CCD) module was selected in RSM in this study. The experimental design matrix contained four factors and five levels. The four factors were laser power (LP), scanning speed (SS), TiC weight percentage powder ratio (PR), and powder feed rate (PF). The variables for the factors were set to 0, ±1, and ±2 in the Design Expert software (version 10.0), as shown in

Table 3. Then, 30 runs of the experiment were generated by the Design Expert software, according to these factors and levels (

Table A1).

A total of 30 specimens were made following the processing parameters setup in

Table A1. The selected responses of micro-hardness, wear volume, and defect area were obtained; shown in

Table A1. Then, the mathematical models were obtained by the Design Expert software after importing the experimental results in 30 runs. These fitted models illustrate the interaction between the input variables (LENS process parameters) and the output (selected responses). Equation (1) is the expression of these polynomial regression function, where y stands for the response value,

xi and

xj represent the processing parameter. β

0 stands for the intercept factor. β

j, β

ij, and β

jj indicates the coefficients for the linear term, interaction term, and the quadratic term, respectively. Additionally,

k represents the number of factors and ε denotes the residual [

17]. Afterwards, analysis of variance (ANOVA) and the respond surface methodology was used to analyze the model. The significance level (α) in ANOVA was set at 0.05.