Low Deposition Temperature-Induced Changes of the Microstructure and Tribological Property of WS2 Film

Abstract

1. Introduction

2. Experiment

2.1. Sample Preparation

2.2. Film Characterization and Tribological Measurements

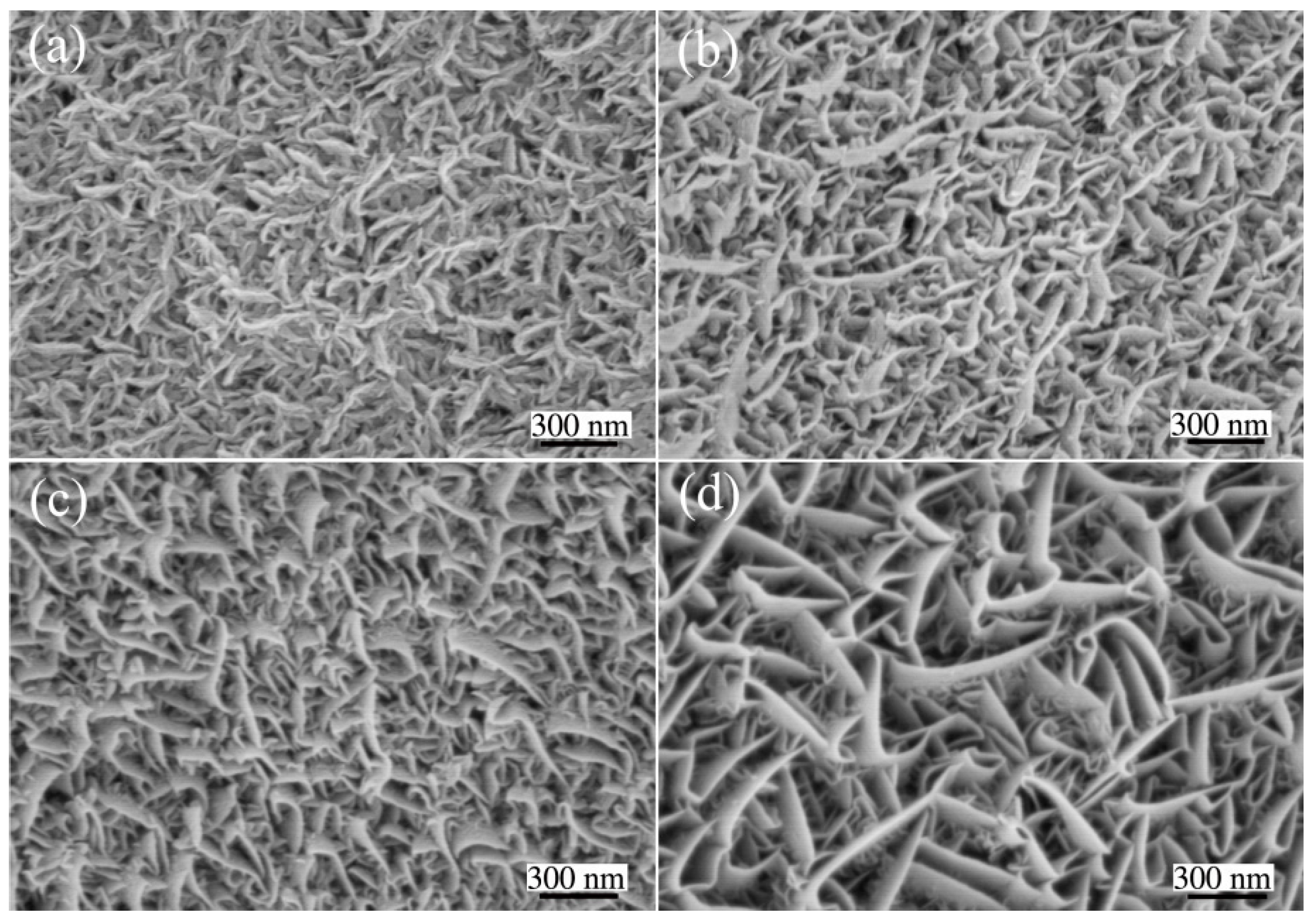

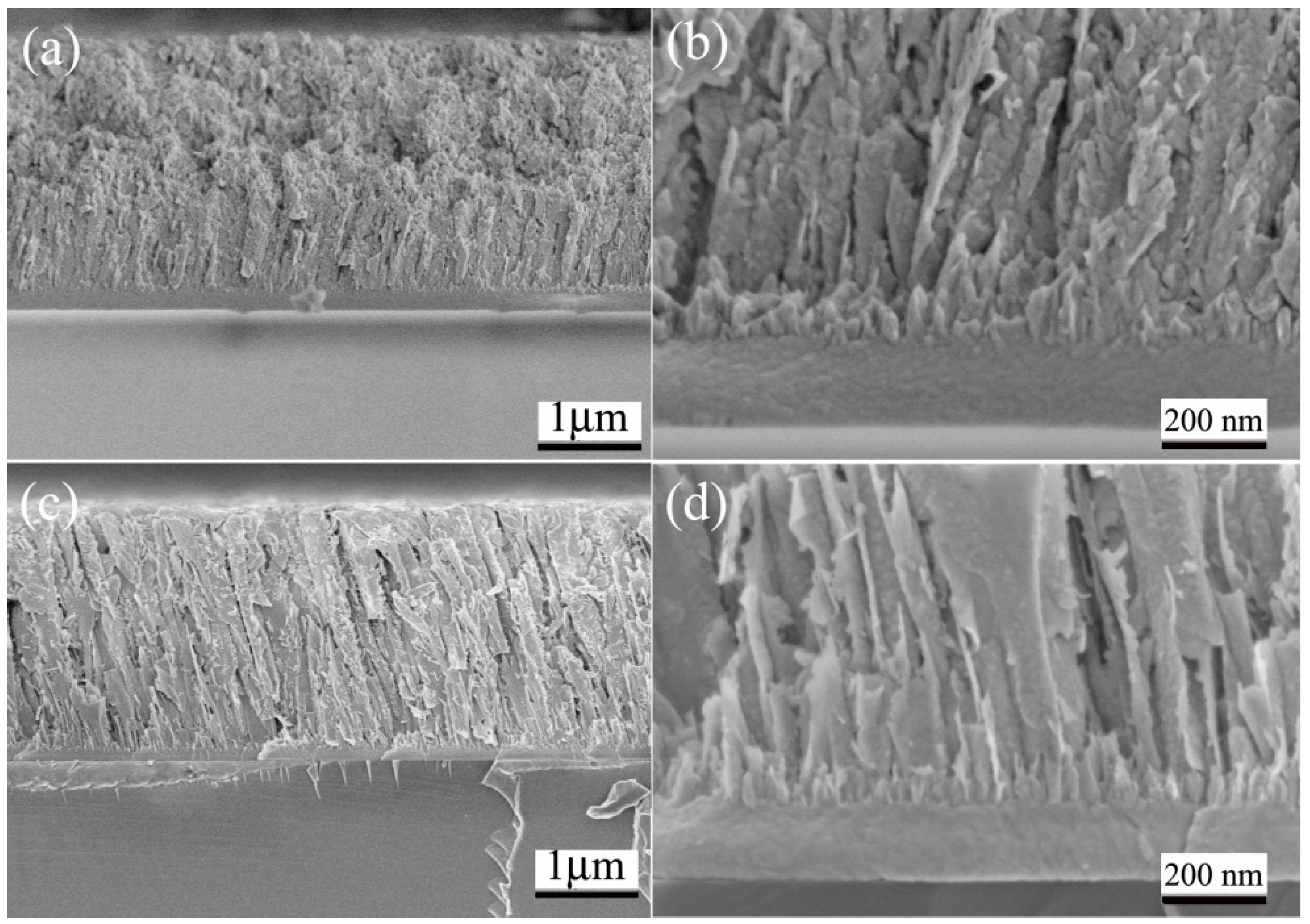

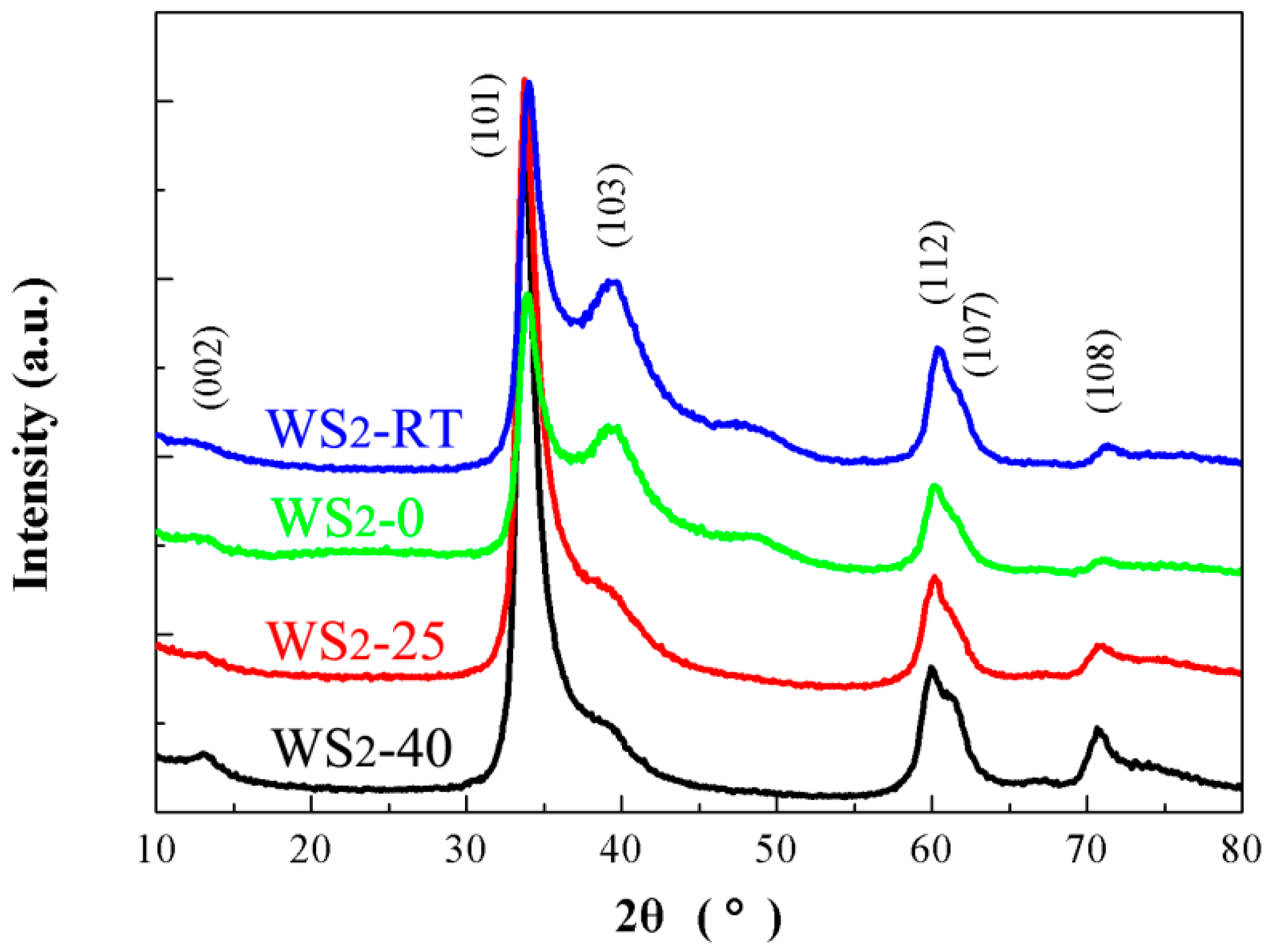

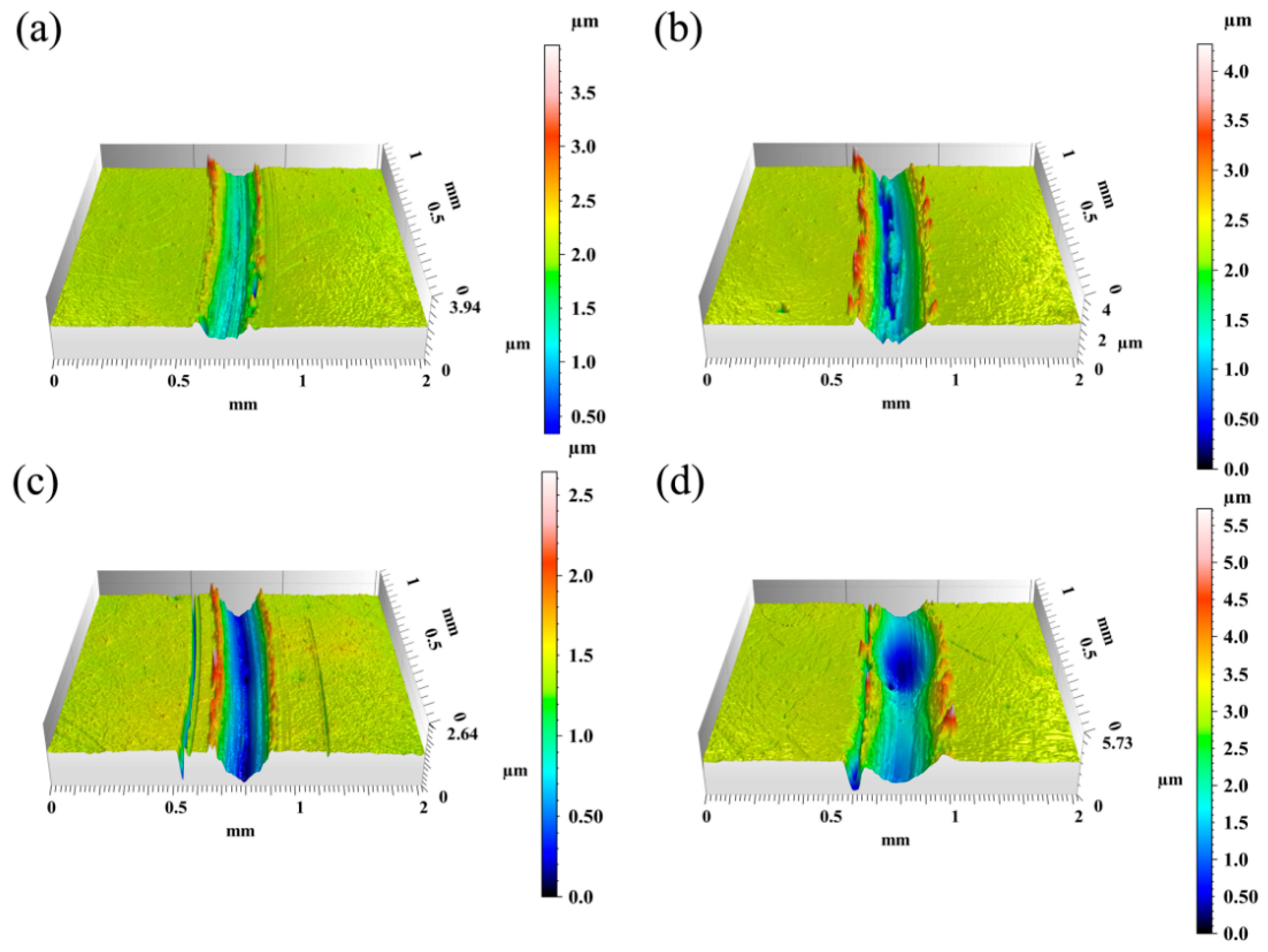

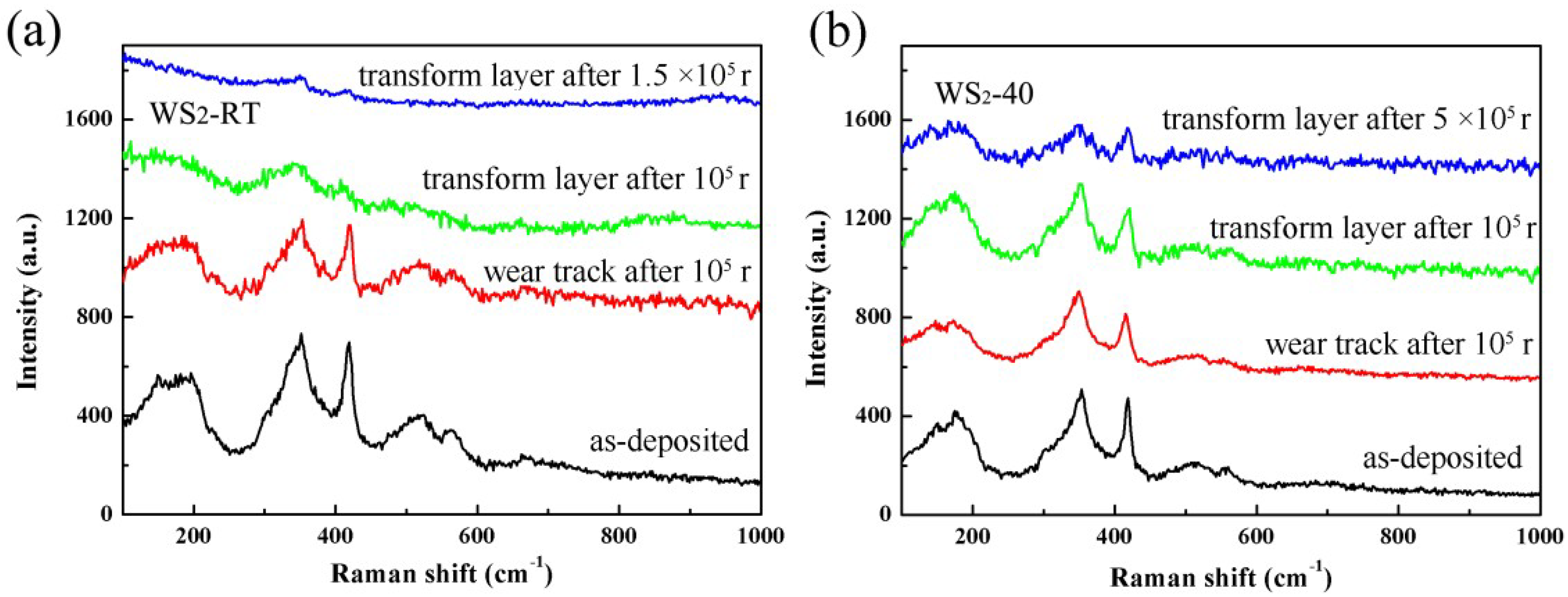

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Banerjee, T.; Chattopadhyay, A. Influence of substrate bias on structural and tribo-mechanical properties of pulsed magnetron sputtered TiN–WSx hard-lubricious coating. Tribol. Int. 2018, 123, 81–91. [Google Scholar] [CrossRef]

- Luo, T.; Wang, P.; Qiu, Z.; Yang, S.; Zeng, H.; Cao, B. Smooth and solid WS2 submicrospheres grown by a new laser fragmentation and reshaping process with enhanced tribological properties. Chem. Commun. 2016, 52, 10147–10150. [Google Scholar] [CrossRef] [PubMed]

- Scharf, T.; Prasad, S.; Dugger, M.; Kotula, P.; Goeke, R.; Grubbs, R. Growth, structure, and tribological behavior of atomic layer-deposited tungsten disulphide solid lubricant coatings with applications to MEMS. Acta Mater. 2006, 54, 4731–4743. [Google Scholar] [CrossRef]

- Zeng, Y.; He, F.; Wang, Q.; Yan, X.; Xie, G. Friction and wear behaviors of molybdenum disulfide nanosheets under normal electric field. Appl. Surf. Sci. 2018, 455, 527–532. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Bulbul, F.; Efeoğlu, I.; Arslan, E.; Efeoglu, I. The effect of bias voltage and working pressure on S/Mo ratio at MoS2–Ti composite films. Appl. Surf. Sci. 2007, 253, 4415–4419. [Google Scholar] [CrossRef]

- Shi, J.P.; Tong, R.; Zhou, X.B.; Gong, Y.; Zhang, Z.P.; Ji, Q.Q.; Zhang, Y.; Fang, Q.Y.; Gu, L.; Wang, X.N.; et al. Temperature-mediated selective growth of MoS2/WS2 and WS2/MoS2 vertical stacks on Au foils for direct photocatalytic applications. Adv. Mater. 2016, 28, 10664. [Google Scholar] [CrossRef]

- Arslan, E.; Totik, Y.; Efeoglu, I. Comparison of structure and tribological properties of MoS2–Ti films deposited by biased-dc and pulsed-dc. Prog. Org. Coat. 2012, 74, 772–776. [Google Scholar] [CrossRef]

- Gustavsson, F.; Jacobson, S.; Cavaleiro, A.; Polcar, T. Ultra-low friction W–S–N solid lubricant coating. Surf. Coat. Technol. 2013, 232, 541–548. [Google Scholar] [CrossRef]

- Polcar, T.; Gustavsson, F.; Thersleff, T.; Jacobson, S.; Cavaleiro, A. Complex frictional analysis of self-lubricant W–S–C/Cr coating. Faraday Discuss. 2012, 156, 383–401. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Sun, J.; Weng, L.; Hua, Y.; Liu, W.; Neville, A.; Hu, M.; Gao, X. In-situ friction and wear responses of WS2 films to space environment: Vacuum and atomic oxygen. Appl. Surf. Sci. 2018, 447, 368–373. [Google Scholar] [CrossRef]

- Singh, H.; Mutyala, K.C.; Mohseni, H.; Scharf, T.W.; Evans, R.D.; Doll, G.L. Tribological performance and coating characteristics of sputter deposited Ti doped MoS2 in rolling and sliding contact. Tribol. Trans. 2015, 58, 767–777. [Google Scholar] [CrossRef]

- Hsu, K.W.; Zhu, Y.; Yao, N.; Firth, S.; Clark, R.; Kroto, H.W.; Walton, D. Titanium-doped molybdenum disulfide nanostructures. Adv. Funct. Mater. 2001, 11, 69–74. [Google Scholar] [CrossRef]

- Strapasson, G.; Badin, P.C.; Soares, G.V.; Machado, G.; Figueroa, C.A.; Hubler, R.; Gasparin, A.L.; Baumvol, I.J.R.; Aguzzoli, C.; Tentardini, E.K. Structure, composition, and mechanical characterization of dc sputtered TiN–MoS2 nanocomposite thin films. Surf. Coat. Technol. 2011, 205, 3810–3815. [Google Scholar] [CrossRef]

- Scharf, T.; Kotula, P.; Prasad, S.; Kotula, P. Friction and wear mechanisms in MoS2/Sb2O3/Au nanocomposite coatings. Acta Mater. 2010, 58, 4100–4109. [Google Scholar] [CrossRef]

- Stoyanov, P.; Chromik, R.R.; Goldbaum, D.; Lince, J.R.; Zhang, X. Microtribological performance of Au–MoS2 and Ti–MoS2 coatings with varying contact pressure. Tribol. Lett. 2010, 40, 199–211. [Google Scholar] [CrossRef]

- Arslan, E.; Bulbul, F.; Alsaran, A.; Çelik, A.; Efeoglu, I. The effect of deposition parameters and Ti content on structural and wear properties of MoS2Ti coatings. Wear 2005, 259, 814–819. [Google Scholar] [CrossRef]

- Lince, J.R. Tribology of Co-sputtered Nanocomposite Au/MoS2 solid lubricant films over a wide contact stress range. Tribol. Lett. 2004, 17, 419–428. [Google Scholar] [CrossRef]

- Shang, K.; Zheng, S.; Ren, S.; Pu, J.; He, D.; Liu, S. Improving the tribological and corrosive properties of MoS2-based coatings by dual-doping and multilayer construction. Appl. Surf. Sci. 2018, 437, 233–244. [Google Scholar] [CrossRef]

- Hu, J.; Bultman, J.; Zabinski, J. Microstructure and lubrication mechanism of multilayered MoS2/Sb2O3 thin films. Tribol. Lett. 2006, 21, 169–174. [Google Scholar] [CrossRef]

- Pimentel, J.V.; Polcar, T.; Cavaleiro, A. Structural, mechanical and tribological properties of Mo–S–C solid lubricant coating. Surf. Coat. Technol. 2011, 205, 3274–3279. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. Review on self-lubricant transition metal dichalcogenide nanocomposite coatings alloyed with carbon. Surf. Coat. Technol. 2011, 206, 686–695. [Google Scholar] [CrossRef]

- Li, S.; Deng, J.; Yan, G.; Zhang, K.; Zhang, G. Microstructure, mechanical properties and tribological performance of TiSiN–WS2 hard-lubricant coatings. Appl. Surf. Sci. 2014, 309, 209–217. [Google Scholar] [CrossRef]

- Wang, D.; Hu, M.; Jiang, D.; Gao, X.; Fu, Y.; Sun, J.; Weng, L. Cabbage-like WS2/Ni bilayer thin film for improved tribological property. Surf. Coat. Technol. 2019, 358, 50–56. [Google Scholar] [CrossRef]

- Wang, D.; Hu, M.; Gao, X.; Jiang, D.; Fu, Y.; Weng, L.; Sun, J. Tailoring of the interface morphology of WS2/CrN bilayered thin film for enhanced tribological property. Vacuum 2018, 156, 157–164. [Google Scholar] [CrossRef]

- Arenas, M.A.; Ahuir-Torres, J.I.; García, I.; Carvajal, H.; de Damborenea, J. Tribological behaviour of laser textured Ti6Al4V alloy coated with MoS2 and graphene. Tribol. Int. 2018, 128, 240–247. [Google Scholar] [CrossRef]

- Scharf, T.; Rajendran, A.; Banerjee, R.; Sequeda, F. Growth, structure and friction behavior of titanium doped tungsten disulphide (Ti–WS2) nanocomposite thin films. Thin Solid Films 2009, 517, 5666–5675. [Google Scholar] [CrossRef]

- Bozheyev, F.; Valiev, D.; Nemkayeva, R. Pulsed cathodoluminescence and Raman spectra of MoS2 and WS2 nanocrystals and their combination MoS2/WS2 produced by self-propagating high-temperature synthesis. Appl. Phys. Lett. 2016, 108, 093111. [Google Scholar] [CrossRef]

- Chen, F.; Wang, L.; Ji, X.; Zhang, Q. Temperature-dependent two-dimensional transition metal dichalcogenide heterostructures: controlled synthesis and their properties. ACS Appl. Mater. Interfaces 2017, 9, 30821–30831. [Google Scholar] [CrossRef] [PubMed]

- Spalvins, T. Tribological properties of sputtered MoS2 films in relation to film morphology. Thin Solid Films 1980, 73, 291–297. [Google Scholar] [CrossRef]

- Gao, X.; Sun, J.; Fu, Y.; Jiang, D.; Wang, D.; Weng, L.; Hu, M. Improved wear resistance of WS2 film by LT-deposited Ti interlayer with ω phase structure. Vacuum 2018, 155, 423–427. [Google Scholar] [CrossRef]

- Hilton, M.R.; Jayaram, G.; Marks, L.D. Microstructure of cosputter-deposited metal- and oxide-MoS2 solid lubricant thin films. Tribol. Int. 2011, 13, 1022–1032. [Google Scholar] [CrossRef]

- Deepthi, B.; Barshilia, H.C.; Rajam, K.; Konchady, M.S.; Pai, D.M.; Sankar, J. Structural, mechanical and tribological investigations of sputter deposited CrN–WS2 nanocomposite solid lubricant coatings. Tribol. Int. 2011, 44, 1844–1851. [Google Scholar] [CrossRef]

- Perea-López, N.; Elías, A.L.; Berkdemir, A.; Castro-Beltran, A.; Gutiérrez, H.R.; Feng, S.; Lv, R.; Hayashi, T.; López-Urías, F.; Ghosh, S.; et al. Photosensor device based on few-layered WS2 films. Adv. Funct. Mater. 2013, 23, 5511–5517. [Google Scholar] [CrossRef]

- Moser, J.; Levy, F. MoS2−x lubricating films: Structure and wear mechanisms investigated by cross-sectional transmission electron microscopy. Thin Solid Films 1993, 228, 257–260. [Google Scholar] [CrossRef]

- Spalvins, T. Frictional and morphological properties of Au–MoS2 films sputtered from a compact target. Thin Solid Films 1984, 118, 375–384. [Google Scholar] [CrossRef]

- Zhang, X.; Qiao, L.; Chai, L.; Xu, J.; Shi, L.; Wang, P. Structural, mechanical and tribological properties of Mo–S–N solid lubricant films. Surf. Coat. Technol. 2016, 296, 185–191. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, M.; Dong, Y.; Wang, Y.; Wang, D.; Jiang, D.; Fu, Y.; Weng, L.; Sun, J.; Gao, X. Low Deposition Temperature-Induced Changes of the Microstructure and Tribological Property of WS2 Film. Coatings 2019, 9, 227. https://doi.org/10.3390/coatings9040227

Hu M, Dong Y, Wang Y, Wang D, Jiang D, Fu Y, Weng L, Sun J, Gao X. Low Deposition Temperature-Induced Changes of the Microstructure and Tribological Property of WS2 Film. Coatings. 2019; 9(4):227. https://doi.org/10.3390/coatings9040227

Chicago/Turabian StyleHu, Ming, Yi Dong, Yan Wang, Desheng Wang, Dong Jiang, Yanlong Fu, Lijun Weng, Jiayi Sun, and Xiaoming Gao. 2019. "Low Deposition Temperature-Induced Changes of the Microstructure and Tribological Property of WS2 Film" Coatings 9, no. 4: 227. https://doi.org/10.3390/coatings9040227

APA StyleHu, M., Dong, Y., Wang, Y., Wang, D., Jiang, D., Fu, Y., Weng, L., Sun, J., & Gao, X. (2019). Low Deposition Temperature-Induced Changes of the Microstructure and Tribological Property of WS2 Film. Coatings, 9(4), 227. https://doi.org/10.3390/coatings9040227