Coating of Titanium Substrates with ZrO2 and ZrO2-SiO2 Composites by Sol-Gel Synthesis for Biomedical Applications: Structural Characterization, Mechanical and Corrosive Behavior

Abstract

:1. Introduction

2. Materials and Methods

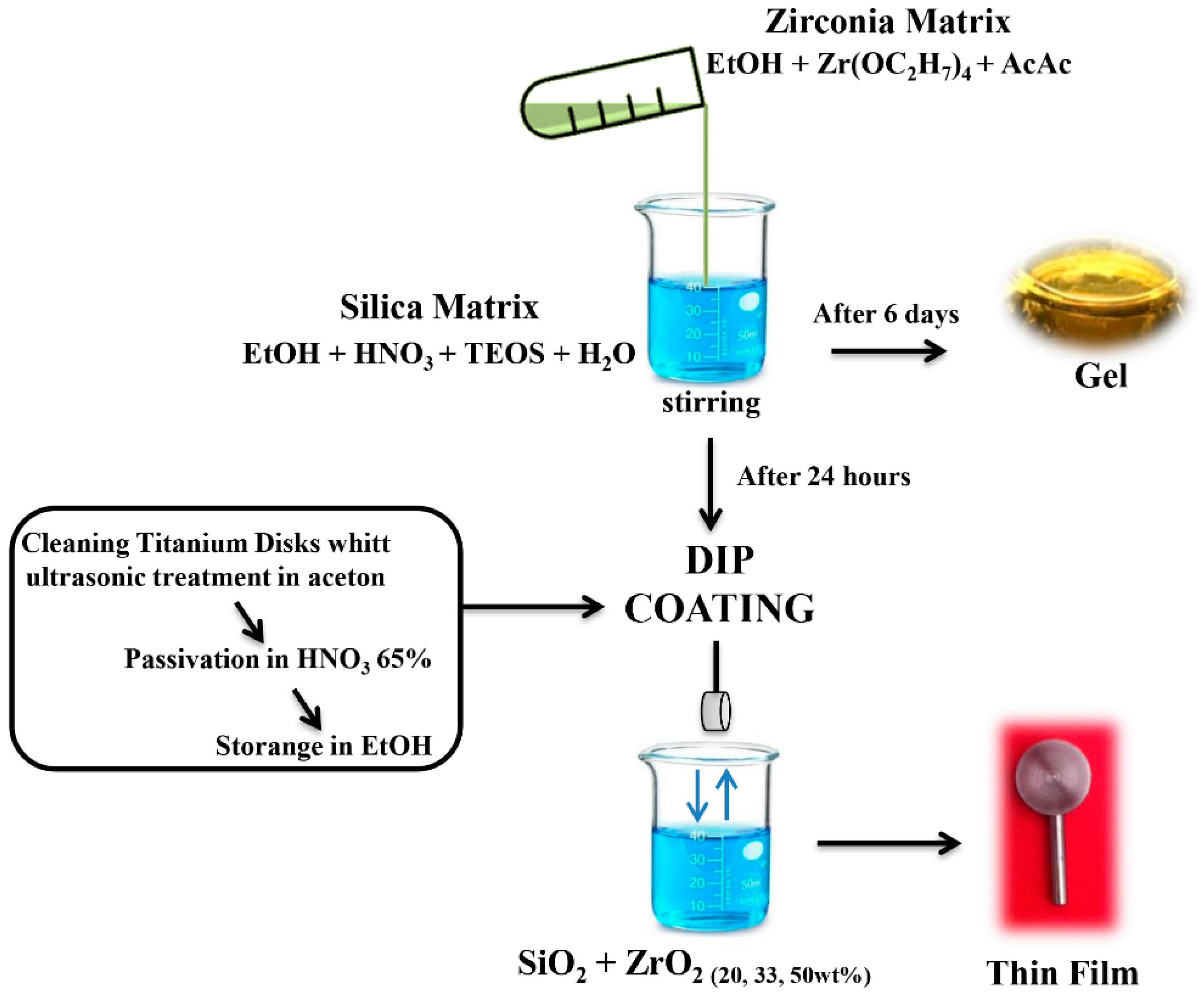

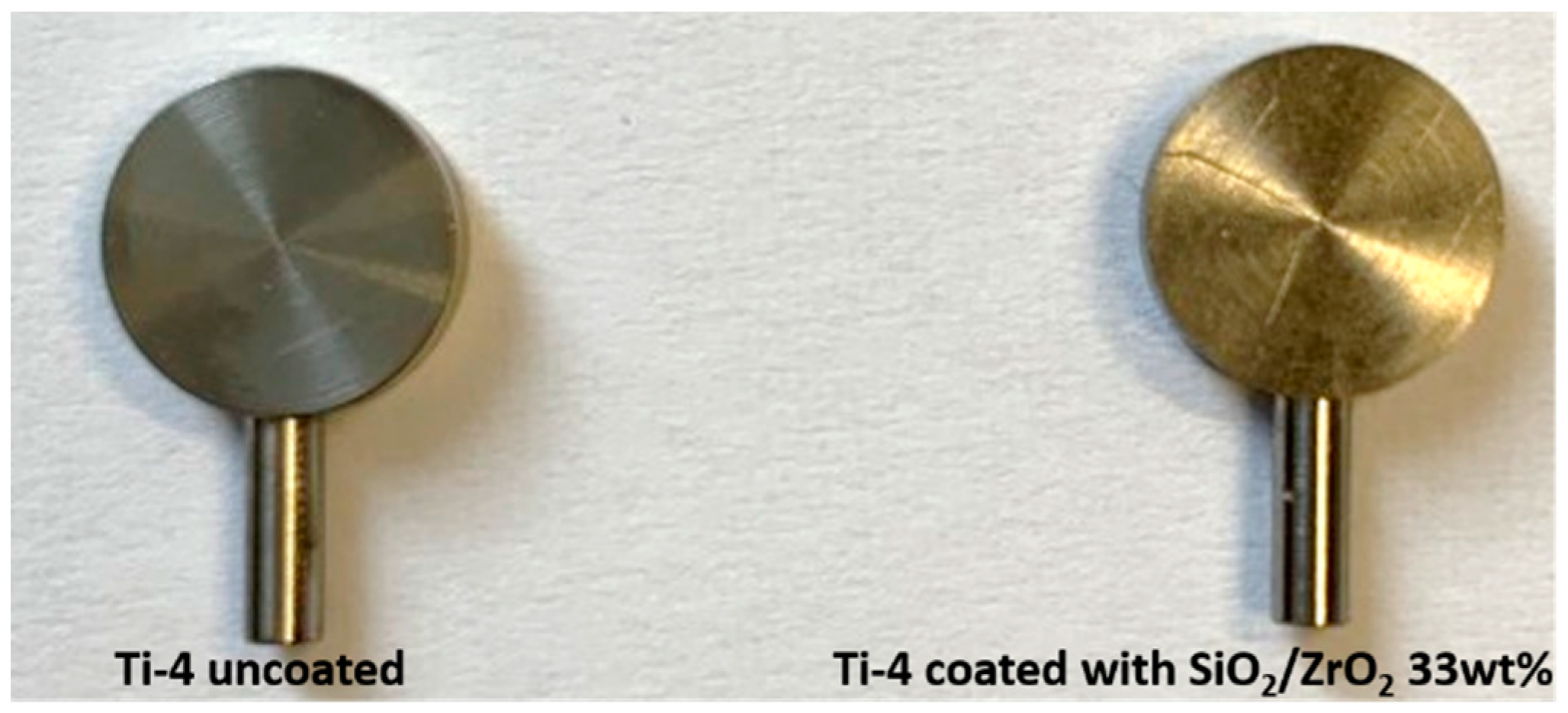

2.1. Sol-Gel Synthesis and Coating

2.2. Coating Characterization

2.3. Mechanical Characterization Techniques

2.4. Corrosion Tests

2.5. Bioactivity Test

2.6. Antibacterial Properties

3. Results

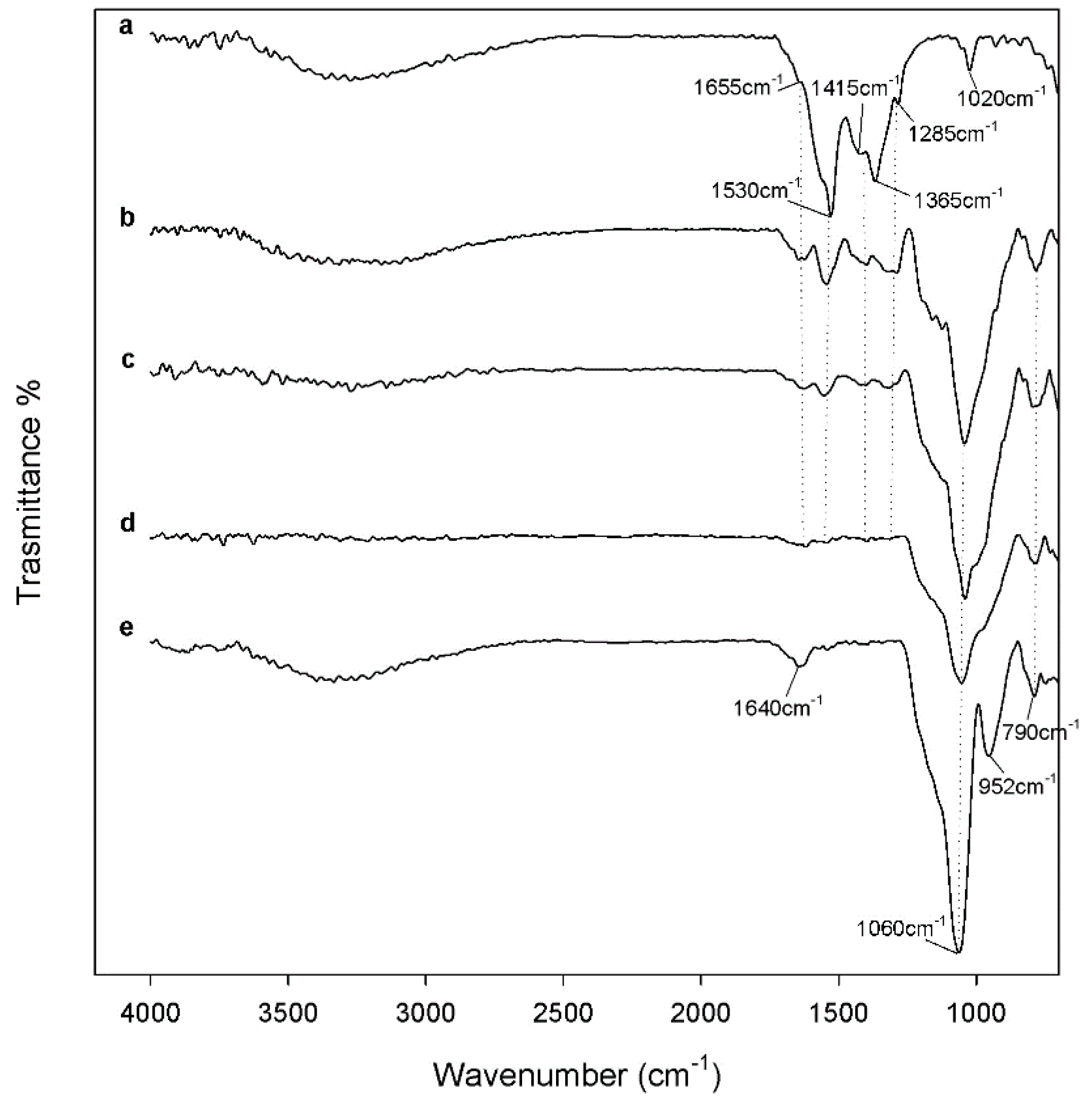

3.1. Coating Characterization: ATR-FTIR

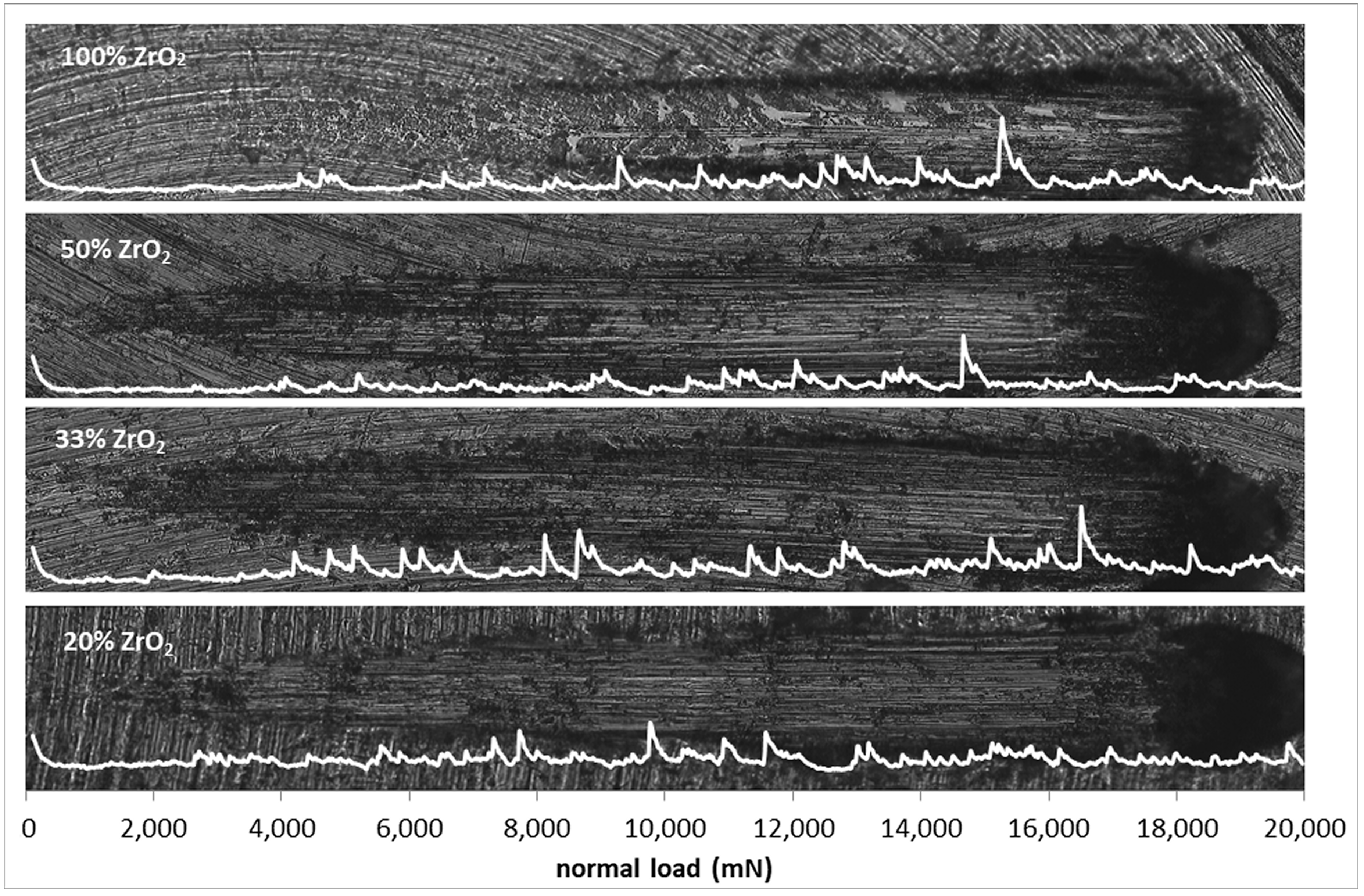

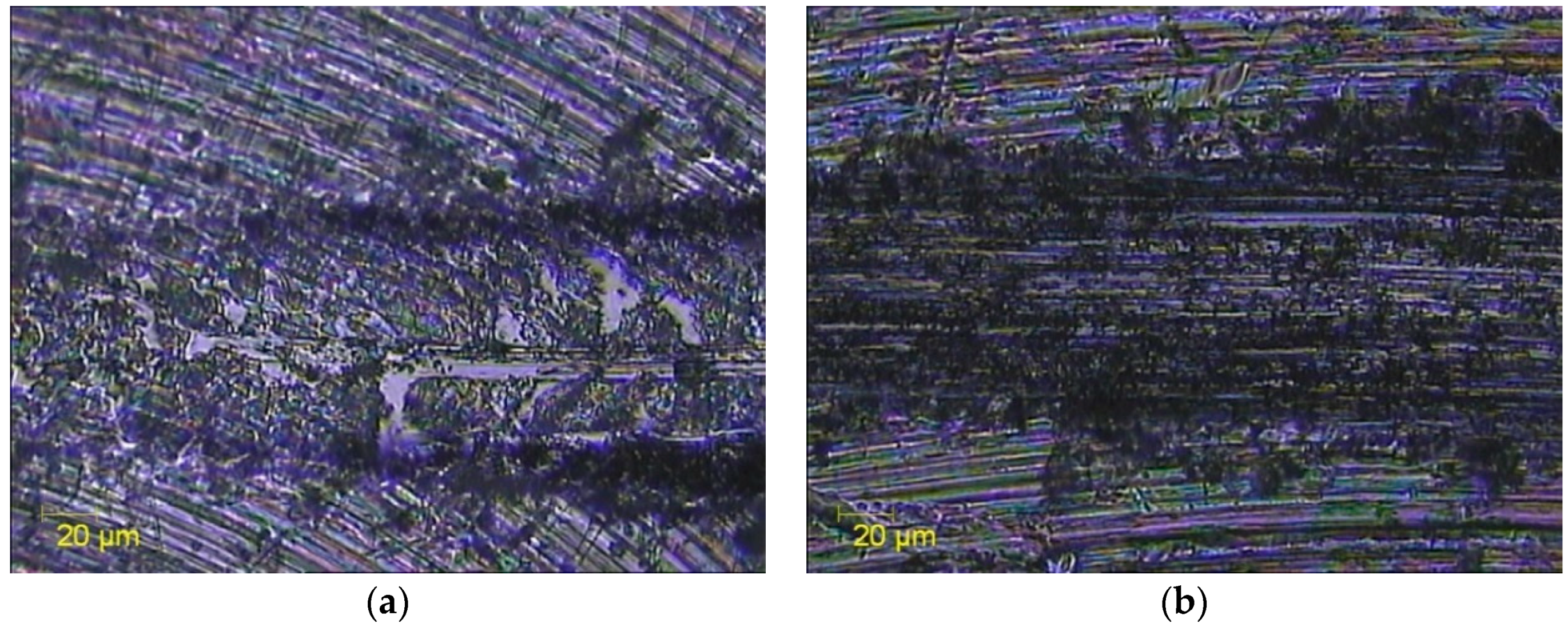

3.2. Mechanical Characterization Techniques

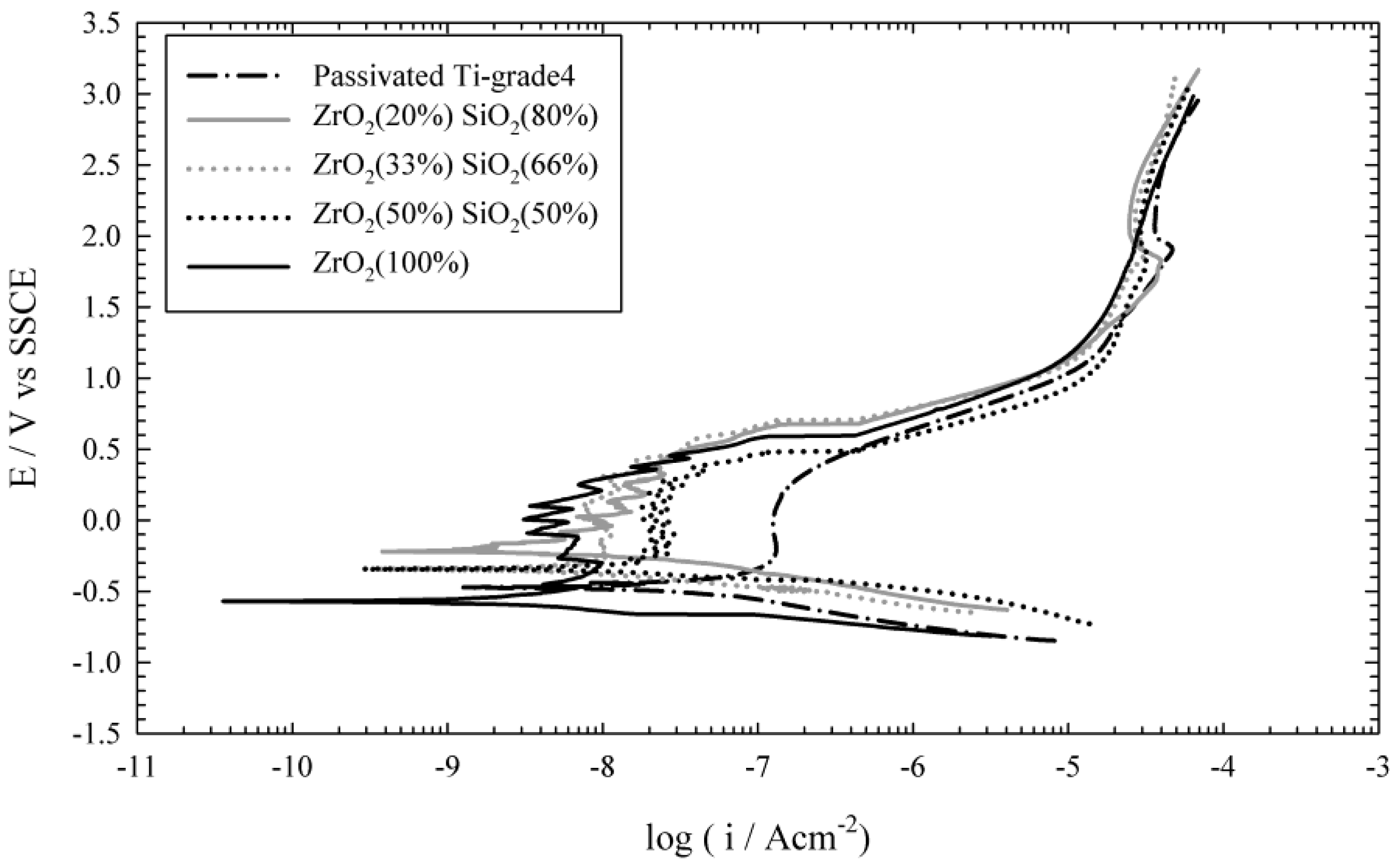

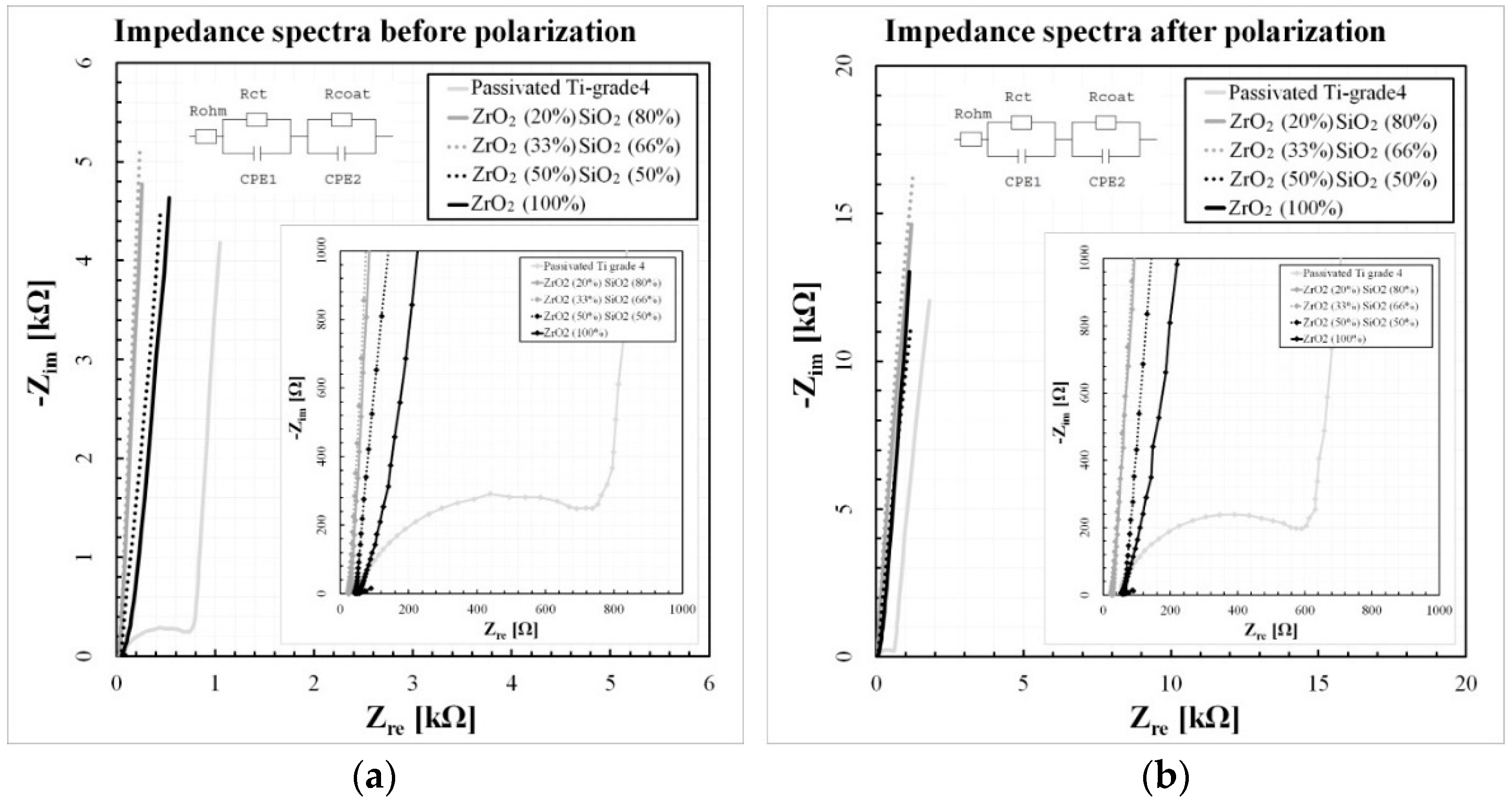

3.3. Corrosion Tests

3.4. Bioactivity Test

3.5. Antibacterial Properties

4. Conclusions

- ATR-FTIR spectroscopy suggests that interaction between both inorganic matrixes occurred.

- FTIR spectra and SEM/EDX analysis showed the same bioactivity among all materials, in fact, the bioactive proprieties are due to a synergy between both inorganic components.

- A decrease of the bacterial growth was not observed when the Ti-4 disks coated with SiO2/ZrO2 composites were incubated with gram-negative and gram-positive bacteria, suggesting that the coating materials are non-toxic and could be used in clinical applications.

- All the coatings improved the corrosion resistance of the Ti substrate, as all the coated samples showed an evident decrease of corrosion current density in the passivation region of the potentiodynamic curves.

- As far as the mechanical properties are concerned, the SiO2-containing coatings showed the best performances due to a better adhesion to the Ti substrate, as proved by the scratch tests.

- On the other hand, the SiO2-containing coatings did not show the absolute best results in the corrosion tests because of the presence of microcracks which allow the electrolyte to come into contact with the substrate underneath.

- Considering the SiO2-containing coatings performed best in the scratch tests, they can be considered as the best compromise between corrosion resistance and mechanical properties.

Author Contributions

Funding

Conflicts of Interest

References

- Neoh, K.; Shi, Z.; Kang, E. Anti-adhesive and antibacterial polymer brushes. In Biomaterials Associated Infection; Springer: Berlin, Germany, 2013; pp. 405–432. [Google Scholar]

- Balamurugan, A.; Rajeswari, S.; Balossier, G.; Rebelo, A.; Ferreira, J. Corrosion aspects of metallic implants—An overview. Mater. Corros. 2008, 59, 855–869. [Google Scholar] [CrossRef]

- Manivasagam, G.; Dhinasekaran, D.; Rajamanickam, A. Biomedical implants: Corrosion and its prevention-a review. J. Recent Patents Corros. Sci. 2010. [Google Scholar] [CrossRef]

- Asri, R.; Harun, W.; Samykano, M.; Lah, N.; Ghani, S.; Tarlochan, F.; Raza, M. Corrosion and surface modification on biocompatible metals: A review. J. Mater. Sci. Eng. C 2017, 77, 1261–1274. [Google Scholar] [CrossRef]

- Catauro, M.; Bollino, F.; Papale, F. Biocompatibility improvement of titanium implants by coating with hybrid materials synthesized by sol-gel technique. J. Biomed. Mater. Res. Part A 2014, 102, 4473–4479. [Google Scholar] [CrossRef] [PubMed]

- Catauro, M.; Bollino, F.; Papale, F.; Gallicchio, M.; Pacifico, S. Synthesis and chemical characterization of new silica polyethylene glycol hybrid nanocomposite materials for controlled drug delivery. J. Drug Deliv. Sci. Technol. 2014, 24, 320–325. [Google Scholar] [CrossRef]

- Coli, P.; Karlsson, S. Fit of a new pressure-sintered zirconium dioxide coping. Int. J. Prosthodont. 2004, 17, 59–64. [Google Scholar] [PubMed]

- Evans, A.; Heuer, A. Transformation toughening in ceramics: Martensitic transformations in crack-tip stress fields. J. Am. Ceram. Soc. 1980, 63, 241–248. [Google Scholar] [CrossRef]

- Soon, G.; Pingguan-Murphy, B.; Lai, K.W.; Akbar, S.A. Review of zirconia-based bioceramic: Surface modification and cellular response. J. Ceram. Int. 2016, 42, 12543–12555. [Google Scholar] [CrossRef]

- Pessoa, R.; Cerqueira, M.; Nasar, R.; Yoshida, I. Synthesis of stabilized zirconia without dopants. Cerâmica 2008, 54, 253–258. [Google Scholar] [CrossRef]

- Długoń, E.; Pach, K.; Gawęda, M.; Jadach, R.; Wajda, A.; Leśniak, M.; Benko, A.; Dziadek, M.; Sowa, M.; Simka, W. Anticorrosive ZrO2 and ZrO2-SiO2 layers on titanium substrates for biomedical applications. Surf. Coat. Technol. 2017, 331, 221–229. [Google Scholar] [CrossRef]

- Ciesielczyk, F.; Goscianska, J.; Zdarta, J.; Jesionowski, T. The development of zirconia/silica hybrids for the adsorption and controlled release of active pharmaceutical ingredients. Colloids Surf. A 2018, 545, 39–50. [Google Scholar] [CrossRef]

- Fu, L.; Wu, C.; Grandfield, K.; Unosson, E.; Chang, J.; Engqvist, H.; Xia, W. Transparent single crystalline ZrO2-SiO2 glass nanoceramic sintered by SPS. J. Eur. Ceram. Soc. 2016, 36, 3487–3494. [Google Scholar] [CrossRef]

- Catauro, M.; Dell’Era, A.; Vecchio Ciprioti, S. Synthesis, structural, spectroscopic and thermoanalytical study of sol-gel derived SiO2-CaO-P2O5 gel and ceramic materials. Thermochim. Acta 2016, 625, 20–27. [Google Scholar] [CrossRef]

- Nguyen, K.; Garcia, A.; Sani, M.A.; Diaz, D.; Dubey, V.; Clayton, D.; Dal Poggetto, G.; Cornelius, F.; Payne, R.J.; Separovic, F.; et al. Interaction of N-terminal peptide analogues of the Na+,K+-ATPase with membranes. Biochim. Biophys. Acta Biomembr. 2018, 1860, 1282–1291. [Google Scholar] [CrossRef] [PubMed]

- Catauro, M.; Tranquillo, E.; Salzillo, A.; Capasso, L.; Illiano, M.; Sapio, L.; Naviglio, S. Silica/Polyethylene glycol hybrid materials prepared by a sol-Gel method and containing chlorogenic acid. Molecules 2018, 23. [Google Scholar] [CrossRef]

- Tranquillo, E.; Barrino, F.; Dal Poggetto, G.; Blanco, I. Sol-gel synthesis of silica-based materials with different percentages of PEG or PCL and high chlorogenic acid content. Materials 2019, 12. [Google Scholar] [CrossRef]

- Morks, M.; Kobayashi, A. Development of ZrO2/SiO2 bioinert ceramic coatings for biomedical application. J. Mech. Behav. Biomed. Mater. 2008, 1, 165–171. [Google Scholar] [CrossRef]

- Brinker, C.; Scherer, G. Sol-Gel Science: The Physics and Chemistry of Sol-Gel Processing; Academic Press: San Diego, CA, USA, 1989. [Google Scholar]

- Catauro, M.; Bollino, F.; Giovanardi, R.; Veronesi, P. Modification of Ti6Al4V implant surfaces by biocompatible TiO2/PCL hybrid layers prepared via sol-gel dip coating: Structural characterization, mechanical and corrosion behavior. Mater. Sci. Eng. C 2017, 74, 501–507. [Google Scholar] [CrossRef]

- Catauro, M.; Bollino, F.; Papale, F.; Ferrara, C.; Mustarelli, P. Silica-polyethylene glycol hybrids synthesized by sol-gel: Biocompatibility improvement of titanium implants by coating. Mater. Sci. Eng. C 2015, 55, 118–125. [Google Scholar] [CrossRef] [PubMed]

- Dehghanghadikolaei, A.; Ibrahim, H.; Amerinatanzi, A.; Hashemi, M.; Moghaddam, N.S.; Elahinia, M. Improving corrosion resistance of additively manufactured nickel–titanium biomedical devices by micro-arc oxidation process. J. Mater. Sci. 2019, 54, 7333–7355. [Google Scholar] [CrossRef]

- Fahmi, A.; Abdullah, S.; Amin, F.; Ali, A. Precursor selection for sol–gel synthesis of titanium carbide nanopowders by a new cubic fuzzy multi-attribute group decision-making model. J. Intell. Syst. 2017, 15, 145–167. [Google Scholar] [CrossRef]

- Roehling, S.; Gahlert, M.; Janner, S.; Meng, B.; Woelfler, H.; Cochran, D. Ligature-Induced Peri-implant Bone Loss Around Loaded Zirconia and Titanium implants. Int. J. Oral Maxillofac. Implant 2019. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Kokubo, T.; Takadama, H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef] [PubMed]

- Catauro, M.; Barrino, F.; Poggetto, G.D.; Crescente, G.; Piccolella, S.; Pacifico, S. Chlorogenic acid entrapped in hybrid materials with high PEG content: A strategy to obtain antioxidant functionalized biomaterials? Materials 2019, 12. [Google Scholar] [CrossRef]

- Catauro, M.; Tranquillo, E.; Risoluti, R.; Ciprioti, S.V. Sol-Gel synthesis, spectroscopic and thermal behavior study of SiO2/PEG composites containing different amount of chlorogenic acid. Polymers 2018, 10. [Google Scholar] [CrossRef]

- Yoshino, H.; Kamiya, K.; Nasu, H. IR study on the structural evolution of sol-gel derived SiO2 gels in the early stage of conversion to glasses. J. Non-Cryst. Solids 1990, 126, 68–78. [Google Scholar] [CrossRef]

- Catauro, M.; Tranquillo, E.; Dell’Era, A.; Tuffi, R.; Vecchio Ciprioti, S. Thermal behavior and structural study of ZrO2/poly(ε-caprolactone) hybrids synthesized via sol-gel route. Ceram. Int. 2019, 45, 2771–2778. [Google Scholar] [CrossRef]

- Ramesh, S.; Kim, H.S.; Lee, Y.-J.; Hong, G.-W.; Jung, D.; Kim, J.-H. Synthesis of cellulose-L-tyrosine-SiO2/ZrO2 hybrid nanocomposites by sol-gel process and its potential. Int. J. Precis. Eng. Manuf. 2017, 18, 1297–1306. [Google Scholar] [CrossRef]

- Miller, J.B.; Rankin, S.E.; Ko, E. Strategies in controlling the homogeneity of zirconia-silica aerogels: Effect of preparation on textural and catalytic properties. J. Catal. 1994, 148, 673–682. [Google Scholar] [CrossRef]

- Wu, Z.-G.; Zhao, Y.-X.; Liu, D.-S. The synthesis and characterization of mesoporous silica–zirconia aerogels. Microporous Mesoporous Mater. 2004, 68, 127–132. [Google Scholar] [CrossRef]

- Catauro, M.; Bollino, F.; Papale, F.; Giovanardi, R.; Veronesi, P. Corrosion behavior and mechanical properties of bioactive sol-gel coatings on titanium implants. Mater. Sci. Eng. C 2014, 43, 375–382. [Google Scholar] [CrossRef] [PubMed]

- de Assis, S.L.; Wolynec, S.; Costa, I. Corrosion characterization of titanium alloys by electrochemical techniques. Electrochim. Acta 2006, 51, 1815–1819. [Google Scholar] [CrossRef]

- Cheng, X.; Roscoe, S.G. Corrosion behavior of titanium in the presence of calcium phosphate and serum proteins. Biomaterials 2005, 26, 7350–7356. [Google Scholar] [CrossRef] [PubMed]

- Kokubo, T.; Ito, S.; Huang, Z.; Hayashi, T.; Sakka, S.; Kitsugi, T.; Yamamuro, T. Ca, P-rich layer formed on high-strength bioactive glass-ceramic A-W. J. Biomed. Mater. Res. 1990, 24, 331–343. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Wang, Y.; Huang, Y.; Cheng, H.; Seo, H.J. Surface reactivity and hydroxyapatite formation on Ca5MgSi3O12 ceramics in simulated body fluid. Appl. Surf. Sci. 2017, 423, 900–908. [Google Scholar] [CrossRef]

- Kokubo, T.; Kushitani, H.; Sakka, S.; Kitsugi, T.; Yamamuro, T. Solutions able to reproduce in vivo surface-structure changes in bioactive glass-ceramic A-W3. J. Biomed. Mater. Res. 1990, 24, 721–734. [Google Scholar] [CrossRef]

| Formulation | Na+ | K+ | Mg2+ | Ca2+ | Cl− | HCO3− | HPO42− | SO42− | Buffer |

|---|---|---|---|---|---|---|---|---|---|

| Blood plasma | 142.0 | 5.0 | 1.5 | 2.5 | 103.0 | 27.0 | 1.0 | 0.5 | - |

| SBF | 142.0 | 5.0 | 1.5 | 2.5 | 144.0 | 4.2 | 1.0 | 0.5 | HEPES |

| Coatings Mechanical Properties | 20% ZrO2 | 33% ZrO2 | 50% ZrO2 | 100% ZrO2 | ||||

|---|---|---|---|---|---|---|---|---|

| Avg | SD | Avg | SD | Avg | SD | Avg | SD | |

| HV | 283.67 | 33.50 | 303.39 | 38.05 | 340.00 | 74.22 | 367.67 | 42.16 |

| E (GPa) | 61.81 | 25.79 | 64.95 | 9.41 | 72.60 | 5.76 | 117.00 | 9.17 |

| Energy (pJ) | 19,842 | 2789 | 17,002 | 822 | 16,509 | 620 | 16,076 | 1203 |

| %el | 25.68% | 6.12% | 27.84% | 1.87% | 27.51% | 1.93% | 18.45% | 1.01% |

| %pl | 74.32% | 6.12% | 72.16% | 1.87% | 72.49% | 1.93% | 81.55% | 1.01% |

| Tafel Analysis Results | Icor [Acm−2] | Ecor [V versus SSCE] | %P.E. |

|---|---|---|---|

| Passivated Ti-4 | 2.31 × 10−8 | −0.483 | - |

| ZrO2 (20%) SiO2 (80%) | 1.99 × 10−9 | −0.178 | 91% |

| ZrO2 (33%) SiO2 (66%) | 5.57 × 10−9 | −0.344 | 76% |

| ZrO2 (50%) SiO2 (50%) | 8.92 × 10−9 | −0.344 | 61% |

| ZrO2 (100%) | 1.80 × 10−9 | −0.582 | 92% |

| EIS Spectra Fitting Results | Rohm [Ω] | Rct [Ω] | Y0dl [F sn−1] | ndl [—] | Rcoating [Ω] | Y0coating [F sn−1] | ncoating [—] | χ2 |

|---|---|---|---|---|---|---|---|---|

| Passivated Ti-4 (before) | 45.5 | 784.8 | 4.95 × 10−6 | 0.75 | 1.6 × 105 | 3.86 × 10−5 | 0.98 | 1.7 × 10−4 |

| Passivated Ti-4 (after) | 44.8 | 602.1 | 1.54 × 10−6 | 0.80 | 3.7 × 105 | 1.39 × 10−5 | 0.95 | 2.7 × 10−4 |

| ZrO2 100% (before) | 51.9 | 309.1 | 4.64 × 10−4 | 0.60 | 1.7 × 105 | 3.53 × 10−5 | 0.98 | 9.6 × 10−5 |

| ZrO2 100% (after) | 50.3 | 224.0 | 3.45 × 10−4 | 0.56 | 1.8 × 106 | 1.29 × 10−5 | 0.96 | 1.4 × 10−4 |

| SiO2 50% ZrO2 50% (before) | 41.7 | 4.9 | 3.41 × 10−4 | 0.70 | 5.7 × 105 | 3.83 × 10−5 | 0.94 | 5.2 × 10−5 |

| SiO2 50% ZrO2 50% (after) | 56.4 | 9.3 | 1.96 × 10−4 | 0.68 | 4.4 × 105 | 1.50 × 10−5 | 0.95 | 1.0 × 10−4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Catauro, M.; Barrino, F.; Bononi, M.; Colombini, E.; Giovanardi, R.; Veronesi, P.; Tranquillo, E. Coating of Titanium Substrates with ZrO2 and ZrO2-SiO2 Composites by Sol-Gel Synthesis for Biomedical Applications: Structural Characterization, Mechanical and Corrosive Behavior. Coatings 2019, 9, 200. https://doi.org/10.3390/coatings9030200

Catauro M, Barrino F, Bononi M, Colombini E, Giovanardi R, Veronesi P, Tranquillo E. Coating of Titanium Substrates with ZrO2 and ZrO2-SiO2 Composites by Sol-Gel Synthesis for Biomedical Applications: Structural Characterization, Mechanical and Corrosive Behavior. Coatings. 2019; 9(3):200. https://doi.org/10.3390/coatings9030200

Chicago/Turabian StyleCatauro, Michelina, Federico Barrino, Massimiliano Bononi, Elena Colombini, Roberto Giovanardi, Paolo Veronesi, and Elisabetta Tranquillo. 2019. "Coating of Titanium Substrates with ZrO2 and ZrO2-SiO2 Composites by Sol-Gel Synthesis for Biomedical Applications: Structural Characterization, Mechanical and Corrosive Behavior" Coatings 9, no. 3: 200. https://doi.org/10.3390/coatings9030200

APA StyleCatauro, M., Barrino, F., Bononi, M., Colombini, E., Giovanardi, R., Veronesi, P., & Tranquillo, E. (2019). Coating of Titanium Substrates with ZrO2 and ZrO2-SiO2 Composites by Sol-Gel Synthesis for Biomedical Applications: Structural Characterization, Mechanical and Corrosive Behavior. Coatings, 9(3), 200. https://doi.org/10.3390/coatings9030200