Dental Resin-Zirconia Bonding Promotion Using High-Silica PVD Coating with High Ionization Sputtering Processing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Zirconia Surface Preparation

2.2. TSC Specimens’ Preparation

2.3. High Silica Content Coating by PVD-High Ionization Sputtering Technique

2.4. Preparation of the Silane Primer

2.5. Bonding of Resin Composite to Silica-Coated and Silanized Zirconia

2.6. Shear Bond Strength (SBS) Test

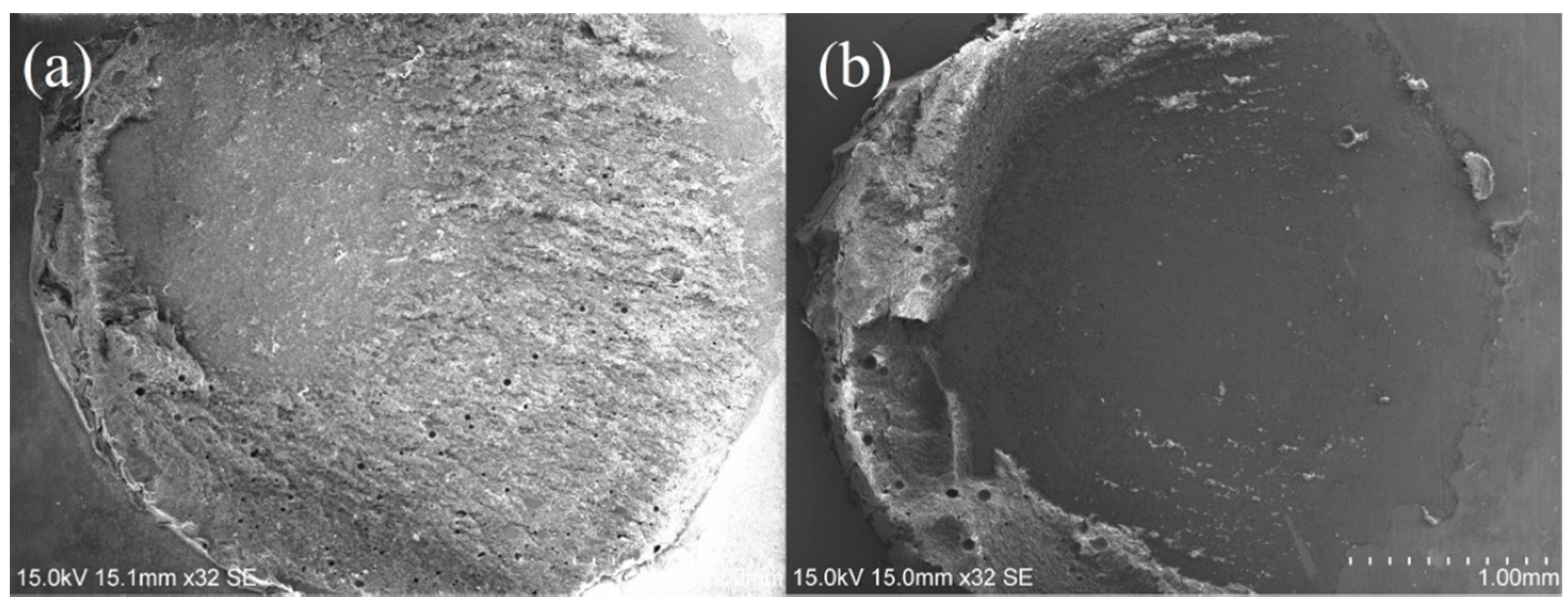

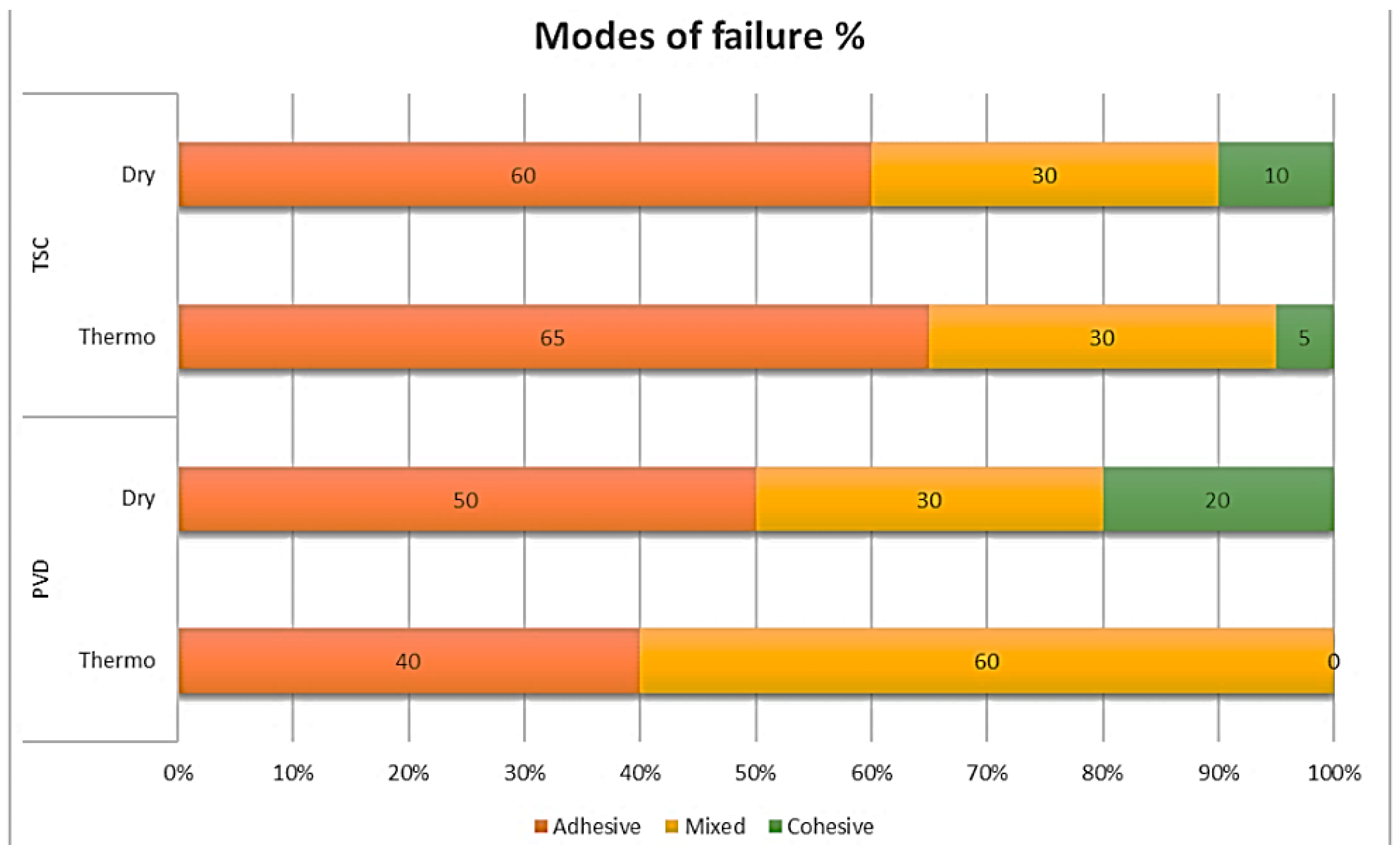

2.7. Mode of Failure

2.8. Surface Roughness (Ra)

2.9. Characterization of Phase Transformation of Zirconia Using X-ray Diffraction (XRD)

2.10. Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDX) Analysis

2.11. Statistical Analysis

3. Results

3.1. Shear Bond Strength (SBS)

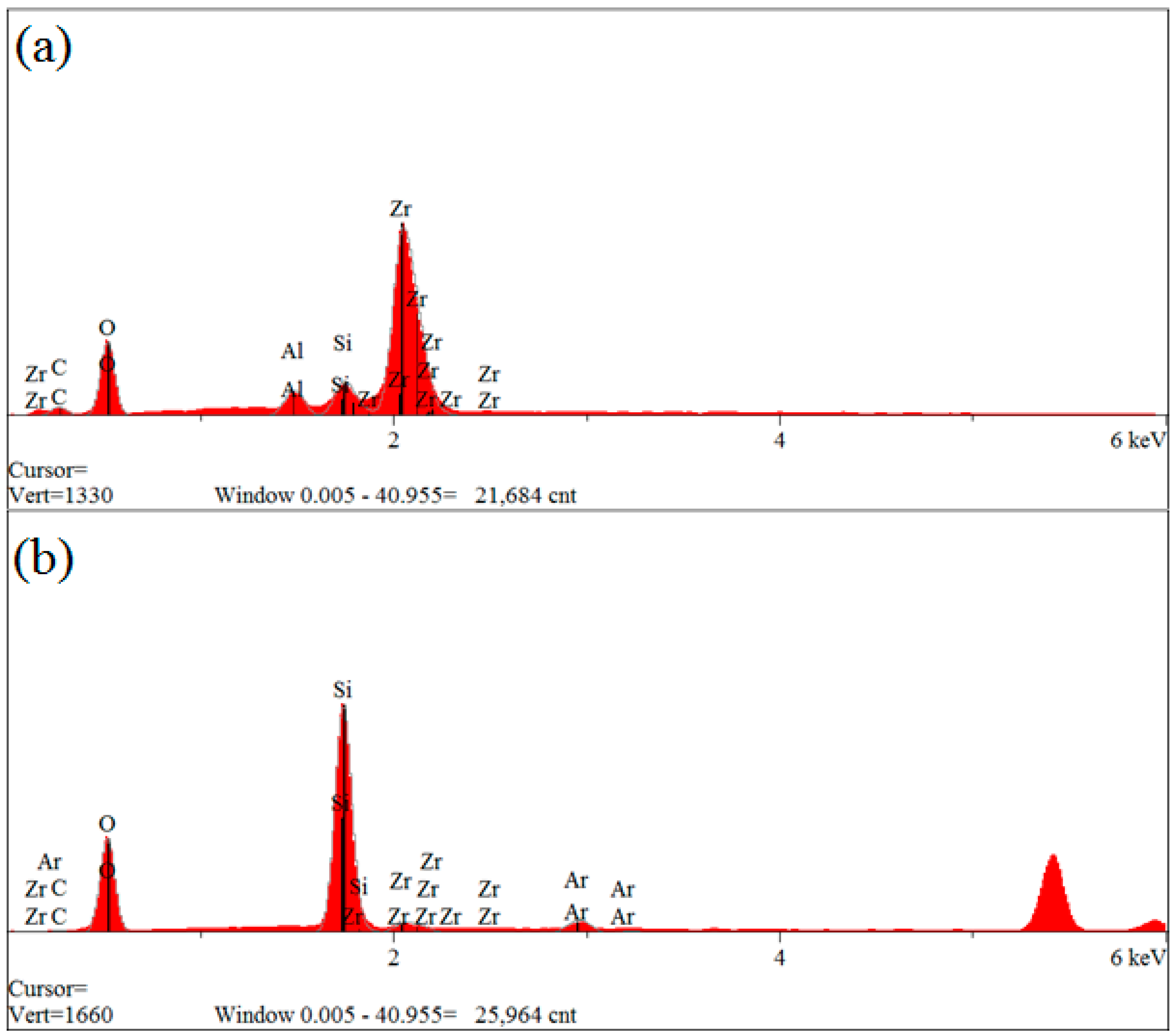

3.2. EDX Elemental Analysis of Treated Surfaces

3.3. Mode of Failure Assessment

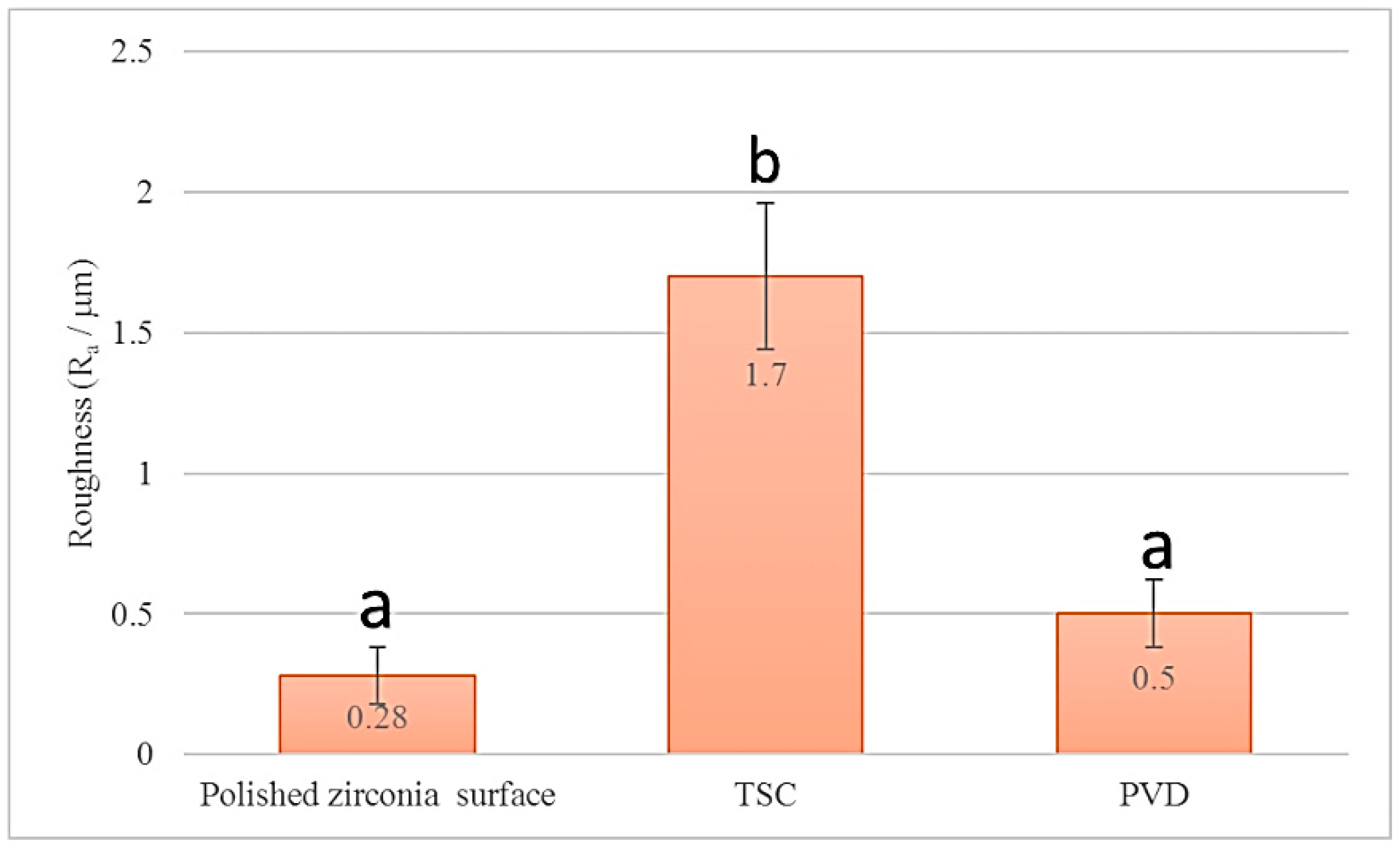

3.4. Surface Roughness

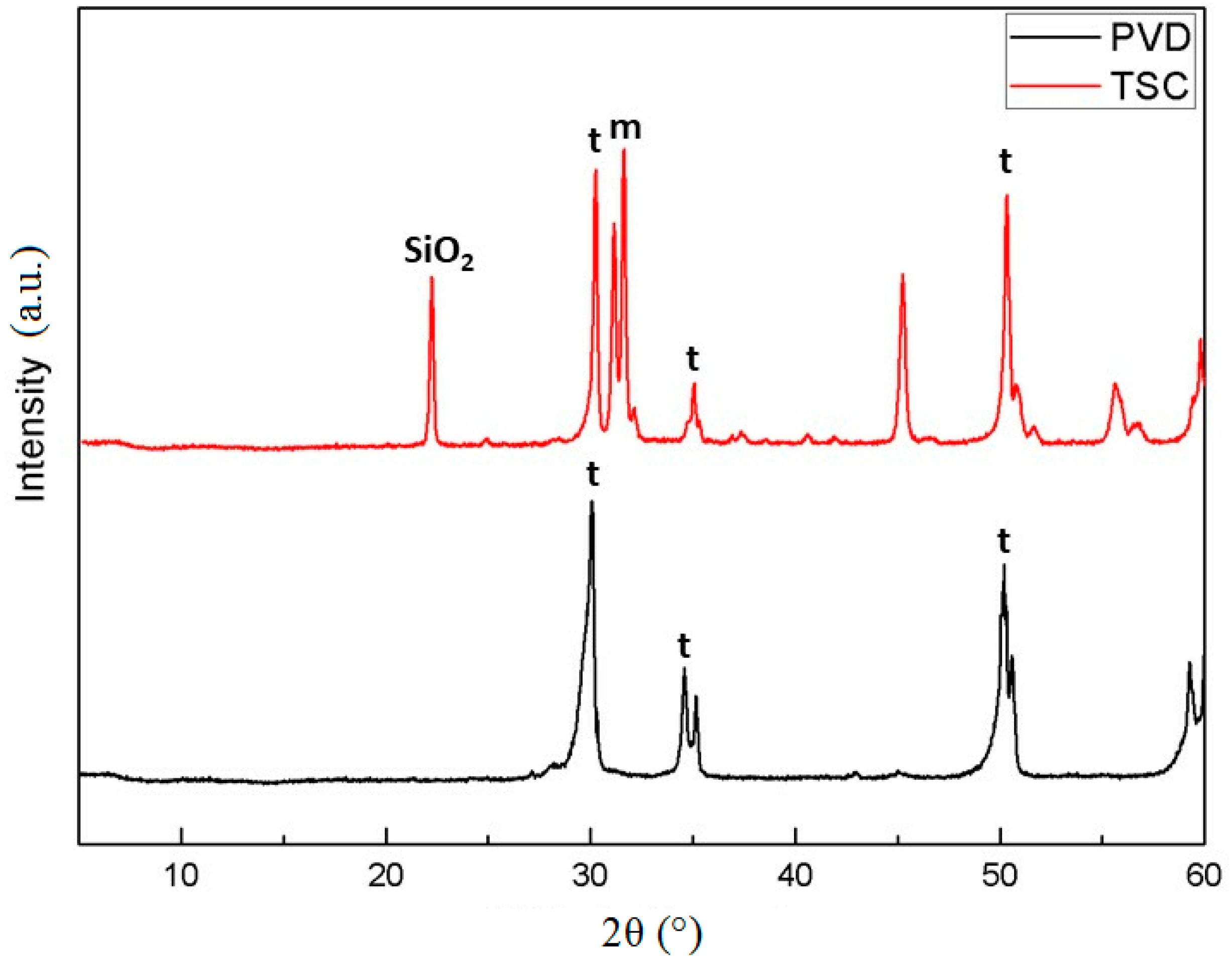

3.5. XRD Analysis

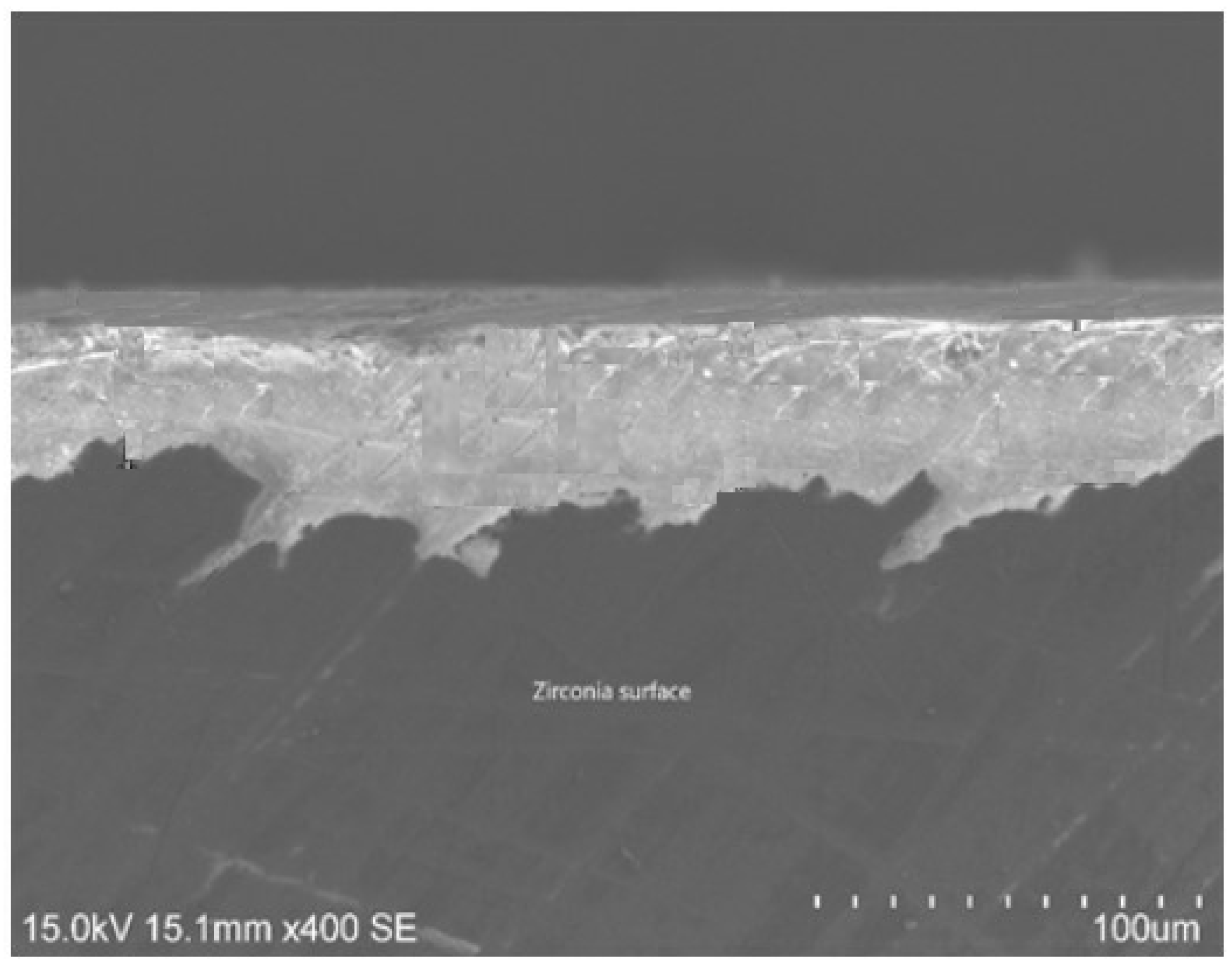

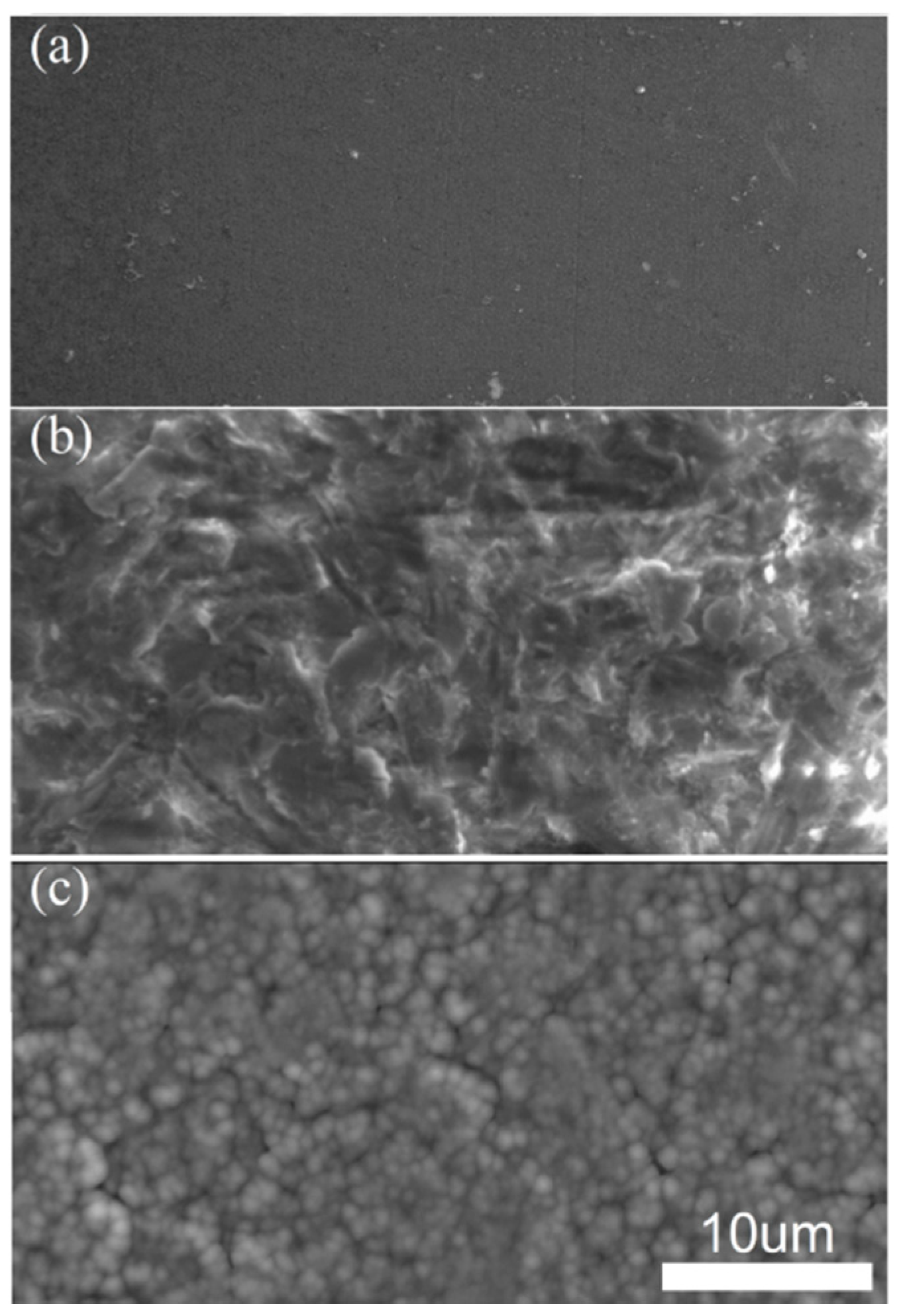

3.6. Surface Morphology Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Piascik, J.R.; Swift, E.J.; Thompson, J.Y.; Grego, S.; Stoner, B.R. Surface modification for enhanced silanation of zirconia ceramics. Dent. Mater. 2009, 25, 1116–1121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Blatz, M.B.; Sadan, A.; Kern, M. Resin-ceramic bonding: A review of the literature. J. Prosthet. Dent. 2003, 89, 268–274. [Google Scholar] [CrossRef] [PubMed]

- Della Bona, A.; Pecho, O.E.; Alessandretti, R. Zirconia as a dental biomaterial. Materials 2015, 8, 4978–4991. [Google Scholar] [CrossRef] [PubMed]

- Pittayachawan, P.; McDonald, A.; Petrie, A.; Knowles, J.C. The biaxial flexural strength and fatigue property of Lava Y-TZP dental ceramic. Dent. Mater. 2007, 23, 1018–1029. [Google Scholar] [CrossRef] [PubMed]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef] [PubMed]

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation toughening in zirconia-containing ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Borges, G.A.; Sophr, A.M.; de Goes, M.F.; Sobrinho, L.C.; Chan, D.C. Effect of etching and airborne particle abrasion on the microstructure of different dental ceramics. J. Prosthet. Dent. 2003, 89, 479–488. [Google Scholar] [CrossRef]

- Soares, C.J.; Soares, P.V.; Pereira, J.C.; Fonseca, R.B. Surface treatment protocols in the cementation process of ceramic and laboratory-processed composite restorations: A literature review. J. Esthet. Restor. Dent. 2005, 17, 224–235. [Google Scholar] [CrossRef] [PubMed]

- Tinschert, J.; Schulze, K.A.; Natt, G.; Latzke, P.; Heussen, N.; Spiekermann, H. Clinical behavior of zirconia-based fixed partial dentures made of DC-Zirkon: 3-year results. Int. J. Prosthodont. 2008, 21, 217–222. [Google Scholar] [PubMed]

- Chen, J.H.; Matsumura, H.; Atsuta, M. Effect of different etching periods on the bond strength of a composite resin to a machinable porcelain. J. Dent. 1998, 26, 53–58. [Google Scholar] [CrossRef]

- Tian, T.; Tsoi, J.K.; Matinlinna, J.P.; Burrow, M.F. Aspects of bonding between resin luting cements and glass ceramic materials. Dent. Mater. 2014, 30, e147–e162. [Google Scholar] [CrossRef] [PubMed]

- Wong, A.C.H.; Tian, T.; Tsoi, J.K.H.; Burrow, M.F.; Matinlinna, J.P. Aspects of adhesion tests on resin-glass ceramic bonding. Dent. Mater. 2017, 33, 1045–1055. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Tsoi, J.K.; Matinlinna, J.P.; Wong, H.M. Effects of some chemical surface modifications on resin zirconia adhesion. J. Mech. Behav. Biomed. Mater. 2015, 46, 23–30. [Google Scholar] [CrossRef] [PubMed]

- Kitayama, S.; Nikaido, T.; Maruoka, R.; Zhu, L.; Ikeda, M.; Watanabe, A.; Foxton, R.M.; Miura, H.; Tagami, J. Effect of an internal coating technique on tensile bond strengths of resin cements to zirconia ceramics. Dent. Mater. J. 2009, 28, 446–453. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kern, M.; Wegner, S.M. Bonding to zirconia ceramic: Adhesion methods and their durability. Dent. Mater. 1998, 14, 64–71. [Google Scholar] [CrossRef]

- Liu, D.; Matinlinna, J.P.; Tsoi, J.K.; Pow, E.H.; Miyazaki, T.; Shibata, Y.; Kan, C.W. A new modified laser pretreatment for porcelain zirconia bonding. Dent. Mater. 2013, 29, 559–565. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Pow, E.H.N.; Tsoi, J.K.; Matinlinna, J.P. Evaluation of four surface coating treatments for resin to zirconia bonding. J. Mech. Behav. Biomed. Mater. 2014, 32, 300–309. [Google Scholar] [CrossRef] [PubMed]

- Aboushelib, M.N.; Kleverlaan, C.J.; Feilzer, A.J. Selective infiltration-etching technique for a strong and durable bond of resin cements to zirconia-based materials. J. Prosthet. Dent. 2007, 98, 379–388. [Google Scholar] [CrossRef]

- Wolfart, M.; Lehmann, F.; Wolfart, S.; Kern, M. Durability of the resin bond strength to zirconia ceramic after using different surface conditioning methods. Dent. Mater. 2007, 23, 45–50. [Google Scholar] [CrossRef] [PubMed]

- Kern, M. Bonding to oxide ceramics—Laboratory testing versus clinical outcome. Dent. Mater. 2015, 31, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Matinlinna, J.P.; Areva, S.; Lassila, L.V.; Vallittu, P.K. Characterization of siloxane films on titanium substrate derived from three aminosilanes. Surf. Interface Anal. 2004, 36, 1314–1322. [Google Scholar] [CrossRef]

- Lung, C.Y.; Matinlinna, J.P. Aspects of silane coupling agents and surface conditioning in dentistry: An overview. Dent. Mater. 2012, 28, 467–477. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lawn, B.R. Novel zirconia materials in dentistry. J. Dent. Res. 2018, 97, 140–147. [Google Scholar] [CrossRef] [PubMed]

- Nishigawa, G.; Maruo, Y.; Irie, M.; Oka, M.; Yoshihara, K.; Minagi, S.; Nagaoka, N.; Yoshida, Y.; Suzuki, K. Ultrasonic cleaning of silica-coated zirconia influences bond strength between zirconia and resin luting material. Dent. Mater. J. 2008, 27, 842–848. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Queiroz, J.R.C.; Duarte, D.A.; Souza, R.O.A.; Fissmer, S.F.; Massi, M.; Bottino, M.A. Deposition of SiOx thin films on Y-TZP by reactive magnetron sputtering: Influence of plasma parameters on the adhesion properties between Y-TZP and resin cement for application in dental prosthesis. Mater. Res. 2011, 14, 212–216. [Google Scholar] [CrossRef]

- Sesthan, K.; Schepis, D. Handbook of Thin Film Deposition, 4th ed.; Elsevier: Cambridge, MA, USA, 2018. [Google Scholar]

- Cakir-Omur, T.; Gozneli, R.; Ozkan, Y. Effects of silica coating by physical vapor deposition and repeated firing on the low-temperature degradation and flexural strength of a zirconia ceramic. J. Prosthodont. 2019, 28, e186–e194. [Google Scholar] [CrossRef] [PubMed]

- Matinlinna, J.P.; Lassila, L.V.; Vallittu, P.K. Pilot evaluation of resin composite cement adhesion to zirconia using a novel silane system. Acta Odontol. Scand. 2007, 65, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Ho, B.J.; Tsoi, J.K.; Liu, D.; Lung, C.Y.; Wong, H.M.; Matinlinna, J.P. Effects of sandblasting distance and angles on resin cement bonding to zirconia and titanium. Int. J. Adhes. Adhes. 2015, 62, 25–31. [Google Scholar] [CrossRef]

- Matinlinna, J.P.; Lassila, L.V.; Vallittu, P.K. The effect of five silane coupling agents on the bond strength of a luting cement to a silica-coated titanium. Dent. Mater. 2007, 23, 1173–1180. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.C.; Tsoi, J.H.; Zwahlen, R.A.; Matinlinna, J.P. Effects of silica-coating and a zirconate coupling agent on shear bond strength of flowable resin–zirconia bonding. Int J. Adhes. Adhes. 2014, 50, 11–16. [Google Scholar] [CrossRef]

- Matinlinna, J.P.; Heikkinen, T.; Ozcan, M.; Lassila, L.V.; Vallittu, P.K. Evaluation of resin adhesion to zirconia ceramic using some organosilanes. Dent. Mater. 2006, 22, 824–831. [Google Scholar] [CrossRef] [PubMed]

- Atsu, S.S.; Kilicarslan, M.A.; Kucukesmen, H.C.; Aka, P.S. Effect of zirconium-oxide ceramic surface treatments on the bond strength to adhesive resin. J. Prosthet. Dent. 2006, 95, 430–436. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lawn, B.; Rekow, E.D.; Thompson, V.P. Effect of sandblasting on the long-term performance of dental ceramics. J. Biomed. Mater. Res. Part B Appl. Biomater. 2004, 71, 381–386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rasmussen, S.T. Analysis of dental shear bond strength tests, shear or tensile? Int. J. Adhes. Adhes. 1996, 16, 147–154. [Google Scholar] [CrossRef]

- Placido, E.; Meira, J.B.; Lima, R.G.; Muench, A.; de Souza, R.M.; Ballester, R.Y. Shear versus micro-shear bond strength test: A finite element stress analysis. Dent. Mater. 2007, 23, 1086–1092. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.Z.; Homaei, E.; Matinlinna, J.P.; Tsoi, J.K. A new concept and finite-element study on dental bond strength tests. Dent. Mater. 2016, 32, e238–e250. [Google Scholar] [CrossRef] [PubMed]

- Ho, C.M.; Ding, H.; Chen, X.; Tsoi, J.K.; Botelho, M.G. The effects of dry and wet grinding on the strength of dental zirconia. Ceram. Int. 2018, 44, 10451–10462. [Google Scholar] [CrossRef]

- Matinlinna, J.P.; Lassila, L.V. Enhanced resin-composite bonding to zirconia framework after pretreatment with selected silane monomers. Dent. Mater. 2011, 27, 273–280. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lung, C.Y.; Liu, D.; Matinlinna, J.P. Surface treatment of titanium by a polydimethylsiloxane coating on bond strength of resin to titanium. J. Mech. Behav. Biomed. Mater. 2015, 41, 168–176. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.J.; Kang, C.K.; Oh, J.W.; Seo, J.M.; Park, J.M. Evaluation of shear bond strength between dual cure resin cement and zirconia ceramic after thermocycling treatment. J. Adv. Prosthodont. 2015, 7, 1–7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Külünk, S.; Külünk, T.; Ural, C.; Kurt, M.; Baba, S. Effect of air abrasion particles on the bond strength of adhesive resin cement to zirconia core. Acta Odontol. Scand. 2011, 69, 88–94. [Google Scholar] [CrossRef] [PubMed]

- Vanderlei, A.; Bottino, M.A.; Valandro, L.F. Evaluation of resin bond strength to yttria-stabilized tetragonal zirconia and framework marginal fit: Comparison of different surface conditionings. Oper. Dent. 2014, 39, 50–63. [Google Scholar] [CrossRef] [PubMed]

- Han, A.; Tsoi, J.K.H.; Matinlinna, J.P.; Chen, Z. Influence of grit-blasting and hydrofluoric acid etching treatment on surface characteristics and biofilm formation on zirconia. Coatings 2017, 7, 130. [Google Scholar] [CrossRef]

| Groups | Storage | Shear Bond Strength in MPa (Mean ± SD) |

|---|---|---|

| TSC | Dry storage | 10.2 ± 1.2 a/I/α |

| Thermo-cycled | 12.0 ± 1.0 b/i/αβ | |

| PVD | Dry storage | 11.7 ± 1.3 A/II/αβ |

| Thermo-cycled | 12.7 ± 1.9 A/i/β | |

| Level 1 | Capital and small letters alphabets indicate significant difference within test groups-TSC and PVD (Independent t-test); | |

| Level 2 | Capital and small roman numerals indicate significant differences between the storage conditions–Dry and Thermo-cycled (Independent t-test); | |

| Level 3 | Greek alphabets indicate significant differences between the groups overall (One-way ANOVA with the Tukey’s HSD post hoc test); p < 0.05 is significant. | |

| Element | TSC (at.%) | PVD (at.%) |

|---|---|---|

| C | 14.691 | 20.437 |

| O | 48.122 | 17.563 |

| Al | 5.336 | 0 |

| Si | 5.462 | 51.853 |

| Zr | 26.389 | 4.656 |

| Ar | 0 | 5.491 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdalla, M.M.; Lung, C.Y.K.; Tsoi, J.K.H.; Matinlinna, J.P. Dental Resin-Zirconia Bonding Promotion Using High-Silica PVD Coating with High Ionization Sputtering Processing. Coatings 2019, 9, 182. https://doi.org/10.3390/coatings9030182

Abdalla MM, Lung CYK, Tsoi JKH, Matinlinna JP. Dental Resin-Zirconia Bonding Promotion Using High-Silica PVD Coating with High Ionization Sputtering Processing. Coatings. 2019; 9(3):182. https://doi.org/10.3390/coatings9030182

Chicago/Turabian StyleAbdalla, Mohamed Mahmoud, Christie Ying Kei Lung, James Kit Hon Tsoi, and Jukka Pekka Matinlinna. 2019. "Dental Resin-Zirconia Bonding Promotion Using High-Silica PVD Coating with High Ionization Sputtering Processing" Coatings 9, no. 3: 182. https://doi.org/10.3390/coatings9030182

APA StyleAbdalla, M. M., Lung, C. Y. K., Tsoi, J. K. H., & Matinlinna, J. P. (2019). Dental Resin-Zirconia Bonding Promotion Using High-Silica PVD Coating with High Ionization Sputtering Processing. Coatings, 9(3), 182. https://doi.org/10.3390/coatings9030182