Synthesis of Solution-Stable PEDOT-Coated Sulfonated Polystyrene Copolymer PEDOT:P(SS-co-St) Particles for All-Organic NIR-Shielding Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials for P(SS-co-St) and PEDOT:P(SS-co-St) Synthesis

2.2. Preparation of P(SS-co-St) Copolymers

2.3. Synthesis of PEDOT:P(SS-co-St)

2.4. Characterization of P(SS-co-St) and PEDOT:P(SS-co-St)

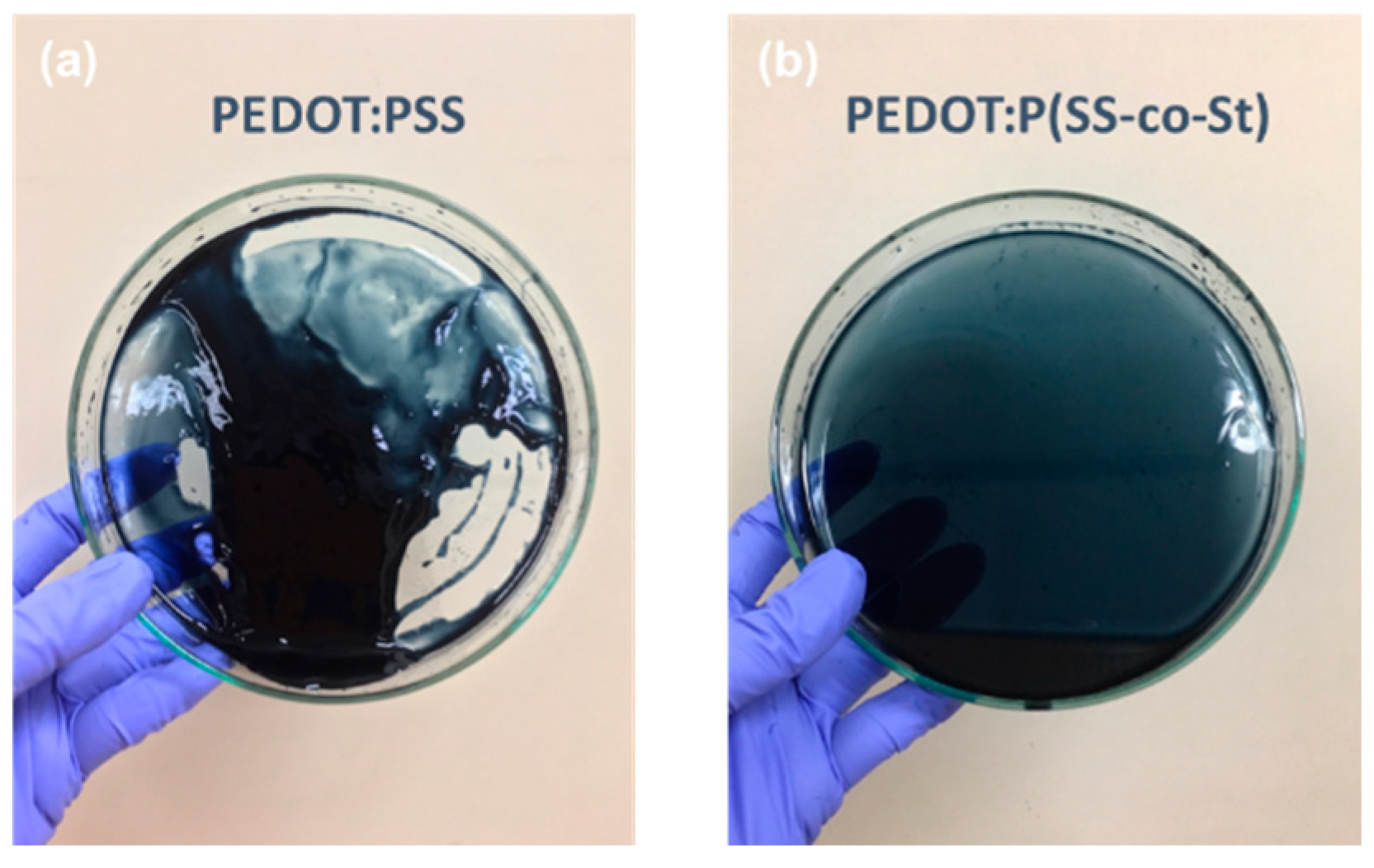

3. Results and Discussion

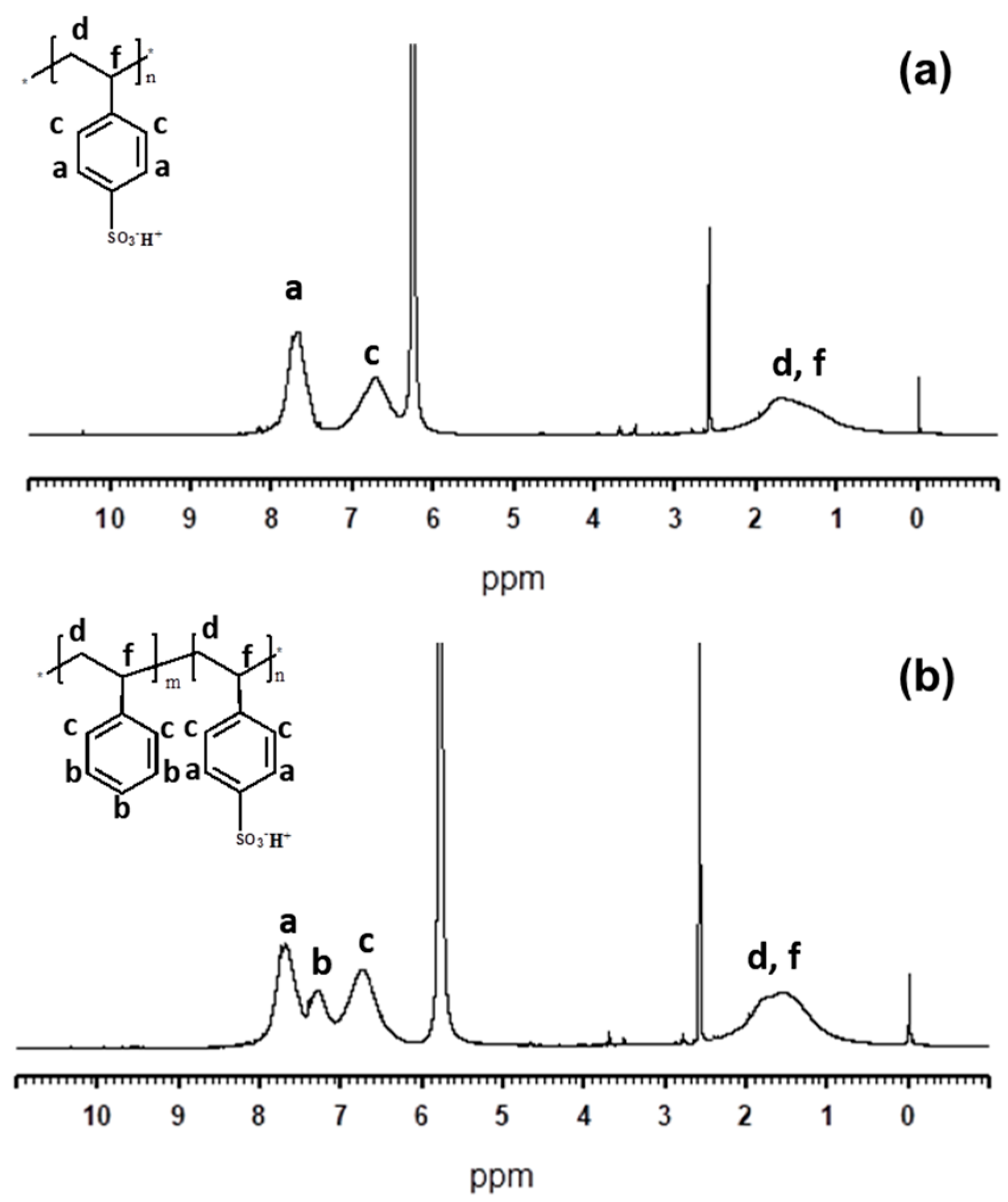

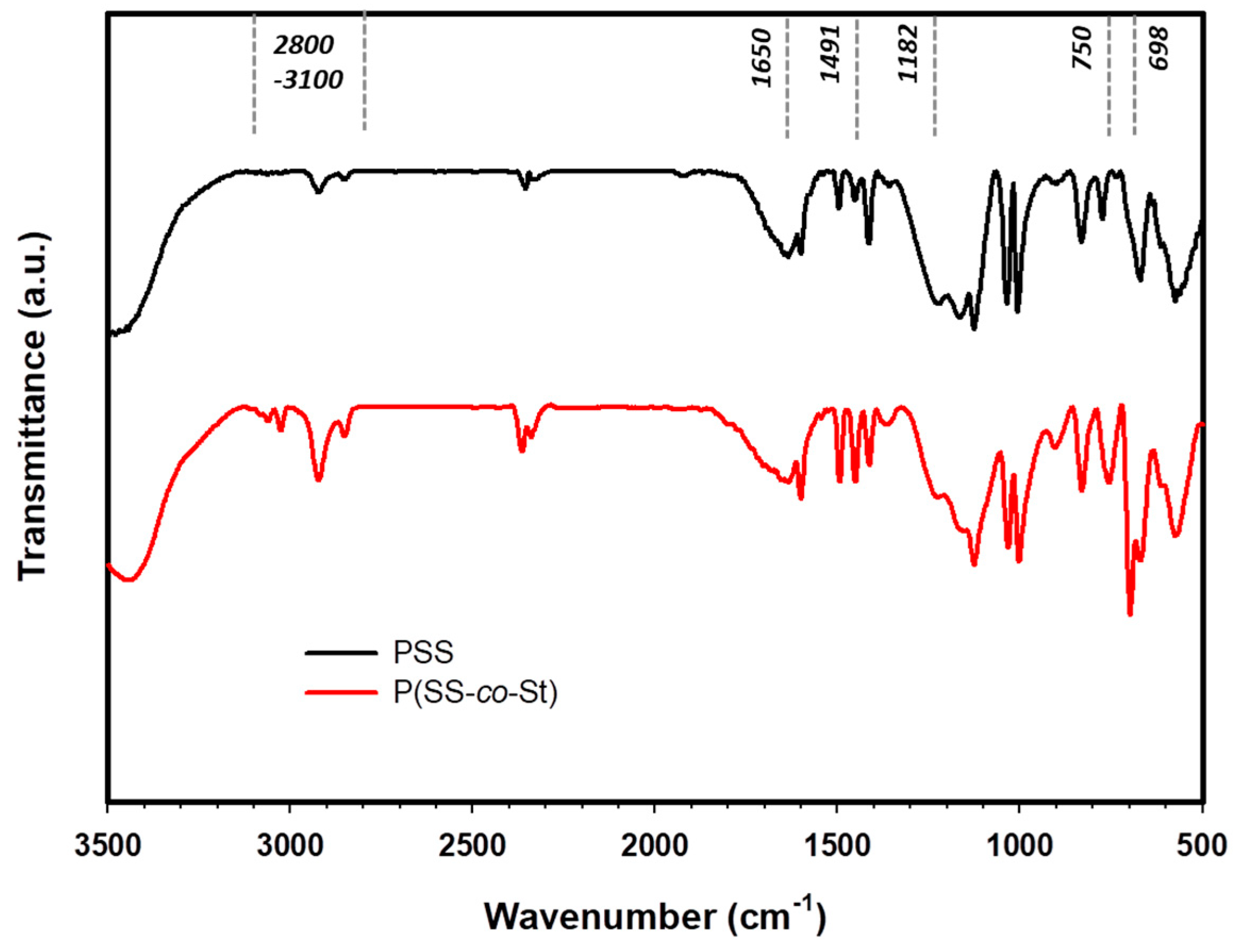

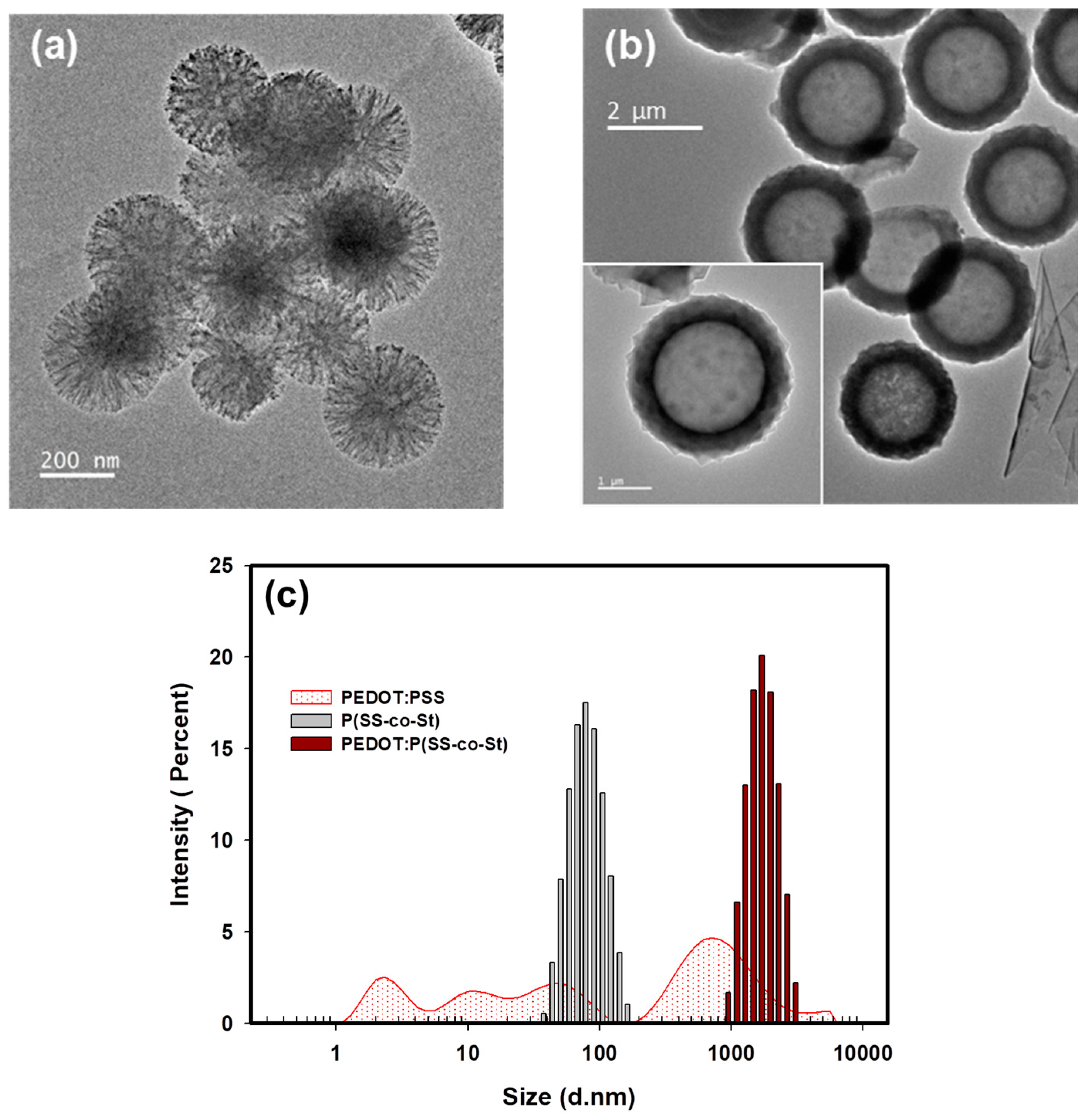

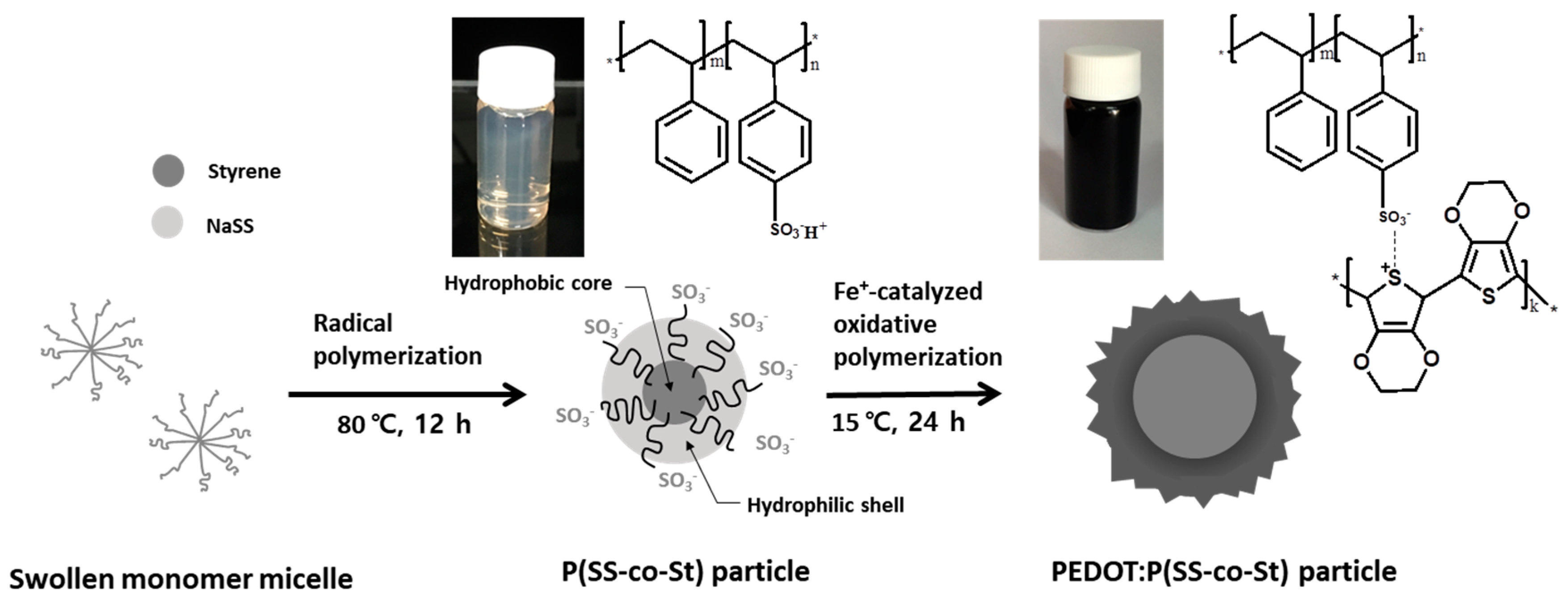

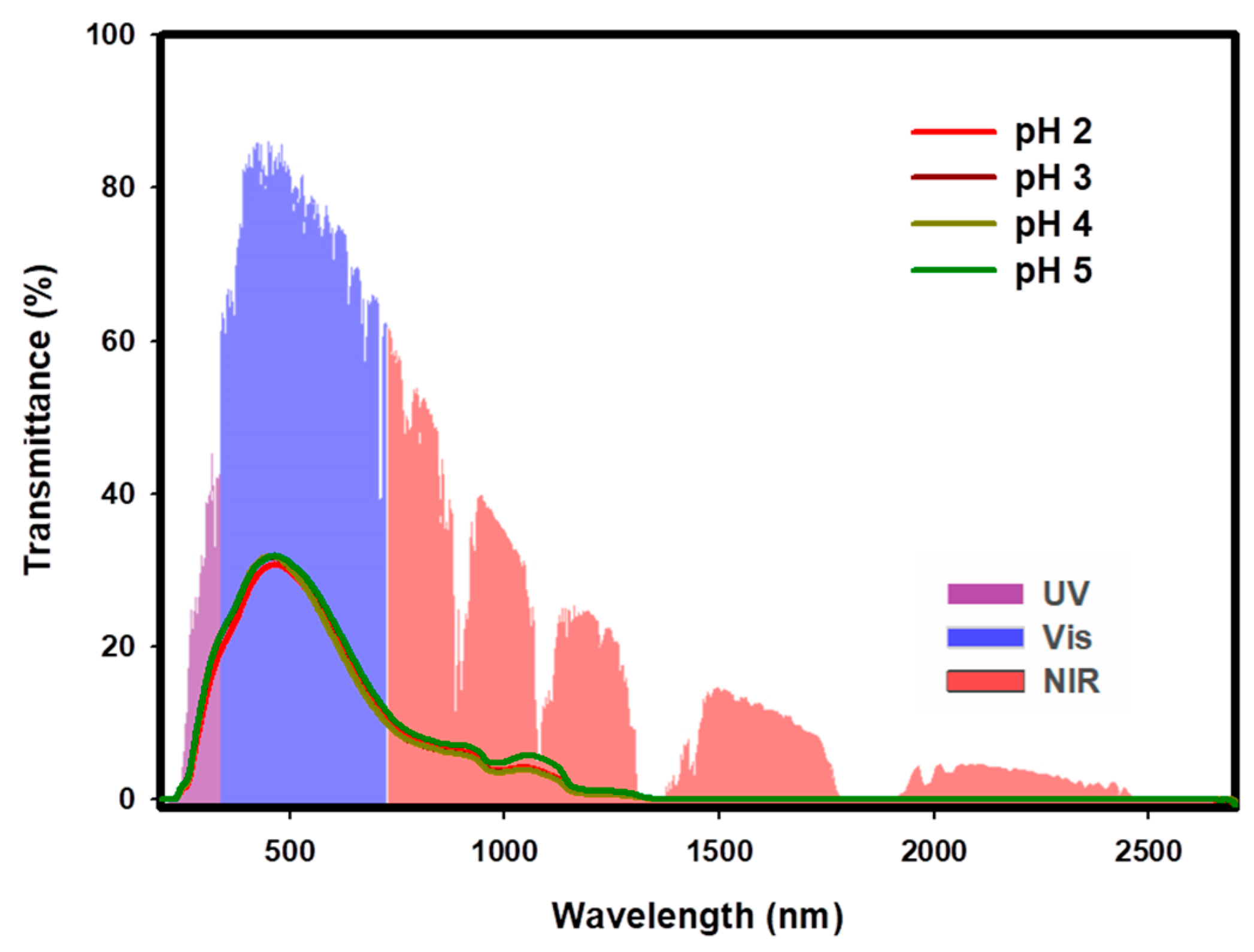

3.1. Synthesis and Characterization of P(SS-co-St) Copolymers

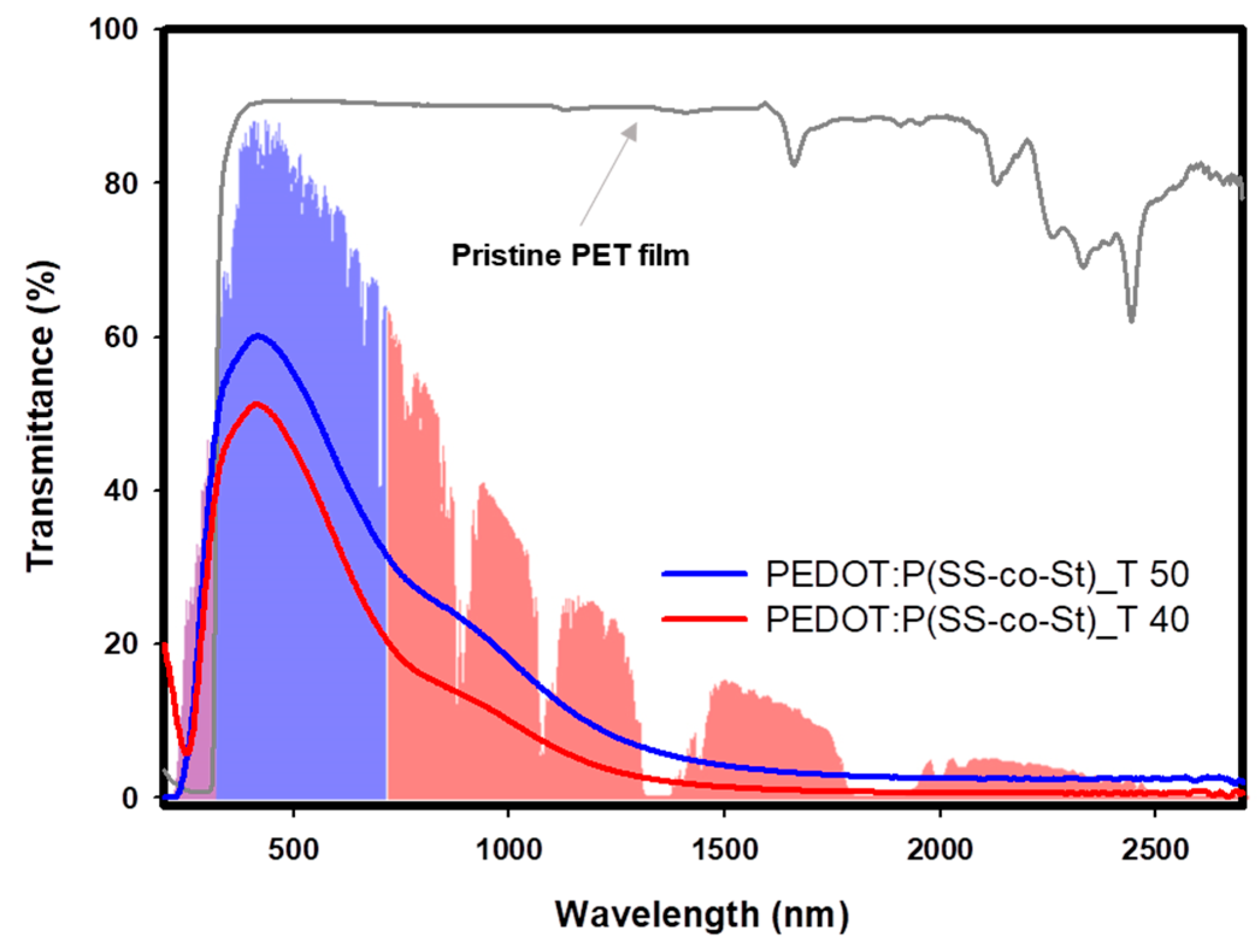

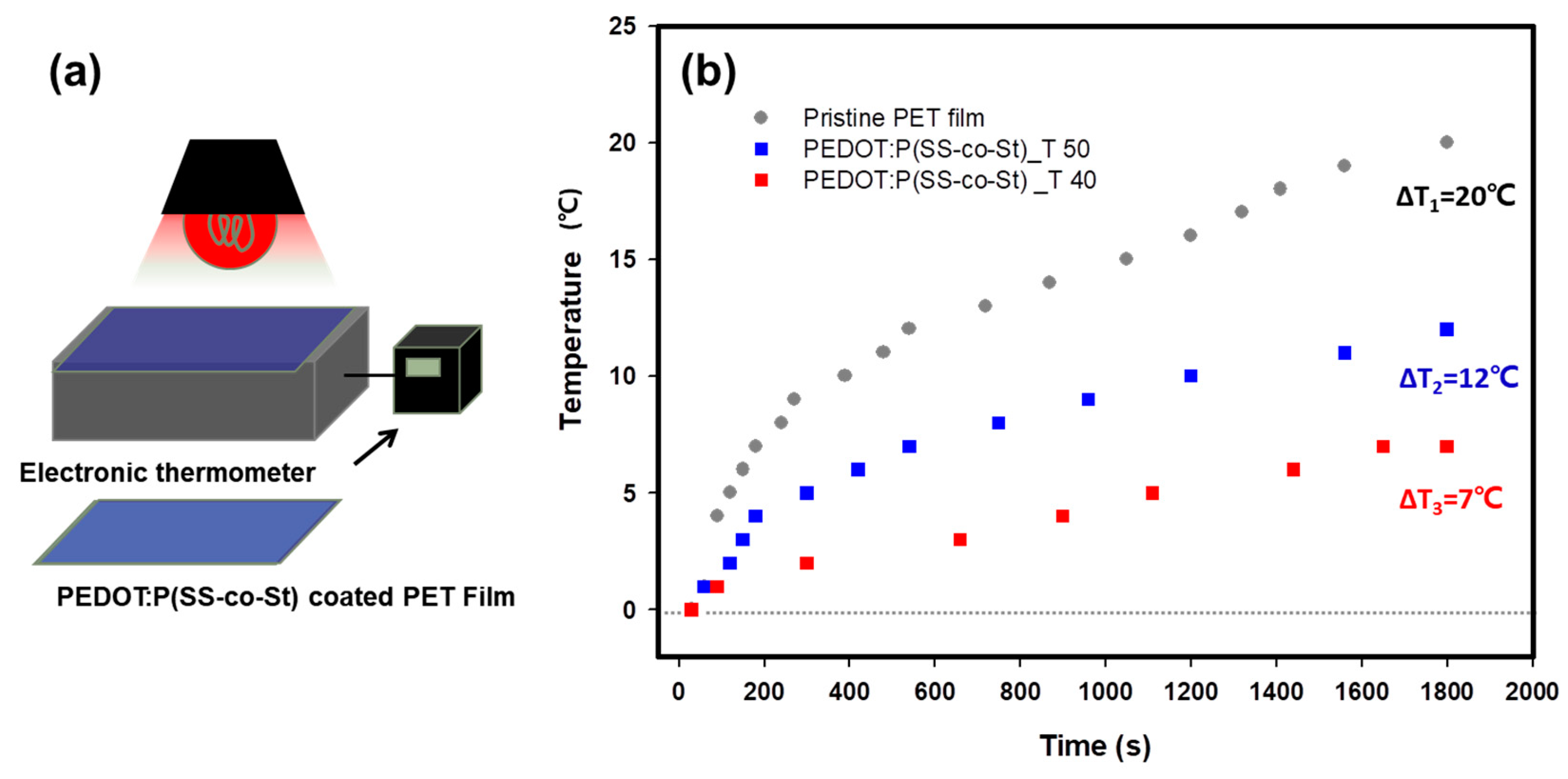

3.2. Heat-Shielding Efficiency of PEDOT:P(SS-co-St) NIR-Shielding Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vierkötter, A.; Krutmann, J. Environmental influences on skin aging and ethnic-specific manifestations. Derm.-Endocrinol. 2012, 4, 227–231. [Google Scholar] [CrossRef] [PubMed]

- Krutmann, J.; Morita, A.; Chung, J.H. Sun exposure: What molecular photodermatology tells us about its good and bad sides. J. Investig. Dermatol. 2012, 132, 976–984. [Google Scholar] [CrossRef] [PubMed]

- Park, C.; Im, S.; Cho, W.; Kim, Y.; Kim, J.H. Facile synthesis of p (edot/ani): Pss with enhanced heat shielding efficiency via two-stage shot growth. RSC Adv. 2018, 8, 12992–12998. [Google Scholar] [CrossRef]

- Chen, X.; Yu, N.; Zhang, L.; Liu, Z.; Wang, Z.; Chen, Z. Synthesis of polypyrrole nanoparticles for constructing full-polymer uv/nir-shielding film. RSC Adv. 2015, 5, 96888–96895. [Google Scholar] [CrossRef]

- Matsui, H.; Hasebe, T.; Hasuike, N.; Tabata, H. Plasmonic heat shielding in the infrared range using oxide semiconductor nanoparticles based on sn-doped in2o3: Effect of size and interparticle gap. ACS Appl. Nano Mater. 2018, 1, 1853–1862. [Google Scholar] [CrossRef]

- Miao, D.; Jiang, S.; Shang, S.; Chen, Z. Effect of heat treatment on infrared reflection property of al-doped zno films. Solar Energy Mater. Solar Cells 2014, 127, 163–168. [Google Scholar] [CrossRef]

- Liu, T.; Liu, B.; Wang, J.; Yang, L.; Ma, X.; Li, H.; Zhang, Y.; Yin, S.; Sato, T.; Sekino, T. Smart window coating based on f-tio 2-k x wo 3 nanocomposites with heat shielding, ultraviolet isolating, hydrophilic and photocatalytic performance. Sci. Rep. 2016, 6, 27373. [Google Scholar] [CrossRef] [PubMed]

- Im, S.; Kim, W.; Cho, W.; Shin, D.; Chun, D.H.; Rhee, R.; Kim, J.K.; Yi, Y.; Park, J.H.; Kim, J.H. Improved stability of interfacial energy-level alignment in inverted planar perovskite solar cells. ACS Appl. Mater. Interfaces 2018, 10, 18964–18973. [Google Scholar] [CrossRef] [PubMed]

- Cho, W.; Hong, J.K.; Lee, J.J.; Kim, S.; Kim, S.; Im, S.; Yoo, D.; Kim, J.H. Synthesis of conductive and transparent pedot: P (ss-co-pegma) with excellent water-, weather-, and chemical-stabilities for organic solar cells. RSC Adv. 2016, 6, 63296–63303. [Google Scholar] [CrossRef]

- Kim, W.; Kim, S.; Chai, S.U.; Jung, M.S.; Nam, J.K.; Kim, J.-H.; Park, J.H. Thermodynamically self-organized hole transport layers for high-efficiency inverted-planar perovskite solar cells. Nanoscale 2017, 9, 12677–12683. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Kim, S.Y.; Kim, J.; Kim, J.H. Highly reliable agnw/pedot: Pss hybrid films: Efficient methods for enhancing transparency and lowering resistance and haziness. J. Mater. Chem. C 2014, 2, 5636–5643. [Google Scholar] [CrossRef]

- Cho, W.; Im, S.; Kim, S.; Kim, S.; Kim, J.H. Synthesis and characterization of pedot: P (ss-co-vtms) with hydrophobic properties and excellent thermal stability. Polymers 2016, 8, 189. [Google Scholar] [CrossRef]

- Kim, Y.; Cho, W.; Kim, Y.; Cho, H.; Kim, J.H. Electrical characteristics of heterogeneous polymer layers in pedot: Pss films. J. Mater. Chem. C 2018, 6, 8906–8913. [Google Scholar] [CrossRef]

- Kim, J.; Chainey, M.L.; El-Aasser, M.; Vanderhoff, J. Emulsifier-free emulsion copolymerization of styrene and sodium styrene sulfonate. J. Polym. Sci. Part A Polym. Chem. 1992, 30, 171–183. [Google Scholar] [CrossRef]

- Sen, A.K.; Roy, S.; Juvekar, V.A. Effect of structure on solution and interfacial properties of sodium polystyrene sulfonate (napss). Polym. Int. 2007, 56, 167–174. [Google Scholar] [CrossRef]

- Arunbabu, D.; Sanga, Z.; Seenimeera, K.M.; Jana, T. Emulsion copolymerization of styrene and sodium styrene sulfonate: Kinetics, monomer reactivity ratios and copolymer properties. Polym. Int. 2009, 58, 88–96. [Google Scholar] [CrossRef]

- Lee, D.K.; Park, J.T.; Roh, D.K.; Min, B.R.; Kim, J.H. Synthesis of crosslinked polystyrene-b-poly (hydroxyethyl methacrylate)-b-poly (styrene sulfonic acid) triblock copolymer for electrolyte membranes. Macromol. Res. 2009, 17, 325–331. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, J.H.; Choi, H.J.; Park, J. Pickering emulsion polymerized poly (3,4-ethylenedioxythiophene): Poly (styrenesulfonate)/polystyrene composite particles and their electric stimuli-response. RSC Adv. 2015, 5, 72387–72393. [Google Scholar] [CrossRef]

- Brijmohan, S.B.; Swier, S.; Weiss, R.; Shaw, M.T. Synthesis and characterization of cross-linked sulfonated polystyrene nanoparticles. Ind. Eng. Chem. Res. 2005, 44, 8039–8045. [Google Scholar] [CrossRef]

- Zhu, C.; Chen, Z.; Ni, C.; Yu, J.; Huang, B.; Shan, M. Degradation of sodium polystyrene sulfonate and the radical initiated polymerization of styrene under ultrasonic irradiation. Polym.-Plast. Technol. Eng. 2011, 50, 1262–1265. [Google Scholar] [CrossRef]

- Ryu, H.W.; Kim, Y.S.; Kim, J.H.; Cheong, I.W. Direct synthetic route for water-dispersible polythiophene nanoparticles via surfactant-free oxidative polymerization. Polymer 2014, 55, 806–812. [Google Scholar] [CrossRef]

- Horikawa, M.; Fujiki, T.; Shirosaki, T.; Ryu, N.; Sakurai, H.; Nagaoka, S.; Ihara, H. The development of a highly conductive pedot system by doping with partially crystalline sulfated cellulose and its electric conductivity. J. Mater. Chem. C 2015, 3, 8881–8887. [Google Scholar] [CrossRef]

- Yao, Q.; Wilkie, C.A. Thermal degradation of blends of polystyrene and poly (sodium 4-styrenesulfonate) and the copolymer, poly (styrene-co-sodium 4-styrenesulfonate). Polym. Degrad. Stab. 1999, 66, 379–384. [Google Scholar] [CrossRef]

- Fan, X.; Niu, L.; Xia, Z. Preparation of raspberry-like silica microcapsules via sulfonated polystyrene template and aniline medium assembly method. Colloid Polym. Sci. 2014, 292, 3251–3259. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, S.J.; Kim, J.H.; Cheong, I.W. Synthesis of polystyrene/polythiophene core/shell nanoparticles by dual initiation. Polymer 2011, 52, 4227–4234. [Google Scholar] [CrossRef]

- Chang-Jian, C.W.; Cho, E.C.; Yen, S.C.; Ho, B.C.; Lee, K.C.; Huang, J.H.; Hsiao, Y.S. Facile preparation of wo3/pedot: PSS composite for inkjet printed electrochromic window and its performance for heat shielding. Dyes Pigments 2018, 148, 465–473. [Google Scholar] [CrossRef]

- Yoon, H.J.; Jeong, S.Y.; Lee, S.; jic Shin, G.; Choi, K.H. Near infrared shielding properties of pedot: PSS with different additives. In Proceedings of the 2012 4th International Conference on Chemical, Biological and Environmental Engineering, Phuket, Thailand, 1 September 2012. [Google Scholar]

- Kim, J.; Jung, J.; Lee, D.; Joo, J. Enhancement of electrical conductivity of poly (3,4-ethylenedioxythiophene)/poly (4-styrenesulfonate) by a change of solvents. Synth. Metals 2002, 126, 311–316. [Google Scholar] [CrossRef]

- Cho, A.; Kim, S.; Kim, S.; Cho, W.; Park, C.; Kim, F.S.; Kim, J.H. Influence of imidazole-based acidity control of pedot: PSS on its electrical properties and environmental stability. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1530–1536. [Google Scholar] [CrossRef]

- Mochizuki, Y.; Horii, T.; Okuzaki, H. Effect of ph on structure and conductivity of pedot/pss. Trans. Mater. Res. Soc. Jpn. 2012, 37, 307–310. [Google Scholar] [CrossRef]

- Han, M.G.; Foulger, S.H. Crystalline colloidal arrays composed of poly (3,4-ethylenedioxythiophene)-coated polystyrene particles with a stop band in the visible regime. Adv. Mater. 2004, 16, 231–234. [Google Scholar] [CrossRef]

- Han, M.G.; Foulger, S.H. Preparation of poly (3,4-ethylenedioxythiophene)(pedot) coated silica core–shell particles and pedot hollow particles. Chem. Commun. 2004, 19, 2154–2155. [Google Scholar] [CrossRef] [PubMed]

| Material | Z-average d (nm) | PDI | Zeta Potential (mV) |

|---|---|---|---|

| P(SS-co-St) | 68.93 | 0.236 | −74.9 |

| PEDOT:P(SS-co-St) | 1695 | 0.261 | −70.4 |

| PEDOT:PSS | 56.84 | 0.726 | −40.4 |

| Sample | Transmittance (%) (550 nm) | NIR Shielding Efficiency (%) (780–1440 nm) |

|---|---|---|

| T 50 | 50.05 | 86.25 |

| T 40 | 39.89 | 92.05 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Im, S.; Park, C.; Cho, W.; Kim, J.; Jeong, M.; Kim, J.H. Synthesis of Solution-Stable PEDOT-Coated Sulfonated Polystyrene Copolymer PEDOT:P(SS-co-St) Particles for All-Organic NIR-Shielding Films. Coatings 2019, 9, 151. https://doi.org/10.3390/coatings9030151

Im S, Park C, Cho W, Kim J, Jeong M, Kim JH. Synthesis of Solution-Stable PEDOT-Coated Sulfonated Polystyrene Copolymer PEDOT:P(SS-co-St) Particles for All-Organic NIR-Shielding Films. Coatings. 2019; 9(3):151. https://doi.org/10.3390/coatings9030151

Chicago/Turabian StyleIm, Soeun, Chanil Park, Wonseok Cho, Jooyoung Kim, Minseok Jeong, and Jung Hyun Kim. 2019. "Synthesis of Solution-Stable PEDOT-Coated Sulfonated Polystyrene Copolymer PEDOT:P(SS-co-St) Particles for All-Organic NIR-Shielding Films" Coatings 9, no. 3: 151. https://doi.org/10.3390/coatings9030151

APA StyleIm, S., Park, C., Cho, W., Kim, J., Jeong, M., & Kim, J. H. (2019). Synthesis of Solution-Stable PEDOT-Coated Sulfonated Polystyrene Copolymer PEDOT:P(SS-co-St) Particles for All-Organic NIR-Shielding Films. Coatings, 9(3), 151. https://doi.org/10.3390/coatings9030151