Expanding Plasma Process for Nitriding Mo–Ti Bilayer Thin Films

Abstract

:1. Introduction

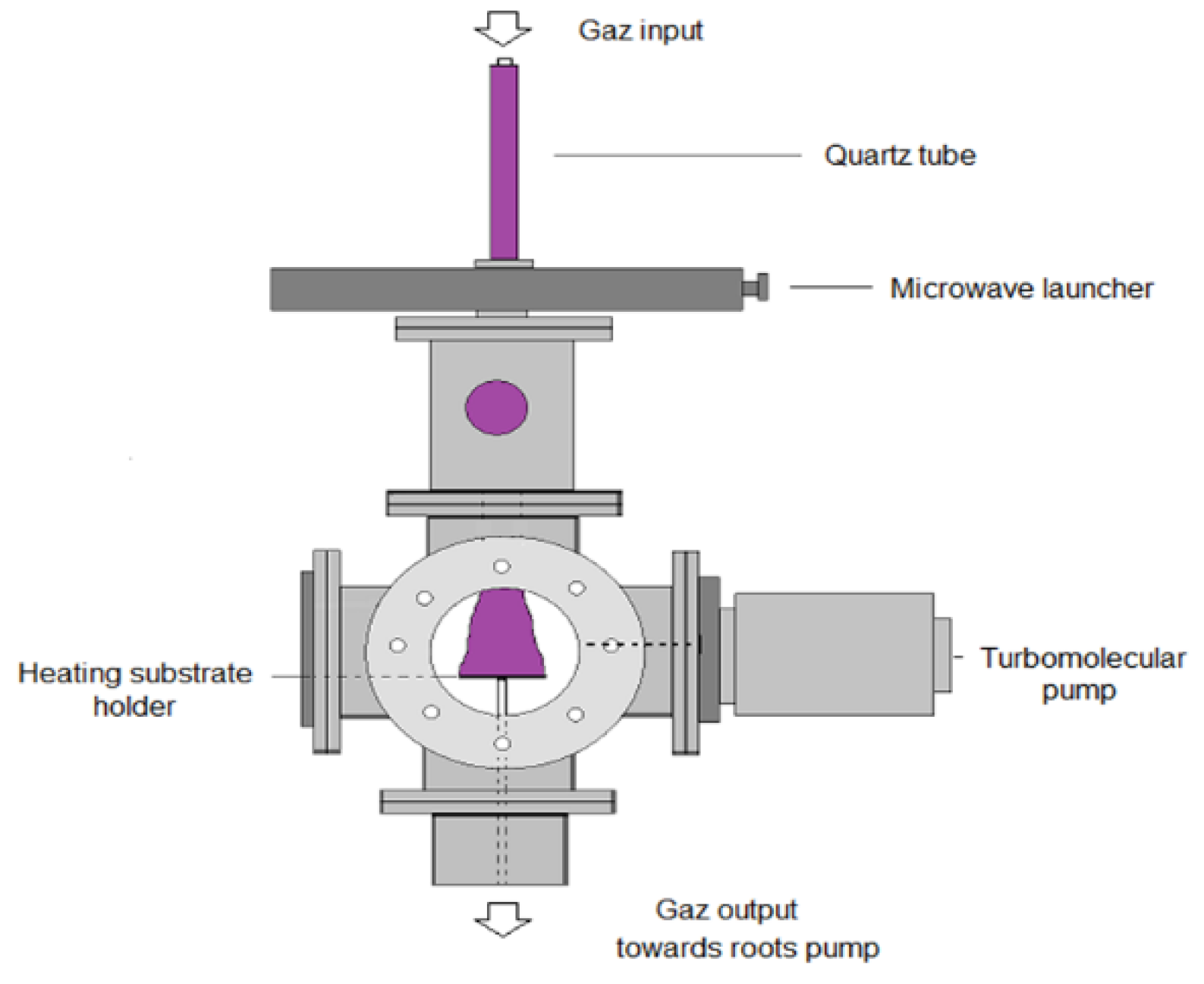

2. Materials and Methods

2.1. Conditions of Formation of an Expanding Plasma

2.2. Deposition of Thin Films

2.3. Plasma Nitriding Process

2.4. Investigations of Mo–Ti Bilayer Films

3. Results

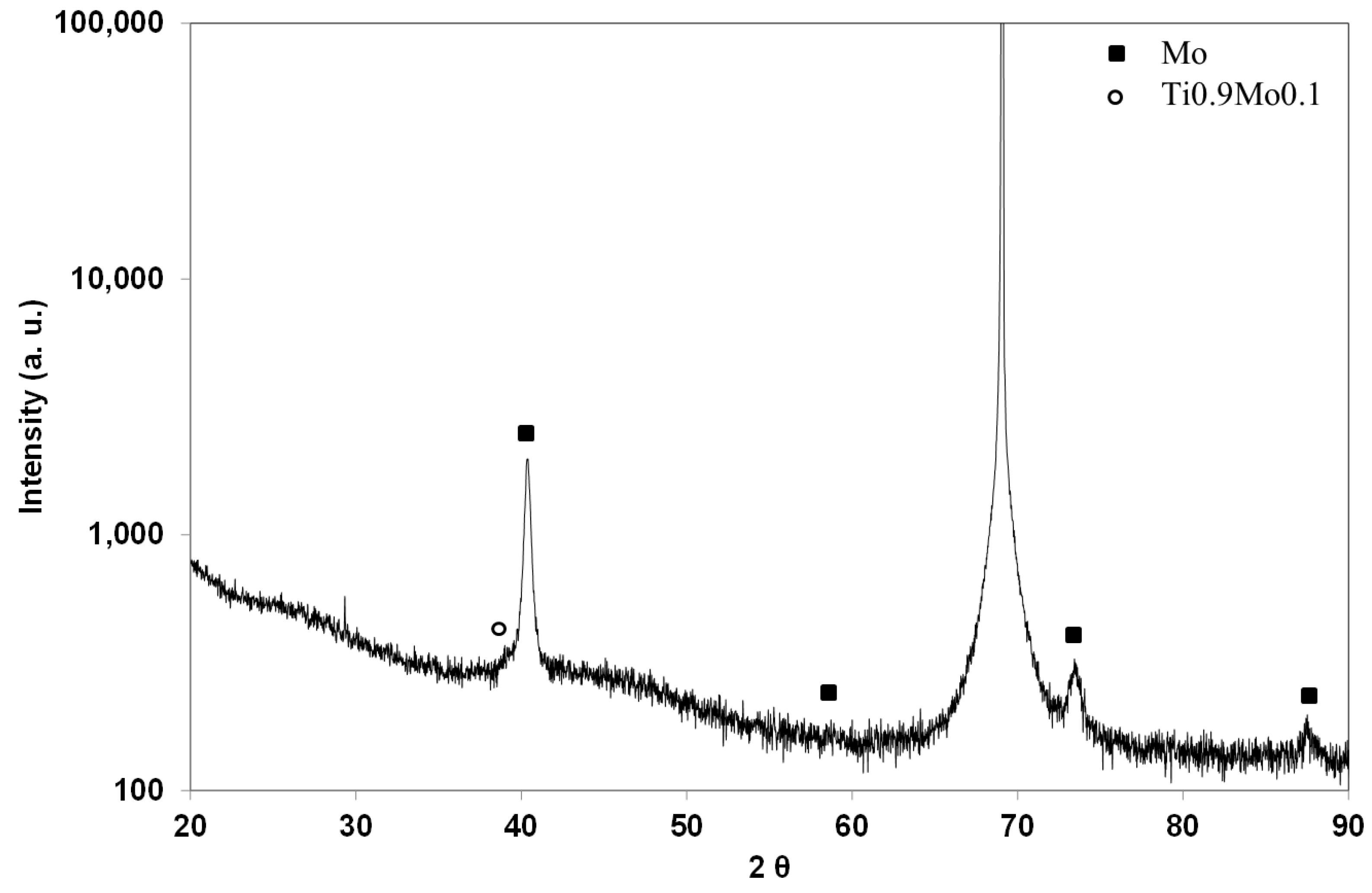

3.1. Mo–Ti Interface Formation of Mo–Ti Solid Solution

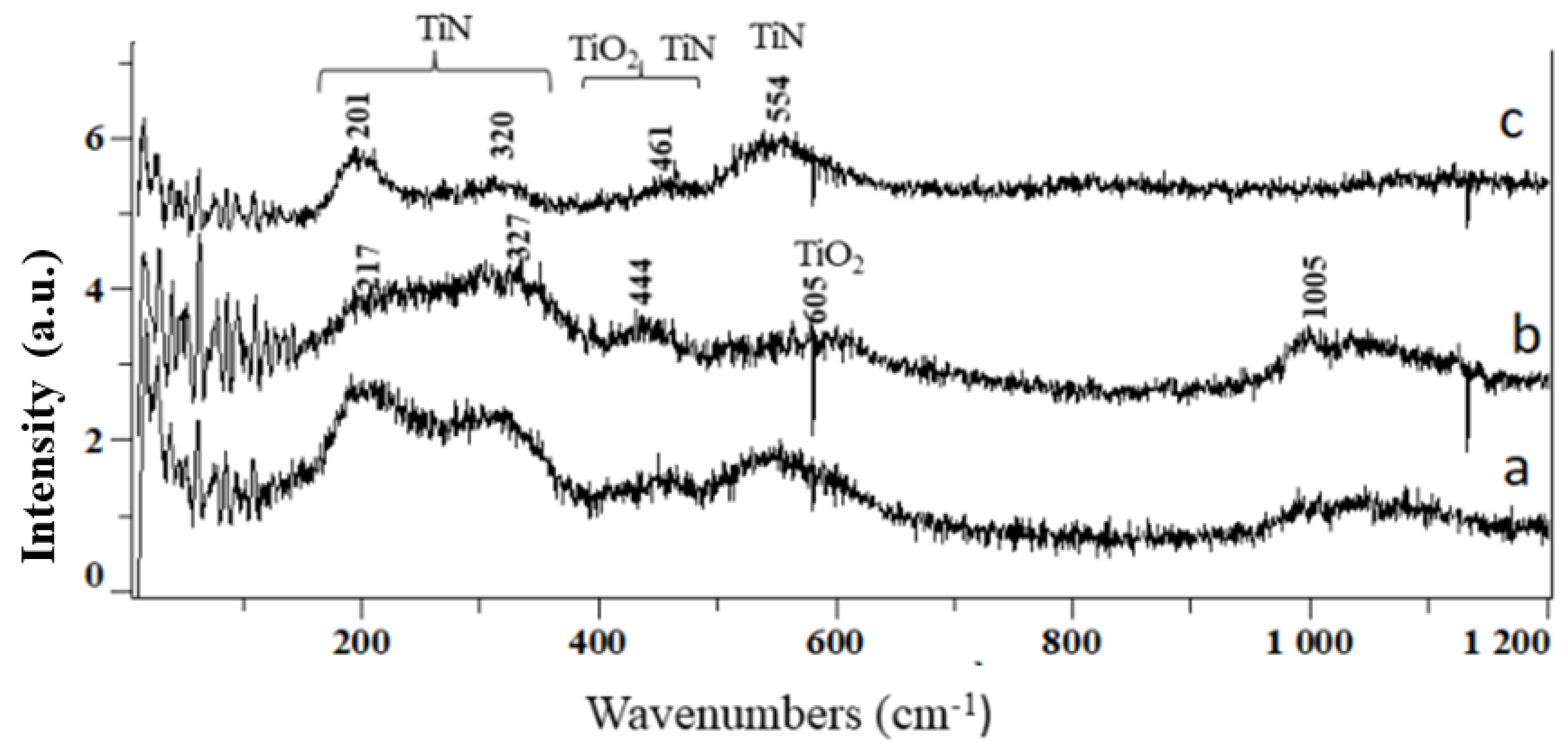

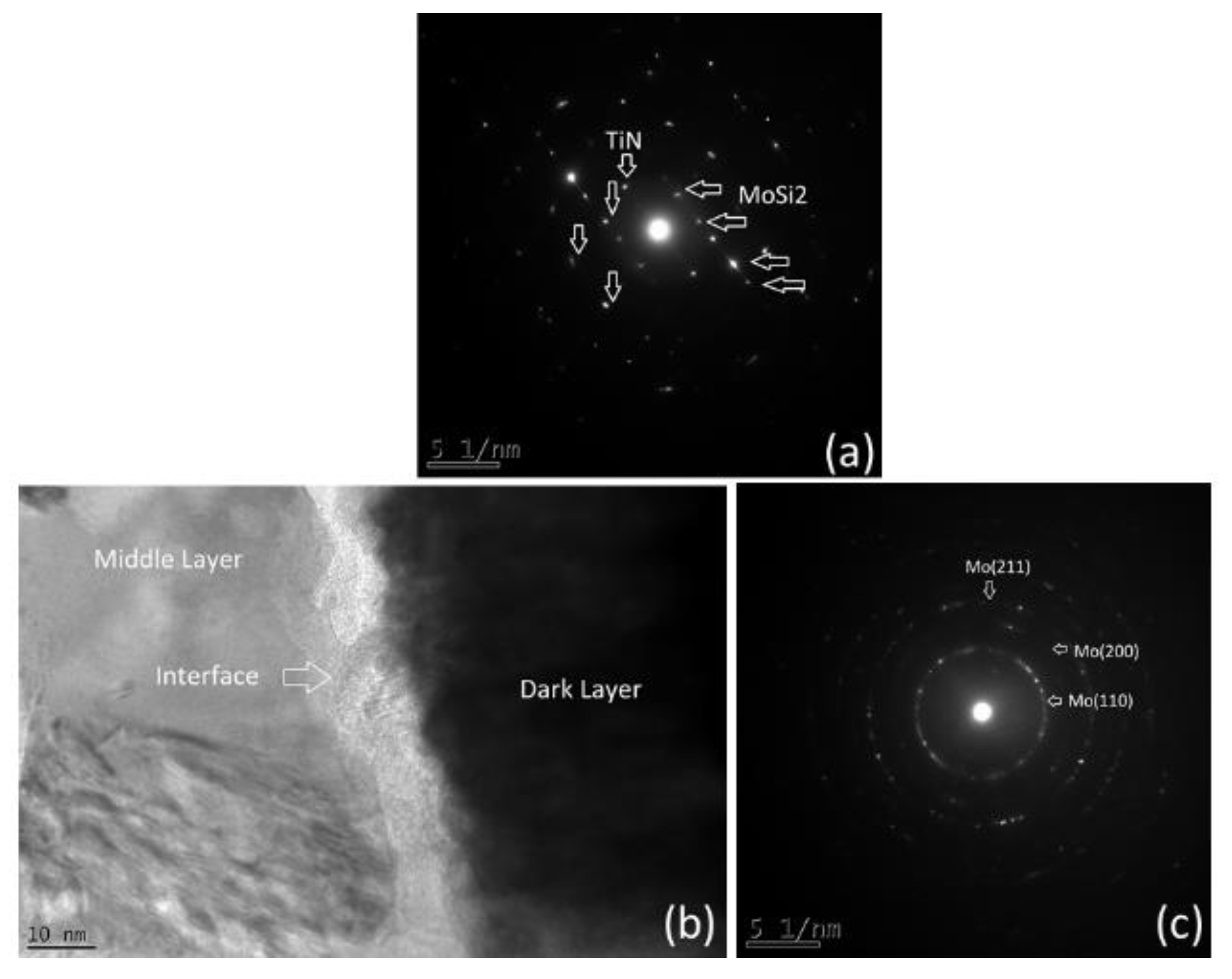

3.2. Formation of TiN and MoSi2 in Mo–Ti Bilayer Films Processed in Expanding Plasma

3.2.1. XRD Investigations

3.2.2. Raman Investigations

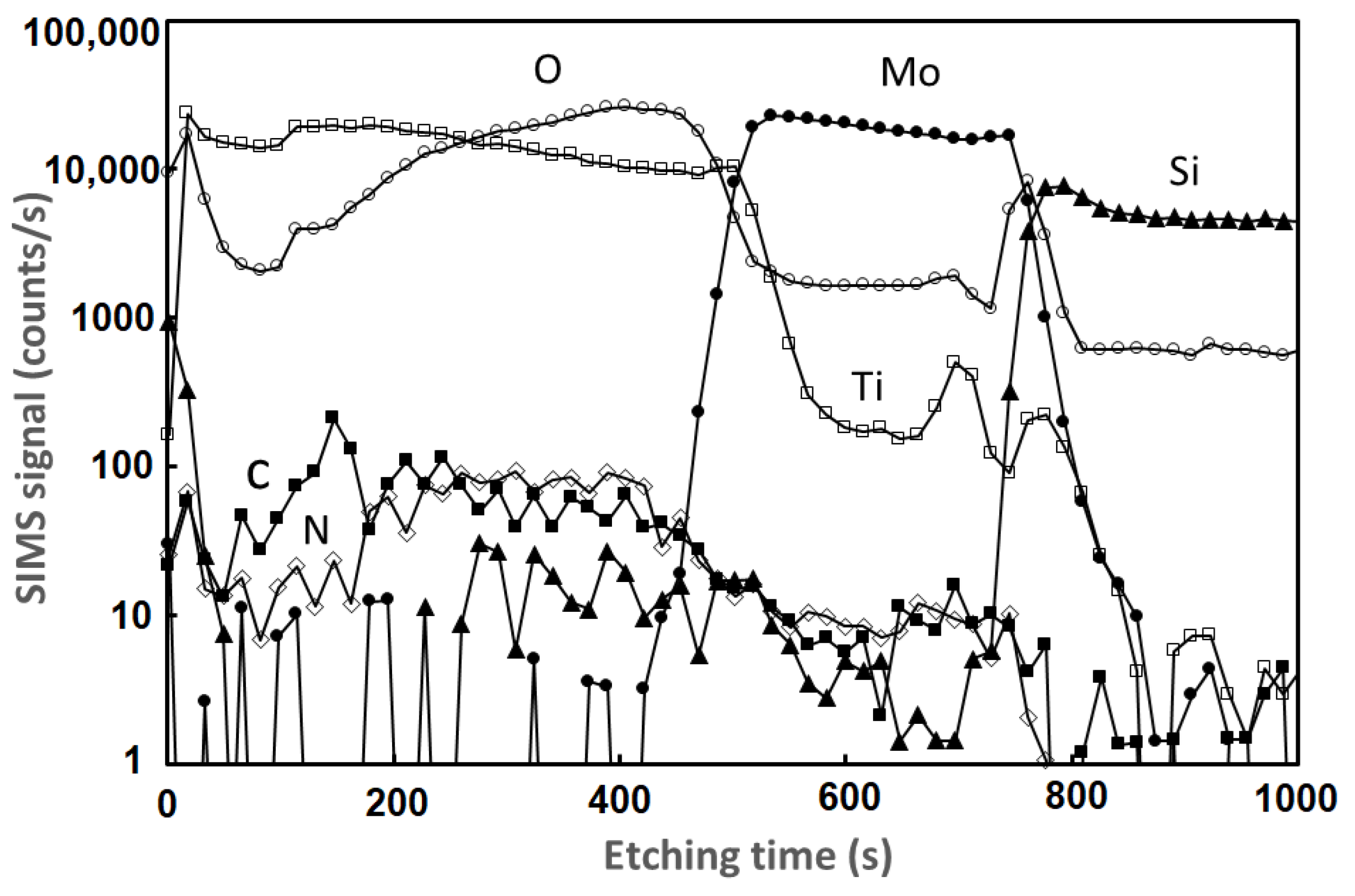

3.3. Diffusion at Ti Surface and Ti–Mo and Mo–Si Interfaces

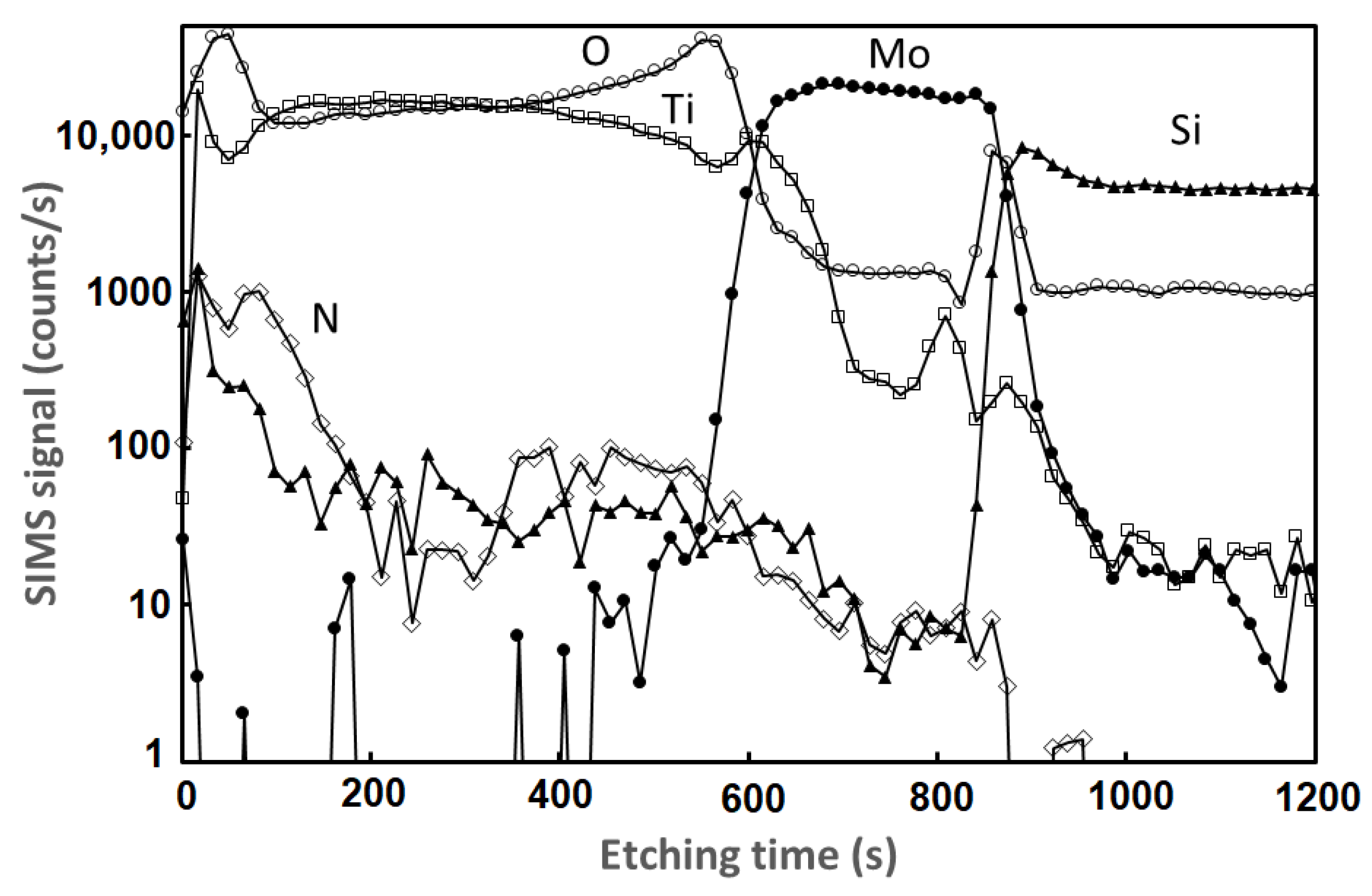

3.3.1. Mo–Ti Bilayer Films Processed at 400 °C

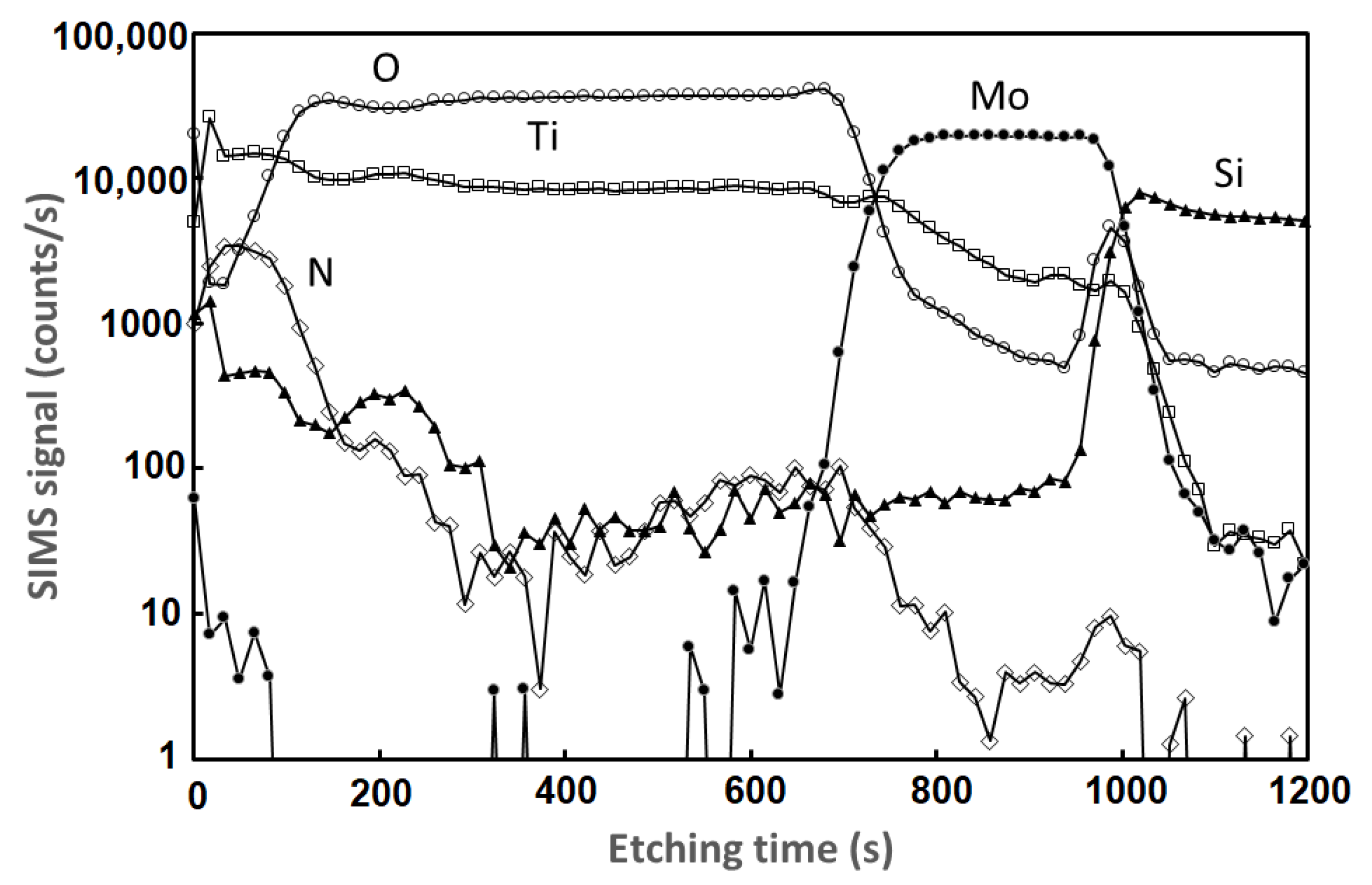

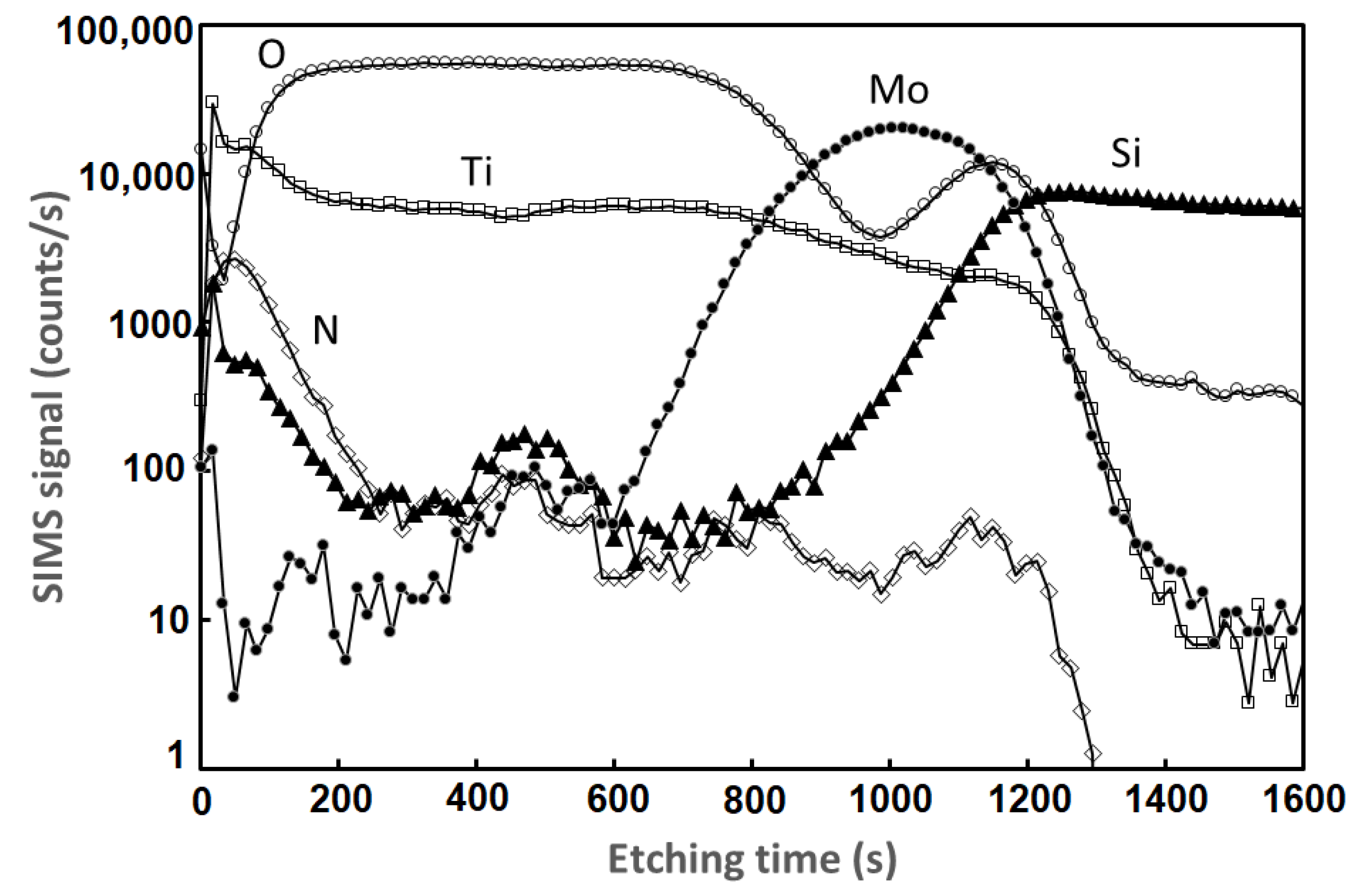

3.3.2. Mo–Ti Bilayer Films Processed at 600 and 800 °C

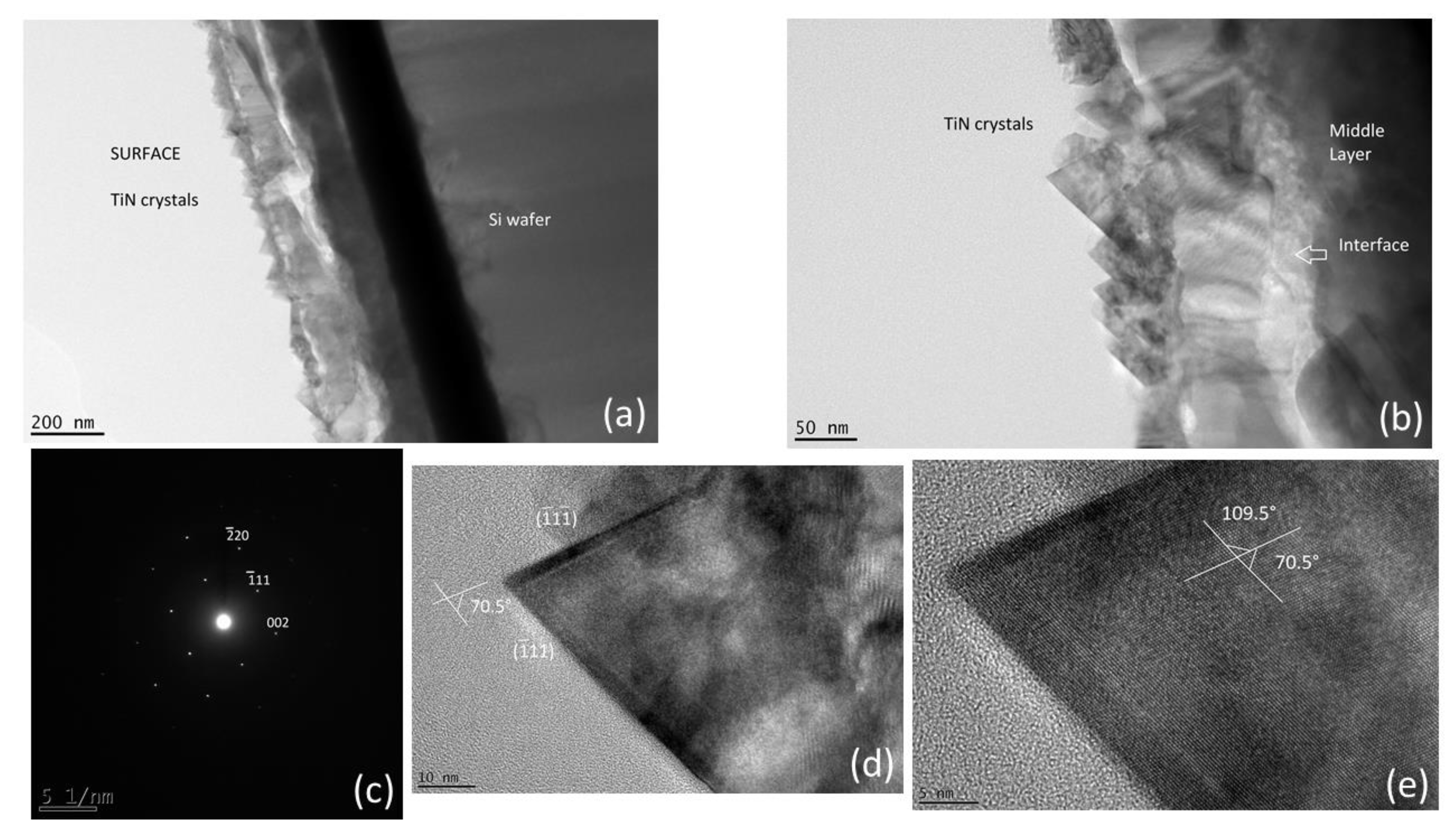

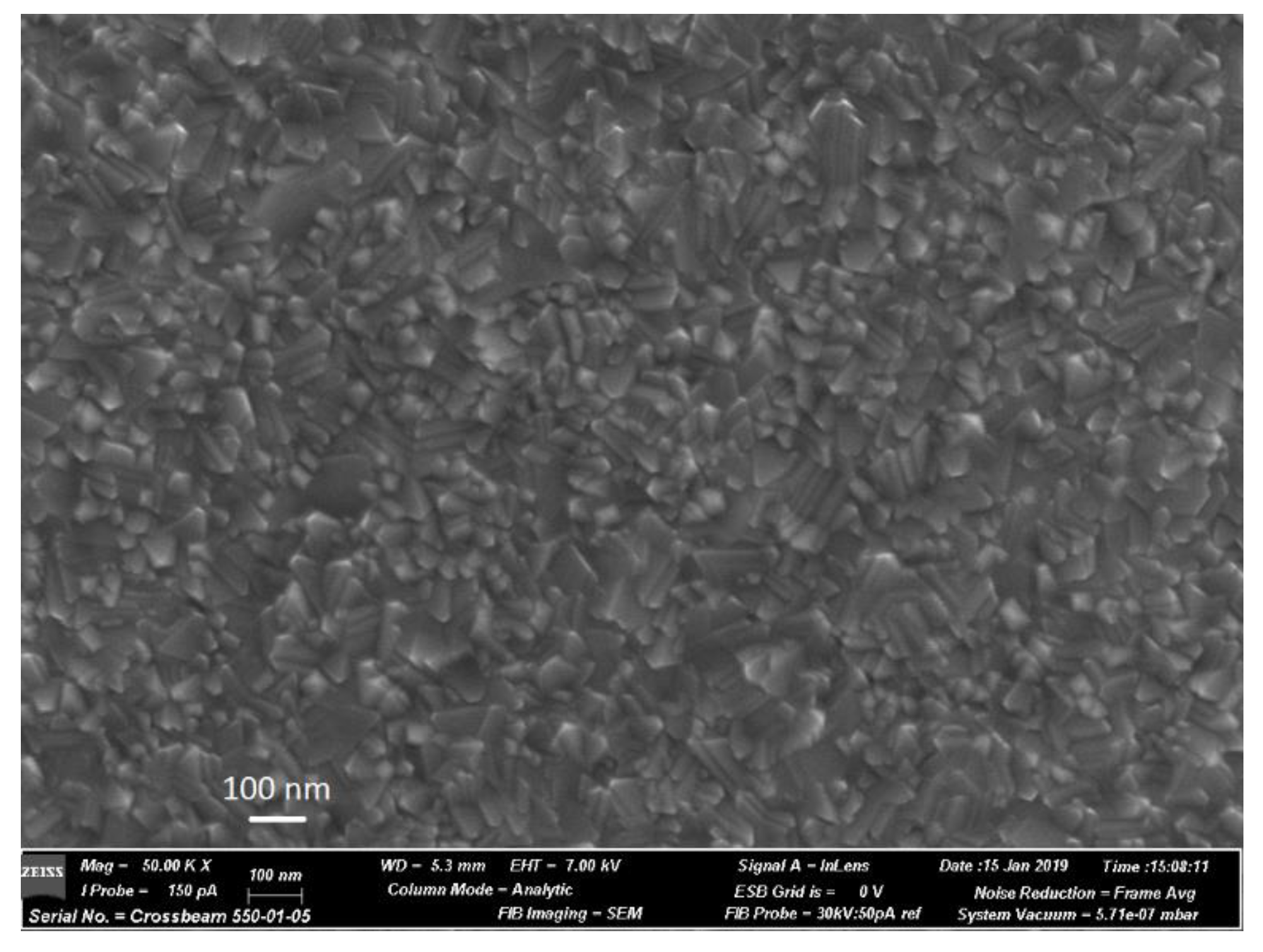

3.4. Microstructural Properties of Mo–Ti Bilayer Processed at 800 °C

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Oyama, S.T. Introduction to the chemistry of transition metal carbides and nitrides. In The Chemistry of Transition Carbides and Nitrides, 1st ed.; Oyama, S.T., Ed.; Springer: Dordrecht, The Netherlands, 1996; pp. 2–10. [Google Scholar]

- Jauberteau, I.; Bessaudou, A.; Mayet, R.; Cornette, J.; Jauberteau, J.L.; Carles, P.; Merle-Méjean, T. Molybdenum nitride films: Crystal structures, synthesis, mechanical, electrical and some other properties. Coatings 2015, 5, 656–687. [Google Scholar] [CrossRef]

- Ponon, N.K.; Appleby, D.J.; Arac, E.; King, P.J.; Ganti, S.; Kwa, K.S.K.; O’Neill, A. Effect of deposition conditions and postdeposition anneal on reactively sputtered titanium nitride films. Thin Solid Films 2015, 578, 31–37. [Google Scholar] [CrossRef]

- Bhaskaran, M.; Sriram, S.; Short, K.T.; Mitchell, D.R.G.; Holland, A.S.; Reeves, G.K. Characterization of C54 titanium silicide thin films by spectroscopy, microscopy and diffraction. J. Phys. D Appl. Phys. 2007, 40, 5213–5219. [Google Scholar] [CrossRef]

- Yanisagawa, S.; Fukuyama, T. Preparation of molybdenum silicide films by reactive sputtering. J. Electrochem. Soc. 1980, 127, 1120–1124. [Google Scholar] [CrossRef]

- Lima, L.P.B.; Diniz, J.A.; Doi, I.; Fo, J.G. Titanium nitride as electrode for MOS technology and Schottky diode: Alternative extraction method of titanium nitride work function. Microelectron. Eng. 2012, 92, 86–90. [Google Scholar] [CrossRef]

- Wang, L.-L.; Peng, W.; Jiang, Y.-L.; Li, B.-Z. Effective Schottky barrier height lowering by TiN capping layer for TiSix/Si power diode. IEEE Electron Device Lett. 2015, 36, 597–599. [Google Scholar] [CrossRef]

- Pshyk, A.V.; Kravchenko, Y.; Coy, E.; Kempinski, M.; Iatsunskyi, I.; Zaleski, K.; Pogrebnjak, A.D.; Jurga, S. Microstructure, phase composition and mechanical properties of novel nanocomposite (TiAlSiY)N and nano-scale (TiAlSiY)N/MoN multifunctional heterostructures. Surf. Coat. Technol. 2018, 350, 376–390. [Google Scholar] [CrossRef]

- Ting, Y.-J.; Lian, K.; Kherani, N. Fabrication of titanium nitride and molybdenum nitride for supercapacitor electrode application. ECS Trans. 2011, 35, 133–139. [Google Scholar] [CrossRef]

- Xie, Y.; Tian, F. Capacitive performance of molybdenum nitride/titanium nitride nanotube array for supercapacitor. Mater. Sci. Eng. B 2017, 215, 64–70. [Google Scholar] [CrossRef]

- Blösch, P.; Güttler, D.; Chirila, A.; Tiwari, A.N. Optimization of Ti/TiN/Mo back contact properties of Cu (In,Ga)Se2 solar cells on polyimide foils. Thin Solid Films 2011, 519, 7453–7457. [Google Scholar] [CrossRef]

- Li, W.; Yan, X.; Aberle, A.G.; Venkataraj, S. Effect of a TiN alkali diffusion barrier layer on the physical properties of Mo back electrodes for CIGS solar cell applications. Curr. Appl. Phys. 2017, 17, 1747–1753. [Google Scholar] [CrossRef]

- Jauberteau, I.; Mayet, R.; Cornette, J.; Bessaudou, A.; Carles, P.; Jauberteau, J.L.; Merle-Méjean, T. A reduction-nitridation process of molybdenum films in expanding microwave plasma: Crystal structure of molybdenum nitrides. Surf. Coat. Technol. 2015, 270, 77–85. [Google Scholar] [CrossRef]

- Jauberteau, I.; Carles, P.; Mayet, R.; Cornette, J.; Bessaudou, A.; Jauberteau, J.L. Competing growth of titanium nitrides and silicides in Ti films processed in expanding microwave plasma: Morphology and microstructural properties. AIP Adv. 2018, 8, 095105. [Google Scholar] [CrossRef]

- Jauberteau, I.; Mayet, R.; Cornette, J.; Mangin, D.; Bessaudou, A.; Carles, P.; Jauberteau, J.L.; Passelergue, A. Silicides and nitrides formation in Ti films coated on Si and exposed to (Ar-N2-H2) expanding plasma. Coatings 2017, 7, 23. [Google Scholar] [CrossRef]

- Xin, C.; Liu, W.; Li, N.; Yan, J.; Shi, S. Metallization of Al2O3 ceramic by magnetron sputtering Ti/Mo bilayer thin films for robust brazing to Kovar alloy. Ceram. Int. 2016, 42, 9599–9604. [Google Scholar] [CrossRef]

- Ruzic, J.; Emura, S.; Ji, X.; Watanabe, I. Mo segregation and distribution in Ti-Mo alloys investigated using nanoindentation. Mater. Sci. Eng. A 2018, 718, 48–55. [Google Scholar] [CrossRef]

- Fan, J.; Lu, M.; Cheng, H.; Tian, J.; Huang, B. Effect of alloying elements Ti, Zr, on the property and microstructure of molybdenum. Int. J. Refract. Hard Mater. 2009, 27, 78–82. [Google Scholar] [CrossRef]

- Kislitin, S.B.; Potekaev, A.I.; Uglov, V.V.; Klopotov, A.A.; Klopotov, V.D.; Ivanov, Y.F.; Parpiev, A.T. Steel suface TiCrN, TiMoN coatings structural phase state change features after low-energy alpha particles irradiation. IOP Conf. Ser. Mater. Sci. Eng. 2018, 289, 012010. [Google Scholar] [CrossRef]

- Oliveira, N.T.C.; Aleixo, G.; Caram, R.; Guastaldi, A.C. Development of Ti-Mo alloys for biomedical applications: Microstructures and electrochemical characterization. Mater. Sci. Eng. A 2007, 452, 727–731. [Google Scholar] [CrossRef]

- Simka, W.; Krzakala, A.; Korotin, D.M.; Zhidkov, I.S.; Kurmaev, E.Z.; Cholakh, S.O.; Kuna, K.; Dercz, G.; Michalska, J.; Suchanek, K.; et al. Modification of a Ti–Mo alloy surface via plasma electrolytic oxidation in a solution containing calcium and phosphorus. Electrochem. Acta 2013, 96, 180–190. [Google Scholar] [CrossRef]

- Zhang, W.-D.; Liu, Y.; Wu, H.; Song, M.; Zhang, X.-D.; Lan, X.-D.; Yao, T.-H. Elastic modulus of phases in Ti–Mo alloys. Mater. Charact. 2015, 106, 302–309. [Google Scholar] [CrossRef]

- Gu, M.; Bai, S.; Xia, X.; Huang, X.; Li, X.; Shi, X.; Chen, L. Study of the high temperature interfacial stability of Ti/Mo/Yb0.3Co4Sb12 thermoelectric joints. Appl. Sci. 2017, 7, 952. [Google Scholar] [CrossRef]

- Cai, M.; Allred, D.D. Raman spectroscopic study of the formation of t-MoSi2 from Mo/Si multilayers. J. Vac. Sci. Technol. A 1994, 12, 1535–1541. [Google Scholar] [CrossRef]

- Chi, E.; Shim, J.; Kwak, J.; Baik, H. Silicide formation by solid-state diffusion in Mo/Si multilayer thin films. J. Mater. Sci. 1996, 31, 3567–3572. [Google Scholar] [CrossRef]

- Constable, C.P.; Yarwood, J.; Münz, W.D. Raman microscopic studies of PVD hard coatings. Surf. Coat. Technol. 1999, 116, 155–159. [Google Scholar] [CrossRef]

- Stoehr, M.; Shin, C.-S.; Petrov, I.; Greene, J.E. Raman scattering from TiNx(0.67 < x < 1.00) single crystals grown on MgO (001). J. Appl. Phys. 2011, 110, 083503. [Google Scholar] [CrossRef]

- Stampfl, S.R.; Chen, Y.; Dumesic, J.A.; Niu, C.; Hill, C.G., Jr. Interactions of molybdenum oxide with various oxide supports. Calcination of mechanical mixtures. J. Catal. 1987, 105, 445–454. [Google Scholar] [CrossRef]

- Barhai, P.K.; Kumari, N.; Banerjee, I.; Pabi, S.K.; Mahapatra, S.K. Study of the effect of plasma current density on the formation of titanium nitride ant titanium oxynitride thin films prepared by reactive DC magnetron sputtering. Vacuum 2010, 84, 896–901. [Google Scholar] [CrossRef]

- Birtill, J.J.; Dickens, P.G. Thermochemistry of hydrogen molybdenum bronze phases HxMoO3. J. Solid State Chem. 1979, 29, 367–372. [Google Scholar] [CrossRef]

- O’Hare, P.A.G. Thermodynamic properties of silicides. III. Specific energy of combustion in fluorine of a hyperstoichiometric disilicide. The standard molar enthalpy of formation ΔfH°m of MoSi2.067±0.002 at the temperature 298.15 K. J. Chem. Thermodyn. 1993, 25, 1333–1343. [Google Scholar] [CrossRef]

- Ohishi, Y.; Kurosaki, K.; Suzuki, T.; Muta, H.; Yamanaka, S.; Uchida, N.; Tada, T.; Kanayama, T. Synthesis of silicon and molybdenum-silicide nanocrystal composite films having low thermal conductivity. Thin Solid Films 2013, 534, 238–241. [Google Scholar] [CrossRef]

- Shugani, M.; Aynyas, M.; Sanyal, S.P.; Rajagopalan, M. Electronic properties of MoSi2. Indian J. Pure Appl. Phys. 2013, 51, 634–637. (In English) [Google Scholar]

- Mattheiss, L.F. Calculated structural properties of CrSi2, MoSi2 and WSi2. Phys. Rev. B 1992, 45, 3252–3259. [Google Scholar] [CrossRef]

- Pankhurst, D.A.; Yuan, Z.; Nguyen-Manh, D.; Abel, M.-L.; Shao, G.; Watts, J.F.; Pettifor, D.G.; Tsakiropoulos, P. Electronic structure and bonding in MoSi3, Mo5Si3 and Mo(Si,Al)2 alloys investigated by X-ray photoelectron spectroscopy and density-functional theory. Phys. Rev. B 2005, 71, 075114. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jauberteau, I.; Mayet, R.; Cornette, J.; Carles, P.; Mangin, D.; Bessaudou, A.; Jauberteau, J.L.; Passelergue, A. Expanding Plasma Process for Nitriding Mo–Ti Bilayer Thin Films. Coatings 2019, 9, 96. https://doi.org/10.3390/coatings9020096

Jauberteau I, Mayet R, Cornette J, Carles P, Mangin D, Bessaudou A, Jauberteau JL, Passelergue A. Expanding Plasma Process for Nitriding Mo–Ti Bilayer Thin Films. Coatings. 2019; 9(2):96. https://doi.org/10.3390/coatings9020096

Chicago/Turabian StyleJauberteau, Isabelle, Richard Mayet, Julie Cornette, Pierre Carles, Denis Mangin, Annie Bessaudou, Jean Louis Jauberteau, and Armand Passelergue. 2019. "Expanding Plasma Process for Nitriding Mo–Ti Bilayer Thin Films" Coatings 9, no. 2: 96. https://doi.org/10.3390/coatings9020096

APA StyleJauberteau, I., Mayet, R., Cornette, J., Carles, P., Mangin, D., Bessaudou, A., Jauberteau, J. L., & Passelergue, A. (2019). Expanding Plasma Process for Nitriding Mo–Ti Bilayer Thin Films. Coatings, 9(2), 96. https://doi.org/10.3390/coatings9020096