Verification Study of Nanostructure Evolution with Heating Treatment between Thin and Thick Fullerene-Like Hydrogen Carbon Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparations

2.2. Characterization Methods

3. Result

3.1. The Results of ERD

3.2. The Results of HRTEM

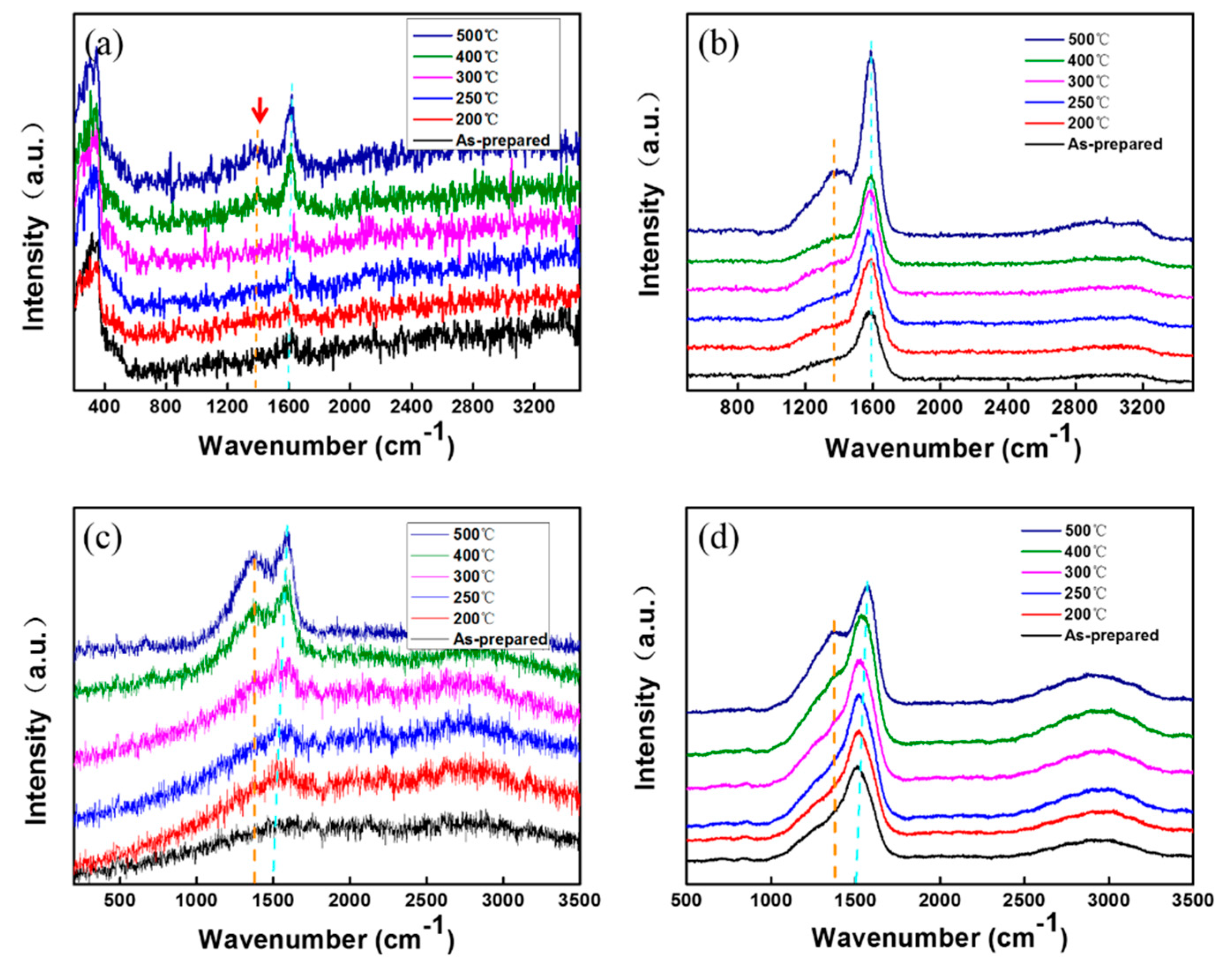

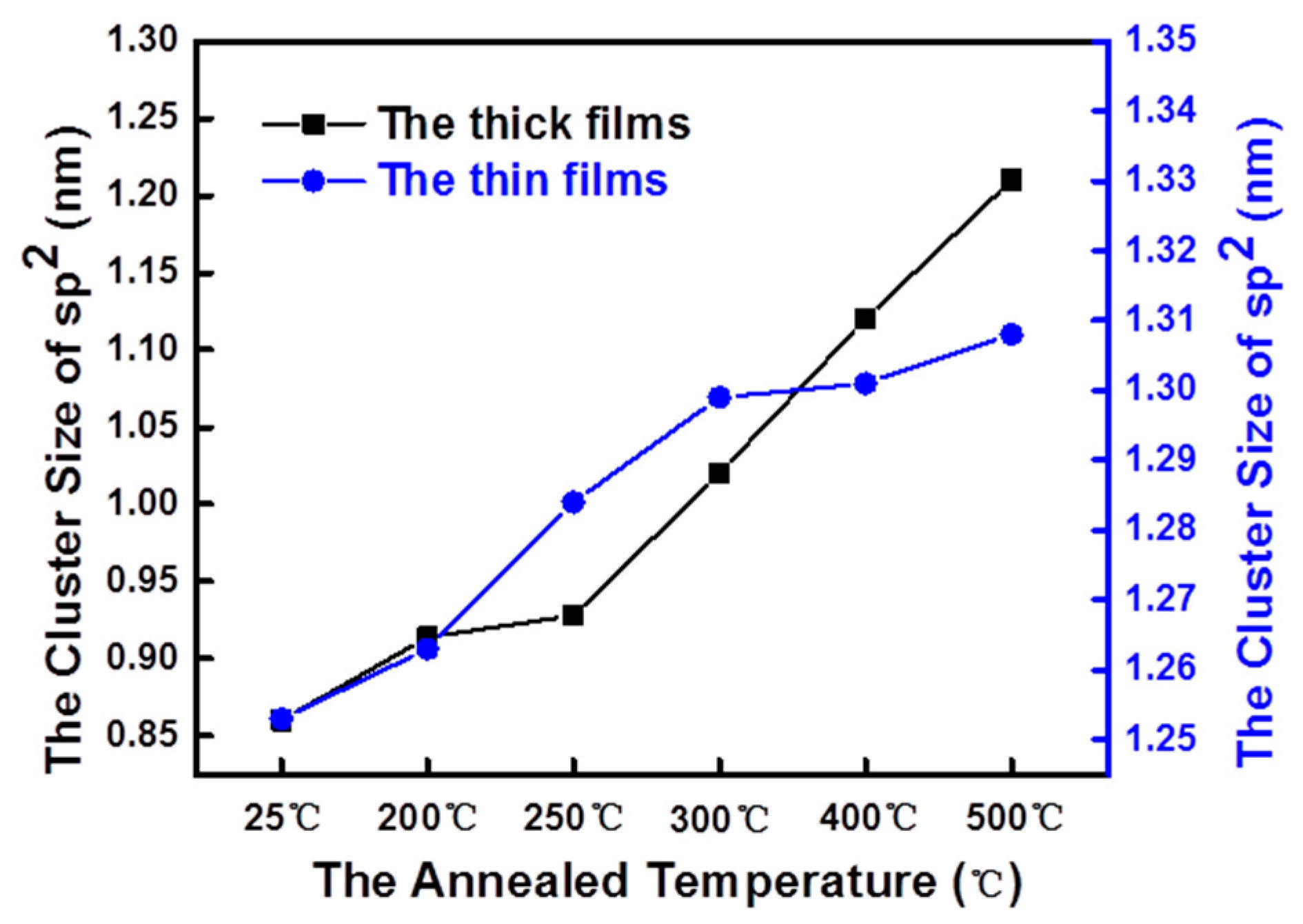

3.3. The Analysis of Raman Spectrums

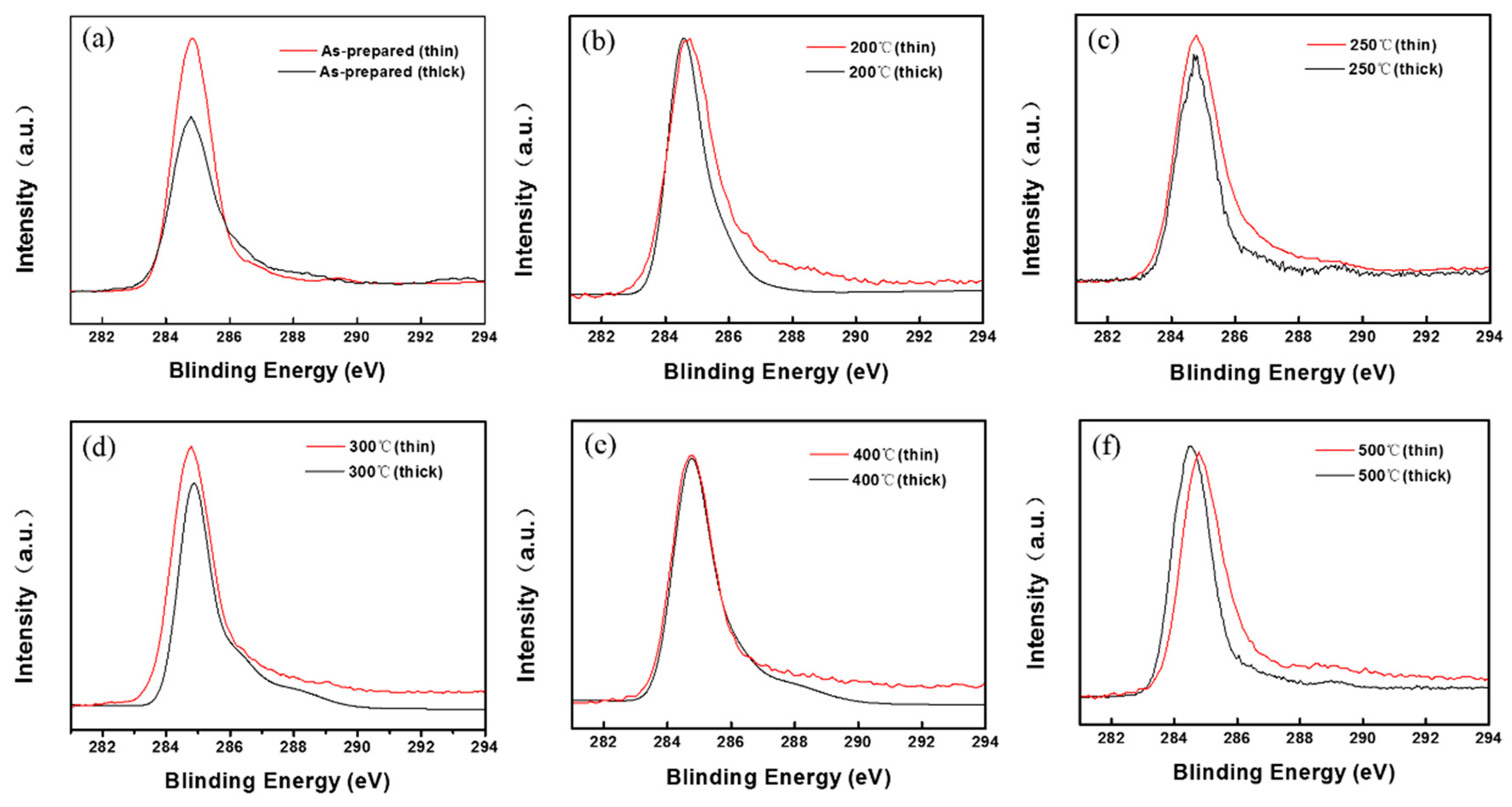

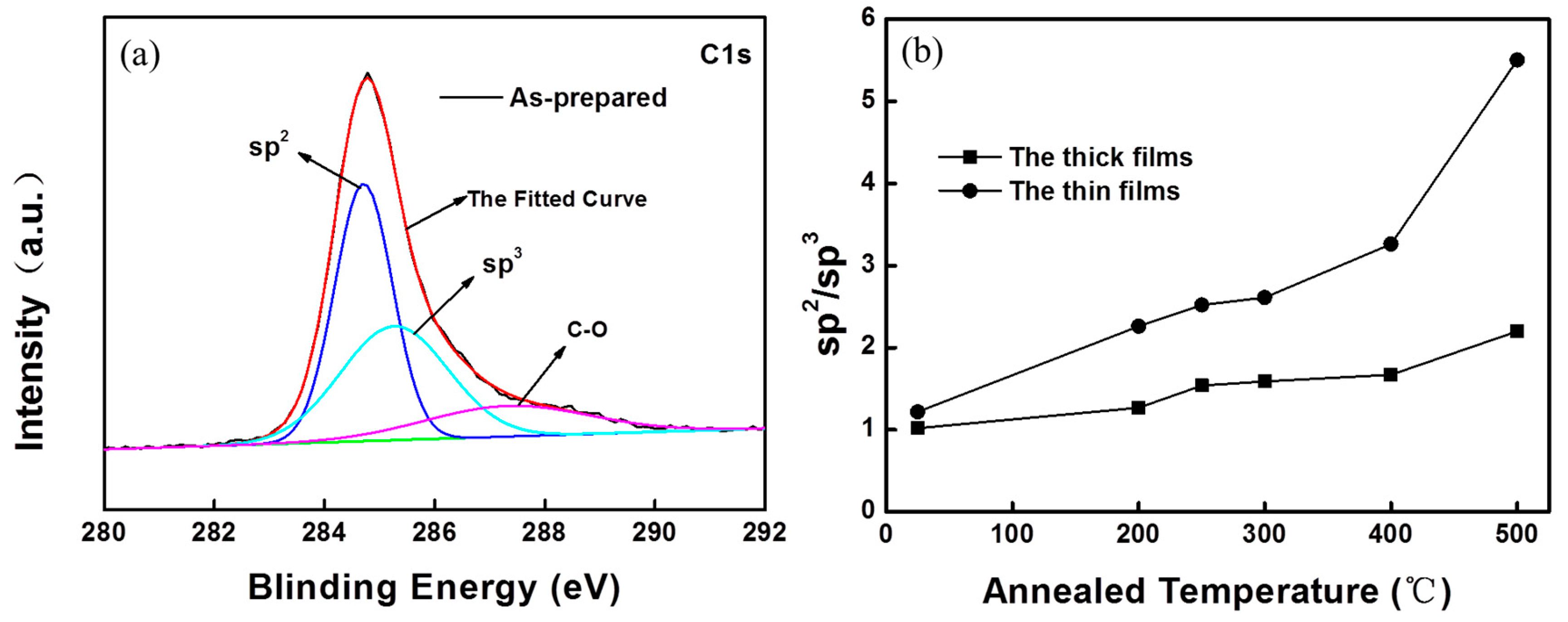

3.4. The Results of XPS

4. Discussion

5. Conclusions

- The content of hydrogen of the annealed samples remained constant, thus, the influence of hydrogen could be negligible in this study.

- Under low temperature annealing of 200, 250, and 300 °C, the curved graphene structures gradually increased in films. However, beyond 400 °C, onions structures were present, particularly if annealed under 500 °C.

- Both Raman and XPS spectra show us that after the annealed treatment, for original films, both thin and thick films have the near sp2 bonding content and size, but with the annealing temperature increase, sp2 bonding content increases more quickly for thick FL-C:H films due to the higher internal stress compared to thin films

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hirano, M.; Shinjo, K. Atomistic locking and friction. Phys. Rev. B 1990, 41, 11837. [Google Scholar] [CrossRef]

- Martin, J.M.; Donnet, C.; le Mogne, T.; Epicier, T. Superlubricity of molybdenum disulphide. Phys. Rev. B 1993, 48, 10583. [Google Scholar] [CrossRef]

- Chhowalla, M.; Amaratunga, G.A. Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear. Nature 2000, 407, 164–167. [Google Scholar] [CrossRef] [PubMed]

- Dienwiebel, M.; Verhoeven, G.S.; Pradeep, N.; Frenken, J.W.; Heimberg, J.A.; Zandbergen, H.W. Superlubricity of graphite. Phys. Rev. Lett. 2004, 92, 126101. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Ning, Z.; Zhang, Y.; Zheng, Q.; Chen, Q.; Xie, H.; Wei, F. Superlubricity in centimetres-long double-walled carbon nanotubes under ambient conditions. Nat. Nanotechnol. 2013, 8, 912–916. [Google Scholar] [CrossRef]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K. Carbon-based tribofilms from lubricating oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef] [PubMed]

- Gong, Z.; Shi, J.; Zhang, B.; Zhang, J. Graphenenano scrolls responding to superlow friction of amorphous carbon. Carbon 2017, 116, 310–317. [Google Scholar] [CrossRef]

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.; Erdemir, A.; Sumant, A.V. Macroscale superlubricity enabled by graphenen anoscroll formation. Science 2015, 348, 1118–1122. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, K.; Yu, Y.; Zhang, J. Super-Lubricious, Fullerene-like, Hydrogenated Carbon Films, Fullerenes and Relative Materials-Properties and Application; InTech: London, UK, 2018; Chapter 6; pp. 95–109. [Google Scholar]

- Gong, Z.; Bai, C.; Qiang, L.; Gao, K.; Zhang, J.; Zhang, B. Onion-like carbon films endow macro-scale superlubricity, published online. Diam. Relat. Mater. 2018, 87, 172–176. [Google Scholar] [CrossRef]

- Wang, P.; Wang, X.; Zhang, B.; Liu, W. Formation of hydrogenated amorphous carbon films containing fullerene-like structures. J. Non-Cryst. Solids 2009, 355, 1742–1746. [Google Scholar] [CrossRef]

- Gong, Z.; Shi, J.; Ma, W.; Zhang, B.; Zhang, J. Engineering-scale superlubricity of the fingerprint-like carbon films based on high power pulsed plasma enhanced chemical vapor deposition. RSC Adv. 2016, 6, 115092. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, K.; Shi, J.; Zhang, J. Bond topography and nanostructure of hydrogenated fullerene-like carbon films: A comparative study. Chem. Phys. Lett. 2016, 660, 160–163. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, Y.; Zhang, B.; Gao, K.; Qiang, L.; Zhang, J. Monitoring the nanostructure of a hydrogenated fullerene-like film by pulse bias duty cycle. RSC Adv. 2016, 6, 59039–59044. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Jones, J.G.; Zabinski, J.S.; Czigány, Z.; Hultman, L. Growth and structure of fullerene-like CNx thin films produced by pulsed laser ablation of graphite in nitrogen. J. Appl. Phys. 2002, 92, 4980–4988. [Google Scholar] [CrossRef]

- Li, H.; Xu, T.; Wang, C.; Chen, J.; Zhou, H.; Liu, H. Annealing effect on the structure, mechanical and tribological properties of hydrogenated diamond-like carbon films. Thin Solid Film. 2006, 515, 2153–2160. [Google Scholar] [CrossRef]

- Manimunda, P.; Al-Azizi, A.; Kim, S.H.; Chromik, R.R. Shear-Induced Structural Changes and Origin of Ultralow Friction of Hydrogenated Diamond-like Carbon (DLC) in Dry Environment. ACS Appl. Mater. Interfaces 2017, 9, 16704–16714. [Google Scholar] [CrossRef]

- Catena, A.; Agnello, S.; Cannas, M.; Gelardi, F.M.; Wehner, S.; Fischer, C.B. Evolution of the sp2 content and revealed multilayer growth of amorphous hydrogenated carbon (a-C:H) films on selected thermoplastic materials. Carbon 2017, 117, 351–359. [Google Scholar] [CrossRef]

- Wang, Z.; Gong, Z.; Zhang, B.; Wang, Y.; Gao, K.; Zhang, J. Heating induced nanostructure and superlubricity envolution of fullerene-like hydrogenated carbon films. Cryst. Growth Des. 2018. submitted. [Google Scholar]

- Ahmed, M.H.; Byrne, J.A.; McLaughlin, J.A.D.; Elhissi, A.; Ahmed, W. Comparison between FTIR and XPS characterization of amino acid glycine adsorption onto diamond-like carbon (DLC) and silicon doped DLC. Appl. Surf. Sci. 2013, 273, 507–514. [Google Scholar] [CrossRef]

- Takeno, T.; Komiyama, T.; Miki, H.; Takagic, T.; Aoyama, T. XPS and TEM study of W-DLC/DLC double-layered film. Thin Solid Film. 2009, 517, 5010–5013. [Google Scholar] [CrossRef]

- Wang, P.; Takeno, T.; Adachi, K.; Miki, H.; Takagi, T. Preparation and tribological characterization of amorphous carbon nitride coatings in a RF PECVD–DC PVD hybrid coating process. Appl. Surf. Sci. 2012, 258, 6576–6582. [Google Scholar] [CrossRef]

- Sugimoto, I.; Honda, F.; Inoue, K. Analysis of wear behavior and graphitization of hydrogenated DLC under boundary lubricant with MoDTC. Wear 2013, 305, 124–128. [Google Scholar] [CrossRef]

- Wang, Q.; He, D.; Wang, C.; Wang, Z.; Zhang, J. The evolution of the structure and mechanical properties of fullerenelike hydrogenated amorphous carbon films upon annealing. J. Appl. Phys. 2008, 104, 04351. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Gao, K.; Zhang, B.; Gong, Z.; Wei, X.; Zhang, J. Verification Study of Nanostructure Evolution with Heating Treatment between Thin and Thick Fullerene-Like Hydrogen Carbon Films. Coatings 2019, 9, 82. https://doi.org/10.3390/coatings9020082

Wang Z, Gao K, Zhang B, Gong Z, Wei X, Zhang J. Verification Study of Nanostructure Evolution with Heating Treatment between Thin and Thick Fullerene-Like Hydrogen Carbon Films. Coatings. 2019; 9(2):82. https://doi.org/10.3390/coatings9020082

Chicago/Turabian StyleWang, Zhaolong, Kaixiong Gao, Bin Zhang, Zhenbin Gong, Xiaoli Wei, and Junyan Zhang. 2019. "Verification Study of Nanostructure Evolution with Heating Treatment between Thin and Thick Fullerene-Like Hydrogen Carbon Films" Coatings 9, no. 2: 82. https://doi.org/10.3390/coatings9020082

APA StyleWang, Z., Gao, K., Zhang, B., Gong, Z., Wei, X., & Zhang, J. (2019). Verification Study of Nanostructure Evolution with Heating Treatment between Thin and Thick Fullerene-Like Hydrogen Carbon Films. Coatings, 9(2), 82. https://doi.org/10.3390/coatings9020082