Structure, Mechanical and Tribological Properties of MoSN/MoS2 Multilayer Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Deposition of MoSN/MoS2 Multilayer Films

2.2. Structure and Chemical Characterization of MoSN/MoS2 Multilayer Films

2.3. Ball-on-Disk Tribotests in Vacuum Environment

3. Results and Discussion

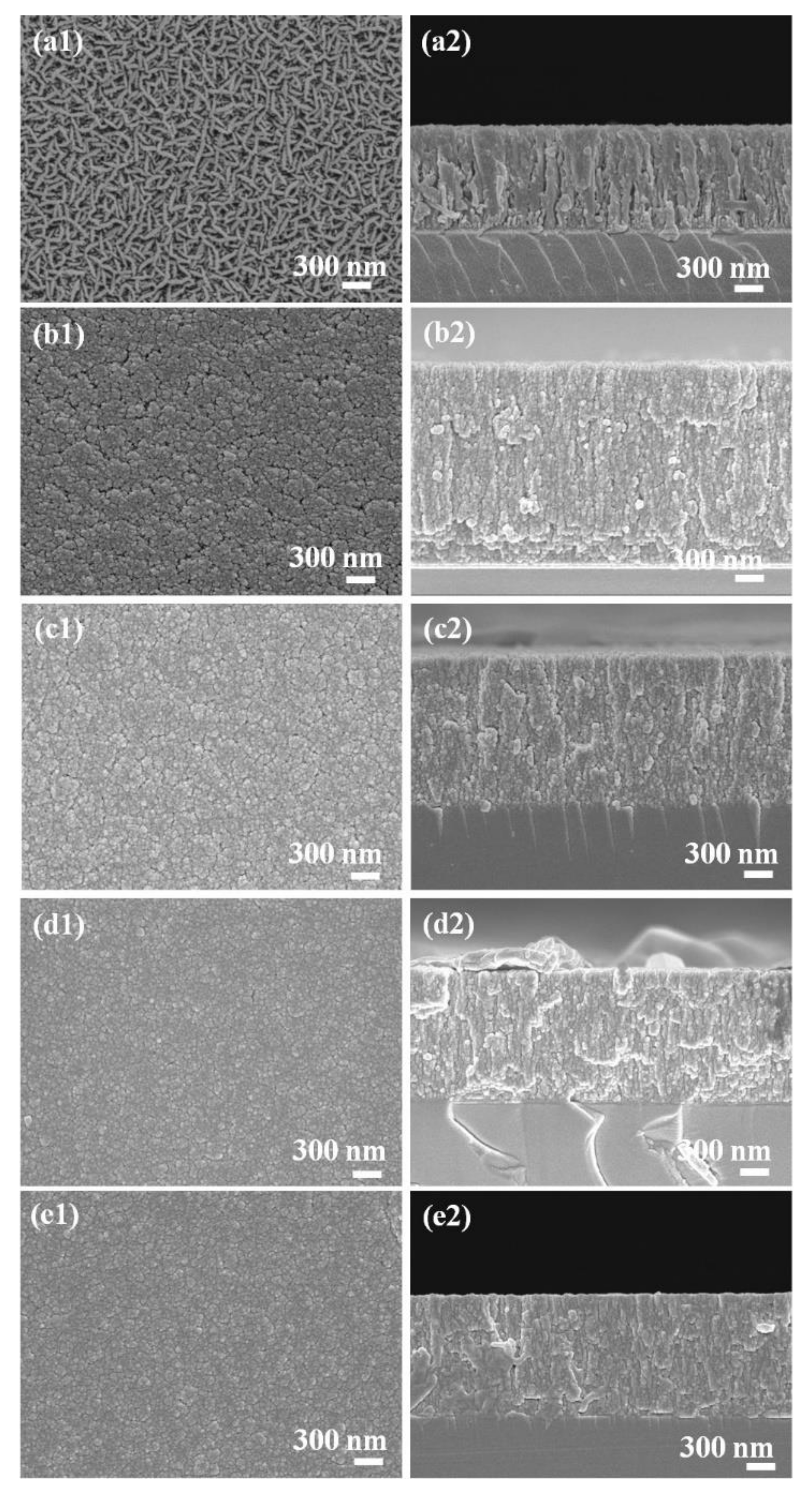

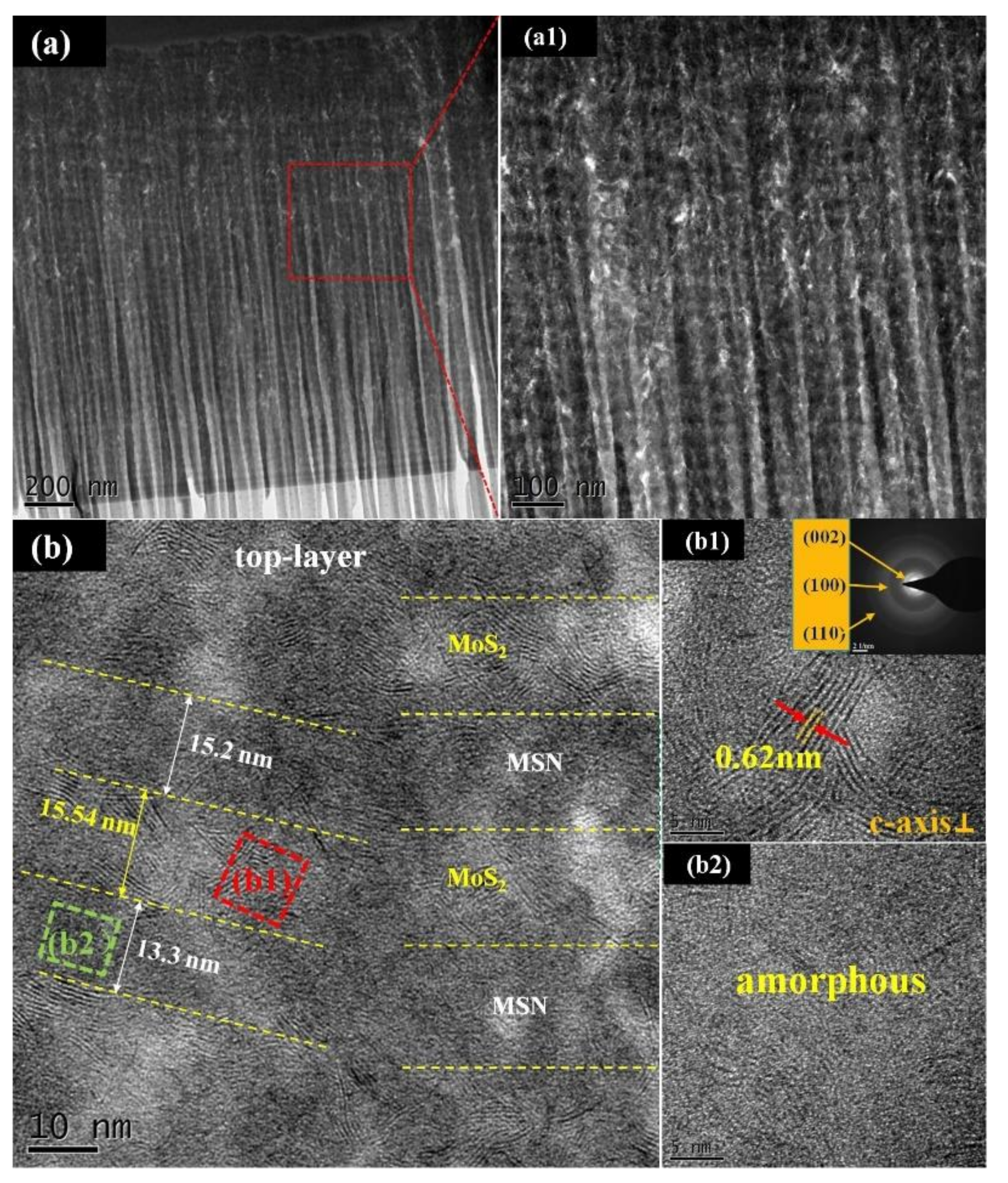

3.1. Structure Characterizations of MoSN/MoS2 Multilayer Films

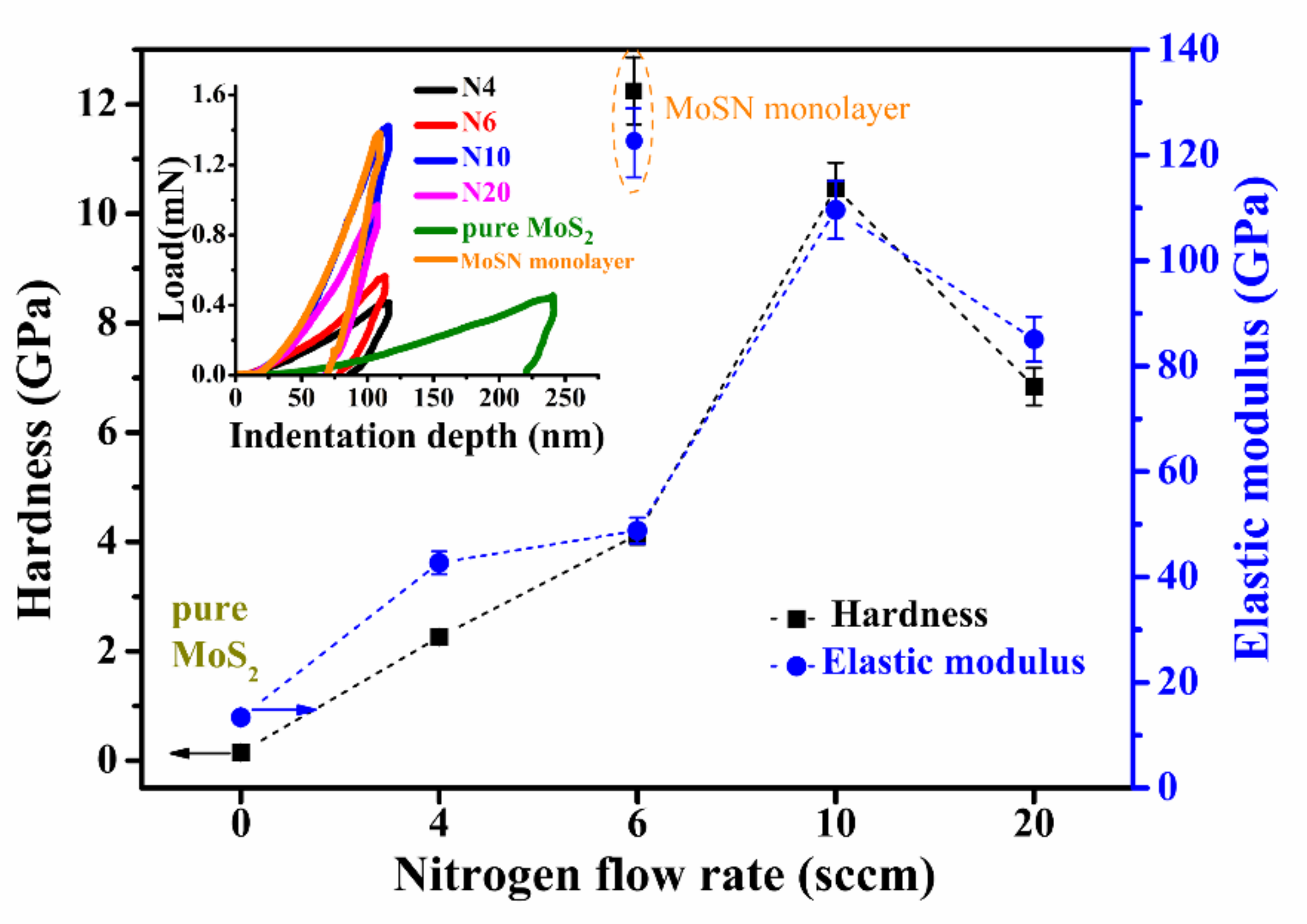

3.2. Mechanical Properties of MoSN/MoS2 Multilayer Films

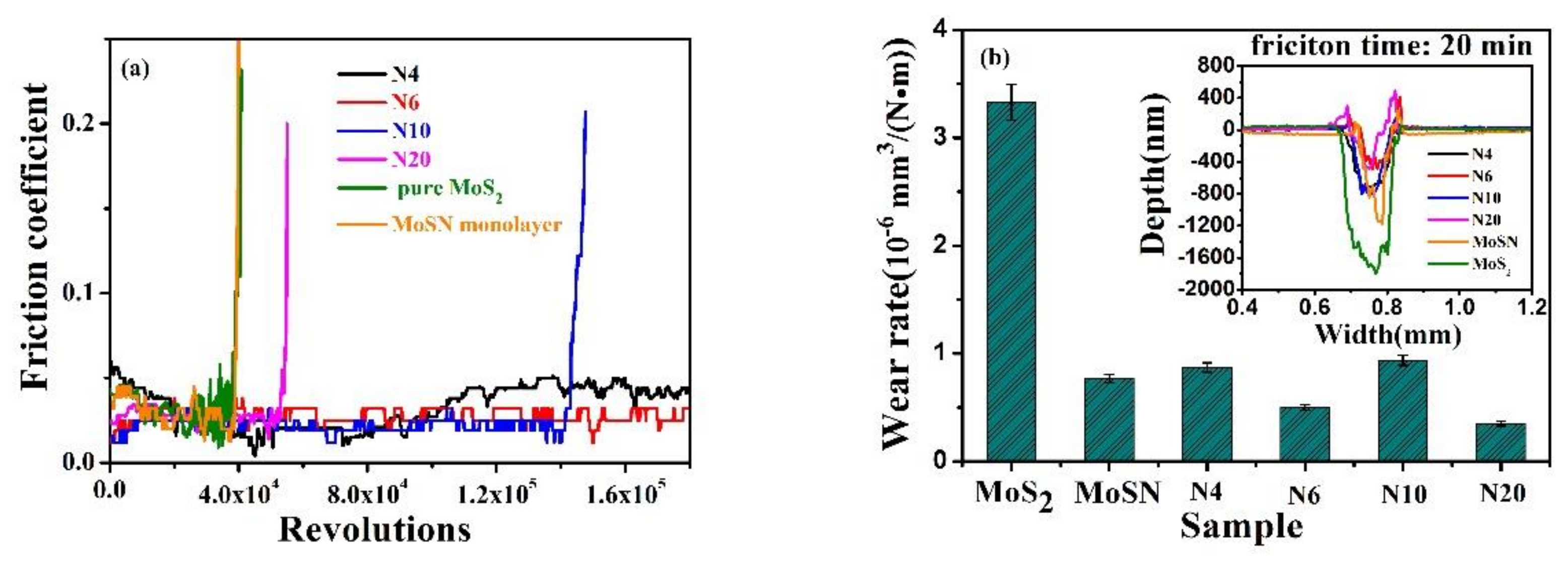

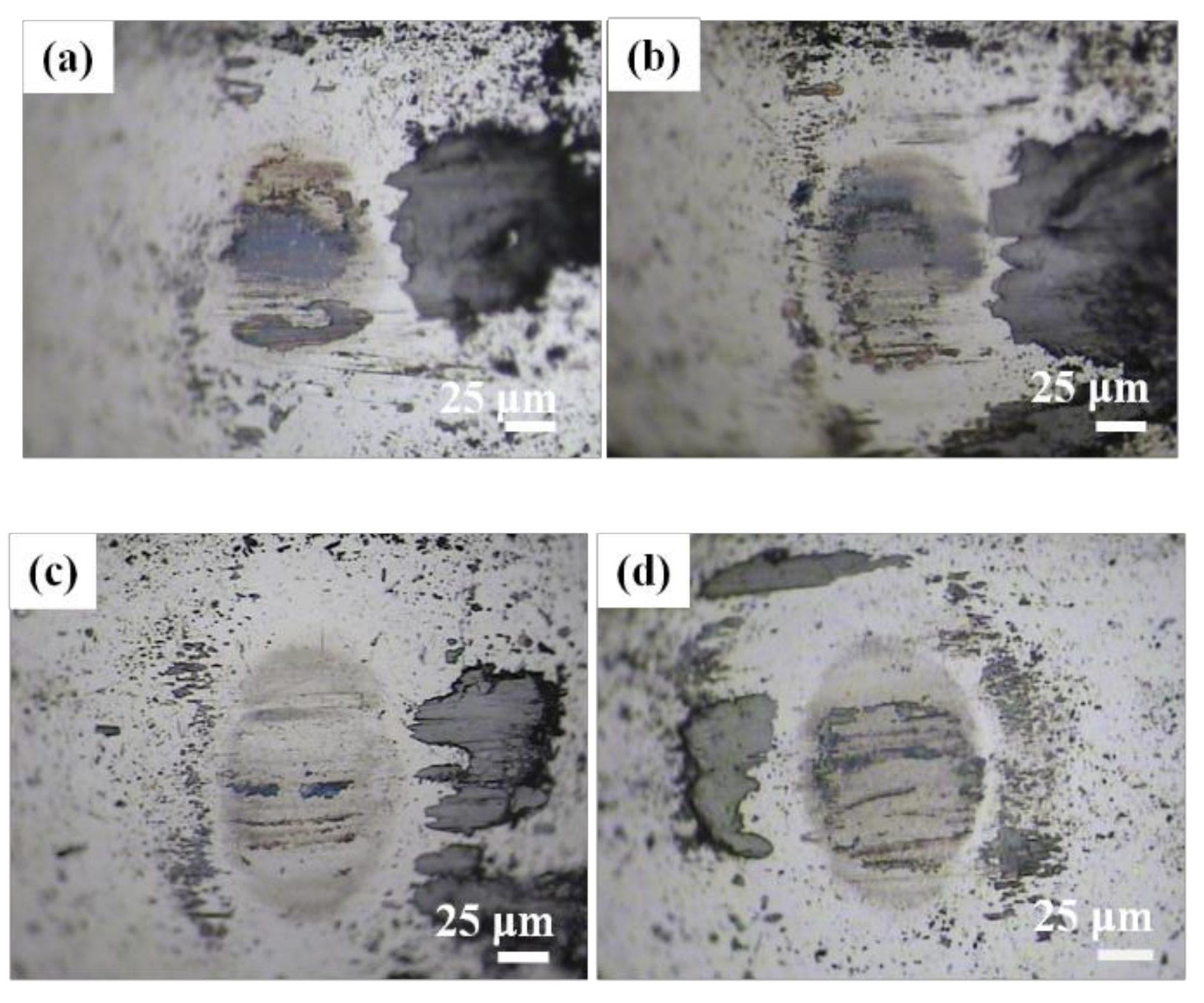

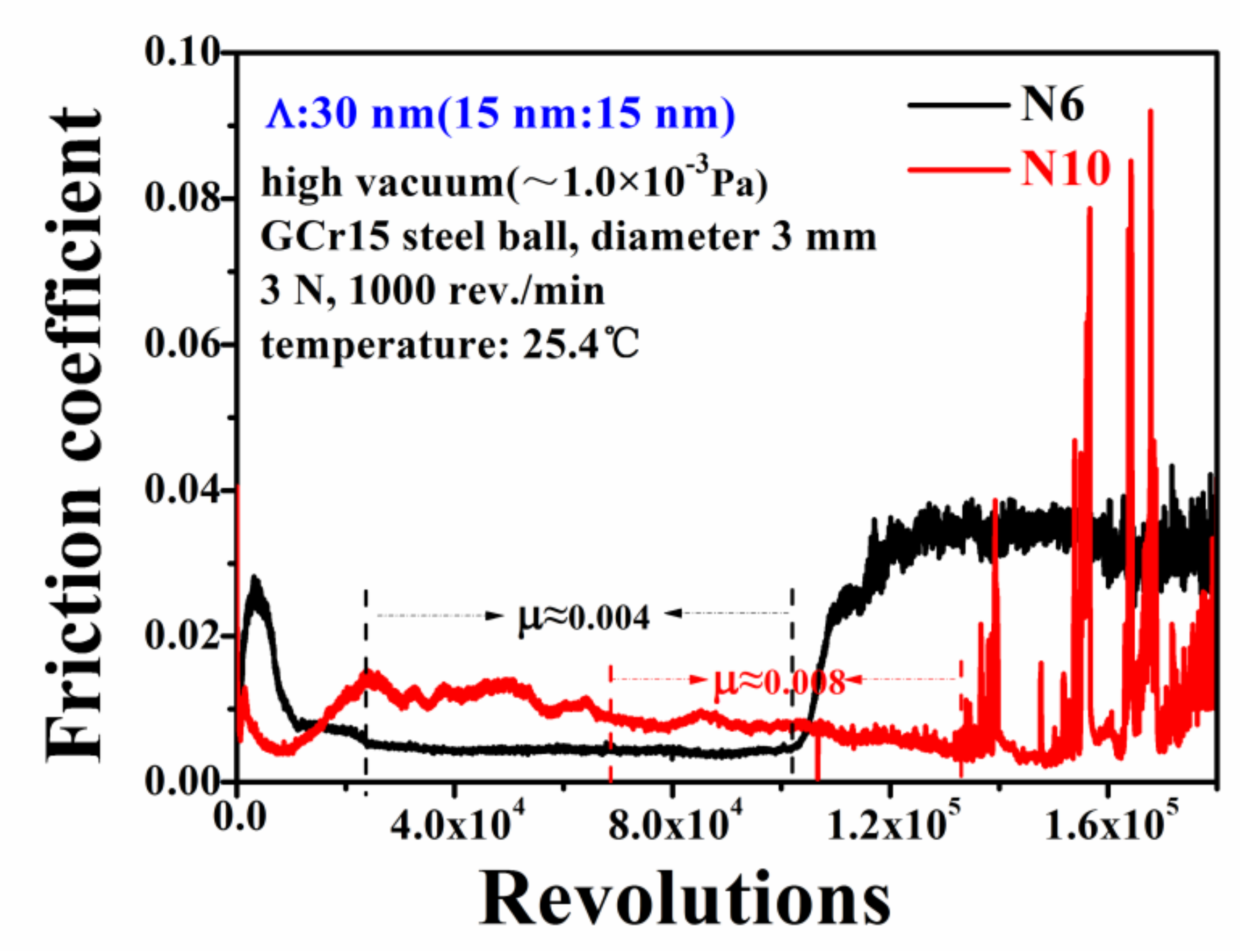

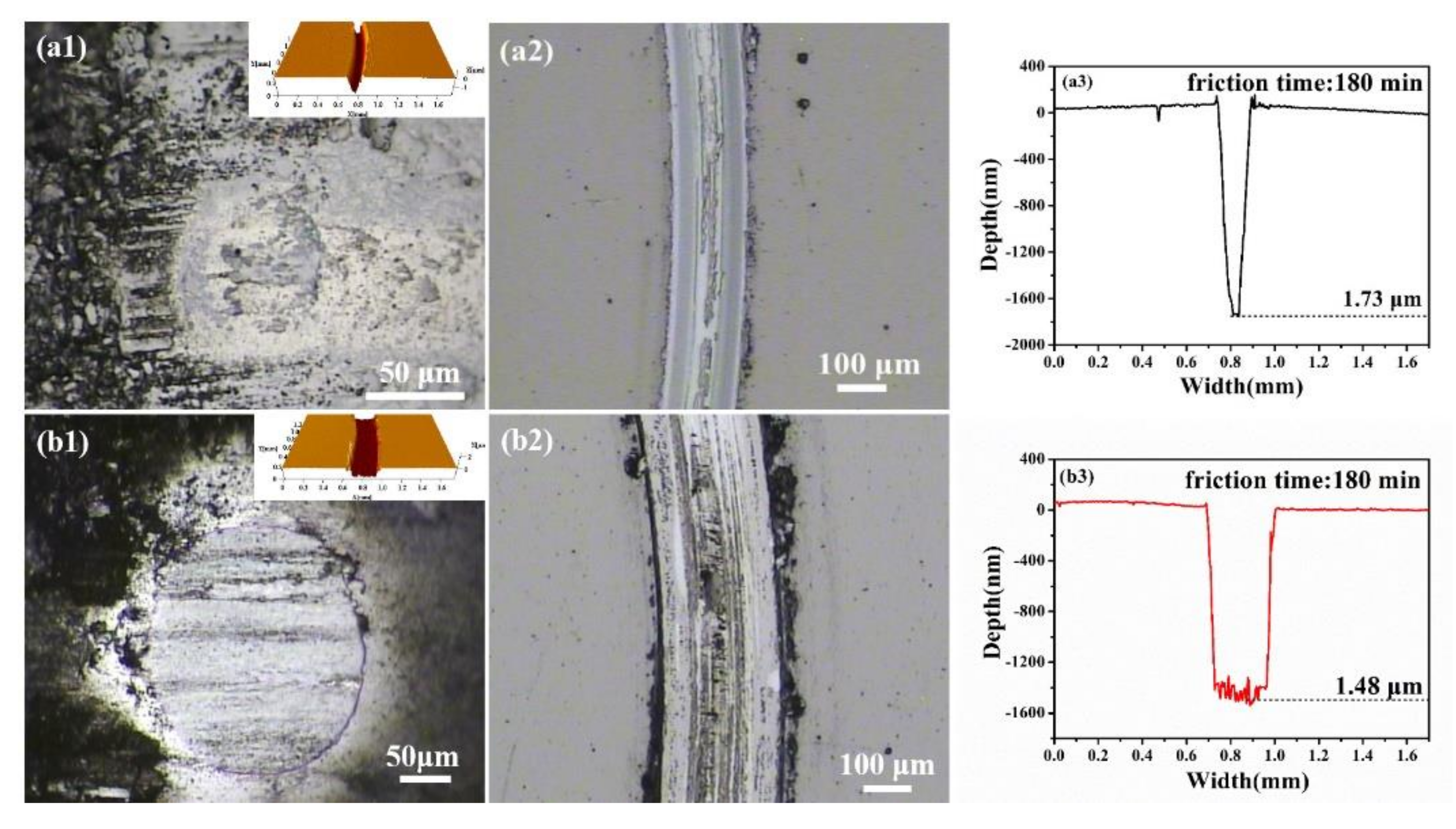

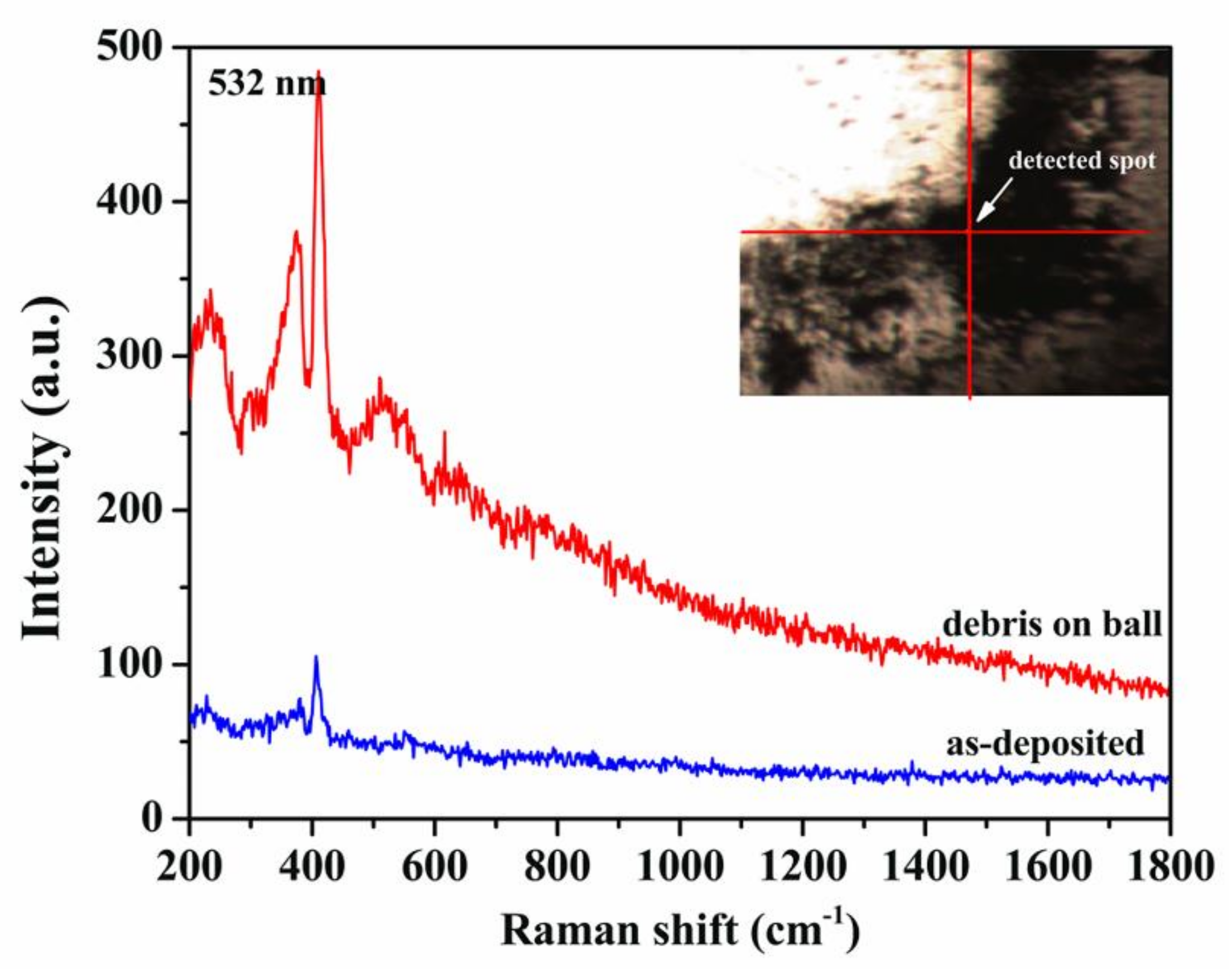

3.3. Tribological Properties of MoSN/MoS2 Multilayer Films

4. Conclusions

- By alternately depositing the MoSN and MoS2 sublayers, the prepared MoSN/MoS2 multilayer film exhibited a compact structure due to the suppression of the columnar growth of the sputtered MoS2. The MoS2 sublayers showed a nanocrystalline structure with a preferred orientation of an (002) plane while the MoSN sublayers exhibited an amorphous structure.

- The hardness of the MoSN/MoS2 multilayer film showed a great increase compared to the MoS2 and increased from 2.3 to 10.5 GPa as the nitrogen flow rate increased from 4 to 10 sccm. The MoSN/MoS2 multilayer films deposited with nitrogen flow rates of 4 and 6 sccm exhibited low friction coefficients below 0.03 and wear lives higher than 1.8 × 105 revolutions in a high vacuum condition, which is much longer than that of pure MoS2 or MoSN film. The improved wear life for the MoSN/MoS2 multilayer with low nitrogen content was mainly attributed to the lower wear rate, which resulted from the enhanced hardness as well as the sustainably formed MoS2 tribofilms.

- The MoSN/MoS2 multilayer film deposited with a nitrogen flow rate of 6 sccm exhibited ultra-low friction coefficients of 0.004–0.01 and a wear rate of 4.7 × 10−7 mm3/N·m in an ultrahigh vacuum condition. The ultralow friction coefficient for the MoSN/MoS2 multilayer film was mainly due to the formation of the MoS2 tribofilm with a long-range ordered lamellar structure on the sliding interface.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhu, L.-N.; Wang, C.-B.; Wang, H.-D.; Xu, B.-S.; Zhuang, D.-M.; Liu, J.-J.; Li, G.-L. Microstructure and tribological properties of WS2/MoS2 multilayer films. Appl. Surf. Sci. 2012, 258, 1944–1948. [Google Scholar]

- Wu, Y.; Li, H.; Ji, L.; Ye, Y.; Chen, J.; Zhou, H. A long-lifetime MoS2/a-C:H nanoscale multilayer film with extremely low internal stress. Surf. Coat. Tech. 2013, 236, 438–443. [Google Scholar] [CrossRef]

- Kim, S.S.; Ahn, C.W.; Kim, T.H. Tribological characteristics of magnetron sputtered MoS2 films in various atmospheric conditions. KSME Int. J. 2002, 16, 1065–1071. [Google Scholar] [CrossRef]

- Donnet, C.; Martin, J.M.; Le Mogne, T.; Belin, M. Super-low friction of MoS2 coatings in various environments. Tribol. Int. 1996, 29, 123–128. [Google Scholar] [CrossRef]

- Zhang, X.; Qiao, L.; Chai, L.; Xu, J.; Shi, L.; Wang, P. Structural, mechanical and tribological properties of Mo–S–N solid lubricant films. Surf. Coat. Tech. 2016, 296, 185–191. [Google Scholar] [CrossRef]

- Xu, S.; Gao, X.; Hu, M.; Wang, D.; Jiang, D.; Sun, J.; Zhou, F.; Weng, L.; Liu, W. Microstructure evolution and enhanced tribological properties of Cu-doped WS2 films. Tribol. Lett. 2014, 55, 1–13. [Google Scholar] [CrossRef]

- Xu, J.; Chai, L.; Qiao, L.; He, T.; Wang, P. Influence of C dopant on the structure mechanical and tribological properties of r.f.-sputtered MoS2/a-C composite. Appl. Surf. Sci. 2016, 364, 249–256. [Google Scholar] [CrossRef]

- Fleischauer, P.D.; Lince, J.R. A comparison of oxidation and oxygen substitution in MoS2 solid film lubricants. Tribol. Int. 1999, 32, 627–636. [Google Scholar] [CrossRef]

- Khare, H.S.; Burris, D.L. Surface and subsurface contributions of oxidation and moisture to room temperature friction of molybdenum disulfide. Tribol. Lett. 2014, 53, 329–336. [Google Scholar] [CrossRef]

- Ding, X.Z.; Zeng, X.T.; He, X.Y.; Chen, Z. Tribological properties of Cr- and Ti-doped MoS2 composite coatings under different humidity atmosphere. Surf. Coat. Tech. 2010, 205, 224–231. [Google Scholar] [CrossRef]

- Gu, L.; Ke, P.; Zou, Y.; Li, X.; Wang, A. Amorphous self-lubricant MoS2-C sputtered coating with high hardness. Appl. Surf. Sci. 2015, 33, 166–171. [Google Scholar] [CrossRef]

- Nossa, A.; Cavaleiro, A. Chemical and physical characterization of C(N)-doped W–S sputtered films. J. Mater. Res. 2004, 19, 2356–2365. [Google Scholar] [CrossRef]

- Nossa, A.; Cavaleiro, A. Behaviour of nanocomposite coatings of WSN/C system under pin-on-disk testing. Mater. Sci. Forum. 2004, 455, 515–519. [Google Scholar] [CrossRef]

- Nossa, A.; Cavaleiro, A. Tribological behaviour of N (C)-alloyed W–S films. Tribol. Lett. 2007, 28, 59–70. [Google Scholar] [CrossRef]

- Nossa, A.; Cavaleiro, A. Mechanical behaviour of W–S–N and W–S–C sputtered coatings deposited with a Ti interlayer. Surf. Coat. Tech. 2003, 163, 552–560. [Google Scholar] [CrossRef]

- Watanabe, S.; Noshiro, J.; Miyake, S. Tribological characteristics of WS2/MoS2 solid lubricating multilayer films. Surf. Coat. Tech. 2004, 183, 347–351. [Google Scholar] [CrossRef]

- Watanabe, S.; Noshiro, J.; Miyake, S. Friction properties of WS2/MoS2 multilayer films under vacuum environment. Surf. Coat. Tech. 2004, 188, 644–648. [Google Scholar] [CrossRef]

- Miyake, S.; Sekine, Y.; Noshiro, J.; Watanabe, S. Low-friction and long-life solid lubricant films structured of nanoperiod tungsten disulfide and molybdenum disulfide multilayer. Jap. J. Appl. Phys. 2004, 43, 4338. [Google Scholar] [CrossRef]

- Mikhailov, S.; Savan, A.; Pflüger, E.; Knoblauch, L.; Hauert, R.; Simmonds, M.; Van Swygenhoven, H. Morphology and tribological properties of metal (oxide)–MoS2 nanostructured multilayer coatings. Surf. Coat. Tech. 1998, 105, 175–183. [Google Scholar] [CrossRef]

- Simmonds, M.C.; Savan, A.; Van Swygenhoven, H.; Pflüger, E.; Mikhailov, S. Structural, morphological, chemical and tribological investigations of sputter deposited MoSx/metal multilayer coatings. Surf. Coat. Tech. 1998, 108, 340–344. [Google Scholar] [CrossRef]

- Zhao, X.; Lu, Z.; Wu, G.; Zhang, G.; Wang, L.; Xue, Q. Preparation and properties of DLC/MoS2 multilayer coatings for high humidity tribology. Mater. Res. Exp. 2016, 3, 066401. [Google Scholar] [CrossRef]

- Wang, Y.; Chang, C.; Ho, W. Microstructure analysis of MoS2 deposited on diamond-like carbon films for wear improvement. Surf. Coat. Tech. 1999, 111, 123–127. [Google Scholar] [CrossRef]

- Sun, G.; Bhowmick, S.; Alpas, A.T. Effects of atmosphere and temperature on the tribological behavior of the Ti containing MoS2 coatings against aluminum. Tribol. Lett. 2017, 65, 158. [Google Scholar] [CrossRef]

- Zhou, H.; Zheng, J.; Wen, Q.-P.; Wan, Z.-H.; Sang, R.-P. The effect of Ti content on the structural and mechanical properties of MoS2-Ti composite coatings deposited by unbalanced magnetron sputtering system. Phys. Procedia. 2011, 18, 234–239. [Google Scholar]

- Mutafov, P.; Evaristo, M.; Cavaleiro, A.; Polcar, T. Structure, mechanical and tribological properties of self-lubricant W–S–N coatings. Surf. Coat. Tech. 2015, 261, 7–14. [Google Scholar] [CrossRef]

- Gustavsson, F.; Jacobson, S.; Cavaleiro, A.; Polcar, T. Ultra-low friction W–S–N solid lubricant coating. Surf. Coat. Tech. 2013, 232, 541–548. [Google Scholar] [CrossRef]

- Isaeva, L.; Sundberg, J.; Mukherjee, S.; Pelliccione, C.J.; Lindblad, A.; Segre, C.U.; Jansson, U.; Sarma, D.D.; Eriksson, O.; Kádas, K. Amorphous W–S–N thin films: The atomic structure behind ultra-low friction. Acta Mater. 2015, 82, 84–93. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X. Improved tribological properties of sputtered MoS2 films through N+ implantation. Thin Solid Films 1994, 240, 97–100. [Google Scholar] [CrossRef]

- Sundberg, J.; Nyberg, H.; Särhammar, E.; Nyberg, T.; Jacobson, S.; Jansson, U. Influence of composition, structure and testing atmosphere on the tribological performance of W–S–N coatings. Surf. Coat. Tech. 2014, 258, 86–94. [Google Scholar] [CrossRef]

- Abadias, G.; Miche, A.; Tromas, C.; Jaouen, C.; Dub, S.N. Stress Interfacial effects and mechanical properties of nanoscale multilayered coatings. Surf. Coat. Tech. 2007, 202, 844–853. [Google Scholar] [CrossRef]

- Yashar, P.C.; Sproul, W.D. Nanometer scale multilayered hard coatings. Vacuum 1999, 55, 179–190. [Google Scholar] [CrossRef]

- Beliardouh, N.E.; Bouzid, K.; Nouveau, C.; Tlili, B.; Walock, M.J. Tribological and electrochemical performances of Cr/CrN and Cr/CrN/CrAlN multilayer coatings deposited by RF magnetron sputtering. Tribol. Int. 2015, 82, 443–452. [Google Scholar] [CrossRef]

- Koehler, J.S. Attempt to design a strong solid. Phys. Rev. B 1970, 2, 547. [Google Scholar] [CrossRef]

- Chu, X.; Barnett, S.A. Model of superlattice yield stress and hardness enhancements. J. Appl. Phys. 1995, 77, 4403–4411. [Google Scholar] [CrossRef]

- Anderson, P.M.; Li, C. Hall-Petch relations for multilayered materials. Nanostructure Mater. 1995, 5, 349–362. [Google Scholar] [CrossRef]

- Kato, M.; Mori, T.; Schwartz, L.H. Hardening by spinodal modulated structure. Acta Met. 1980, 28, 285–290. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Pouchou, J.L. Standardless X-ray analysis of bulk specimens. Mikrochim Acta 1994, 114–115, 33–52. [Google Scholar] [CrossRef]

- Pouchou, J.L.; Pichoir, F.; Boivin, D. Further improvements in quantitation procedures for X-ray microanalysis. In Proceedings of the XII International Symposium on X-ray Optics and Microanalysis, Cracow, Poland, 1990; pp. 52–59. [Google Scholar]

- Hopf, C.; Jacob, W.; Keudell, A.V. Ion-induced surface activation, chemical sputtering, and hydrogen release during plasma-assisted hydrocarbon film growth. J. Appl. Phys. 2005, 094904, 97. [Google Scholar] [CrossRef]

- Chu, X.; Barnett, S.A.; Wong, M.S.; Sproul, W.D. Reactive unbalanced magnetron sputter deposition of polycrystalline TiN/NbN superlattice coatings. Surf. Coat. Tech. 1993, 57, 13–18. [Google Scholar] [CrossRef]

- Yashar, P.; Barnett, S.A.; Rechner, J.; Sproul, W.D. Structure and mechanical properties of polycrystalline CrN/TiN superlattices. J. Vac. Sci. Technol. 1998, A16, 2913. [Google Scholar] [CrossRef]

- Abadias, G.; Dub, S.; Shmegera, R. Nanoindentation hardness and structure of ion beam sputtered TiN, W and TiN/W multilayer hard coatings. Surf. Coat. Tech. 2006, 200, 6538. [Google Scholar] [CrossRef]

- Suszko, T.; Gulbinski, W.; Jagielski, J. The role of surface oxidation in friction processes on molybdenum nitride thin films. Surf. Coat. Tech. 2005, 194, 319. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, J.; Chai, L.; He, T.; Yu, F.; Wang, P. Carbon and nitrogen co-doping self-assembled MoS2. Appl. Surf. Sci. 2017, 406, 30–38. [Google Scholar] [CrossRef]

| Samples | Chemical Composition (at.%) | |||

|---|---|---|---|---|

| N | C | O | S/Mo | |

| pure MoS2 | 0 | 25.2 | 2.5 | 1.86 |

| MoSN monolayer | 5.2 | 23.7 | 4.1 | 1.31 |

| N4 | 3.6 | 25.8 | 3.6 | 1.58 |

| N6 | 4.8 | 23.4 | 5.2 | 1.42 |

| N10 | 7.9 | 23.7 | 2.8 | 1.28 |

| N20 | 10.3 | 27.3 | 3.5 | 1.03 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Y.; He, T.; Yang, W.; Xu, J.; Mu, B.; Pang, X.; Wang, P. Structure, Mechanical and Tribological Properties of MoSN/MoS2 Multilayer Films. Coatings 2019, 9, 108. https://doi.org/10.3390/coatings9020108

Fu Y, He T, Yang W, Xu J, Mu B, Pang X, Wang P. Structure, Mechanical and Tribological Properties of MoSN/MoS2 Multilayer Films. Coatings. 2019; 9(2):108. https://doi.org/10.3390/coatings9020108

Chicago/Turabian StyleFu, Yanlong, Tengfei He, Wu Yang, Jiao Xu, Bo Mu, Xianjuan Pang, and Peng Wang. 2019. "Structure, Mechanical and Tribological Properties of MoSN/MoS2 Multilayer Films" Coatings 9, no. 2: 108. https://doi.org/10.3390/coatings9020108

APA StyleFu, Y., He, T., Yang, W., Xu, J., Mu, B., Pang, X., & Wang, P. (2019). Structure, Mechanical and Tribological Properties of MoSN/MoS2 Multilayer Films. Coatings, 9(2), 108. https://doi.org/10.3390/coatings9020108