Influence of Annealing Temperature on the Properties of ZnGa2O4 Thin Films by Magnetron Sputtering

Abstract

1. Introduction

2. Experimental Methods

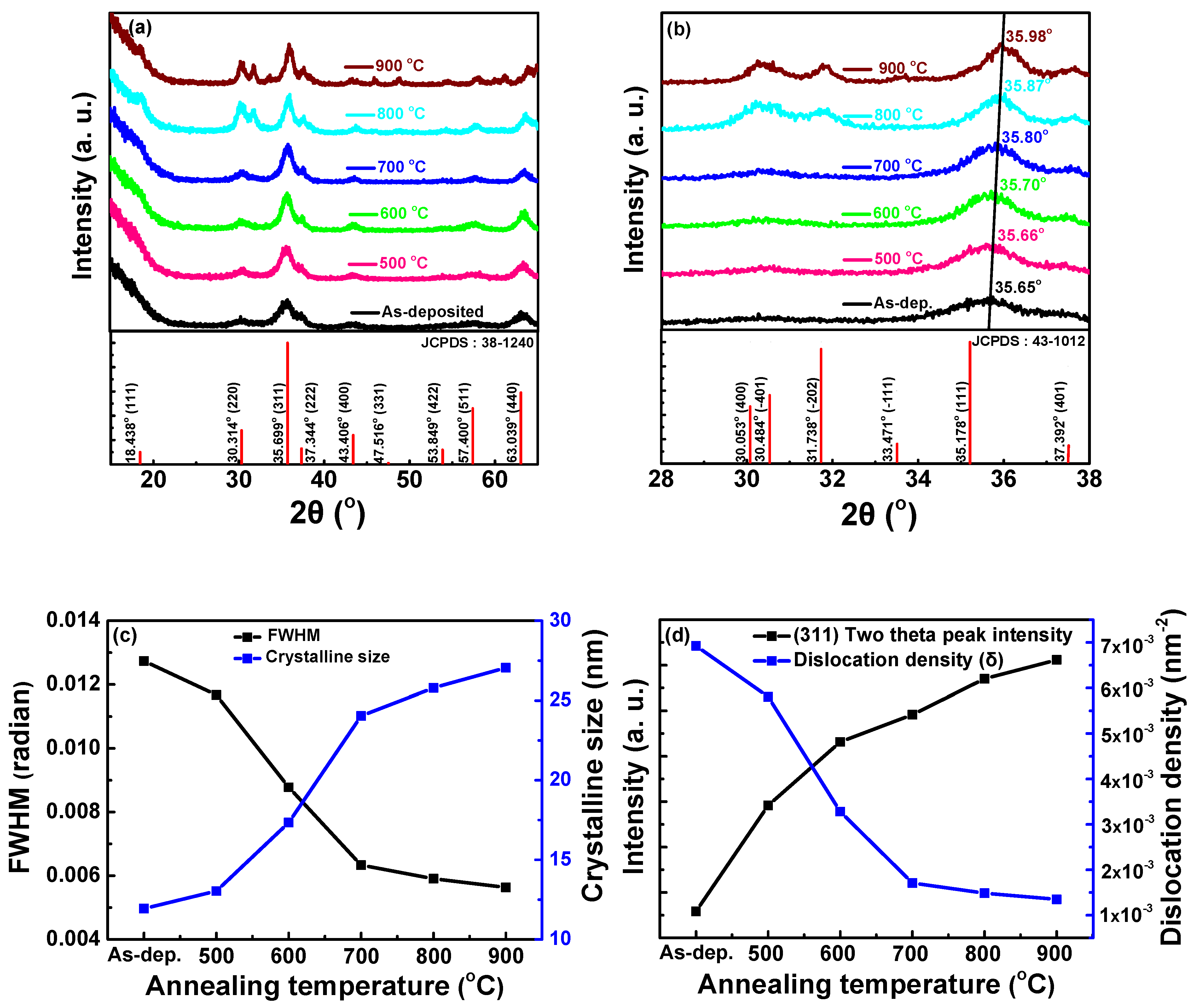

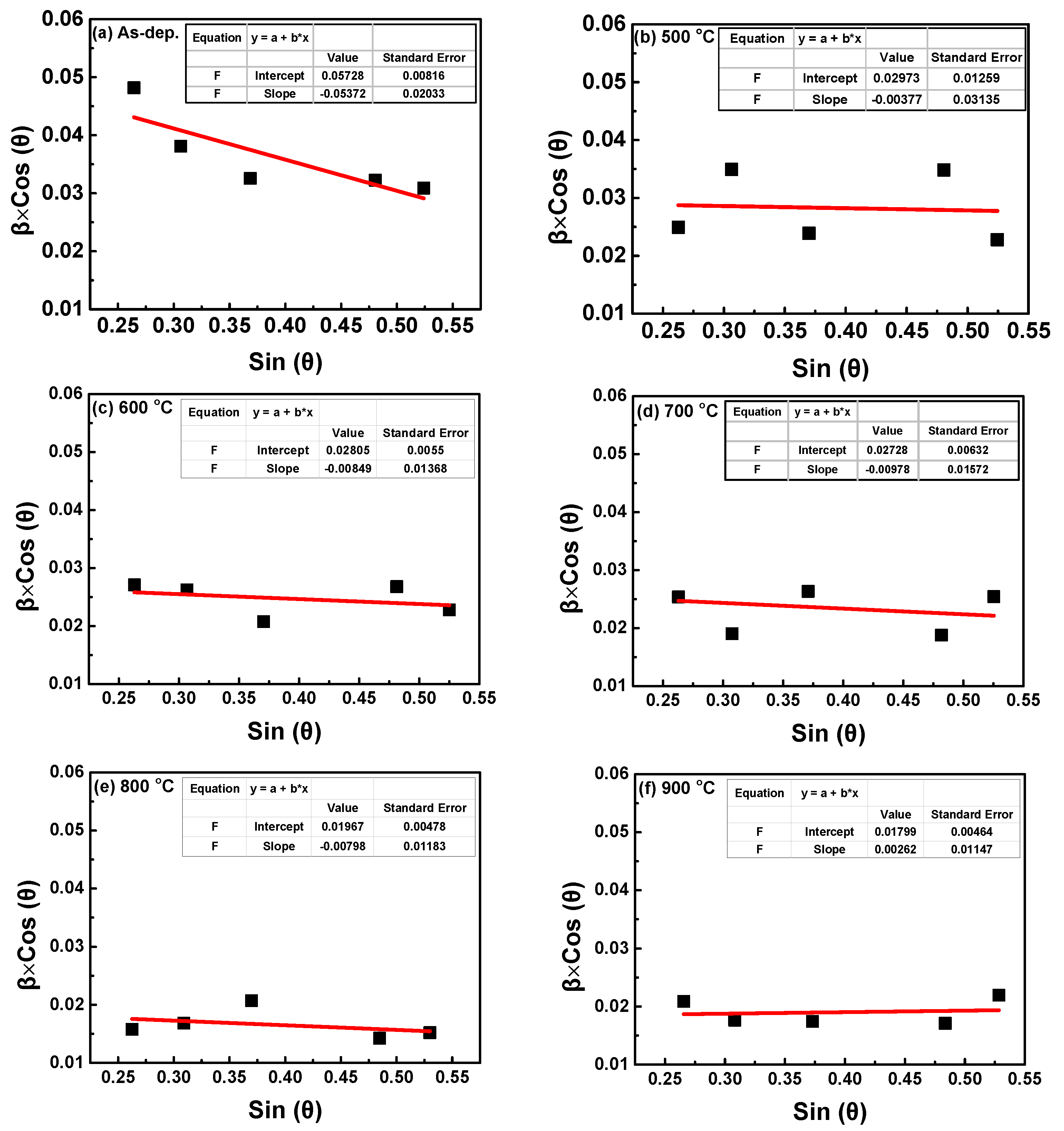

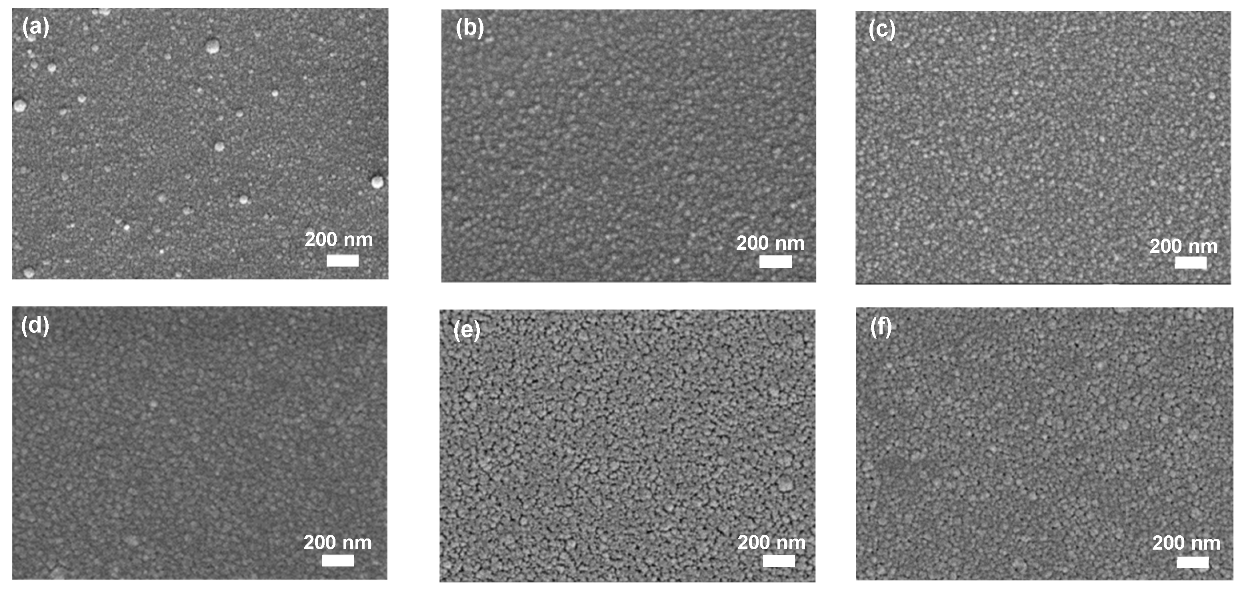

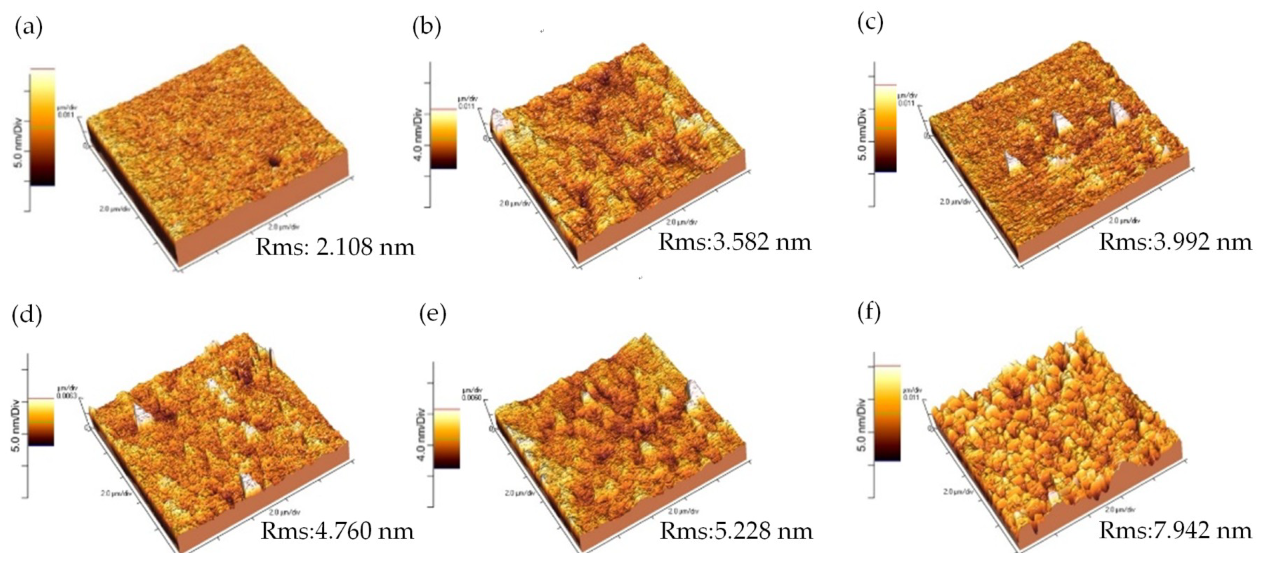

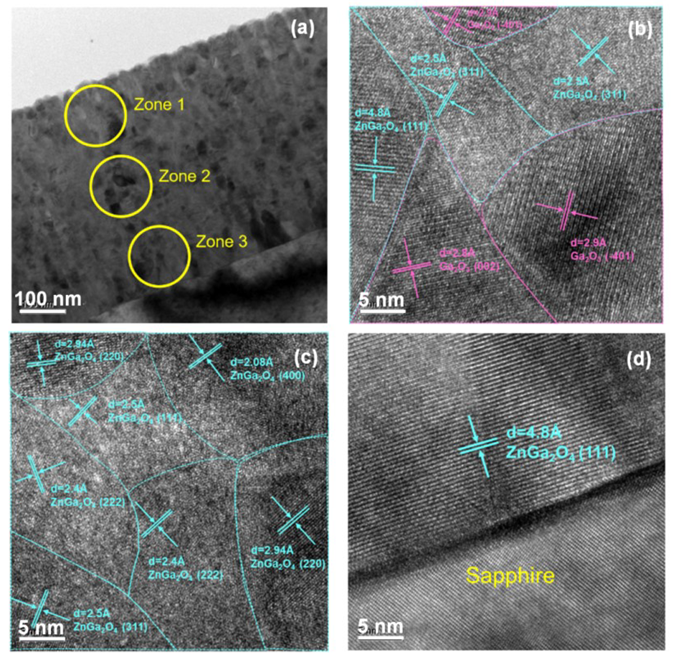

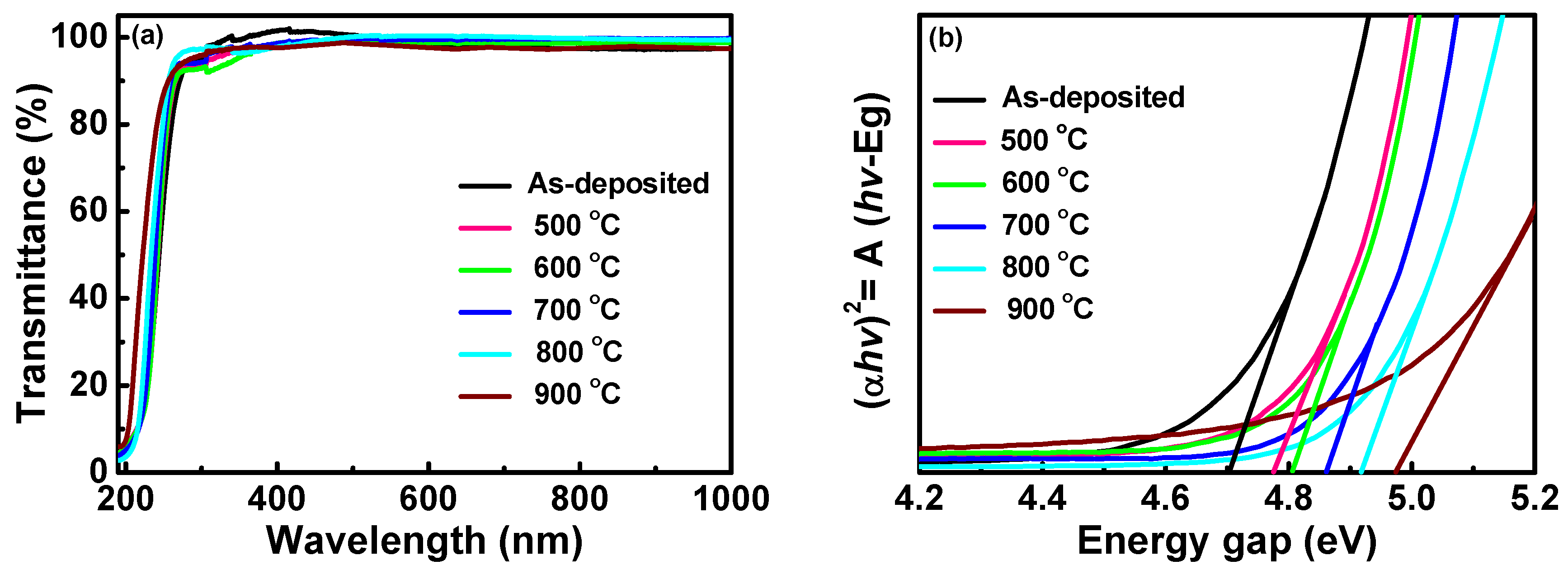

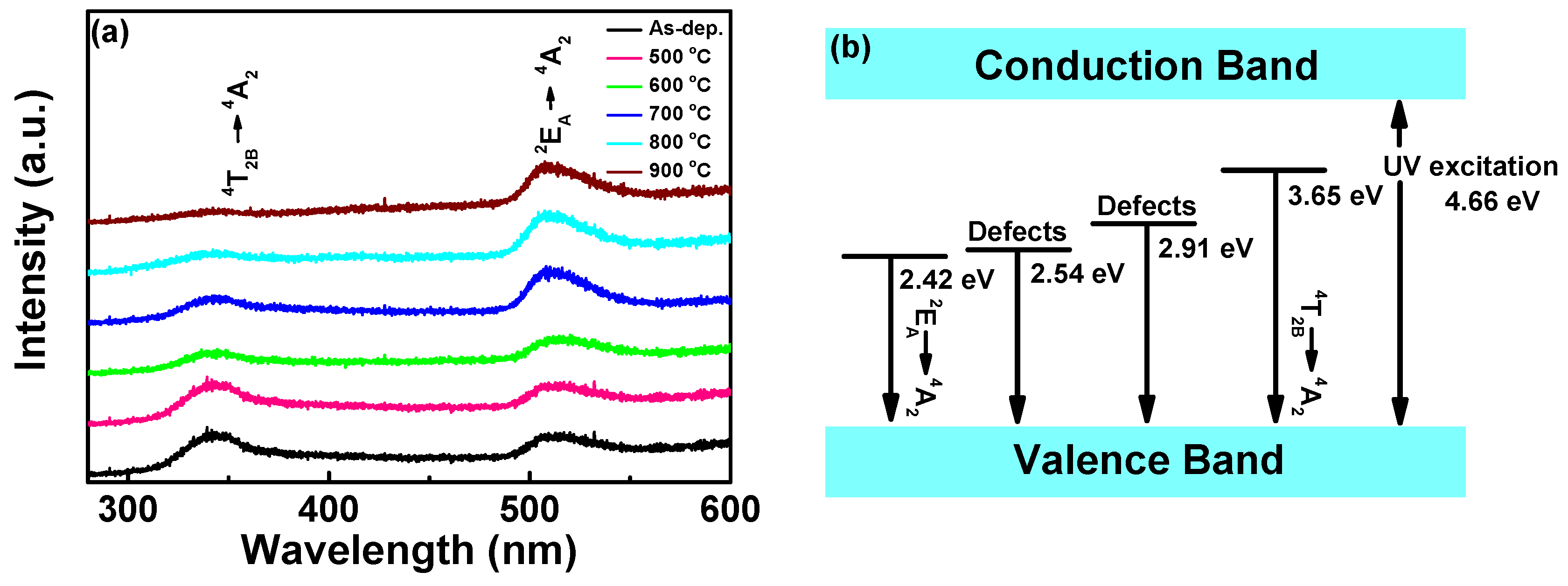

3. Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Omata, T.; Ueda, N.; Ueda, K.; Kawazoe, H. New ultraviolet-transport electroconductive oxide, ZnGa2O4 spinel. Appl. Phys. Lett. 1994, 64, 1077–1078. [Google Scholar] [CrossRef]

- Tsai, S.H.; Shen, Y.C.; Huang, C.Y.; Horng, R.H. Deep-ultraviolet Schottky photodetectors with high deep-ultraviolet/visible rejection based on a ZnGa2O4 thin film. Appl. Surf. Sci. 2019, 496, 143670. [Google Scholar] [CrossRef]

- Lee, H.; Bark, C.W.; Choi, H.W. Fabrication and characterization of perovskite solar cells with ZnGa2O4 mixed TiO2 photoelectrode. Jpn. J. Appl. Phys. 2019, 58, SDDE15. [Google Scholar] [CrossRef]

- Horng, R.H.; Huang, C.I.; Ou, H.L.; Juang, T.K.; Liu, P.L. Epitaxial growth of ZnGa2O4: A new, deep ultraviolet semiconductor candidate. Cryst. Growth Des. 2017, 17, 6071–6078. [Google Scholar] [CrossRef]

- Jiao, Z.; Ye, G.; Chen, F.; Li, M.; Liu, J. The preparation of ZnGa2O4 nano crystals by spray coprecipitation and its gas sensitive characteristics. Sensors 2002, 2, 71–78. [Google Scholar] [CrossRef]

- Lee, Y.E.; Norton, D.P.; Budai, J.D.; Wei, Y. Enhanced ultraviolet photoconductivity in semiconducting ZnGa2O4 thin films. J. Appl. Phys. 2001, 90, 3863. [Google Scholar] [CrossRef]

- Kamal, C.S.; Boddu, S.; Vishwanadh, B.; Rao, K.R.; Sudarsan, V.; Vatsa, R.K. Blue luminescence from ZnGa2O4: Effect of lattice distortion and particle size. J. Lumin. 2017, 188, 429–435. [Google Scholar] [CrossRef]

- Liang, H.F.; Meng, F.; Lamb, B.K.; Ding, Q.; Li, L.S.; Wang, Z.C.; Jin, S. Solution growth of screw dislocation driven alpha-GaOOH nanorod arrays and their conversion to porous ZnGa2O4 nanotubes. Chem. Mater. 2017, 29, 7278–7287. [Google Scholar] [CrossRef]

- Hirano, M.; Okumura, S.; Hasegawa, Y.; Inagaki, M. Direct precipitation of spinel type oxide ZnGa2O4 from aqueous solutions at low temperature below 90 °C. Inorg. Mater. 2001, 3, 797–801. [Google Scholar] [CrossRef]

- Lou, Z.; Li, L.; Shen, G. High-performance rigid and flexible ultraviolet photodetectors with single-crystalline ZnGa2O4 nanowires. Nano Res. 2015, 8, 2162–2169. [Google Scholar] [CrossRef]

- Li, C.; Bando, Y.; Liao, M.; Koide, Y.; Golberg, D. Visible-blind deep-ultraviolet schottky photodetector with a photocurrent gain based on individual Zn2GeO4 nanowire. Appl. Phys. Lett. 2010, 97, 161102. [Google Scholar] [CrossRef]

- Hussen, M.K.; Dejene, F.B.; Gonfa, G.G. Effect of citric acid on material properties of ZnGa2O4:Cr3+ nanopowder by sol-gel method. Appl. Phys. A Mater. 2018, 124, 390. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, C.Z.; Zhang, D.; Li, S.H.; Zhang, L.M.; Wang, W.J.; Zhang, J.Y. Luminescence of Cr3+ doped ZnGa2O4 thin films deposited by pulsed laser ablation. Thin Solid Film. 2012, 520, 6845–6849. [Google Scholar] [CrossRef]

- Lina, X.; Chen, D.; Niu, W.; Huang, C.Y.; Horng, R.H.; Cheng, L.C.; Talwar, D.N.; Lin, H.H.; Lee, J.F.; Feng, Z.C.; et al. Evolution of the local structure and crystal phase for thin ZnGaO films grown by metal organic chemical vapor deposition. J. Cryst. Growth 2019, 520, 89–95. [Google Scholar] [CrossRef]

- Wang, W.K.; Xu, Y.J.; Huang, S.Y.; Liu, K.F.; Tsai, P.C. Structural characteristics and photoluminescence properties of sputter-deposition ZnGa2O4 thin films on sapphire and Si(100) substrates. Coatings 2019, 9, 469. [Google Scholar] [CrossRef]

- Shen, Y.S.; Wang, W.K.; Horng, R.H. Characterizations of metal-oxide-semiconductor field-effect transistors of ZnGaO grown on sapphire substrate. IEEE J. Electron Devices Soc. 2017, 5, 112–116. [Google Scholar] [CrossRef]

- Wu, M.R.; Li, W.Z.; Tung, C.Y.; Huang, C.Y.; Chiang, Y.H.; Liu, P.L.; Horng, R.H. NO gas sensor based on ZnGa2O4 epilayer grown by metalorganic chemical vapor deposition. Sci. Rep. 2019, 9, 7459. [Google Scholar] [CrossRef]

- Huang, W.L.; Li, C.H.; Chang, S.P.; Chang, S.J. The Effect of oxygen partial pressure and annealing process on the characteristics of ZnGa2O4 MSM UV photodetector. ECS J. Solid State Sci. Technol. 2019, 8, Q3213–Q3216. [Google Scholar] [CrossRef]

- Yi, S.S.; Bae, J.S.; Moon, B.K.; Jeong, J.H.; Kim, I.W.; Park, H.L. Photoluminescence behavior of pulsed laser deposited ZnGa2O4 thin-film phosphors grown on various substrates. Appl. Phys. A 2003, 76, 433–437. [Google Scholar] [CrossRef]

- Chandolu, A.; Nikishin, S.; Holtz, M.; Temkin, H. X-ray diffraction study of AlN/AlGaN short period superlattices. J. Appl. Phys. 2007, 102, 114909. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kim, H.S.; Chang, J.H.; Yang, M.; Ahn, H.S.; Ryu, S.O. Structural and luminescence characteristics of post-annealed ZnO films on Si (111) in H2O ambient. Jpn. J. Appl. Phys. 2005, 44, L205–L207. [Google Scholar] [CrossRef]

- Sharma, S.; Vyas, S.; Periasamy, C.; Chakrabarti, P. Structural and optical characterization of ZnO thin films for optoelectronic device applications by RF sputtering technique. Superlattices Microstruct. 2014, 75, 378–389. [Google Scholar] [CrossRef]

- Son, H.; Choi, Y.J.; Hwang, J.; Jeon, D.W. Influence of post-annealing on properties of α-Ga2O3 epilayer. ECS J. Solid State Sci. Technol. 2019, 8, Q3024–Q3027. [Google Scholar] [CrossRef]

- Zak, A.K.; Majid, W.H.A.; Abrishami, M.E.; Yousefi, R. X-ray analysis of ZnO nanoparticles by Williamson–Hall and size-strain plot methods. Solid State Sci. 2011, 13, 251–256. [Google Scholar]

- Somasundaram, K.; Abhilash, K.P.; Sudarsan, V.; Christopher Selvin, P.; Kadam, R.M. Defect luminescence and lattice strain in Mn2+ doped ZnGa2O4. Phys. B 2016, 491, 79–83. [Google Scholar] [CrossRef]

- Sharma, S.; Varma, T.; Asokan, K.; Periasamy, C.; Boolchandani, D. Annealing temperature dependent structural and optical properties of RF sputtered ZnO thin films. J. Nanosci. Nanotechnol. 2017, 17, 300–305. [Google Scholar] [CrossRef]

- Shi, F.F.; Han, J.; Xing, Y.H.; Li, J.H.; Zhang, L.; He, T.; Li, T.; Deng, X.U.; Zhang, X.D.; Zhang, B.H. Annealing effects on properties of Ga2O3 films deposited by plasma-enhanced atomic layer deposition. Mater. Lett. 2019, 237, 105–108. [Google Scholar] [CrossRef]

- Chen, P.W.; Huang, S.Y.; Yuan, S.H.; Chen, Y.A.; Hsiao, P.W.; Wuu, D.S. Quasi-single-crystalline ZnGa2O4 films via solid phase epitaxy for enhancing deep-ultraviolet photoresponse. Adv. Mater. Interfaces 2019, 6, 1901075. [Google Scholar] [CrossRef]

- Hsieh, I.J.; Chu, K.T.; Yu, C.F.; Feng, M.S. Cathodoluminescent characteristics of ZnGa2O4 phosphor grown by radio frequency magnetron sputtering. J. Appl. Phys. 1994, 76, 3735–3739. [Google Scholar] [CrossRef]

- Lee, Y.E.; Norton, D.P.; Park, C.; Rouleau, C.M. Blue photoluminescence in ZnGa2O4 thin-film phosphors. J. Appl. Phys. 2001, 89, 1653–1656. [Google Scholar] [CrossRef]

| Temperature | Scherrer’s Method | Williamson-Hall | Energy Gap (eV) | |||

|---|---|---|---|---|---|---|

| D (mm) | δ × 1015 | D (mm) | δ × 1015 | ε × 10−3 | ||

| As-deposited | 11.94 | 6.93 | 13.40 | 5.57 | 53.7 | 4.69 |

| 500 °C | 13.04 | 5.80 | 14.64 | 4.66 | 3.77 | 4.77 |

| 600 °C | 17.34 | 3.28 | 19.22 | 2.71 | 8.49 | 4.80 |

| 700 °C | 24.03 | 1.71 | 26.98 | 1.37 | 9.78 | 4.86 |

| 800 °C | 25.79 | 1.48 | 28.98 | 1.19 | 7.98 | 4.92 |

| 900 °C | 27.05 | 1.35 | 30.43 | 1.08 | 2.62 | 4.98 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.-K.; Liu, K.-F.; Tsai, P.-C.; Xu, Y.-J.; Huang, S.-Y. Influence of Annealing Temperature on the Properties of ZnGa2O4 Thin Films by Magnetron Sputtering. Coatings 2019, 9, 859. https://doi.org/10.3390/coatings9120859

Wang W-K, Liu K-F, Tsai P-C, Xu Y-J, Huang S-Y. Influence of Annealing Temperature on the Properties of ZnGa2O4 Thin Films by Magnetron Sputtering. Coatings. 2019; 9(12):859. https://doi.org/10.3390/coatings9120859

Chicago/Turabian StyleWang, Wei-Kai, Kuo-Feng Liu, Pi-Chuen Tsai, Yi-Jie Xu, and Shih-Yung Huang. 2019. "Influence of Annealing Temperature on the Properties of ZnGa2O4 Thin Films by Magnetron Sputtering" Coatings 9, no. 12: 859. https://doi.org/10.3390/coatings9120859

APA StyleWang, W.-K., Liu, K.-F., Tsai, P.-C., Xu, Y.-J., & Huang, S.-Y. (2019). Influence of Annealing Temperature on the Properties of ZnGa2O4 Thin Films by Magnetron Sputtering. Coatings, 9(12), 859. https://doi.org/10.3390/coatings9120859