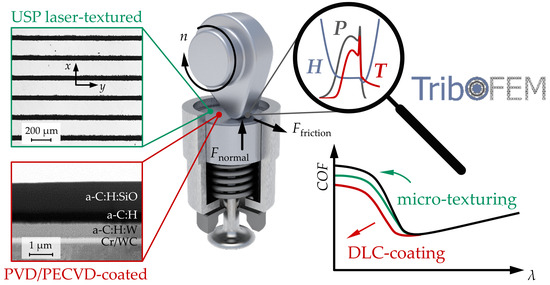

On Friction Reduction by Surface Modifications in the TEHL Cam/Tappet-Contact-Experimental and Numerical Studies

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Methods

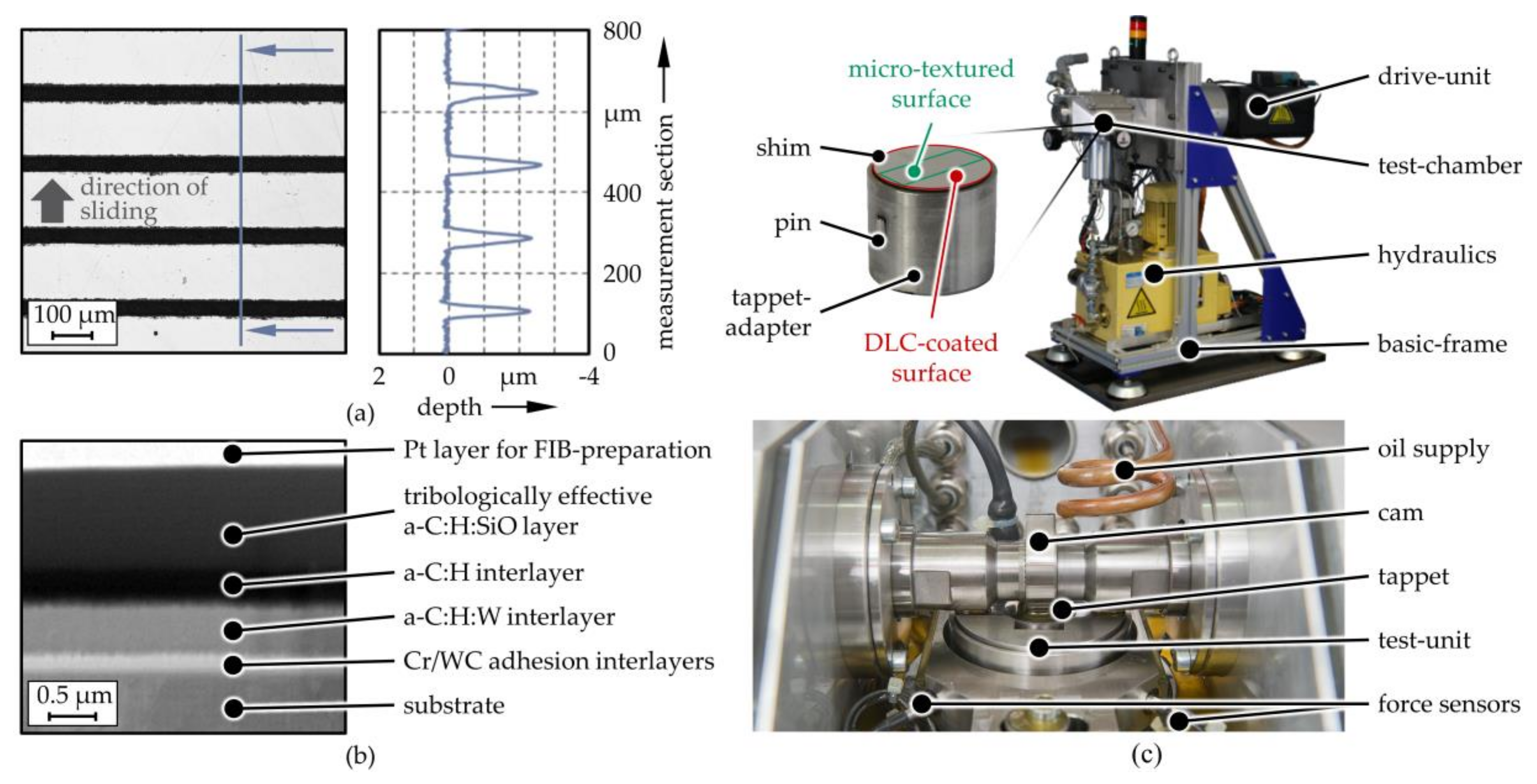

2.1.1. Materials

2.1.2. Microtexturing

2.1.3. Coating

2.1.4. Characterization and Tribological Testing

2.2. Numerical Methods

2.2.1. Hydrodynamics

2.2.2. Contact Mechanics

2.2.3. Thermodynamics

2.2.4. Numerical Procedure

2.2.5. Load Cases, Material and Lubricant Properties

3. Results and Discussion

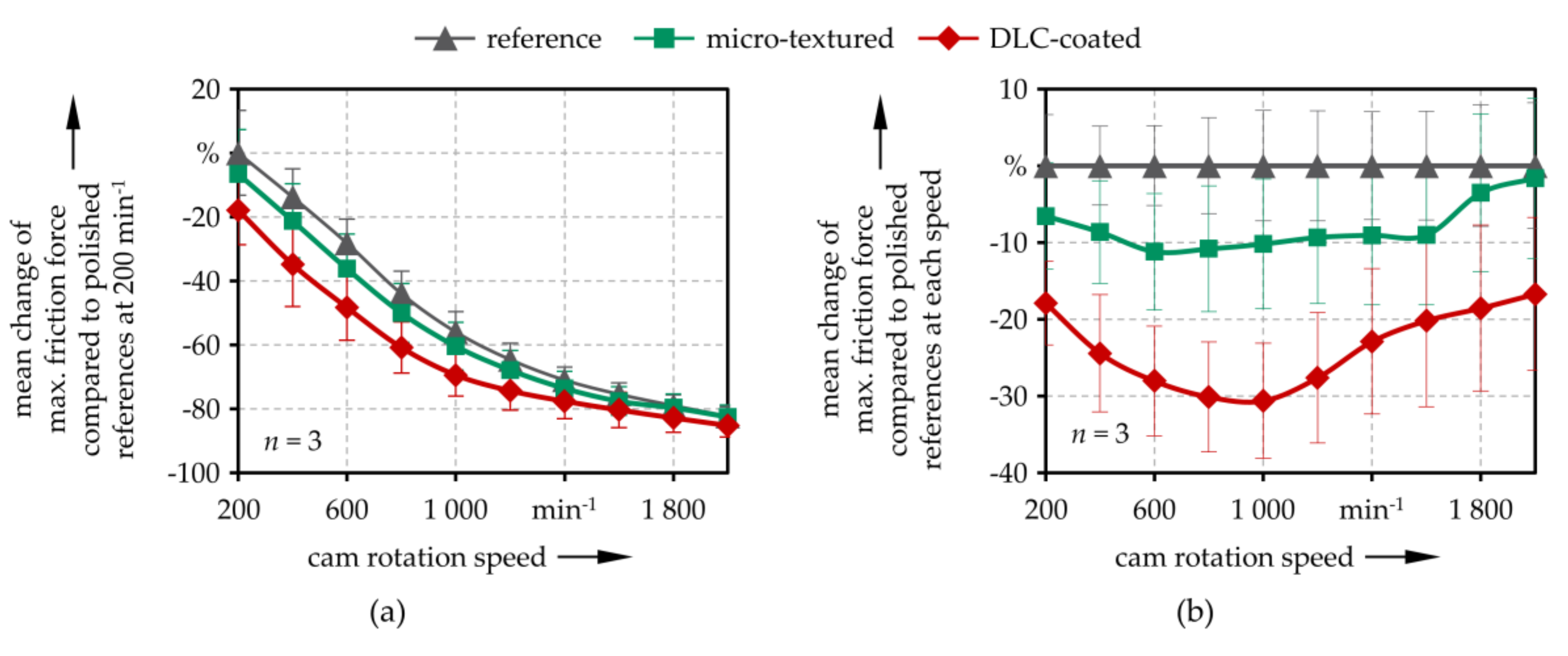

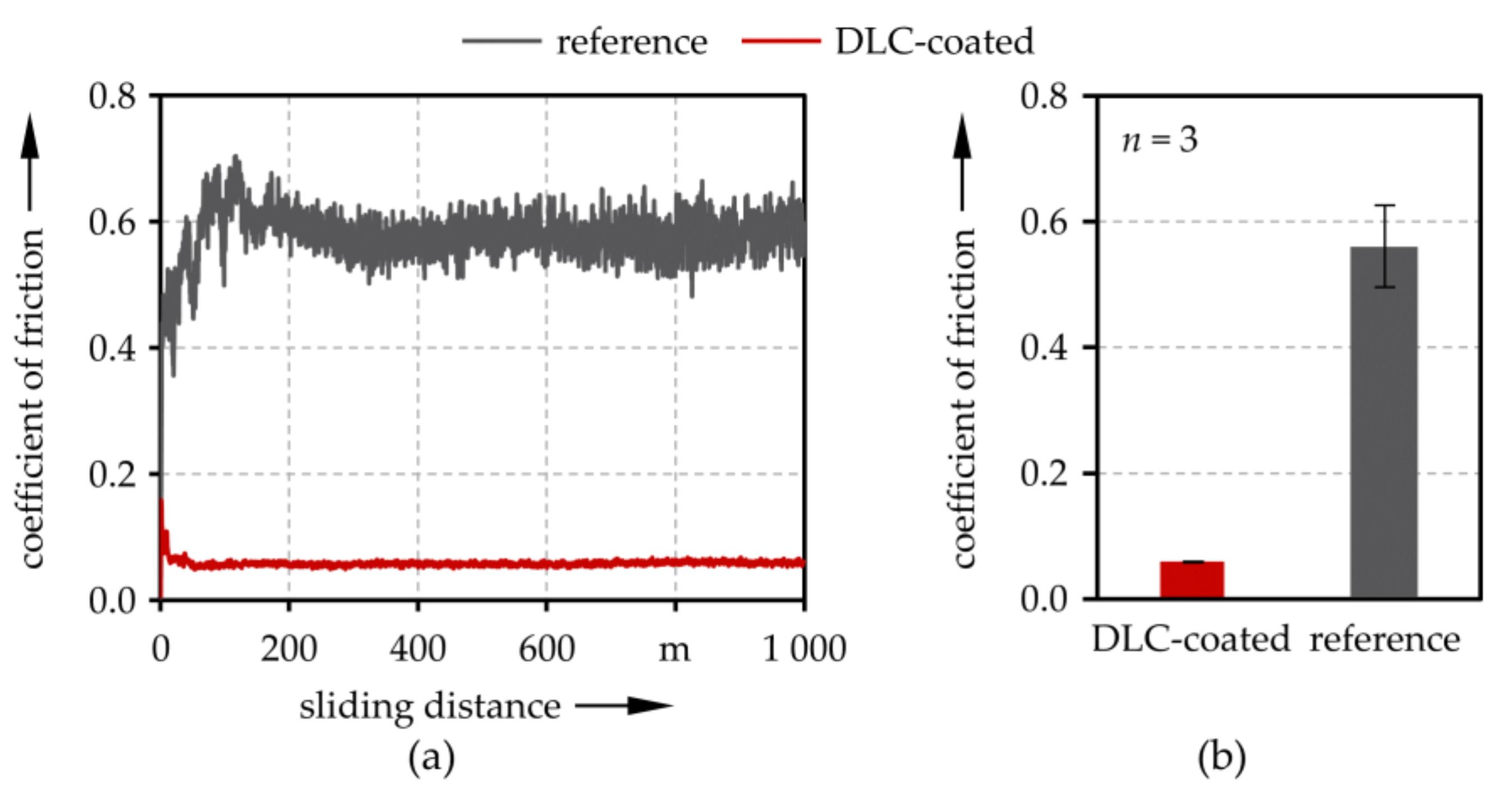

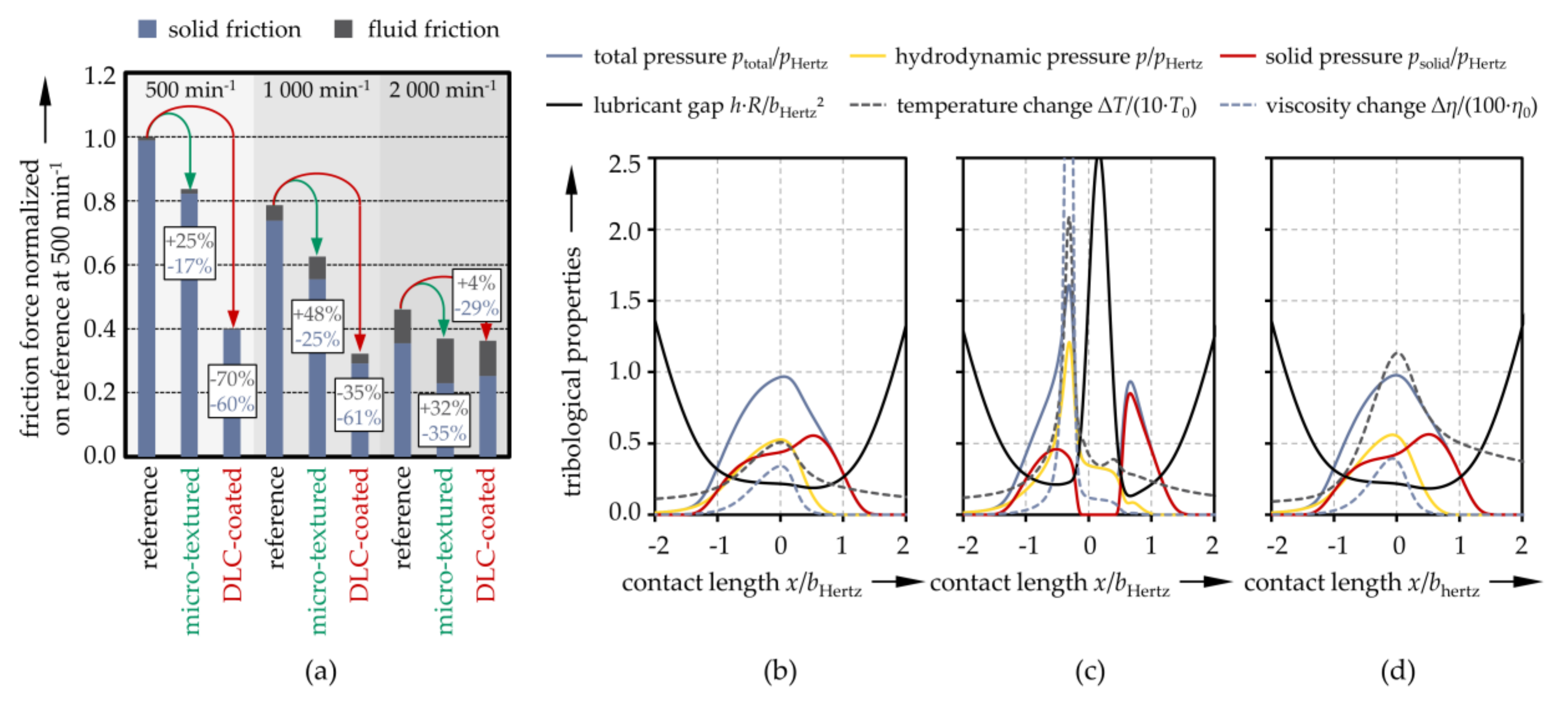

3.1. Experimental Results

3.2. Numerical Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ac | Carreau parameter |

| atexture | micro-texture amplitude |

| bHertz | Hertzian contact half-width |

| cp | specific heat capacity |

| C | compliance matrix |

| dtexture | micro-texture distance |

| E | Young’s modulus |

| EIT | indentation modulus |

| F | normal force |

| Ffluid | fluid friction force |

| Fsolid | solid friction force |

| g | zero level correction parameter |

| Gc | critical shear stress |

| h | lubricant gap |

| h0 | rigid body motion |

| HIT | indentation hardness |

| l | cam width in y-direction |

| L | Moe’s dimensionless material properties parameter |

| M | Moe’s dimensionless load parameter |

| nc | Carreau parameter |

| p | hydrodynamic pressure |

| pHertz | Hertzian contact pressure |

| psolid | solid contact pressure |

| ptotal | total contact pressure |

| R | equivalent radius |

| SRR | slide-to-roll ratio |

| u1 | sliding velocity of body 1 |

| u2 | sliding velocity of body 2 |

| um | mean hydrodynamic velocity |

| Uz | displacement in z-direction |

| t | time |

| T | temperature |

| wtexture | micro-texture width in x-direction |

| x, y, z | space coordinates |

| xstart | starting position of the micro-texture in x-direction |

| αp | pressure viscosity coefficient |

| βp | volume expansion coefficient |

| βη | Roelands temperature viscosity coefficient |

| δelastic | elastic deformation in z-direction |

| ε | strain tensor |

| η | lubricant viscosity |

| η0 | lubricant viscosity at reference state |

| λ | thermal conductivity |

| μsolid | solid friction coefficient |

| ρ | density |

| σ | stress tensor of the equivalent body |

| τzx | shear stress |

| υ | Poisson’s ratio |

| Ω | computational domain |

References

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Kalghatgi, G. Is it really the end of internal combustion engines and petroleum in transport? Appl. Energy 2018, 225, 965–974. [Google Scholar] [CrossRef]

- Serrano, J.R.; Novella, R.; Piqueras, P. Why the development of internal combustion engines is still necessary to fight against global climate change from the perspective of transportation. Appl. Sci. 2019, 9, 4597. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I. Tribology of electric vehicles: A review of critical components, current state and future improvement trends. Tribol. Int. 2019, 138, 473–486. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Kalin, M.; Velkavrh, I.; Vižintin, J.; Ožbolt, L. Review of boundary lubrication mechanisms of DLC coatings used in mechanical applications. Meccanica 2008, 43, 623–637. [Google Scholar] [CrossRef]

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D Appl. Phys. 2006, 39, R311–R327. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Grützmacher, P.G.; Gachot, C.; Costa, H.L. Surface texturing in machine elements—A critical discussion for rolling and sliding contacts. Adv. Eng. Mater. 2019, 86, 1900194. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Profito, F.J.; Rosenkranz, A. Multi-scale surface texturing in tribology—Current knowledge and future perspectives. Lubricants 2019, 7, 95. [Google Scholar] [CrossRef]

- Pettersson, U.; Jacobson, S. Textured surfaces in sliding boundary lubricated contacts—Mechanisms, possibilities and limitations. Tribol. Mater. Surf. Interfaces 2013, 1, 181–189. [Google Scholar] [CrossRef]

- Löffler, M.; Andreas, K.; Engel, U.; Schulte, R.; Groebel, D.; Krebs, E.; Freiburg, D.; Biermann, D.; Stangier, D.; Tillmann, W.; et al. Tribological measures for controlling material flow in sheet-bulk metal forming. Prod. Eng. 2016, 10, 459–470. [Google Scholar] [CrossRef]

- Borghi, A.; Gualtieri, E.; Marchetto, D.; Moretti, L.; Valeri, S. Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear 2008, 265, 1046–1051. [Google Scholar] [CrossRef]

- Etsion, I. Modeling of surface texturing in hydrodynamic lubrication. Friction 2013, 1, 195–209. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. Tribological behaviours of textured surfaces under conformal and non-conformal starved lubricated contact conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 398–409. [Google Scholar] [CrossRef]

- Grabon, W.; Koszela, W.; Pawlus, P.; Ochwat, S. Improving tribological behaviour of piston ring–cylinder liner frictional pair by liner surface texturing. Tribol. Int. 2013, 61, 102–108. [Google Scholar] [CrossRef]

- Evans, R.D.; Cogdell, J.D.; Richter, G.A.; Doll, G.L. Traction of lubricated rolling contacts between thin-film coatings and steel. Tribol. Trans. 2008, 52, 106–113. [Google Scholar] [CrossRef]

- Kalin, M.; Polajnar, M. The wetting of steel, DLC coatings, ceramics and polymers with oils and water: The importance and correlations of surface energy, surface tension, contact angle and spreading. Appl. Surf. Sci. 2014, 293, 97–108. [Google Scholar] [CrossRef]

- Kalin, M.; Polajnar, M. The effect of wetting and surface energy on the friction and slip in oil-lubricated contacts. Tribol. Lett. 2013, 52, 185–194. [Google Scholar] [CrossRef]

- Björling, M.; Larsson, R.; Marklund, P. The Effect of DLC Coating Thickness on Elstohydrodynamic Friction. Tribol. Lett. 2014, 55, 353–362. [Google Scholar] [CrossRef]

- Björling, M.; Habchi, W.; Bair, S.; Larsson, R.; Marklund, P. Friction Reduction in Elastohydrodynamic Contacts by Thin-Layer Thermal Insulation. Tribol. Lett. 2014, 53, 477–486. [Google Scholar] [CrossRef]

- Björling, M.; Isaksson, P.; Marklund, P.; Larsson, R. The Influence of DLC Coating on EHL Friction Coefficient. Tribol. Lett. 2012, 47, 285–294. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Stahl, K.; Michaelis, K.; Mayer, J.; Hinterstoißer, M. Friction reduction of highly-loaded rolling-sliding contacts by surface modifications under elasto-hydrodynamic lubrication. Wear 2015, 328–329, 217–228. [Google Scholar] [CrossRef]

- Elsharkawy, A.A.; Hamrock, B.J. EHL of Coated Surfaces: Part I—Newtonian Results. J. Tribol. 1994, 116, 29. [Google Scholar] [CrossRef]

- Habchi, W. A numerical model for the solution of thermal elastohydrodynamic lubrication in coated circular contacts. Tribol. Int. 2014, 73, 57–68. [Google Scholar] [CrossRef]

- Bobach, L.; Bartel, D.; Beilicke, R.; Mayer, J.; Michaelis, K.; Stahl, K.; Bachmann, S.; Schnagl, J.; Ziegele, H. Reduction in EHL Friction by a DLC Coating. Tribol. Lett. 2015, 60, 1270. [Google Scholar] [CrossRef]

- Ebner, M.; Ziegltrum, A.; Lohner, T.; Michaelis, K.; Stahl, K. Measurement of EHL temperature by thin film sensors—Thermal insulation effects. Tribol. Int. 2018, 105515. [Google Scholar] [CrossRef]

- Choo, J.W.; Olver, A.V.; Spikes, H.A. The influence of transverse roughness in thin film, mixed elastohydrodynamic lubrication. Tribol. Int. 2007, 40, 220–232. [Google Scholar] [CrossRef]

- Choo, J.W.; Olver, A.V.; Spikes, H.A.; Dumont, M.-L.; Ioannides, E. The Influence of Longitudinal Roughness in Thin-Film, Mixed Elastohydrodynamic Lubrication. Tribol. Trans. 2006, 49, 248–259. [Google Scholar] [CrossRef]

- Ehret, P.; Dowson, D.; Taylor, C.M. Waviness Orientation in EHL Point Contact. In The Third Body Concept Interpretation of Tribological Phenomena; Elsevier: Amsterdam, The Netherlands, 1996; pp. 235–244. ISBN 9780444825025. [Google Scholar]

- Venner, C.H.; Lubrecht, A.A. Numerical Simulation of a Transverse Ridge in a Circular EHL Contact Under Rolling/Sliding. J. Tribol. 1994, 116, 751. [Google Scholar] [CrossRef]

- Cusano, C.; Wedeven, L.D. The Effects of Artificially-Produced Defects on the Film Thickness Distribution in Sliding EHD Point Contacts. J. Lubr. Technol. 1982, 104, 365. [Google Scholar] [CrossRef][Green Version]

- Ai, X.; Cheng, H.S. The Influence of Moving Dent on Point EHL Contacts. Tribol. Trans. 1994, 37, 323–335. [Google Scholar] [CrossRef]

- Mourier, L.; Mazuyer, D.; Lubrecht, A.A.; Donnet, C. Transient increase of film thickness in micro-textured EHL contacts. Tribol. Int. 2006, 39, 1745–1756. [Google Scholar] [CrossRef]

- Mourier, L.; Mazuyer, D.; Ninove, F.-P.; Lubrecht, A.A. Lubrication mechanisms with laser-surface-textured surfaces in elastohydrodynamic regime. Proc. Inst. Mech. Eng. Part. J J. Eng. Tribol. 2010, 224, 697–711. [Google Scholar] [CrossRef]

- Krupka, I.; Hartl, M. The effect of surface texturing on thin EHD lubrication films. Tribol. Int. 2007, 40, 1100–1110. [Google Scholar] [CrossRef]

- Krupka, I.; Vrbka, M.; Hartl, M. Effect of surface texturing on mixed lubricated non-conformal contacts. Tribol. Int. 2008, 41, 1063–1073. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Szurdak, A.; Gachot, C.; Hirt, G.; Mücklich, F. Friction reduction under mixed and full film EHL induced by hot micro-coined surface patterns. Tribol. Int. 2016, 95, 290–297. [Google Scholar] [CrossRef]

- Marian, M.; Grützmacher, P.; Rosenkranz, A.; Tremmel, S.; Mücklich, F.; Wartzack, S. Designing surface textures for EHL point-contacts—Transient 3D simulations, meta-modeling and experimental validation. Tribol. Int. 2019, 137, 152–163. [Google Scholar] [CrossRef]

- Beilicke, R.; Bobach, L.; Bartel, D. Transient thermal elastohydrodynamic simulation of a DLC coated helical gear pair considering limiting shear stress behavior of the lubricant. Tribol. Int. 2016, 97, 136–150. [Google Scholar] [CrossRef]

- Ziegltrum, A.; Lohner, T.; Stahl, K. TEHL Simulation on the Influence of Lubricants on the Frictional Losses of DLC Coated Gears. Lubricants 2018, 6, 17. [Google Scholar] [CrossRef]

- Kano, M. Super low friction of DLC applied to engine cam follower lubricated with ester-containing oil. Tribol. Int. 2006, 39, 1682–1685. [Google Scholar] [CrossRef]

- Dobrenizki, L.; Tremmel, S.; Wartzack, S.; Hoffmann, D.C.; Brögelmann, T.; Bobzin, K.; Bagcivan, N.; Musayev, Y.; Hosenfeldt, T. Efficiency improvement in automobile bucket tappet/camshaft contacts by DLC coatings—Influence of engine oil, temperature and camshaft speed. Surf. Coat. Technol. 2016, 308, 360–373. [Google Scholar] [CrossRef]

- Yu, C.; Meng, X.; Xie, Y. Numerical simulation of the effects of coating on thermal elastohydrodynamic lubrication in cam/tappet contact. Proc. Inst. Mech. Eng. Part. J J. Eng. Tribol. 2017, 231, 221–239. [Google Scholar] [CrossRef]

- Meng, X.; Yu, C.; Xie, Y.; Mei, B. Thermal insulation effect on EHL of coated cam/tappet contact during start up. Ind. Lubr. Tribol. 2018, 70, 917–926. [Google Scholar] [CrossRef]

- Gangopadhyay, A.; McWatt, D.G. The Effect of Novel Surface Textures on Tappet Shims on Valvetrain Friction and Wear. Tribol. Trans. 2008, 51, 221–230. [Google Scholar] [CrossRef]

- Krupka, I.; Hartl, M.; Zimmerman, M.; Houska, P.; Jang, S. Effect of surface texturing on elastohydrodynamically lubricated contact under transient speed conditions. Tribol. Int. 2011, 44, 1144–1150. [Google Scholar] [CrossRef]

- Marian, M.; Tremmel, S.; Wartzack, S. Microtextured surfaces in higher loaded rolling-sliding EHL line-contacts. Tribol. Int. 2018, 127, 420–432. [Google Scholar] [CrossRef]

- Tremmel, S.; Marian, M.; Zahner, M.; Wartzack, S.; Merklein, M. Friction reduction in EHL contacts by surface microtexturing—Tribological performance, manufacturing and tailored design. Ind. Lubr. Tribol. 2018, 0306. [Google Scholar] [CrossRef]

- Marian, M.; Weikert, T.; Tremmel, S. Numerical and experimental studies on friction reduction by surface modification in TEHL contacts. In Proceedings of the STLE 2019—74th Annual Meeting and Exhibition of the Society of Tribologists and Lubrication Engineers, Nashville, TN, USA, 19–23 May 2019. [Google Scholar]

- ISO 14577-1:2015. Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part. 1: Test, Method; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Habchi, W.; Demirci, I.; Eyheramendy, D.; Morales-Espejel, G.; Vergne, P. A finite element approach of thin film lubrication in circular EHD contacts. Tribol. Int. 2007, 40, 1466–1473. [Google Scholar] [CrossRef]

- Yang, P.; Wen, S. A Generalized Reynolds Equation for Non-Newtonian Thermal Elastohydrodynamic Lubrication. J. Tribol. 1990, 112, 631–636. [Google Scholar] [CrossRef]

- Marian, M.; Weschta, M.; Tremmel, S.; Wartzack, S. Simulation of Microtextured Surfaces in Starved EHL Contacts Using Commercial FE Software. Mater. Perform. Charact. 2017, 6, 165–181. [Google Scholar] [CrossRef]

- Liu, S.; Peyronnel, A.; Wang, Q.J.; Keer, L.M. An extension of the Hertz theory for 2D coated components. Tribol. Lett. 2005, 18, 505–511. [Google Scholar] [CrossRef]

- Zhao, Y.; Maietta, D.M.; Chang, L. An Asperity Microcontact Model Incorporating the Transition from Elastic Deformation to Fully Plastic Flow. J. Tribol. 2000, 122, 86. [Google Scholar] [CrossRef]

- Masjedi, M.; Khonsari, M.M. Film Thickness and Asperity Load Formulas for Line-Contact Elastohydrodynamic Lubrication With Provision for Surface Roughness. J. Tribol. 2012, 134, 11503. [Google Scholar] [CrossRef]

- Habchi, W. Finite Element Modeling of Elastohydrodynamic Lubrication Problems; John Wiley & Sons Incorporated: Newark, NJ, USA, 2018; ISBN 978-1119225126. [Google Scholar]

- Tan, X.; Goodyer, C.E.; Jimack, P.K.; Taylor, R.I.; Walkley, M.A. Computational approaches for modelling elastohydrodynamic lubrication using multiphysics software. Proc. Inst. Mech. Eng. Part. J J. Eng. Tribol. 2012, 226, 463–480. [Google Scholar] [CrossRef]

- Lohner, T.; Ziegltrum, A.; Stemplinger, J.-P.; Stahl, K. Engineering Software Solution for Thermal Elastohydrodynamic Lubrication Using Multiphysics Software. Adv. Tribol. 2016, 2016, 1–13. [Google Scholar] [CrossRef]

- Weschta, M. Untersuchungen zur Wirkungsweise von Mikrotexturen in elastohydrodynamischen Gleit/Wälz-Kontakten. Ph.D. Thesis, Friedrich-Alexander-Universität, Erlangen-Nürnberg, Germany, 2017. urn:nbn:de:bvb:29-opus4-91095. [Google Scholar]

- Sadeghi, F.; Sui, P.C. Thermal Elastohydrodynamic Lubrication of Rolling/Sliding Contacts. J. Tribol. 1990, 112, 189–195. [Google Scholar] [CrossRef]

- Bair, S. A Rough Shear-Thinning Correction for EHD Film Thickness. Tribol. Trans. 2004, 47, 361–365. [Google Scholar] [CrossRef]

- Dowson, D.; Higginson, G.R. Elasto-Hydrodynamic Lubrication, SI ed.; Pergamon Press: Oxford, UK, 1977; ISBN 0080213022. [Google Scholar]

| Coating Layer | Duration in s | Arc Current of Cr-Target in A | Sputtering Power of WC-Target in W | Bias Voltage in V (Operating Mode) | Acetylene Gas Flow in sccm | Argon Gas Flow in sccm | HMDSO Gas Flow in sccm | Temperature in °C |

|---|---|---|---|---|---|---|---|---|

| Cr | 280 | 70 | − | −100 (DC) | − | 70 | − | 140 |

| WC | 1080 | − | 1200 | −50 (DC) | − | 195 | − | 110 |

| a-C:H:W | 2267 | − | 1200 | −130 (DC) | 28 | 180 | − | 100 |

| a-C:H | 1155 | − | − | −450 (bipolar pulsed) | 250 | 100 | − | 100 |

| a-C:H:SiO | 2050 | − | − | −575 (unipolar pulsed) | 250 | 100 | 6 | 100 |

| Parameter | Cam(100Cr6) | Tappet (16MnCr5) | Coating (a-C:H:SiO) |

|---|---|---|---|

| Young’s/indentation modulus E in MPa | 209,000 1 | 216,000 2 | 110,000 2 |

| Poisson’s ratio ν | 0.3 1 | 0.3 1 | 0.3 1 |

| density ρ in kg/m³ | 7850 1 | 7760 1 | 4655 1 |

| thermal conductivity λ in W/(m∙K) | 47 1 | 44 1 | 1.1 1 |

| specific heat capacity cp in J/(kg∙K) | 460 1 | 431 1 | 8263 1 |

| dry coefficient of friction against 100Cr6 μsolid | − | 0.5 2, 3 | 0.2 2,3 |

| Base Density at 90 °C ρ in kg/m³ | 840 |

| Base Viscosity at 90 °C η0 in Pa∙s | 0.03 |

| Pressure Viscosity Coefficient αp in Pa−1, | 1.31∙10−8 |

| Roelands Temperature Coefficient βη | 0.042 |

| Critical Shear Stress Gc | 0.2 η0 |

| Carreau Parameter ac | 2.2 |

| Carreau Parameter nc | 0.8 |

| Thermal Conductivity λ in W/(m∙K) | 0.14 |

| Specific Heat Capacity cp in J/(kg∙K) | 2000 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marian, M.; Weikert, T.; Tremmel, S. On Friction Reduction by Surface Modifications in the TEHL Cam/Tappet-Contact-Experimental and Numerical Studies. Coatings 2019, 9, 843. https://doi.org/10.3390/coatings9120843

Marian M, Weikert T, Tremmel S. On Friction Reduction by Surface Modifications in the TEHL Cam/Tappet-Contact-Experimental and Numerical Studies. Coatings. 2019; 9(12):843. https://doi.org/10.3390/coatings9120843

Chicago/Turabian StyleMarian, Max, Tim Weikert, and Stephan Tremmel. 2019. "On Friction Reduction by Surface Modifications in the TEHL Cam/Tappet-Contact-Experimental and Numerical Studies" Coatings 9, no. 12: 843. https://doi.org/10.3390/coatings9120843

APA StyleMarian, M., Weikert, T., & Tremmel, S. (2019). On Friction Reduction by Surface Modifications in the TEHL Cam/Tappet-Contact-Experimental and Numerical Studies. Coatings, 9(12), 843. https://doi.org/10.3390/coatings9120843