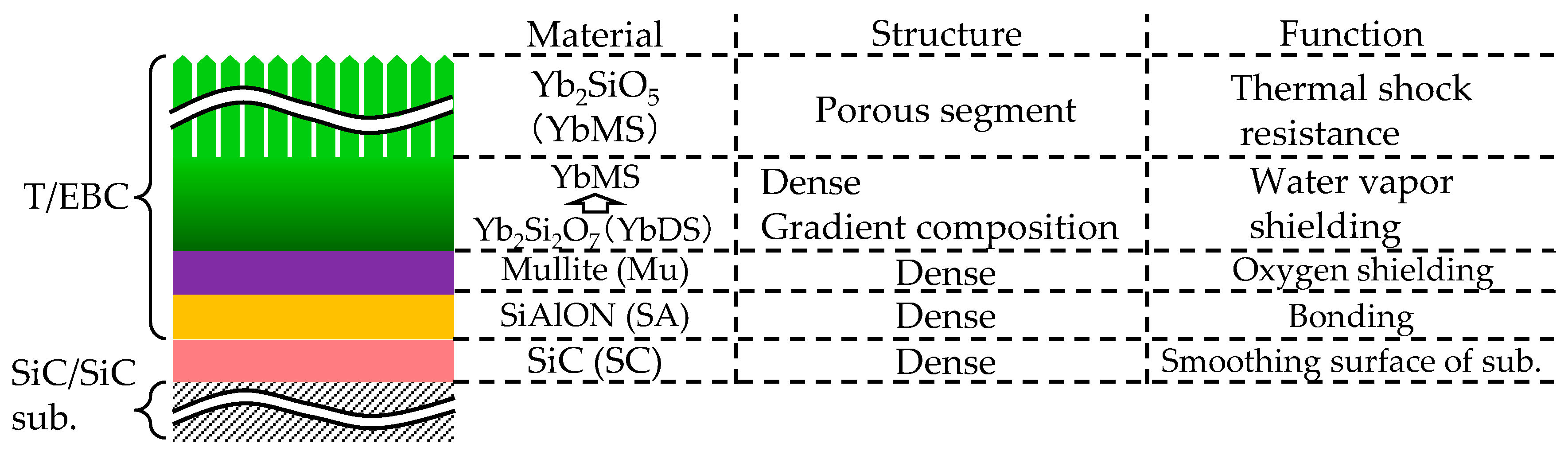

4.1. and for Objective Interface Cracks in Fabricated T/EBC

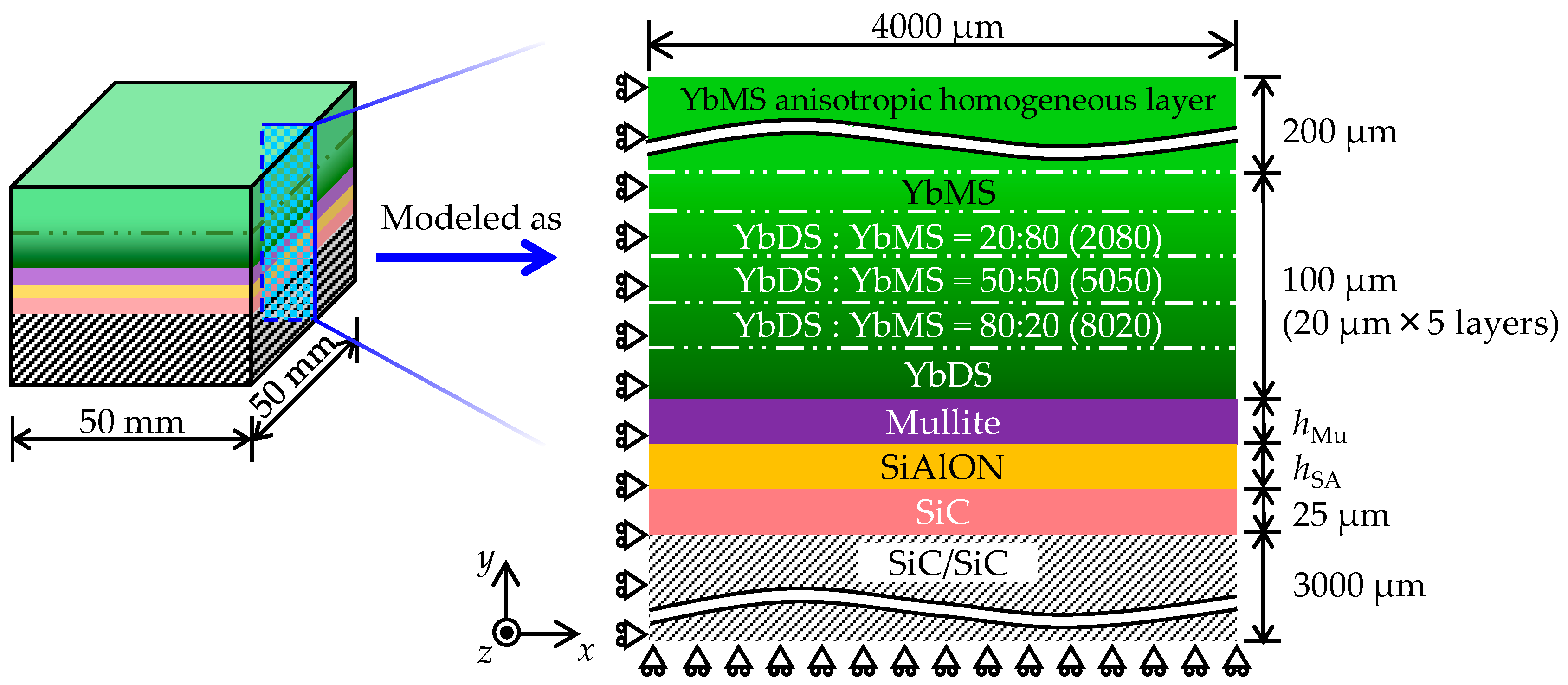

Table 10 lists

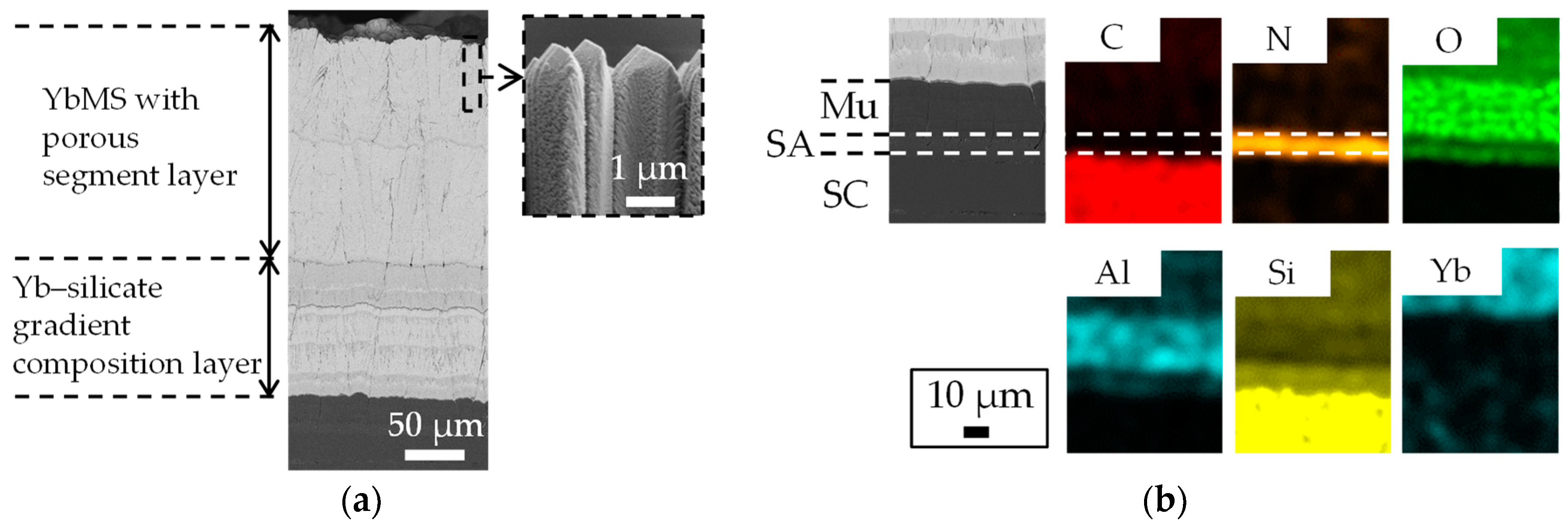

of the objective interface cracks for the T/EBC model with

hSA = 5 µm and

hMu = 20 µm. From this result, the SiAlON/mullite interface is found to possess the highest

of the objective interfaces.

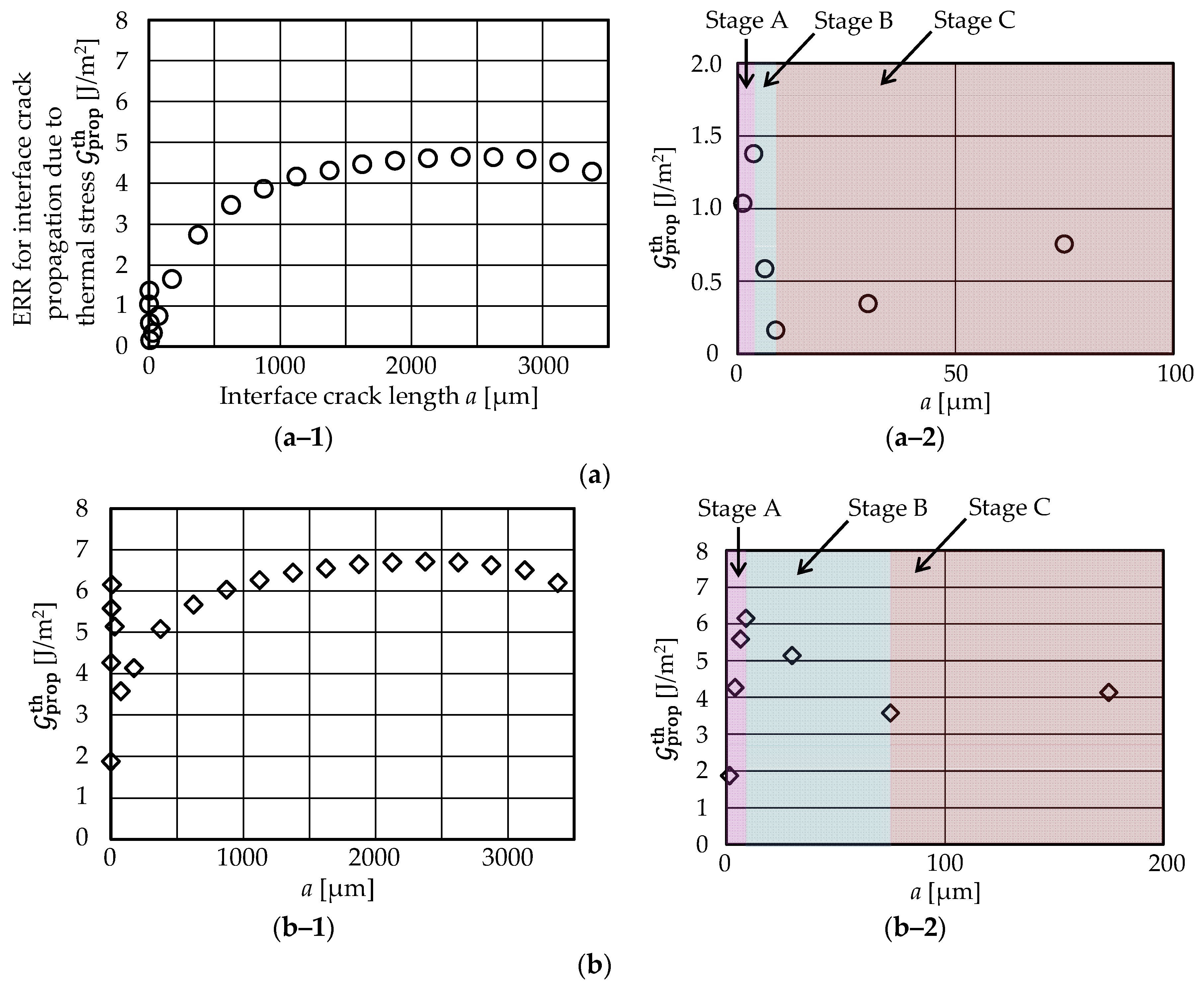

Figure 7 shows the relationships between

and

a at the objective interfaces in the T/EBC with

hSA = 5 µm and

hMu = 20 µm. In the

–

a relationships at all the objective interfaces, we observe three stages with increasing

a: (A)

shows a relatively rapid increase; (B)

decreases; (C)

increases again.

The reason for the decrease in

at Stage B is explained by the distribution of out-of-plane thermal stress in the vicinity of the interface edge.

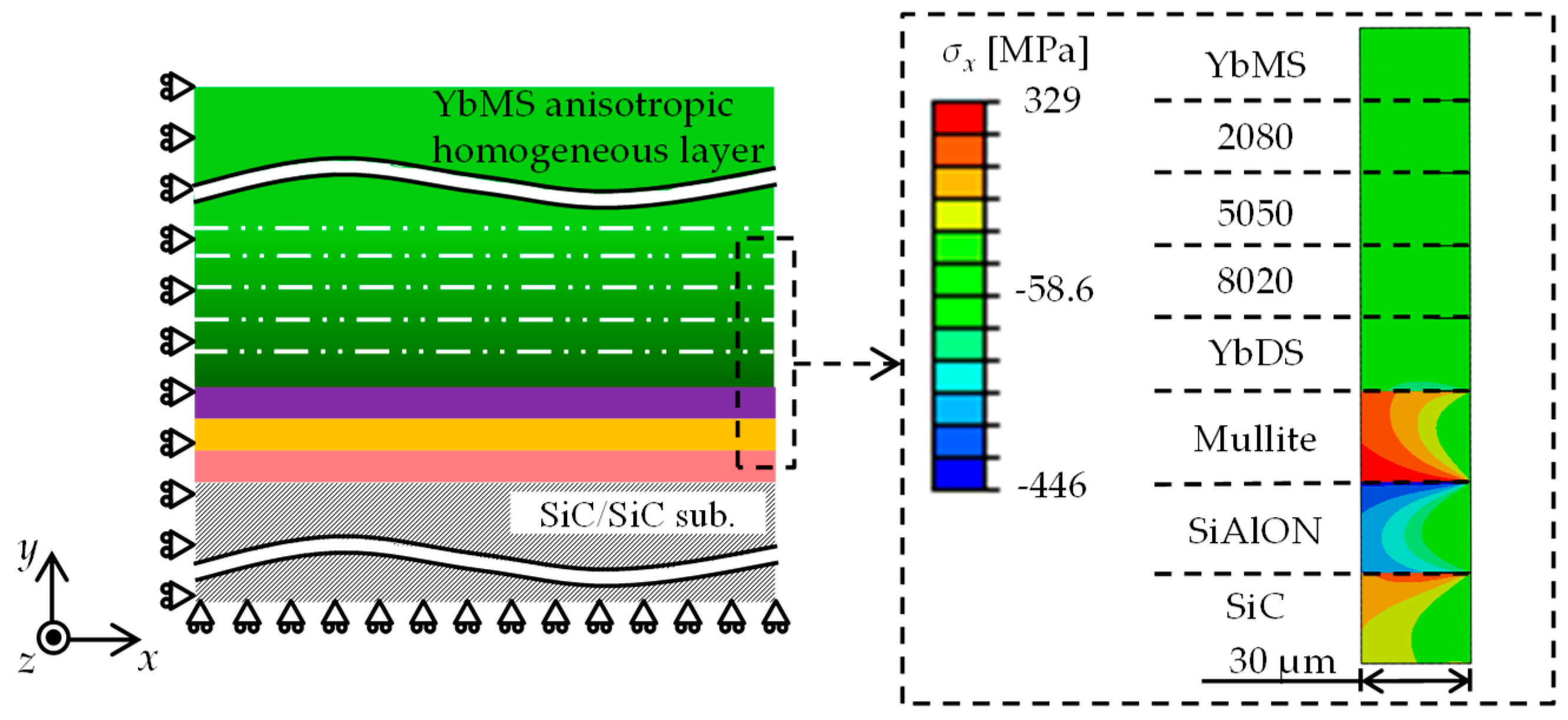

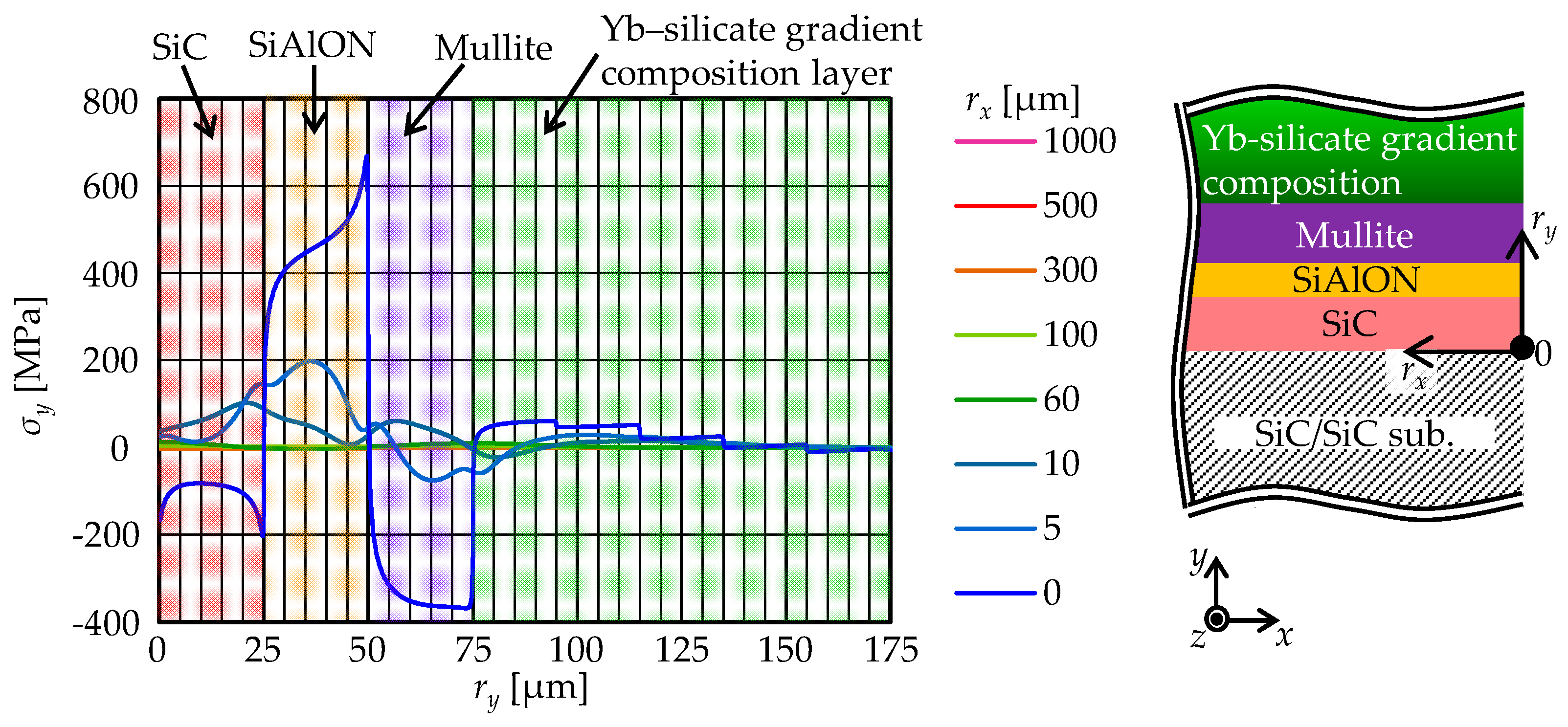

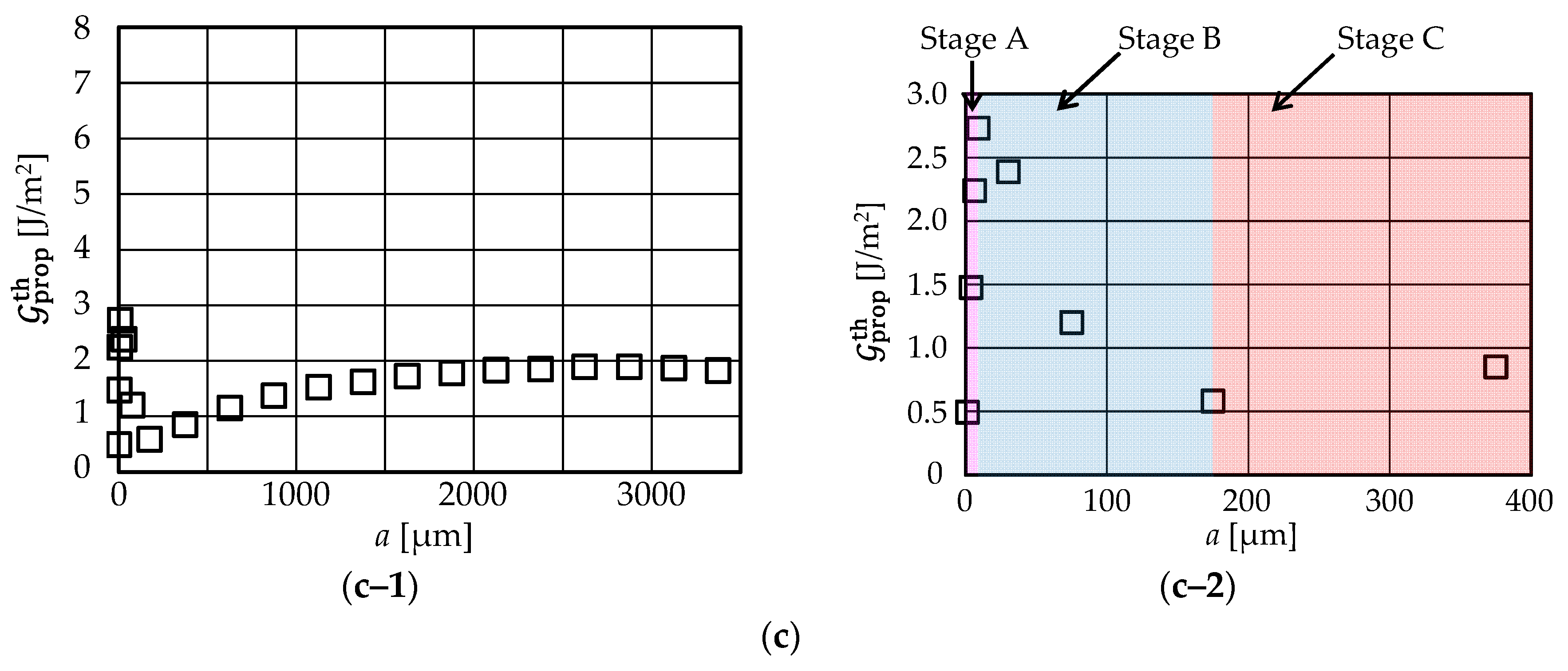

Figure 8a shows the

σy distributions in the coating layers along the

y axis, which are obtained at the positions

rx distant from the right interface edge in the

x direction (

rx = 0, 5, 10, 20, 30 and 40 μm). The highest level of

σy was observed at the interface edge (

rx = 0 μm), and the

σy distribution reduces immediately to a negligible level within

rx = 30 μm. Thus, the effect of

σy on the coating layers is significant but extremely localized in the vicinity of interface edge, while that is negligible inside the simulation model. Note that the effect of

σx on

is marginal for sufficiently small

a because we find

σx ~ 0 at the interface edge (

rx = 0 μm) directly from the balance of stress component in the

x direction.

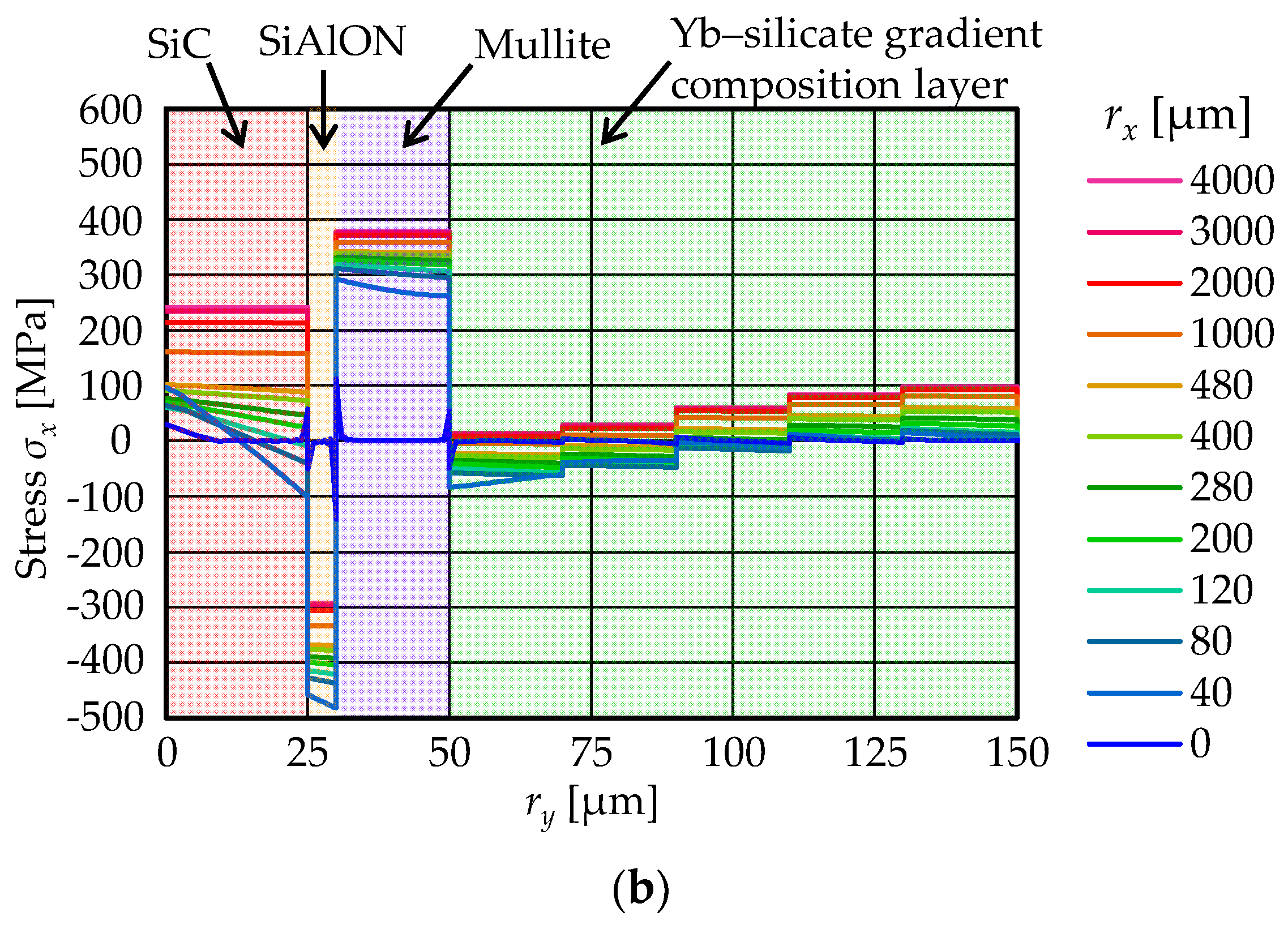

Figure 8b shows the

σx distributions in the coating layers along the

y axis at various

rx. These results indicate that

σy has a dominating effect on

for very short cracks. The mechanism of the second rise in

at Stage C is attributed to the increase in the level of

σx inside the simulation model as shown in

Figure 8b. Therefore, the three-stage behavior in the

–

a relationship is explained as follows: in the beginning,

rises as a crack propagates owing to the strong

σy near the interface edge (Stage A); then

decreases because of a steep drop in

σy inside the model (Stage B); for a sufficiently long crack,

is mainly affected by

σx and rises again with increasing

σx (Stage C).

4.2. Interface Fracture Toughness of T/EBC

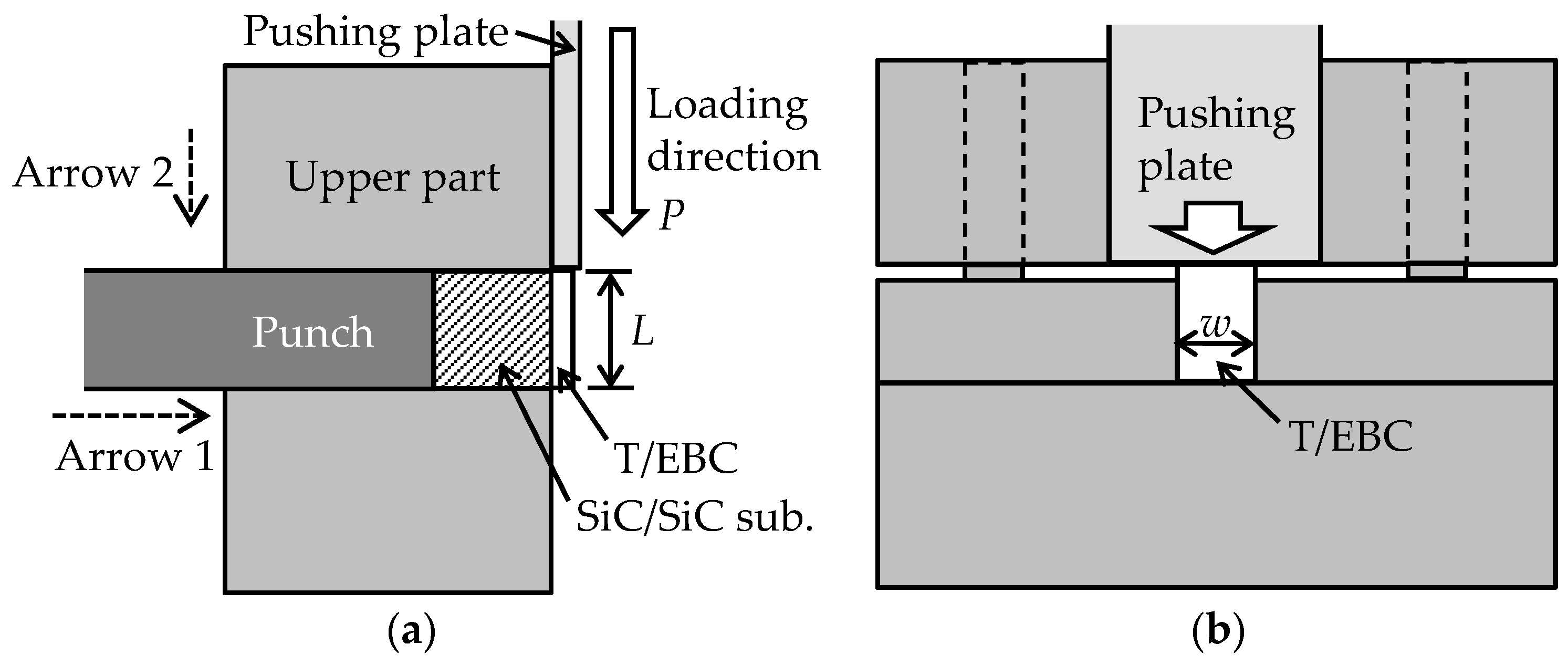

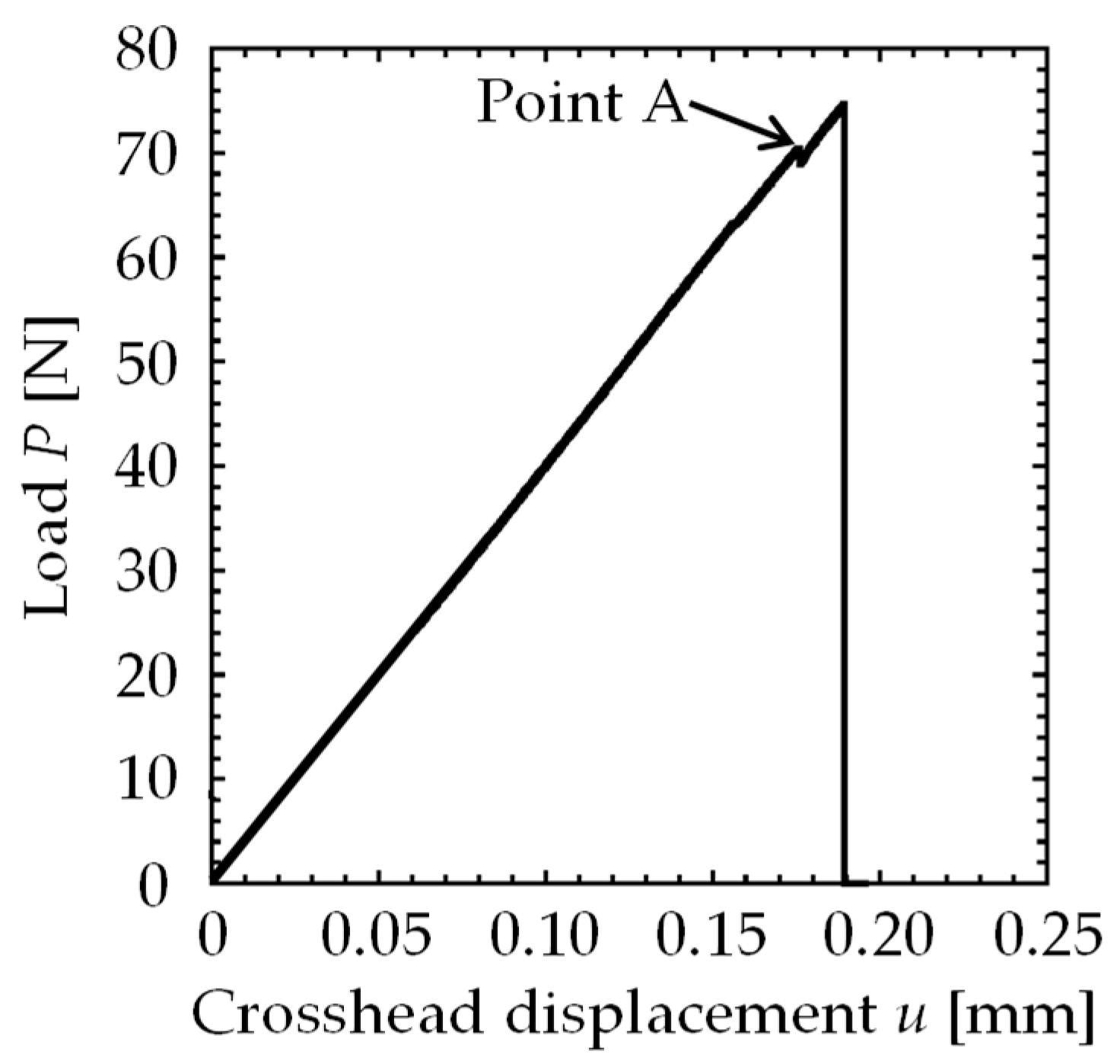

Figure 9 shows a typical

P–

u curve during the tests. By the cross-sectional optical microscopy, the onset of interface fracture near the loaded edge was identified at Point A in

P–

u curve before the maximum load. The load at Point A is defined as

. The crack then propagated down through the interface to the midway till the load reached the maximum; finally it grew unstably to the complete delamination at the maximum load. Buckling or compressive fracture of the coating was not observed during the test. The measured

values for respective tests are listed in

Table 11.

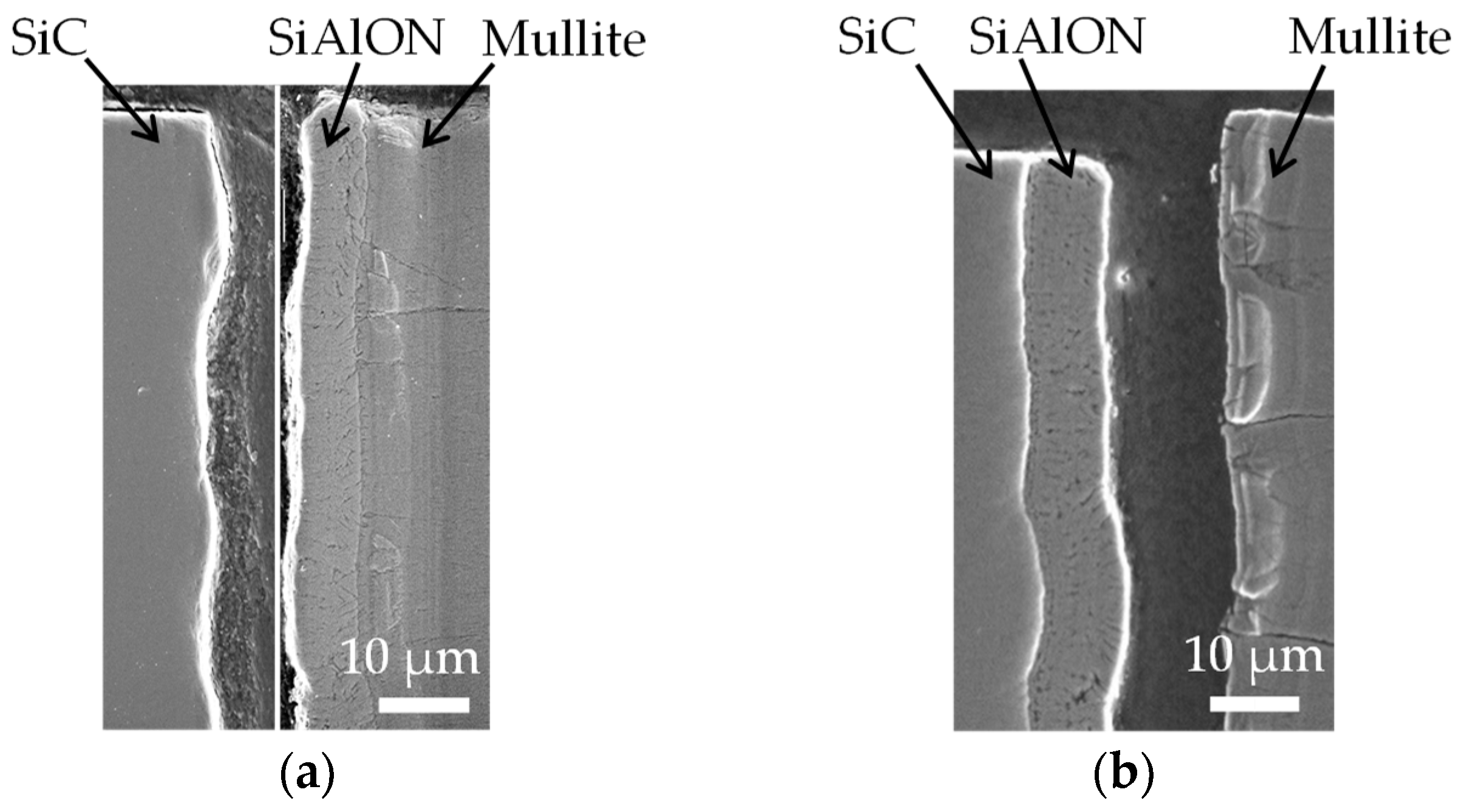

Examples of the cross-sectional SEM images of the specimens after the tests were shown in

Figure 10. At the loaded edge where the interface crack started to propagate, fracture occurred below or above the SiAlON layer, i.e., either at the interface between the SiC and SiAlON layers (

Figure 10a) or at the interface between the SiAlON and mullite layers (

Figure 10b). The crack path was along either of the two interfaces, and it was switched to each other by crack kinking across the SiAlON layer. However, crack propagation within a layer, such as a crack passing through the inside of layer parallel to the coating plane, was not observed.

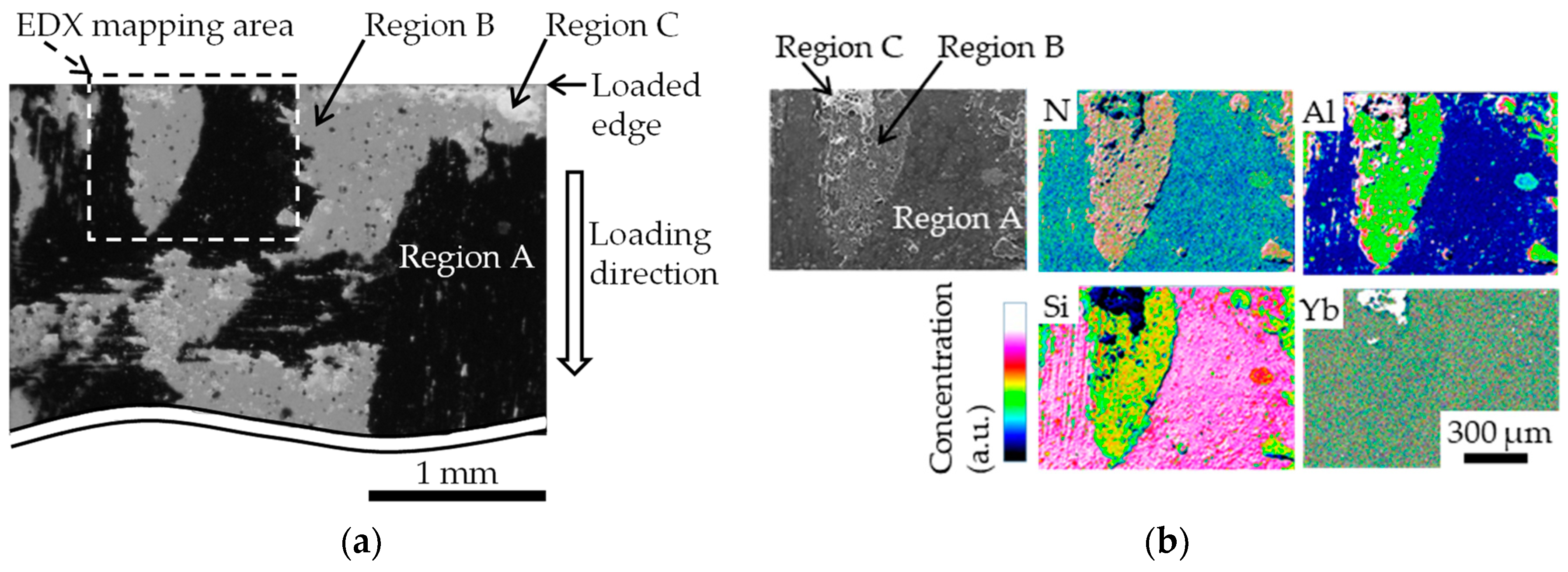

Figure 11a shows a fracture surface near the loaded edge after the tests observed by optical microscopy. The fracture surface was classified into three according to their colors: the largest black area denoted by Region A, the gray area by Region B, and the small white area by Region C as illustrated in

Figure 11a. EDX maps of a selected area in the fracture surface (indicated by a dashed rectangle in

Figure 11a) are shown in

Figure 11b. Mapping of element distributions shows the concentration of Si in Region A. In Region B the existence of Si, Al and N was detected. Region C was characterized by Yb concentration. Apparently Al also looks rich in Region C, but it is due to misdetection because the M

α line of Yb is very close to K

α line of Al which was used for the mapping of Al distribution. These results suggest that Region A with the largest area corresponds to the fracture surface created by the interface fracture between the SiC and SiAlON layers observed in

Figure 10a; Region B showing the second largest area corresponds to the surface created by the SiAlON/mullite interface fracture (

Figure 10b). We could not observe the fractured interface corresponding to Region C in the cross-sectional SEM observation of the T/EBC and substrate (

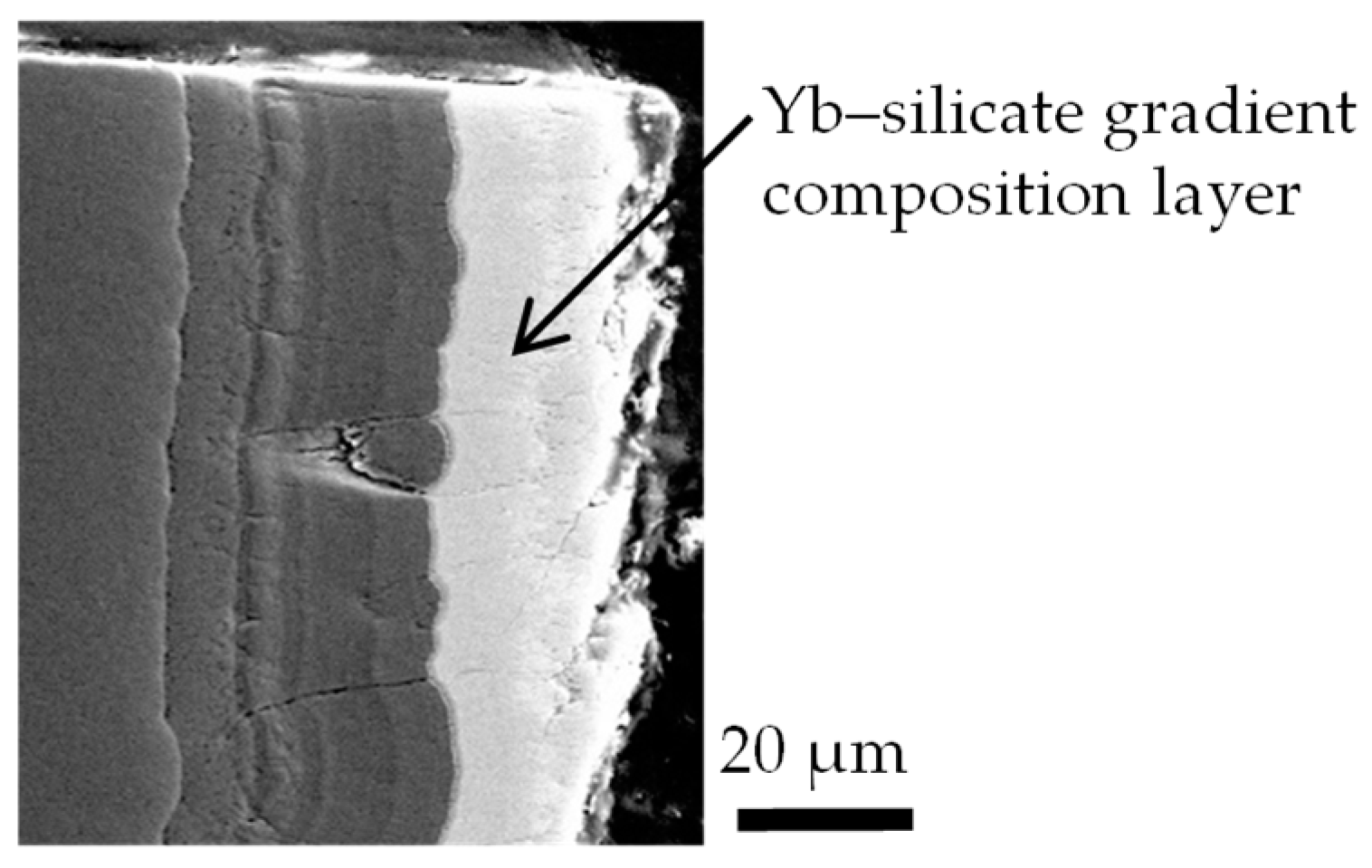

Figure 10) because of the limited area of Region C. To determine the exact location of the fracture surface in Region C, we cut after the tests one of the substrate in the cross-section including Region C. The result is shown in

Figure 12 suggesting that the fracture occurred in the Yb-silicate gradient composition layer.

To calculate the line fractions of Regions A, B and C along the loaded edge, the fracture surfaces near the edge were analyzed using image processing software (Image J 1.48v, National Institute of Health, Bethesda, MD, USA) (

Table 12). As shown in

Table 12, fracture surface was dominantly composed of Regions A and B; the ratio of Region C was relatively small. Thus the crack initiation at the edge was supposed to occur primarily either at the interface between the SiC and SiAlON layers or at the interface between the SiAlON and mullite layers.

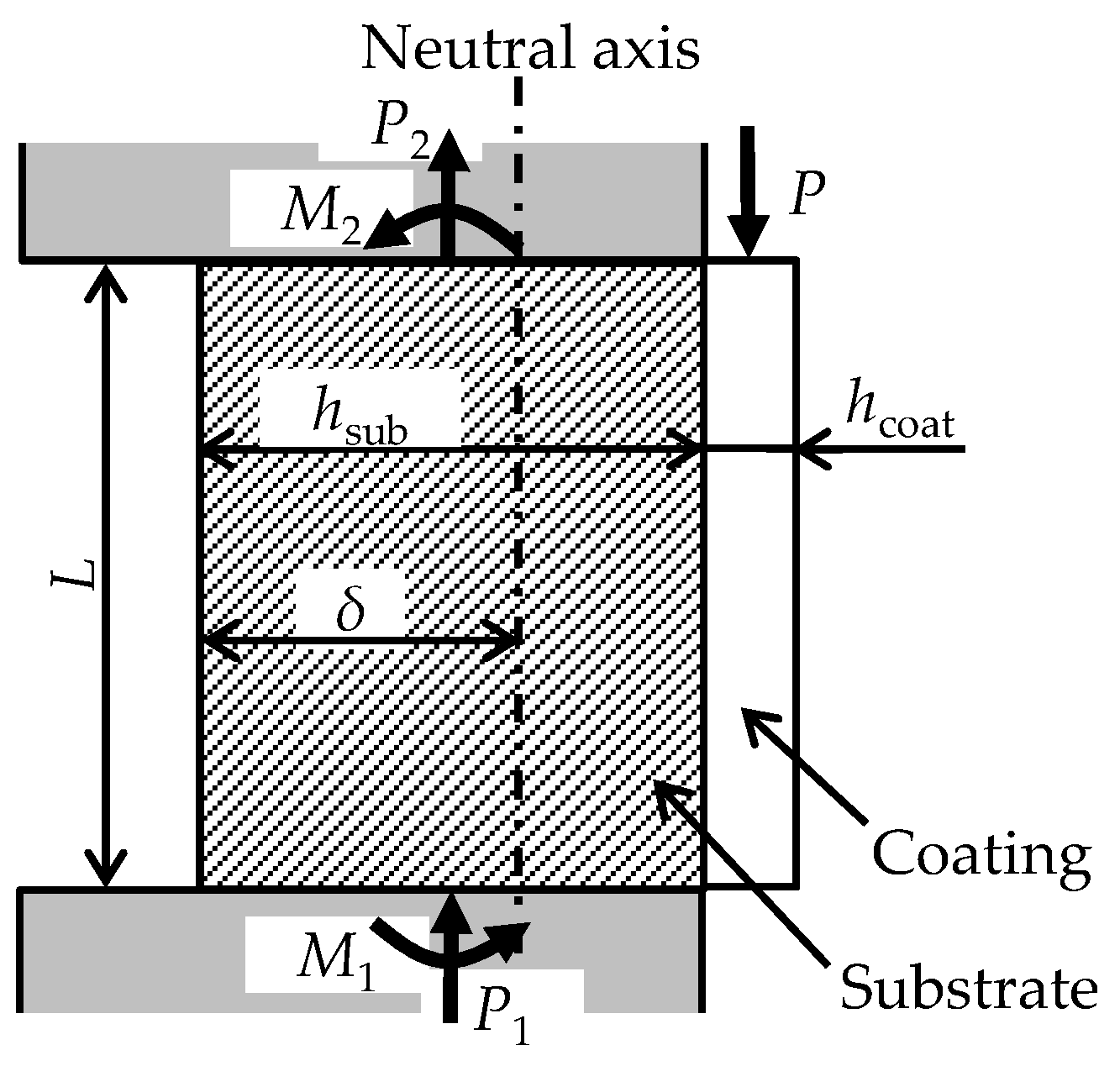

The energy release rate for the edge crack initiation along the SiC/SiAlON interface under

(in

Table 11) was calculated from Equations (A14)–(A18) and (4), regarding the SiC/SiC plate and the SiC layer as “substrate” and the rest of the layers as “coating” in Equation (A14); the mean value of 6.4 J/m

2 was obtained. When the SiAlON layer is counted as part of the substrate in addition to the SiC/SiC and SiC, the mean energy release rate for the crack along the SiAlON/mullite interface becomes 6.5 J/m

2. These values of energy release rates are very close to each other because the thickness of the SiAlON layer lying between the two interfaces is quite small compared to the total thickness of the system. Under the assumption that the edge crack was initiated simultaneously through the edge (i.e., in the direction of depth) at

regardless of the fractured interfaces, we can estimate that the SiC/SiAlON interface fracture and the SiAlON/mullite interface fracture both occur with significant proportions at almost the same energy release rates. This suggests that the interface toughness of these two interfaces are very close; both the interfaces should have an interface toughness of ~6.4 J/m

2. The mean energy release rate at

when the edge crack was initiated along the mullite/YbDS interface, which was supposed to have large thermal stress according to the FEM analysis, was calculated to be 6.8 J/m

2. Since no fracture occurred at this interface at

, we can expect that the toughness of the interface should be larger than 6.8 J/m

2. The abovementioned results indicate that the approximate

for the SiC/SiAlON and SiAlON/mullite interfaces are 6.4 J/m

2 and the lower limit of

for the mullite/YbDS interface is 6.8 J/m

2.

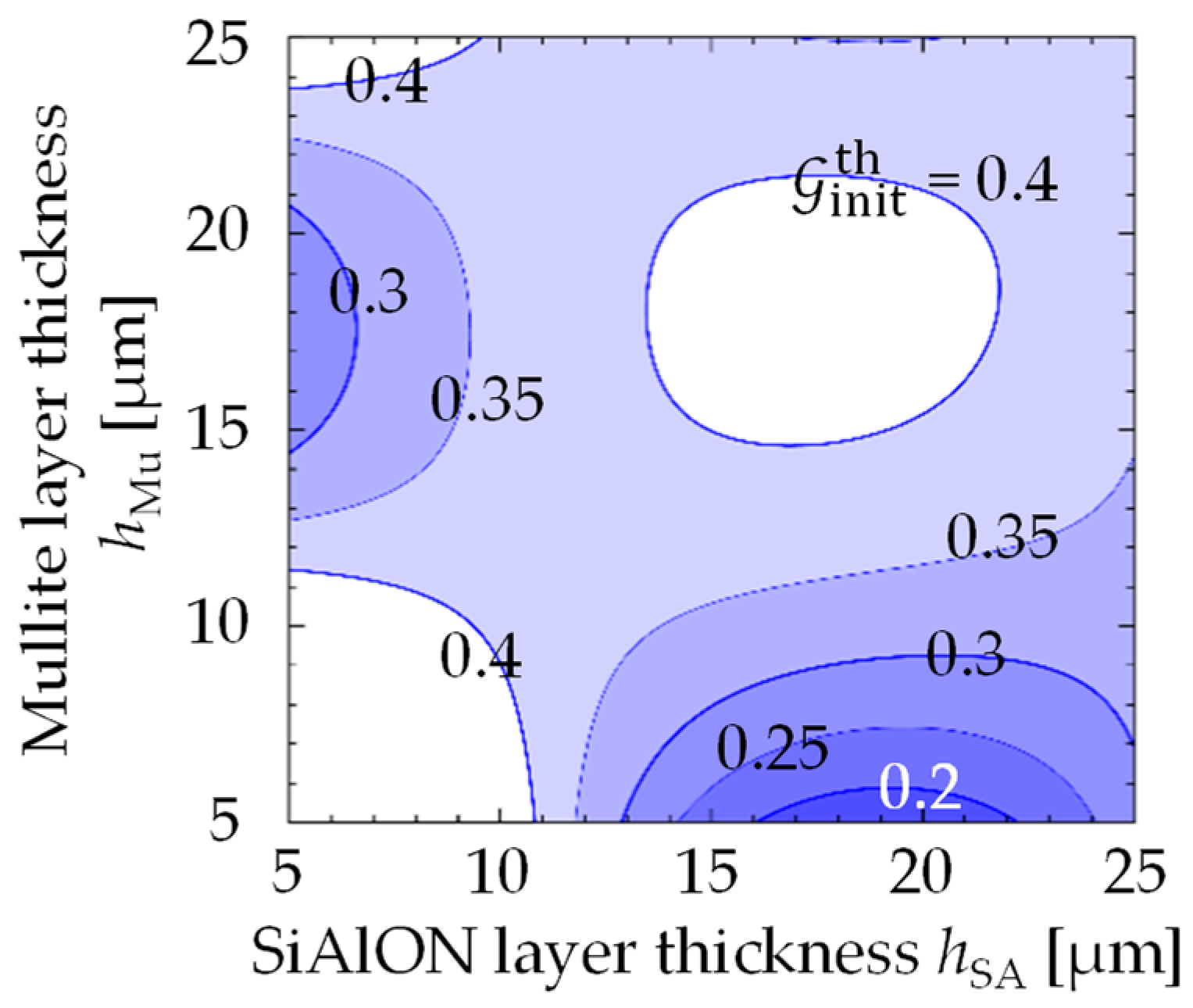

Table 13 shows comparison between

of the SiC/SiAlON, SiAlON/mullite and mullite/YbDS interface cracks and

of the corresponding interfaces.

s of every objective interface crack are smaller than

. This result suggests that the effect of thermal residual stress on the intrinsic fracture toughness for interface crack initiation is sufficiently small. Therefore, in this study, we regard the nominal value as the fracture toughness of interface crack initiation.

Table 13 also suggests that the SiC/SiAlON, SiAlON/mullite and mullite/YbDS interface cracks are not likely to initiate by cooling in the T/EBC fabrication process.

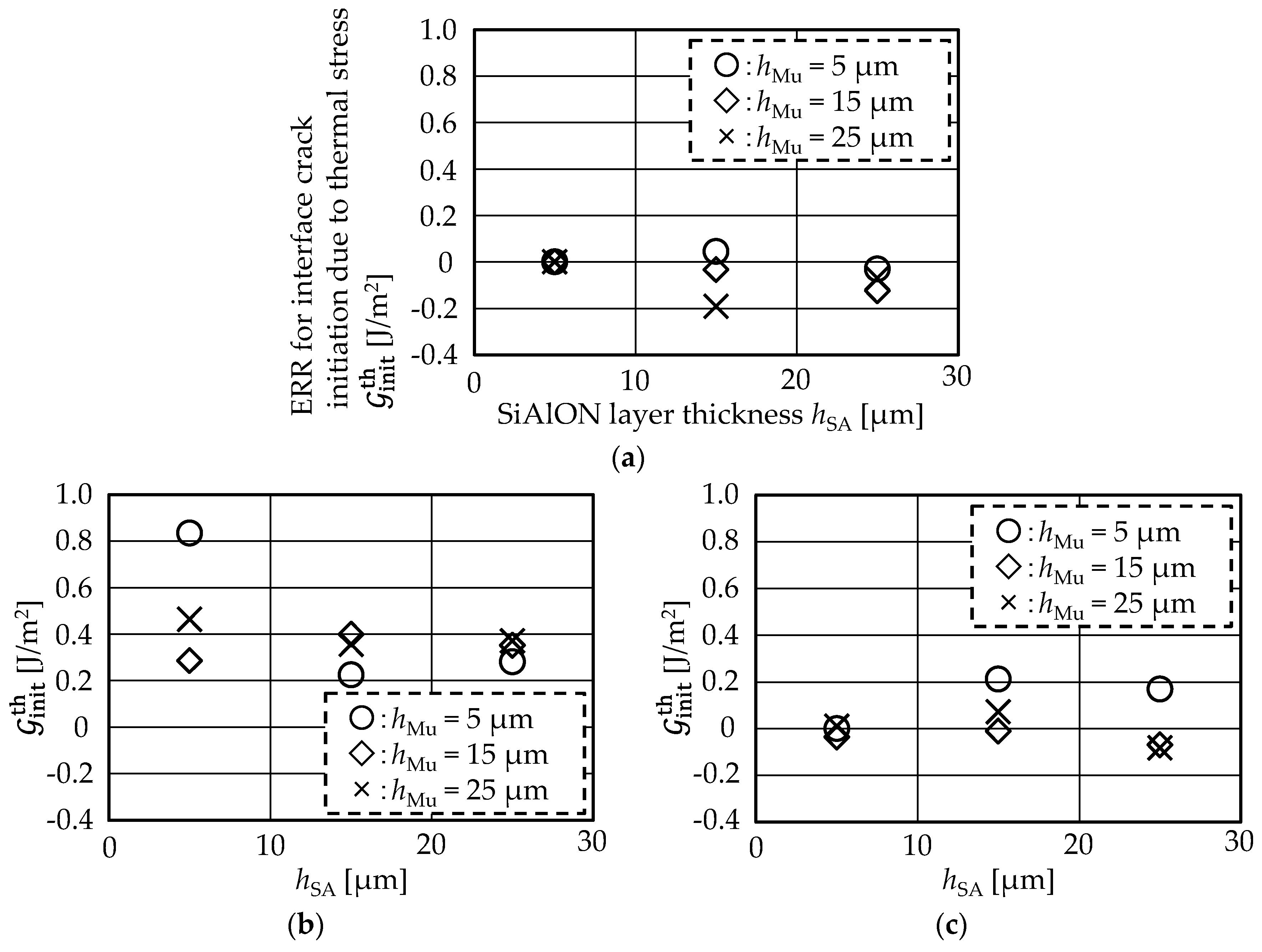

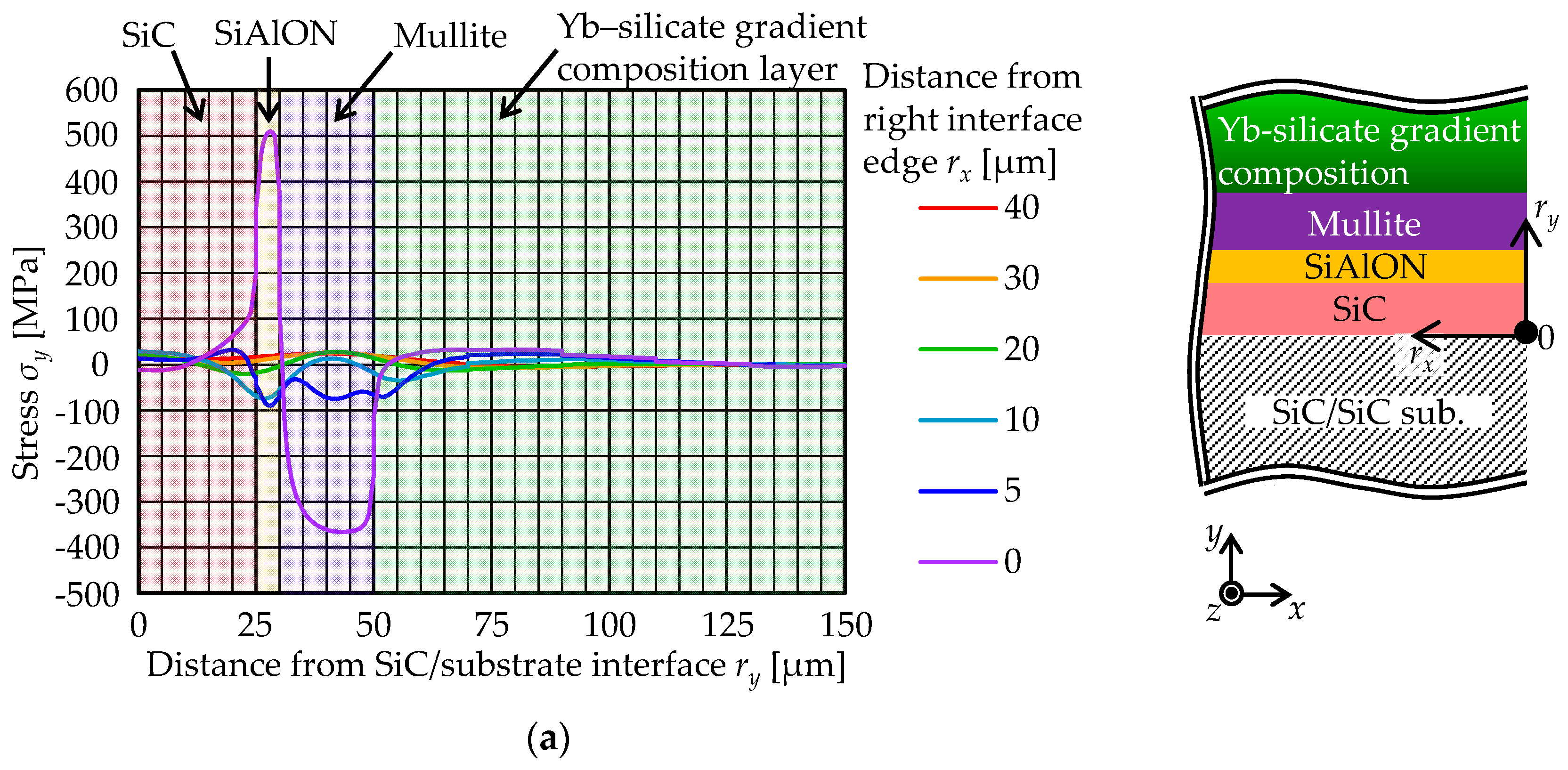

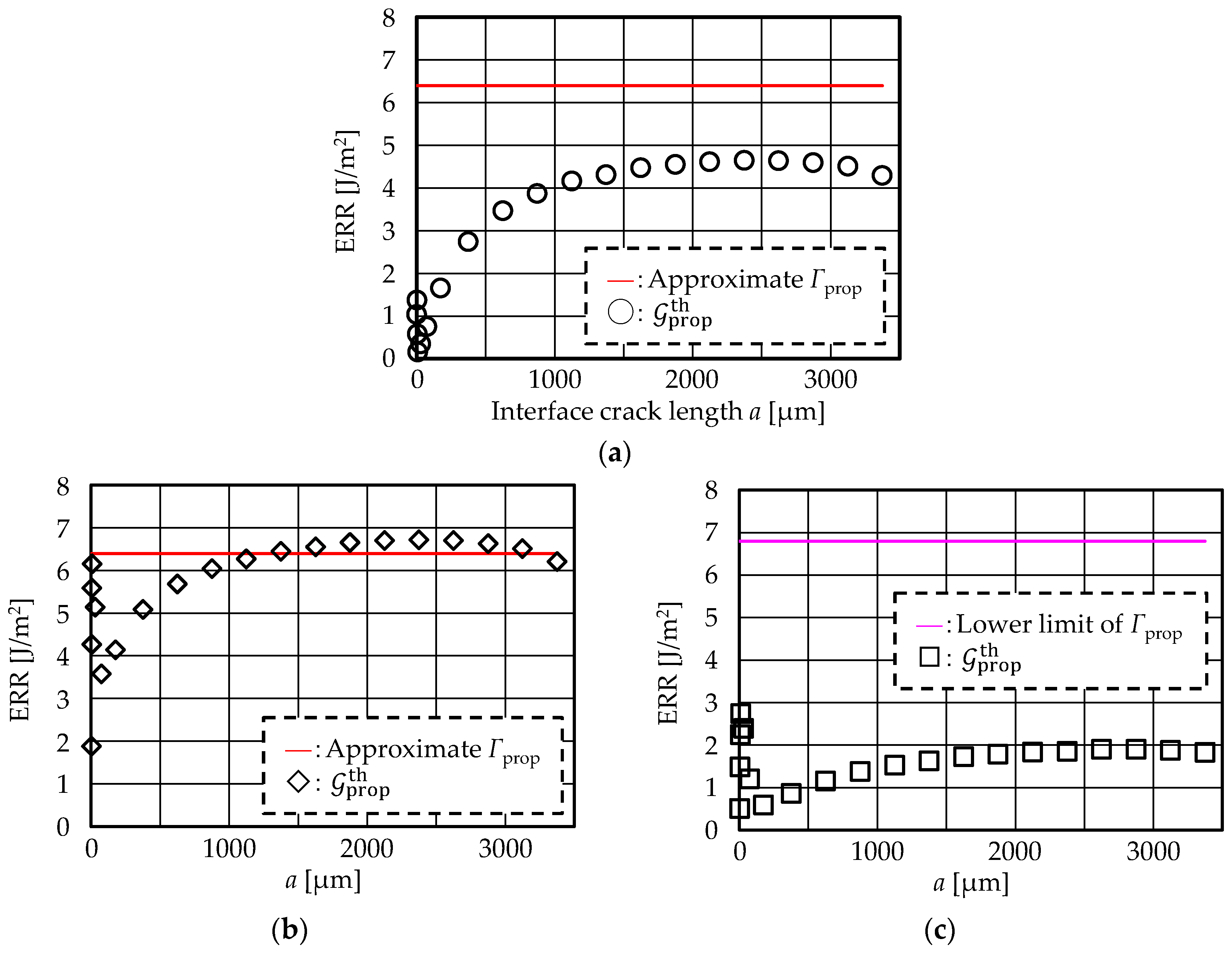

Figure 13a–c show comparisons between

and fracture toughness for interface crack propagation,

, at the SiC/SiAlON, SiAlON/mullite and mullite/YbDS interfaces. Here, we assumed that fracture surfaces formed by interface crack initiation and propagation were the same and regarded

as equal to

. As shown in

Figure 13a,c,

of the SiC/SiAlON and mullite/YbDS interface cracks are smaller than

of the corresponding interfaces. The results suggest that these interface cracks are not likely to propagate regardless of initial interface crack length.

Figure 13b suggests that, if the T/EBC has an initial length of the SiAlON/mullite interface crack of about 1200 μm, the crack should propagate instantly because

exceeds

at the crack length of 1200 µm. However, delamination along the SiAlON/mullite interface was not observed in the experiment (see

Section 3.2). These results suggest that there was no initial crack exceeding the length threshold at the SiAlON/mullite interface.

The results shown in this section reveal that the T/EBC with the proposed layer thicknesses can be fabricated without delamination along interfaces by cooling in the fabrication process. This is confirmed by the result that no delamination along interface is observed as described in

Section 3.2.