Microstructural and Corrosion Characteristics of Al-Fe Alloys Produced by High-Frequency Induction-Sintering Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of Pure Al and Al-Fe Alloys

2.2. Characterization Using X-ray Diffraction (XRD)

2.3. Microstructure Characterization of Sintered Alloys

2.4. Hardness Measurement

2.5. Electrochemical Cell

2.6. Electrochemical Experiments

3. Results and Discussion

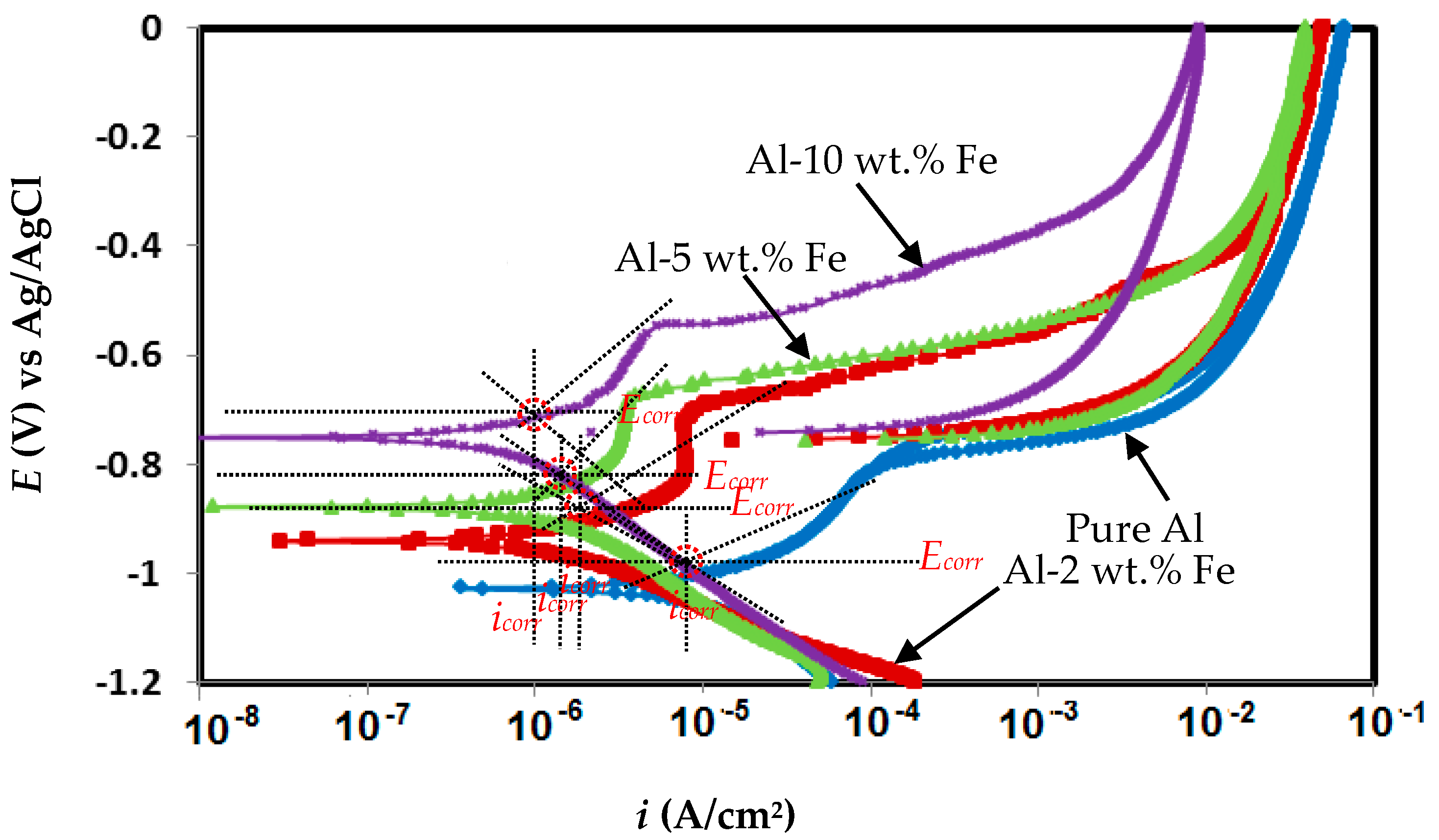

3.1. Electrochemical Measurements

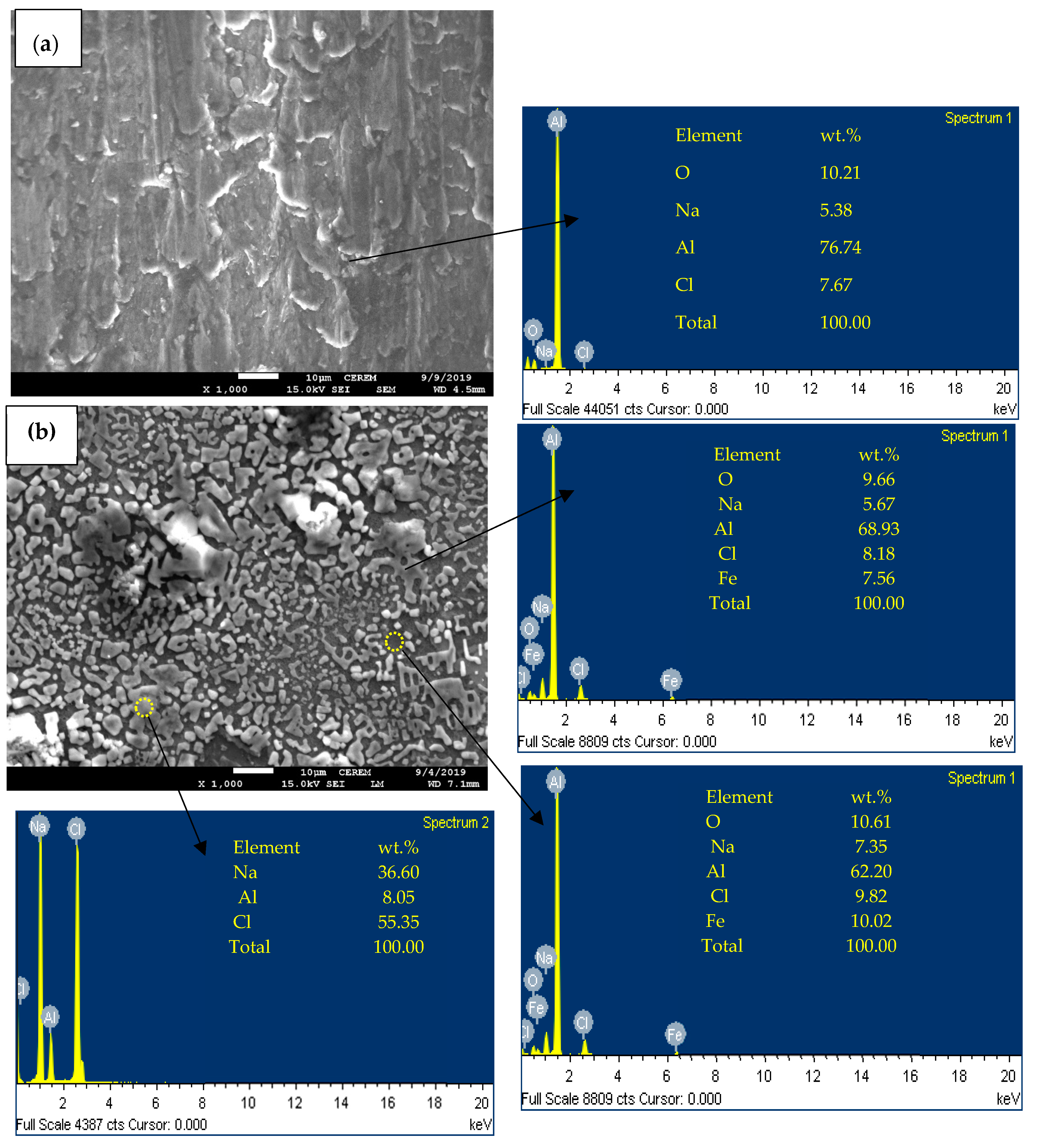

3.2. Characterization of Corroded Alloys

4. Conclusions

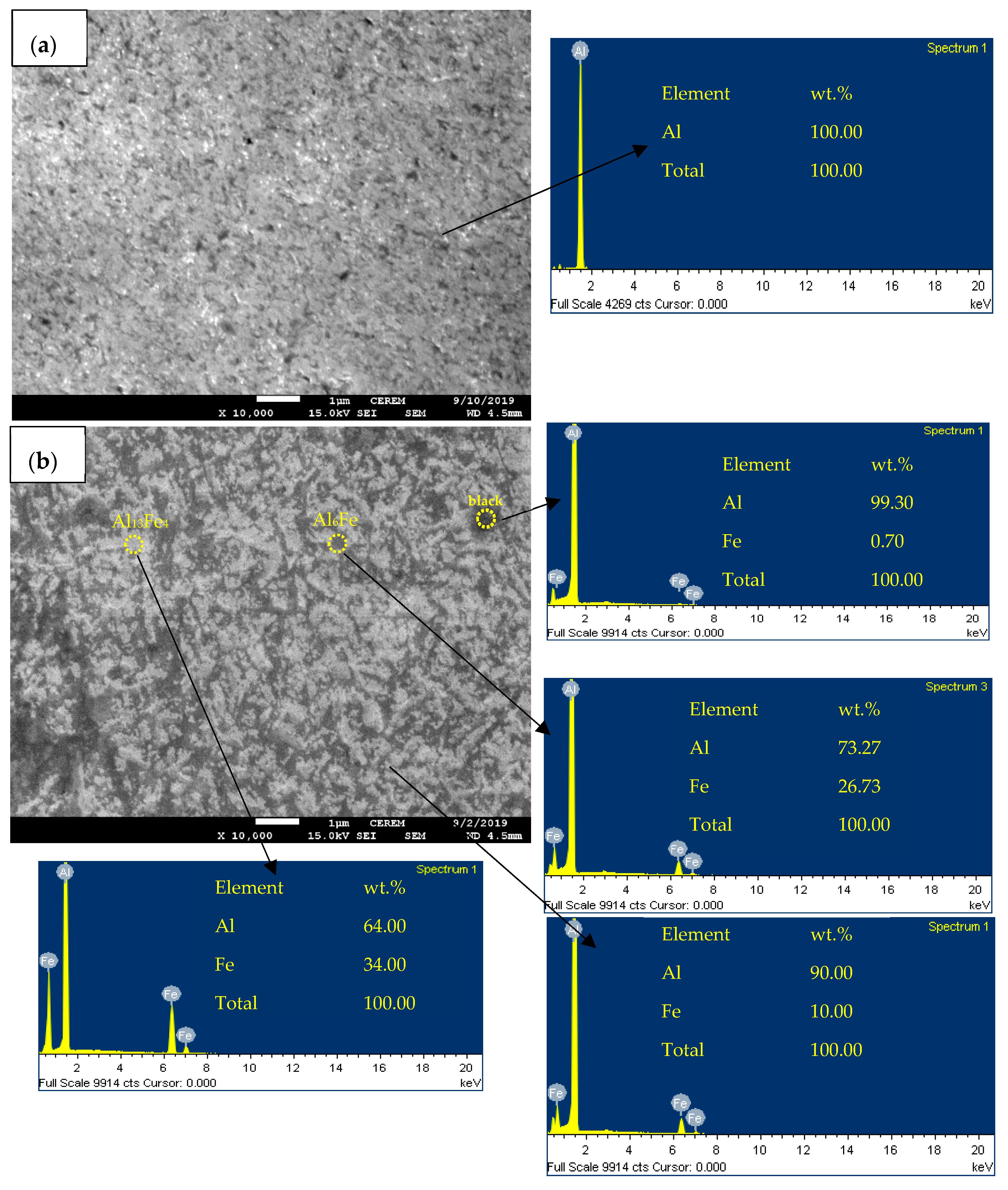

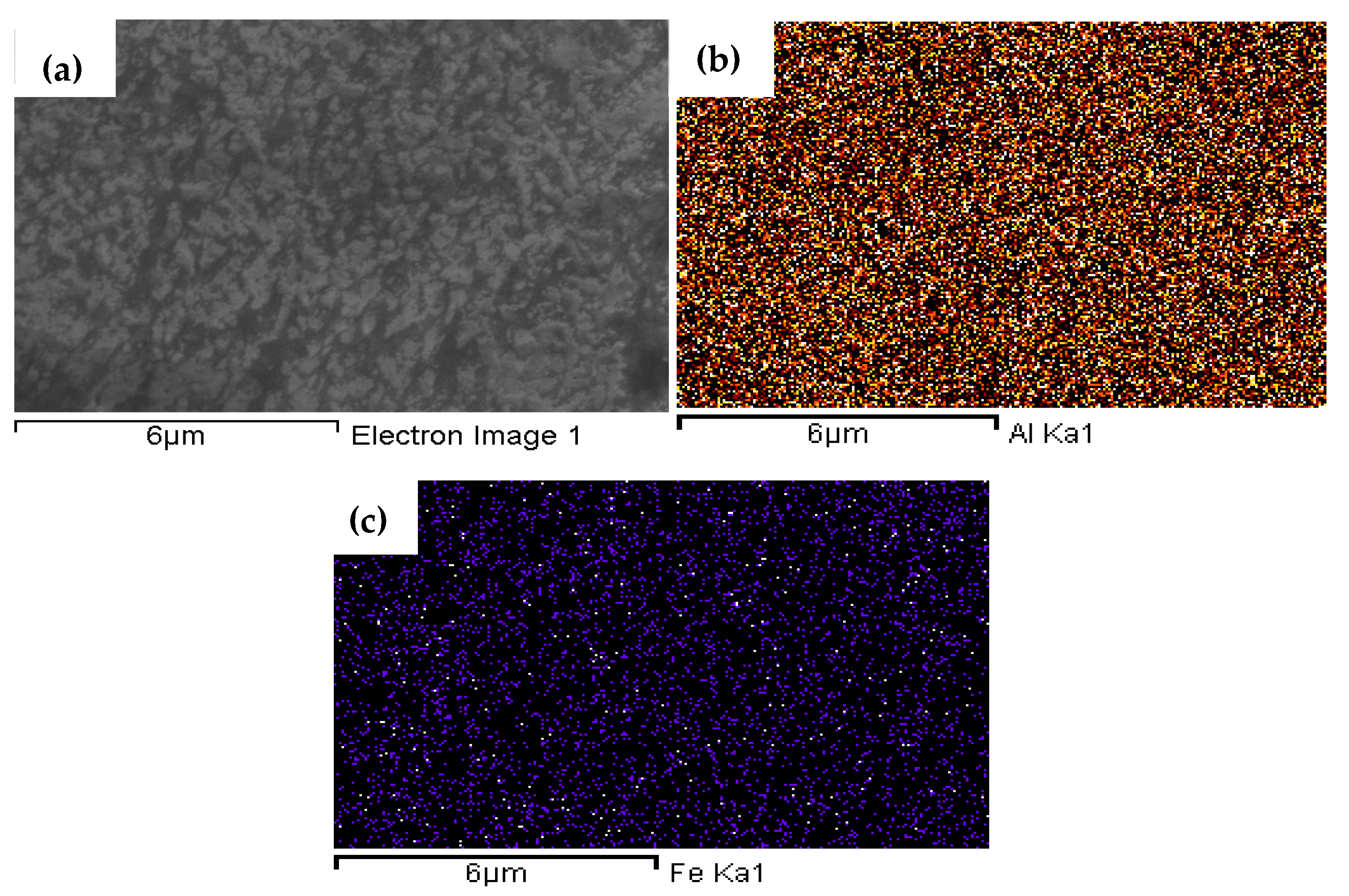

- Uniform distribution of Fe in an Al matrix was revealed by FESEM and EDS mapping, achieved by the combined process of MA and HFIS.

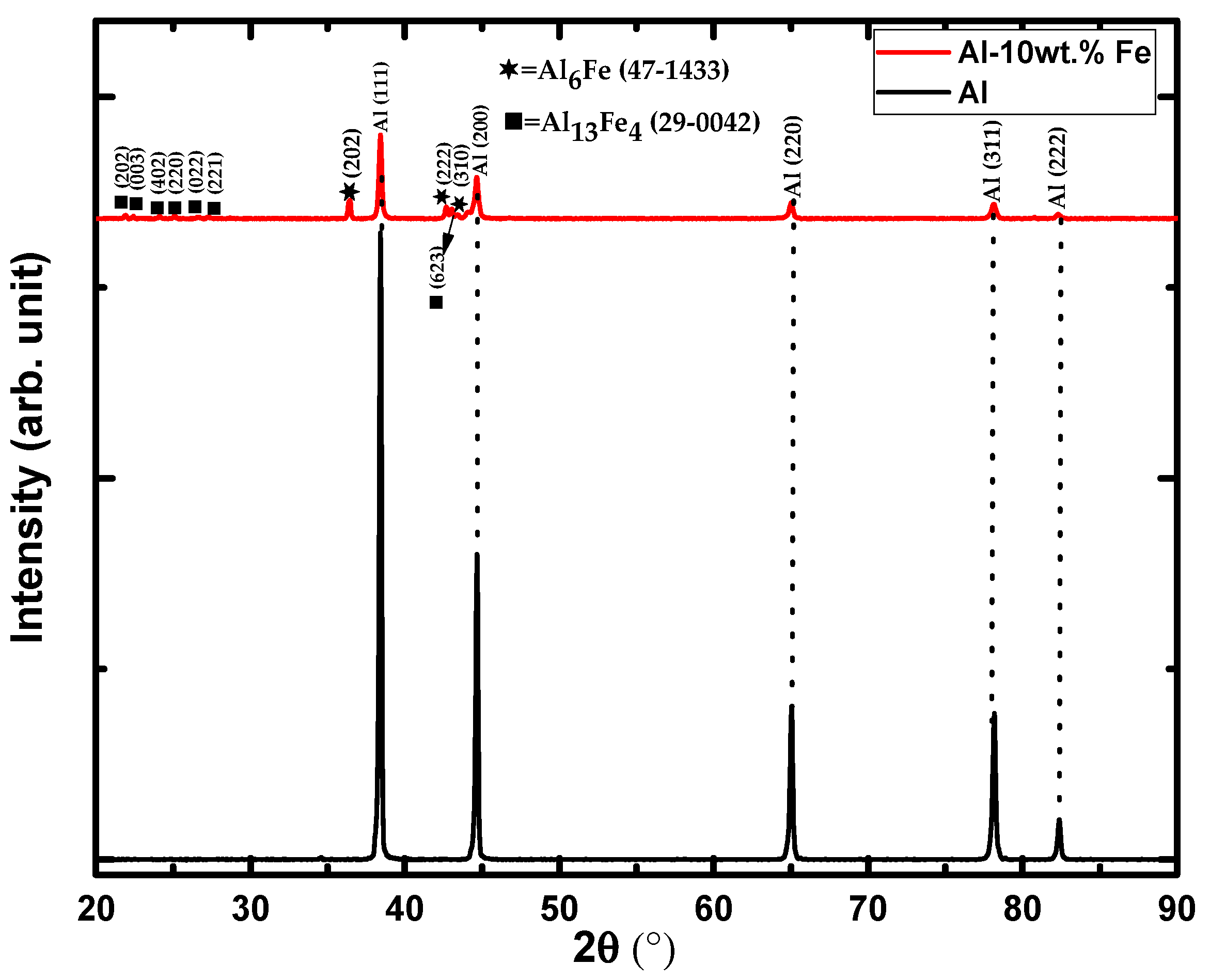

- XRD results confirmed that as the Fe amount was increased in the Al-Fe alloys, intermetallic-compound, i.e., Al6Fe and Al13Fe4, formation was increased.

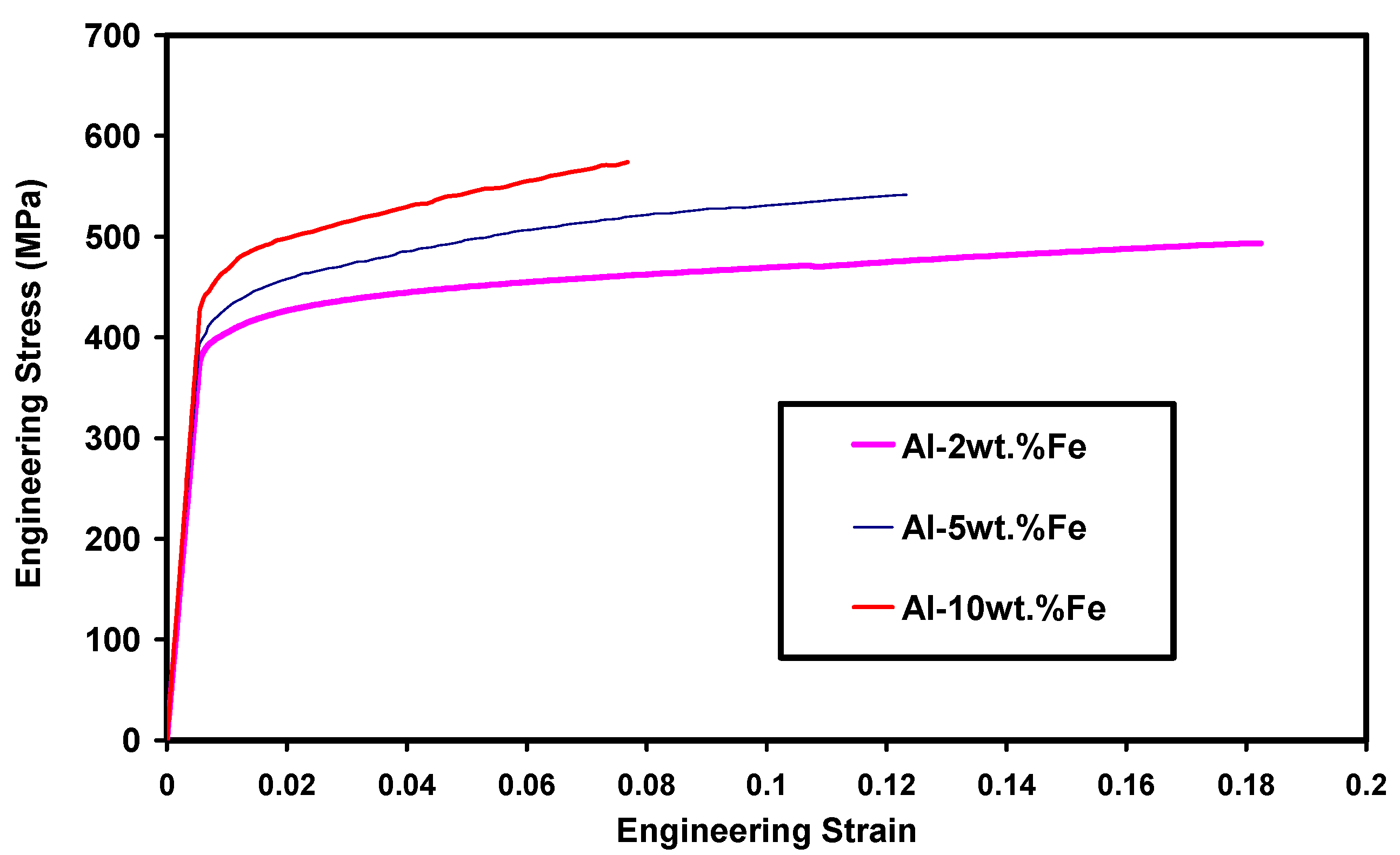

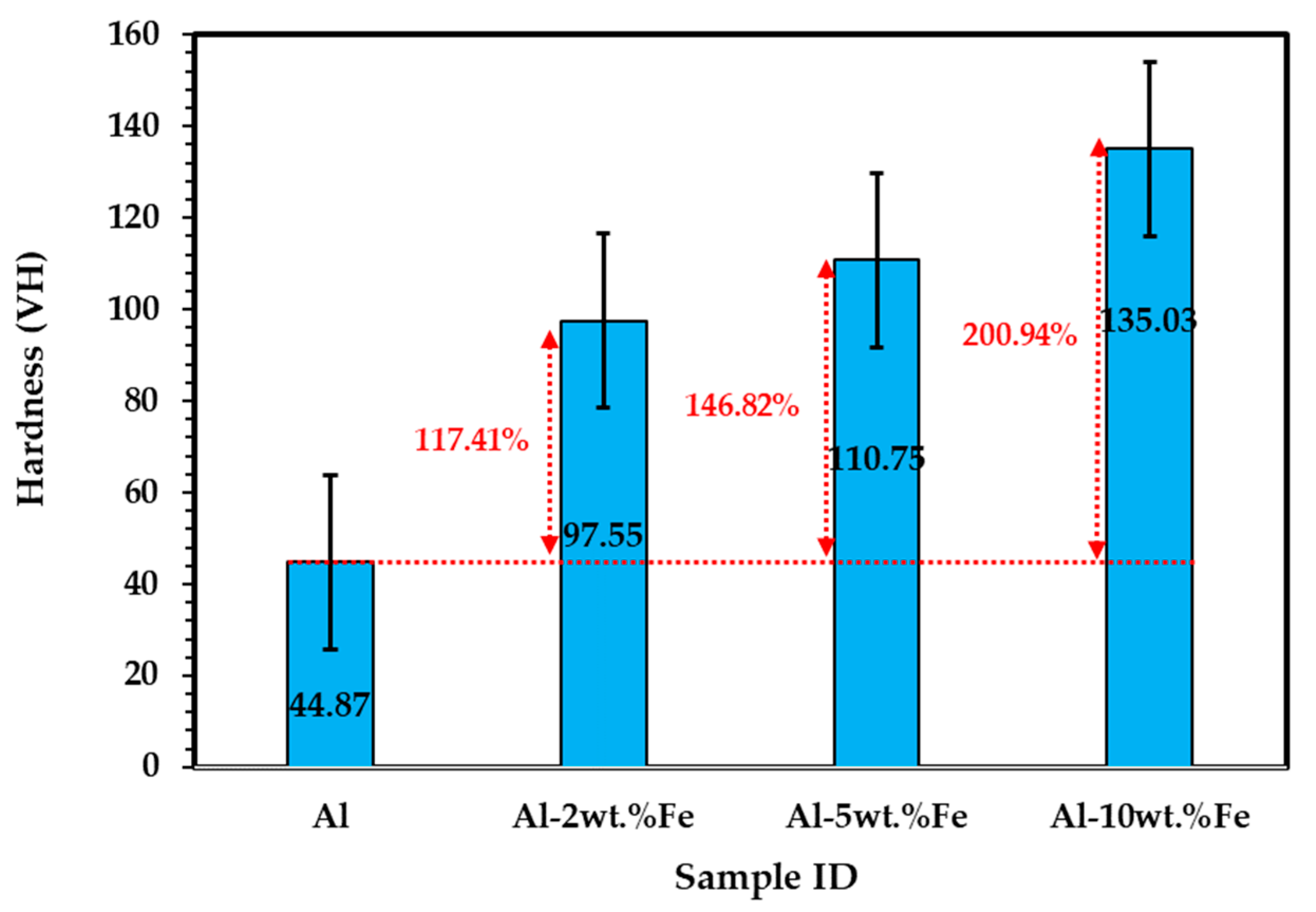

- The presence of intermetallic compounds enhanced the hardness of the Al-Fe alloys due to the influence of grain-size refinement, where the crystallite size was decreased after the addition of Fe in Al.

- Addition of Fe in the Al matrix facilitated the formation of a passive film in the NaCl solution as well as the dramatic decrease of the corrosion rate compared to pure Al.

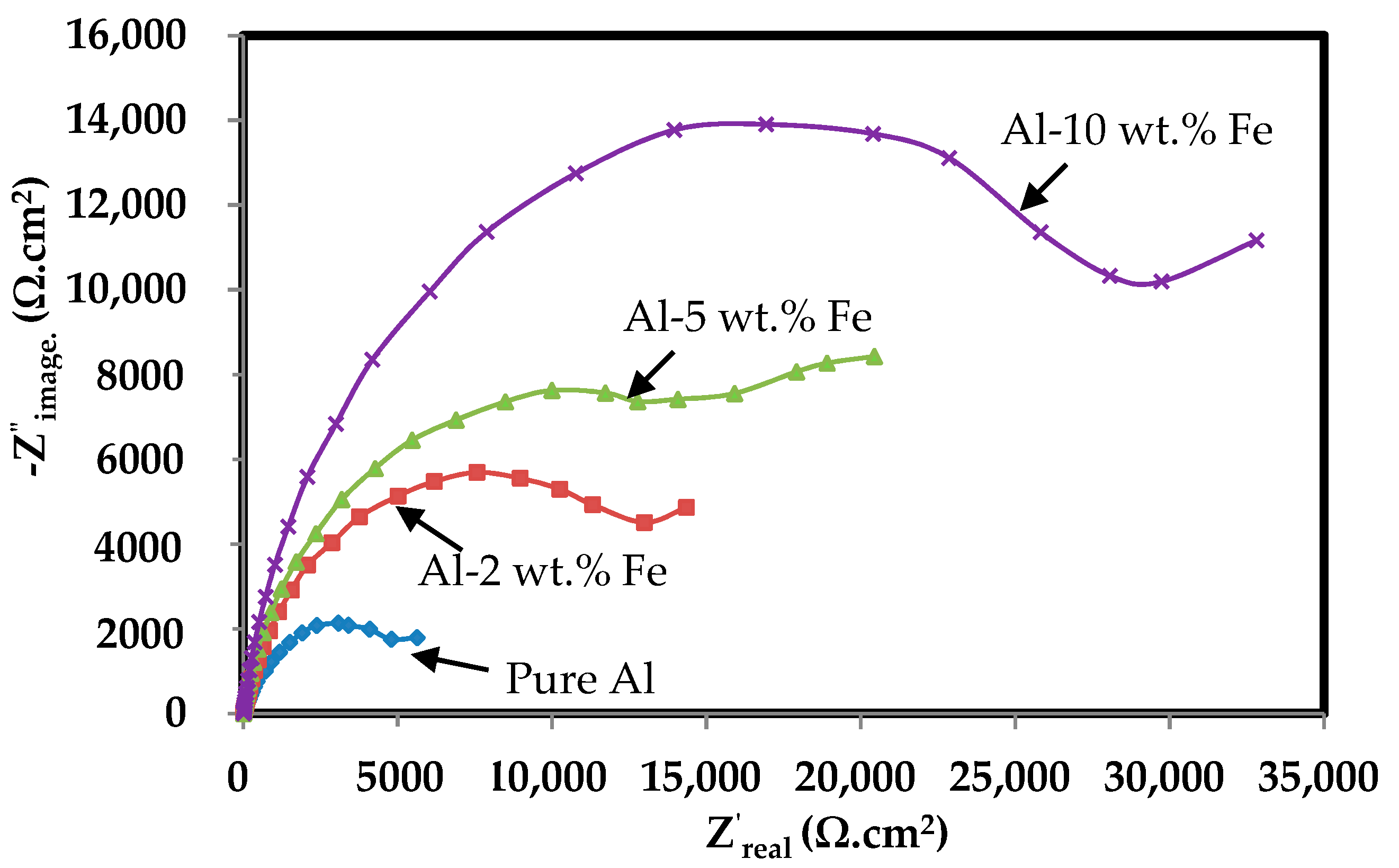

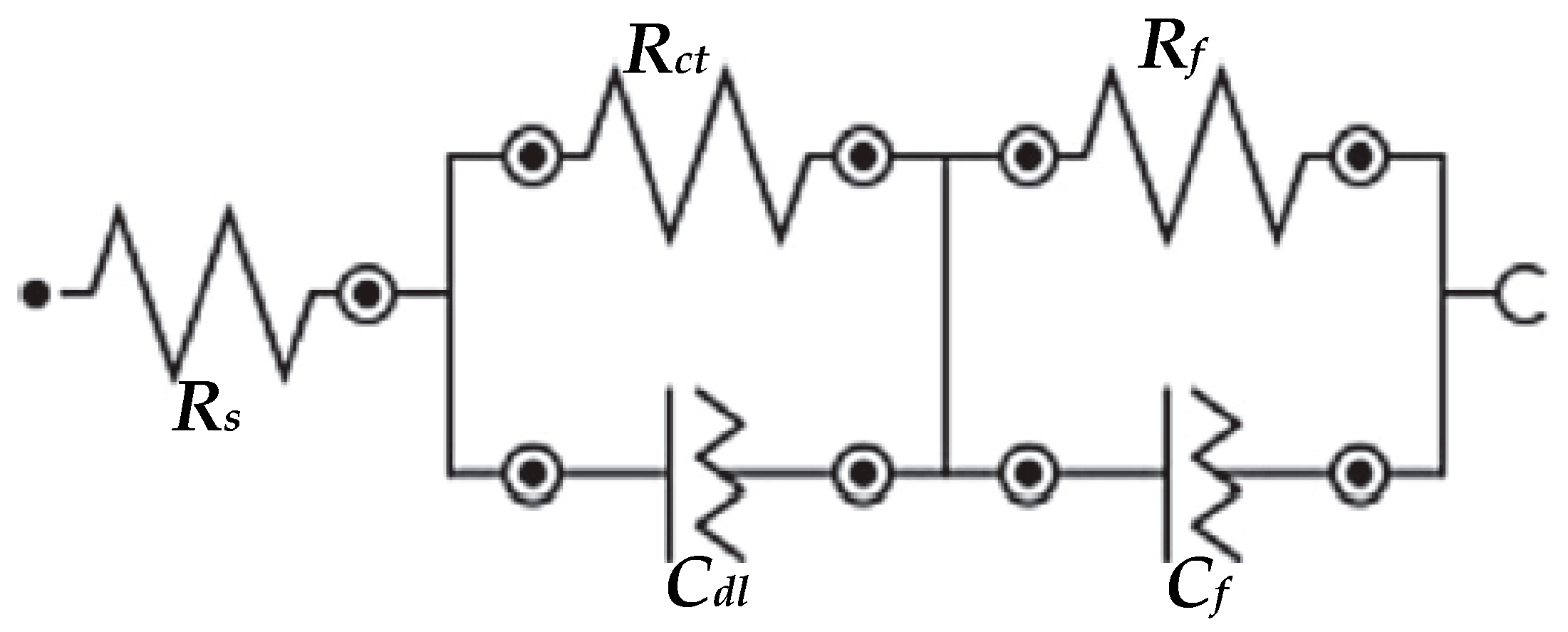

- EIS studies confirmed that the improved Rct and Rf in Al-Fe alloys compared to pure Al was due to the formation of a protective film on the alloy surface.

- SEM micrographs of the corrosion products formed on the Al-10 wt.% Fe alloys exhibited regular deposition, while pure Al showed pits, craters, and flakes due to the localized attack of chloride ions on the surface.

- XRD results of the corrosion products confirmed the formation of γ-Fe2O3 and α-Al(OH)3 on the Al-10 wt.% Fe alloys, which are protective, adherent, and stable in nature, whereas pure Al corrosion products showed an absence of γ-Fe2O3.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Froes, F.H.; Pickens, J.R. Powder metallurgy of light metal alloys for demanding applications. JOM J. Miner. Met. Mater. Soc. 1984, 36, 14–28. [Google Scholar] [CrossRef]

- Pickens, J.R. Aluminium powder metallurgy technology for high-strength applications. J. Mater. Sci. 1981, 16, 1437–1457. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Lyle, J.P.; Cebulak, W.S. Powder metallurgy approach for control of microstructure and properties in high strength aluminum alloys. Metall. Trans. A 1975, 6, 685. [Google Scholar] [CrossRef]

- Prabhu, B.; Suryanarayana, C.; An, L.; Vaidyanathan, R. Synthesis and characterization of high volume fraction Al-Al2O3 nanocomposite powders by high-energy milling. Mater. Sci. Eng. A 2006, 425, 192–200. [Google Scholar] [CrossRef]

- Lu, L.; Zhang, Y.F. Influence of process control agent on interdiffusion between Al and Mg during mechanical alloying. J. Alloy. Compd. 1999, 290, 279–283. [Google Scholar] [CrossRef]

- Miracle, D.B. Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Torralba, J.M.; Da Costa, C.E.; Velasco, F. P/M aluminum matrix composites: An overview. Proc. J. Mater. Process. Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Mukai, T.; Hono, K. A high-strength bulk nanocrystalline Al-Fe alloy processed by mechanical alloying and spark plasma sintering. Scr. Mater. 2007, 57, 189–192. [Google Scholar] [CrossRef]

- Osório, W.R.; Freire, C.M.; Garcia, A. The effect of the dendritic microstructure on the corrosion resistance of Zn-Al alloys. J. Alloy. Compd. 2005, 397, 179–191. [Google Scholar] [CrossRef]

- Ralston, K.D.; Fabijanic, D.; Birbilis, N. Effect of grain size on corrosion of high purity aluminium. Electrochim. Acta 2011, 56, 1729–1736. [Google Scholar] [CrossRef]

- Osório, W.R.; Spinelli, J.E.; Ferreira, I.L.; Garcia, A. The roles of macrosegregation and of dendritic array spacings on the electrochemical behavior of an Al-4.5 wt.% Cu alloy. Electrochim. Acta 2007, 52, 3265–3273. [Google Scholar] [CrossRef]

- Song, D.; Ma, A.; Jiang, J.; Lin, P.; Yang, D.; Fan, J. Corrosion behavior of equal-channel-angular-pressed pure magnesium in NaCl aqueous solution. Corros. Sci. 2010, 52, 481–490. [Google Scholar] [CrossRef]

- Birbilis, N.; Ralston, K.D.; Virtanen, S.; Fraser, H.L.; Davies, C.H. Grain character influences on corrosion of ECAPed pure magnesium. Corros. Eng. Sci. Technol. 2010, 45, 224–230. [Google Scholar] [CrossRef]

- Osório, W.R.; Spinelli, J.E.; Afonso, C.R.M.; Peixoto, L.C.; Garcia, A. Microstructure, corrosion behaviour and microhardness of a directionally solidified Sn-Cu solder alloy. Electrochim. Acta 2011, 56, 8891–8899. [Google Scholar] [CrossRef]

- Son, I.J.; Nakano, H.; Oue, S.; Kobayashi, S.; Fukushima, H.; Horita, Z. Pitting corrosion resistance of ultrafine-grained aluminum processed by severe plastic deformation. Nippon Kinzoku Gakkaishi/J. Jpn. Inst. Met. 2006, 47, 1163–1169. [Google Scholar] [CrossRef]

- Kubaski, E.T.; Cintho, O.M.; Capocchi, J.D.T. Effect of milling variables on the synthesis of NiAl intermetallic compound by mechanical alloying. Powder Technol. 2011, 214, 77–82. [Google Scholar] [CrossRef]

- Mishra, R.; Balasubramaniam, R. Effect of nanocrystalline grain size on the electrochemical and corrosion behavior of nickel. Corros. Sci. 2004, 46, 3019–3029. [Google Scholar] [CrossRef]

- Luo, W.; Xu, Y.; Wang, Q.; Shi, P.; Yan, M. Effect of grain size on corrosion of nanocrystalline copper in NaOH solution. Corros. Sci. 2010, 52, 3509–3513. [Google Scholar] [CrossRef]

- Kim, S.H.; Aust, K.T.; Erb, U.; Gonzalez, F.; Palumbo, G. A comparison of the corrosion behaviour of polycrystalline and nanocrystalline cobalt. Scr. Mater. 2003, 48, 1379–1384. [Google Scholar] [CrossRef]

- Shingu, P.H.; Huang, B.; Nishitani, S.R.; Nasu, S. Nano-meter order crystalline structure of Al-Fe alloys produced by mechanical alloying. Suppl. Trans. JIM 1988, 29, 3–10. [Google Scholar]

- Dong, Y.D.; Wang, W.H.; Liu, L.; Xiao, K.Q.; Tong, S.H.; He, Y.Z. Structural investigation of a mechanically alloyed A1-Fe system. Mater. Sci. Eng. A 1991, 134, 867–871. [Google Scholar] [CrossRef]

- Niu, X.P.; Froyen, L.; Delaey, L.; Peytour, C. Effect of Fe content on the mechanical alloying and mechanical properties of AI-Fe alloys. J. Mater. Sci. 1994, 29, 3724–3732. [Google Scholar] [CrossRef]

- Nayak, S.S.; Murty, B.S.; Pabi, S.K. Structure of nanocomposites of Al-Fe alloys prepared by mechanical alloying and rapid solidification processing. Bull. Mater. Sci. 2008, 31, 449–454. [Google Scholar] [CrossRef]

- Braun, R. Stress corrosion cracking behaviour of Al-Li alloy 8090-T8171 plate exposed to various synthetic environments. Mater. Corros. 2004, 55, 241–248. [Google Scholar] [CrossRef]

- González-Rodríguez, J.G.; Salazar, M.; Luna-Ramírez; Porcayo-Calderon, J.; Rosas, G.; Villfane, A.M. Effect of Li, Ce and Ni on the corrosion resistance of Fe3Al in molten Na2SO4 and NaVO3. High Temp. Mater. Process. 2004, 23, 177–183. [Google Scholar]

- Cai, C.; Zhang, Z.; Cao, F.; Gao, Z.; Zhang, J.; Cao, C. Analysis of pitting corrosion behavior of pure Al in sodium chloride solution with the wavelet technique. J. Electroanal. Chem. 2005, 578, 143–150. [Google Scholar] [CrossRef]

- Gudić, S.; Smoljko, I.; Klikić, M. The effect of small addition of tin and indium on the corrosion behavior of aluminium in chloride solution. J. Alloy. Compd. 2010, 505, 54–63. [Google Scholar] [CrossRef]

- LI, S.; Zhang, H.; LIU, J. Corrosion behavior of aluminum alloy 2024-T3 by 8-hydroxy-quinoline and its derivative in 3.5% chloride solution. Trans. Nonferr. Met. Soc. China (Engl. Ed.) 2007, 17, 318–325. [Google Scholar] [CrossRef]

- Shen, D.; Li, G.; Guo, C.; Zou, J.; Cai, J.; He, D.; Ma, H.; Liu, F. Microstructure and corrosion behavior of micro-arc oxidation coatingon 6061 aluminum alloy pre-treated by high-temperature oxidation. Appl. Surf. Sci. 2013, 287, 451–456. [Google Scholar] [CrossRef]

- Ralston, K.D.; Birbilis, N. Effect of grain size on corrosion: A review. Corrosion 2010, 66, 075005-075005-13. [Google Scholar] [CrossRef]

- Gupta, R.K.; Fabijanic, D.; Zhang, R.; Birbilis, N. Corrosion behaviour and hardness of in situ consolidated nanostructured Al and Al-Cr alloys produced via high-energy ball milling. Corros. Sci. 2015, 98, 643–650. [Google Scholar] [CrossRef]

- Sherif, E.S.M.; Ammar, H.R.; Khalil, K.A. Effects of copper and titanium on the corrosion behavior of newly fabricated nanocrystalline aluminum in natural seawater. Appl. Surf. Sci. 2014, 301, 142–148. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Dey, G.K.; Dusane, R.O.; Grover, A.K. Improved pitting corrosion behaviour of electrodeposited nanocrystalline Ni-Cu alloys in 3.0 wt.% NaCl solution. J. Alloy. Compd. 2006, 426, 235–243. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y.; Wang, F. Electrochemical corrosion behavior of nanocrystalline materials-a review. J. Mater. Sci. Technol. 2010, 26, 1–14. [Google Scholar] [CrossRef]

- Raju, K.S.; Krishna, M.G.; Padmanabhan, K.A.; Muraleedharan, K.; Gurao, N.P.; Wilde, G. Grain size and grain boundary character distribution in ultra-fine grained (ECAP) nickel. Mater. Sci. Eng. A 2008, 491, 1–7. [Google Scholar] [CrossRef]

- Osório, W.R.; Freire, C.M.; Garcia, A. The role of macrostructural morphology and grain size on the corrosion resistance of Zn and Al castings. Mater. Sci. Eng. A 2005, 402, 22–32. [Google Scholar] [CrossRef]

- Cai, S.; Lei, T.; Li, N.; Feng, F. Effects of Zn on microstructure, mechanical properties and corrosion behavior of Mg-Zn alloys. Mater. Sci. Eng. C 2012, 32, 2570–2577. [Google Scholar] [CrossRef]

- Barbucci, A.; Farnè, G.; Matteazzi, P.; Riccieri, R.; Cerisola, G. Corrosion behaviour of nanocrystalline Cu90Ni10 alloy in neutral solution containing chlorides. Corros. Sci. 1998, 41, 463–475. [Google Scholar] [CrossRef]

- Chianpairot, A.; Lothongkum, G.; Schuh, C.A.; Boonyongmaneerat, Y. Corrosion of nanocrystalline Ni-W alloys in alkaline and acidic 3.5 wt.% NaCl solutions. Corros. Sci. 2011, 53, 1066–1071. [Google Scholar] [CrossRef]

- Lo, P.H.; Tsai, W.T.; Lee, J.T.; Hung, M.P. Role of phosphorus in the electrochemical behavior of electroless Ni-P alloys in 3.5 wt.% NaCl solutions. Surf. Coat. Technol. 1994, 67, 27–34. [Google Scholar] [CrossRef]

- Mote, V.D.; Purushotham, Y.; Dole, B.N. Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J. Theor. Appl. Phys. 2012, 6, 1–8. [Google Scholar] [CrossRef]

- Prabhu, Y.T.; Rao, K.V.; Kumar, V.S.S.; Kumari, B.S. X-ray analysis by Williamson-Hall and size-strain plot methods of ZnO nanoparticles with fuel variation. World J. Nano Sci. Eng. 2014, 4, 21–28. [Google Scholar] [CrossRef]

- Seikh, A.H.; Baig, M.; Ammar, H.R. Corrosion behavior of nanostructure Al-Fe alloy processed by mechanical alloying and high frequency induction heat sintering. Int. J. Electrochem. Sci. 2015, 10, 3054–3064. [Google Scholar]

- Lee, I.S.; Kao, P.W.; Ho, N.J. Microstructure and mechanical properties of Al-Fe in situ nanocomposite produced by friction stir processing. Intermetallics 2008, 16, 1104–1108. [Google Scholar] [CrossRef]

- Zhang, L.C.; Shen, Z.Q.; Xu, J. Glass formation in a (Ti, Zr, Hf)–(Cu, Ni, Ag)–Al high-order alloy system by mechanical alloying. J. Mater. Res. 2003, 18, 2141–2149. [Google Scholar] [CrossRef]

- Lu, P.-J.; Huang, S.-C.; Chen, Y.-P.; Chiueh, L.-C.; Shih, D.Y.-C. Analysis of titanium dioxide and zinc oxide nanoparticles in cosmetics. J. Food Drug Anal. 2015, 23, 587–594. [Google Scholar] [CrossRef]

- Yang, H.; Wen, J.; Quan, M.; Wang, J. Evaluation of the volume fraction of nanocrystalsdevitrified in Al-based amorphous alloys. J. Non-Cryst. Solids 2009, 355, 235–238. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Liu, Y.; Cao, G.; Zhang, L.-C. Influence of Nb on the β → α″ martensitic phase transformation and properties of the newly designed Ti-Fe-Nb alloys. Mater. Sci. Eng. C 2016, 60, 503–510. [Google Scholar] [CrossRef]

- Nayak, S.S.; Wollgarten, M.; Banhart, J.; Pabi, S.K.; Murty, B.S. Nanocomposites and an extremely hard nanocrystalline intermetallic of Al-Fe alloys prepared by mechanical alloying. Mater. Sci. Eng. A 2010, 527, 2370–2378. [Google Scholar] [CrossRef]

- Basariya, M.I.R.; Mukhopadhyay, N.K. Chapter 5, Structural and mechanical behaviour of Al-Fe intermetallics. In Intermetallics Compounds; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Keong, P.G.; Sames, J.A.; Adam, C.M.; Sharp, R.M. Influence of various elements on Al-Al6Fe eutectic system. In Proceedings of the International Conference on Solidification and Casting of Metals, London, UK, 18–21 July 1977; pp. 110–114. [Google Scholar]

- Campbell, J. Castings; Butterworth-Heinemann: Oxford, MS, UK, 2003. [Google Scholar]

- Seri, O.; Tagashira, K. The interpretation of polarization curves for A1-Fe alloys in de-aerated NaCl solution. Corros. Sci. 1990, 30, 87–94. [Google Scholar] [CrossRef]

- Liang, J.; Gao, L.J.; Miao, N.N.; Chai, Y.J.; Wang, N.; Song, X.Q. Hydrogen generation by reaction of Al-M(M = Fe, Co, Ni) with water. Energy 2016, 113, 282–287. [Google Scholar] [CrossRef]

- Grosjean, M.H.; Zidoune, M.; Roue, L. Hydrogen production from highly corroding Mg-based materials elaborated by ball milling. J. Alloy. Compd. 2005, 404, 712–715. [Google Scholar] [CrossRef]

- Flores-Chan, J.E.; Bedolla-Jacuinde, A.; Patiño-Carachure, C.; Rosas, G.; Espinosa-Medina, M.A. Corrosion study of Al-Fe (20 wt-%) alloy in artificial sea water with NaOH additions. Can. Metall. Q. 2018, 57, 201–209. [Google Scholar] [CrossRef]

- Seri, O.; Furumata, K. Effect of Al-Fe-Si intermetallic compound phases on initiation and propagation of pitting attacks for aluminum 1100. Mater. Corros. 2002, 53, 111–120. [Google Scholar] [CrossRef]

- Dean, S.W. Electrochemical methods of corrosion testing. In Electrochemical Techniques for Corrosion; Baboian, R., Ed.; NACE: Houston, TX, USA, 1977; p. 52. [Google Scholar]

- Pariona, M.; Micene, K.T.; Zara, J. Effect of microstructure on microhardness and electrochemical behavior in hypereutectic Al-Fe alloy processed by laser surface remelting. In Aerospace Engineering; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Sherif, E.M.; Park, S.M. Effects of 1,4-naphthoquinone on aluminum corrosion in 0.50 M sodium chloride solutions. Electrochim. Acta 2006, 51, 1313–1321. [Google Scholar] [CrossRef]

- Ma, H.; Chen, S.; Niu, L.; Zhao, S.; Li, S.; Li, D. Inhibition of copper corrosion by several Schiff bases in aerated halide solutions. J. Appl. Electrochem. 2002, 32, 65–72. [Google Scholar] [CrossRef]

- Singh, A.K.; Shukla, S.K.; Singh, M.; Quraishi, M.A. Inhibitive effect of ceftazidime on corrosion of mild steel in hydrochloric acid solution. Mater. Chem. Phys. 2011, 129, 68–76. [Google Scholar] [CrossRef]

- Sherif, E.M.; Park, S.M. Effects of 2-amino-5-ethylthio-1,3,4-thiadiazole on copper corrosion as a corrosion inhibitor in aerated acidic pickling solutions. Electrochim. Acta 2006, 51, 6556–6562. [Google Scholar] [CrossRef]

- Rehim, S.S.A.; Hassan, H.H.; Amin, M.A. Corrosion and corrosion inhibition of Al and some alloys in sulphate solutions containing halide ions investigated by an impedance technique. Appl. Surf. Sci. 2002, 187, 279–290. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Niinomi, M.; Akahori, T.; Fukui, H.; Toda, H. Corrosion resistance and biocompatibility of Ti-Ta alloys for biomedical applications. Mater. Sci. Eng. A 2005, 398, 28–36. [Google Scholar] [CrossRef]

- Seri, O. The effect of NaCl concentration on the corrosion behavior of Aluminum containing iron. Corros. Sci. 1994, 36, 1789–1803. [Google Scholar] [CrossRef]

- Gupta, R.K.; Birbilis, N. The influence of nanocrystalline structure and processing route on corrosion of stainless steel: A review. Corros. Sci. 2015, 92, 1–15. [Google Scholar] [CrossRef]

- Frankel, G.S. On the pitting resistance of sputter-deposited aluminum alloys. J. Electrochem. Soc. 1993, 140, 2192–2197. [Google Scholar] [CrossRef]

| Materials | Crystallite Size (Error), nm | Microstrain (Error), % |

|---|---|---|

| Pure Al | 53.67 ± 1.78 | 0.17 ± 0.05 |

| Al-2 wt.% Fe | 39.16 ± 4.23 | 0.22 ± 0.03 |

| Al-5 wt.% Fe | 39.13 ± 2.70 | 0.23 ± 0.04 |

| Al-10 wt.% Fe | 37.33 ± 3.56 | 0.24 ± 0.04 |

| Materials | Electrochemical Parameters | |||||

|---|---|---|---|---|---|---|

| Ecorr (mV) vs Ag/AgCl | icorr (µA·cm−2) | Epit (mV) vs Ag/AgCl | ipit (µA·cm−2) | Rp (kΩ·cm2) | Corrosion Rate (µm/year) | |

| Pure Al | –1047 | 14.48 | –824 | 89.3 | 4.873 | 157.83 |

| Al-2 wt.% Fe | –940 | 1.35 | –714 | 8.43 | 21.58 | 14.77 |

| Al-5 wt.% Fe | –884 | 1.27 | –698 | 4.64 | 38.23 | 14.38 |

| Al-10 wt.% Fe | –752 | 1.05 | –569 | 4.48 | 53.05 | 11.63 |

| Materials | EIS Parameters | ||||||

|---|---|---|---|---|---|---|---|

| RS (Ω cm2) | Q1 | Rct (kΩ·cm2) | Q2 | Rf (kΩ·cm2) | |||

| Cdl (μF·cm−2) | n | Cf (μF·cm−2) | n | ||||

| Pure Al | 3.84 | 248.3 | 0.977 | 1.11 | 617 | 0.58 | 2.81 |

| Al-2% Fe | 11.5 | 15.4 | 0.778 | 7.12 | 37.6 | 0.884 | 9.6 |

| Al-5% Fe | 13.8 | 12.8 | 0.887 | 11.1 | 23.4 | 0.92 | 13.6 |

| Al-10% Fe | 22.1 | 10.1 | 0.843 | 21.5 | 13.6 | 0.862 | 35.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seikh, A.H.; Baig, M.; Singh, J.K.; Mohammed, J.A.; Luqman, M.; Abdo, H.S.; Khan, A.R.; Alharthi, N.H. Microstructural and Corrosion Characteristics of Al-Fe Alloys Produced by High-Frequency Induction-Sintering Process. Coatings 2019, 9, 686. https://doi.org/10.3390/coatings9100686

Seikh AH, Baig M, Singh JK, Mohammed JA, Luqman M, Abdo HS, Khan AR, Alharthi NH. Microstructural and Corrosion Characteristics of Al-Fe Alloys Produced by High-Frequency Induction-Sintering Process. Coatings. 2019; 9(10):686. https://doi.org/10.3390/coatings9100686

Chicago/Turabian StyleSeikh, Asiful H., Muneer Baig, Jitendra Kumar Singh, Jabair A. Mohammed, Monis Luqman, Hany S. Abdo, Amir Rahman Khan, and Nabeel H. Alharthi. 2019. "Microstructural and Corrosion Characteristics of Al-Fe Alloys Produced by High-Frequency Induction-Sintering Process" Coatings 9, no. 10: 686. https://doi.org/10.3390/coatings9100686

APA StyleSeikh, A. H., Baig, M., Singh, J. K., Mohammed, J. A., Luqman, M., Abdo, H. S., Khan, A. R., & Alharthi, N. H. (2019). Microstructural and Corrosion Characteristics of Al-Fe Alloys Produced by High-Frequency Induction-Sintering Process. Coatings, 9(10), 686. https://doi.org/10.3390/coatings9100686