In Situ Creep Behavior Characterization of Single Crystal Superalloy by UV-DIC at 980 °C

Abstract

1. Introduction

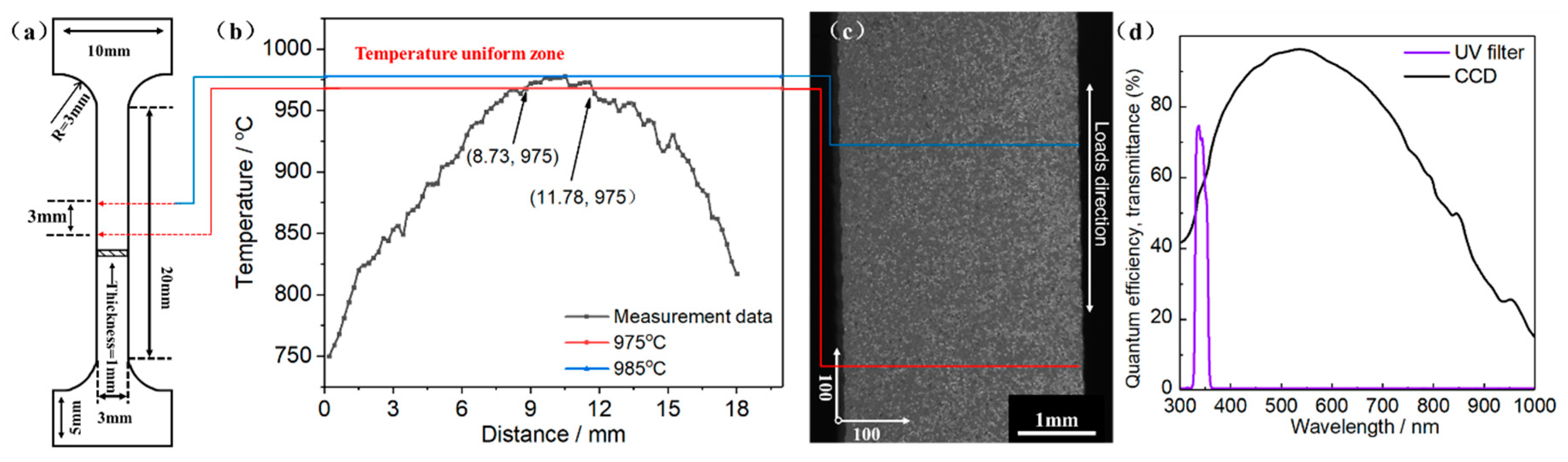

2. Materials and Experimental Procedures

2.1. Materials and Specimen Preparation

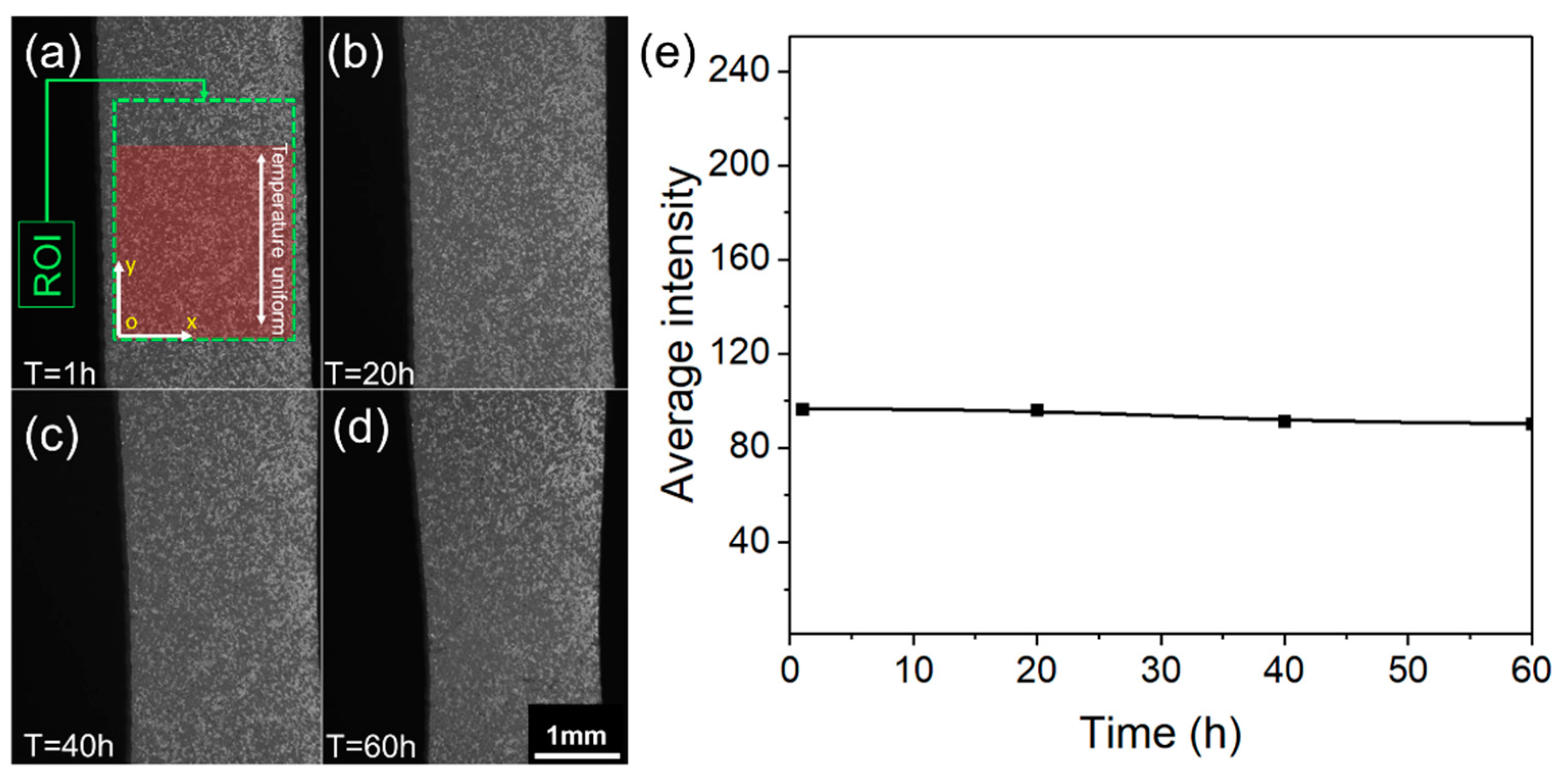

2.2. In Situ DIC Observation at 980 °C during Creep Test

2.3. Image Analysis

2.4. Microstructure Analysis

3. Results and Discussion

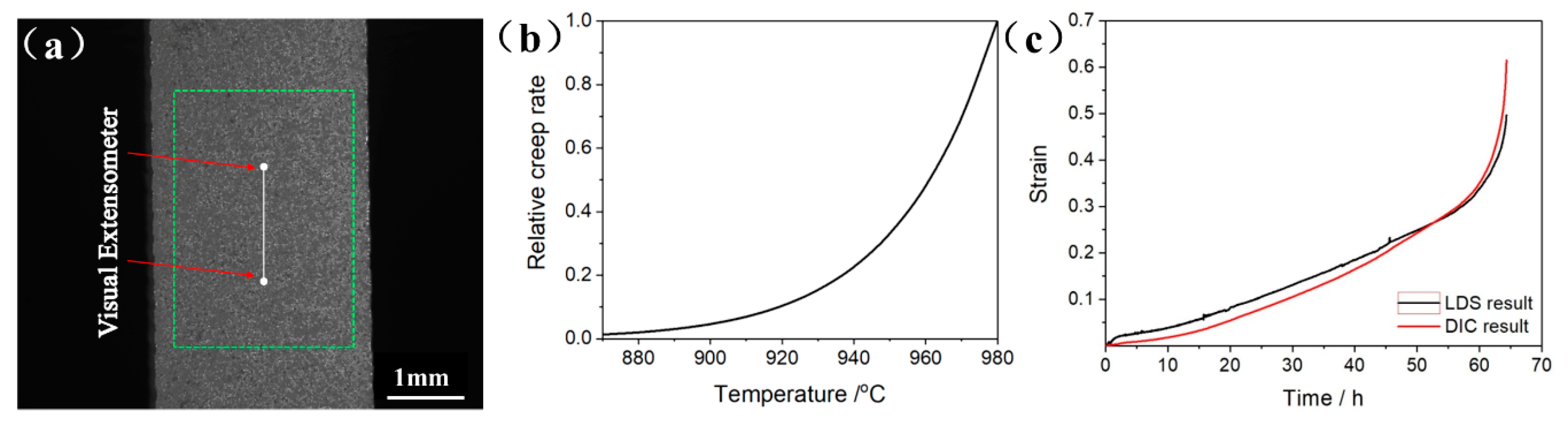

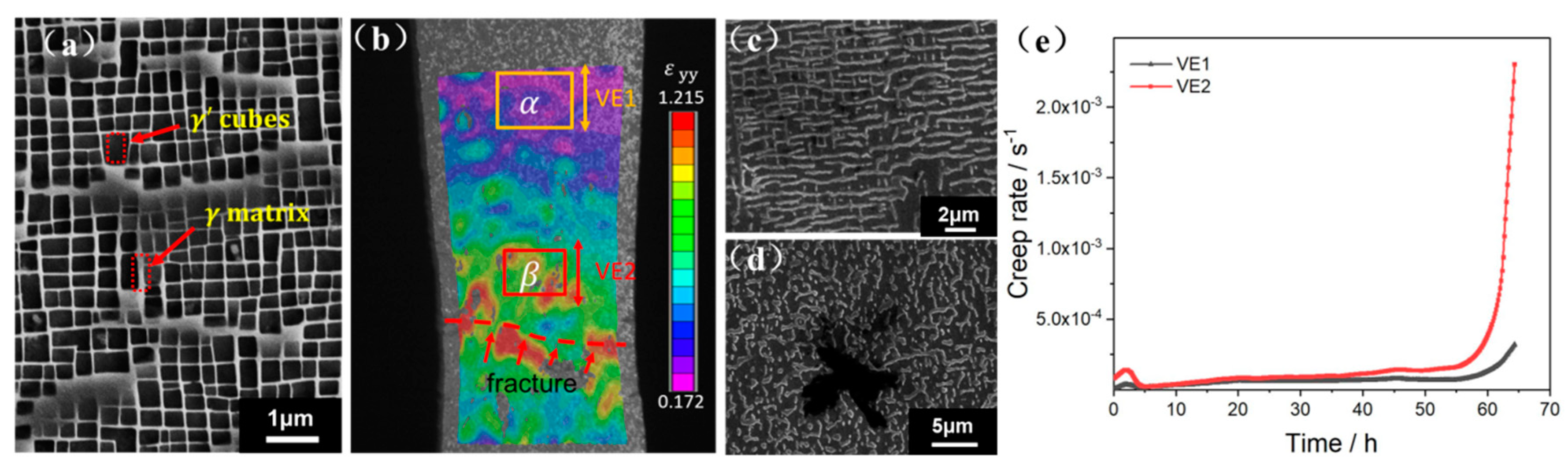

3.1. The Characterization of Creep Behaviors by UV-DIC System

3.2. Comparison between DIC and LDS Deformation Results

3.3. Microstructure Analysis of TW Specimen

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shi, Z.X.; Liu, S.Z.; Jian, Y.U.; Li, J.R. Tensile behavior of the second generation single crystal superalloy DD6. J. Iron Steel Res. Int. 2015, 22, 738–742. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall. Mater. 1992, 40, 1–30. [Google Scholar] [CrossRef]

- Nathal, M.V.; Ebert, L.J. Elevated temperature creep-Rupture behavior of the single crystal nickel-Base superalloy NASAIR 100. Metall. Trans. A 1985, 16, 427–439. [Google Scholar] [CrossRef]

- Jiang, L.W.; Li, S.S.; Wu, M.L. Investigation on creep mechanism of a Ni3Al-based single crystal superalloy IC6SX under 760oC/540MPa. Mater. Sci. Forum 2013, 747, 804–809. [Google Scholar] [CrossRef]

- Mughrabi, H.; Tetzlaff, U. Microstructure and high-temperature strength of monocrystalline nickel-Base superalloys. Adv. Eng. Mater. 2000, 2, 319–326. [Google Scholar] [CrossRef]

- McEnteggart, I. Contacting and non-contacting extensometry for ultra-high temperature testing. In Ultra High Temperature Mechanical Testing; Woodhead Publishing: Cambridge, UK, 1995; pp. 157–169. [Google Scholar]

- Peters, W.H.; Ranson, W.F. Digital imaging techniques in experimental stress analysis. Opt. Eng. 1982, 21, 213427. [Google Scholar] [CrossRef]

- Dong, Y.L.; Pan, B. A review of speckle pattern fabrication and assessment for digital image correlation. Exp. Mech. 2017, 57, 1161–1181. [Google Scholar] [CrossRef]

- Hild, F.; Roux, S. Digital image correlation: from displacement measurement to identification of elastic properties—A review. Strain 2006, 42, 69–80. [Google Scholar] [CrossRef]

- Dong, Y.; Kakisawa, H.; Kagawa, Y. Development of microscale pattern for digital image correlation up to 1400 C. Opt. Lasers Eng. 2015, 68, 7–15. [Google Scholar] [CrossRef]

- Turner, J.L.; Russell, S.S. Application of digital image analysis to strain measurement at elevated temperature. Strain 1990, 26, 55–59. [Google Scholar] [CrossRef]

- Liu, J.; Lyons, J.; Sutton, M.; Reynolds, A. Experimental characterization of crack tip deformation fields in alloy 718 at high temperatures. J. Eng. Mater. Technol. 1998, 120, 71–78. [Google Scholar] [CrossRef]

- Grant, B.M.B.; Stone, H.J.; Withers, P.J.; Preuss, M. High-temperature strain field measurement using digital image correlation. J. Strain Anal. Eng. Des. 2009, 44, 263–271. [Google Scholar] [CrossRef]

- Novak, M.D.; Zok, F.W. High-temperature materials testing with full-field strain measurement: Experimental design and practice. Rev. Sci. Instrum. 2011, 82, 115101. [Google Scholar] [CrossRef]

- Mao, W.G.; Chen, J.; Si, M.S.; Zhang, R.F.; Ma, Q.S.; Fang, D.N.; Chen, X. High temperature digital image correlation evaluation of in-situ failure mechanism: An experimental framework with application to C/SiC composites. Mater. Sci. Eng. 2016, 665, 26–34. [Google Scholar] [CrossRef]

- Chen, X.; Yang, L.; Xu, N.; Xie, X.; Sia, B.; Xu, R. Cluster approach based multi-Camera digital image correlation: Methodology and its application in large area high temperature measurement. Opt. Laser Technol. 2014, 57, 318–326. [Google Scholar] [CrossRef]

- Dong, Y.; Kakisawa, H.; Kagawa, Y. Optical system for microscopic observation and strain measurement at high temperature. Meas. Sci. Technol. 2014, 25, 025002. [Google Scholar] [CrossRef]

- Dong, Y. In-Situ evaluation of C/SiC composites via an ultraviolet imaging system and microstructure based digital image correlation. Nondestruct. Test. Eval. 2018, 33, 427–437. [Google Scholar] [CrossRef]

- Dong, Y.; Zhao, J.; Pan, B. Ultraviolet 3D digital image correlation applied for deformation measurement in thermal testing with infrared quartz lamps. Chin. J. Aeronaut. 2019. [Google Scholar] [CrossRef]

- Dong, Y.; Pan, B. In-Situ 3D shape and recession measurements of ablative materials in an arc-Heated wind tunnel by UV stereo-Digital image correlation. Opt. Lasers Eng. 2019, 116, 75–81. [Google Scholar] [CrossRef]

- Dong, Y.L.; Kakisawa, H.; Kagawa, Y. Development of new observation system used for deformation measurement of ceramic matrix composites at high temperature. Des. Dev. Appl. Struct. Ceram. Compos. Nanomater. 2014, 244, 81. [Google Scholar]

- Shang, Y.; Zhang, H.; Hou, H.; Ru, Y.; Pei, Y.; Li, S.; Gong, S.; Xu, H. High temperature tensile behavior of a thin-Walled Ni based single-Crystal superalloy with cooling hole: In-Situ experiment and finite element calculation. J. Alloys Compd. 2019, 782, 619–631. [Google Scholar] [CrossRef]

- Ru, Y.; Zhang, H.; Pei, Y.; Li, S.; Zhao, X.; Gong, S.; Xu, H. Improved 1200 °C stress rupture property of single crystal superalloys by γ′-Forming elements addition. Scr. Mater. 2018, 147, 21–26. [Google Scholar] [CrossRef]

- Kakehi, K.; Latief, F.H.; Sato, T. Influence of primary and secondary orientations on creep rupture behavior of aluminized single crystal Ni-Based superalloy. Mater. Sci. Eng. 2014, 604, 148–155. [Google Scholar] [CrossRef]

- Xin, R.; Liu, Z.; Sun, Y.; Wang, H.; Guo, C.; Ren, W.; Liu, Q. Understanding common grain boundary twins in Mg alloys by a composite Schmid factor. Int. J. Plast. 2019. [Google Scholar] [CrossRef]

- Yu, H.; Su, Y.; Tian, N.; Tian, S.; Li, Y.; Yu, X.; Yu, L. Microstructure evolution and creep behaviors of a [111] oriented single crystal nickel-based superalloy during tensile creep. Mater. Sci. Eng. 2013, 565, 292–300. [Google Scholar] [CrossRef]

- Müller, L.; Glatzel, U.; Feller-Kniepmeier, M. Calculation of the internal stresses and strains in the microstructure of a single crystal nickel-base superalloy during creep. Acta Metall. Mater. 1993, 41, 3401–3411. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Directional coarsening in nickel-Base single crystals with high volume fractions of coherent precipitates. Acta Metall. Mater. 1994, 42, 1859–1874. [Google Scholar] [CrossRef]

- Reed, R.C.; Matan, N.; Cox, D.C.; Rist, M.A.; Rae, C.M.F. Creep of CMSX-4 superalloy single crystals: effects of rafting at high temperature. Acta Mater. 1999, 47, 3367–3381. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, Y.; Dong, Y.; Pei, Y.; Ma, C.; Li, S.; Gong, S. In Situ Creep Behavior Characterization of Single Crystal Superalloy by UV-DIC at 980 °C. Coatings 2019, 9, 598. https://doi.org/10.3390/coatings9100598

Shang Y, Dong Y, Pei Y, Ma C, Li S, Gong S. In Situ Creep Behavior Characterization of Single Crystal Superalloy by UV-DIC at 980 °C. Coatings. 2019; 9(10):598. https://doi.org/10.3390/coatings9100598

Chicago/Turabian StyleShang, Yong, Yali Dong, Yanling Pei, Chaoli Ma, Shusuo Li, and Shengkai Gong. 2019. "In Situ Creep Behavior Characterization of Single Crystal Superalloy by UV-DIC at 980 °C" Coatings 9, no. 10: 598. https://doi.org/10.3390/coatings9100598

APA StyleShang, Y., Dong, Y., Pei, Y., Ma, C., Li, S., & Gong, S. (2019). In Situ Creep Behavior Characterization of Single Crystal Superalloy by UV-DIC at 980 °C. Coatings, 9(10), 598. https://doi.org/10.3390/coatings9100598