Durability of Selected Transparent and Semi-Transparent Coatings on Siberian and European Larch during Artificial Weathering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wood Material

2.2. Coatings and Their Application

2.3. Artificial Weathering (AW)

2.4. Gloss Measurements (G*)

2.5. Colour Measurements (L*a*b*)

2.6. Surface Wetting Measurements—Contact Angle (CA*)

2.7. Mould Test

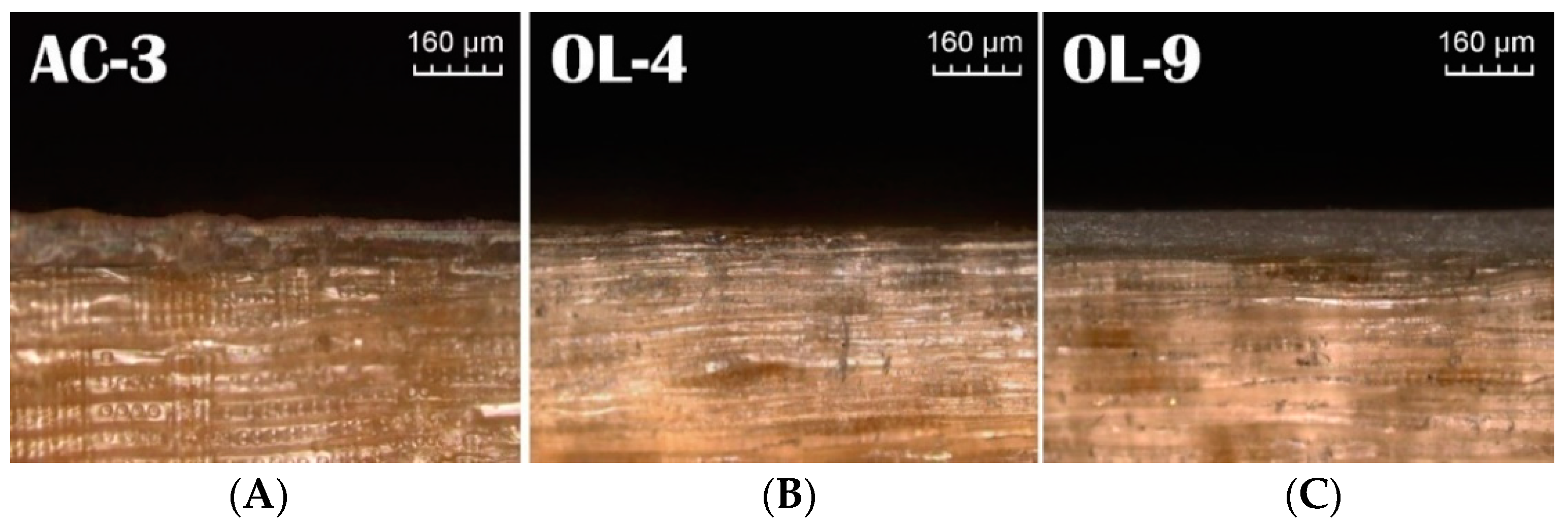

2.8. Visual Evaluation and Microscopic Analyses

2.9. Statistical Analysis

3. Results and Discussion

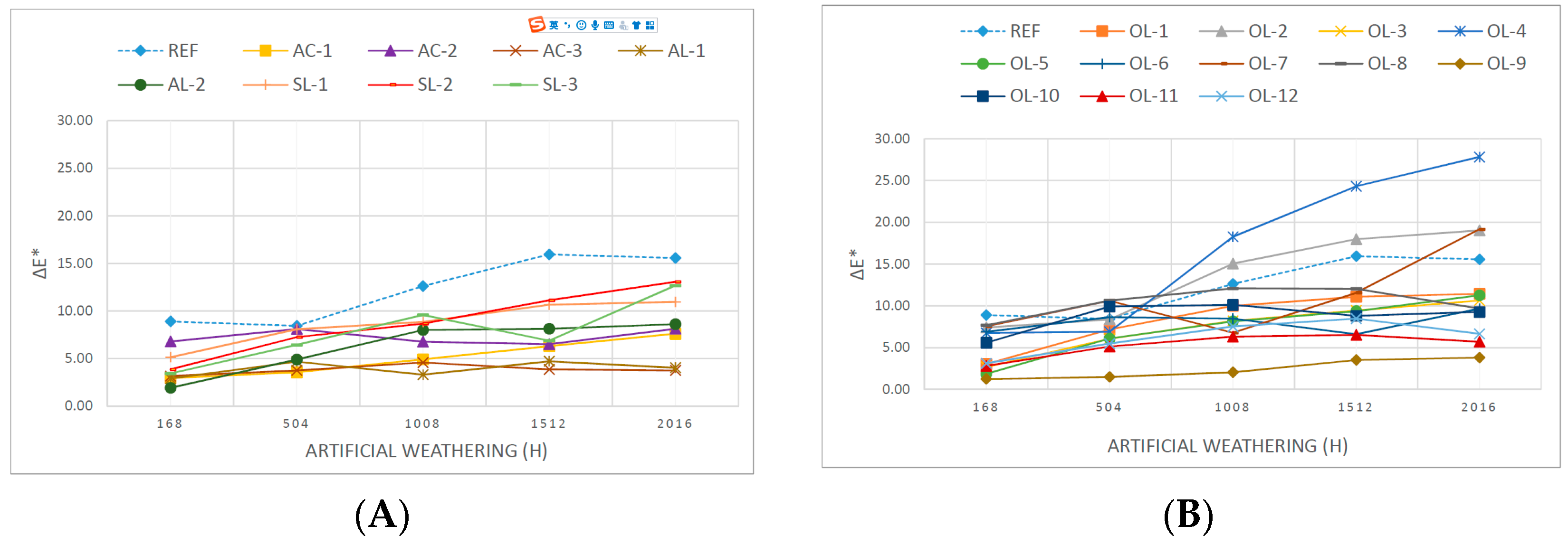

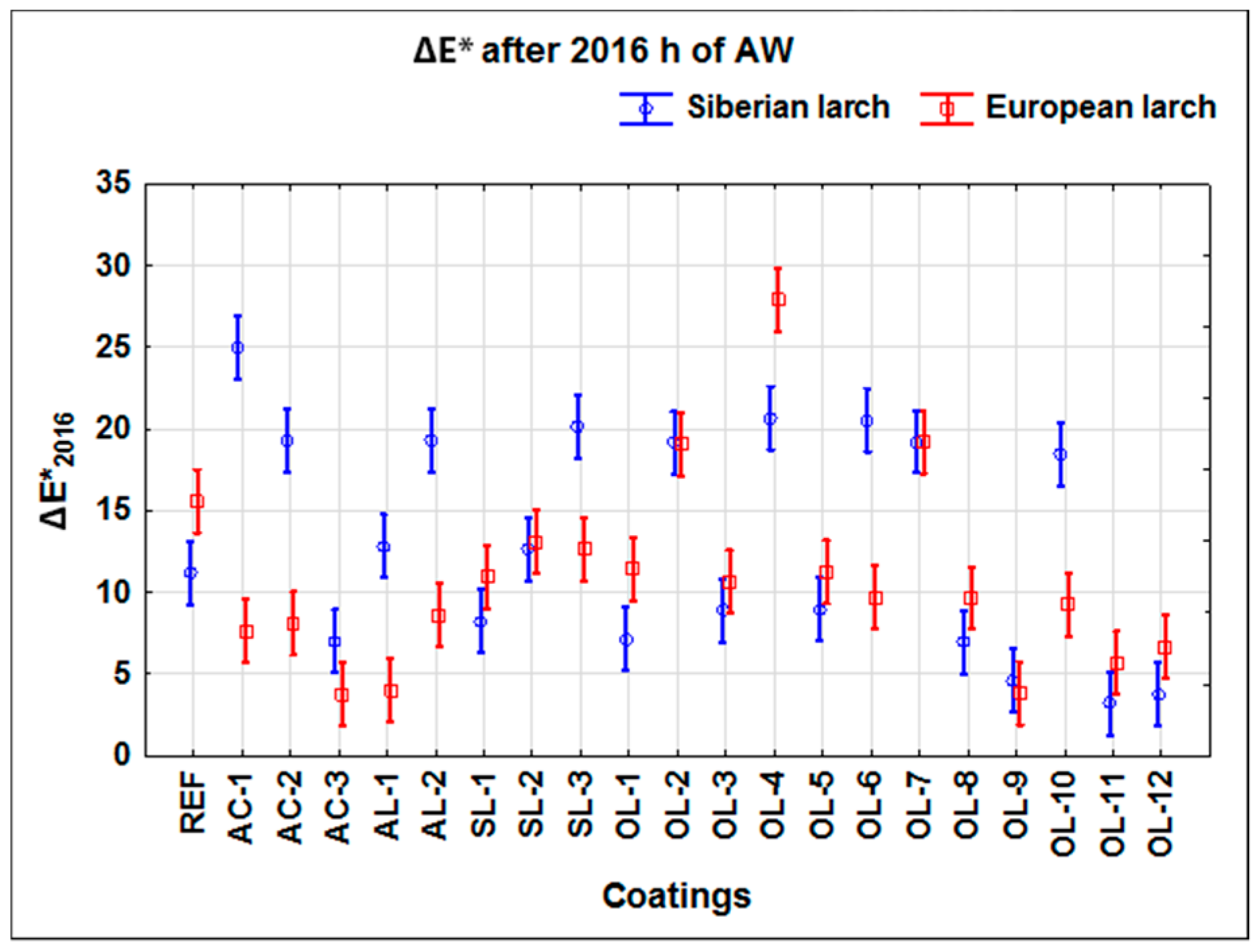

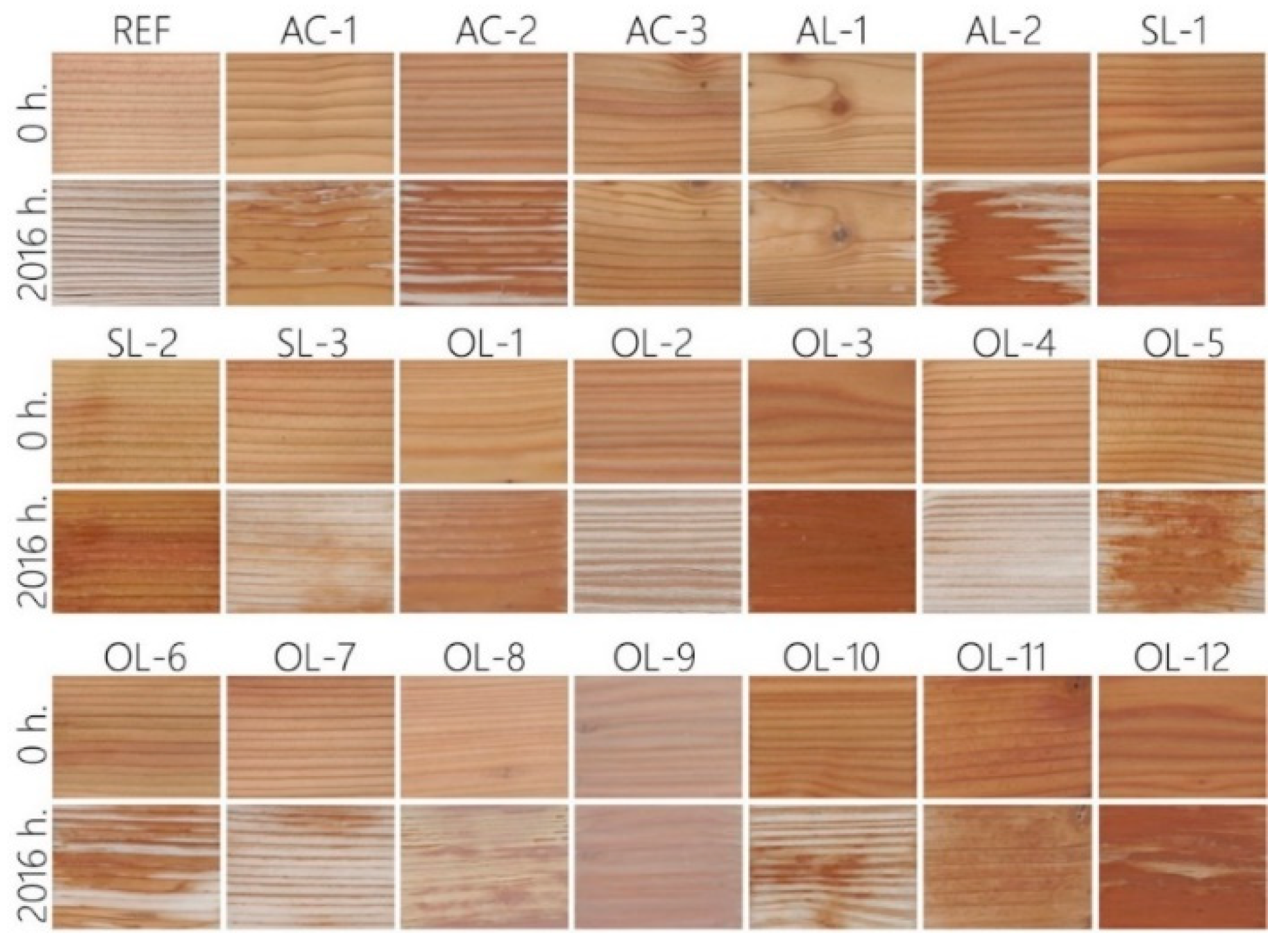

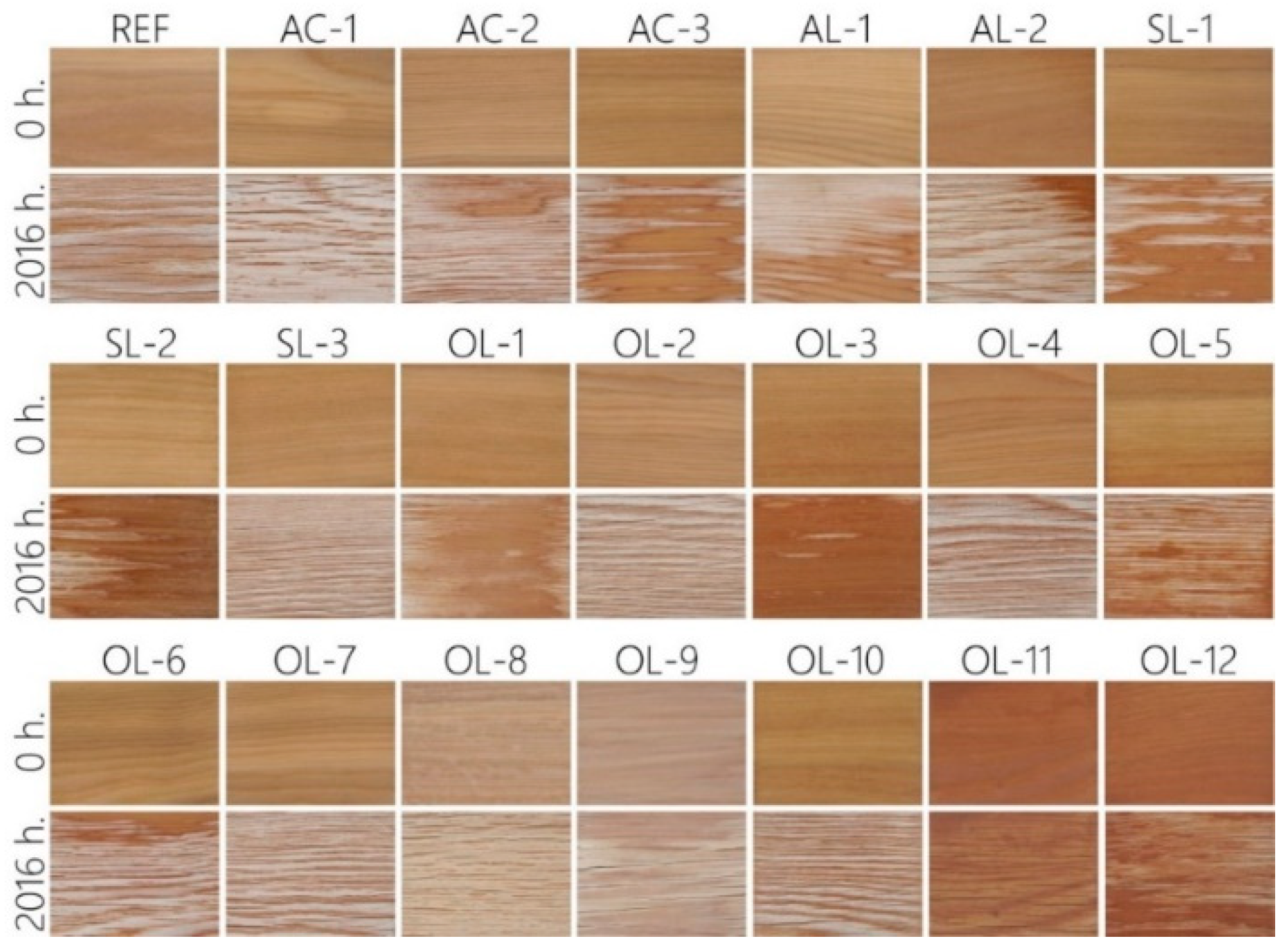

3.1. Changes in Colour (∆E*), Gloss (∆G*) and Visual Appearance

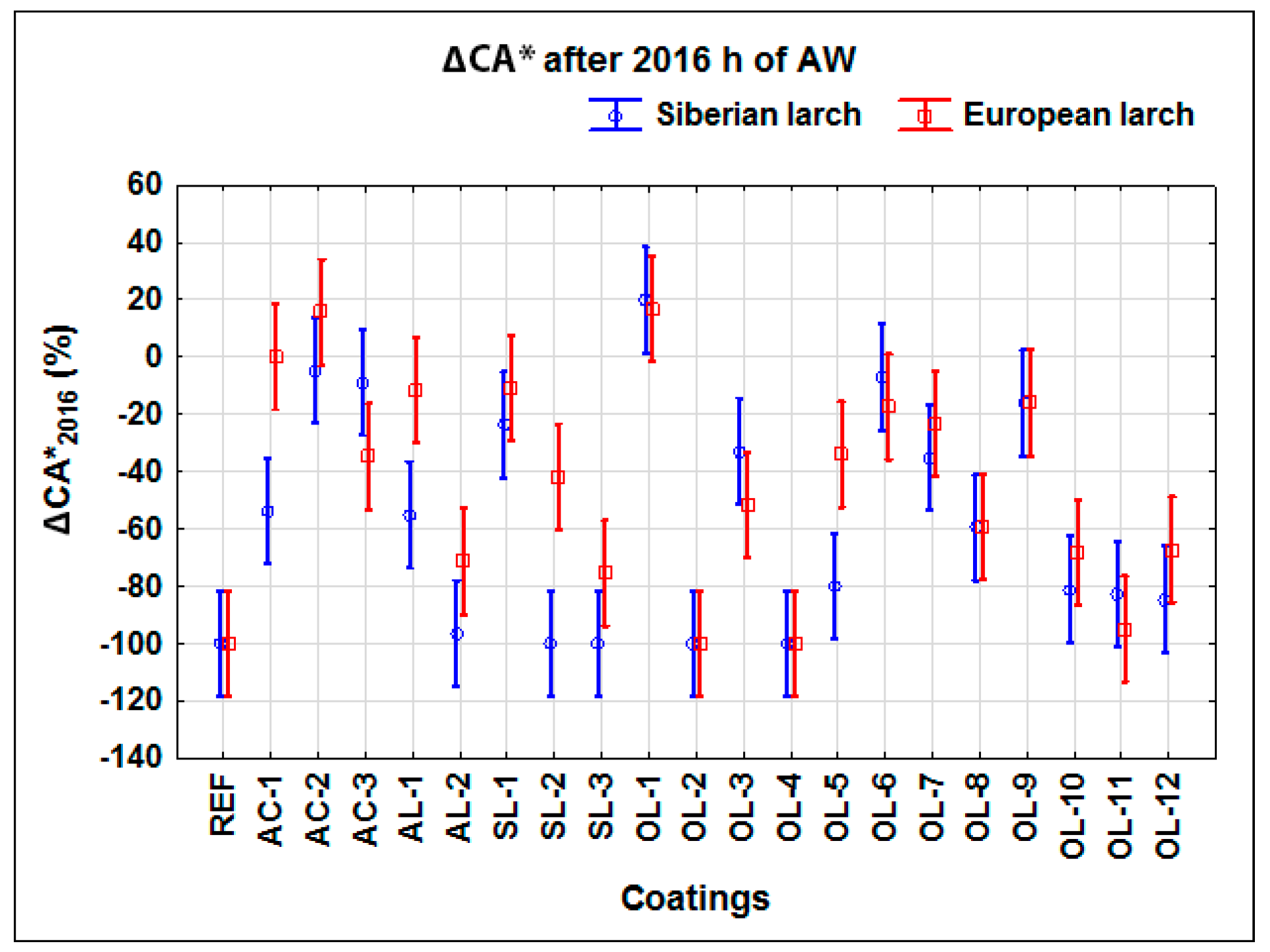

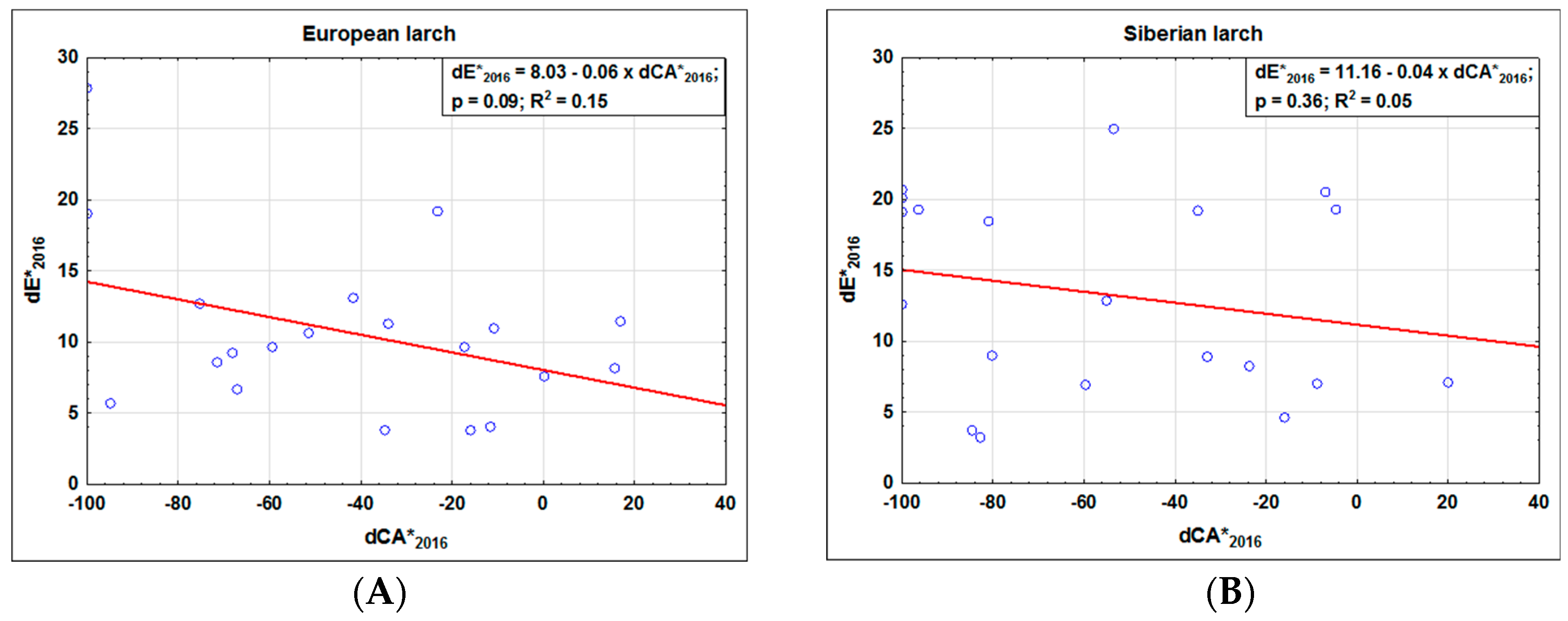

3.2. Changes in Wetting

3.3. Effect of Moulds

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Feist, W.C. Weathering of wood in structural uses. In Structural Use of Wood in Adverse Environments; Meyer, R.W., Kellong, R.M., Eds.; Van Nostrand Reinhold: New York, NY, USA, 1982; pp. 156–178. [Google Scholar]

- Cogulet, A.; Blanchet, P.; Landry, V. The multifactorial aspect of wood weathering: A review based on a holistic approach of wood degradation protected by clear coating. BioResources 2018, 13, 2116–2138. [Google Scholar] [CrossRef]

- Feist, W.C. Weathering and Protection of Wood, American Wood; Preservers’ Association: Kansas City, KS, USA, 1983. [Google Scholar]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials. Forests 2018, 9, 488. [Google Scholar] [CrossRef]

- Hockberger, P.E. The discovery of the damaging effect of sunlight on bacteria. J. Photochem. Photobiol. B Biol. 2000, 58, 185–191. [Google Scholar] [CrossRef]

- Evans, P. Weathering of Wood and Wood Composites. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 166–231. [Google Scholar]

- Pandey, K.K. A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J. Appl. Polym. Sci. 1999, 71, 1969–1975. [Google Scholar] [CrossRef]

- Sudiyani, Y. Chemical characteristics of surfaces of hardwood and softwood deteriorated by weathering. J. Wood Sci. 1999, 45, 348–353. [Google Scholar] [CrossRef]

- Reinprecht, L.; Mamoňová, M.; Pánek, M.; Kačík, F. The impact of natural and artificial weathering on the. visual, colour and structural changes of seven tropical woods. Eur. J. Wood Wood Prod. 2018, 76, 175–190. [Google Scholar] [CrossRef]

- Duncan, C.G. Role of microorganisms in weathering of wood and degradation of exterior finishes. Off. Dig. J. Paint Technol. Eng. 1963, 35, 1003–1012. [Google Scholar]

- Evans, P.D.; Haase, J.G.; Shakri, A.; Seman, B.M.; Kiguchi, M. The search for durable exterior clear coatings for wood. Coatings 2015, 5, 830–864. [Google Scholar] [CrossRef]

- Grüll, G.; Forsthuber, B.; Tscherne, F.; Spitaler, I. Weathering indicator for artificial and natural weathering of wood coatings. Eur. J. Wood Wood Prod. 2014, 72, 681–684. [Google Scholar] [CrossRef]

- De Meijer, M. Comparison between laboratory water permeability tests and wood moisture content of full-scale window frames. Surf. Coat. Int. Part B Coat. Trans. 2003, 85, 79–168. [Google Scholar] [CrossRef]

- Hýsek, Š.; Fidan, H.; Pánek, M.; Böhm, M.; Trgala, K. Water permeability of exterior wood Coatings: Waterborne acrylate dispersions for windows. J. Green Build. 2018, 13, 1–16. [Google Scholar] [CrossRef]

- Samyn, P.; Stanssens, D.; Paredes, A.; Becker, G. Performance of organic nanoparticle coatings for hydrophobization of hardwood surfaces. J. Coat. Technol. Res. 2014, 11, 461–471. [Google Scholar] [CrossRef]

- Bardage, S.L.; Bjurman, J. Adhesion of waterborne paints to wood. J. Coat. Technol. 1998, 70, 39–47. [Google Scholar] [CrossRef]

- Ghosh, M.; Gupta, S.; Kumar, V.S.K. Studies on the loss of gloss of shellac and polyurethane finishes exposed to UV. Maderas Cienc. Tecnol. 2015, 17, 39–44. [Google Scholar] [CrossRef]

- Gobakken, L.R.; Høibø, O.A.; Solheim, H. Mould growth on paints with different surface structures when applied on wooden claddings exposed outdoors. Int. Biodeterior. Biodegrad. 2010, 64, 339–345. [Google Scholar] [CrossRef]

- Oberhofnerová, E.; Hýsek, Š.; Pánek, M.; Böhm, M. Effect of artificial weathering and temperature cycling on the performance of coating systems used for wooden windows. J. Coat. Technol. Res. 2018, 15, 851–865. [Google Scholar] [CrossRef]

- Jankowska, A.; Szczęsna, M. The study of colour changes of chosen species of wood from southeast asia caused by transparent coatings and exposure to sunlight. Drewno Prace Naukowe Doniesienia Komun. 2011, 54, 51–59. [Google Scholar]

- Forsthuber, B.; Ecker, M.; Truskaller, M.; Grüll, G. Rapid prediction of surface characteristics of European and Siberian larch wood by FT-NIRS. Eur. J. Wood Wood Prod. 2017, 75, 569–580. [Google Scholar] [CrossRef]

- Evans, P.; Chowdhury, M.J.; Mathews, B.; Schmalzl, K.; Ayer, S.; Kiguchi, M.; Kataoka, Y. Weathering and surface protection of wood. In Handbook of Environmental Degradation of Materials; Kutz, M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2005; pp. 277–297. [Google Scholar]

- George, B.; Suttie, E.; Merlin, A.; Deglise, X. Photodegradation and photostabilisation of wood—The state of the art. Polym. Degrad. Stabil. 2005, 88, 268–274. [Google Scholar] [CrossRef]

- Aloui, F.; Ahajji, A.; Irmouli, Y.; George, B.; Charrier, B.; Merlin, A. Inorganic UV absorbers for the photostabilisation of wood-clearcoating systems: Comparison with organic UV absorbers. Appl. Surf. Sci. 2007, 253, 3737–3745. [Google Scholar] [CrossRef]

- Pánek, M.; Oberhofnerová, E.; Zeidler, A.; Šedivka, P. Efficacy of hydrophobic coatings in protecting oak wood surfaces during accelerated weathering. Coatings 2017, 7, 172. [Google Scholar] [CrossRef]

- Gierlinger, N.; Jacques, D.; Schwanninger, M.; Wimmer, R.; Pâques, L.E. Heartwood extractives and lignin content of different larch species (Larix sp.) and relationships to brown-rot decay-resistance. Trees 2004, 18, 230–236. [Google Scholar] [CrossRef]

- Gobakken, L.R.; Westin, M. Surface mould growth on five modified wood substrates coated with three different coating systems when exposed outdoors. Int. Biodeterior. Biodegrad. 2008, 62, 397–402. [Google Scholar] [CrossRef]

- Forsthuber, B.; Illy, A.; Grüll, G. Photo-scanning colorimetry of wood and transparent wood coatings. Eur. J. Wood Wood Prod. 2014, 72, 487–495. [Google Scholar] [CrossRef]

- Žlahtič, M.; Humar, M. Influence of artificial and natural weathering on the hydrophobicity and surface properties of wood. BioResources 2016, 11, 4964–4989. [Google Scholar] [CrossRef]

- Grüll, G.; Forsthuber, B.; Ecker, M. Sensitivity of waterborne coatings to high acidity and content of arabinogalactan in larch heartwood. Prog. Organ. Coat. 2016, 101, 367–378. [Google Scholar] [CrossRef]

- Forsthuber, B.; Grüll, G. Prediction of wood surface discoloration for applications in the field of architecture. Wood Sci. Technol. 2018, 52, 1093–1111. [Google Scholar] [CrossRef]

- EN 350:2016 Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials; European Committee for Standardization: Brussels, Belgium, 2016.

- Gierlinger, N.; Jacques, D.; Schwanninger, M.; Wimmer, R.; Hinterstoisser, B.; Pâques, L.E. Rapid prediction of natural durability of larch heartwood using Fourier transform near-infrared spectroscopy. Can. J. For. Res. 2003, 33, 1727–1736. [Google Scholar] [CrossRef]

- Viitanen, H.; Paajanen, L.; Saranpää, P.; Viitaniemi, P. Durability of Larch (Larix spp) Wood against Brown-Rot Fungi; The International Research Group on Wood Preservation: Stockholm, Sweden, 1997. [Google Scholar]

- Heseltine, E.; Rosen, J. (Eds.) WHO Guidelines for Indoor Air Quality: Dampness and Mould; WHO Regional Office Europe: København, Denmark, 2009. [Google Scholar]

- Oberhofnerová, E.; Pánek, M.; Böhm, M. Effect of surface pretreatment with natural essential oils on the weathering performance of spruce wood. BioResources 2018, 13, 7053–7070. [Google Scholar]

- Bardage, S.L. Colonization of Painted Wood by Blue Stain Fungi. Ph.D. Thesis, Acta Universitatis Agriculturae Sueciae, Silvestria, Sweden, 1997. [Google Scholar]

- Bravery, A.F.; Miller, E.R. The role of pretreatment in the finishing of exterior softwood. In Proceedings of the Annual Convention of the British Wood Preserving Association, Cambridge, UK, 24–27 June 1980; pp. 14–22. [Google Scholar]

- Sharpe, P.R.; Dickinson, D.J. Blue Stain in Service on Wood Surface Coatings—Part 2: The Ability of Aureobasidium pullulans to Penetrate Wood Surface Coatings; The International Research Group on Wood Preservation: Stockholm, Sweden, 1992. [Google Scholar]

- Winters, H.; Isquit, I.R.; Gall, M. A study of the ecological succession in biodeterioration of vinyl acrylic paint film. Dev. Ind. Micrbiol. 1978, 17, 167–171. [Google Scholar]

- Johansson, P.; Ekstrand-Tobin, A.; Svensson, T.; Bok, G. Laboratory study to determine the critical moisture level for mould growth on building materials. Int. Biodeterior. Biodegrad. 2012, 73, 23–32. [Google Scholar] [CrossRef]

- Gaylarde, C.C.; Morton, L.H.G.; Loh, K.; Shirakawa, M.A. Biodeterioration of extrenal architectural paint films—A review. Int. Biodeterior. Biodegrad. 2011, 65, 1189–1198. [Google Scholar] [CrossRef]

- EN ISO 2813:2015 Paints and Varnishes, Determination of Gloss Value at 20°, 60° and 85°; European Committee for Standardization: Brussels, Belgium, 2015.

- D2244-16:2016 Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates; ASTM International: West Conshohocken, PA, USA, 2016.

- Bastani, A.; Adamopoulos, S.; Militz, H. Water uptake and wetting behaviour of furfurylated, N-methylol melamine modified and heat-treated wood. Eur. J. Wood Wood Prod. 2015, 73, 627–634. [Google Scholar] [CrossRef]

- STN 49 0604 Protection of Wood. Methods of Determining the Biocidal Properties of Wood Preservatives; Úrad pre Normalizáciu, Metrológiu a Skúšobníctvo: Bratislava, Slovakia, 1980.

- Viitanen, H. Mould Growth on Painted Wood. 9p. Subtask of the EU-Project CT94-2463. 1998. Available online: http:/virtual.vtt.fi (accessed on 16 November 2018).

- Sharratt, V.; Hill, C.A.S.; Kint, D.P.R. A study of early colour change due to simulated accelerated sunlight exposure in Scots pine (Pinus sylvestris). Polym. Degrad. Stabil. 2009, 94, 1589–1594. [Google Scholar] [CrossRef]

- Reinprecht, L.; Pánek, M. Effects of wood roughness, light pigments, and water repellent on the color stability of painted spruce subjected to natural and accelerated weathering. BioResources 2015, 10, 7203–7219. [Google Scholar] [CrossRef]

- Sehlstedt-Persson, M. Colour responses to heat-treatment of extractives and sap from pine and spruce. In Proceedings of the 8th IUFRO International Wood Drying Conference, Brasov, Romania, 24–29 August 2003; pp. 459–464. [Google Scholar]

- Moya, R.; Rodríguez-Zuniga, A.; Vega-Baudrit, J.; Puente-Urbina, A. Effects of adding TiO2 nanoparticles to a water-based varnish for wood applied to nine tropical woods of Costa Rica exposed to natural and accelerated weathering. J. Coat. Technol. Res. 2016, 14, 141–152. [Google Scholar] [CrossRef]

- Pánek, M.; Reinprecht, L. Effect of vegetable oils on the colour stability of four tropical woods during natural and artificial weathering. J. Wood Sci. 2016, 62, 74–84. [Google Scholar]

- Winowski, K. Biocide Optimization: Blends of Actives. PCI e Paint and Coatings Industry. 2004. Available online: http://www.pcimag.com/CDA/Archives (accessed on 21 January 2011).

- Schmitt, J.A. The microecology of mold growth. J. Paint Technol. 1974, 46, 59–64. [Google Scholar]

- Salem, M.Z.M.; Mansour, M.M.A.; Mohamed, W.S.; Ali, H.M.; Hatamleh, A.A. Evaluation of the antifungal activity of treated Acacia saligna wood with Paraloid B-72/TiO2 nanocomposites against the growth of Alternaria tenuissima, Trichoderma harzianum and Fusarium culmorum. BioResources 2017, 12, 7615–7627. [Google Scholar] [CrossRef]

- Viitanen, H.; Ahola, P. Resistance of Painted Pine Sapwood to Mould Fungi. Part 1. The Effect of Water-borne Paints and Fungicides on Mould Growth. IRG/ WP 97-10233; The International Research Group on Wood Preservation: Stockholm, Sweden, 1997. [Google Scholar]

- Buchner, J.; Irle, M.; Belloncle, Ch.; Michaud, F.; Macchioni, N. Fungal and bacterial colonies growing on weathered wood surfaces. Wood Mater. Sci. Eng. 2018, 14, 33–41. [Google Scholar] [CrossRef]

- EN 15457 Paints and Varnishes. Laboratory Method for Testing the Efficacy of Film Preservatives in a Coating against Fungi; European Committee for Standardization: Brussels, Belgium, 2007.

- ASTM D5590-17. Standard Test Method for Determining the Resistance of Paint Films and Related Coatings to Fungal Defacement by Accelerated Four-Week Agar Plate Assay; ASTM International: West Conshohocken, PA, USA, 2017. Available online: www.astm.org (accessed on 16 November 2018). [CrossRef]

- Gradeci, K.; Labonnote, N.; Time, B.; Köhler, J. Mould growth criteria and design avoidance approaches in wood-based materials—A systematic review. Constr. Build. Mater. 2017, 150, 77–88. [Google Scholar] [CrossRef]

- EN 927-6 Paints and Varnishes. Coating Materials and Coating Systems for Exterior Wood. Exposure of Wood Coatings to Artificial Weathering Using Fluorescent UV Lamps and Water; European Committee for Standardization: Brussels, Belgium, 2008.

- Gobakken, L.R.; Lebow, P.K. Modelling mould growth on coated modified and unmodified wood substrates exposed outdoors. Wood Sci. Technol. 2010, 44, 315–333. [Google Scholar] [CrossRef]

- EN 927-3 Paints and Varnishes—Coating Materials and Coating Systems for Exterior Wood—Part 3: Natural Weathering Test; European Committee for Standardization: Brussels, Belgium, 2012.

- ASTM D3456-18 Standard Practice for Determining by Exterior Exposure Tests the Susceptibility of Paint Films to Microbiological Attack; ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 16 November 2018). [CrossRef]

- Gerullis, S.; Kretzschmar, B.S.M.; pfuch, A.; Beier, O.; Beyer, M.; Grünler, B. Influence of atmospheric plasma jet and diffuse coplanar surface barrier discharge treatments on wood surface properties: A comparative study. Plasma Process. Polym. 2018, 15, 1800058. [Google Scholar] [CrossRef]

- Haase, J.G.; Leung, L.H.; Evans, P.D. Plasma pre-treatments to improve the weather resistance of polyurethane coatings on black spruce wood. Coatings 2019, 9, 8. [Google Scholar] [CrossRef]

- Reinprecht, L.; Šomšák, M. Effect of plasma and UV-additives in transparent coatings on the colour stability of spruce (Picea abies) wood at its weathering in xenotest. Acta Fac. Xylologiae Zvolen 2015, 57, 49–59. [Google Scholar] [CrossRef]

- Fukuta, S.; Nomura, M.; Ikeda, T.; Yoshizawa, M.; Yamasaki, M.; Sasaki, Y. UV-laser incisions to apply wood-plastic compositions to wood surfaces. Mokuzai Gakkaishi 2018, 64, 28–35. [Google Scholar] [CrossRef]

| Coating | Type and Specification of Coating * | Coating Base | Transparent/ Semitransp. | Number of Layers | Spreading Rate (g·m−2) |

|---|---|---|---|---|---|

| REF | Reference without coating | x | x | x | x |

| AC-1 | Acrylate water-based lasur with nanoparticles UV-stabilizers | Acrylate | T | 2 | 100 |

| AC-2 | Acrylate water-based lasur with UV-stabilizers and fungicides | Acrylate | T | 1 + 2 | 100 |

| AC-3 | Acrylate thick-layer water-based lasur with fungicides (5-chlor-2-methylisothiazol-3(2H)-on) | Acrylate | T | 3 | 100 |

| AL-1 | Alkyd water-based lasur with fungicides (IPBC 0.4%) and UV-stabilizers (benzotriazoles < 0.8%) | Alkyd | T | 2 | 100 |

| AL-2 | Thixotropic alkyd lasur with UV-stabilizers | Alkyd | T | 1 + 1 | 100 |

| SL-1 | Synthetic lasur with fungicides (IPBC 0.3%) and UV-stabilizers | Synthetic lasur | T | 2 | 100 |

| SL-2 | Hybrid polyurethane-alkyd synthetic yacht varnish with butanone oxime as additive | Synthetic lasur | T | 3 | 100 |

| SL-3 | Synthetic lasur with fungicides (BIT 0.3%) and butanone oxime (0.5%) | Synthetic lasur | T | 3 | 100 |

| OL-1 | Oil-based with waxes, natural resins, essential oils | Oil | T | 2 | 80 |

| OL-2 | Oil-based with fungicides (BIT and IPBC) | Oil | T | 2 | 80 |

| OL-3 | Hemp oils with denaturized white spirit | Oil | T | 1 + 2 | 100 |

| OL-4 | Oil water emulsion | Oil | T | 2 | 100 |

| OL-5 | Linseed oil | Oil | T | 2 | 100 |

| OL-6 | Oil-based with fungicides (propiconazole 0.5%) | Oil | T | 1 + 2 | 100 |

| OL-7 | Oil-based with UV-stabilizers (benzotriazoles) | Oil | T | 2 | 100 |

| OL-8 | Oil-based with nanoUV-absorbers, plant essential oils | Oil | S | 2 | 80 |

| OL-9 | Thin layering oil-based with micronized pigments (TiO2) and fungicides (propiconazole < 1%) | Oil | S | 2 | 100 |

| OL-10 | enetrating oil-based with pigments and terpineol (<2.5%) | Oil | S | 2 | 100 |

| OL-11 | Penetrating oil-based with pigments | Oil | S | 2 | 100 |

| OL-12 | Thin layering oil-based with micronized pigments (Fe2O3) and fungicides (propiconazole < 1%) | Oil | S | 2 | 100 |

| Coating | European Larch | Siberian Larch | |||||||

|---|---|---|---|---|---|---|---|---|---|

| – | L* | a* | b* | G* | L* | a* | b* | G* | CA* |

| REF | 73.85 | 8.84 | 23.63 | 3.56 | 60.98 | 10.28 | 27.15 | 8.12 | 76.24 |

| 0.47 | 0.23 | 0.14 | 0.05 | 1.38 | 0.77 | 1.00 | 0.65 | 2.33 | |

| AC-1 | 68.83 | 8.51 | 30.56 | 28.78 | 65.73 | 9.33 | 32.30 | 32.22 | 85.74 |

| 0.82 | 0.53 | 0.34 | 1.44 | 2.70 | 0.51 | 1.05 | 1.42 | 1.05 | |

| AC-2 | 65.02 | 11.02 | 25.92 | 7.50 | 64.29 | 9.23 | 28.59 | 7.44 | 94.33 |

| 1.37 | 0.31 | 0.20 | 0.68 | 1.57 | 0.21 | 0.21 | 0.15 | 1.70 | |

| AC-3 | 63.96 | 11.54 | 25.72 | 53.80 | 62.49 | 9.90 | 31.04 | 44.78 | 86.78 |

| 1.93 | 0.38 | 1.14 | 0.85 | 1.53 | 0.20 | 0.52 | 0.92 | 3.20 | |

| AL-1 | 67.73 | 8.98 | 30.12 | 8.04 | 67.82 | 7.99 | 30.53 | 9.70 | 96.24 |

| 2.45 | 1.32 | 0.44 | 0.73 | 1.26 | 0.19 | 0.55 | 0.28 | 1.81 | |

| AL-2 | 63.63 | 12.60 | 29.37 | 48.72 | 58.23 | 11.43 | 29.17 | 20.60 | 106.68 |

| 0.32 | 0.21 | 0.70 | 2.80 | 0.96 | 0.38 | 0.63 | 0.88 | 1.16 | |

| SL-1 | 60.26 | 15.26 | 33.50 | 24.80 | 61.56 | 10.78 | 32.98 | 22.56 | 111.21 |

| 1.35 | 0.60 | 1.06 | 0.37 | 0.85 | 0.33 | 0.20 | 0.36 | 1.08 | |

| SL-2 | 66.81 | 11.93 | 33.19 | 41.62 | 68.37 | 9.48 | 32.90 | 52.30 | 100.42 |

| 1.73 | 1.04 | 0.73 | 3.24 | 0.32 | 0.17 | 0.55 | 3.15 | 0.93 | |

| SL-3 | 68.56 | 11.55 | 33.15 | 6.44 | 62.34 | 10.81 | 32.15 | 8.32 | 100.67 |

| 1.99 | 1.20 | 0.61 | 0.13 | 1.17 | 0.50 | 0.62 | 0.24 | 2.40 | |

| OL-1 | 68.50 | 11.06 | 32.36 | 17.54 | 62.47 | 10.75 | 32.05 | 15.38 | 105.32 |

| 0.96 | 0.55 | 0.88 | 0.11 | 0.85 | 0.30 | 0.39 | 0.40 | 3.12 | |

| OL-2 | 63.41 | 11.86 | 28.22 | 7.40 | 62.72 | 10.03 | 29.78 | 9.96 | 107.82 |

| 1.24 | 0.39 | 0.68 | 1.57 | 1.44 | 0.22 | 0.48 | 0.71 | 2.81 | |

| OL-3 | 60.26 | 13.35 | 29.15 | 90.82 | 61.38 | 11.64 | 32.89 | 86.50 | 105.44 |

| 1.26 | 0.41 | 0.44 | 0.55 | 1.13 | 0.50 | 0.55 | 0.60 | 1.62 | |

| OL-4 | 64.88 | 12.31 | 31.94 | 5.70 | 58.75 | 11.84 | 32.03 | 18.60 | 61.02 |

| 1.42 | 0.46 | 0.54 | 0.28 | 1.12 | 0.30 | 0.48 | 1.39 | 3.65 | |

| OL-5 | 66.18 | 12.76 | 34.68 | 48.72 | 65.40 | 9.89 | 34.40 | 64.58 | 99.86 |

| 0.89 | 0.63 | 1.35 | 2.25 | 1.32 | 0.53 | 0.43 | 3.43 | 0.94 | |

| OL-6 | 63.41 | 11.25 | 27.49 | 47.86 | 59.10 | 9.54 | 29.18 | 50.02 | 93.16 |

| 2.31 | 1.36 | 2.14 | 2.44 | 1.70 | 0.34 | 0.70 | 1.61 | 1.84 | |

| OL-7 | 69.30 | 10.44 | 26.29 | 12.84 | 64.95 | 9.79 | 30.34 | 39.30 | 78.60 |

| 0.63 | 0.29 | 0.17 | 0.51 | 2.52 | 0.44 | 0.58 | 2.10 | 2.73 | |

| OL-8 | 72.65 | 10.09 | 25.29 | 27.64 | 68.50 | 7.25 | 21.89 | 30.48 | 93.36 |

| 0.51 | 0.27 | 0.73 | 1.89 | 0.52 | 0.25 | 0.53 | 0.51 | 1.21 | |

| OL-9 | 70.61 | 7.22 | 16.98 | 31.90 | 68.49 | 6.44 | 17.34 | 27.34 | 109.15 |

| 0.74 | 0.75 | 1.06 | 2.08 | 0.22 | 0.16 | 0.36 | 0.34 | 1.73 | |

| OL-10 | 62.50 | 12.96 | 31.47 | 58.42 | 62.78 | 10.20 | 32.72 | 67.66 | 104.47 |

| 1.18 | 0.38 | 0.53 | 2.06 | 1.00 | 0.34 | 0.21 | 1.84 | 3.15 | |

| OL-11 | 55.98 | 18.32 | 33.59 | 10.44 | 52.11 | 16.22 | 31.29 | 26.32 | 103.37 |

| 1.62 | 0.41 | 0.94 | 0.56 | 0.83 | 0.20 | 0.63 | 2.85 | 0.54 | |

| OL-12 | 58.91 | 14.91 | 28.48 | 75.84 | 55.01 | 14.38 | 29.61 | 69.46 | 105.22 |

| 0.74 | 0.18 | 0.35 | 1.61 | 0.57 | 0.23 | 0.50 | 1.40 | 1.9 | |

| Coating Systems | European Larch | Siberian Larch | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ∆G168 | ∆G504 | ∆G1008 | ∆G1512 | ∆G2016 | ∆G168 | ∆G504 | ∆G1008 | ∆G1512 | ∆G2016 | |

| REF | 3.86 | 61.60 | 93.63 | 64.44 | 34.76 | −2.93 | −15.13 | −3.00 | −29.22 | −37.75 |

| AC-1 | 0.28 | −11.01 | −5.53 | −9.29 | −5.45 | −3.16 | −21.48 | −30.13 | −52.44 | −50.69 |

| AC-2 | 20.24 | 38.79 | 47.24 | 40.62 | 44.54 | 13.16 | 15.89 | 19.41 | 20.71 | 26.97 |

| AC-3 | −8.14 | −6.24 | −13.72 | −20.09 | −29.81 | −2.02 | −12.31 | −19.81 | −24.56 | −29.35 |

| AL-1 | −19.37 | −26.88 | −25.17 | −27.22 | −25.12 | −13.78 | −19.20 | −23.29 | −19.44 | −12.47 |

| AL-2 | −2.38 | −5.04 | −14.72 | 6.02 | 12.41 | −4.62 | −5.46 | −4.62 | −18.55 | −42.99 |

| SL-1 | −12.66 | −15.48 | −18.06 | 1.87 | 20.71 | −6.29 | −13.66 | −9.84 | 8.92 | 12.69 |

| SL-2 | 4.68 | 14.40 | 16.92 | 16.53 | 14.91 | 1.00 | −8.26 | −2.57 | −18.24 | −31.99 |

| SL-3 | −31.35 | −41.91 | −40.67 | −9.59 | 0.98 | −46.87 | −55.74 | −43.18 | −37.92 | −39.87 |

| OL-1 | 11.40 | −9.03 | −38.10 | −68.53 | −82.44 | −19.98 | −4.15 | −40.62 | −73.32 | −84.38 |

| OL-2 | −32.12 | −32.21 | −14.00 | −25.55 | −33.16 | −43.01 | −49.15 | −43.95 | −49.37 | −52.03 |

| OL-3 | −7.82 | −17.91 | −20.89 | −23.89 | −21.60 | −16.57 | −37.44 | −44.86 | −42.74 | −42.32 |

| OL-4 | −17.70 | 7.76 | 32.73 | 2.00 | −19.73 | −38.55 | −57.97 | −64.70 | −74.11 | −78.31 |

| OL-5 | −21.72 | −51.77 | −69.50 | −60.82 | −73.08 | −18.38 | −44.94 | −65.70 | −70.54 | −86.97 |

| OL-6 | −3.13 | −32.01 | −43.20 | −58.14 | −68.03 | −13.42 | −37.52 | −52.36 | −62.53 | −68.06 |

| OL-7 | −2.76 | −8.54 | −26.01 | −35.60 | −37.20 | −14.57 | −31.50 | −63.59 | −73.75 | −76.32 |

| OL-8 | 65.89 | 86.50 | 82.04 | 29.59 | −52.05 | 42.75 | 40.40 | 47.26 | −31.74 | −66.75 |

| OL-9 | −43.85 | −60.27 | −60.32 | −63.94 | −70.94 | −49.02 | −61.22 | −64.65 | −64.95 | −73.01 |

| OL-10 | −40.73 | −82.93 | −89.28 | −87.75 | −80.54 | −66.09 | −86.18 | −92.40 | −91.87 | −92.01 |

| OL-11 | −50.04 | −68.00 | −71.39 | −60.53 | −71.34 | −56.11 | −75.75 | −78.02 | −80.74 | −91.31 |

| OL-12 | −28.37 | −35.54 | −41.14 | −49.49 | −57.52 | −24.41 | −39.54 | −51.23 | −56.54 | −73.04 |

| Coating | European Larch (B-AW) | Siberian Larch (B-AW) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GAM (from 1 to 4) | GAM (from 1 to 4) | |||||||||

| 4 Day | 7 Day | 14 Day | 21 Day | 28 Day | 4 Day | 7 Day | 14 Day | 21 Day | 28 Day | |

| REF | 2–3 | 3–4 | 3–4 | 4 | 4 | 3–4 | 4 | 4 | 4 | 4 |

| AC-1 | 0–1 | 1 | 1-2 | 2 | 2–3 | 0 | 0-1 | 1 | 1 | 1–2 |

| AC-2 | 0–1 | 0–1 | 0-1 | 0–1 | 0–1 | 0 | 0 | 0 | 0 | 0 |

| AC-3 | 2–3 | 3 | 3–4 | 3–4 | 3–4 | 1–2 | 2–3 | 2–3 | 2–3 | 2–4 |

| AL-1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| AL-2 | 2 | 3–4 | 3–4 | 3–4 | 3–4 | 2 | 3–4 | 4 | 4 | 4 |

| SL-1 | 0 | 0 | 0 | 0 | 0-1 | 0 | 0 | 0 | 0 | 0 |

| SL-2 | 0–1 | 0–1 | 1 | 1 | 1–2 | 0 | 0–1 | 0–1 | 0–1 | 1 |

| SL-3 | 2–3 | 3–4 | 3–4 | 3–4 | 3–4 | 1–2 | 2 | 2 | 2 | 2 |

| OL-1 | 1 | 1 | 2 | 2–3 | 3 | 1 | 1 | 1–2 | 2 | 2–3 |

| OL-2 | 0 | 0–1 | 0-1 | 0-1 | 0–2 | 0 | 0 | 0 | 0 | 0 |

| OL-3 | 0–1 | 1–2 | 2–3 | 3 | 3 | 0 | 0 | 1 | 2 | 2–3 |

| OL-4 | 2–3 | 4 | 4 | 4 | 4 | 3–4 | 4 | 4 | 4 | 4 |

| OL-5 | 1–2 | 2–3 | 4 | 4 | 4 | 2 | 3 | 4 | 4 | 4 |

| OL-6 | 2–3 | 4 | 4 | 4 | 4 | 1–2 | 3–4 | 4 | 4 | 4 |

| OL-7 | 2 | 4 | 4 | 4 | 4 | 1–2 | 3-4 | 4 | 4 | 4 |

| OL-8 | 0 | 0 | 0–1 | 0–1 | 1–2 | 0 | 0 | 0 | 0 | 0–1 |

| OL-9 | 0 | 0 | 0 | 0–1 | 1 | 0 | 0 | 0 | 0 | 0 |

| OL-10 | 0–1 | 2 | 2–3 | 2–4 | 3–4 | 1 | 2 | 2–3 | 3 | 3–4 |

| OL-11 | 1–3 | 2–4 | 3–4 | 4 | 4 | 1–2 | 2 | 2–3 | 2–3 | 2–3 |

| OL-12 | 0–1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0–1 |

| Coating | European Larch (A-AW) | Siberian Larch (A-AW) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| GAM (from 1 to 4) | GAM (from 1 to 4) | |||||||||

| 4 Day | 7 Day | 14 Day | 21 Day | 28 Day | 4 Day | 7 Day | 14 Day | 21 Day | 28 Day | |

| REF | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| AC-1 | 2–3 | 3–4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| AC-2 | 1–2 | 3–4 | 3–4 | 4 | 4 | 1–3 | 2–3 | 2–4 | 3–4 | 3–4 |

| AC-3 | 2–3 | 3 | 3 | 3–4 | 3–4 | 3 | 3–4 | 3–4 | 3–4 | 3–4 |

| AL-1 | 2–3 | 4 | 4 | 4 | 4 | 2–3 | 3 | 3–4 | 3–4 | 4 |

| AL-2 | 2–3 | 3 | 3–4 | 3–4 | 3–4 | 4 | 4 | 4 | 4 | 4 |

| SL-1 | 1–3 | 3 | 3–4 | 3–4 | 3–4 | 3–4 | 4 | 4 | 4 | 4 |

| SL-2 | 1–2 | 1–2 | 2–3 | 2–3 | 3 | 1–3 | 2–3 | 3–4 | 3–4 | 3–4 |

| SL-3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| OL-1 | 1–2 | 2–3 | 3–4 | 3–4 | 4 | 1–2 | 2–3 | 2–3 | 3–4 | 3–4 |

| OL-2 | 4 | 4 | 4 | 4 | 4 | 3 | 4 | 4 | 4 | 4 |

| OL-3 | 1–2 | 2–3 | 3–4 | 3–4 | 3–4 | 1 | 1–2 | 1–2 | 2–3 | 3 |

| OL-4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| OL-5 | 2–3 | 3 | 3–4 | 3–4 | 3–4 | 3–4 | 3–4 | 4 | 4 | 4 |

| OL-6 | 2–3 | 3–4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| OL-7 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| OL-8 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| OL-9 | 0–1 | 1 | 1–2 | 1–2 | 1–2 | 1–3 | 2–3 | 2–3 | 2–4 | 2–4 |

| OL-10 | 3–4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| OL-11 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| OL-12 | 2–4 | 3–4 | 3–4 | 3–4 | 4 | 4 | 4 | 4 | 4 | 4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šimůnková, K.; Oberhofnerová, E.; Reinprecht, L.; Pánek, M.; Podlena, M.; Štěrbová, I. Durability of Selected Transparent and Semi-Transparent Coatings on Siberian and European Larch during Artificial Weathering. Coatings 2019, 9, 39. https://doi.org/10.3390/coatings9010039

Šimůnková K, Oberhofnerová E, Reinprecht L, Pánek M, Podlena M, Štěrbová I. Durability of Selected Transparent and Semi-Transparent Coatings on Siberian and European Larch during Artificial Weathering. Coatings. 2019; 9(1):39. https://doi.org/10.3390/coatings9010039

Chicago/Turabian StyleŠimůnková, Kristýna, Eliška Oberhofnerová, Ladislav Reinprecht, Miloš Pánek, Milan Podlena, and Irena Štěrbová. 2019. "Durability of Selected Transparent and Semi-Transparent Coatings on Siberian and European Larch during Artificial Weathering" Coatings 9, no. 1: 39. https://doi.org/10.3390/coatings9010039

APA StyleŠimůnková, K., Oberhofnerová, E., Reinprecht, L., Pánek, M., Podlena, M., & Štěrbová, I. (2019). Durability of Selected Transparent and Semi-Transparent Coatings on Siberian and European Larch during Artificial Weathering. Coatings, 9(1), 39. https://doi.org/10.3390/coatings9010039