Pulsed Laser Deposition of Indium Tin Oxide Thin Films on Nanopatterned Glass Substrates

Abstract

1. Introduction

2. Experimental Section

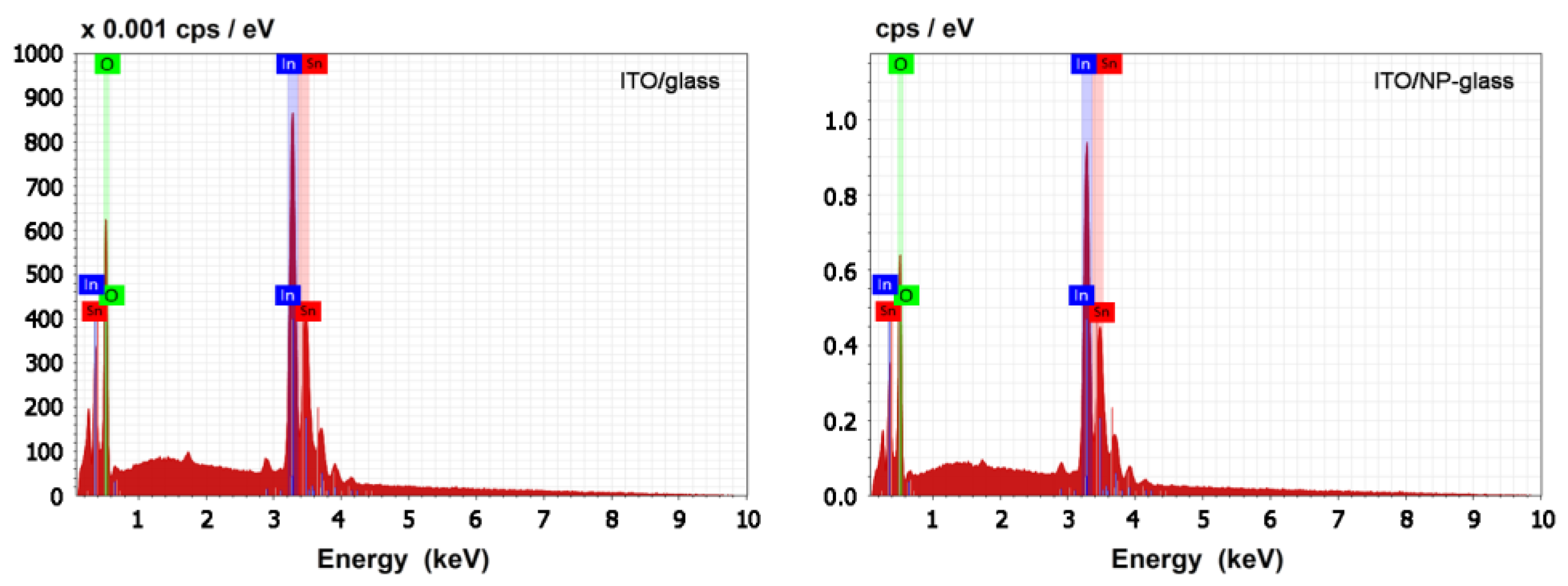

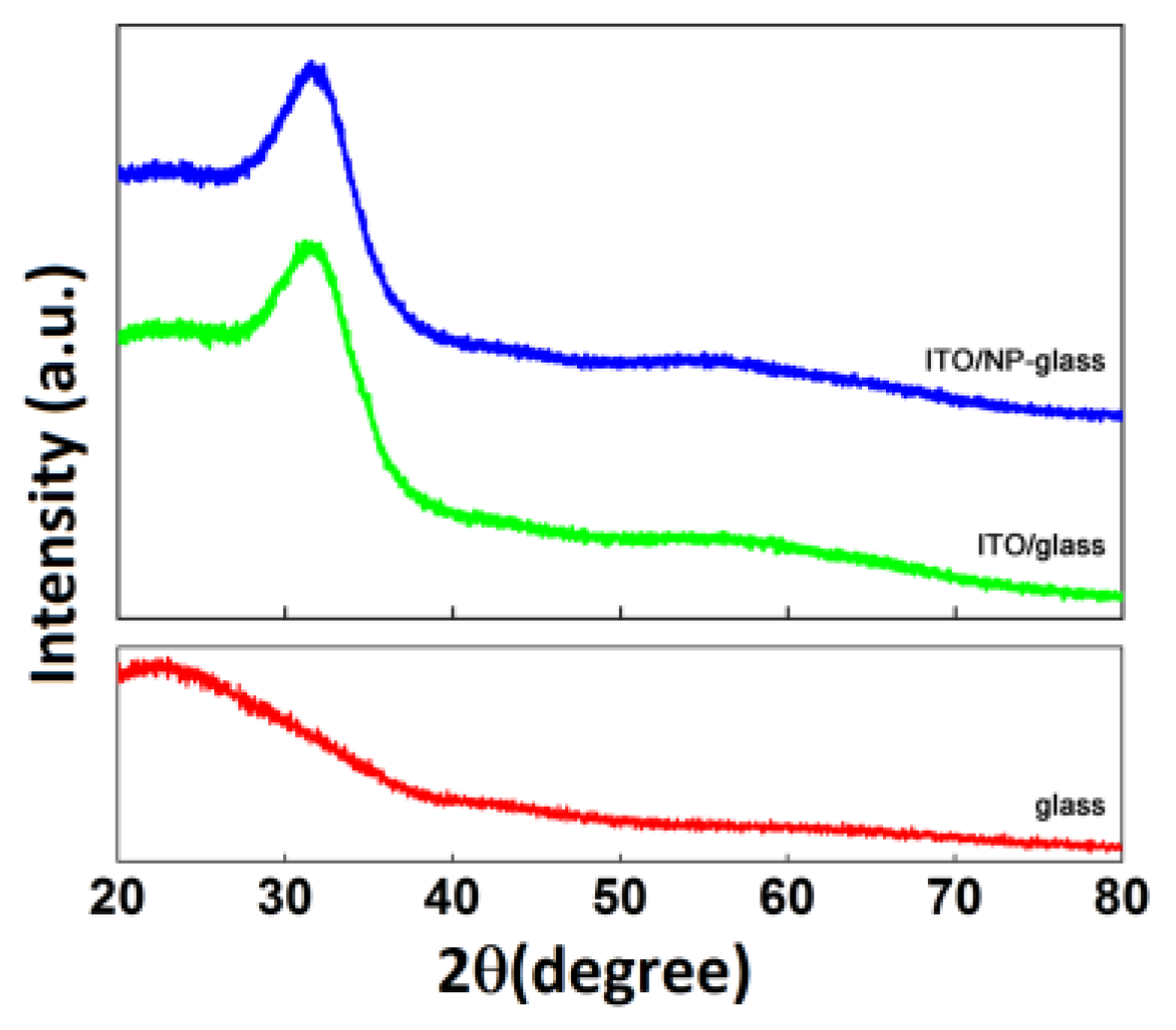

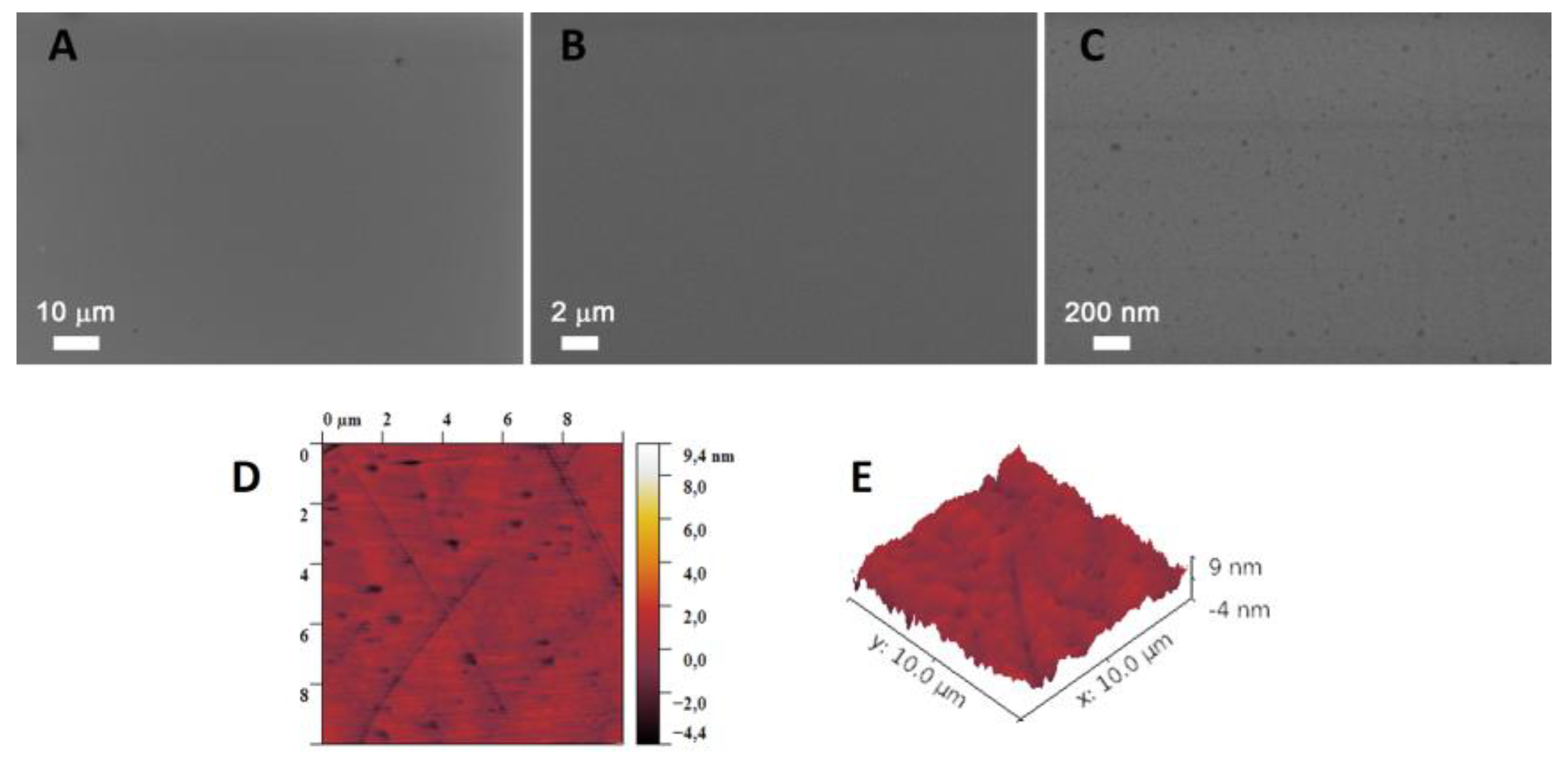

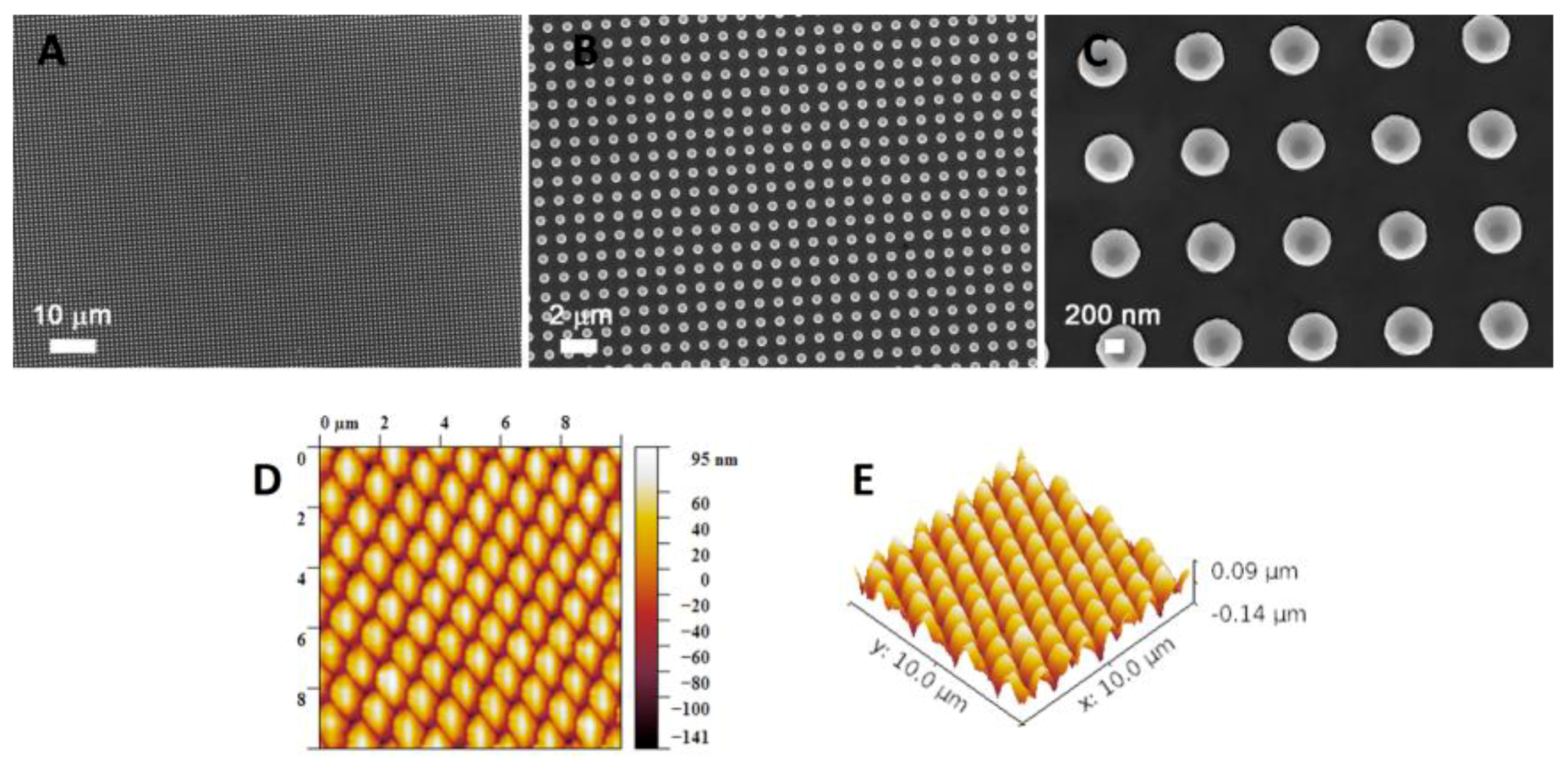

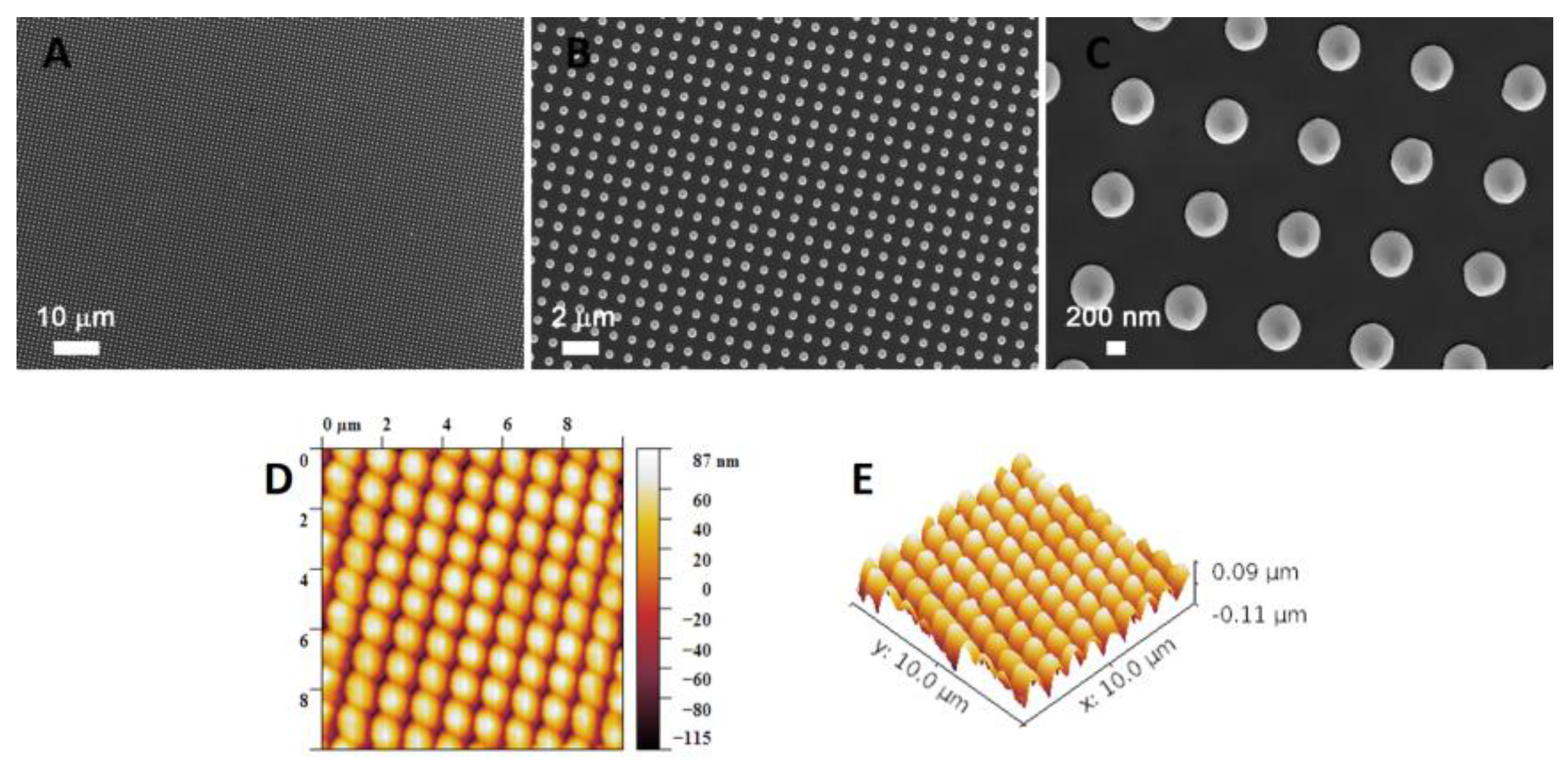

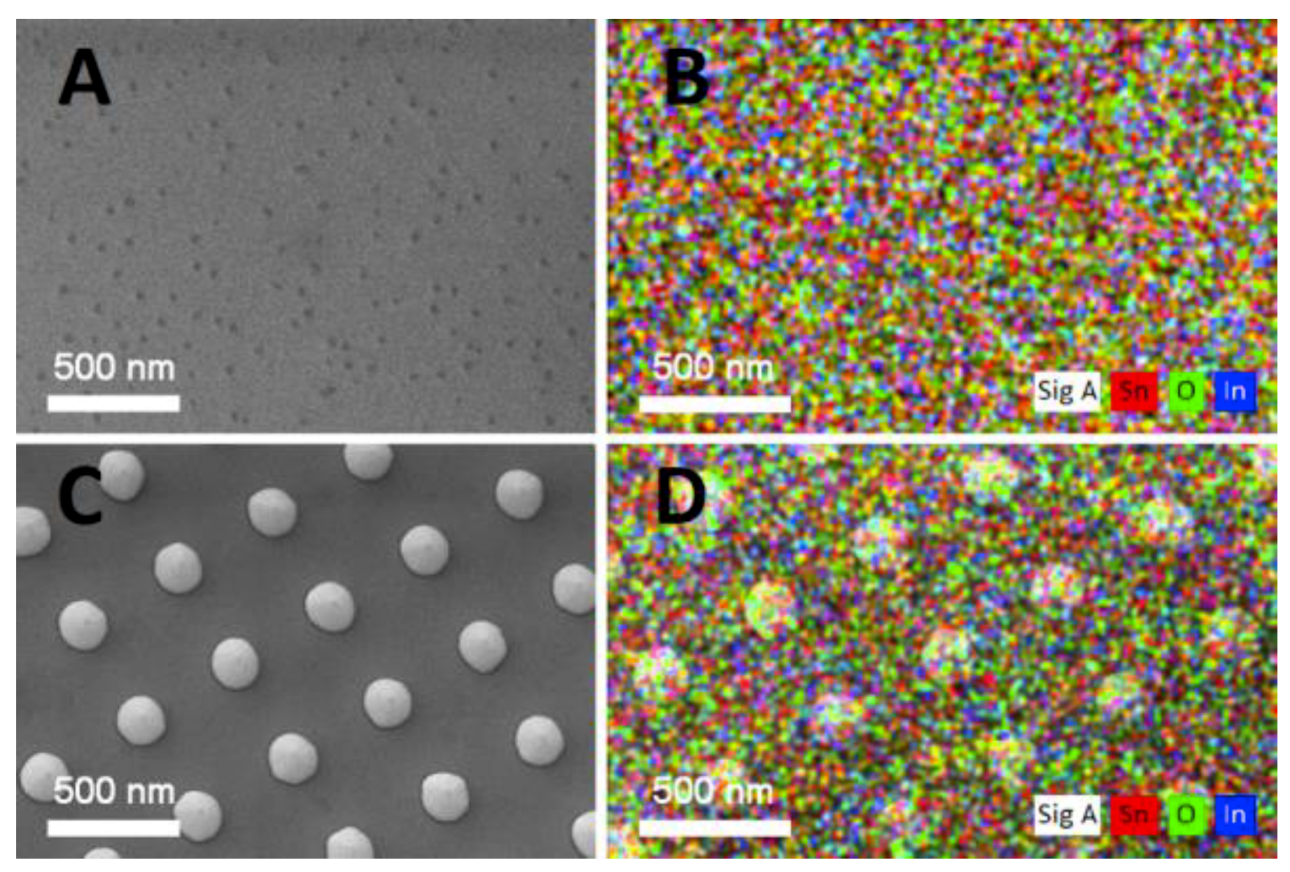

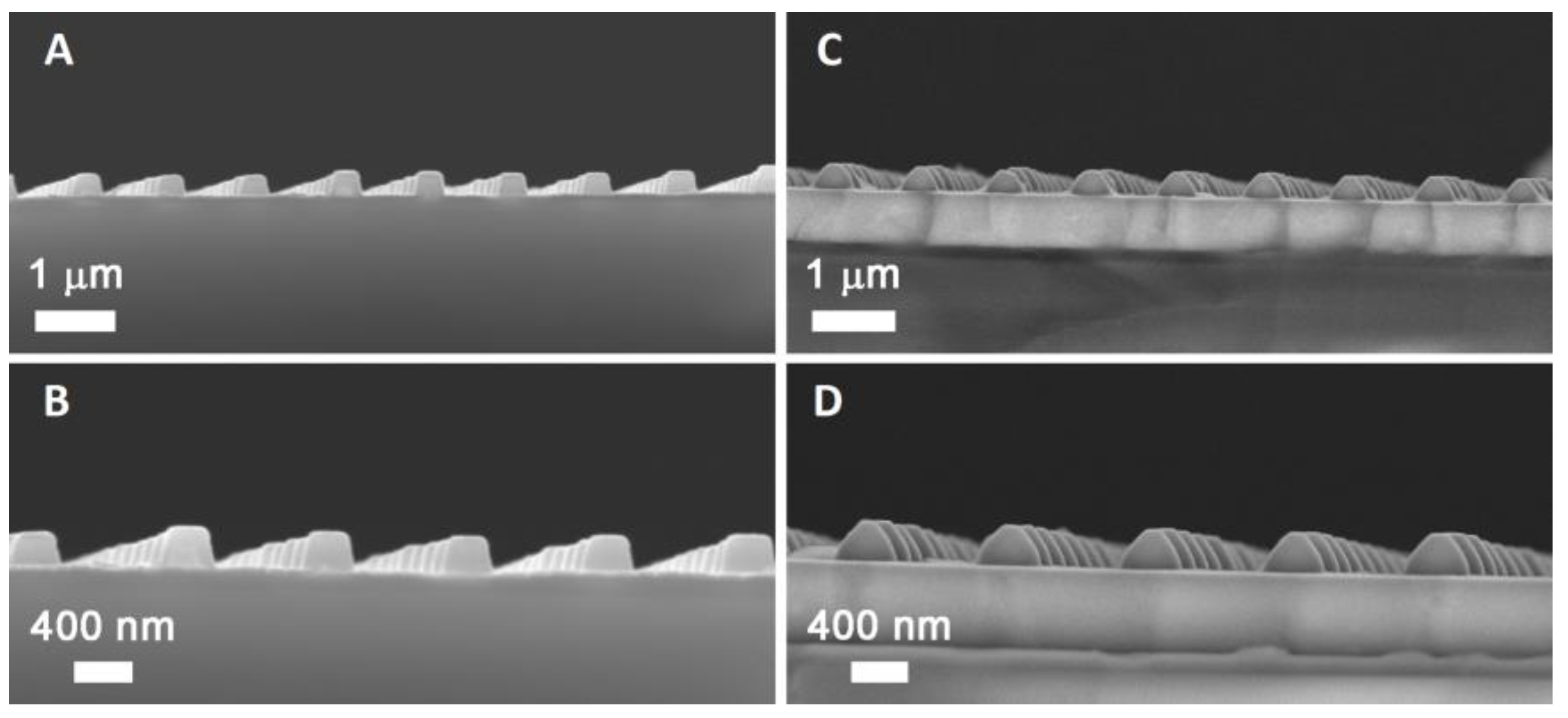

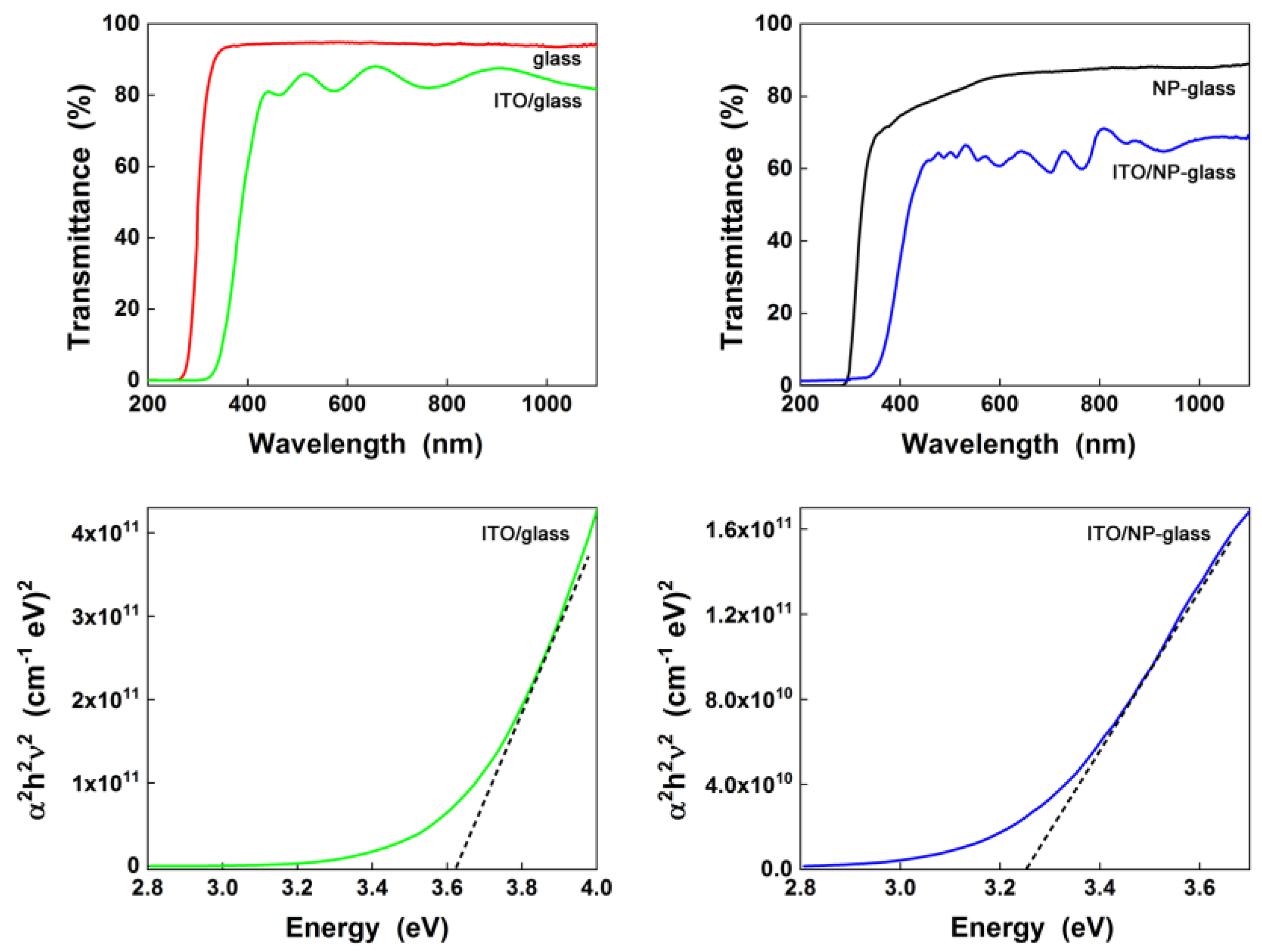

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eason, R. Pulsed Laser Deposition of Thin Films: Applications-Led Growth of Functional Materials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; pp. 240–255. [Google Scholar]

- Bright, C.I. Review of transparent conductive oxides (TCO). In 50 Years of Vacuum Coating Technology and the Growth of the Society of Vacuum Coaters; Society of Vacuum Coaters: Materials Park, OH, USA, 2007. [Google Scholar]

- Afre, R.A.; Sharma, N.; Sharon, M.; Sharon, M. Transparent conducting oxide films for various applications: A review. Rev. Adv. Mater. Sci. 2018, 53, 79–89. [Google Scholar]

- Hosono, H.; Ueda, K. Transparent conductive oxides. In Springer Handbook of Electronic and Photonic Materials; Kasap, S., Capper, P., Eds.; Springer: Berlin, Germany, 2017; pp. 1391–1404. [Google Scholar]

- Cao, W.; Li, J.; Chen, H.; Xue, J. Transparent electrodes for organic optoelectronic devices: A review. J. Photonics Energy 2014, 4, 040990. [Google Scholar] [CrossRef]

- Hosono, H.; Kim, J.; Toda, Y.; Kamiya, T.; Watanabe, S. Transparent amorphous oxide semiconductors for organic electronics: Application to inverted OLEDs. Pro. Nati. Acad. Sci. 2017, 114, 233–238. [Google Scholar] [CrossRef] [PubMed]

- Mbule, P.; Wang, D.; Grieseler, R.; Schaaf, P.; Muhsin, B.; Hoppe, H.; Mothudi, B.; Dhlamini, M. Aluminum-doped ZnO thin films deposited on flat and nanostructured glass substrates: Quality and performance for applications in organic solar cells. Sol. Energy 2018, 172, 219–224. [Google Scholar] [CrossRef]

- Prepelita, P.; Filipescu, M.; Stavarache, I.; Garoi, F.; Craciun, D. Transparent thin films of indium tin oxide: Morphology–optical investigations, inter dependence analyzes. Appl. Surf. Sci. 2017, 424, 368–373. [Google Scholar] [CrossRef]

- Starkov, I.A.; Nyapshaev, I.A.; Starkov, A.S.; Abolmasov, S.N.; Abramov, A.S.; Levitskii, V.S.; Terukov, E.I. Influence of substrate movement on the ITO film thickness distribution during magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Films 2017, 35, 061301. [Google Scholar] [CrossRef]

- Meng, L.J.; Gao, J.; Silva, R.A.; Song, S. Effect of the oxygen flow on the properties of ITO thin films deposited by ion beam assisted deposition (IBAD). Thin Solid Films 2008, 516, 5454–5459. [Google Scholar] [CrossRef]

- Kim, S.J.; Choi, S.Y.; Choi, K. Preparation and characterization of ITO thin films deposition by ion beam assisted deposition. J. Korean Inst. Met. Mater. 2014, 52, 475–484. [Google Scholar] [CrossRef]

- Atabaev, I.G.; Hajiev, M.U.; Pak, V.A. Growth of ITO films by modified chemical vapor deposition method. Int. J. Thin Films Sci. Technol. 2016, 5, 13–16. [Google Scholar]

- Nishinaka, H.; Yoshimoto, M. Mist chemical vapor deposition of single-phase metastable rhombohedral indium tin oxide epitaxial thin films with high electrical conductivity and transparency on various α-Al2O3 substrates. Cryst. Growth Des. 2018, 18, 4022–4028. [Google Scholar] [CrossRef]

- Socol, G.; Socol, M.; Stefan, N.; Axente, E.; Popescu-Pelin, G.; Craciun, D.; Duta, L.; Mihailescu, C.N.; Mihailescu, I.N.; Stanculescu, A.; et al. Pulsed laser deposition of transparent conductive oxide thin films on flexible substrates. Appl. Surf. Sci. 2012, 260, 42–46. [Google Scholar] [CrossRef]

- Craciun, V.; Chiritescu, C.; Kelly, F.; Singh, R.K. Low temperature growth of smooth indium tin oxide films by ultraviolet assisted pulsed laser deposition. J. Optoelectron. Adv. Mater. 2002, 4, 21–25. [Google Scholar]

- Ohta, H.; Orita, M.; Hirano, M.; Tanji, H.; Kawazoe, H.; Hosono, H. Highly electrically conductive indium-tin-oxide thin films epitaxially grown on yttria-stabilized zirconia (100) by pulsed-laser deposition. Appl. Phys. Lett. 2000, 76, 2740–2742. [Google Scholar] [CrossRef]

- Suzuki, A.; Mastsushita, T.; Aoki, T.; Yoneyama, Y.; Okuda, M. Pulsed laser deposition of transparent conducting indium tin oxide films in magnetic field perpendicular to plume. Jpn. J. Appl. Phys. 2001, 40, L401. [Google Scholar] [CrossRef]

- Kim, H.; Horwitz, J.S.; Pique, A.; Gilmore, C.M.; Chrisey, D.B. Electrical and optical properties of indium tin oxide thin films grown by pulsed laser deposition. Appl. Phys. A 1999, 69, S447–S450. [Google Scholar] [CrossRef]

- Kim, H.; Gilmore, C.M.; Pique´, A.; Horwitz, J.S.; Mattoussi, H.; Murata, H.; Kafafi, Z.H.; Chrisey, D.B. Electrical, optical, and structural properties of indium-tin-oxide thin films for organic light-emitting devices. J. Appl. Phys. 1999, 86, 6451–6461. [Google Scholar] [CrossRef]

- Bi, Y.-G.; Feng, J.; Ji, J.-H.; Yi, F.-S.; Li, Y.-F.; Liu, Y.-F.; Zhang, X.-L.; Sun, H.-B. Nanostructures induced light harvesting enhancement in organic photovoltaics. Nanophotonics 2018, 7, 371–391. [Google Scholar] [CrossRef]

- Ferry, V.E.; Verschuuren, M.A.; Lare, M.C.V.; Schropp, R.E.; Atwater, H.A.; Polman, A. Optimized spatial correlations for broadband light trapping nanopatterns in high efficiency ultrathin film a-Si:H solar cells. Nano Lett. 2011, 11, 4239–4245. [Google Scholar] [CrossRef]

- Choo, S.; Choi, J.; Choi, H.-J.; Huh, D.; Son, S.; Kim, Y.D.; Lee, H. Enhancement of light extraction efficiency for GaN-based light emitting diodes using ZrO2 high-aspect-ratio pattern as scattering layer. Ceram. Int. 2017, 43, S609–S612. [Google Scholar] [CrossRef]

- Saxena, K.; Jain, V.K.; Mehta, D.S. A review on the light extraction techniques in organic electroluminescent devices. Opt. Mater. 2009, 32, 221–233. [Google Scholar] [CrossRef]

- Tseng, A.A.; Chen, K.; Chen, C.D.; Ma, K.J. Electron beam lithography in nanoscale fabrication: Recent development. IEEE Trans. Electron. Packag. Manuf. 2003, 26, 141–149. [Google Scholar] [CrossRef]

- Breazu, C.; Preda, N.; Socol, M.; Stanculescu, F.; Matei, E.; Stavarache, I.; Iordache, G.; Girtan, M.; Rasoga, O.; Stanculescu, A.I. Investigations on the properties of a two-dimensional nanopatterned metallic electrode. Dig. J. Nanomater. Biostructures 2016, 11, 1213–1229. [Google Scholar]

- Matsui, S. Three-dimensional nanostructure fabrication by focused-ion-beam chemical-vapor-deposition. Microsc. Microanal. 2006, 12, 130–131. [Google Scholar] [CrossRef]

- Guo, L.J. Recent progress in nanoimprint technology and its applications. J. Phys. D Appl. Phys. 2004, 37, R123. [Google Scholar] [CrossRef]

- Lee, H.; Hong, S.; Yang, K.; Choi, K. Fabrication of nano-sized resist patterns on flexible plastic film using thermal curing nano-imprint lithography. Microelectron. Eng. 2006, 83, 323–327. [Google Scholar] [CrossRef]

- Austin, M.D.; Ge, H.; Wu, W.; Li, M.; Yu, Z.; Wasserman, D.; Lyon, S.A.; Chou, S.Y. Fabrication of 5 nm linewidth and 14 nm pitch features by nanoimprint lithography. Appl. Phys. Lett. 2004, 84, 5299–5301. [Google Scholar] [CrossRef]

- Akita, Y.; Sugimoto, Y.; Kobayashi, K.; Suzuki, T.; Oi, H.; Mita, M.; Yoshimoto, M. Crystal growth control of functional oxide thin films on nanopatterned substrate surfaces. J. Laser Micro/Nanoeng. 2009, 4, 202–206. [Google Scholar] [CrossRef]

- Akita, Y.; Miyake, Y.; Nakai, H.; Oi, H.; Mita, M.; Kaneko, S.; Mitsuhashi, M.; Yoshimoto, M. Evolution of atomically stepped surface of indium tin oxide thin films grown on nanoimprinted glass substrates. Appl. Phys. Express 2011, 4, 035201. [Google Scholar] [CrossRef]

- Liu, Y.; Kirsch, C.; Gadisa, A.; Aryal, M.; Mitran, S.; Samulski, E.T.; Lopez, R. Effects of nano-patterned versus simple flat active layers in upright organic photovoltaic devices. J. Phys. D Appl. Phys. 2013, 46, 024008. [Google Scholar] [CrossRef]

- Stanculescu, A.; Socol, M.; Socol, G.; Mihailescu, I.N.; Girtan, M.; Preda, N.; Albu, A.-M.; Stanculescu, F. Effect of maleic anhydride-aniline derivative buffer layer on the properties of flexible substrate heterostructures: Indium tin oxide/nucleic acid base/metal. Thin Solid Films 2011, 520, 1251–1258. [Google Scholar] [CrossRef]

- Stanculescu, A.; Rasoga, O.; Preda, N.; Socol, M.; Stanculescu, F.; Ionita, I.; Albu, A.-M.; Socol, G. Preparation and characterization of polar aniline functionalized copolymers thin films for optical non-linear applications. Ferroelectrics 2009, 389, 159–173. [Google Scholar] [CrossRef]

- Tseng, K.-S.; Lo, Y.-L. Effects of cumulative ion bombardment on ITO films deposited on PET and Si substrates by DC magnetron sputtering. Opt. Mater. Express 2014, 4, 764–775. [Google Scholar] [CrossRef]

- Ohshima, T.; Matsunaga, T.; Kawasaki, H.; Suda, Y.; Yagyu, Y. Preparation of ITO thin films by pulsed laser deposition for use as transparent electrodes in electrochromic display devices. Trans. Mater. Res. Soc. Jpn. 2010, 35, 583–587. [Google Scholar] [CrossRef]

- Schou, J. Physical aspects of the pulsed laser deposition technique: The stoichiometric transfer of material from target to film. Appl. Surf. Sci. 2009, 255, 5191–5198. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W.; Li, R.; Zhang, Y.; Xu, G.; Cheng, H. Fabrication of highly transparent and conductive indium-tin oxide thin films with a high figure of merit via solution processing. Langmuir 2013, 29, 13836–13842. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Park, N.M.; Kim, T.; Sung, G.Y. Electrical and optical characteristics of ITO films by pulsed laser deposition using a 10 wt.% SnO2-doped In2O3 ceramic target. Thin Solid Films 2005, 475, 262–266. [Google Scholar] [CrossRef]

- Swanepoel, R. Determination of surface roughness and optical constants of inhomogeneous amorphous silicon films. J. Phys. E Sci. Instrum. 1984, 17, 896–903. [Google Scholar] [CrossRef]

- Xia, G.; Wang, S. Solution patterning of ultrafine ITO and ZnRh2O4 nanowire array below 20 nm without etching process. Nanoscale 2011, 3, 3598–3600. [Google Scholar] [CrossRef]

- Babu, S.H.; Rao, N.M.; Kaleemulla, S.; Amarendra, G.; Krishnamoorthi, C. Room-temperature ferromagnetic and photoluminescence properties of indium–tin-oxide nanoparticles synthesized by solid-state reaction. Bull. Mater. Sci. 2017, 40, 17–23. [Google Scholar] [CrossRef]

- Luo, S.; Kohiki, S.; Okada, K.; Shoji, F.; Shishido, T. Hydrogen effects on crystallinity, photoluminescence, and magnetization of indium tin oxide thin films sputter-deposited on glass substrate without heat treatment. Phys. Status Solidi A 2010, 207, 386–390. [Google Scholar] [CrossRef]

- Lee, M.S.; Choi, W.C.; Kim, E.K.; Kim, C.K.; Min, S.K. Characterization of the oxidized indium thin films with thermal oxidation. Thin Solid Films 1996, 279, 1–3. [Google Scholar] [CrossRef]

- Thirumoorthi, M.; Thomas Joseph Prakash, J. Structure, optical and electrical properties of indium tin oxide ultrathin films prepared by jet nebulizer spray pyrolysis technique. J. Asian Ceram. Soc. 2016, 4, 124–132. [Google Scholar] [CrossRef]

- Venkatesh, P.S.; Ramakrishnan, V.; Jeganathan, K. Vertically aligned indium doped zinc oxide nanorods for the application of nanostructured anodes by radio frequency magnetron sputtering. CrystEngComm 2012, 14, 3907–3914. [Google Scholar] [CrossRef]

- Fang, X.; Mak, C.L.; Zhang, S.; Wang, Z.; Yuan, W.; Ye, H. Pulsed laser deposited indium tin oxides as alternatives to noble metals in the near-infrared region. J. Phys. Condens. Matter 2016, 28, 224009. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Maree, C.H.M.; Haglund, R.F., Jr.; Hamilton, J.D.; Morales Paliza, M.A.; Huang, M.B.; Feldman, L.C.; Weller, R.A. Resistivity and oxygen content of indium tin oxide films deposited at room temperature by pulsed-laser ablation. J. Appl. Phys. 1999, 86, 991–994. [Google Scholar] [CrossRef]

| Sample | Resistivity (Ωcm) | Mobility (cm2/Vs) | Carrier Concentration (cm−3) | Sheet Resistance (Ω/sq) |

|---|---|---|---|---|

| ITO/glass | 1.8 × 10−4 | 10.6 | 3.3 × 1021 | 5.3 |

| ITO/NP-glass | 2.8 × 10−4 | 15.1 | 1.5 × 1021 | 8 |

| ITO/NP-glass_bis | 2.7 × 10−4 | 14.6 | 1.6 × 1021 | 7.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Socol, M.; Preda, N.; Rasoga, O.; Costas, A.; Stanculescu, A.; Breazu, C.; Gherendi, F.; Socol, G. Pulsed Laser Deposition of Indium Tin Oxide Thin Films on Nanopatterned Glass Substrates. Coatings 2019, 9, 19. https://doi.org/10.3390/coatings9010019

Socol M, Preda N, Rasoga O, Costas A, Stanculescu A, Breazu C, Gherendi F, Socol G. Pulsed Laser Deposition of Indium Tin Oxide Thin Films on Nanopatterned Glass Substrates. Coatings. 2019; 9(1):19. https://doi.org/10.3390/coatings9010019

Chicago/Turabian StyleSocol, Marcela, Nicoleta Preda, Oana Rasoga, Andreea Costas, Anca Stanculescu, Carmen Breazu, Florin Gherendi, and Gabriel Socol. 2019. "Pulsed Laser Deposition of Indium Tin Oxide Thin Films on Nanopatterned Glass Substrates" Coatings 9, no. 1: 19. https://doi.org/10.3390/coatings9010019

APA StyleSocol, M., Preda, N., Rasoga, O., Costas, A., Stanculescu, A., Breazu, C., Gherendi, F., & Socol, G. (2019). Pulsed Laser Deposition of Indium Tin Oxide Thin Films on Nanopatterned Glass Substrates. Coatings, 9(1), 19. https://doi.org/10.3390/coatings9010019