Fabrication of Transparent Very Thin SiOx Doped Diamond-Like Carbon Films on a Glass Substrate

Abstract

1. Introduction

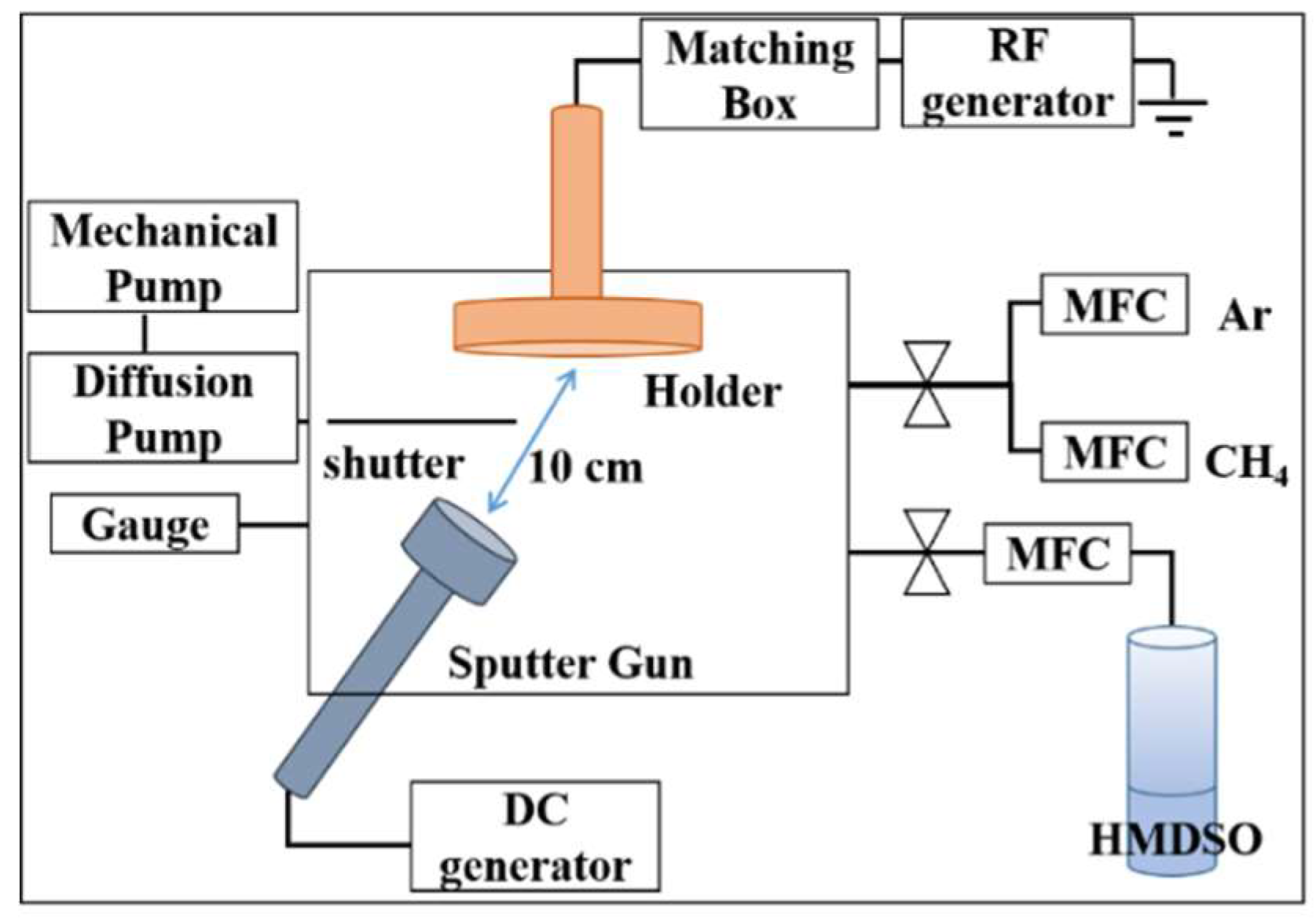

2. Experimental Section

2.1. Deposition of Transparent Very Thin Films

2.2. Measurements

3. Results and Discussion

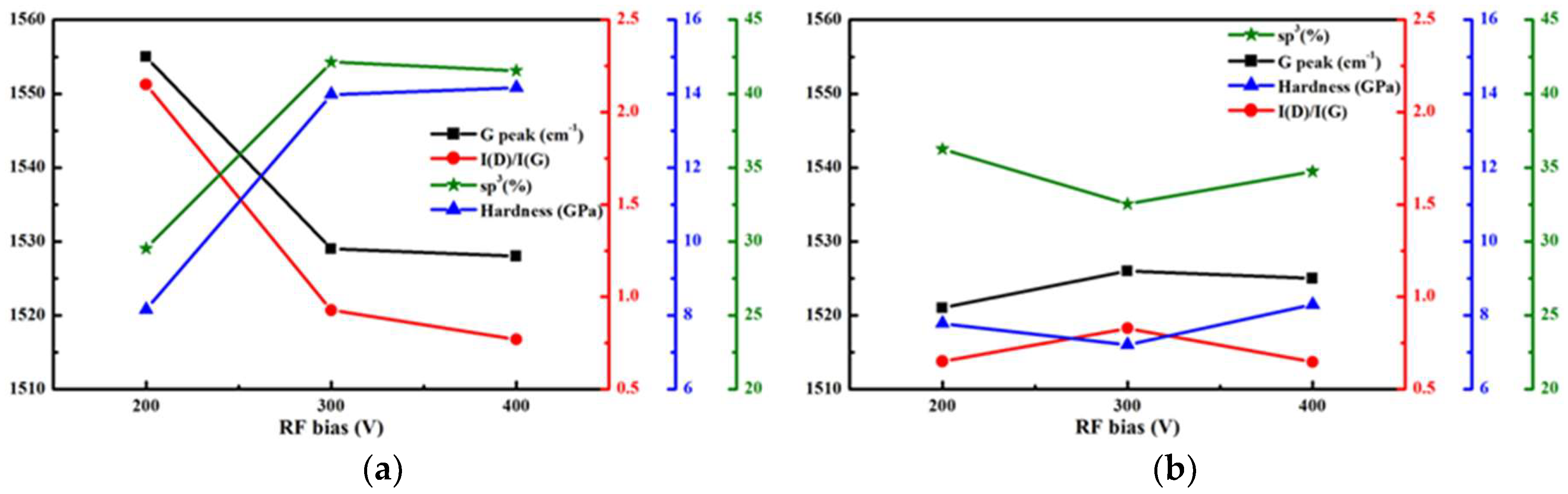

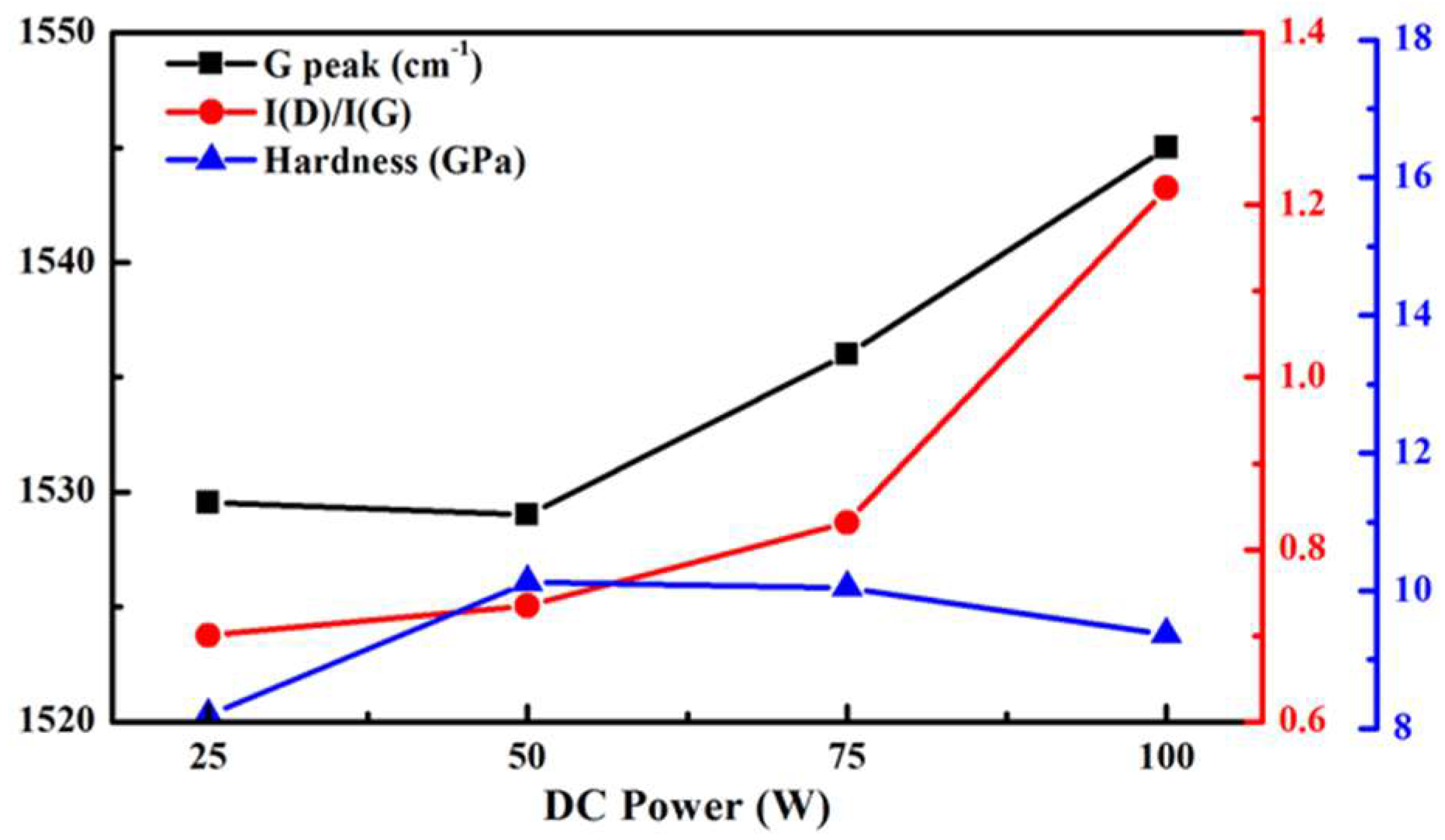

3.1. The Optimized DLC Films

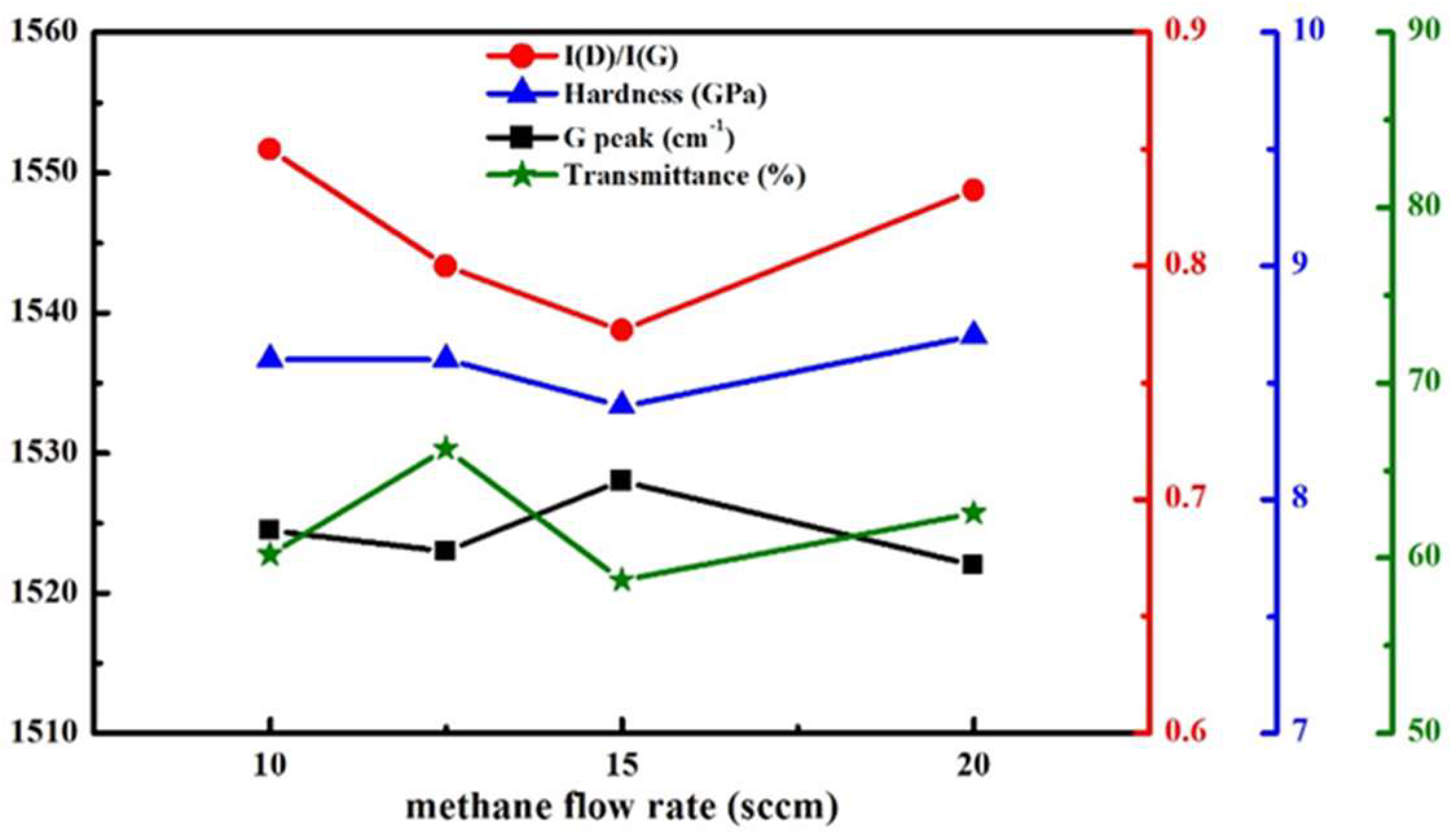

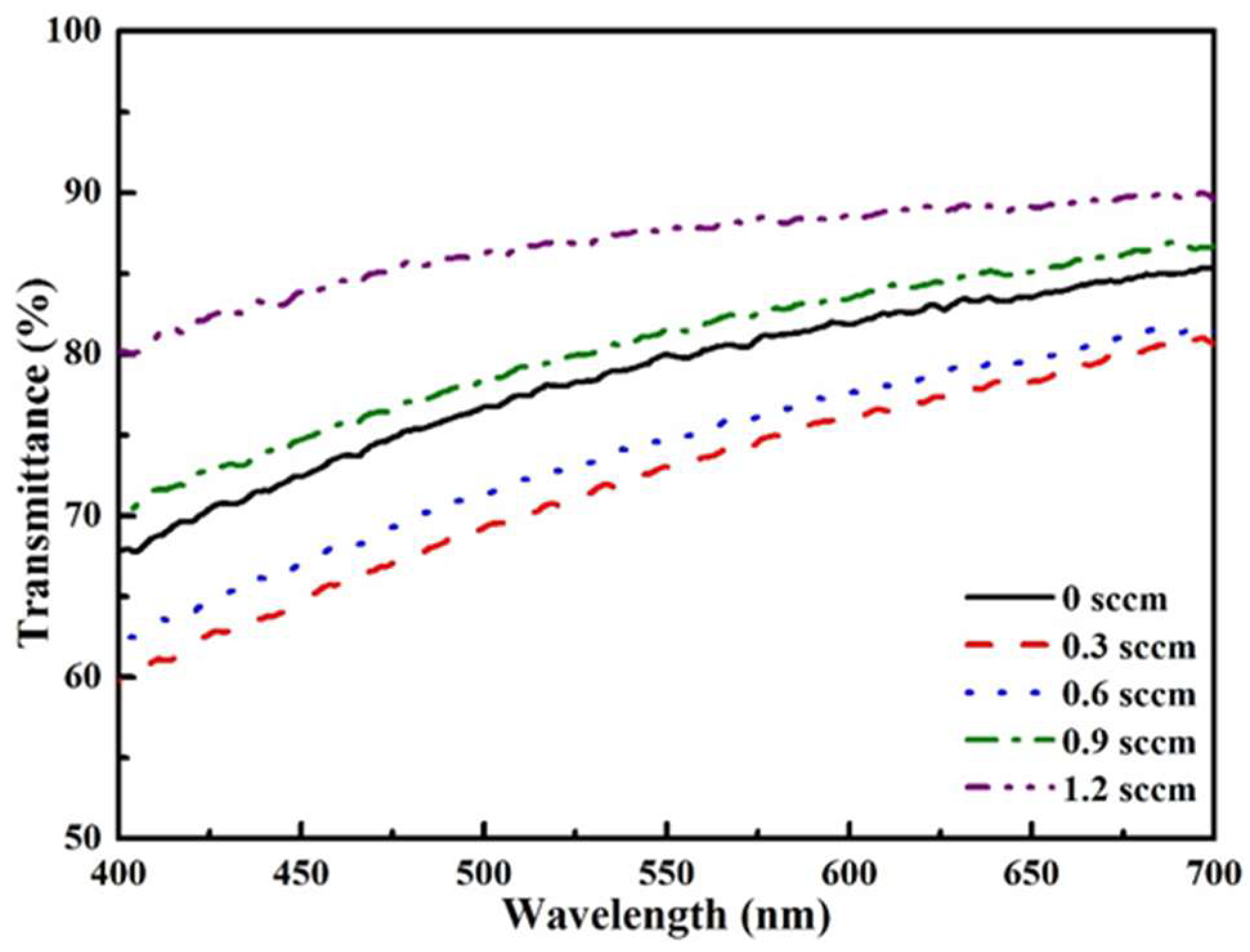

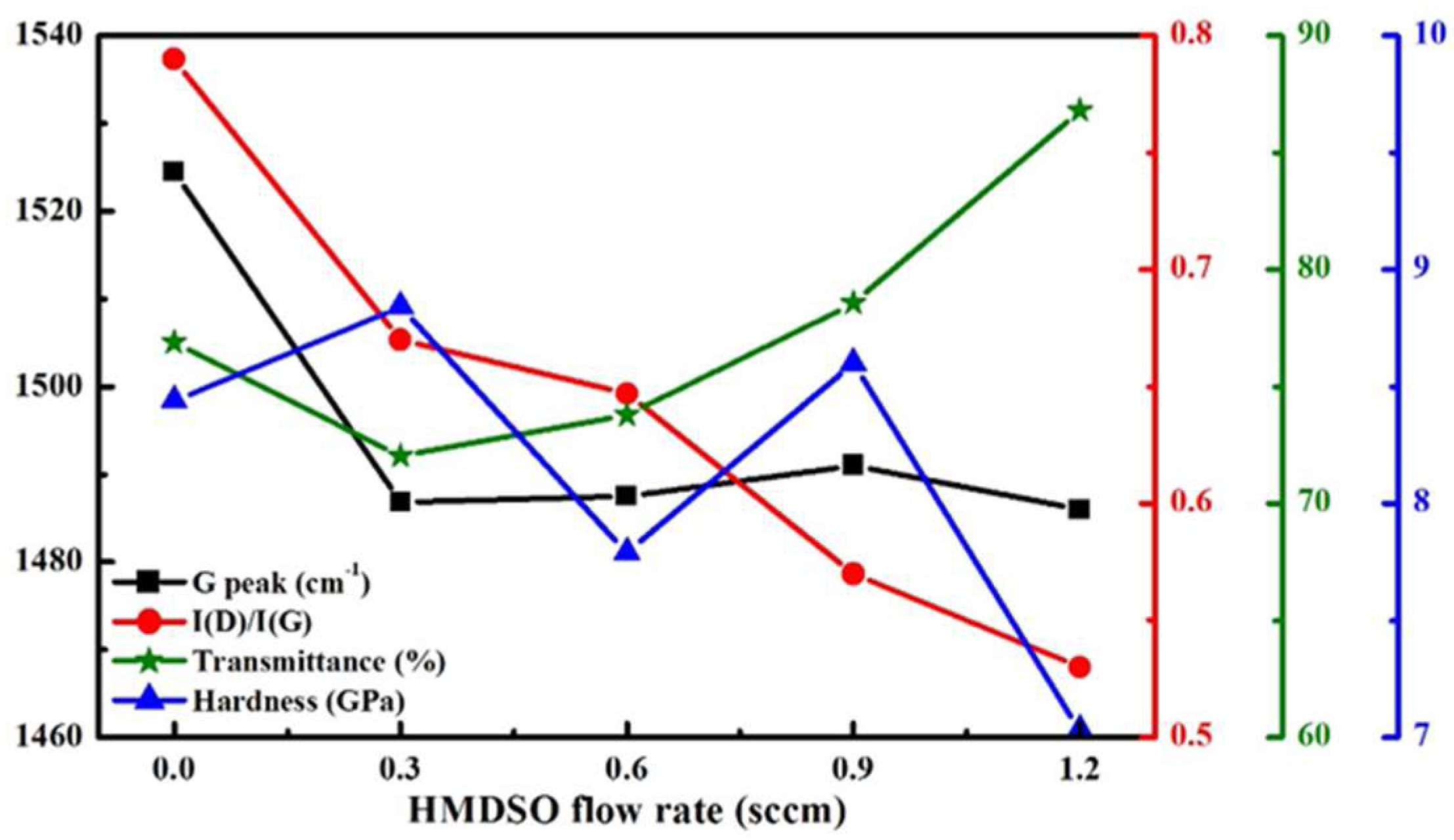

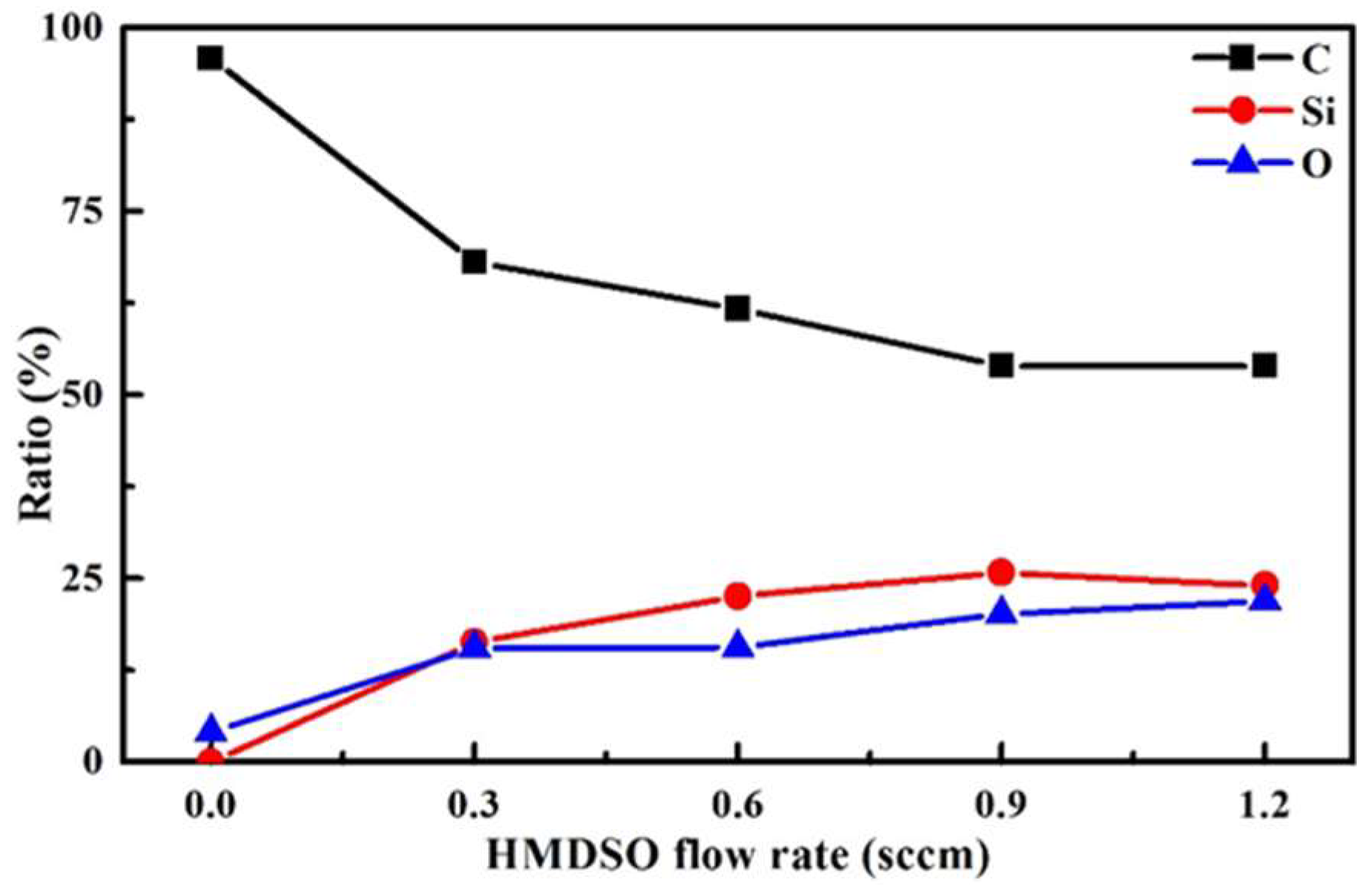

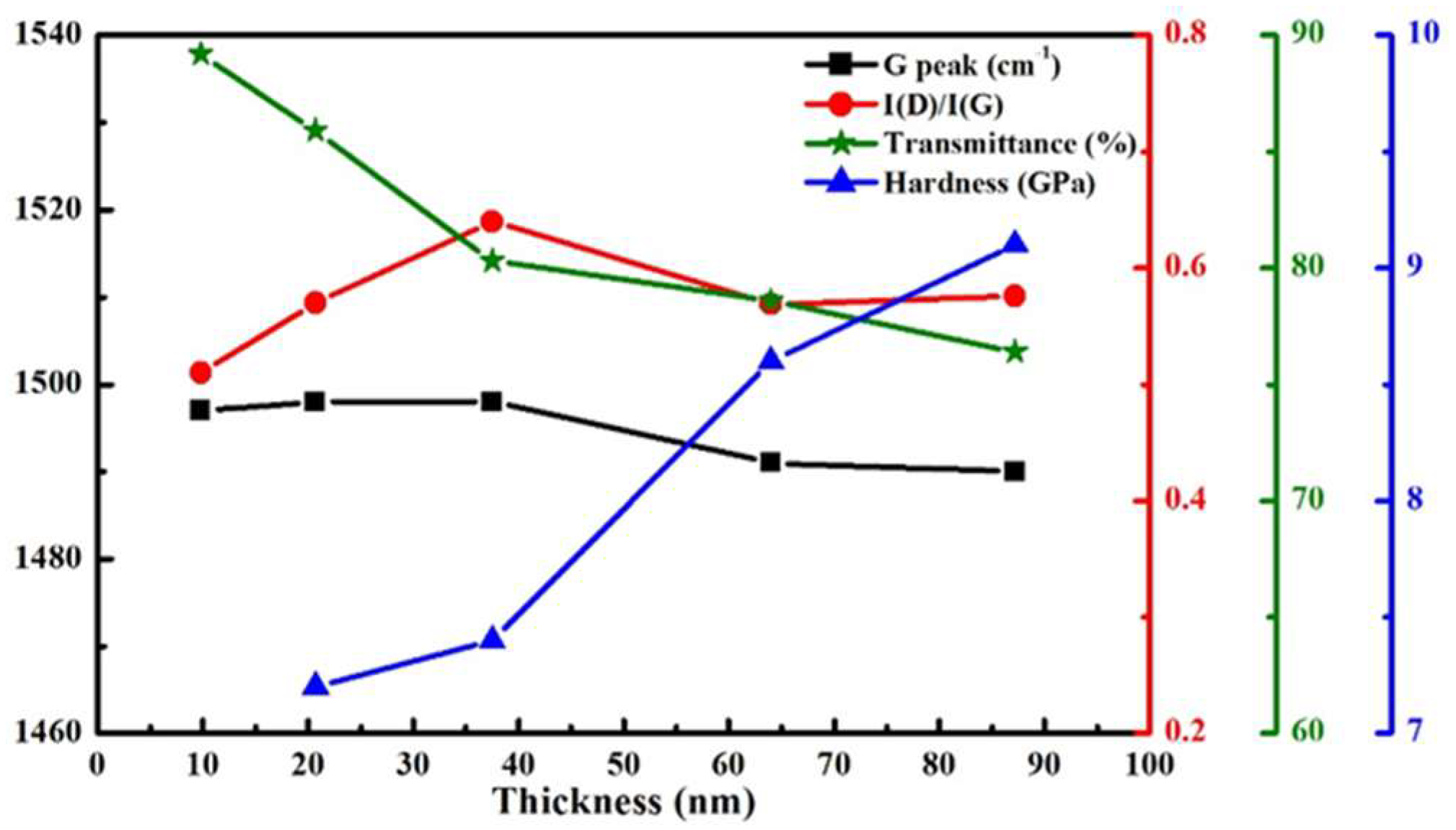

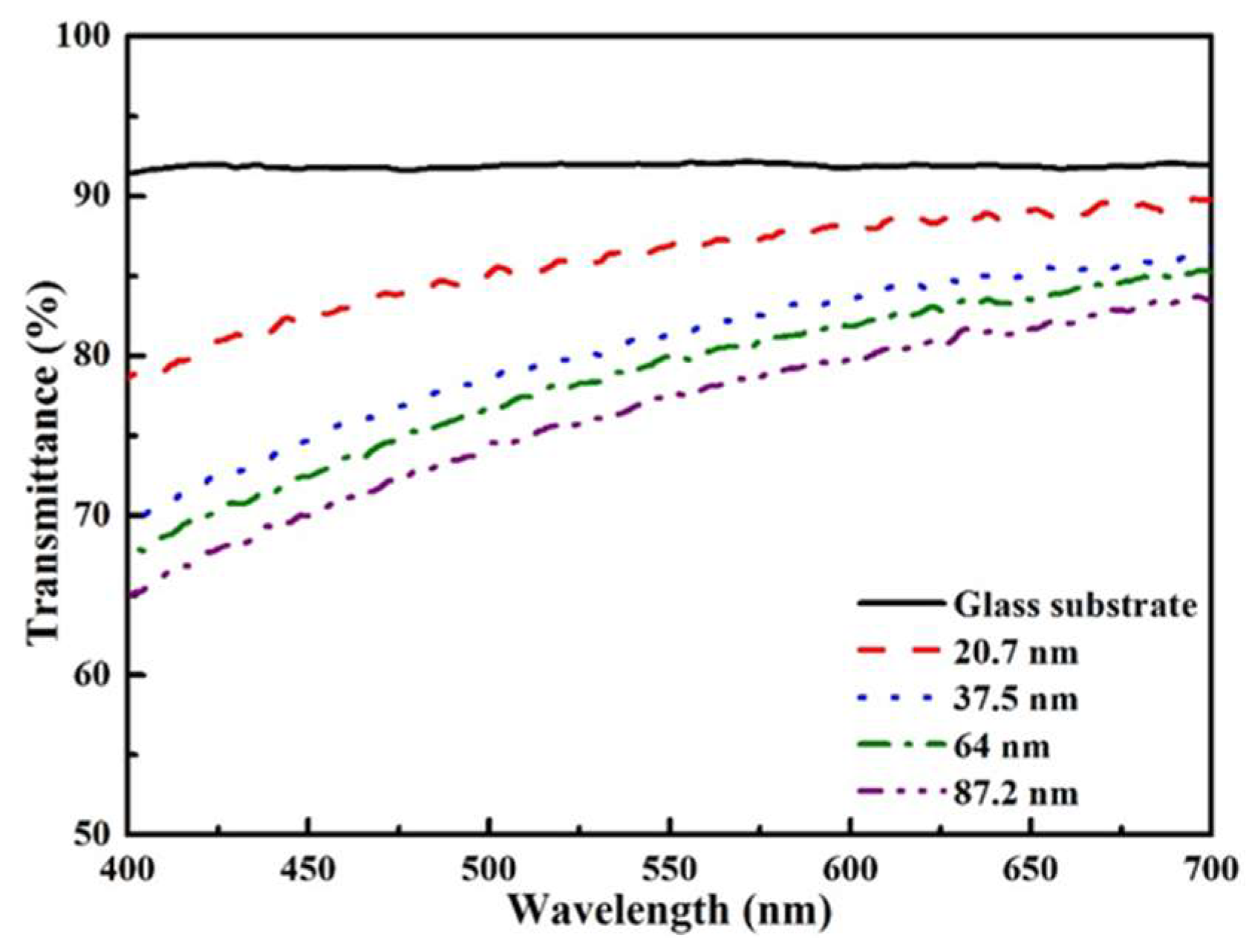

3.2. The Transparent Very Thin SiOx:DLC Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aisenberg, S.; Chabot, R. Deposition of carbon films with diamond properties. Carbon 1972, 10, 356. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Aisenberg, S.; Chabot, R. Ion-beam deposition of thin films of diamondlike carbon. J. Appl. Phys. 1971, 42, 2953–2958. [Google Scholar] [CrossRef]

- Grill, A. Plasma-deposited diamondlike carbon and related materials. IBM J. Res. Dev. 1999, 43, 147–162. [Google Scholar] [CrossRef]

- Bewilogua, K.; Hofmann, D. History of diamond-like carbon films—From first experiments to worldwide applications. Surf. Coat. Technol. 2014, 242, 214–225. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like carbon coatings as biocompatible materials—An overview. Diam. Relat. Mater. 2003, 12, 166–170. [Google Scholar] [CrossRef]

- Hauert, R. An overview on the tribological behavior of diamond-like carbon in technical and medical applications. Tribol. Int. 2004, 37, 991–1003. [Google Scholar] [CrossRef]

- Bewilogua, K.; Bräuer, G.; Dietz, A.; Gäbler, J.; Goch, G.; Karpuschewski, B.; Szyszka, B. Surface technology for automotive engineering. CIRP Ann. Manuf. Technol. 2009, 58, 608–627. [Google Scholar] [CrossRef]

- Treutler, C.P. Industrial use of plasma-deposited coatings for components of automotive fuel injection systems. Surf. Coat. Technol. 2005, 200, 1969–1975. [Google Scholar] [CrossRef]

- Sapawe, N.; Samion, S.; Ibrahim, M.I.; Daud, M.R.; Yahya, A.; Hanafi, M.F. Tribological testing of hemispherical titanium pin lubricated by novel palm oil: Evaluating anti-wear and anti-friction properties. Chin. J. Mech. Eng. 2017, 30, 644–651. [Google Scholar] [CrossRef]

- Huang, L.Y.; Xu, K.W.; Lu, J.; Guelorget, B.; Chen, H. Nano-scratch and fretting wear study of DLC coatings for biomedical application. Diam. Relat. Mater. 2001, 10, 1448–1456. [Google Scholar] [CrossRef]

- Hauert, R.; Thorwarth, K.; Thorwarth, G. An overview on diamond-like carbon coatings in medical applications. Surf. Coat. Technol. 2013, 233, 119–130. [Google Scholar] [CrossRef]

- Borzdov, Y.; Pal’Yanov, Y.; Kupriyanov, I.; Gusev, V.; Khokhryakov, A.; Sokol, A.; Efremov, A. HPHT synthesis of diamond with high nitrogen content from an Fe3N–C system. Diam. Relat. Mater. 2002, 11, 1863–1870. [Google Scholar] [CrossRef]

- Ferro, S. Synthesis of diamond. J. Mater. Chem. 2002, 12, 2843–2855. [Google Scholar] [CrossRef]

- Namba, Y. Attempt to grow diamond phase carbon films from an organic solution. J. Vac. Sci. Technol. 1992, 10, 3368–3370. [Google Scholar] [CrossRef]

- Su, C.H.; Lin, C.R.; Chang, C.Y.; Hung, H.C.; Lin, T.Y. Mechanical and optical properties of diamond-like carbon thin films deposited by low temperature process. Thin Solid Films 2006, 498, 220–223. [Google Scholar] [CrossRef]

- Liu, W.J.; Guo, X.J.; Chang, C.L.; Lu, J.H. Diamond-like carbon thin films synthesis by low temperature atmospheric pressure plasma method. Thin Solid Films 2009, 517, 4229–4232. [Google Scholar] [CrossRef]

- Rohrbeck, M.; Körsten, S.; Fischer, C.B.; Wehner, S.; Kessler, B. Diamond-like carbon coating of a pure bioplastic foil. Thin Solid Films 2013, 545, 558–563. [Google Scholar] [CrossRef]

- Miyoshi, K.; Murakawa, M.; Watanabe, S.; Takeuchi, S.; Miyake, S.; Wu, R.L.C. CVD diamond, DLC, and c-BN coatings for solid film lubrication. Tribol. Lett. 1998, 5, 123–129. [Google Scholar] [CrossRef]

- Cho, Y.H.; Choi, W.S.; Park, Y.S.; Cho, H.J.; Hong, B. Study of the tribological properties of DLC double-layer films grown by using plasma enhanced chemical-vapor deposition and closed-field unbalanced magnetron sputtering. J. Korean Phys. Soc. 2007, 51, 1129–1133. [Google Scholar] [CrossRef]

- Ding, X.Z.; Zhang, F.M.; Liu, X.H.; Wang, P.W.; Durrer, W.G.; Cheung, W.Y.; Wong, S.P.; Wilson, I.H. Ion beam assisted deposition of diamond-like nanocomposite films in an acetylene atmosphere. Thin Solid Films 1999, 346, 82–85. [Google Scholar] [CrossRef]

- Zajíčková, L.; Buršíková, V.; Peřina, V.; Mackova, A.; Janča, J. Correlation between SiOx content and properties of DLC: SiOx films prepared by PECVD. Surf. Coat. Technol. 2003, 174, 281–285. [Google Scholar] [CrossRef]

- Vanhulsel, A.; Celis, J.P.; Dekempeneer, E.; Meneve, J.; Smeets, J.; Vercammen, K. Inductively coupled r.f. plasma assisted chemical vapour deposition of diamond-like carbon coatings. Diam. Relat. Mater. 1999, 8, 1193–1197. [Google Scholar] [CrossRef]

- Flege, S.; Hatada, R.; Ensinger, W.; Baba, K. Properties of hydrogenated DLC films as prepared by a combined method of plasma source ion implantation and unbalanced magnetron sputtering. J. Mater. Res. 2012, 27, 845–849. [Google Scholar] [CrossRef]

- Singh, A.; Lavigne, P. Deposition of diamond-like carbon films by low energy ion beam and dc magnetron sputtering. Surf. Coat. Technol. 1991, 47, 188–200. [Google Scholar] [CrossRef]

- Zhao, F.; Li, H.; Ji, L.; Wang, Y.; Zhou, H.; Chen, J. Ti-DLC films with superior friction performance. Diam. Relat. Mater. 2010, 19, 342–349. [Google Scholar] [CrossRef]

- Zou, C.W.; Wang, H.J.; Feng, L.; Xue, S.W. Effects of Cr concentrations on the microstructure, hardness, and temperature-dependent tribological properties of Cr-DLC coatings. Appl. Surf. Sci. 2013, 286, 137–141. [Google Scholar] [CrossRef]

- Sharma, R.; Barhai, P.K.; Kumari, N. Corrosion resistant behaviour of DLC films. Thin Solid Films 2008, 516, 5397–5403. [Google Scholar] [CrossRef]

- Paul, R.; Dalui, S.; Das, S.N.; Bhar, R.; Pal, A. Hydrophobicity in DLC films prepared by electrodeposition technique. Appl. Surf. Sci. 2008, 255, 1705–1711. [Google Scholar] [CrossRef]

- Ding, X.L.; Li, Q.S.; Kong, X.H. Optical and electrical properties evolution of diamond-like carbon thin films with deposition temperature. Chin. Phys. Lett. 2009, 26, 027802. [Google Scholar]

- Damasceno, J.C.; Camargo, S.S. Plasma deposition and characterization of silicon oxide-containing diamond-like carbon films obtained from CH4:SiH4:O2 gas mixtures. Thin Solid Films 2008, 516, 1890–1897. [Google Scholar] [CrossRef]

- Paul, R.; Das, S.N.; Dalui, S.; Gayen, R.N.; Roy, R.K.; Bhar, R.; Pal, A.K. Synthesis of DLC films with different sp2/sp3 ratios and their hydrophobic behavior. J. Phys. D Appl. Phys. 2008, 41, 055309. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Moon, M.W.; Lee, K.R. Effect of silver doping on optical property of diamond like carbon films. Thin Solid Films 2009, 517, 4035–4038. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Banerjee, D.; Chattopadhyay, K.K. The influence of fluorine doping on the optical properties of diamond-like carbon thin films. Vacuum 2010, 84, 837–842. [Google Scholar] [CrossRef]

- Lee, D.H.; He, X.M.; Walter, K.C.; Nastasi, M.; Tesmer, J.R.; Tuszewski, M.; Tallant, D.R. Diamondlike carbon deposition on silicon using radio-frequency inductive plasma of Ar and C2H2 gas mixture in plasma immersion ion deposition. Appl. Phys. Lett. 1998, 73, 2423–2425. [Google Scholar] [CrossRef]

- Yu, S.J.; Ding, Z.F.; Xu, J.; Zhang, J.L.; Ma, T.C. CVD of hard DLC films in a radio frequency inductively coupled plasma source. Thin Solid Films 2001, 390, 98–103. [Google Scholar] [CrossRef]

- Lifshitz, Y. Pitfalls in amorphous carbon studies. Diam. Relat. Mater. 2003, 12, 130–140. [Google Scholar] [CrossRef]

- Cui, W.G.; Lai, Q.B.; Zhang, L.; Wang, F.M. Quantitative measurements of sp3 content in DLC films with raman spectroscopy. Surf. Coat. Technol. 2010, 205, 1995–1999. [Google Scholar] [CrossRef]

- Zou, J.W.; Reichelt, K.; Schmidt, K.; Dischler, B. The deposition and study of hard carbon films. J. Appl. Phys. 1989, 65, 3914–3918. [Google Scholar] [CrossRef]

- Batory, D.; Jedrzejczak, A.; Szymanski, W.; Niedzielski, P.; Fijalkowski, M.; Louda, P.; Kotela, I.; Hromadka, M.; Musil, J. Mechanical characterization of a-C:H:SiOx coatings synthesized using radio-frequency plasma-assisted chemical vapor deposition method. Thin Solid Films 2015, 590, 299–305. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.C.; Liao, W.B.; Wei, H.S.; Liao, Y.Y.; Chen, H.P.; Kuo, C.C. Fabrication of Transparent Very Thin SiOx Doped Diamond-Like Carbon Films on a Glass Substrate. Coatings 2018, 8, 240. https://doi.org/10.3390/coatings8070240

Chang YC, Liao WB, Wei HS, Liao YY, Chen HP, Kuo CC. Fabrication of Transparent Very Thin SiOx Doped Diamond-Like Carbon Films on a Glass Substrate. Coatings. 2018; 8(7):240. https://doi.org/10.3390/coatings8070240

Chicago/Turabian StyleChang, Ya Chen, Wei Bo Liao, Hung Sen Wei, Yan Yu Liao, Hung Pin Chen, and Chien Cheng Kuo. 2018. "Fabrication of Transparent Very Thin SiOx Doped Diamond-Like Carbon Films on a Glass Substrate" Coatings 8, no. 7: 240. https://doi.org/10.3390/coatings8070240

APA StyleChang, Y. C., Liao, W. B., Wei, H. S., Liao, Y. Y., Chen, H. P., & Kuo, C. C. (2018). Fabrication of Transparent Very Thin SiOx Doped Diamond-Like Carbon Films on a Glass Substrate. Coatings, 8(7), 240. https://doi.org/10.3390/coatings8070240