Hot Embossing for Whole Teflon Superhydrophobic Surfaces

Abstract

1. Introduction

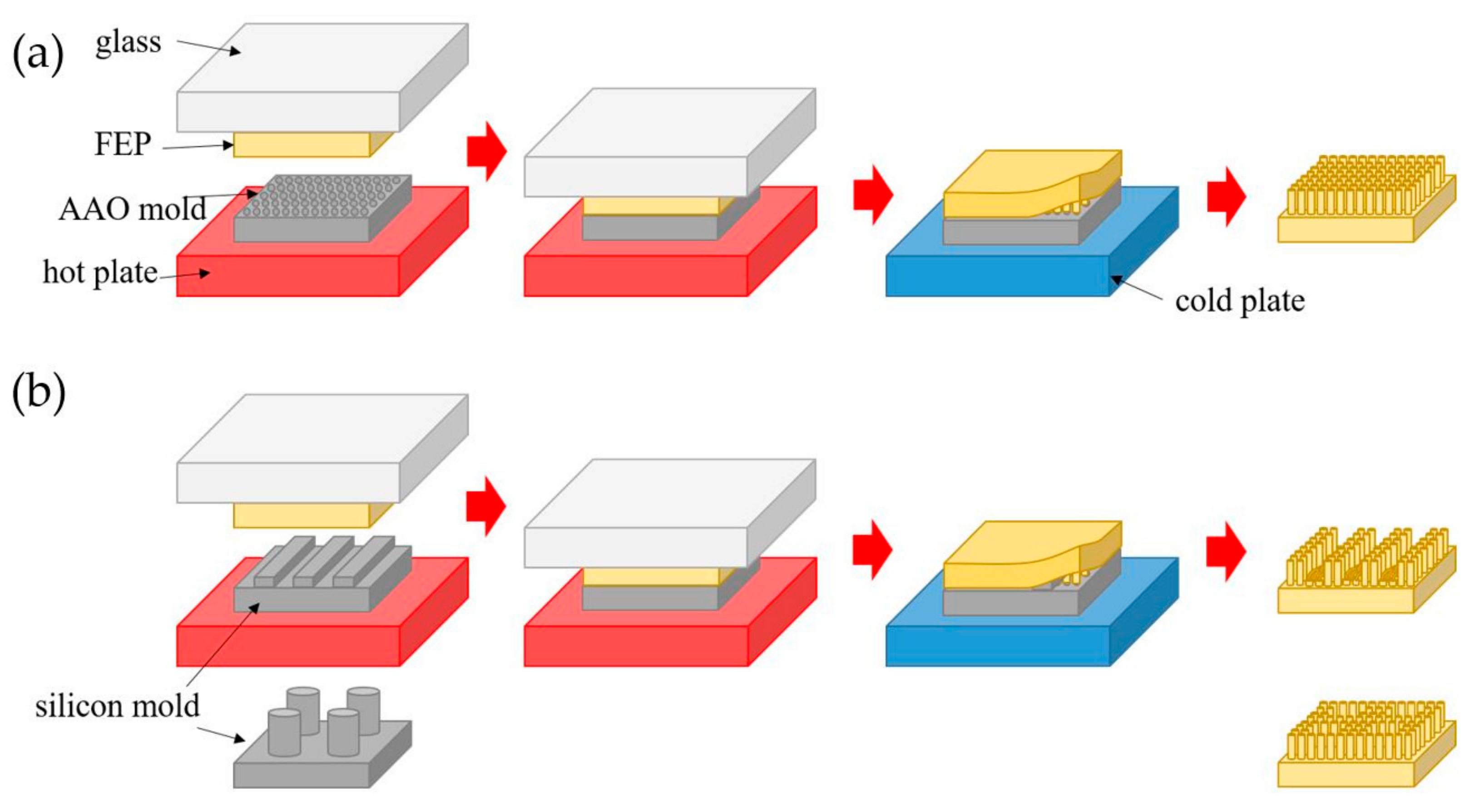

2. Fabrication Scheme

3. Methods and Materials

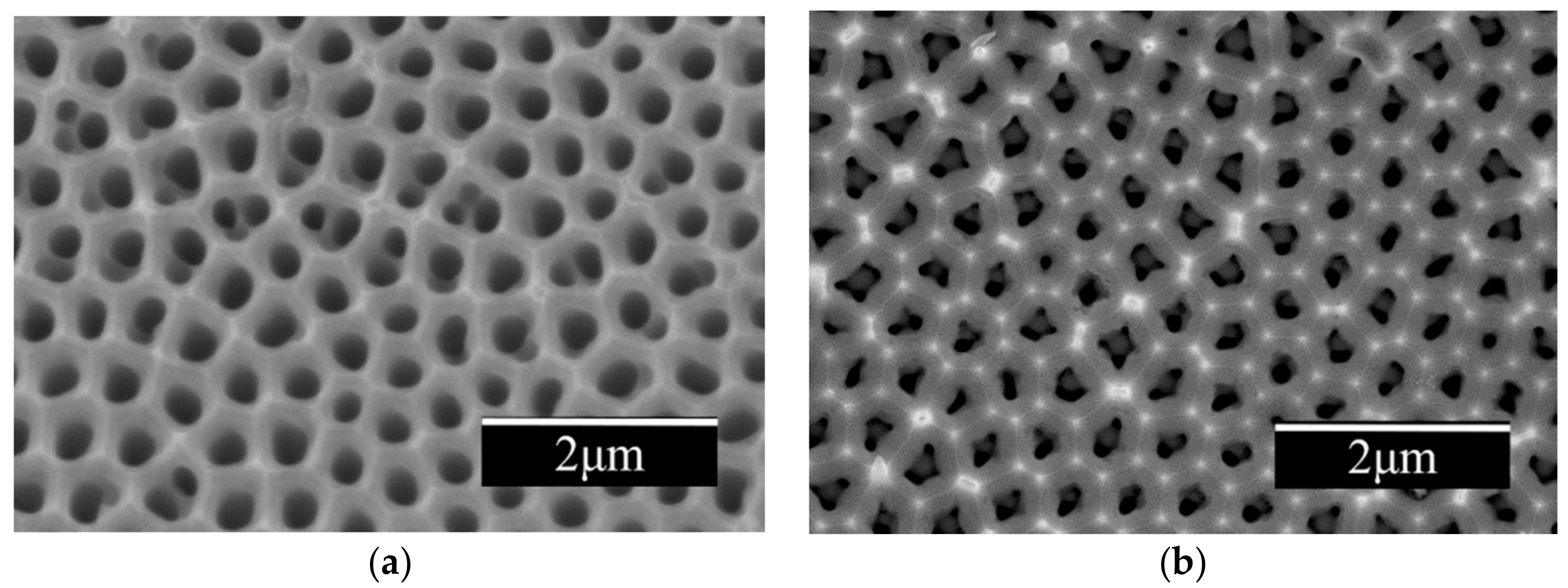

3.1. Preparation of AAO Molds

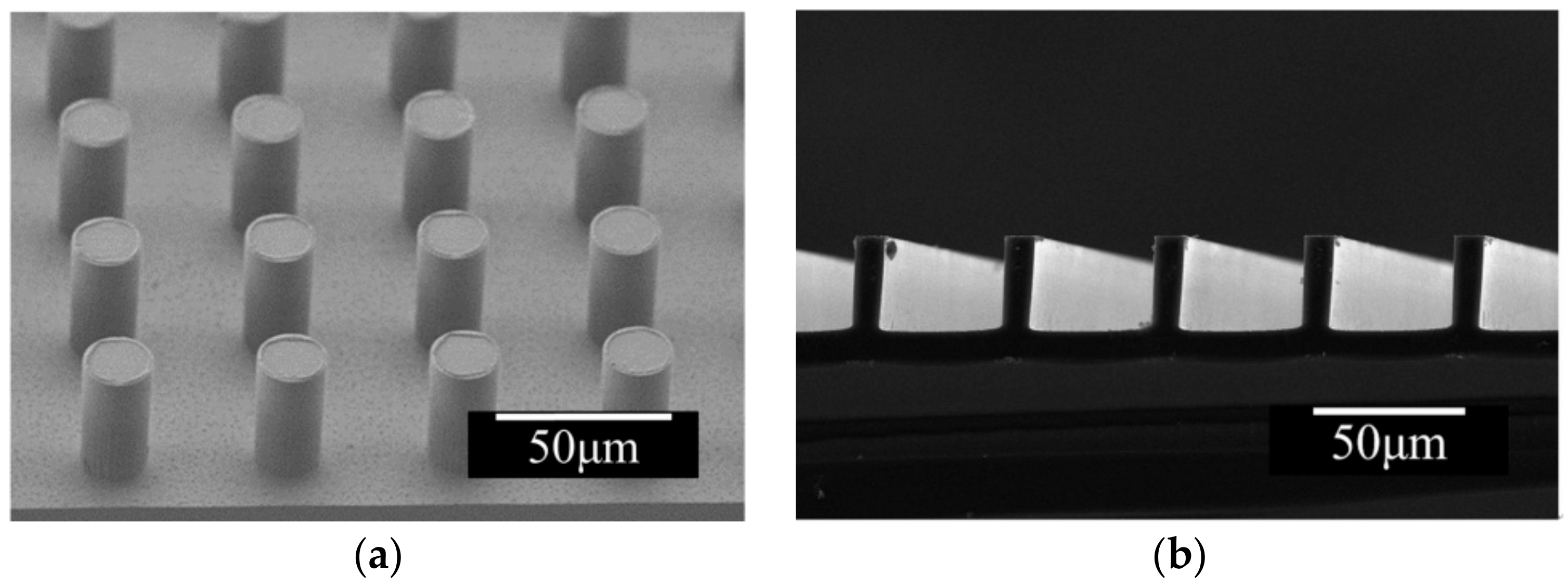

3.2. Fabrication of Micromachined Silicon Molds

3.3. Hot Embossing

3.4. Contact Angle Measurement

3.5. Measurement of Underwater Superhydrophobicity in Turbulent Flow

4. Results and Discussion

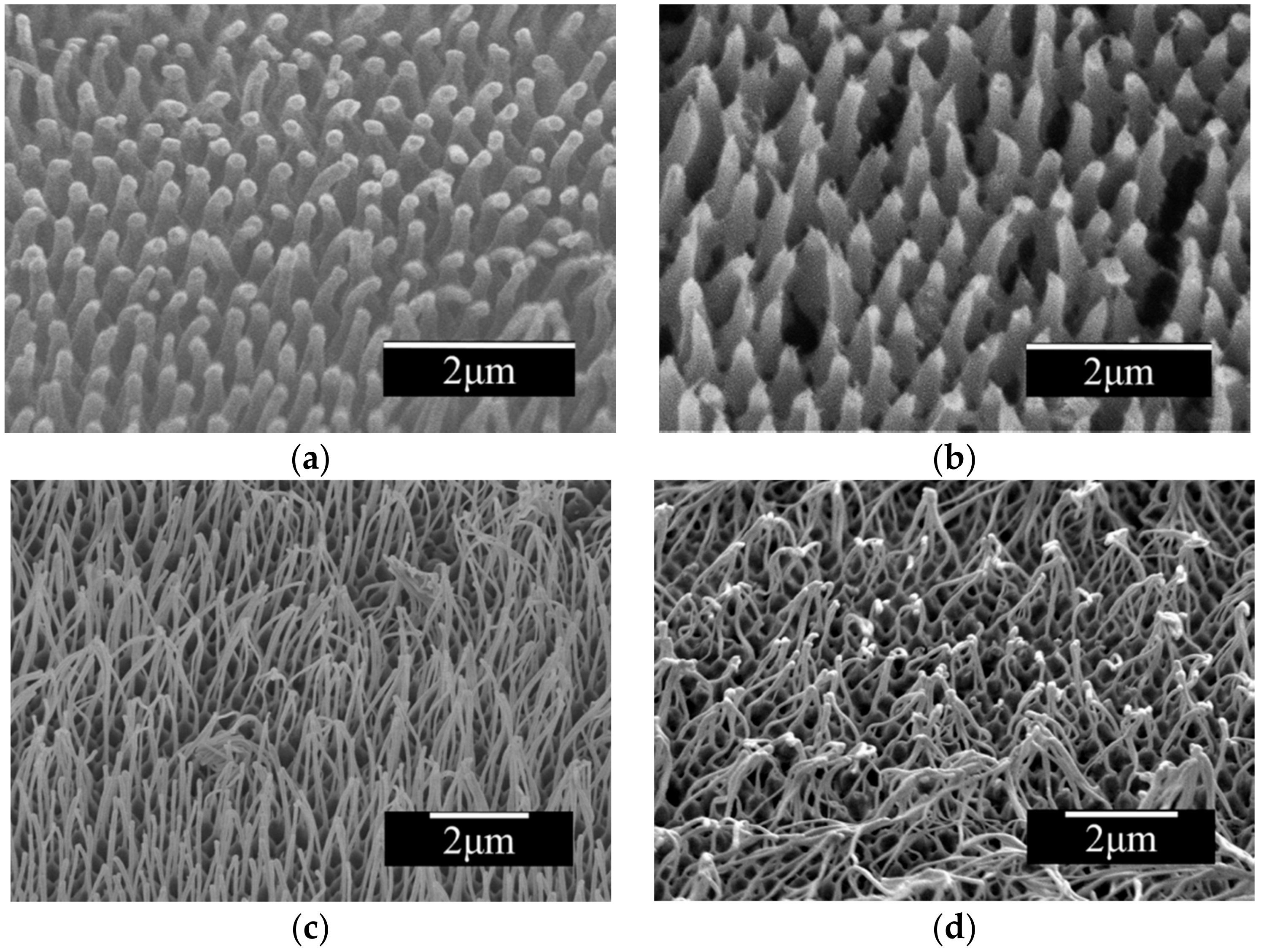

4.1. Effects of Aspect Ratio

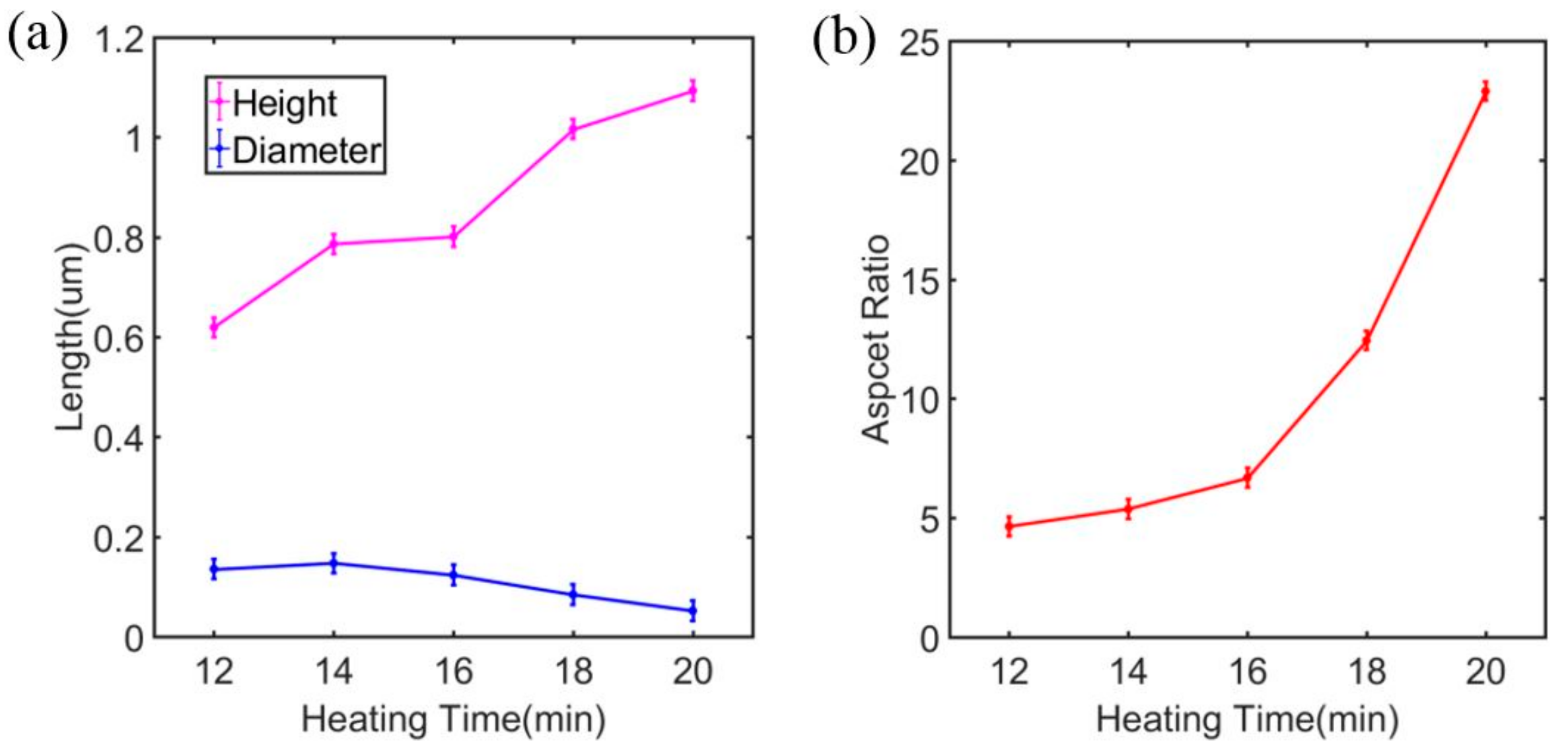

4.2. Effects of Heating Time

4.3. Apparent Contact Angles of Nanowired Teflon FEP Surfaces

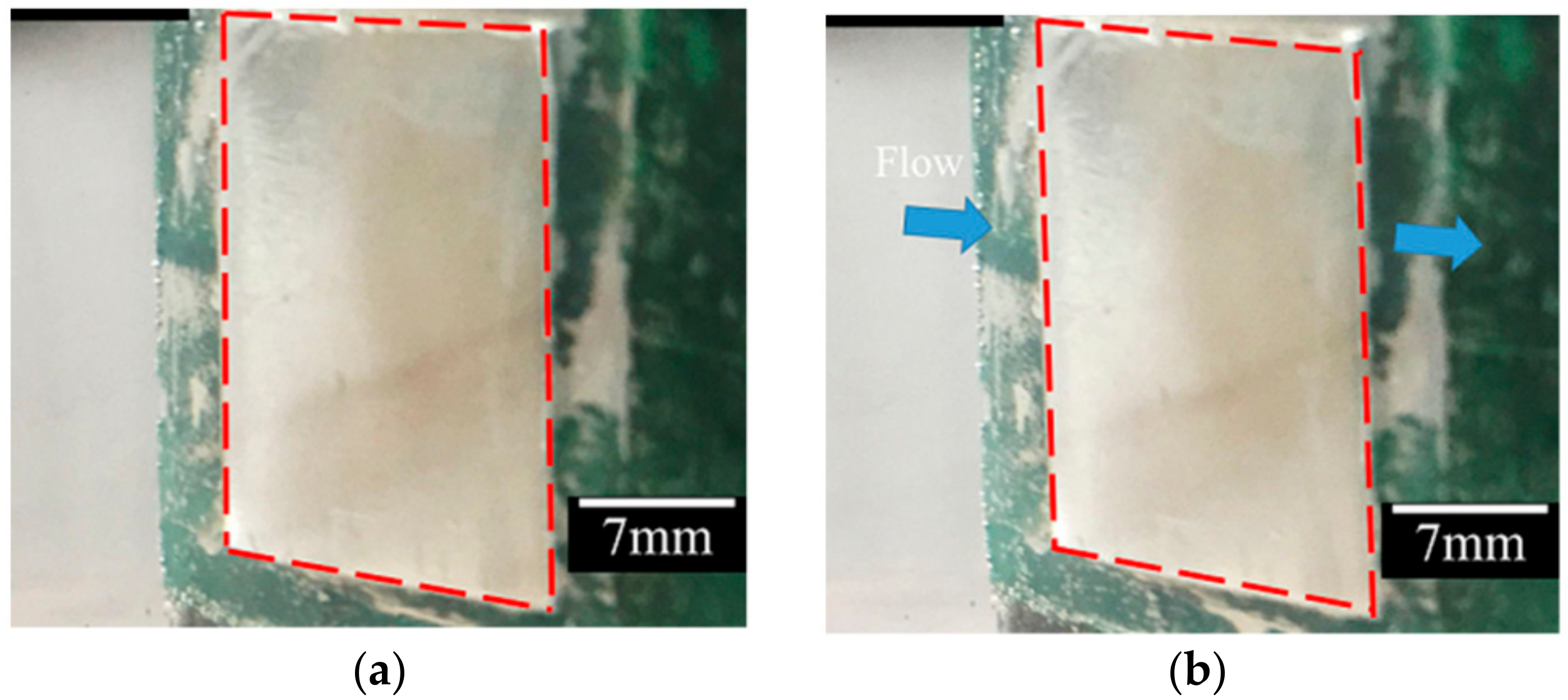

4.4. Underwater Superhydrophobicity of Nanowired Teflon FEP Surfaces in Turbulent Flow

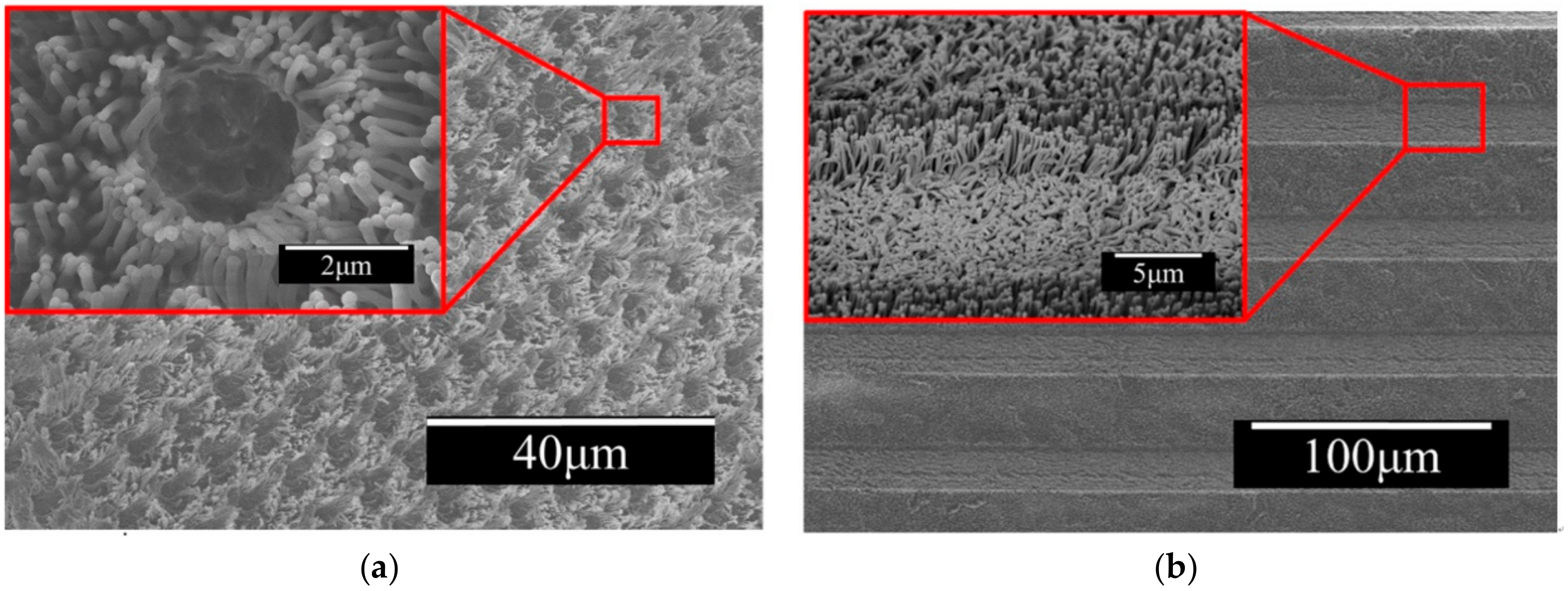

4.5. Hierarchical Micro/Nanostructures of Whole Teflon

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Feng, L.; Li, S.; Li, Y.; Li, H.; Zhang, L.; Zhai, J.; Song, Y.; Liu, B.; Jiang, L.; Zhu, D. Super-hydrophobic surfaces: From natural to artificial. Adv. Mater. 2002, 14, 1857–1860. [Google Scholar] [CrossRef]

- Yilgor, I.; Bilgin, S.; Isik, M.; Yilgor, E. Facile preparation of superhydrophobic polymer surfaces. Polymer 2012, 53, 1180–1188. [Google Scholar] [CrossRef]

- Roach, P.; Shirtcliffe, N.J.; Newton, M.I. Progress in superhydrophobic surface development. Soft Matter 2008, 4, 224–240. [Google Scholar] [CrossRef]

- Hou, X.; Hu, Y.; Grinthal, A.; Khan, M.; Aizenberg, J. Liquid-based gating mechanism with tunable multiphase selectivity and antifouling behaviour. Nature 2015, 519, 70–73. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, X.; Fei, B.; Hu, H.; Lai, C.; Xin, J.H. Bioinspired, stimuli-responsive, multifunctional superhydrophobic surface with directional wetting, adhesion, and transport of water. Adv. Funct. Mater. 2015, 25, 5047–5056. [Google Scholar] [CrossRef]

- Lu, Y.; Sathasivam, S.; Song, J.; Crick, C.R.; Carmalt, C.J.; Parkin, I.P. Robust self-cleaning surfaces that function when exposed to either air or oil. Science 2015, 347, 1132–1135. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Park, S.H.; Kim, K.B.; Lee, J.K. Fabrication of hierarchical structures on a polymer surface to mimic natural superhydrophobic surfaces. Adv. Mater. 2007, 19, 2330–2335. [Google Scholar] [CrossRef]

- Blossey, R. Self-cleaning surfaces—Virtual realities. Nat. Mater. 2003, 2, 301–306. [Google Scholar] [CrossRef] [PubMed]

- Genzer, J.; Efimenko, K. Creating long-lived superhydrophobic polymer surfaces through mechanically assembled monolayers. Science 2000, 290, 2130–2133. [Google Scholar] [CrossRef] [PubMed]

- Zhao, N.; Weng, L.; Zhang, X.; Xie, Q.; Zhang, X.; Xu, J. A lotus-leaf-like superhydrophobic surface prepared by solvent-induced crystallization. ChemPhysChem 2006, 7, 824–827. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Lu, X.; Huang, W.; Han, Y. Reversible superhydrophobicity to superhydrophilicity transition by extending and unloading an elastic polyamide film. Macromol. Rapid Commun. 2005, 26, 477–480. [Google Scholar] [CrossRef]

- Erbil, H.Y.; Demirel, A.L.; Avcı, Y.; Mert, O. Transformation of a simple plastic into a superhydrophobic surface. Science 2003, 299, 1377–1380. [Google Scholar] [CrossRef] [PubMed]

- Jin, M.; Feng, X.; Xi, J.; Zhai, J.; Cho, K.; Feng, L.; Jiang, L. Super-hydrophobic PDMS surface with ultra-low adhesive force. Macromol. Rapid Commun. 2005, 26, 1805–1809. [Google Scholar] [CrossRef]

- Guo, Z.; Zhou, F.; Hao, J.; Liu, W. Stable biomimetic super-hydrophobic engineering materials. J. Am. Chem. Soc. 2005, 127, 15670–15671. [Google Scholar] [CrossRef] [PubMed]

- Qian, B.; Shen, Z. Fabrication of superhydrophobic surfaces by dislocation-selective chemical etching on aluminum, copper, and zinc substrates. Langmuir 2005, 21, 9007–9009. [Google Scholar] [CrossRef] [PubMed]

- Northen, M.T.; Turner, K.L. Meso-scale adhesion testing of integrated micro- and nano-scale structures. Sens. Actuators A Phys. 2006, 130–131, 583–587. [Google Scholar] [CrossRef]

- Hang, T.; Li, M.; Hu, A.; Mao, D. Super-hydrophobic nickel films with micro-nano hierarchical structure prepared by electrodeposition for appliance industry. In Proceedings of the International Conference on Electronic Packaging Technology and High Density Packaging, Beijing, China, 10–13 August 2009; pp. 684–686. [Google Scholar]

- Xu, J.; Wang, K.; Zu, S.Z.; Han, B.H.; We, Z. Hierarchical nanocomposites of polyaniline nanowire arrays on graphene oxide sheets with synergistic effect for energy storage. ACS Nano 2010, 4, 5019–5026. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhu, G.; Yang, J.; Jing, Q.; Bai, P.; Yang, W.; Qi, X.; Su, Y.; Wang, Z.L. Personalized keystroke dynamics for self-powered human–machine interfacing. ACS Nano 2015, 9, 105–116. [Google Scholar] [CrossRef] [PubMed]

- Chu, P. A very dennison micro-nano replication capabilities for MEMS and microfluidics. In Proceedings of the International Conference on MEMS, Nano and Smart Systems, Banff, AB, Canada, 24–27 July 2005; pp. 27–29. [Google Scholar]

- Huang, C.F.; Lin, Y.; Shen, Y.K.; Fan, Y.M. Optimal processing for hydrophobic nanopillar polymer surfaces using nanoporous alumina template. Adv. Mater. Res. 2014, 646, 84–89. [Google Scholar] [CrossRef]

- Tawfick, S.; Volder, M.D.; Copic, D.; Park, S.J.; Oliver, C.R.; Polsen, E.S.; Roberts, M.J.; Hart, A.J. Engineering of micro- and nanostructured surfaces with anisotropic geometries and properties. Adv. Mater. 2012, 24, 1628–1674. [Google Scholar] [CrossRef] [PubMed]

- Becker, H.; Heim, U. Hot embossing as a method for the fabrication of polymer high aspect ratio structures. Sens. Actuators A Phys. 2000, 83, 130–135. [Google Scholar] [CrossRef]

- Konstantinou, D.; Shirazi, A.; Sadri, A.; Young, E.W.K. Combined hot embossing and milling for medium volume production of thermoplastic microfluidic devices. Sens. Actuators B Chem. 2016, 234, 209–221. [Google Scholar] [CrossRef]

- Pethrick, R.A. Polymer Physics; Rubinstein, M., Colby, R.H., Eds.; Oxford University Press: Oxford, UK, 2003; Volume 53, ISBN 019852059X; p. 440. [Google Scholar] [CrossRef]

- Carlson, D.P.; Schmiegel, W. Fluoropolymers, Organic. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2000. [Google Scholar]

- Koponen, H.K.; Saarikoski, I.; Korhonen, T.; Pääkkö, M.; Kuisma, R.; Pakkanen, T.T.; Suvanto, M.; Pakkanen, T.A. Modification of cycloolefin copolymer and poly (vinyl chloride) surfaces by superimposition of nano- and microstructures. Appl. Surf. Sci. 2007, 253, 5208–5213. [Google Scholar] [CrossRef]

- Wu, J.; Zan, X.; Li, S.; Liu, Y.; Cui, C.; Zou, B.; Zhang, W.; Xu, H.; Duan, H.; Tian, D.; et al. In situ synthesis of large-area single sub-10 nm nanoparticle arrays by polymer pen lithography. Nanoscale 2014, 6, 749–752. [Google Scholar] [CrossRef] [PubMed]

- Madaria, A.R.; Yao, M.; Chi, C.Y.; Huang, N.F.; Lin, C.X.; Li, R.J.; Povinelli, M.L.; Dapkus, P.D.; Zhou, C. Toward optimized light utilization in nanowire arrays using scalable nanosphere lithography and selected area growth. Nano Lett. 2012, 12, 2839–2845. [Google Scholar] [CrossRef] [PubMed]

- Fujita, J.; Ohnishi, Y.; Ochiai, Y.; Matsui, S. Ultrahigh resolution of calixarene negative resist in electron beam lithography. Appl. Phys. Lett. 1996, 68, 1297–1299. [Google Scholar] [CrossRef]

- Du, K.; Wathuthanthri, I.; Liu, Y.; Kang, Y.T.; Choi, C.-H. Fabrication of polymer nanowires via maskless O2 plasma etching. Nanotechnology 2014, 25, 165301. [Google Scholar] [CrossRef] [PubMed]

- Canham, L.T. Silicon quantum wire array fabrication by electrochemical and chemical dissolution of wafers. Appl. Phys. Lett. 1990, 57, 1046–1048. [Google Scholar] [CrossRef]

- Lee, W.; Jin, M.K.; Yoo, W.C.; Lee, J.K. Nanostructuring of a polymeric substrate with well-defined nanometer-scale topography and tailored surface wettability. Langmuir 2004, 20, 7665–7669. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Feng, L.; Zhai, J.; Wang, G.; Song, Y.; Jiang, L.; Zhu, D. Large-area fabrication of a nanostructure-induced hydrophobic surface from a hydrophilic polymer. ChemPhysChem 2004, 5, 750–753. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.J.; Jiang, L. Design and creation of superwetting/antiwetting surfaces. Adv. Mater. 2006, 18, 3063–3078. [Google Scholar] [CrossRef]

- Wu, J.T.; Chang, W.Y.; Yang, S.Y. Fabrication of a nano/micro hybrid lens using gas-assisted hot embossing with an anodic aluminum oxide (AAO) template. J. Micromech. Microeng. 2010, 20, 669–672. [Google Scholar] [CrossRef]

- Gates, B.D.; Xu, Q.; Stewart, M.; Ryan, D.; Willson, C.G.; Whitesides, G.M. New approaches to nanofabrication: Molding, printing, and other techniques. Chem. Rev. 2005, 36, 1171–1196. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.J. Recent progress in nanoimprint technology and its applications. J. Phys. D Appl. Phys. 2004, 37, 123–141. [Google Scholar] [CrossRef]

- Dirckx, M.E.; Hardt, D.E. Analysis and characterization of demolding of hot embossed polymer microstructures. J. Micromech. Microeng. 2011, 21, 085024. [Google Scholar] [CrossRef]

- Schaper, C.D. Water-soluble polymer templates for high-resolution pattern formation and materials transfer printing. J. Microlithogr. Microfabr. Microsyst. 2004, 3, 174–185. [Google Scholar] [CrossRef]

- Telecka, A.; Murthy, S.; Sun, L.; Pranov, H.; Taboryski, R.J. Superhydrophobic properties of nanotextured polypropylene foils fabricated by roll-to-roll extrusion coating. ACS Macro Lett. 2016, 5, 1034–1038. [Google Scholar] [CrossRef]

- Xu, M.; Sun, G.; Kim, C.J. Infinite lifetime of underwater superhydrophobic states. Phys. Rev. Lett. 2014, 113, 136103. [Google Scholar] [CrossRef] [PubMed]

- Ren, K.; Dai, W.; Zhou, J.; Su, J.; Wu, H. Whole-teflon microfluidic chips. Proc. Natl. Acad. Sci. USA 2011, 108, 8162–8166. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Huang, X.; Zhang, X.; Jiang, F.; Zhang, X.; Wang, Y. Supercritical fluid driven polymer phase separation for microlens with tunable dimension and curvature. ACS Appl. Mater. Interfaces 2016, 8, 8849–8858. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.; Ji, R.; Gösele, U.; Nielsch, K. Fast fabrication of long-range ordered porous alumina membranes by hard anodization. Nat. Mater. 2006, 5, 741–747. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.; Schwirn, K.; Steinhart, M.; Pippel, E.; Scholz, R.; Gösele, U. Structural engineering of nanoporous anodic aluminum oxide by pulse anodization of aluminum. Nat. Nanotechnol. 2008, 3, 234–239. [Google Scholar] [CrossRef] [PubMed]

- Jeong, C.; Choi, C.H. Single-step direct fabrication of pillar-on-pore hybrid nanostructures in anodizing aluminum for superior superhydrophobic efficiency. ACS Appl. Mater. Interfaces 2012, 4, 842–848. [Google Scholar] [CrossRef] [PubMed]

- Saha, B.; Toh, W.Q.; Liu, E.; Tor, S.B.; Hardt, D.E.; Lee, J. A review on the importance of surface coating of micro/nano-mold in micro/nano-molding processes. J. Micromech. Microeng. 2016, 26, 013002. [Google Scholar] [CrossRef]

- Zhao, T.; Jiang, L. Contact angle measurement of natural materials. Colloids Surf. B Biointerfaces 2017, 161, 324–330. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.L.; Chen, Z.; Kim, C.-J. A dynamic cassie-baxter model. Soft Matter 2015, 11, 1589–1596. [Google Scholar] [CrossRef] [PubMed]

- Koch, K.; Barthlott, W. Superhydrophobic and superhydrophilic plant surfaces: An inspiration for biomimetic materials. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 1487–1509. [Google Scholar] [CrossRef] [PubMed]

- Lydéric, B.; Eric, L. A smooth future? Nat. Mater. 2011, 10, 334–337. [Google Scholar]

- Lee, C.; Choi, C.-H.; Kim, C.-J. Superhydrophobic drag reduction in laminar flows: A critical review. Exp. Fluids 2016, 57, 176. [Google Scholar] [CrossRef]

- Daniello, R.J.; Waterhouse, N.E.; Rothstein, J.P. Drag reduction in turbulent flows over superhydrophobic surfaces. Phys. Fluids 2009, 21, 085103. [Google Scholar] [CrossRef]

- Aljallis, E.; Sarshar, M.A.; Datla, R.; Sikka, V.; Jones, A.; Choi, C.-H. Experimental study of skin friction drag reduction on superhydrophobic flat plates in high Reynolds number boundary layer flow. Phys. Fluids 2013, 25, 351–412. [Google Scholar] [CrossRef]

- Hizal, F.; Rungraeng, N.; Lee, J.; Jun, S.; Busscher, H.J.; van der Mei, H.C.; Choi, C.-H. Nanoengineered superhydrophobic surfaces of aluminum with extremely low bacterial adhesivity. ACS Appl. Mater. Interfaces 2017, 9, 12118–12129. [Google Scholar] [CrossRef] [PubMed]

- Jeong, C.; Lee, J.; Sheppard, K.; Choi, C.-H. Air-impregnated nanoporous anodic aluminum oxide layers for enhancing the corrosion resistance of aluminum. Langmuir 2015, 31, 11040–11050. [Google Scholar] [CrossRef] [PubMed]

- Sarshar, M.A.; Swarctz, C.; Hunter, S.; Simpson, J.; Choi, C.-H. Effects of contact angle hysteresis on ice adhesion and growth on superhydrophobic surfaces under dynamic flow conditions. Colloid Polym. Sci. 2013, 291, 427–435. [Google Scholar] [CrossRef]

- Sommerfeld, A. A contribution to hydrodynamic explanation of turbulent fluid motions. Int. Congr. Math. 1908, 3, 116–124. [Google Scholar]

- Mchale, G.; Newton, M.I.; Shirtcliffe, N.J. Immersed superhydrophobic surfaces: Gas exchange, slip and drag reduction properties. Soft Matter 2010, 6, 714–719. [Google Scholar] [CrossRef]

- Søgaard, E.; Andersen, N.K.; Smistrup, K.; Larsen, S.T.; Sun, L.; Taboryski, R. Study of transitions between wetting states on microcavity arrays by optical transmission microscopy. Langmuir 2014, 30, 12960–12968. [Google Scholar] [CrossRef] [PubMed]

- Rosenberg, B.J.; Van Buren, T.; Fu, M.K.; Smits, A.J. Turbulent drag reduction over air- and liquid-impregnated surfaces. Phys. Fluids 2016, 28, 015103. [Google Scholar] [CrossRef]

- More, A.A. Analytical solutions for the Colebrook and White equation and for pressure drop in ideal gas flow in pipes. Chem. Eng. Sci. 2006, 61, 5515–5519. [Google Scholar] [CrossRef]

| Name | Pore Diameter (nm) | Interpore Distance (nm) | Pore Depth (nm) |

|---|---|---|---|

| VM-01 | 400 ± 20 (upper part) | 530 ± 20 | 500 ± 20 |

| 100 ± 20 (bottom part) | |||

| LJ-04 | 150 ± 20 | 530 ± 20 | 2000 ± 20 |

| LJ-05 | 200 ± 20 | 530 ± 20 | 2000 ± 20 |

| SP-01 | 250 ± 20 | 450 ± 20 | 2500 ± 20 |

| SP-03 | 120 ± 20 | 450 ± 20 | 450 ± 20 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Yu, W.; Zheng, D.; Zhao, X.; Choi, C.-H.; Sun, G. Hot Embossing for Whole Teflon Superhydrophobic Surfaces. Coatings 2018, 8, 227. https://doi.org/10.3390/coatings8070227

Li J, Yu W, Zheng D, Zhao X, Choi C-H, Sun G. Hot Embossing for Whole Teflon Superhydrophobic Surfaces. Coatings. 2018; 8(7):227. https://doi.org/10.3390/coatings8070227

Chicago/Turabian StyleLi, Jie, Wentao Yu, Deyin Zheng, Xin Zhao, Chang-Hwan Choi, and Guangyi Sun. 2018. "Hot Embossing for Whole Teflon Superhydrophobic Surfaces" Coatings 8, no. 7: 227. https://doi.org/10.3390/coatings8070227

APA StyleLi, J., Yu, W., Zheng, D., Zhao, X., Choi, C.-H., & Sun, G. (2018). Hot Embossing for Whole Teflon Superhydrophobic Surfaces. Coatings, 8(7), 227. https://doi.org/10.3390/coatings8070227