Gold Catalyst-Assisted Metal Organic Chemical Vapor Deposition of Bi-Te-Ni-Cu-Au Complex Thermoelectric Materials on Anodic Aluminum Oxide Nanoporous Template

Abstract

:1. Introduction

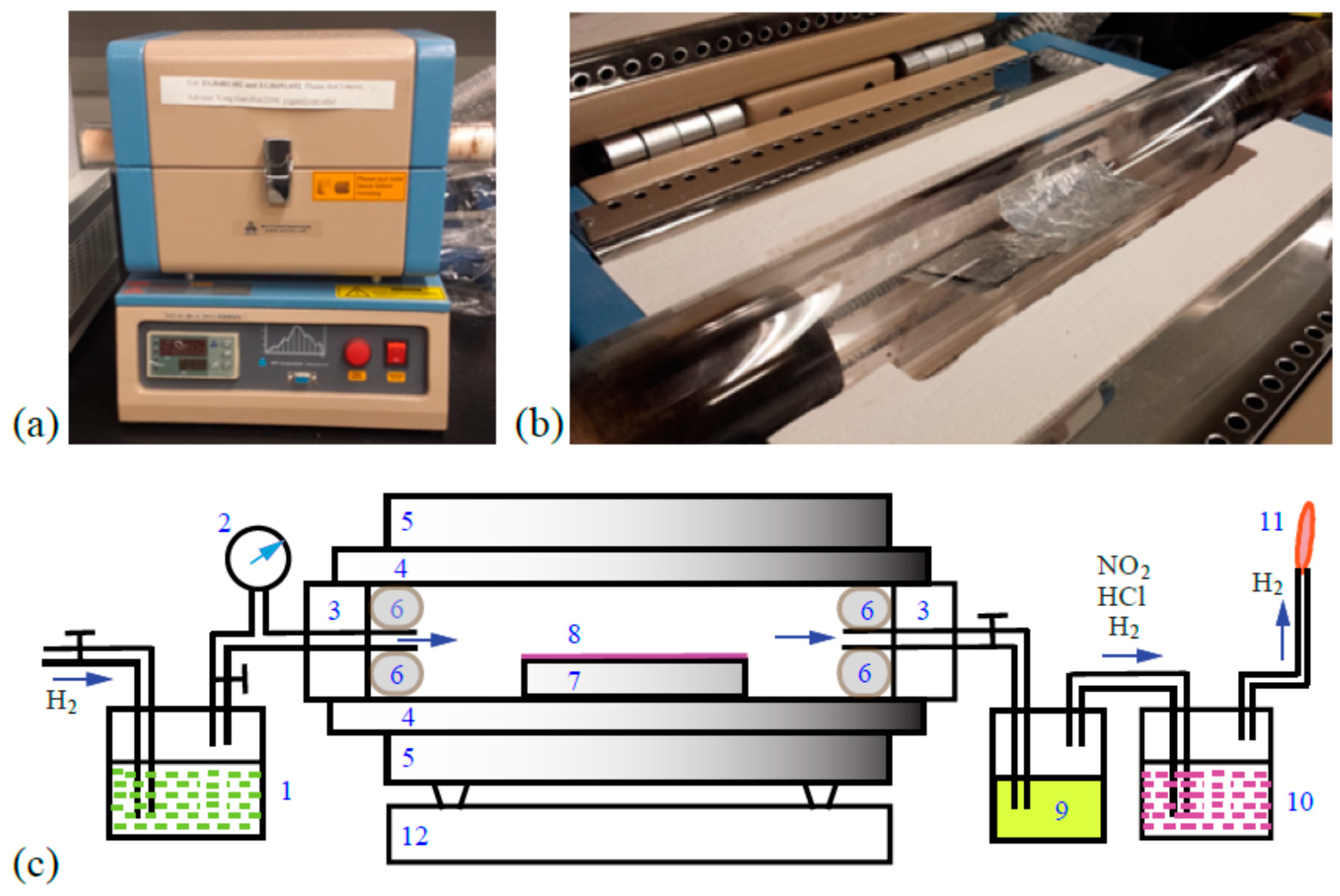

2. Materials and Experimental Methods

3. Results and Discussion

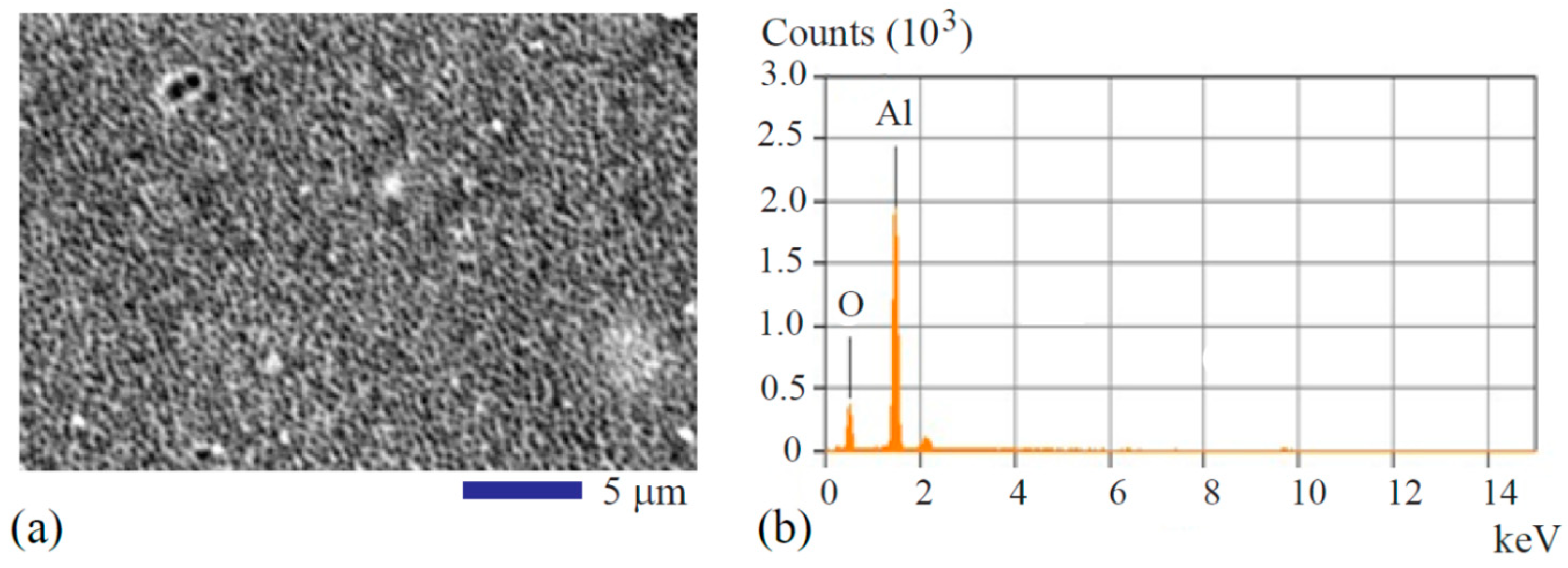

3.1. Morphology and Composition of the Nanostructure

3.2. Nanostructure Growth Mechanism

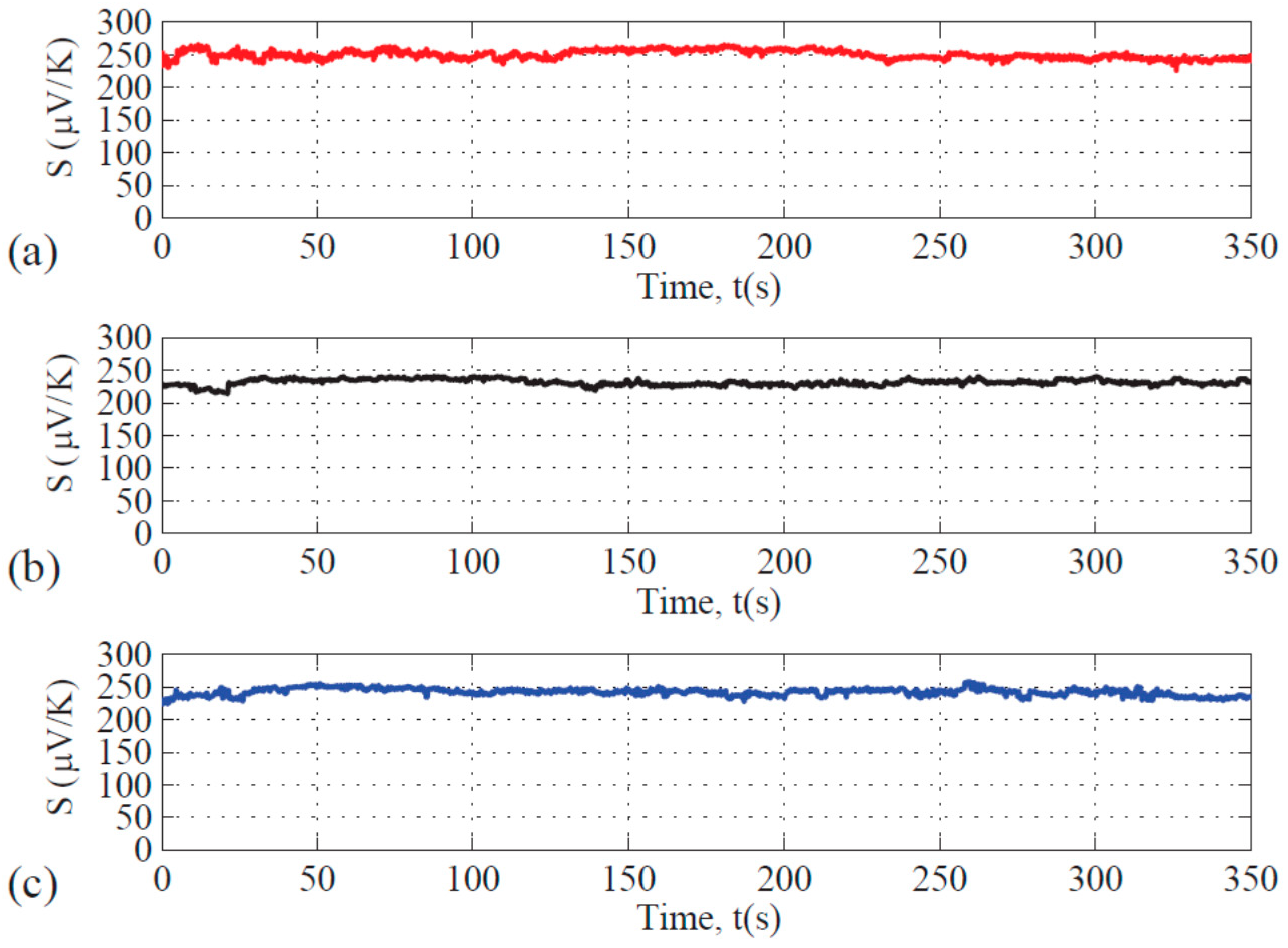

3.3. Thermoelectric Responses of the Nanostructure vs. Bulk Material (Thick Film)

3.4. Composition and Structure Effects on the Thermoelectric Responses

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, G.; Jian, J.; Lei, R.; Cao, B. Single-crystalline Bi2Se3 nanowires grown by catalyst-free ambient pressure chemical vapor deposition. Mater. Lett. 2016, 179, 198–201. [Google Scholar] [CrossRef]

- Tynell, T.; Aizawa, T.; Ohkubo, I.; Nakamura, K.; Mori, T. Deposition of thermoelectric strontium hexaboride thin films by a low pressure CVD method. J. Cryst. Growth 2016, 449, 10–14. [Google Scholar] [CrossRef]

- Chen, P.; Wang, J.; Lu, Y.; Zhang, S.; Liu, X.; Hou, W.; Wang, Z.; Wang, L. The fabrication of ReS2 flowers at controlled locations by chemical vapor deposition. Phys. E Low-Dimens. Syst. Nanostruct. 2017, 89, 115–118. [Google Scholar] [CrossRef]

- Haase, A.; Peters, A.; Rosiwal, S. Growth and thermoelectric properties of nitrogen-doped diamond/graphite. Diam. Relat. Mater. 2016, 63, 222–226. [Google Scholar] [CrossRef]

- Dávila, D.; Tarancón, A.; Calaza, C.; Salleras, M.; Fernández-Regúlez, M.; San Paulo, A.; Fonseca, L. Improved thermal behavior of multiple linked arrays of silicon nanowires integrated into planar thermoelectric microgenerators. J. Electron. Mater. 2013, 42, 1918–1925. [Google Scholar] [CrossRef]

- Wu, Y.; Fan, R.; Yang, P. Block-by-block growth of single-crystalline Si/SiGe superlattice nanowires. Nano Lett. 2002, 2, 83–86. [Google Scholar] [CrossRef]

- Kim, J.G.; Choi, Y.Y.; Choi, D.J.; Choi, S.M. Study on the thermoelectric properties of CVD SiC deposited with inert gases. J. Electron. Mater. 2011, 40, 840–844. [Google Scholar] [CrossRef]

- Kim, J.G.; Choi, Y.Y.; Choi, D.J.; Kim, J.I.; Kim, B.S.; Choi, S.M. A study on the thermoelectric properties of chemical vapor deposited SiC films with temperature and diluent gases variation. J. Ceram. Soc. Jpn. 2009, 117, 574–577. [Google Scholar] [CrossRef]

- Ngamou, P.H.T.; Bahlawane, N. Chemical vapor deposition and electric characterization of perovskite oxides LaMO3 (M = Co, Fe, Cr and Mn) thin films. J. Solid State Chem. 2009, 182, 849–854. [Google Scholar] [CrossRef]

- Cho, H.S.; Kamins, T.I. In situ control of Au-catalyzed chemical vapor deposited (CVD) Ge nanocone morphology by growth temperature variation. J. Cryst. Growth 2010, 312, 2494–2497. [Google Scholar] [CrossRef]

- Grigorian, L.; Fang, S.; Sumanasekera, G.; Rao, A.M.; Schrader, L.; Eklund, P.C. Physical properties of CVD-grown Se—Carbon films. Synth. Met. 1997, 87, 211–217. [Google Scholar] [CrossRef]

- Giani, A.; Boulouz, A.; Pascal-Delannoy, F.; Foucaran, A.; Boyer, A. MOCVD growth of Bi2Te3 layers using diethyltellurium as a precursor. Thin Solid Films 1998, 315, 99–103. [Google Scholar] [CrossRef]

- Giani, A.; Boulouz, A.; Pascal-Delannoy, F.; Foucaran, A.; Boyer, A. Growth of Bi2Te3 and Sb2Te3 thin films by MOCVD. Mater. Sci. Eng. B 1999, 64, 19–24. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Colpitts, T.; Watko, E.; Lamvik, M.; EI-Masry, N. MOCVD of Bi2Te3, Sb2Te3 and their superlattice structures for thin-film thermoelectric applications. J. Cryst. Growth 1997, 170, 817–821. [Google Scholar] [CrossRef]

- Shoko, E. Novel K rattling: A new route to thermoelectric materials? J. Appl. Phys. 2014, 115, 33703–33708. [Google Scholar] [CrossRef]

- Talapin, D.V. Thermoelectric tin selenide: The beauty of simplicity. Angew. Chem. 2014, 53, 9126–9127. [Google Scholar]

- Reddy, P. Electrostatic control of thermoelectricity in molecular junctions. Nat. Nanotechnol. 2014, 9, 881–885. [Google Scholar]

- Xiao, F.; Hangarter, C.; Yoo, B.; Rheem, Y.; Lee, K.H.; Myung, N.V. Recent progress in electrodeposition of thermoelectric thin films and nanostructures. Electrochim. Acta 2008, 53, 8103–8117. [Google Scholar] [CrossRef]

- Tritt, T.M.; Böttner, H.; Chen, L. Thermoelectrics: Direct solar thermal energy conversion. MRS Bull. 2008, 33, 366–368. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O′Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef] [PubMed]

- Majumdar, A. Thermoelectricity in semiconductor nanostructures. Science 2004, 303, 777–778. [Google Scholar] [CrossRef] [PubMed]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Vineis, C.J.; Shakouri, A.; Majumdar, A.; Kanatzidis, M.G. Nanostructured thermoelectrics: Big efficiency gains from small features. Adv. Mater. 2010, 22, 3970–3980. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Tritt, T.M. Advances in thermoelectric materials research: Looking back and moving forward. Science 2017, 357, eaak9997. [Google Scholar] [CrossRef] [PubMed]

- Eklund, P.; Kerdsongpanya, S.; Alling, B. Transition-metal-nitride-based thin films as novel energy harvesting materials. J. Mater. Chem. C 2016, 4, 3905–3914. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Li, X.; Guo, W.; Zhao, M.; Fan, X.; Dong, Y.; Xu, C.; Deng, J.; Fu, Y. Synthesis methods of two-dimensional MoS2: A brief review. Crystal 2017, 7, 198. [Google Scholar] [CrossRef]

- Goldsmid, H.J.; Sheard, A.R.; Wright, D.A. The performance of bismuth telluride thermojunctions. Br. J. Appl. Phys. 1958, 9, 365. [Google Scholar] [CrossRef]

- Wang, Z.L.; Onda, T.; Chen, Z.C. Effect of Cu doping on microstructure and thermoelectric properties of Bi2Te2.85Se0.15 bulk materials. Script. Mater. 2018, 146, 119–122. [Google Scholar] [CrossRef]

- Kassu, A.; Farley, C., III; Sharma, A.; Kim, W.; Guo, J. Effect of pore size and film thickness on gold-coated nanoporous anodic aluminum oxide substrates for surface-enhanced Raman scattering sensor. Sensors 2015, 15, 29924–29937. [Google Scholar] [CrossRef] [PubMed]

- Gan, Y.X.; Hamdan, A.S.; Gan, J.B.; Li, M. Chemical vapor deposition of Bi-Te-Ni-Fe on magnesium oxide substrate and its Seebeck effect. Coatings 2017, 7, 164. [Google Scholar] [CrossRef]

- Zhang, G.; Yu, Q.; Wang, W.; Li, X. Nanostructures for thermoelectric applications: Synthesis, growth mechanism, and property studies. Adv. Mater. 2010, 22, 1959–1962. [Google Scholar] [CrossRef] [PubMed]

- Do, M.T.; Tong, Q.C.; Lidiak, A.; Luong, M.H.; Ledoux-Rak, I.; Lai, N.D. Nano-patterning of gold thin film by thermal annealing combined with laser interference techniques. Appl. Phys. A 2016, 122, 360. [Google Scholar] [CrossRef]

- Goldsmid, H.J. Bismuth telluride and its alloys as materials for thermoelectric generation. Materials 2014, 7, 2577–2592. [Google Scholar] [CrossRef] [PubMed]

- Mahmoud, L.; Alhwarai, M.; Samad, Y.A.; Mohammad, B.; Laio, K.; Elnaggar, I. Characterization of a graphene-based thermoelectric generator using a cost-effective fabrication process. Energy Procedia 2015, 75, 615–620. [Google Scholar] [CrossRef]

- Gan, Y.X.; Koludrovich, M.J.; Zhang, L. Thermoelectric effect of silicon nanofibers capped with Bi-Te nanoparticles. Mater. Lett. 2013, 111, 126–129. [Google Scholar] [CrossRef]

- Mott, N.F. Chapter 3: Heavily doped semiconductors. In Conduction in Non-Crystalline Materials; Clarendon Press: Oxford, UK, 1987; p. 53. [Google Scholar]

- Adachi, J.; Kurosaki, K.; Uno, M.; Yamanaka, S. Effect of porosity on thermal and electrical properties of polycrystalline bulk ZrN prepared by spark plasma sintering. J. Alloys Compd. 2007, 432, 7–10. [Google Scholar] [CrossRef]

- Cao, C.Q.; Zhu, T.J.; Zhao, X.B. Low thermal conductivity and improved figure of merit in fine-grained binary PbTe thermoelectric alloys. J. Phys. D Appl. Phys. 2009, 42, 015406. [Google Scholar] [CrossRef]

- Pang, H.; Piao, Y.Y.; Tan, Y.Q.; Jiang, G.Y.; Wang, J.H.; Li, Z.M. Thermoelectric behavior of segregated conductive polymer composites with hybrid fillers of carbon nanotube and bismuth telluride. Mater. Lett. 2013, 107, 150–153. [Google Scholar] [CrossRef]

- Chatterjee, K.; Suresh, A.; Ganguly, S.; Kargupta, K.; Banerjee, D. Synthesis and characterization of an electro-deposited polyaniline-bismuth telluride nanocomposite—A novel thermoelectric material. Mater. Charact. 2009, 60, 1597–1601. [Google Scholar] [CrossRef]

- Sumithra, S.; Takas, N.J.; Misra, D.K.; Nolting, W.M.; Poudeu, P.F.P.; Stokes, K.L. Enhancement in thermoelectric figure of merit in nanostructured Bi2Te3 with semimetal nanoinclusions. Adv. Energy Mater. 2011, 1, 1141–1147. [Google Scholar] [CrossRef]

- Tan, J.; Kalantar-zadeh, K.; Wlodarski, W.; Bhargava, S.; Akolekar, D.; Holland, A.; Rosengarten, G. Thermoelectric properties of bismuth telluride thin films deposited by radio frequency magnetron sputtering. In Smart Sensors, Actuators, and MEMS II, Proceedings of SPIE—The International Society for Optical Engineering, Seville, Spain, 9–11 May 2005; Cane, C., Chiao, J.-C., Verdu, F.V., Eds.; SPIE: Bellingham, WA, USA, 2005; pp. 711–718. [Google Scholar]

- Jung, W.J.; Kim, I.H. Thermoelectric properties of Cu-doped Bi2−xSbxTe3 prepared by encapsulated melting and hot pressing. Met. Mater. Int. 2018, 24, 415–421. [Google Scholar] [CrossRef]

| Spot No. | O | Au | C | Mg | Al | Ni | Cu | Te | Bi |

|---|---|---|---|---|---|---|---|---|---|

| 001 | 16.1 | 0.0 | 58.5 | 0.0 | 23.7 | 0.0 | 0.6 | 1.2 | 0.0 |

| 002 | 12.6 | 2.6 | 51.6 | 1.4 | 18.9 | 1.3 | 1.1 | 6.8 | 3.7 |

| 003 | 17.6 | 0.0 | 47.3 | 0.0 | 33.0 | 0.0 | 0.6 | 1.5 | 0.0 |

| 004 | 12.2 | 2.4 | 54.5 | 1.1 | 16.8 | 1.5 | 1.0 | 7.0 | 3.4 |

| Test No. | ΔT (°C) | S (μV/K) | Standard Deviation (µV/K) |

|---|---|---|---|

| 1 | 15 | 114 | 9 |

| 2 | 10 | 104 | 5 |

| 3 | 8 | 105 | 11 |

| 4 | 7 | 107 | 12 |

| 5 | 6 | 103 | 13 |

| 6 | 5 | 103 | 16 |

| Savg = 106 ± 11 µV/K | |||

| Test No. | ΔT (°C) | S (µV/K) | Standard Deviation (µV/K) |

|---|---|---|---|

| 1 | 15 | 216 | 11 |

| 2 | 10 | 223 | 13 |

| 3 | 8 | 234 | 20 |

| 4 | 7 | 262 | 8 |

| 5 | 6 | 249 | 7 |

| 6 | 5 | 239 | 9 |

| 7 | 4 | 237 | 22 |

| Savg = 237 ± 13 µV/K | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, Y.X.; Yu, Z.; Gan, J.B.; Cheng, W.; Li, M. Gold Catalyst-Assisted Metal Organic Chemical Vapor Deposition of Bi-Te-Ni-Cu-Au Complex Thermoelectric Materials on Anodic Aluminum Oxide Nanoporous Template. Coatings 2018, 8, 166. https://doi.org/10.3390/coatings8050166

Gan YX, Yu Z, Gan JB, Cheng W, Li M. Gold Catalyst-Assisted Metal Organic Chemical Vapor Deposition of Bi-Te-Ni-Cu-Au Complex Thermoelectric Materials on Anodic Aluminum Oxide Nanoporous Template. Coatings. 2018; 8(5):166. https://doi.org/10.3390/coatings8050166

Chicago/Turabian StyleGan, Yong X., Zhen Yu, Jeremy B. Gan, Wanli Cheng, and Mingheng Li. 2018. "Gold Catalyst-Assisted Metal Organic Chemical Vapor Deposition of Bi-Te-Ni-Cu-Au Complex Thermoelectric Materials on Anodic Aluminum Oxide Nanoporous Template" Coatings 8, no. 5: 166. https://doi.org/10.3390/coatings8050166

APA StyleGan, Y. X., Yu, Z., Gan, J. B., Cheng, W., & Li, M. (2018). Gold Catalyst-Assisted Metal Organic Chemical Vapor Deposition of Bi-Te-Ni-Cu-Au Complex Thermoelectric Materials on Anodic Aluminum Oxide Nanoporous Template. Coatings, 8(5), 166. https://doi.org/10.3390/coatings8050166