Tribological Properties of New Cu-Al/MoS2 Solid Lubricant Coatings Using Magnetron Sputter Deposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Coatings

2.2. Annealing of Coatings

2.3. Structure Characterization

2.4. Tribological Experiments

3. Results and Discussion

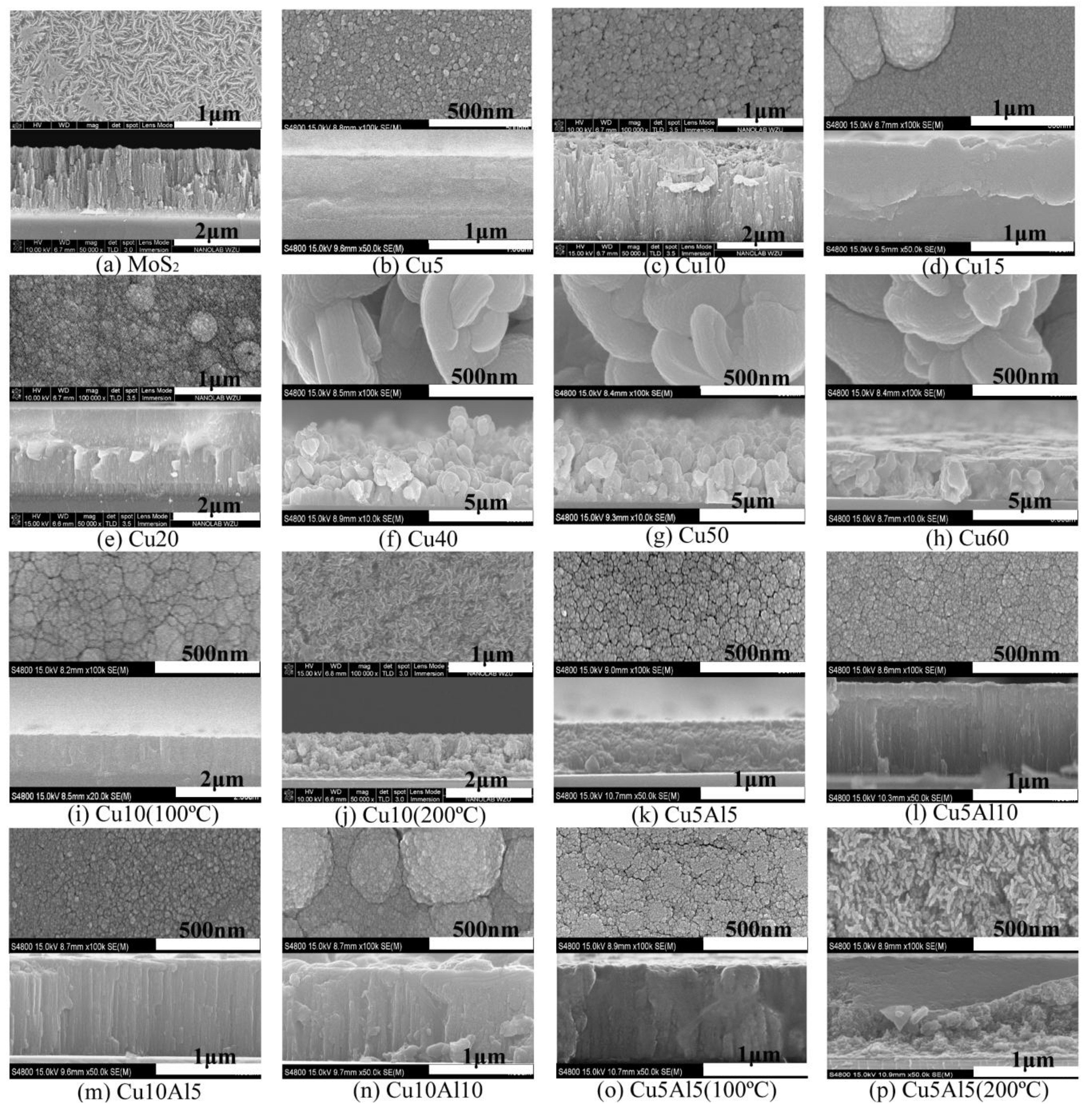

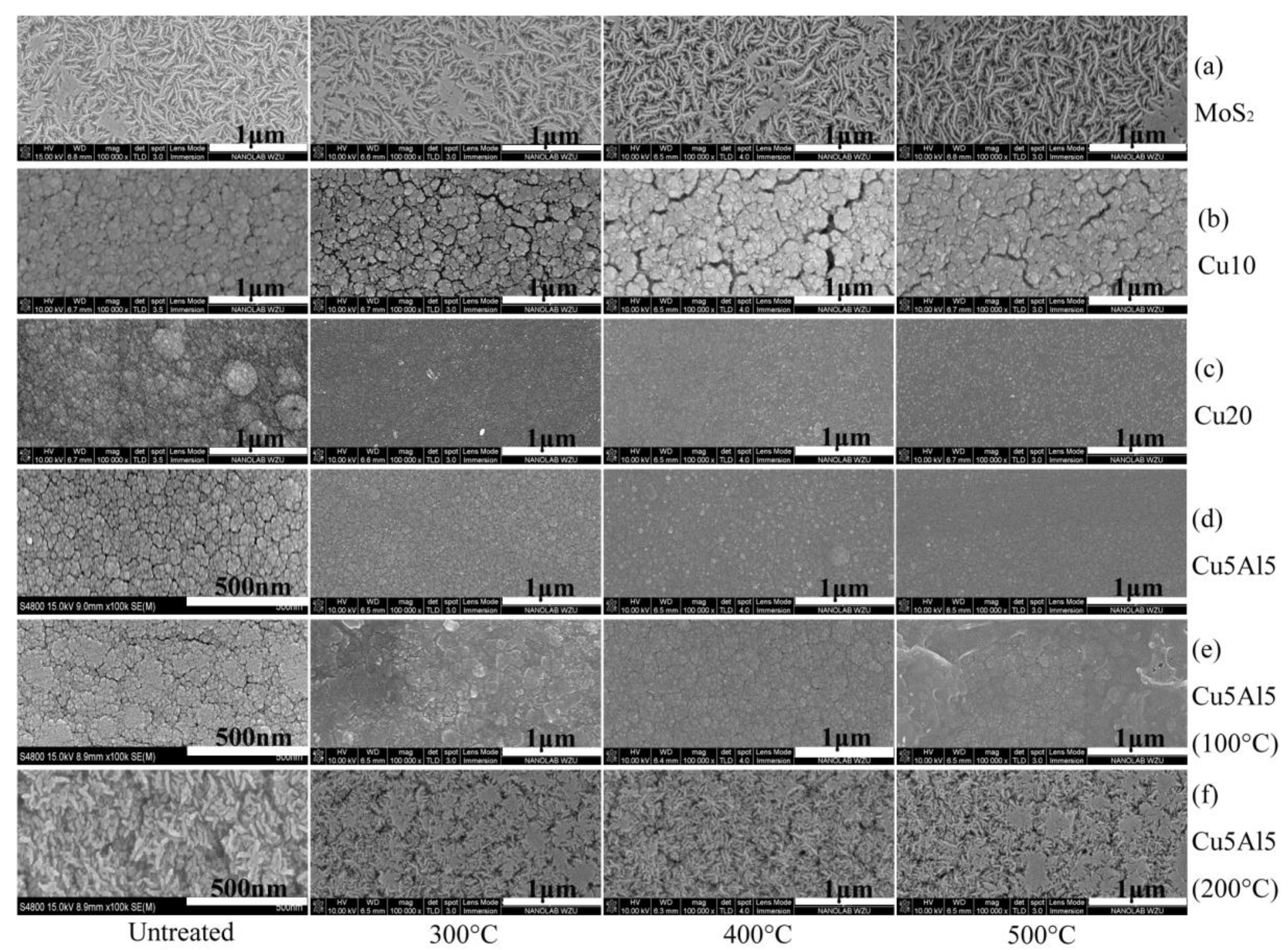

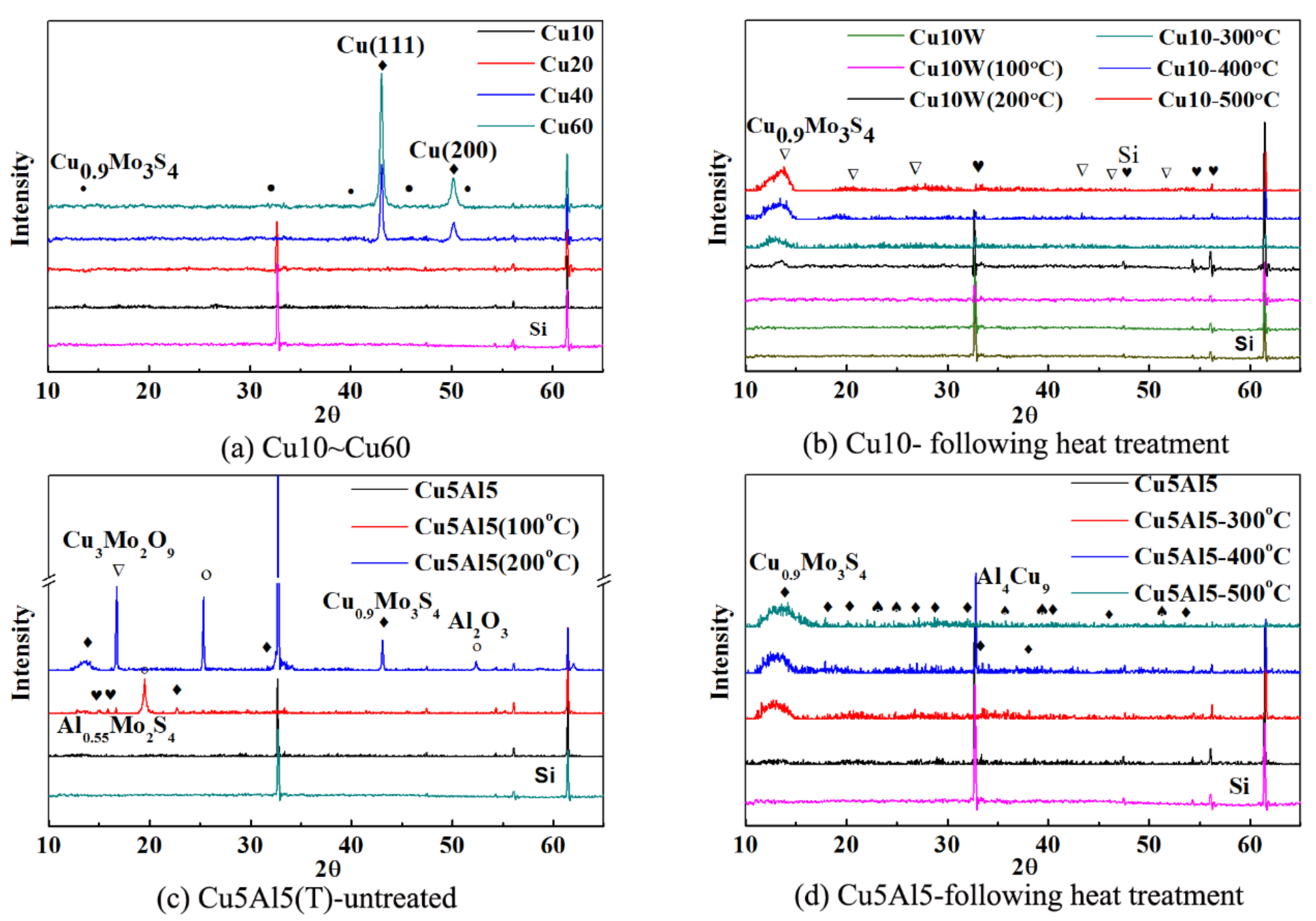

3.1. Coating Composition and Structural Characterization

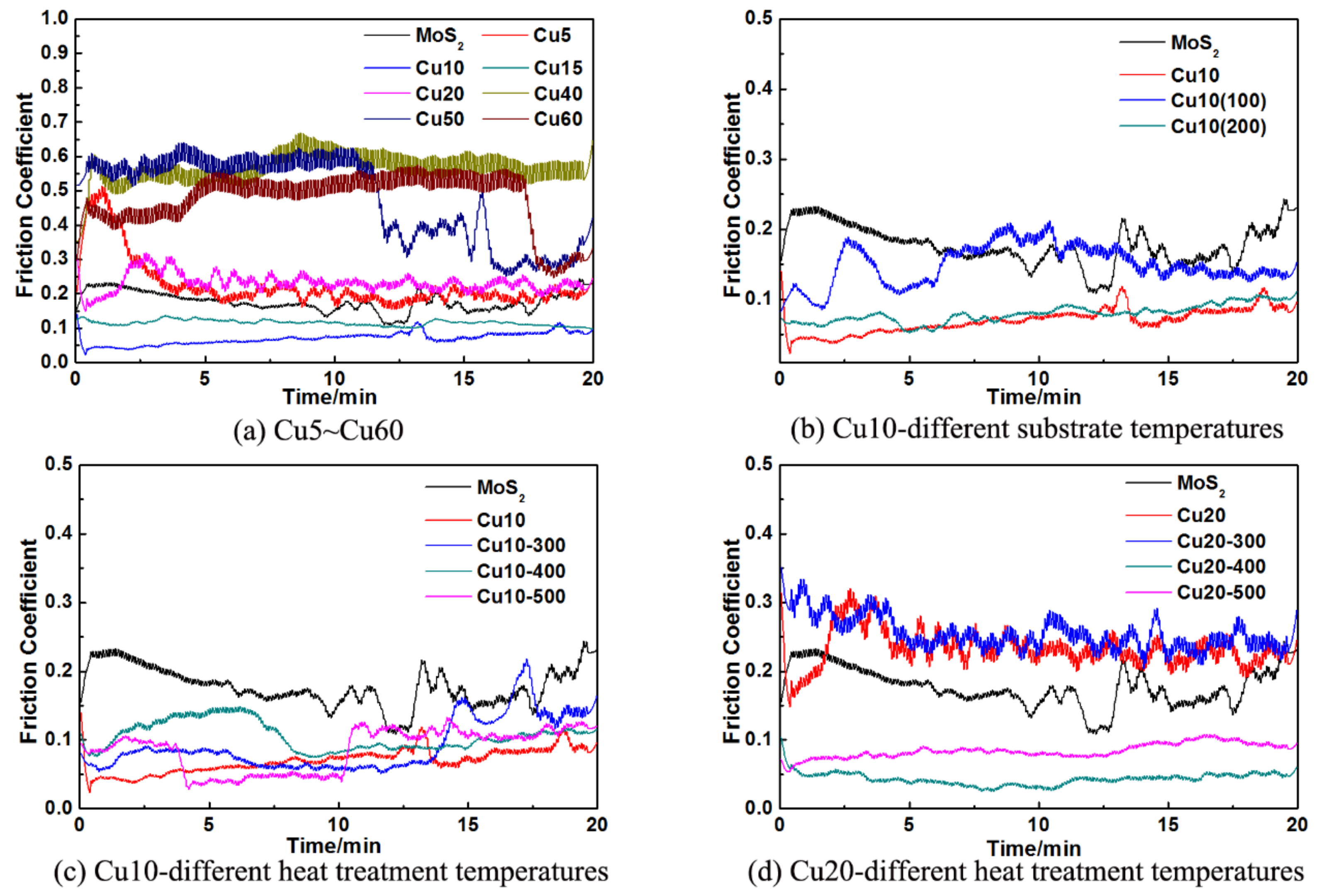

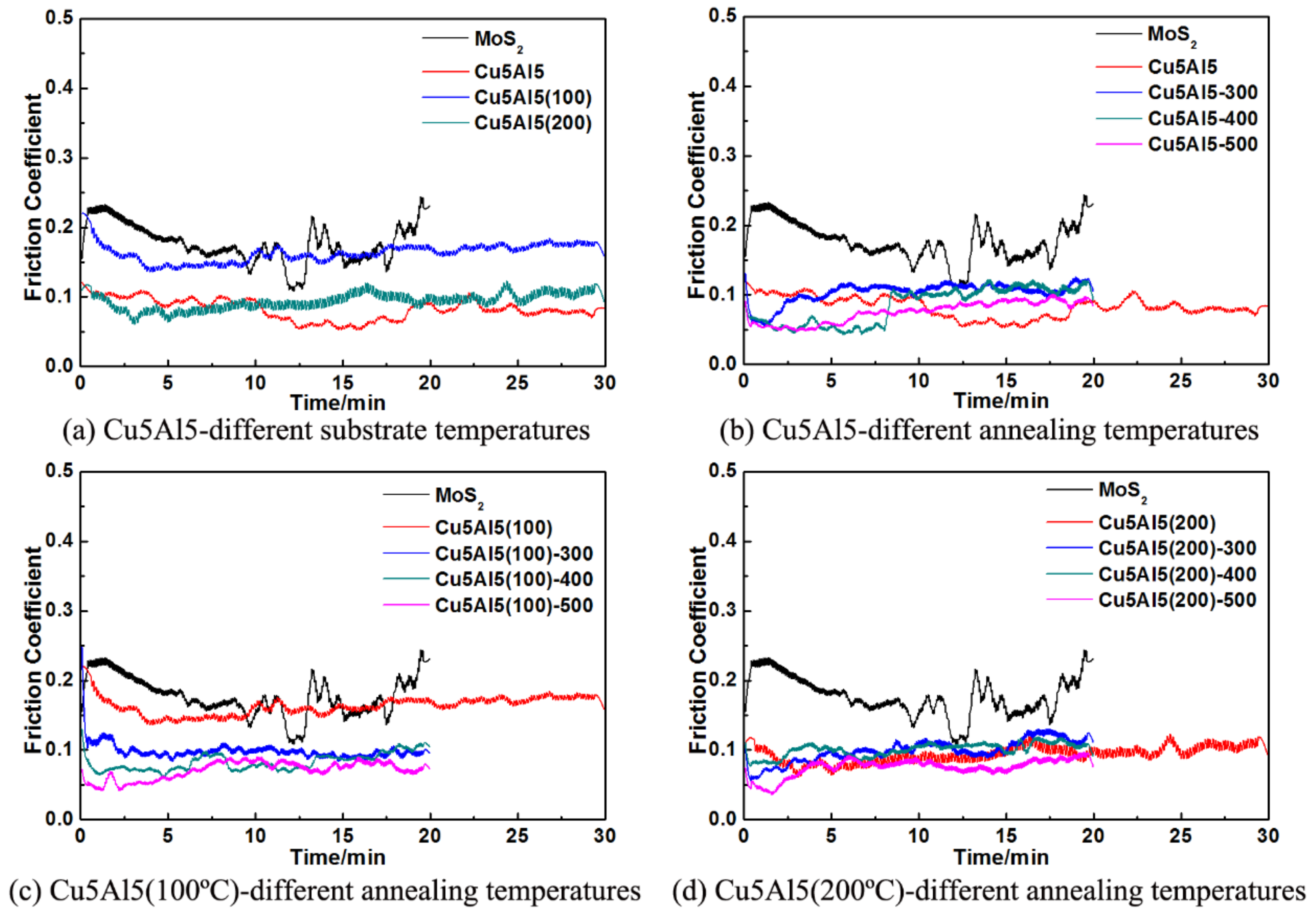

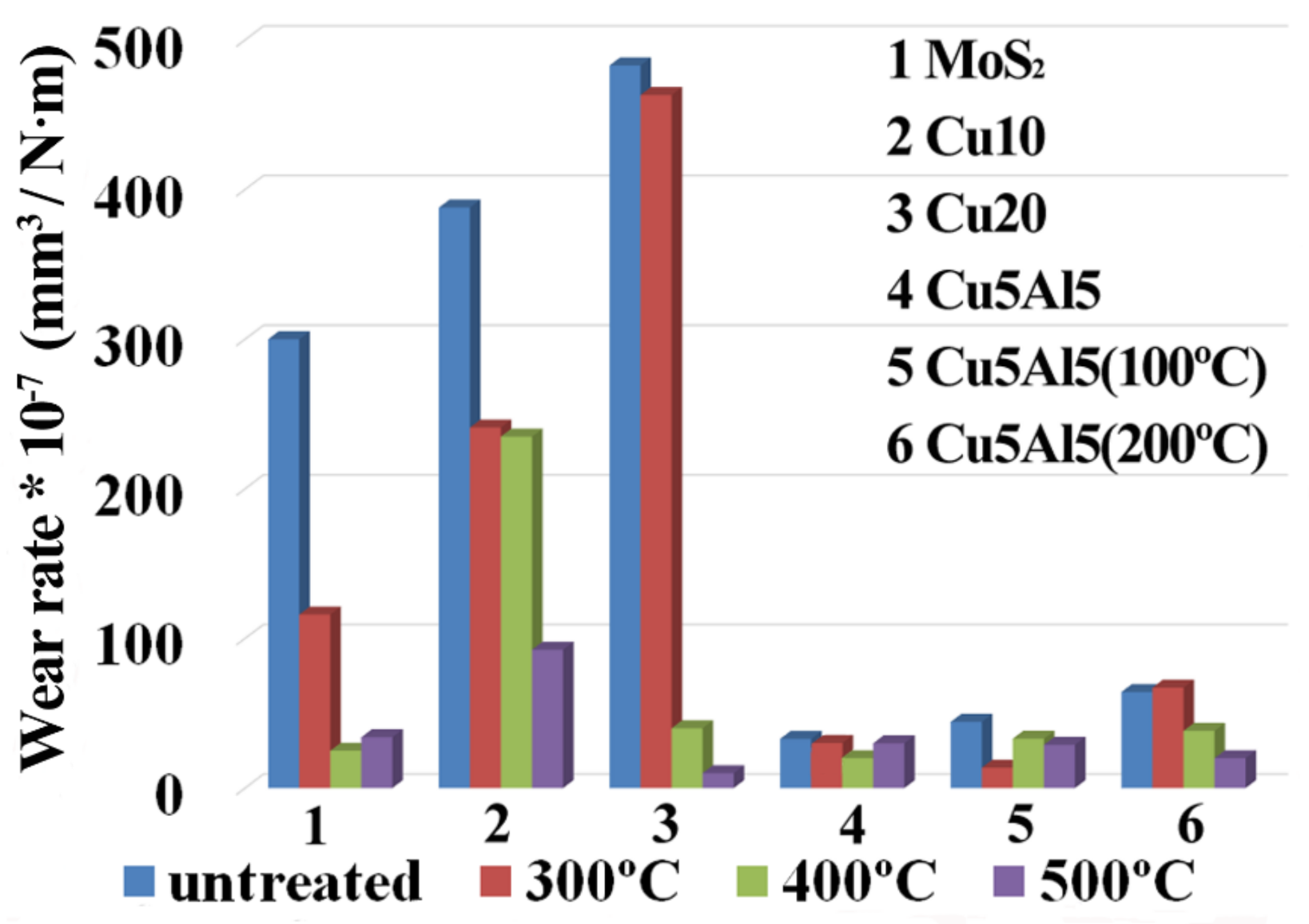

3.2. Friction and Wear Evaluation

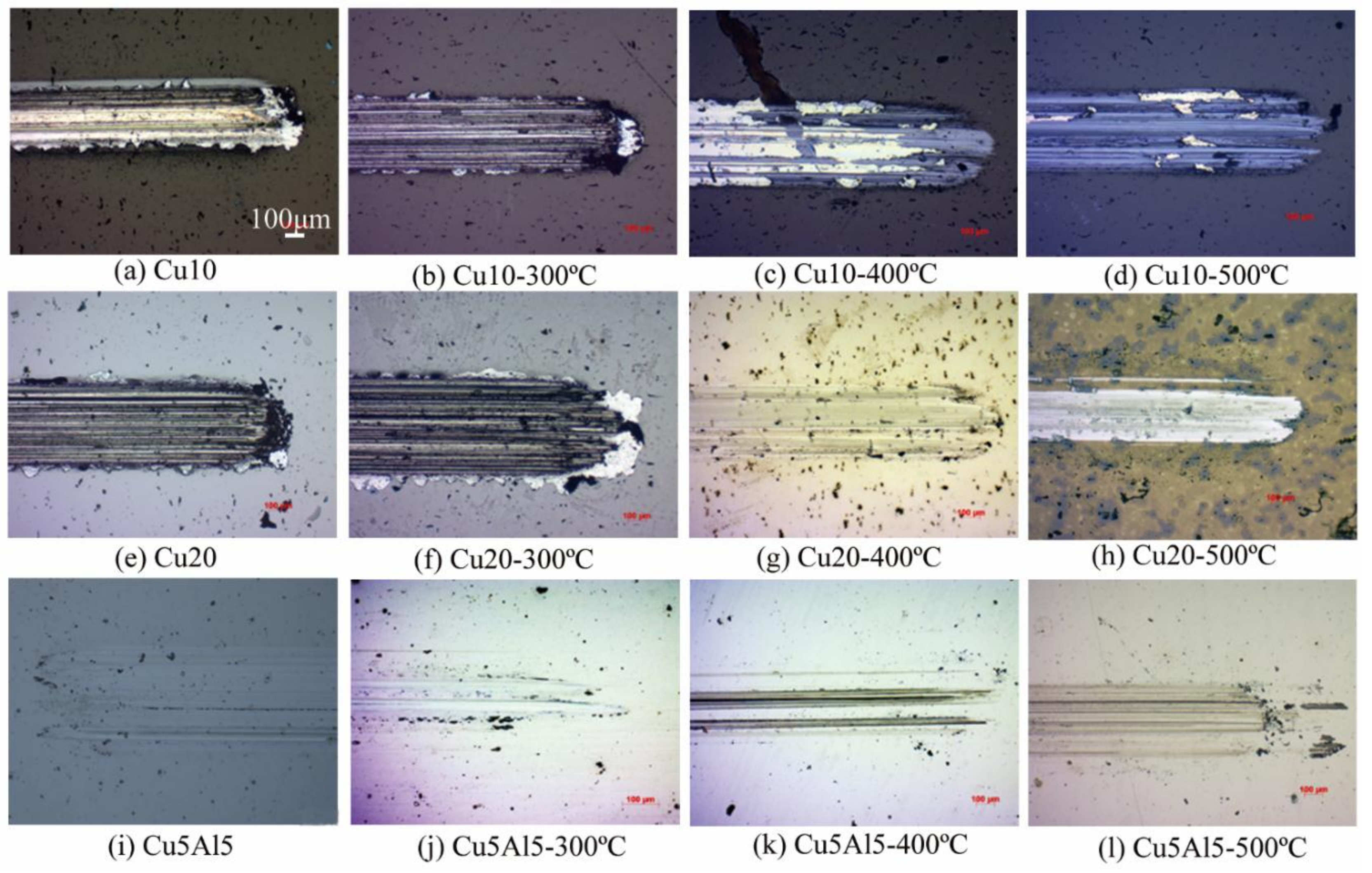

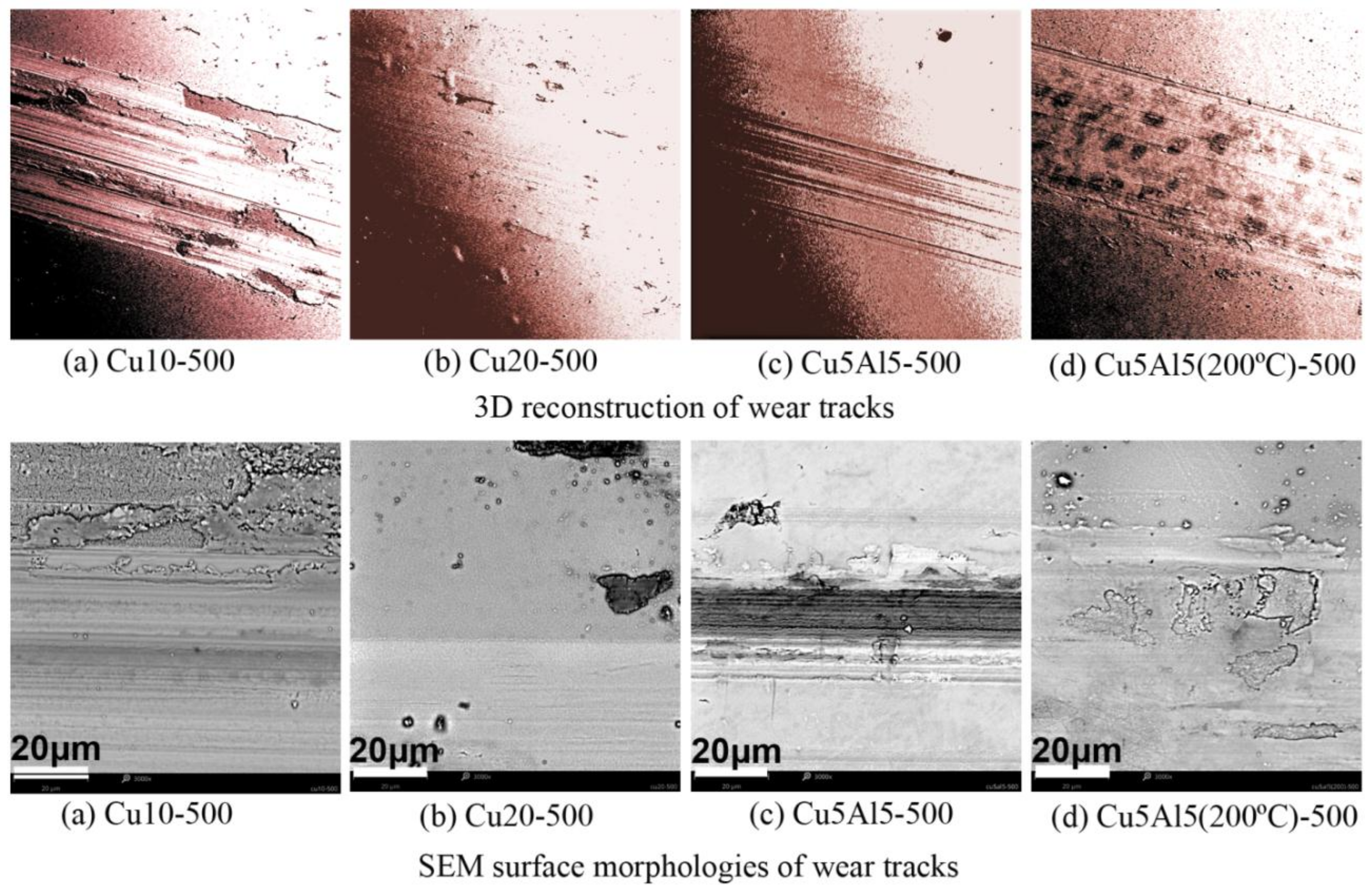

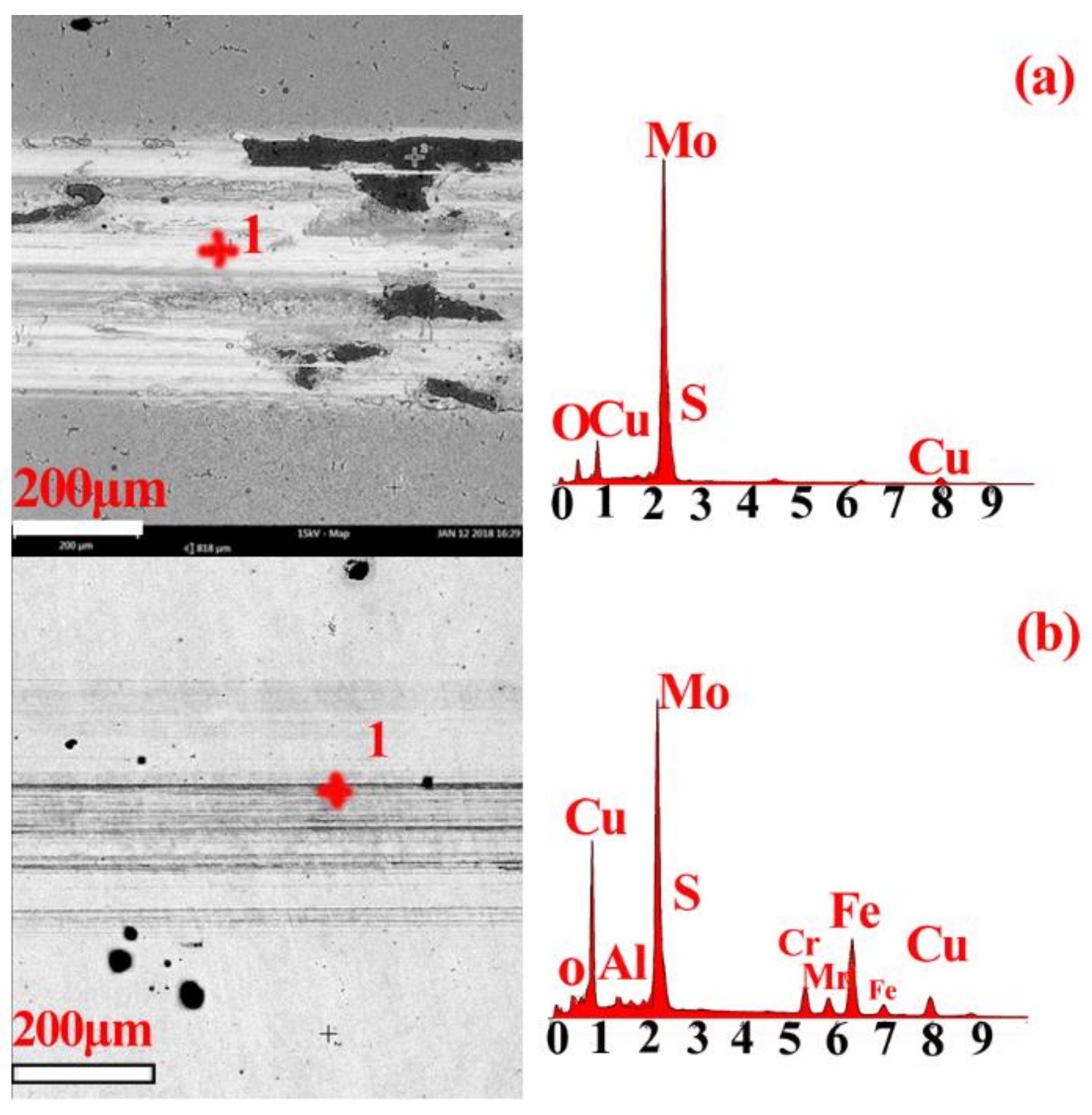

3.3. Wear Mechanisms

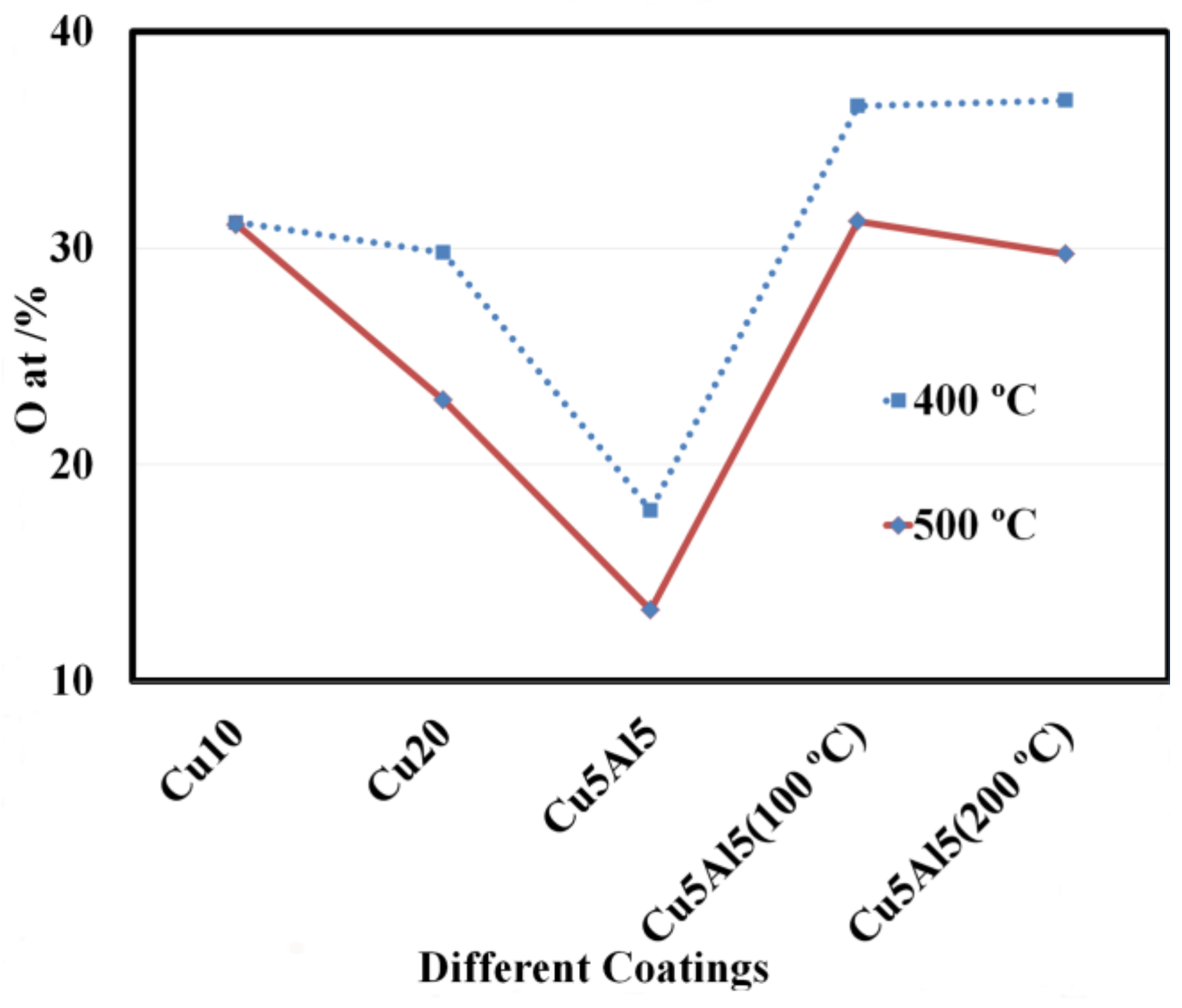

3.4. Oxidation Resistance and Wear Resistance

4. Conclusions

- The Cu/MoS2 composite coatings with various Cu contents were prepared by magnetron sputtering and the tribological properties were tested at room temperature. The Cu10 coating had the lowest friction coefficient among all Cu/MoS2 coatings, whereas the friction coefficient of the Cu5Al5 coating was the lowest in all Cu-Al/MoS2 coatings. The average friction coefficients of the Cu10 and the Cu5Al5 coatings were both lower than the pure MoS2 coating. The abrasion resistance of the coatings co-doped with Cu and Al was significantly enhanced through wear rate qualitative comparison. It was very probable that the γ2-Cu9Al4 phase in the co-sputtered Cu-Al/MoS2 coatings improved the wear resistance.

- Through comparison and analysis of the microstructures observed by SEM, the Cu5Al5 coating with enhanced tribological properties had a smooth surface and a dense cross-sectional non-columnar microstructure. The co-sputtering deposition with Cu and Al led to a smooth surface on the coating. This would lead to the flaking avoidance of the coatings in the friction experiments as well. Following annealing, the grain growth further promoted the compactness of the Cu5Al5 coatings and the wear resistance improvement all at the same time. That was both the low friction coefficient and low wear rate were maintained under the test conditions.

- The surface morphologies of the Cu/MoS2 and Cu-Al/MoS2 coatings turned into a worm-like shape, and the cross-section morphology exhibited a loose microstructure. While the substrate was heated to 200 °C, the friction coefficient and wear rate of the coatings increased. Following annealing at 300 °C, 400 °C and 500 °C, the friction coefficient decreased slightly. It meant that the annealing was more effective than the substrate heating on the friction coefficient reduction. Considering the wear rate, the appropriate range of heat treatment temperature was 400 °C–500 °C.

- The scratch test demonstrated the failure mode of conformal cracking followed by bulking spallation in the Cu-Al/MoS2 coatings, being different from the gross spallation of the Cu10 coating and tensile cracking followed by gross spallation in the Cu20 coating, which had a higher abrasion resistance for the probable cause that the addition of aluminum improved the toughness of the coatings. The worn surface of the Cu5Al5 coating was characterized by typical features of adhesive and abrasive wear.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, H.; Xu, B.; Liu, J. Micro and Nano Sulfide Solid Lubrication, 1st ed.; Springer-Verlag: Berlin/Heidelberg, Germany, 2012; pp. 1–59. ISBN 978-3-642-23101-8. [Google Scholar]

- Materials and Processes for Surface and Interface Engineering; NATO ASI Series E, 290; Pauleau, Y. (Ed.) Kluwer Academic Publishers: Dordrecht, The Netherlands, 1995; pp. 475–527. [Google Scholar]

- Menezes, P.L.; Nosonovsky, M.; Ingole, S.P.; Kailas, S.V.; Lovell, M.R. Tribology for Scientists and Engineers; Springer: New York, NY, USA, 2013; ISBN 978-1-4614-1945-7. [Google Scholar]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Spalvins, T. Lubrication with sputtered MoS2 films: Principles, operation, and limitations. J. Mater. Eng. Perform. 1992, 1, 347–352. [Google Scholar] [CrossRef]

- Yang, J.F.; Jiang, Y.; Hardell, J.; Prakash, B.; Fang, Q.F. Influence of service temperature on tribological characteristics of self-lubricant coatings: A review. Front. Mater. Sci. 2013, 7, 28–39. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, G.; Wang, L.; Xue, Q. The tribological mechanism of MoS2 film under different humidity. Tribol. Lett. 2017, 65, 64–71. [Google Scholar] [CrossRef]

- Spalvins, T. Frictional and morphological properties of Au–MoS2 films sputtered from a compact target. Thin Solid Films 1984, 118, 375–384. [Google Scholar] [CrossRef]

- Goeke, R.S.; Kotula, P.G.; Prasad, S.V.; Scharf, T.W. Synthesis of MoS2–Au Nanocomposite Films by Sputter Deposition; Report No. SAND2012-5081; Department of Energy: Washington, DC, USA, 2012. [Google Scholar]

- Holbery, J.D.; Pflueger, E.; Savan, A.; Gerbig, Y.; Luo, Q.; Lewis, D.B.; Munzd, W.-D. Alloying MoS2 with Al and Au: Structure and tribological performance. Surf. Coat. Technol. 2003, 169, 716–720. [Google Scholar] [CrossRef]

- Li, H.; Zhang, G.; Wang, L. Low humidity-sensitivity of MoS2/Pb nanocomposite coatings. Wear 2016, 350–351, 1–9. [Google Scholar] [CrossRef]

- Wahl, K.J.; Dunn, D.N.; Singer, I.L. Wear behavior of Pb–Mo–S solid lubricating coatings. Wear 1999, 230, 175–183. [Google Scholar] [CrossRef]

- Zhou, H.; Zheng, J.; Wen, Q.P.; Wan, Z.-H.; Sang, R.-P. The effect of Ti content on the structural and mechanical properties of MoS2–Ti composite coatings deposited by unbalanced magnetron sputtering system. Phys. Proced. 2011, 18, 234–239. [Google Scholar]

- Renevier, N.M.; Oosterling, H.; König, U.; Dautzenberg, H.; Kim, B.J.; Geppert, L.; Koopmans, F.G.M.; Leopold, J. Performance and limitations of MoS2/Ti composite coated inserts. Surf. Coat. Technol. 2003, 172, 13–23. [Google Scholar] [CrossRef]

- Mikhailov, S.; Savan, A.; Pflüger, E.; Knoblauchc, L.; Hauertc, R.; Simmondsd, M.; Van Swygenhovend, H. Morphology and tribological properties of metal (oxide)–MoS2 nanostructured multilayer coatings. Surf. Coat. Technol. 1998, 105, 175–183. [Google Scholar] [CrossRef]

- Renevier, N.M.; Fox, V.C.; Teer, D.G.; Hampshire, J. Coating characteristics and tribological properties of sputter-deposited MoS2/metal composite coatings deposited by closed field unbalanced magnetron sputter ion plating. Surf. Coat. Technol. 2000, 127, 24–37. [Google Scholar] [CrossRef]

- Kao, W.H. Tribological properties and high speed drilling application of MoS2–Cr coatings. Wear 2005, 258, 812–825. [Google Scholar] [CrossRef]

- Nainaparampil, J.J.; Phani, A.R.; Krzanowski, J.E.; Zabinski, J.S. Pulsed laser-ablated MoS2–Al films: Friction and wear in humid conditions. Surf. Coat. Technol. 2004, 187, 326–335. [Google Scholar] [CrossRef]

- Song, W.; Deng, J.; Zhang, H.; Yan, P. Study on cutting forces and experiment of MoS2/Zr-coated cemented carbide tool. Int. J. Adv. Manuf. Technol. 2010, 49, 903–909. [Google Scholar]

- Arslan, E.; Totik, Y.; Bayrak, O.; Efeoglu, I.; Celik, A. High temperature friction and wear behavior of MoS2/Nb coating in ambient air. J. Coat. Technol. Res. 2010, 7, 131–137. [Google Scholar] [CrossRef]

- Ilie, F.; Tita, C. Tribological properties of solid lubricant nanocomposite coatings obtained by magnetron sputtered of MoS2/metal (Ti, Mo) nanoparticles. Proc. Romainan Acad. Ser. A 2007, 8, 207–211. [Google Scholar]

- Ren, S.; Li, H.; Cui, M.; Wang, L.; Pu, J. Functional regulation of Pb–Ti/MoS2 composite coatings for environmentally adaptive solid lubrication. Appl. Surf. Sci. 2017, 401, 362–372. [Google Scholar] [CrossRef]

- Kumar, R.; Sudarshan, T.S. Self-lubricating composites: Graphite-copper. Mater. Technol. 1996, 11, 191–194. [Google Scholar] [CrossRef]

- Chen, S.Y.; Wang, J.; Liu, Y.J.; Liang, J.; Liu, C.S. Synthesis of new Cu-based self-lubricating composites with great mechanical properties. J. Compos. Mater. 2011, 45, 51–63. [Google Scholar] [CrossRef]

- Li, S.P.; Deng, J.X.; Yan, G.Y.; Zhang, K.D.; Zhang, G.D. Microstructure, mechanical properties and tribological performance of TiSiN-WS2, hard-lubricant coatings. Appl. Surf. Sci. 2014, 309, 209–217. [Google Scholar] [CrossRef]

- Chang, H.W.; Huang, P.K.; Yeh, J.W.; Davison, A.; Tsau, C.H.; Yang, C.C. Influence of substrate bias, deposition temperature and post-deposition annealing on the structure and properties of multi-principal-component (AlCrMoSiTi)N coatings. Surf. Coat. Technol. 2008, 202, 3360–3366. [Google Scholar] [CrossRef]

- Bolster, R.N.; Singe, I.L.; Wegand, J.C.; Fayeulle, S.; Gossett, C.R. Preparation by ion-beam-assisted deposition, analysis and tribological behavior of MoS2 films. Surf. Coat. Technol. 1991, 46, 207–216. [Google Scholar] [CrossRef]

- Vandenberg, J.M.; Hamm, R.A. An in situ X-ray study of phase formation in Cu–Al thin film couples. Thin Solid Films 1982, 97, 313–323. [Google Scholar] [CrossRef]

- Ramalhoa, A.; Miranda, J.C. The relationship between wear and dissipated energy in sliding systems. Wear 2006, 260, 361–367. [Google Scholar] [CrossRef]

- Buck, V. Morphological properties of sputtered MoS2 films. Wear 1983, 91, 281–288. [Google Scholar] [CrossRef]

- Lian, Y.S.; Deng, J.X.; Li, S.P. Influence of the deposition temperature on the properties of medium-frequency magnetron sputtering WS2 soft coated tools. Adv. Mater. Res. 2012, 472–475, 44–49. [Google Scholar] [CrossRef]

- Teresiak, A. Structure investigations of thin MoSx films. Mikrochim. Acta 1997, 125, 349–353. [Google Scholar] [CrossRef]

- Chen, L.; Paulitsch, J.; Du, Y.; Mayrhofer, P.H. Thermal stability and oxidation resistance of Ti–Al–N coatings. Surf. Coat. Technol. 2012, 206, 2954–2960. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Lu, K. Solid state reaction for magnetron sputtering Cu/Al multilayers. Acta Metall. Sin. 2003, 39, 1–4. (In Chinese) [Google Scholar]

- Zhang, X.L.; Hu, N.-S.; He, J.-W. Study on the methods to improve the properties of sputtering deposited MoS2 films. J. Mater. Eng. 1999, 10, 44–47. (In Chinese) [Google Scholar]

- Fleischauer, P.D. Effects of crystallite orientation on environmental stability and lubrication properties of sputtered MoS2 thin films. ASLE Trans. 1984, 27, 82–88. [Google Scholar] [CrossRef]

| Sample No | Target Power/W | Substrate Heat Temp./°C | ||

|---|---|---|---|---|

| MoS2 | Cu | Al | ||

| Cu5 | 100 | 5 | 0 | Unheated |

| Cu10 | 100 | 10 | 0 | Unheated |

| Cu20 | 100 | 20 | 0 | Unheated |

| Cu40 | 100 | 40 | 0 | Unheated |

| Cu50 | 100 | 50 | 0 | Unheated |

| Cu60 | 100 | 60 | 0 | Unheated |

| Cu10(100 °C) | 100 | 10 | 0 | 100 |

| Cu10(200 °C) | 100 | 10 | 0 | 200 |

| Cu5Al5 | 100 | 5 | 5 | Unheated |

| Cu5Al10 | 100 | 5 | 10 | Unheated |

| Cu10Al5 | 100 | 10 | 5 | Unheated |

| Cu10Al10 | 100 | 10 | 10 | Unheated |

| Cu5Al5(100 °C) | 100 | 5 | 5 | 100 |

| Cu5Al5(200 °C) | 100 | 5 | 5 | 200 |

| Composite Coating | Cu/at.% | NS/NMo |

|---|---|---|

| MoS2 | 1.50 | |

| Cu5 | 7.80 | 0.78 |

| Cu10 | 9.57 | 1.18 |

| Cu20 | 25.13 | 1.34 |

| Cu40 | 40.69 | 1.42 |

| Cu50 | 46.21 | 1.50 |

| Cu60 | 47.99 | 1.78 |

| Cu10 (100 °C) | 28.55 | 1.30 |

| Cu10 (200 °C) | 35.50 | 1.76 |

| Composite Coating | Cu/at.% | Al/at.% | NCu/NAl | NS/NMo |

|---|---|---|---|---|

| MoS2 | 1.5 | |||

| Cu5Al5 | 24.53 | 10.97 | 2.24 | 1.54 |

| Cu5Al10 | 16.26 | 8.78 | 1.85 | 1.92 |

| Cu10Al5 | 28.05 | 4.07 | 6.88 | 1.91 |

| Cu10Al10 | 27.07 | 5.98 | 4.52 | 1.72 |

| Cu5Al5 (100 °C) | 10.95 | 5.63 | 1.94 | 1.39 |

| Cu5Al5 (200 °C) | 11.42 | 3.44 | 3.32 | 1.58 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, M.; Zhao, L.; Wu, L.; Wang, W. Tribological Properties of New Cu-Al/MoS2 Solid Lubricant Coatings Using Magnetron Sputter Deposition. Coatings 2018, 8, 134. https://doi.org/10.3390/coatings8040134

Cao M, Zhao L, Wu L, Wang W. Tribological Properties of New Cu-Al/MoS2 Solid Lubricant Coatings Using Magnetron Sputter Deposition. Coatings. 2018; 8(4):134. https://doi.org/10.3390/coatings8040134

Chicago/Turabian StyleCao, Ming, Lan Zhao, Libin Wu, and Wenquan Wang. 2018. "Tribological Properties of New Cu-Al/MoS2 Solid Lubricant Coatings Using Magnetron Sputter Deposition" Coatings 8, no. 4: 134. https://doi.org/10.3390/coatings8040134

APA StyleCao, M., Zhao, L., Wu, L., & Wang, W. (2018). Tribological Properties of New Cu-Al/MoS2 Solid Lubricant Coatings Using Magnetron Sputter Deposition. Coatings, 8(4), 134. https://doi.org/10.3390/coatings8040134