Microstructure, Microhardness, and Wear Resistance of AlCoCrFeNiTi/Ni60 Coating by Plasma Spraying

Abstract

1. Introduction

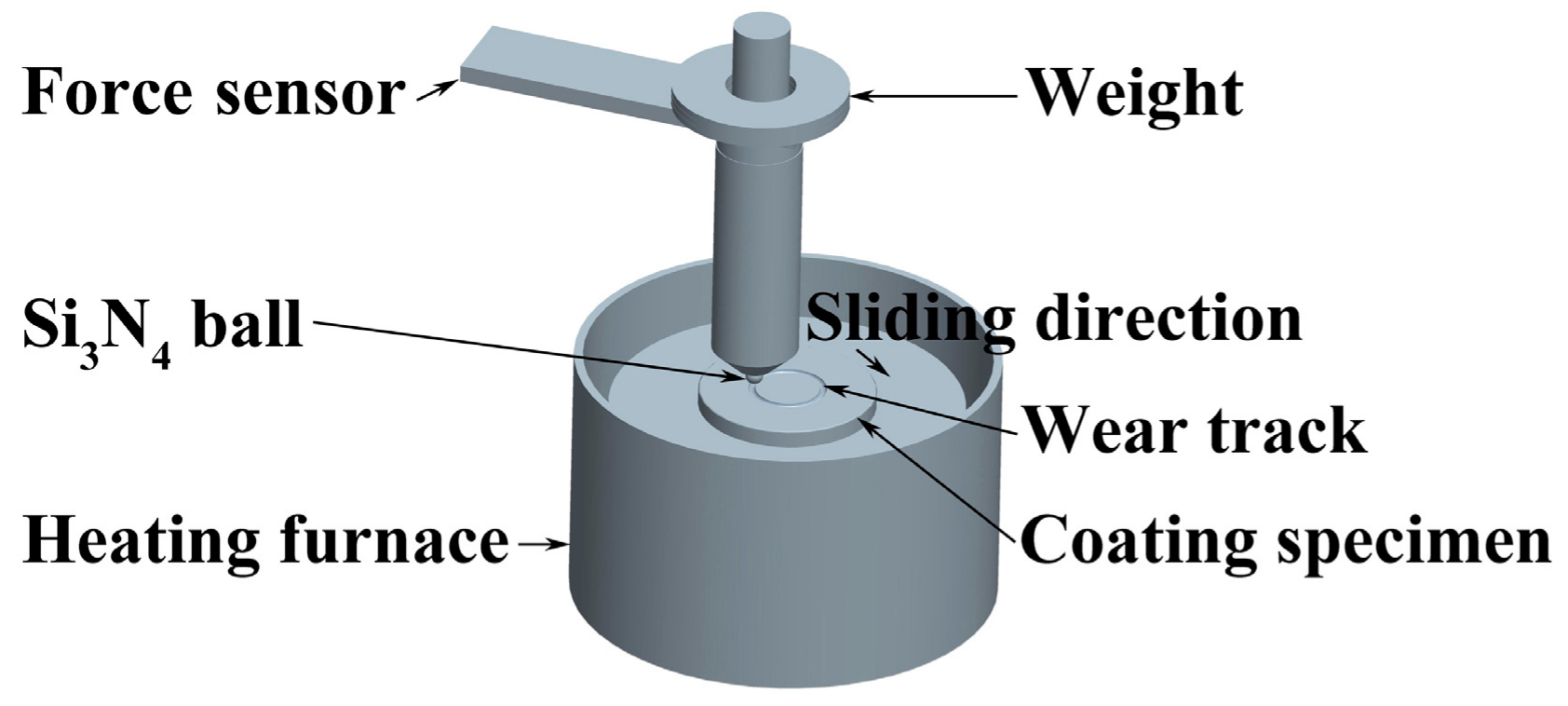

2. Experimental Materials and Procedures

2.1. Materials

2.2. Coating Preparation

2.3. Characterization

3. Results and Discussion

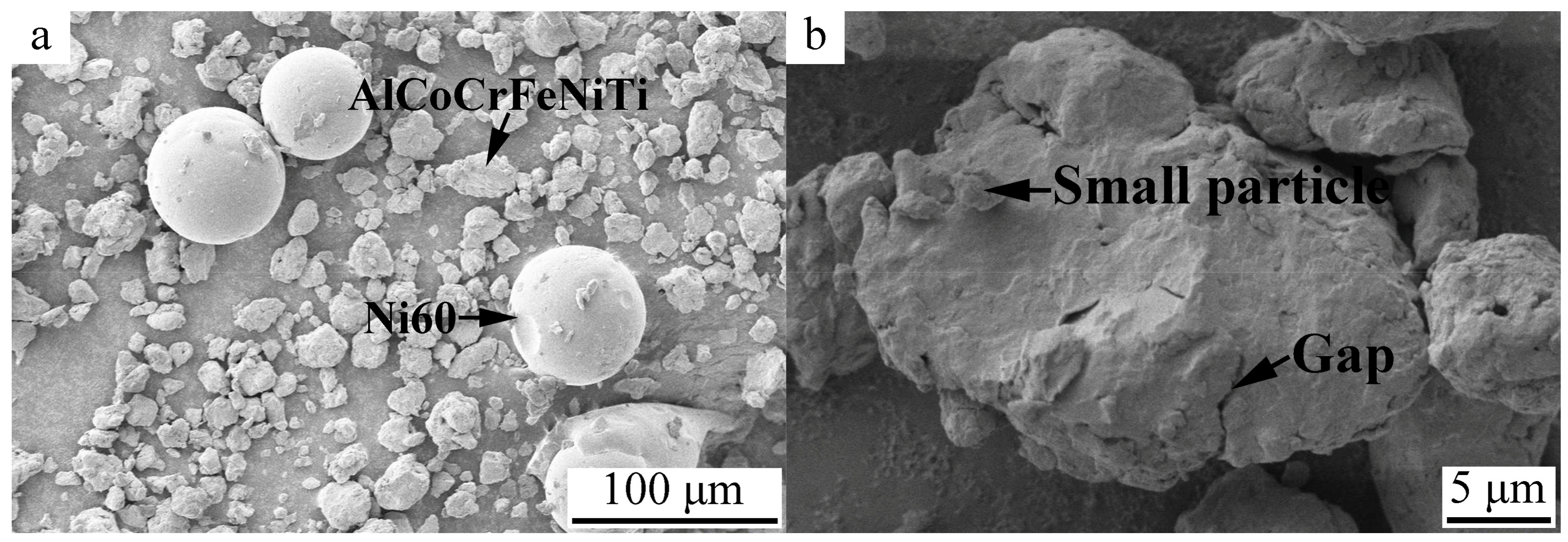

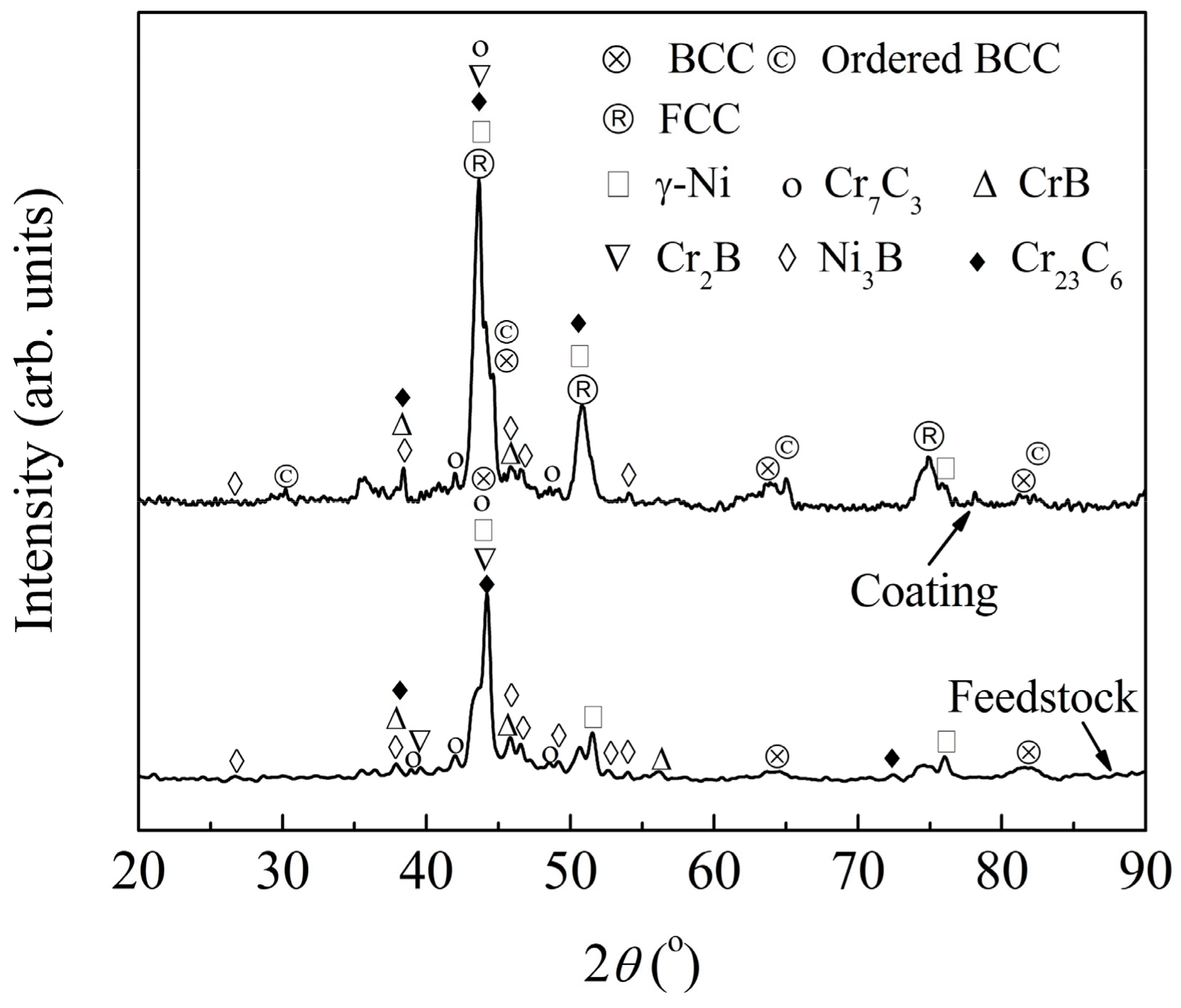

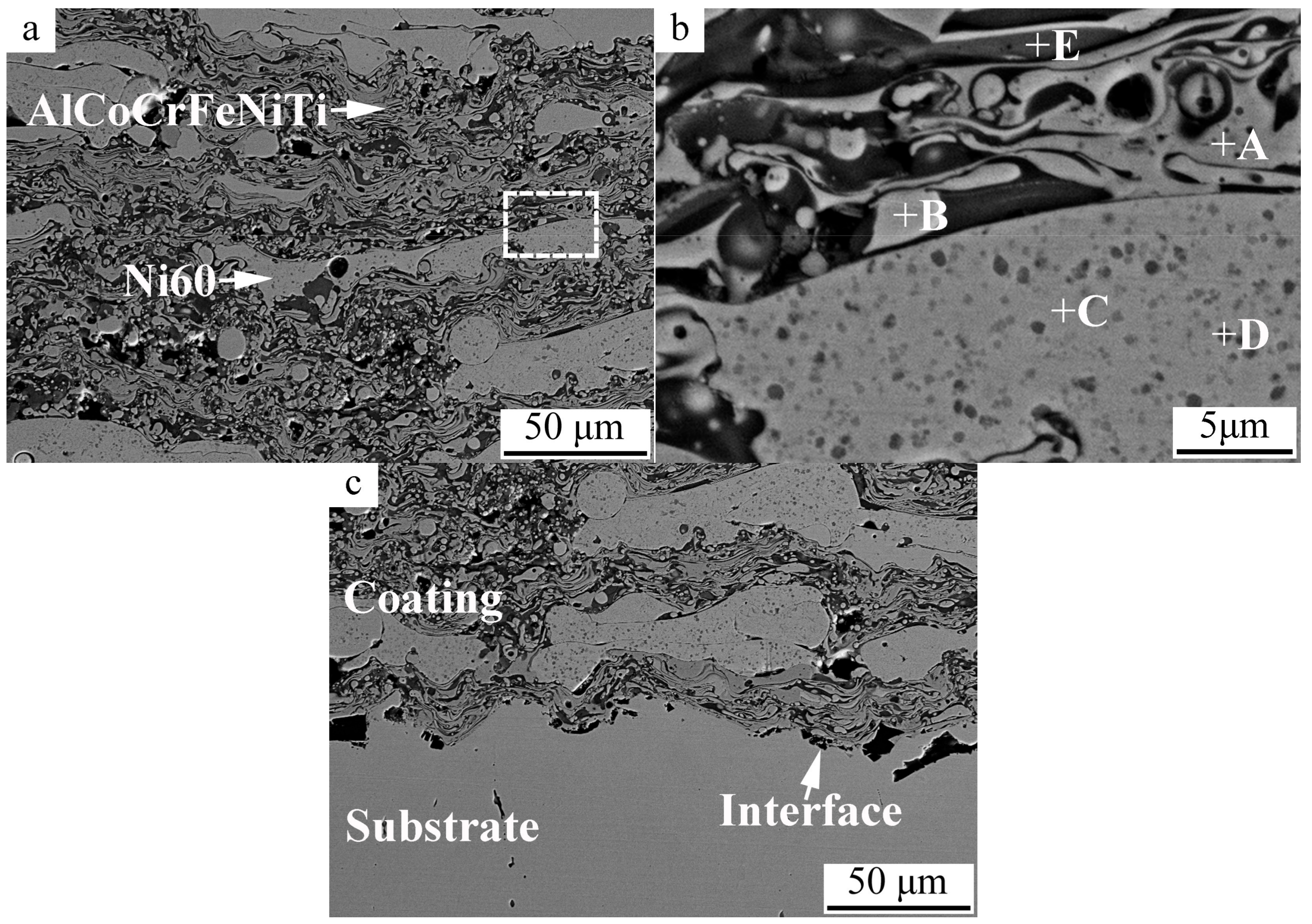

3.1. Microstructure of Feedstock and HEA/Ni60 Coating

3.2. Microhardness of HEA/Ni60 Coating

3.3. Wear Resistance of HEA/Ni60 Coating

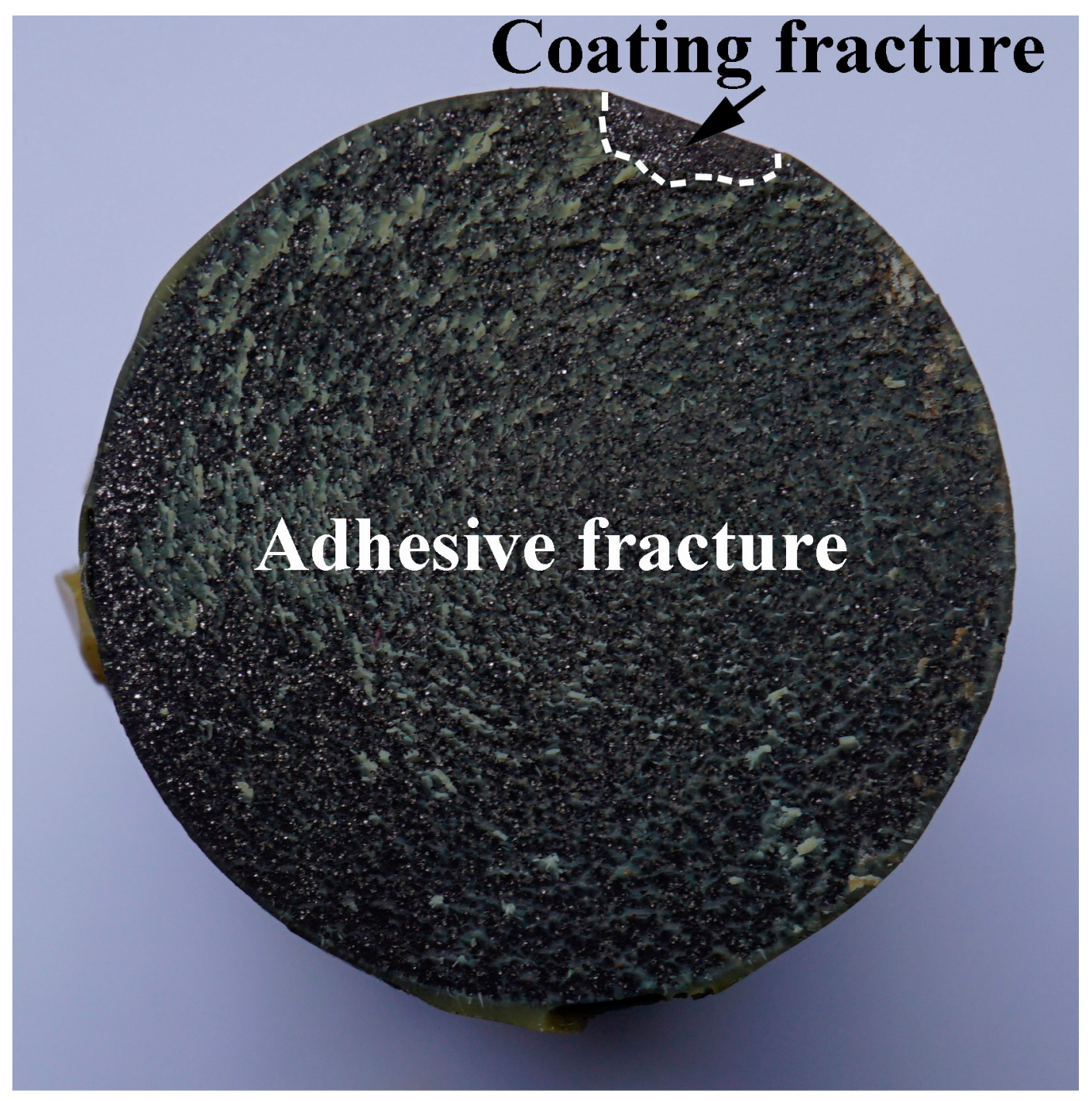

3.3.1. Wear Mechanism

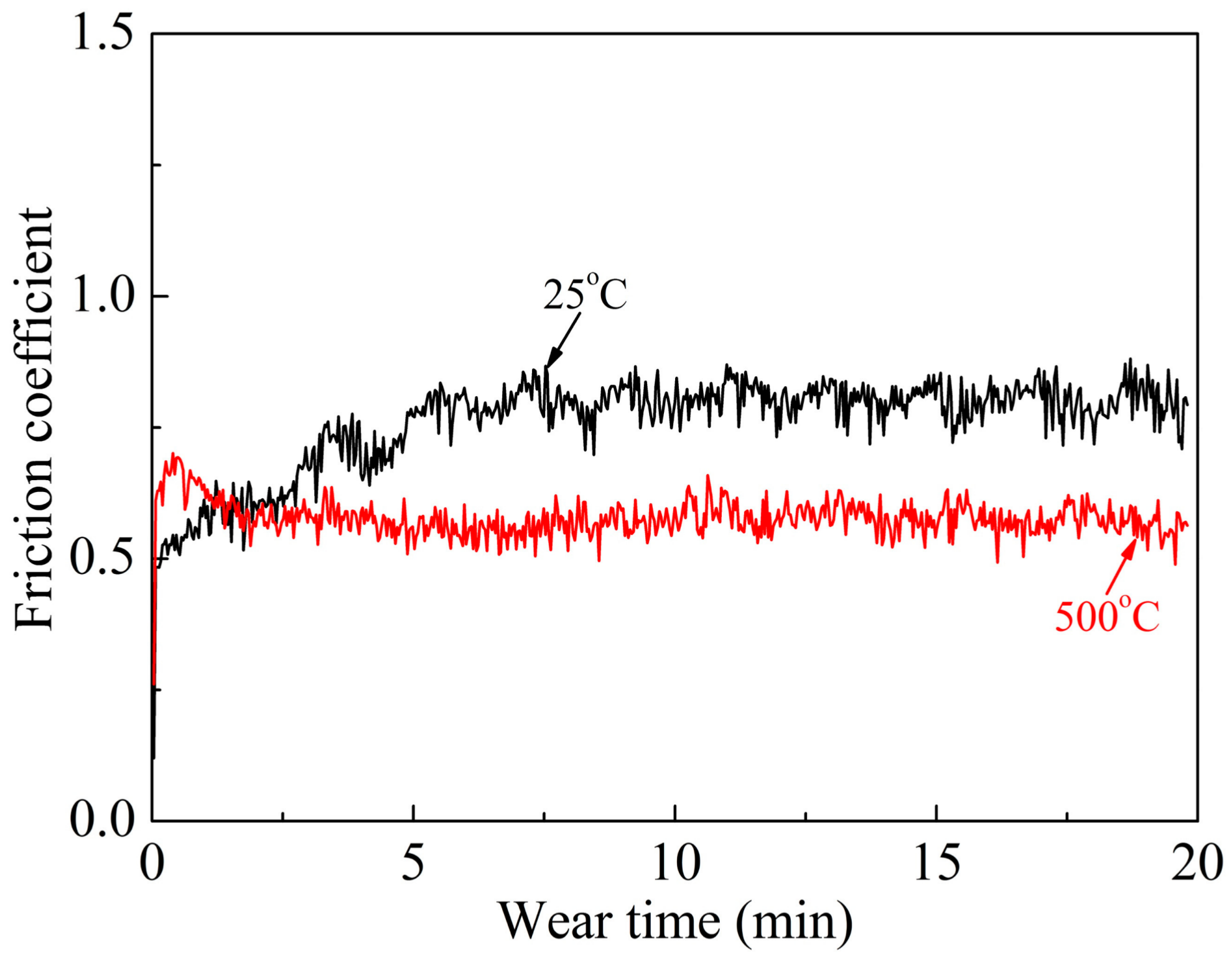

3.3.2. Friction Coefficient

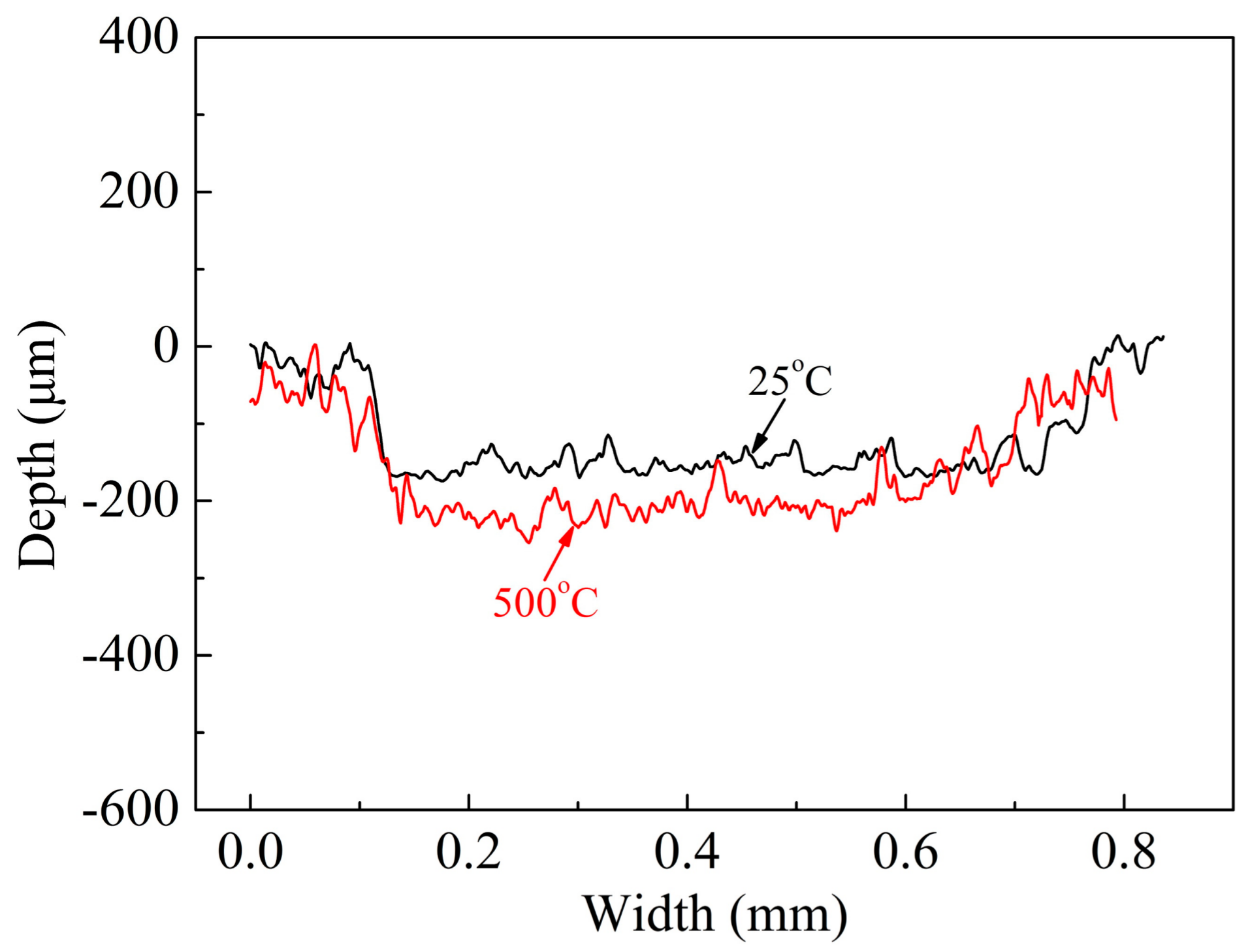

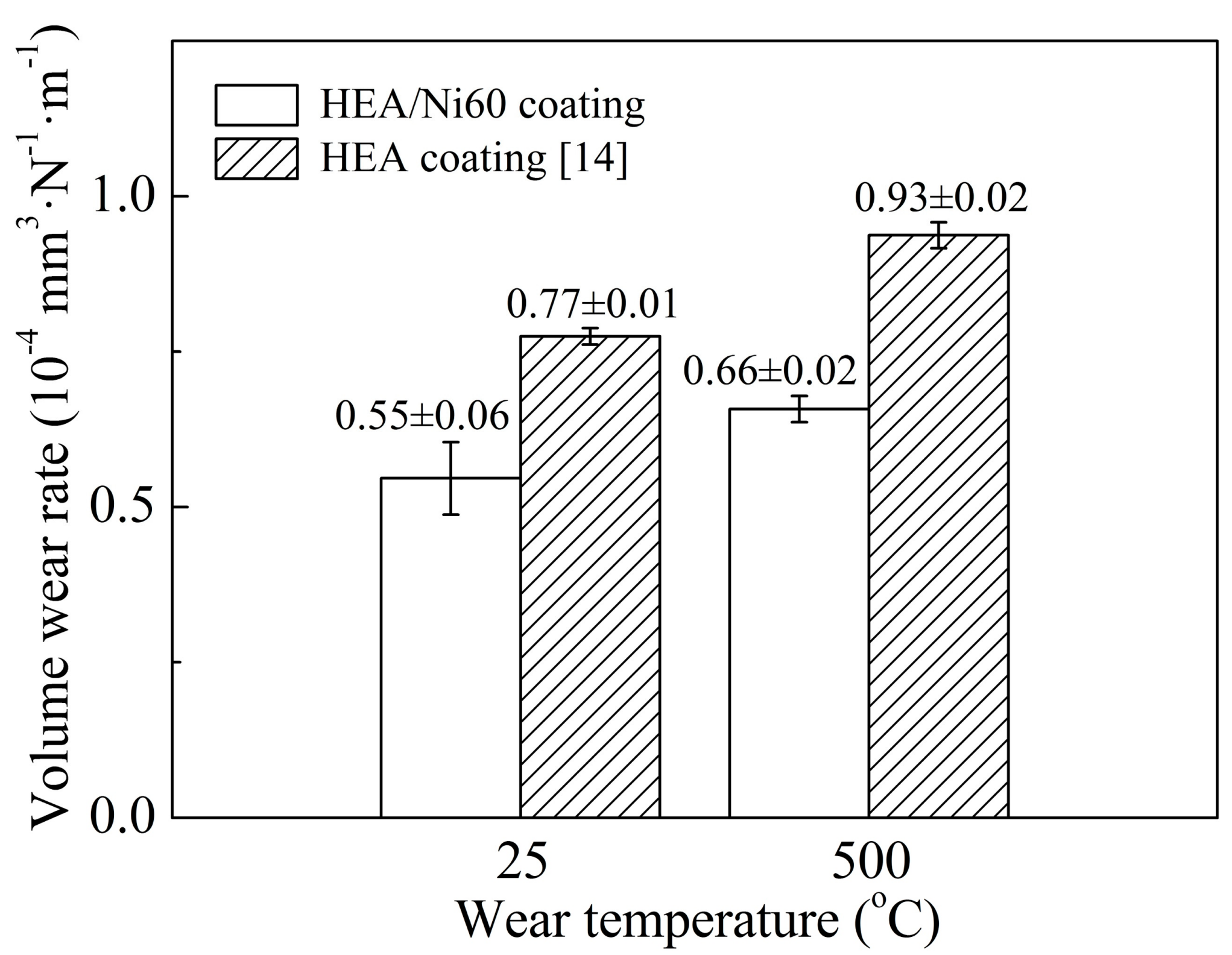

3.3.3. Volume Wear Rate

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Duval, T.; Hung, U.D.; Yeh, J.W.; Shih, H.C. Microstructure and electrochemical properties of high entropy alloys—A comparison with type-304 stainless steel. Corros. Sci. 2005, 47, 2257–2279. [Google Scholar] [CrossRef]

- Niu, S.Z.; Kou, H.C.; Guo, T.; Zhang, Y.; Wang, J.; Li, J.S. Strengthening of nanoprecipitations in an annealed Al0.5CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 2016, 671, 82–86. [Google Scholar] [CrossRef]

- Zhang, K.B.; Fu, Z.Y.; Zhang, J.Y.; Wang, W.M.; Lee, S.W.; Niihara, K. Characterization of nanocrystalline CoCrFeNiTiAl high-entropy solid solution processed by mechanical alloying. J. Alloys Compd. 2010, 495, 33–38. [Google Scholar] [CrossRef]

- Peng, Z.; Liu, N.; Zhang, S.Y.; Wu, P.H.; Wang, X.J. Liquid-phase separation of immiscible CrCuxFeMoyNi high-entropy alloys. Mater. Sci. Technol. 2017, 33, 1352–1359. [Google Scholar] [CrossRef]

- Wu, P.H.; Peng, Z.; Liu, N.; Niu, M.Y.; Zhu, Z.X.; Wang, X.J. The effect of Mn content on the microstructure and properties of CoCrCu0.1Fe0.15Mo1.5MnxNi near equiatomic alloys. Mater. Trans. JIM 2016, 57, 5–8. [Google Scholar] [CrossRef]

- Soare, V.; Burada, M.; Constantin, I.; Mitrică, D.; Bădiliţă, V.; Caragea, A.; Târcolea, M. Electrochemical deposition and microstructural characterization of AlCrFeMnNi and AlCrCuFeMnNi high entropy alloy thin films. Appl. Surf. Sci. 2015, 358, 533–539. [Google Scholar] [CrossRef]

- Braeckman, B.R.; Boydens, F.; Hidalgo, H.; Dutheil, P.; Jullien, M.; Thomann, A.L.; Depla, D. High entropy alloy thin films deposited by magnetron sputtering of powder targets. Thin Solid Films 2015, 580, 71–76. [Google Scholar] [CrossRef]

- Xu, J.H.; Chen, J.; Yu, L.H. Influence of Si content on the microstructure and mechanical properties of VSiN films deposited by reactive magnetron sputtering. Vacuum 2016, 131, 51–57. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y.Z.; Jiao, H.S. Microstructure and properties of 6FeNiCoSiCrAlTi high-entropy alloy coating prepared by laser cladding. Appl. Surf. Sci. 2011, 257, 2259–2263. [Google Scholar] [CrossRef]

- Jin, Y.J.; Li, R.F.; Zheng, Q.C.; Li, H.; Wu, M.F. Structure and properties of laser-cladded Ni-based amorphous composite coatings. Mater. Sci. Technol. 2016, 32, 1206–1211. [Google Scholar] [CrossRef]

- Ang, A.S.M.; Berndt, C.C.; Sesso, M.L.; Anupam, A.; Praveen, S.; Kottada, R.S.; Murty, B.S. Plasma-sprayed high entropy alloys: Microstructure and properties of AlCoCrFeNi and MnCoCrFeNi. Metall. Mater. Trans. A 2015, 46, 791–800. [Google Scholar] [CrossRef]

- Wang, L.M.; Chen, C.C.; Yeh, J.W.; Ke, S.T. The microstructure and strengthening mechanism of thermal spray coating NixCo0.6Fe0.2CrySizAlTi0.2 high-entropy alloys. Mater. Chem. Phys. 2011, 126, 880–885. [Google Scholar] [CrossRef]

- Tian, L.H.; Xiong, W.; Liu, C.; Lu, S.; Fu, M. Microstructure and wear behavior of atmospheric plasma-sprayed AlCoCrFeNiTi high-entropy alloy coating. J. Mater. Eng. Perform. 2016, 25, 5513–5521. [Google Scholar] [CrossRef]

- Oñoro, J. High-temperature mechanical properties of aluminium alloys reinforced with titanium diboride (TiB2) particles. Rare Met. 2011, 499, 421–426. [Google Scholar] [CrossRef]

- Shao, J.Z.; Li, J.; Song, R.; Bai, L.L.; Chen, J.L.; Qu, C.C. Microstructure and wear behaviors of TiB/TiC reinforced Ti2Ni/α(Ti) matrix coating produced by laser cladding. Rare Met. 2016. [Google Scholar] [CrossRef]

- Simunovic, K.; Saric, T.; Simunovic, G. Different approaches to the investigation and testing of the Ni-based self-fluxing alloy coatings—A review. Part 1: General facts, wear and corrosion investigations. Tribol. Trans. 2014, 57, 955–979. [Google Scholar] [CrossRef]

- Simunovic, K.; Saric, T.; Simunovic, G. Different approaches to the investigation and testing of the Ni-based self-fluxing alloy coatings—A review. Part 2: Microstructure, adhesive strength, cracking behavior, and residual stresses investigations. Tribol. Trans. 2014, 57, 980–1000. [Google Scholar] [CrossRef]

- Natarajan, S.; Anand, E.E.; Akhilesh, K.S.; Rajagopal, A.; Nambiar, P.P. Effect of graphite addition on the microstructure, hardness and abrasive wear behavior of plasma sprayed NiCrBSi coatings. Mater. Chem. Phys. 2016, 175, 100–106. [Google Scholar] [CrossRef]

- ISO 14916 Thermal Spraying–Determination of Tensile Adhesive Strength; ISO: Geneva, Switzerland, 1999.

- Tian, L.H.; Fu, M.; Xiong, W. Microstructural evolution of AlCoCrFeNiSi high-entropy alloy powder during mechanical alloying and its coating performance. Materials 2018, 11, 320. [Google Scholar] [CrossRef] [PubMed]

- Houdková, Š.; Smazalová, E.; Vostřák, M.; Schubert, J. Properties of NiCrBSi coating, as sprayed and remelted by different technologies. Surf. Coat. Technol. 2014, 253, 14–26. [Google Scholar] [CrossRef]

- McPherson, R. The relationship between the mechanism of formation, microstructure and properties of plasma-sprayed coatings. Thin Solid Films 1981, 83, 297–310. [Google Scholar] [CrossRef]

- Li, C.J.; Ohmori, A.; McPherson, R. The relationship between microstructure and Young’s modulus of thermally sprayed ceramic coatings. J. Mater. Sci. 1997, 32, 997–1004. [Google Scholar] [CrossRef]

- Li, C.J.; Ohmori, A. Relationships between the microstructure and properties of thermally sprayed deposits. J. Therm. Spray Technol. 2002, 11, 365–374. [Google Scholar] [CrossRef]

- Xing, Y.Z.; Li, C.J.; Li, C.X.; Yang, G.J. Influence of through-lamella grain growth on ionic conductivity of plasma-sprayed yttria-stabilized zirconia as an electrolyte in solid oxide fuel cells. J. Power Sources 2008, 176, 31–38. [Google Scholar] [CrossRef]

- Tung, C.C.; Yeh, J.W.; Shun, T.T.; Chen, S.K.; Huang, Y.S.; Chen, H.C. On the elemental effect of AlCoCrCuFeNi high-entropy alloy system. Mater. Lett. 2007, 61, 1–5. [Google Scholar] [CrossRef]

- Lin, C.W.; Tsai, M.H.; Tsai, C.W.; Yeh, J.W.; Chen, S.K. Microstructure and aging behaviour of Al5Cr32Fe35Ni22Ti6 high entropy alloy. Mater. Sci. Technol. 2015, 31, 1165–1170. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, W.M.; Zhang, T.B.; Li, J.S.; Wang, J.; Kou, H.C.; Li, J. Microstructure and tribological properties of AlCoCrFeNiTi0.5 high-entropy alloy in hydrogen peroxide solution. Metall. Mater. Trans. A 2014, 45, 201–207. [Google Scholar] [CrossRef]

- Leitner, J.; Dubsky, J.; Had, J.; Hanousek, F.; Kolman, B.; Volenik, K. Metastable chromium-rich oxide formed during plasma spraying of high-alloy steel. Oxid. Met. 2000, 54, 549–558. [Google Scholar] [CrossRef]

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Li, J.F.; Ding, C.X. Study on Vickers hardness of plasma sprayed Cr3C2-NiCr coating. J. Chin. Ceram. Soc. 2000, 28, 223–228. [Google Scholar]

- Luo, Q. Temperature dependent friction and wear of magnetron sputtered coating TiAlN/VN. Wear 2011, 271, 2058–2066. [Google Scholar] [CrossRef]

| Element | Content |

|---|---|

| C | 0.63 |

| B | 2.97 |

| Si | 4.50 |

| Fe | 5.31 |

| Cr | 16.20 |

| Ni | Bal. |

| Point | Al | Co | Cr | Fe | Ni | Ti | Si | O | C | B |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 8.66 | 21.65 | 17.72 | 20.16 | 20.98 | 10.83 | 0.00 | 0.00 | 0.00 | 0.00 |

| B | 0.00 | 33.09 | 1.29 | 5.12 | 53.95 | 0.94 | 0.00 | 5.61 | 0.00 | 0.00 |

| C | 0.00 | 0.00 | 39.75 | 4.94 | 49.47 | 0.00 | 5.32 | 0.00 | 0.52 | 0.00 |

| D | 0.00 | 0.00 | 29.21 | 8.44 | 25.76 | 0.00 | 4.49 | 0.00 | 0.00 | 32.10 |

| E | 6.28 | 7.24 | 1.94 | 18.42 | 7.77 | 4.42 | 0.00 | 53.93 | 0.00 | 0.00 |

| Point | Al | Co | Cr | Fe | Ni | Ti | Si | O |

|---|---|---|---|---|---|---|---|---|

| 1 | 2.39 | 3.95 | 4.05 | 3.92 | 11.58 | 5.04 | 4.50 | 64.57 |

| 2 | 0.00 | 0.00 | 25.15 | 5.10 | 47.60 | 0.50 | 5.67 | 15.98 |

| 3 | 0.00 | 0.00 | 15.46 | 4.93 | 71.57 | 0.00 | 8.04 | 0.00 |

| 4 | 3.07 | 6.08 | 4.59 | 6.03 | 12.52 | 6.91 | 0.87 | 59.92 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, L.; Feng, Z.; Xiong, W. Microstructure, Microhardness, and Wear Resistance of AlCoCrFeNiTi/Ni60 Coating by Plasma Spraying. Coatings 2018, 8, 112. https://doi.org/10.3390/coatings8030112

Tian L, Feng Z, Xiong W. Microstructure, Microhardness, and Wear Resistance of AlCoCrFeNiTi/Ni60 Coating by Plasma Spraying. Coatings. 2018; 8(3):112. https://doi.org/10.3390/coatings8030112

Chicago/Turabian StyleTian, Lihui, Zongkang Feng, and Wei Xiong. 2018. "Microstructure, Microhardness, and Wear Resistance of AlCoCrFeNiTi/Ni60 Coating by Plasma Spraying" Coatings 8, no. 3: 112. https://doi.org/10.3390/coatings8030112

APA StyleTian, L., Feng, Z., & Xiong, W. (2018). Microstructure, Microhardness, and Wear Resistance of AlCoCrFeNiTi/Ni60 Coating by Plasma Spraying. Coatings, 8(3), 112. https://doi.org/10.3390/coatings8030112