Extinction Properties of Obliquely Deposited TiN Nanorod Arrays

Abstract

1. Introduction

2. Experiments and Results

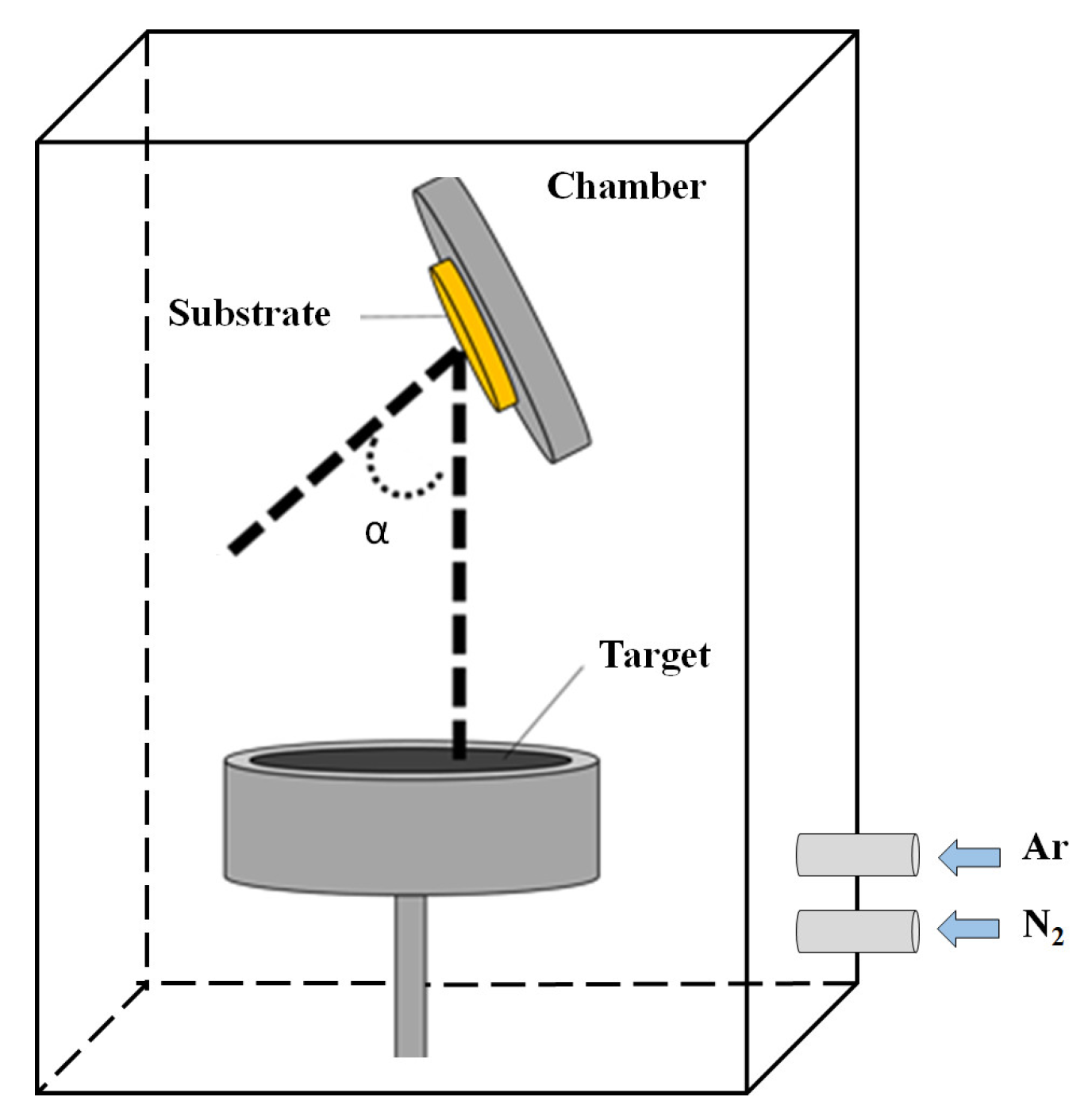

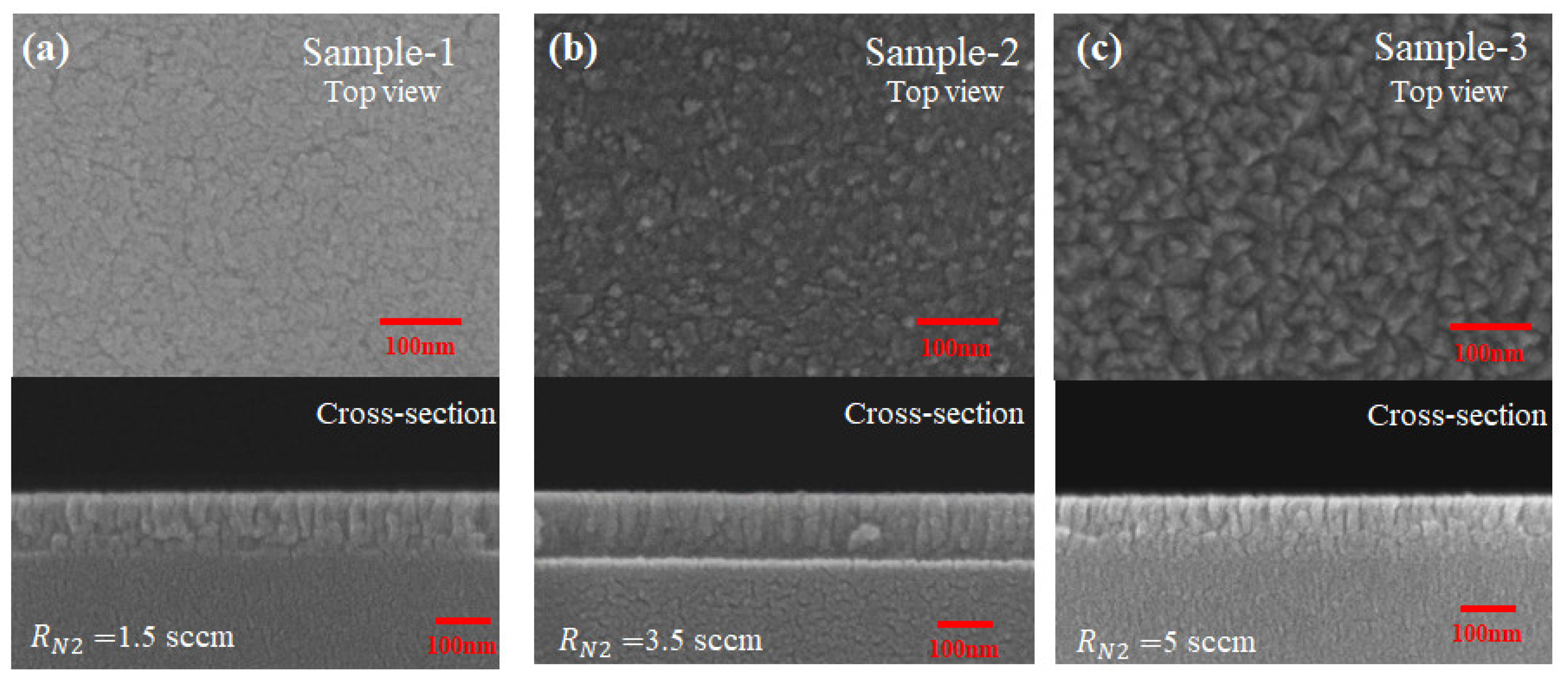

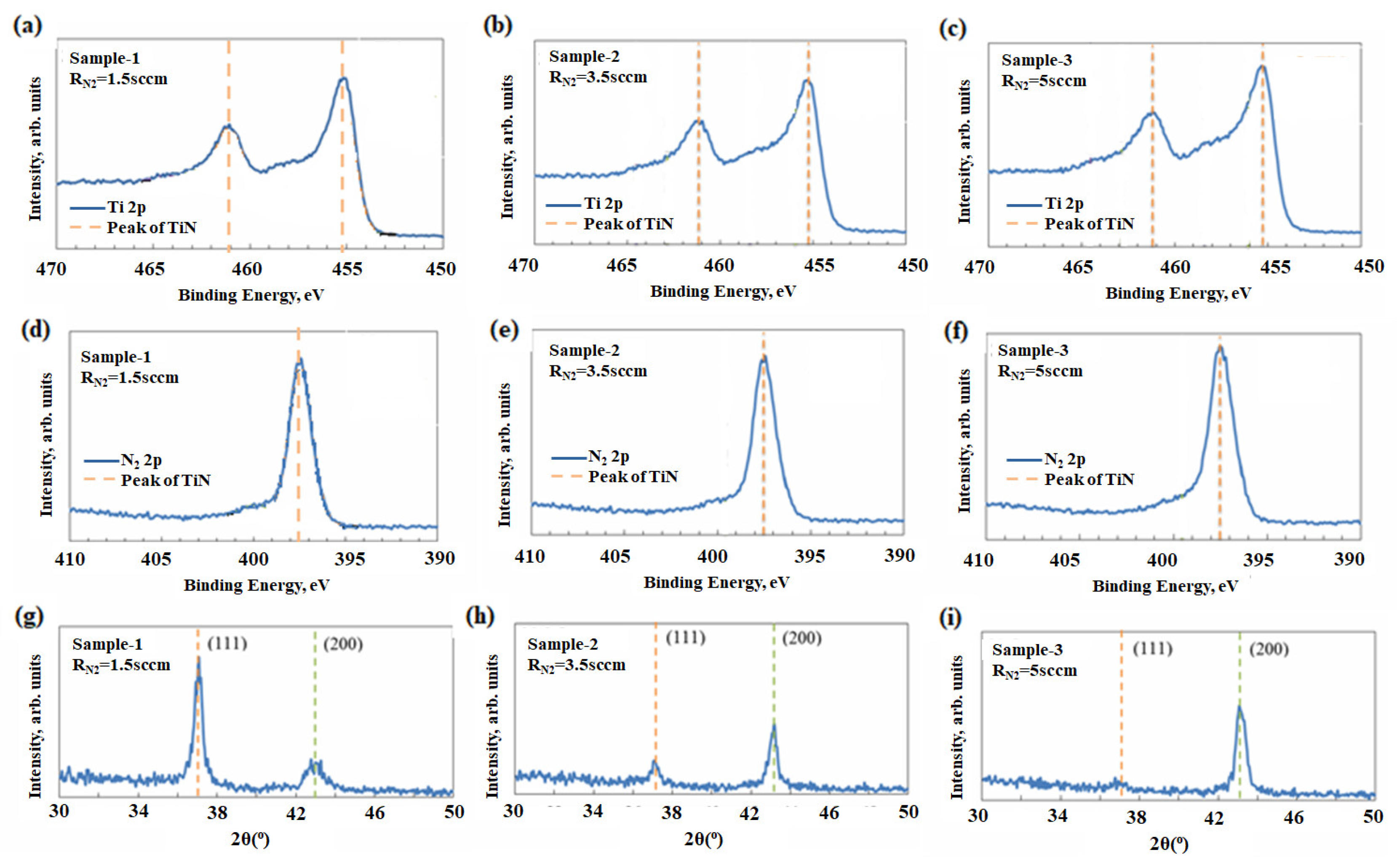

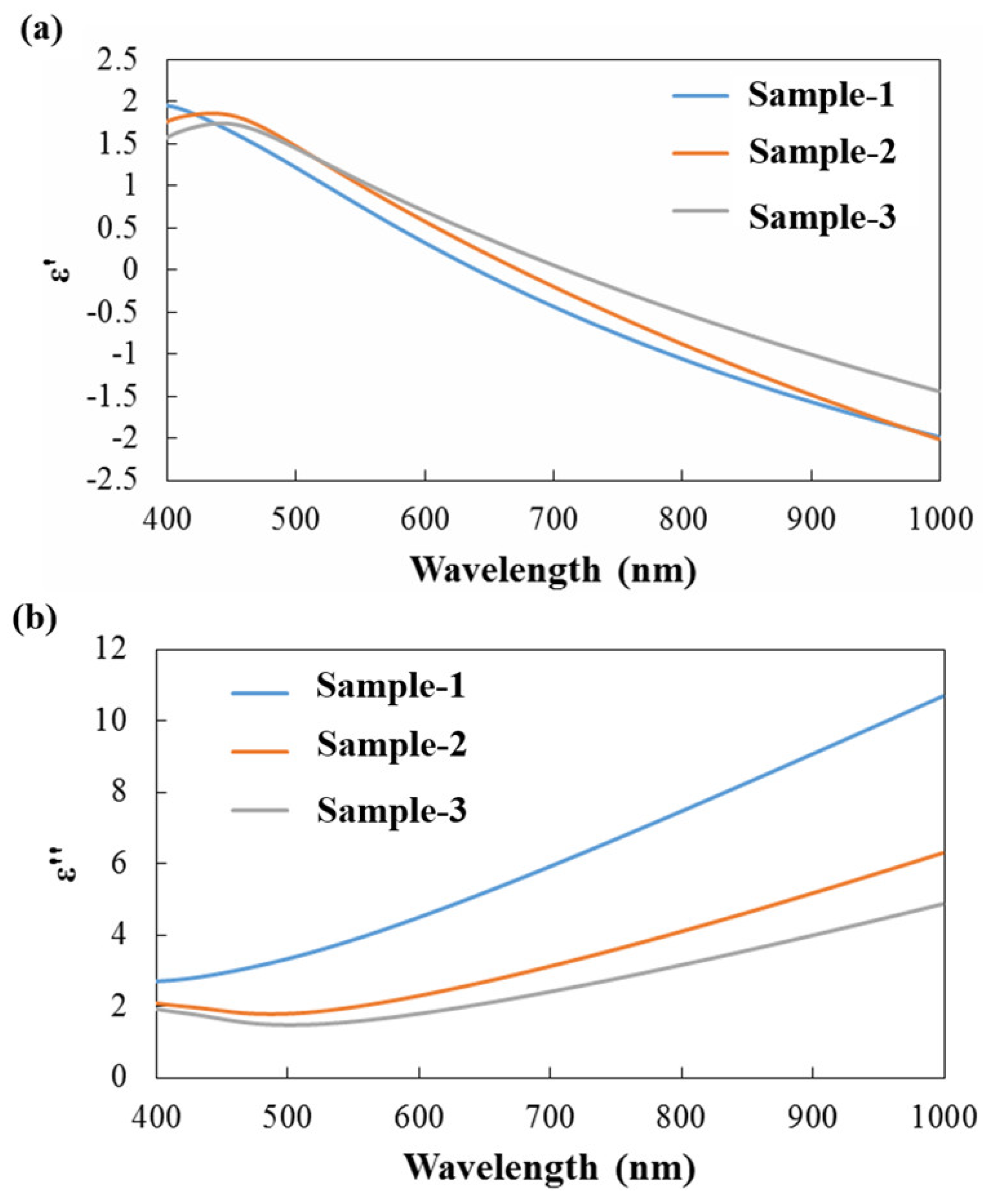

2.1. Fabrication and Measurement of Uniform TiN Thin Films

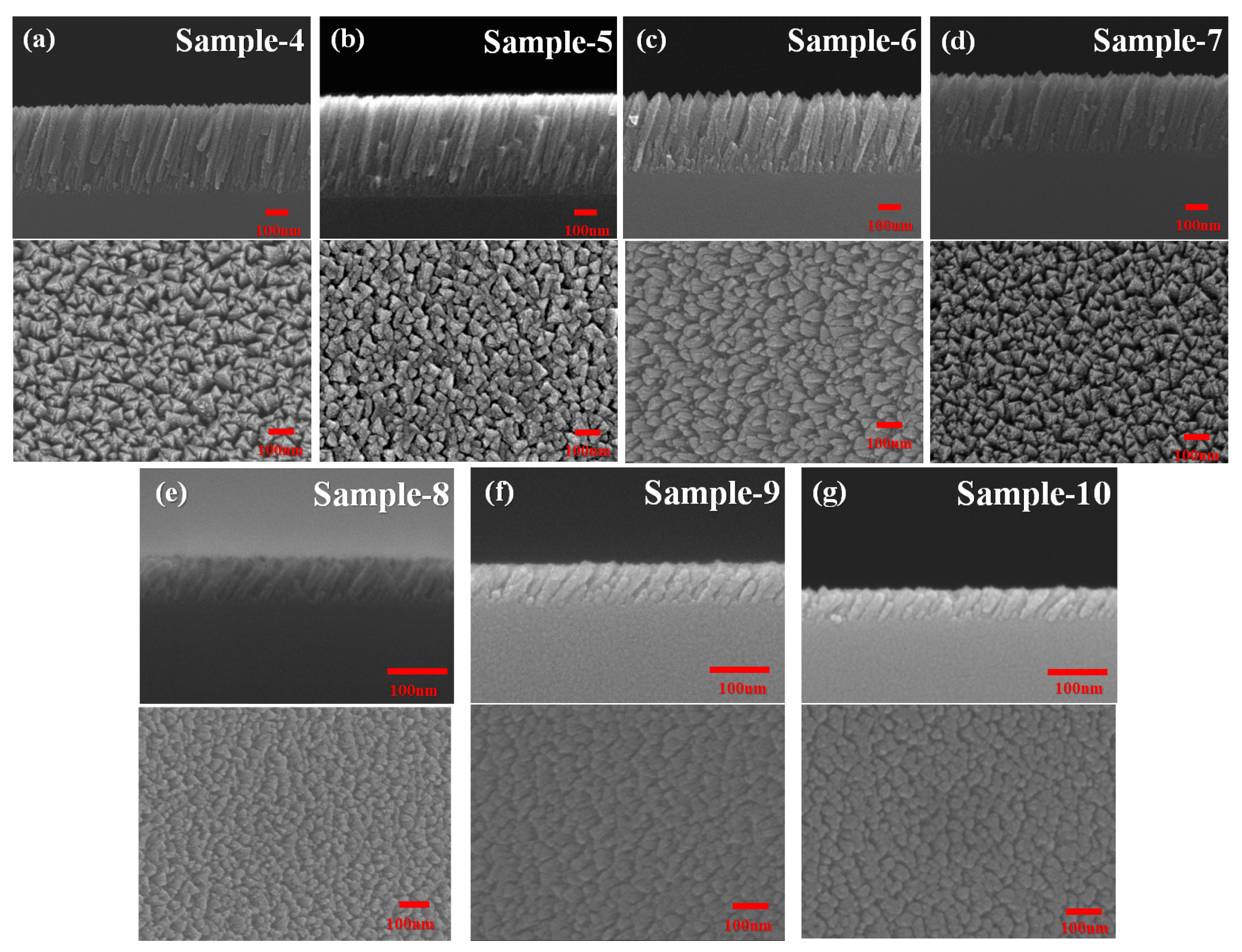

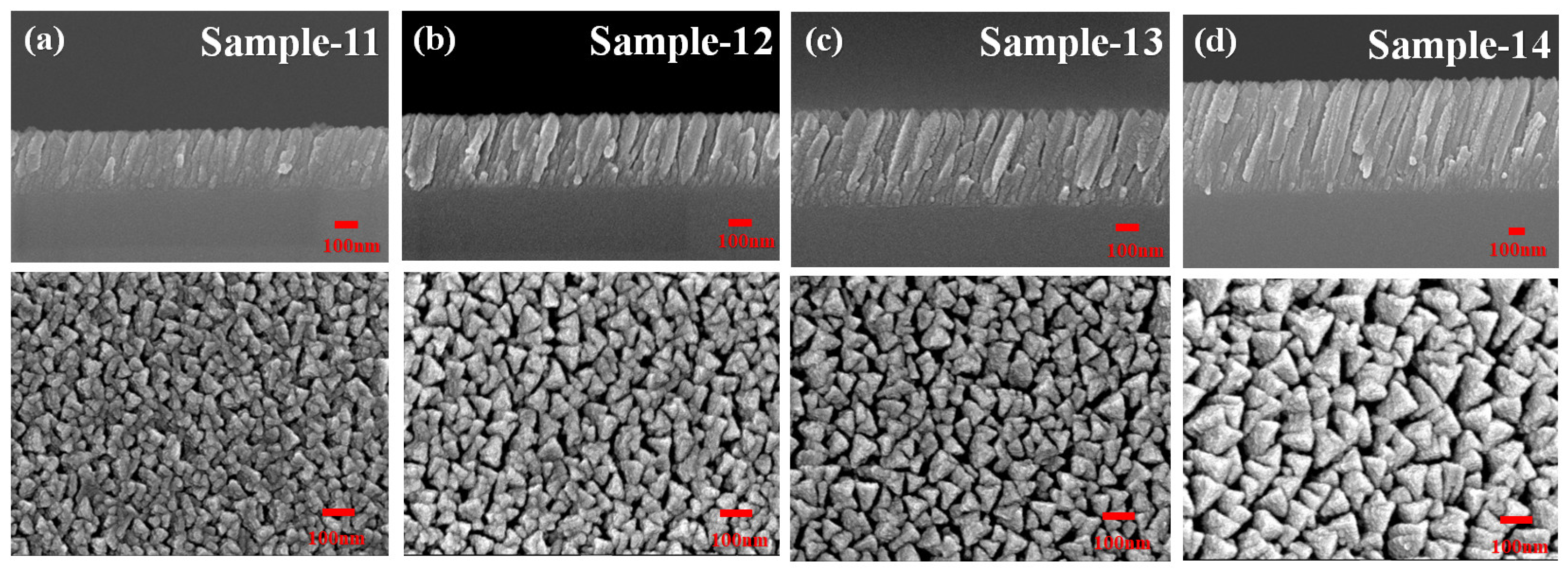

2.2. Glancing Angle-Deposited TiN Nanorod Arrays (NRA)

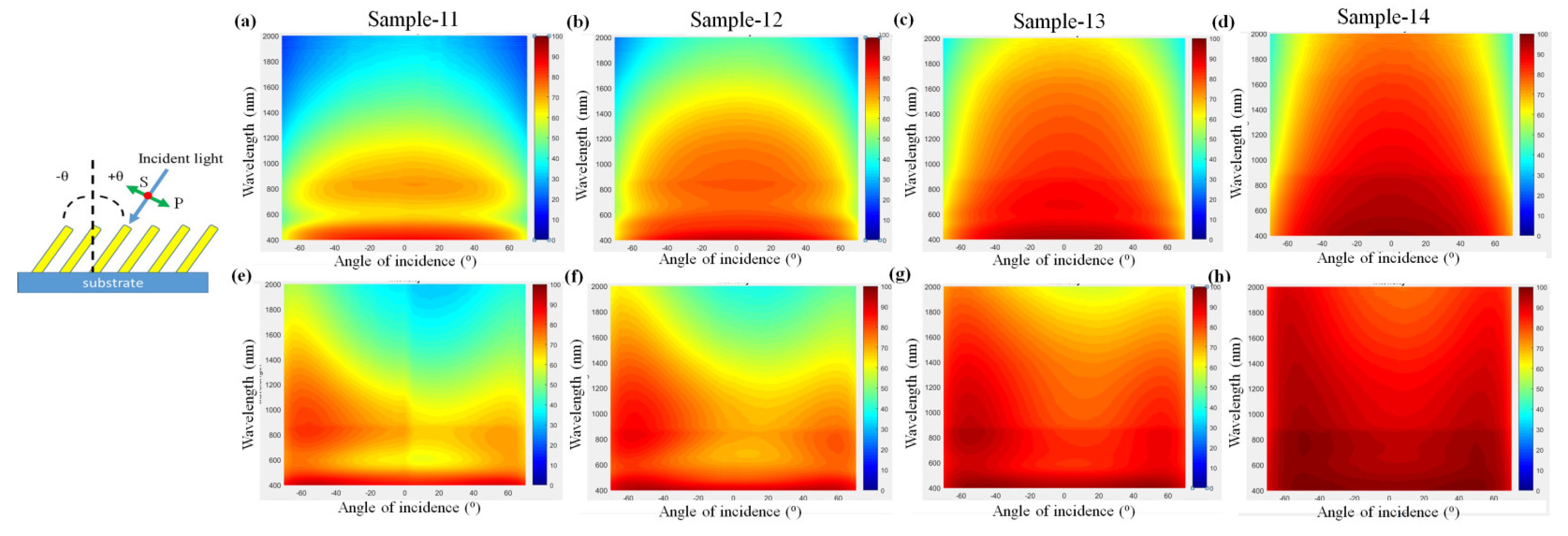

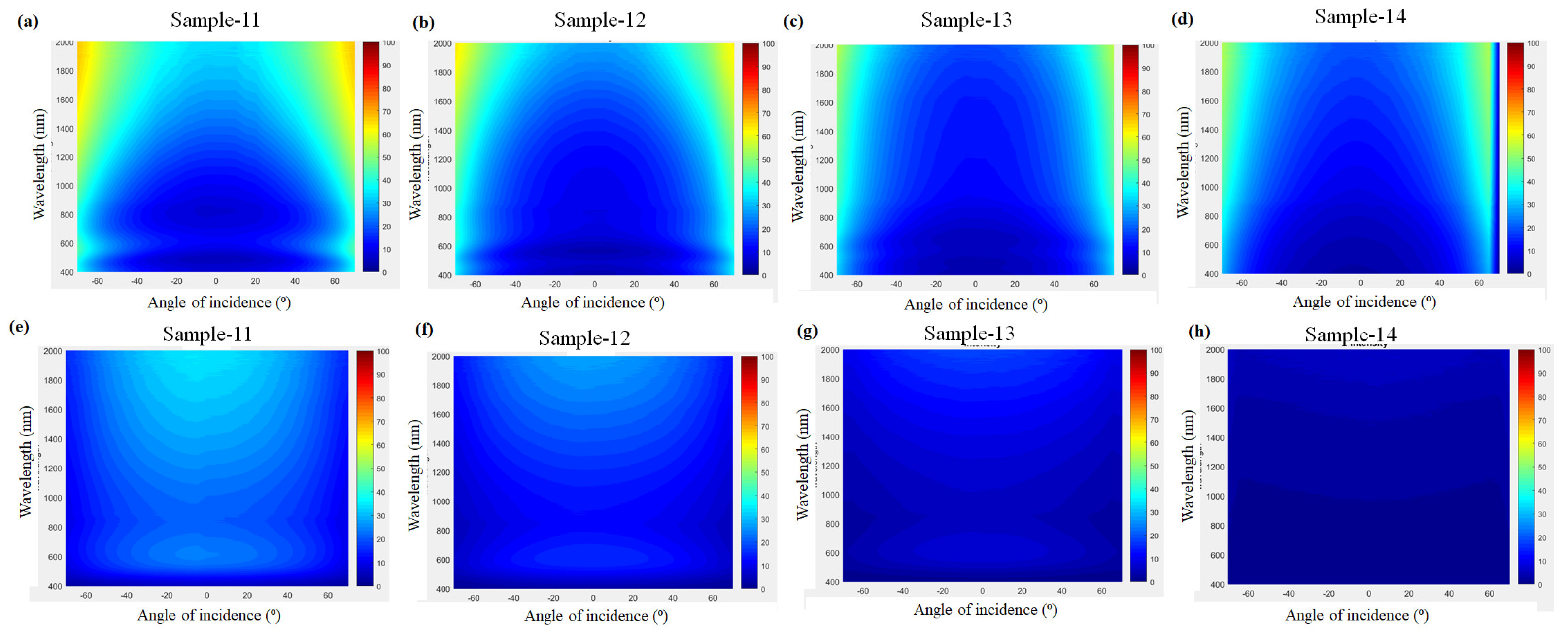

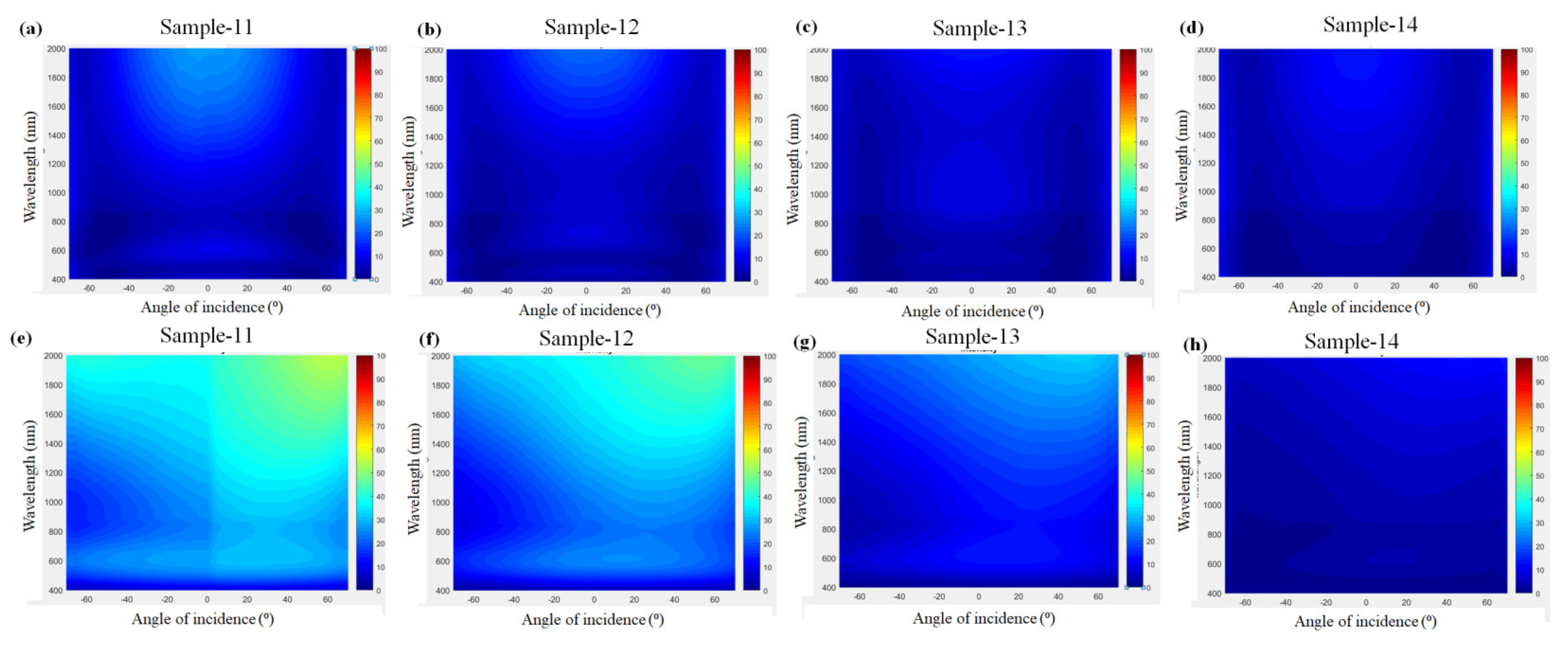

2.3. Optical Measurement and Analysis for TiN NRAs

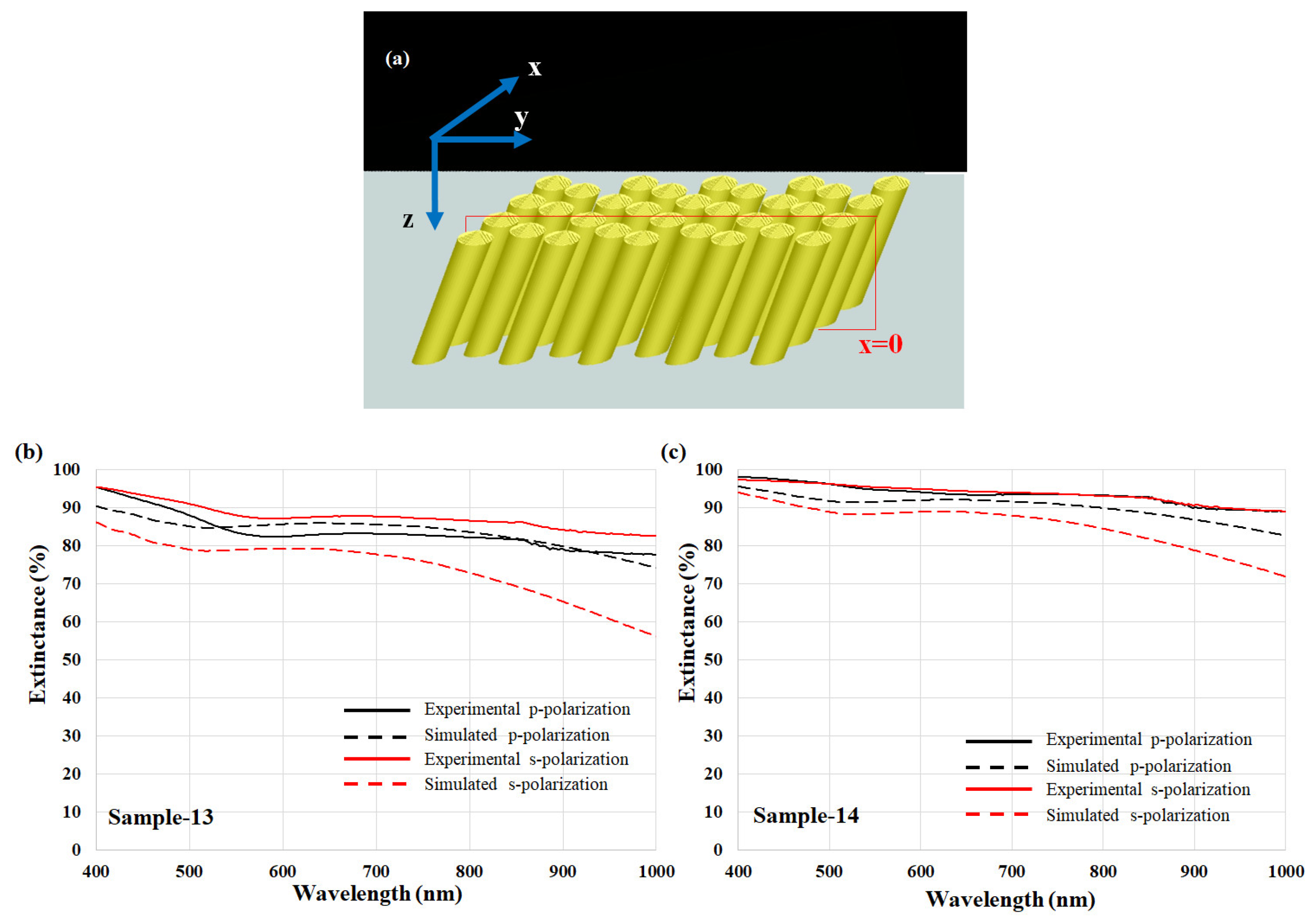

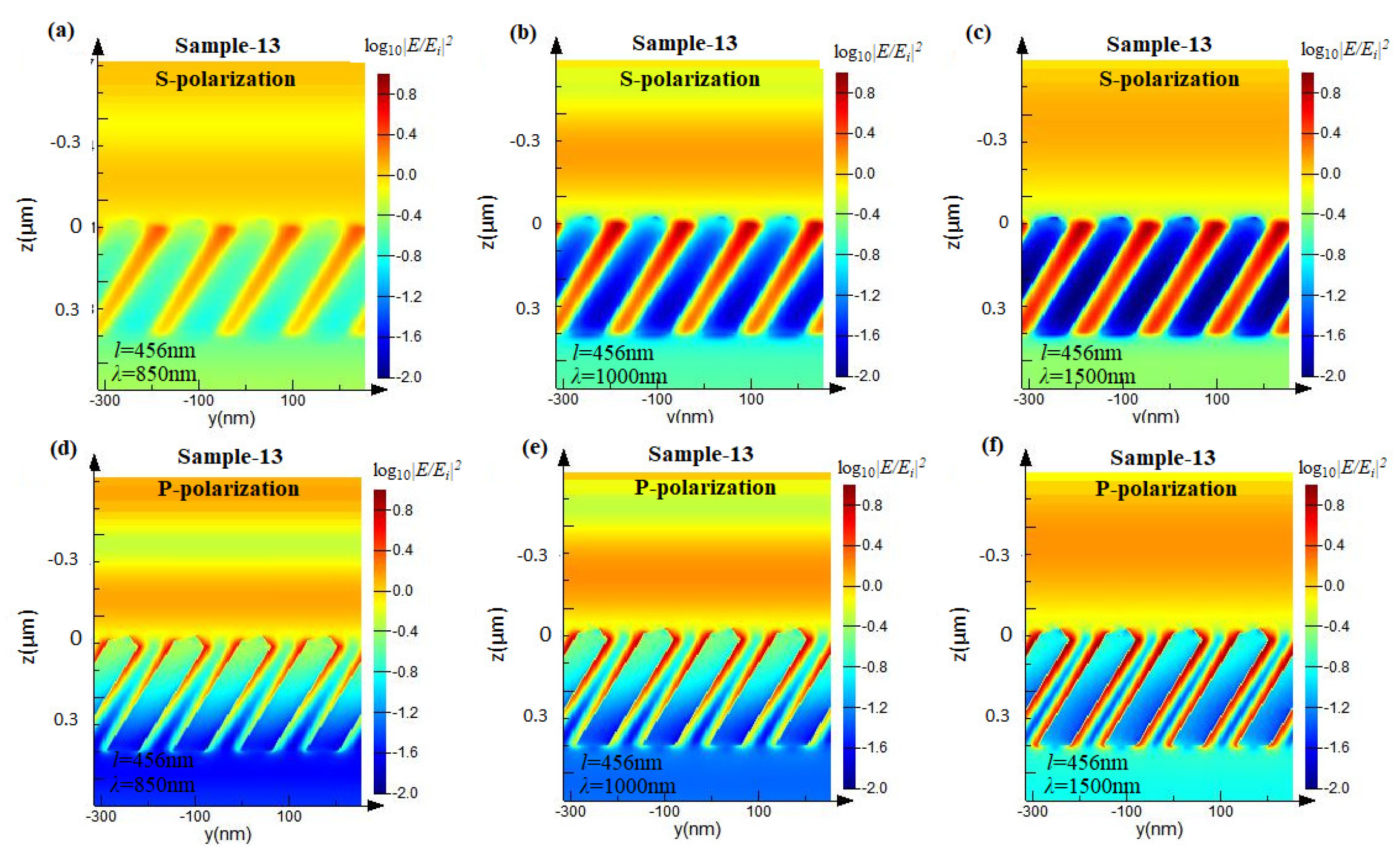

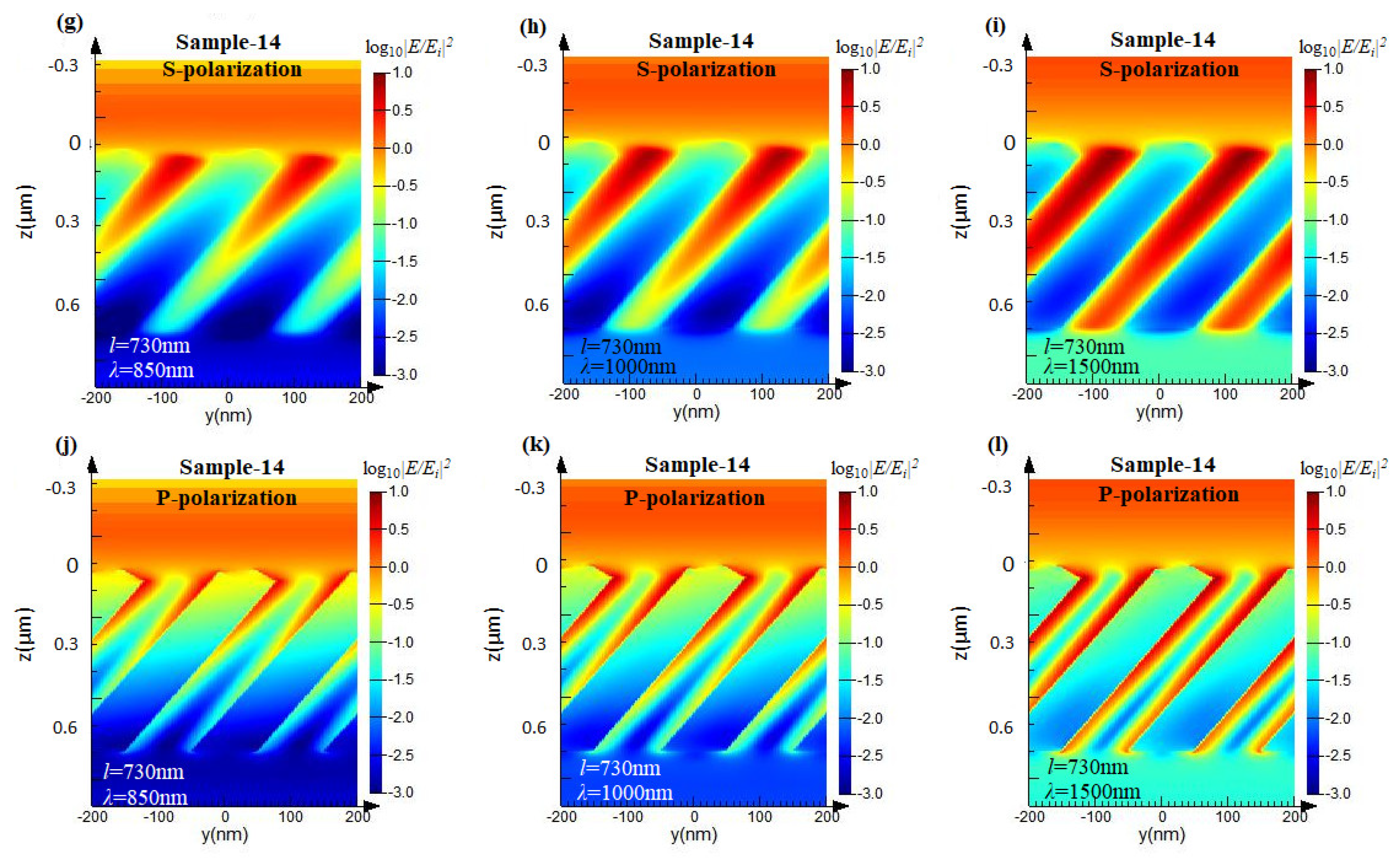

2.4. Near-Field Simulation for TiN NRA

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Stewart, M.E.; Anderton, C.R.; Thompson, L.B.; Maria, J.; Gray, S.K.; Rogers, J.A.; Nuzzo, R.G. Nanostructured plasmonic sensors. Chem. Rev. 2008, 108, 494–521. [Google Scholar] [CrossRef] [PubMed]

- Boltasseva, A.; Nikolajsen, T.; Leosson, K.; Kjaer, K.; Larsen, M.S.; Bozhevolnyi, S.I. Integrated optical components utilizing long-range surface plasmon polaritons. J. Lightwave Technol. 2005, 23, 413. [Google Scholar] [CrossRef]

- Challener, W.A.; Peng, C.; Itagi, A.V.; Karns, D.; Peng, W.; Peng, Y.; Yang, X.; Zhu, X.; Gokemeijer, N.J.; Hsia, Y.-T. Heat-assisted magnetic recording by a near-field transducer with efficient optical energy transfer. Nat. Photonics 2009, 3, 220. [Google Scholar] [CrossRef]

- Naik, G.V.; Kim, J.; Boltasseva, A. Oxides and nitrides as alternative plasmonic materials in the optical range. Opt. Mater. Express 2011, 1, 1090–1099. [Google Scholar] [CrossRef]

- Guler, U.; Naik, G.V.; Boltasseva, A.; Shalaev, V.M.; Kildishev, A.V. Performance analysis of nitride alternative plasmonic materials for localized surface plasmon applications. Appl. Phys. B 2012, 107, 285–291. [Google Scholar] [CrossRef]

- Guler, U.; Shalaev, V.M.; Boltasseva, A. Nanoparticle plasmonics: Going practical with transition metal nitrides. Mater. Today 2015, 18, 227–237. [Google Scholar] [CrossRef]

- Guler, U.; Boltasseva, A.; Shalaev, V.M. Refractory plasmonics. Science 2014, 344, 263–264. [Google Scholar] [CrossRef]

- Boltasseva, A.; Atwater, H.A. Low-loss plasmonic metamaterials. Science 2011, 331, 290–291. [Google Scholar] [CrossRef]

- Pierson, H.O. Handbook of Refractory Carbides & Nitrides: Properties, Characteristics, Processing and Applications; William Andrew Inc.: Norwich, NY, USA, 1996. [Google Scholar]

- Wang, H.; Chen, Q.; Wen, L.; Song, S.; Hu, X.; Xu, G. Titanium-nitride-based integrated plasmonic absorber/emitter for solar thermophotovoltaic application. Photonics Res. 2015, 3, 329–334. [Google Scholar] [CrossRef]

- Li, W.; Guler, U.; Kinsey, N.; Naik, G.V.; Boltasseva, A.; Guan, J.; Shalaev, V.M.; Kildishev, A.V. Refractory plasmonics with titanium nitride: Broadband metamaterial absorber. Adv. Mater. 2014, 26, 7959–7965. [Google Scholar] [CrossRef]

- Guler, U.; Suslov, S.; Kildishev, A.V.; Boltasseva, A.; Shalaev, V.M. Colloidal plasmonic titanium nitride nanoparticles: Properties and applications. Nanophotonics 2015, 4, 269–276. [Google Scholar] [CrossRef]

- He, W.; Ai, K.; Jiang, C.; Li, Y.; Song, X.; Lu, L. Plasmonic titanium nitride nanoparticles for in vivo photoacoustic tomography imaging and photothermal cancer therapy. Biomaterials 2017, 132, 37–47. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Wu, M.; Dong, Z.; Chen, Y.; Bu, J.; Lin, J.; Yu, Y.; Wei, Y.; Cui, Y.; Wang, R. Composition, microstructure and SERS properties of titanium nitride thin film prepared via nitridation of sol-gel derived titania thin films. J. Raman Spectrosc. 2017, 48, 578–585. [Google Scholar] [CrossRef]

- Kaisar, N.; Huang, Y.-T.; Jou, S.; Kuo, H.-F.; Huang, B.-R.; Chen, C.-C.; Hsieh, Y.-F.; Chung, Y.-C. Surface-enhanced Raman scattering substrates of flat and wrinkly titanium nitride thin films by sputter deposition. Surf. Coat. Technol. 2018, 337, 434–438. [Google Scholar] [CrossRef]

- Zhao, J.; Lin, J.; Wei, H.; Li, X.; Zhang, W.; Zhao, G.; Bu, J.; Chen, Y. Surface enhanced Raman scattering substrates based on titanium nitride nanorods. Opt. Mater. 2015, 47, 219–224. [Google Scholar] [CrossRef]

- Ban, R.; Yu, Y.; Zhang, M.; Yin, J.; Xu, B.; Wu, D.-Y.; Wu, M.; Zhang, Z.; Tai, H.; Li, J.; et al. Synergetic SERS Enhancement in a metal-like/metal double-shell structure for sensitive and stable application. ACS Appl. Mater. Interfaces 2017, 9, 13564–13570. [Google Scholar] [CrossRef] [PubMed]

- Mumtaz, A.; Class, W.H. Color of titanium nitride prepared by reactive dc magnetron sputtering. J. Vac. Sci. Technol. 1982, 20, 345–348. [Google Scholar] [CrossRef]

- Håkansson, G.; Hultman, L.; Sundgren, J.-E.; Greene, J.E.; Münz, W.-D. Microstructures of TiN films grown by various physical vapour deposition techniques. Surf. Coat. Technol. 2000, 48, 51–67. [Google Scholar] [CrossRef]

- Ali, M.; Hamzah, E.; Qazi, I.A.; Toff, M.R.M. Effect of cathodic arc PVD parameters on roughness of TiN coating on steel substrate. Cur. App. Phys. 2010, 10, 471–474. [Google Scholar] [CrossRef]

- Ramaseshan, R.; Jose, F.; Rajagopalan, S.; Dash, S. Preferentially oriented electron beam deposited TiN thin films using focused jet of nitrogen gas. Surf. Eng. 2016, 32, 834–839. [Google Scholar] [CrossRef]

- Robbie, K.; Sit, J.C.; Brett, M.J. Advanced techniques for glancing angle deposition. J. Vac. Sci. Technol. B 1998, 16, 1115–1122. [Google Scholar] [CrossRef]

- Jen, Y.-J.; Lakhtakia, A.; Yu, C.-W.; Jhou, J.-J.; Wang, W.-H.; Lin, M.-J.; Wu, H.-M.; Liao, H.-S. Silver/silicon dioxide/silver sandwich films in the blue-to-red spectral regime with negative-real refractive index. Appl. Phys. Lett. 2011, 99, 181117. [Google Scholar] [CrossRef]

- Hodgkinson, I.J.; Wu, Q. Birefringent Thin Films and Polarizing Elements; World Scientific: Singapore, 1998. [Google Scholar]

- Jen, Y.-J.; Lakhtakia, A.; Yu, C.-W.; Lin, C.-F.; Lin, M.-J.; Wang, S.-H.; Lai, J.-R. Biologically inspired achromatic waveplates for visible light. Nat. Commun. 2011, 2, 363. [Google Scholar] [CrossRef] [PubMed]

- Jen, Y.-J.; Lakhtakia, A.; Lin, M.-J.; Wang, W.-H.; Wu, H.-M.; Liao, H.-S. Metal/dielectric/metal sandwich film for broadband reflection reduction. Sci. Rep. 2013, 3, 1672. [Google Scholar] [CrossRef] [PubMed]

- Guler, U.; Zemlyanov, D.; Kim, J.; Wang, Z.; Chandrasekar, R.; Meng, X.; Stach, E.; Kildishev, A.V.; Shalaev, V.M.; Boltasseva, A. Plasmonic titanium nitride nanostructures via nitridation of nanopatterned titanium dioxide. Adv. Opt. Mater. 2017, 5, 1600717. [Google Scholar] [CrossRef]

- Backholm, M.; Foss, M.; Nordlund, K. Roughness of glancing angle deposited titanium thin films: An experimental and computational study. Nanotechnology 2012, 23, 385708. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Liu, X.; Wang, W.; Liu, C.; Li, Z.; Zhang, Z. Fabrication of TiN nanostructure as a hydrogen peroxide sensor by oblique angle deposition. Nanoscale Res. Lett. 2014, 9, 105. [Google Scholar] [CrossRef] [PubMed]

- Bouaouina, B.; Mastail, C.; Besnard, A.; Mareus, R.; Nita, F.; Michel, A.; Abadias, G. Nanocolumnar TiN thin film growth by oblique angle sputter-deposition: Experiments vs. simulations. Mater. Des. 2018, 160, 338–349. [Google Scholar] [CrossRef]

- Ponon, N.K.; Appleby, D.J.; Arac, E.; King, P.; Ganti, S.; Kwa, K.S.; O’Neill, A. Effect of deposition conditions and post deposition anneal on reactively sputtered titanium nitride thin films. Thin Solid Films 2015, 578, 31–37. [Google Scholar] [CrossRef]

- Shah, D.; Reddy, H.; Kinsey, N.; Shalaev, V.M.; Boltasseva, A. Optical properties of plasmonic ultrathin TiN Films. Adv. Opt. Mater. 2017, 5, 1700065. [Google Scholar] [CrossRef]

- Jen, Y.-J.; Lin, Y.W.; Huang, Y.-J.; Chan, T.-L. The effect of glancing angle deposition conditions on the morphology of a silver nanohelix array. Coatings 2017, 7, 140. [Google Scholar] [CrossRef]

- Vick, D.; Friedrich, L.; Dew, S.; Brett, M.; Robbie, K.; Seto, M.; Smy, T. Self-shadowing and surface diffusion effects in obliquely deposited thin films. Thin Solid Films 1999, 339, 88–94. [Google Scholar] [CrossRef]

- Dick, B.; Brett, M.J.; Smy, T.; Belov, M.; Freeman, M.R. Periodic submicrometer structures by sputtering. J. Vac. Sci. Technol. B 2001, 19, 1813–1819. [Google Scholar] [CrossRef]

- Zhao, Y.-P.; Chaney, S.B.; Zhang, Z.-Y. Absorbance spectra of aligned Ag nanorod arrays prepared by oblique angle deposition. J. Appl. Phys. 2006, 100, 063527. [Google Scholar] [CrossRef]

- Leem, J.W.; Yu, J.S. Multi-functional antireflective surface-relief structures based on nanoscale porous germanium with graded refractive index profiles. Nanoscale 2013, 5, 2520–2526. [Google Scholar] [CrossRef] [PubMed]

- Jang, S.J.; Song, Y.M.; Yu, J.S.; Yeo, C.I.; Lee, Y.T. Antireflective properties of porous Si nanocolumnar structures with graded refractive index layers. Opt. Lett. 2011, 36, 253–255. [Google Scholar] [CrossRef] [PubMed]

| TiN Nanorod Arrays | α (°) | β (°) | w (nm) | l (nm) | p (nm) | d (nm) | Porosity (%) |

|---|---|---|---|---|---|---|---|

| Sample-4 | 75 | 18.4 | 34.3 | 374 | 18.8 | 463 | 11.3 |

| Sample-5 | 80 | 17.9 | 40.5 | 470 | 19.1 | 400 | 14.7 |

| Sample-6 | 85 | 18.6 | 54.9 | 364 | 22.4 | 322 | 18.4 |

| Sample-7 | 88 | 18.5 | 55.5 | 359 | 24.2 | 314 | 21.7 |

| Sample-8 | 80 | 37.4 | 18.4 | 79.9 | 17.2 | 97 | 26.5 |

| Sample-9 | 85 | 38.6 | 27.5 | 87.3 | 20.4 | 73 | 27.6 |

| Sample-10 | 88 | 39.1 | 24.2 | 56.7 | 19.6 | 56 | 28.1 |

| Sample-11 | 85 | 18.4 | 57.8 | 283 | 11.7 | 267 | 16.8 |

| Sample-12 | 85 | 18.5 | 62.6 | 348 | 13.5 | 329 | 18.4 |

| Sample-13 | 85 | 18.6 | 66.7 | 456 | 15.5 | 426 | 19.5 |

| Sample-14 | 85 | 18.5 | 93.7 | 730 | 21.6 | 690 | 23.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jen, Y.-J.; Wang, W.-C.; Wu, K.-L.; Lin, M.-J. Extinction Properties of Obliquely Deposited TiN Nanorod Arrays. Coatings 2018, 8, 465. https://doi.org/10.3390/coatings8120465

Jen Y-J, Wang W-C, Wu K-L, Lin M-J. Extinction Properties of Obliquely Deposited TiN Nanorod Arrays. Coatings. 2018; 8(12):465. https://doi.org/10.3390/coatings8120465

Chicago/Turabian StyleJen, Yi-Jun, Wei-Chien Wang, Kai-Lun Wu, and Meng-Jie Lin. 2018. "Extinction Properties of Obliquely Deposited TiN Nanorod Arrays" Coatings 8, no. 12: 465. https://doi.org/10.3390/coatings8120465

APA StyleJen, Y.-J., Wang, W.-C., Wu, K.-L., & Lin, M.-J. (2018). Extinction Properties of Obliquely Deposited TiN Nanorod Arrays. Coatings, 8(12), 465. https://doi.org/10.3390/coatings8120465