Structural and Mechanical Properties of Arc-Sprayed Ni–Cr Coating Post-Treated by Surface Mechanical Attrition Treatment (SMAT)

Abstract

1. Introduction

2. Experimental Details

2.1. Material

2.2. Surface Mechanical Attrition Treatment (SMAT)

2.3. Structural Analysis

2.4. Mechanical Properties

3. Results and Discussion

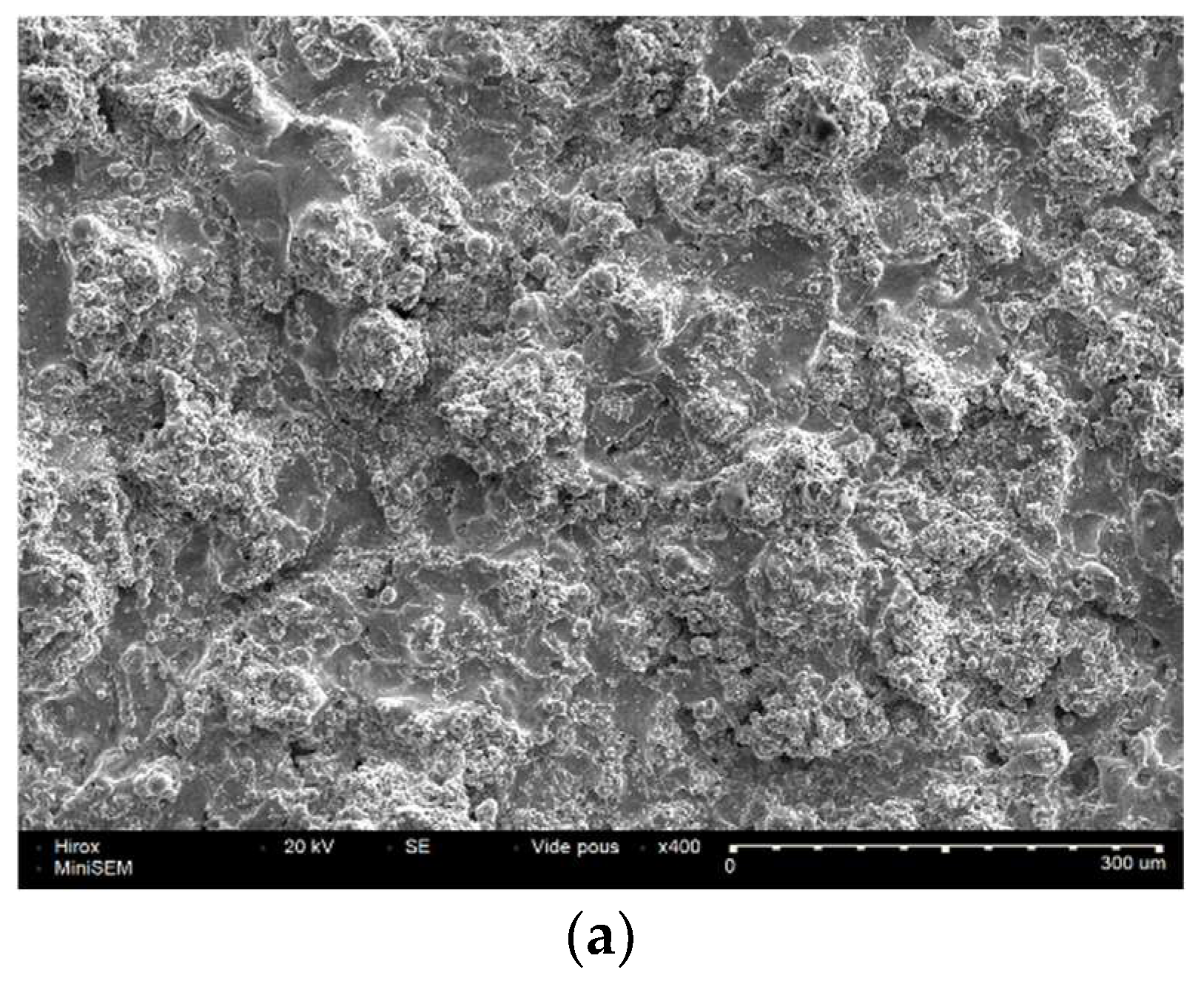

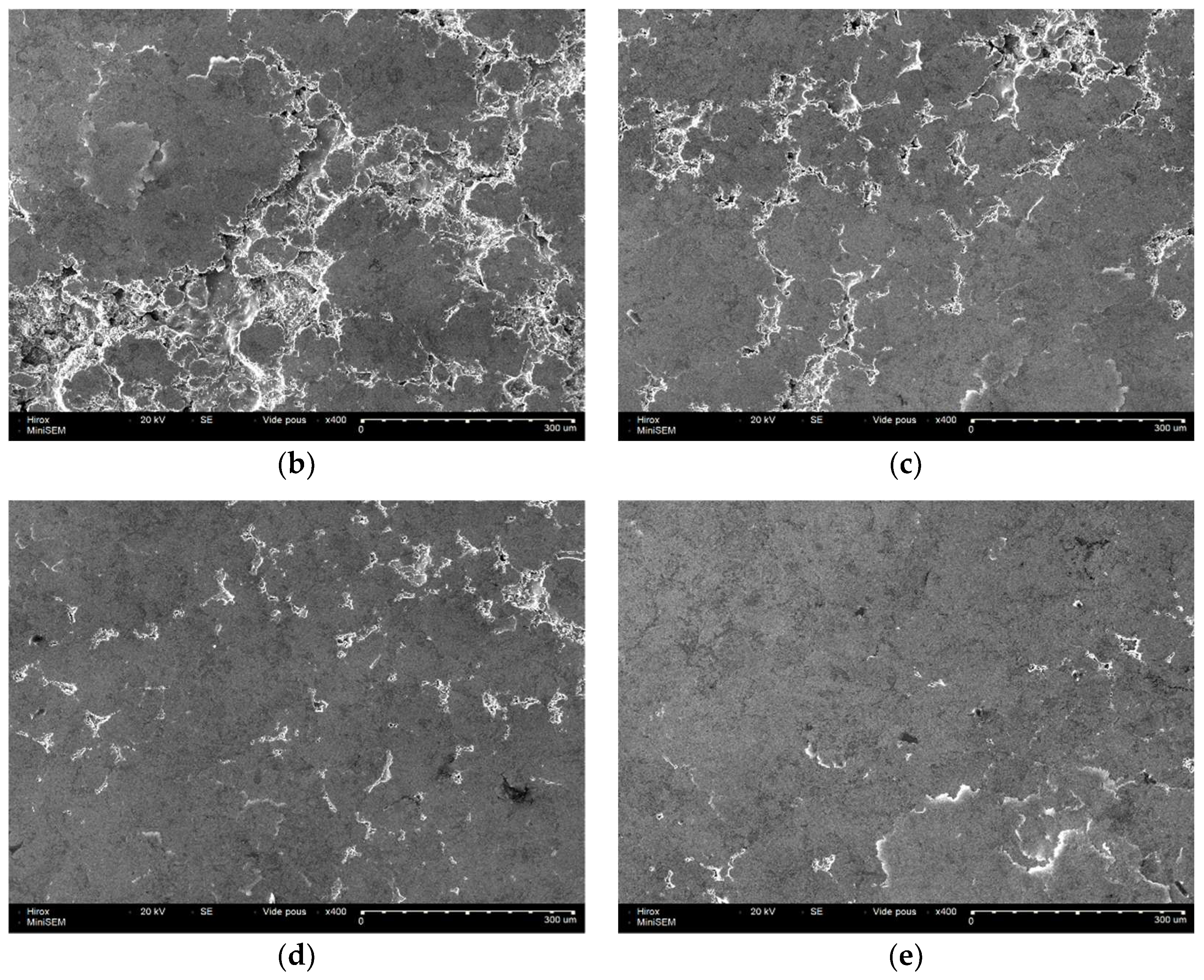

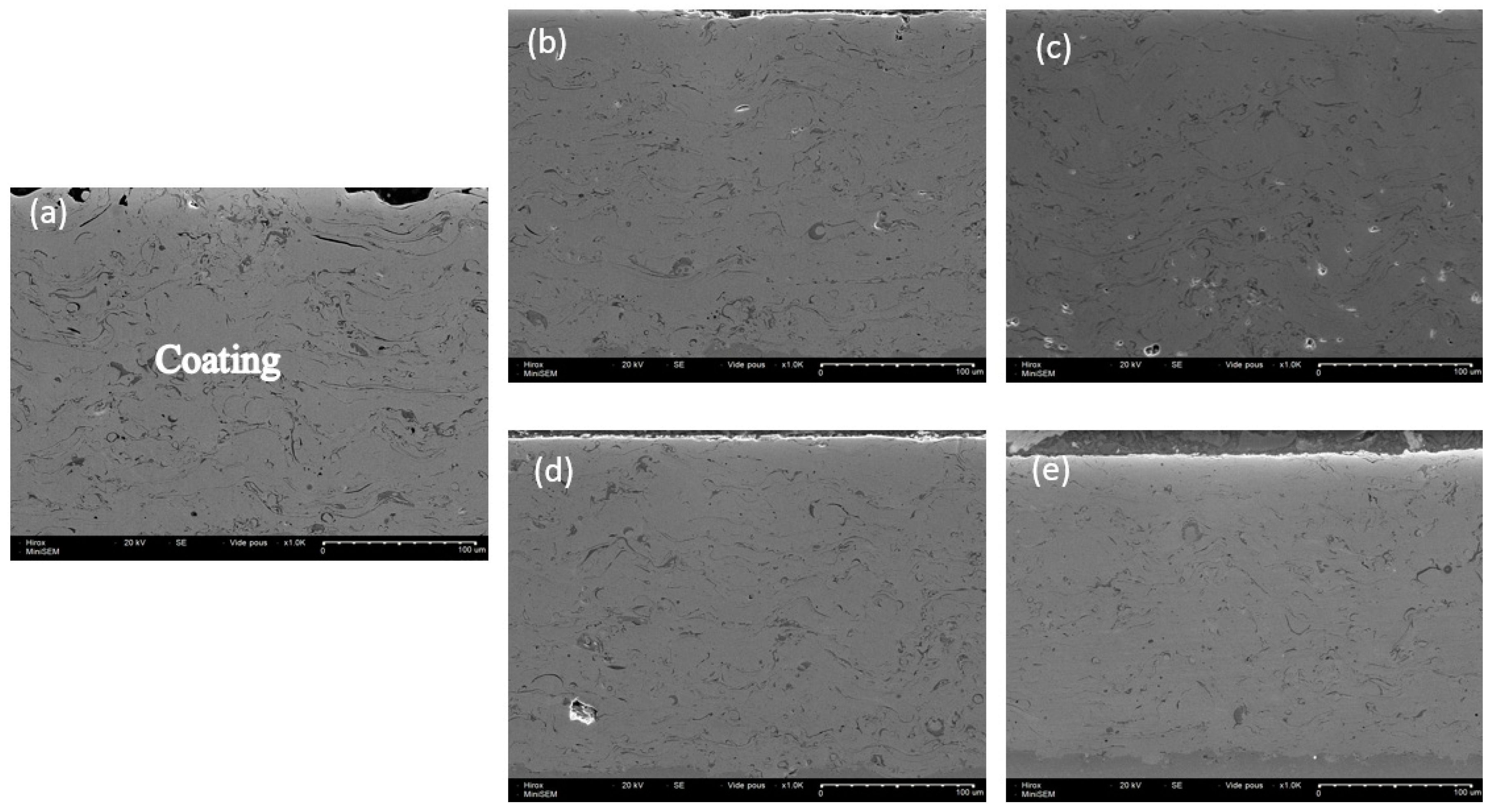

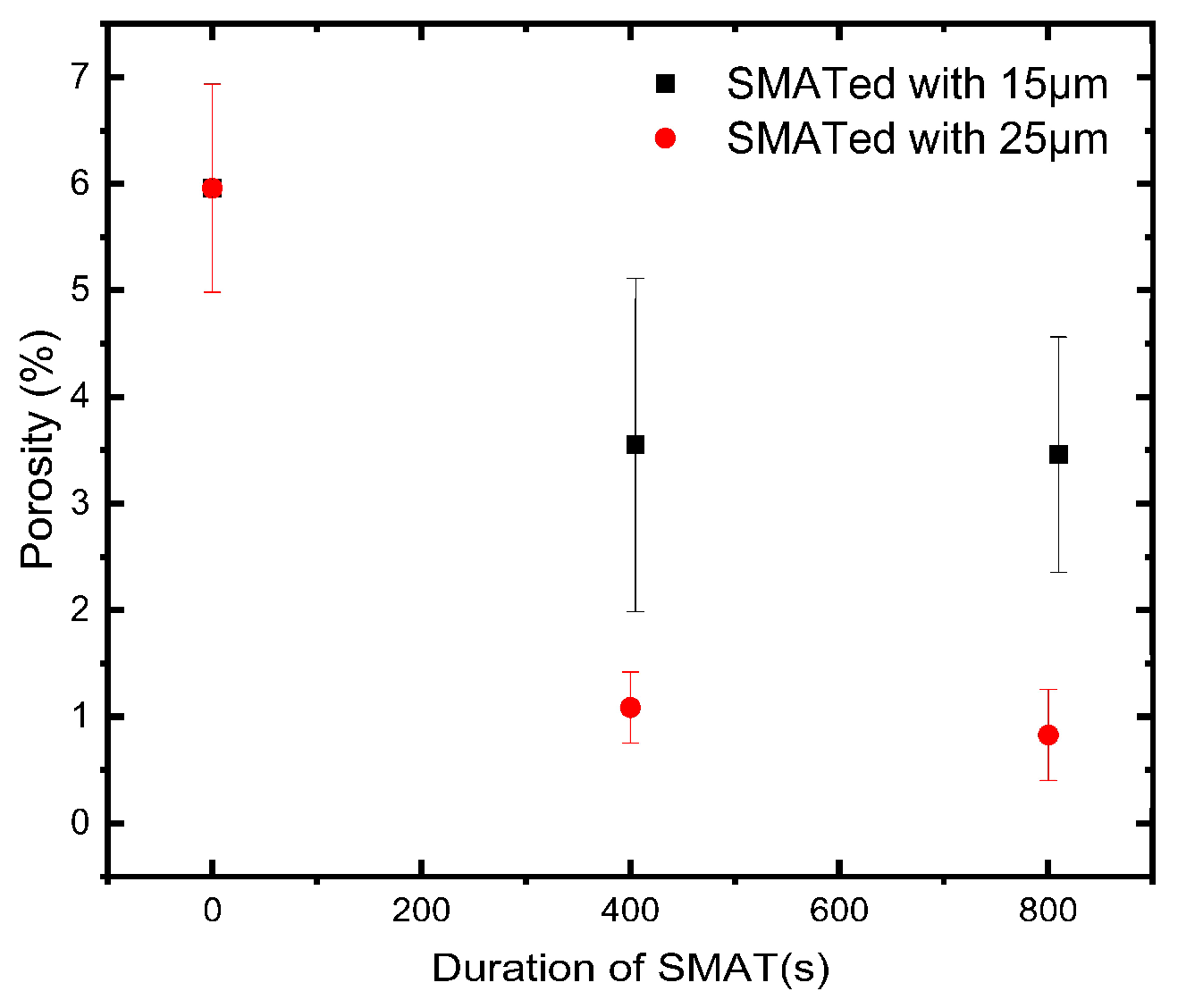

3.1. Morphology

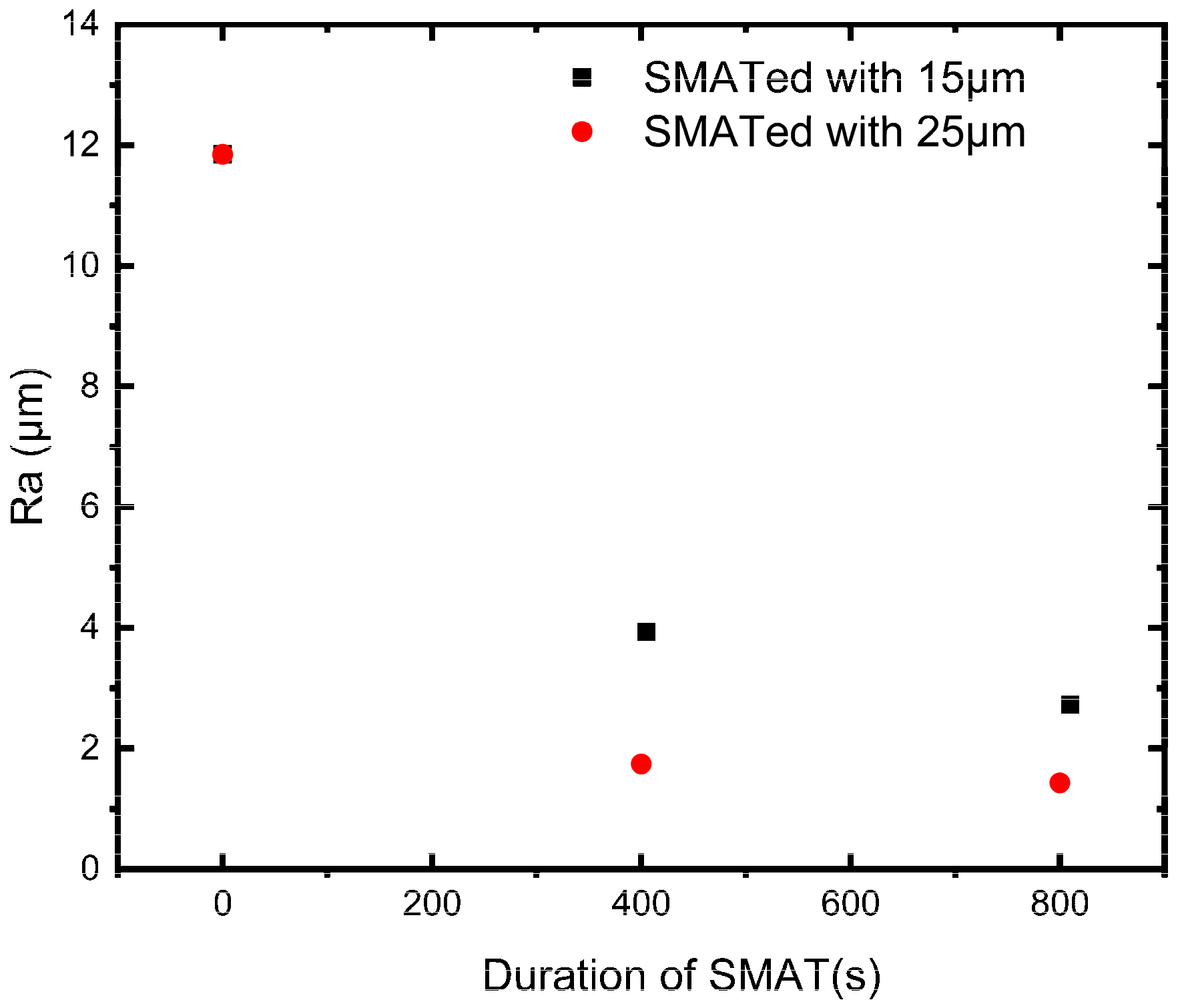

3.2. Roughness

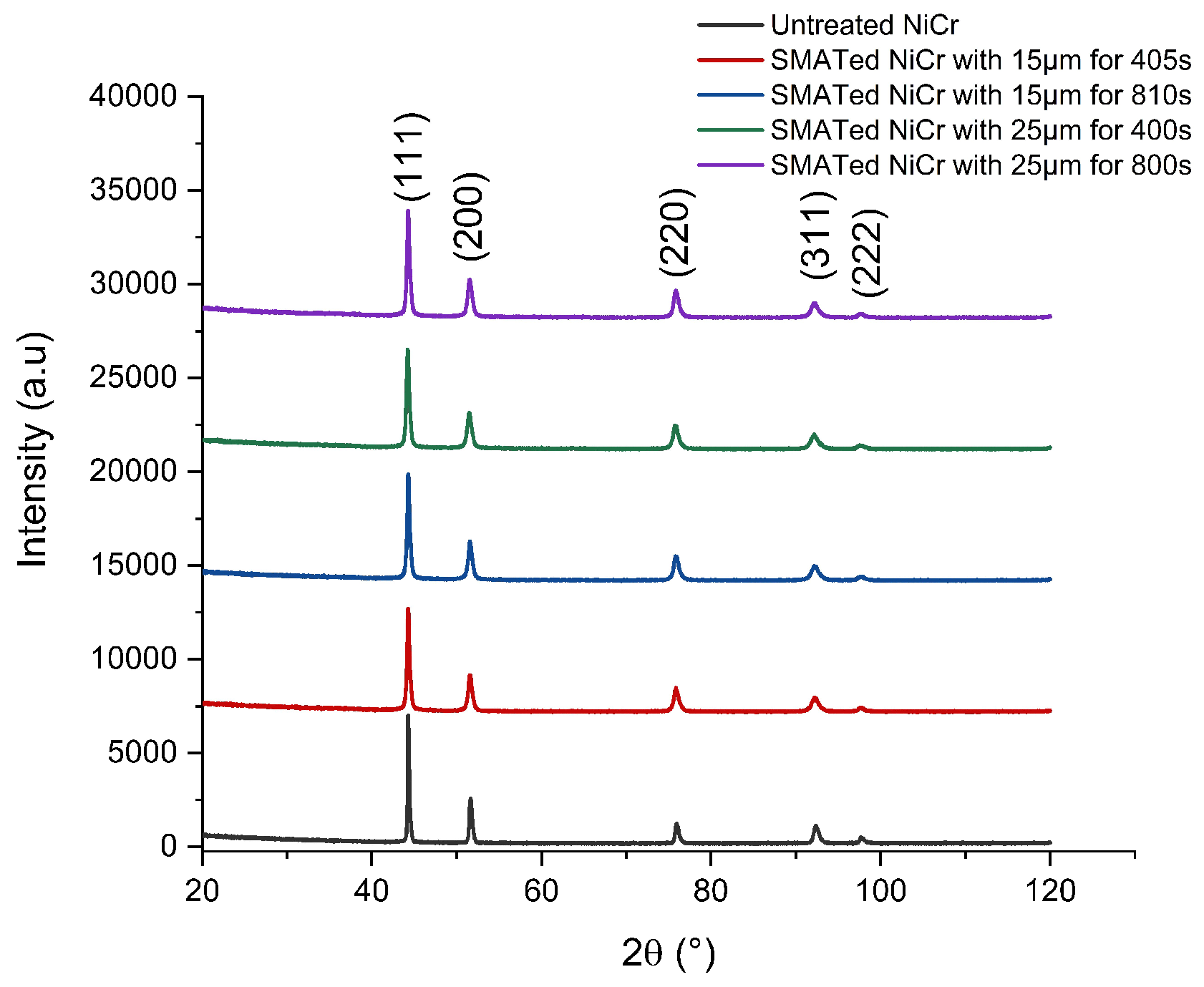

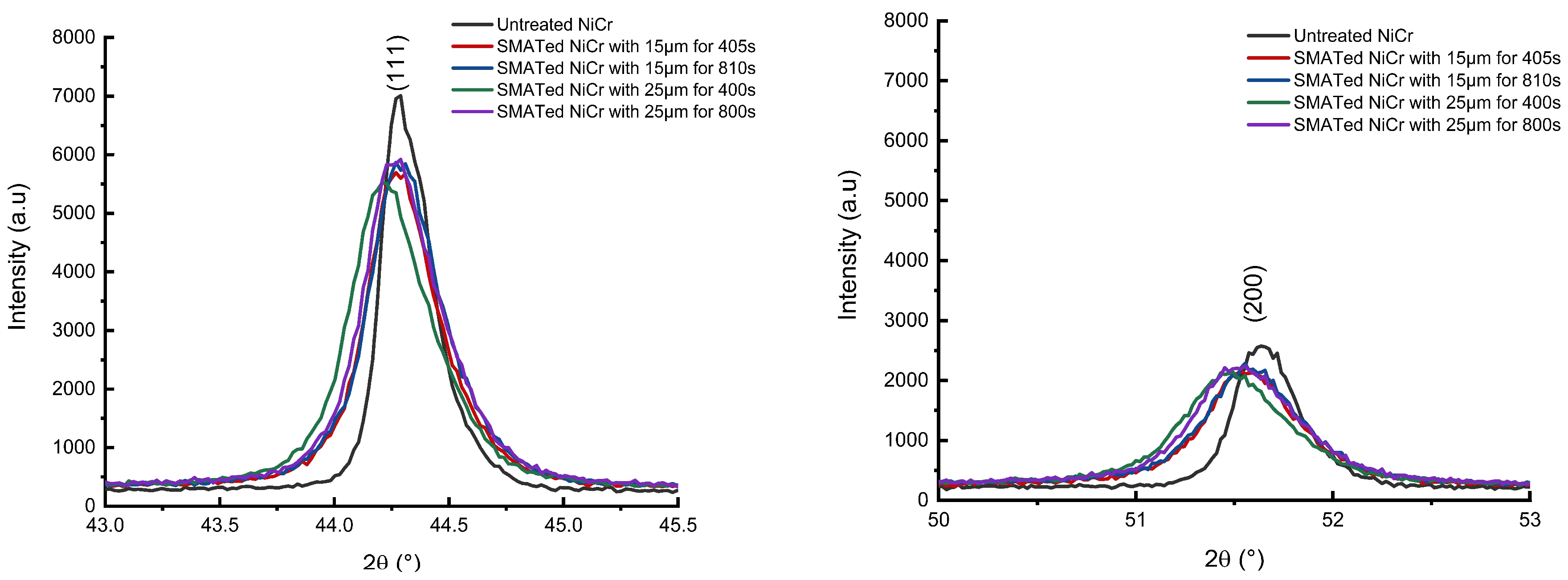

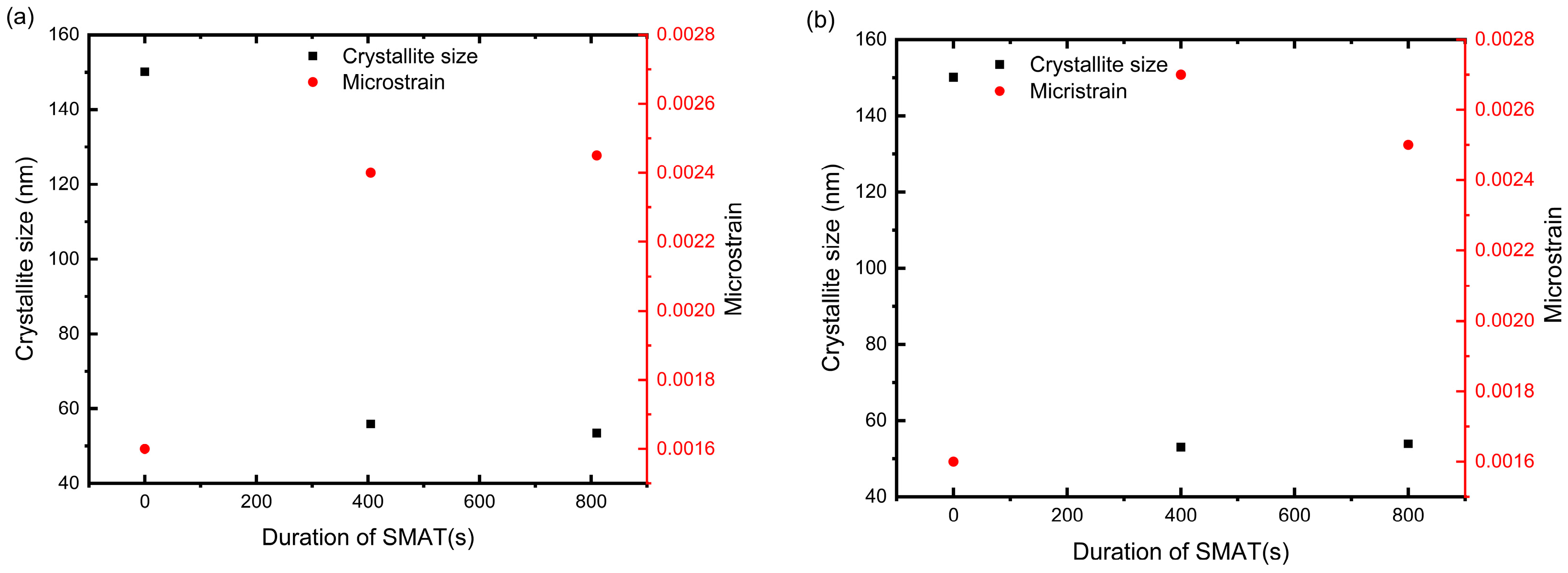

3.3. Structure

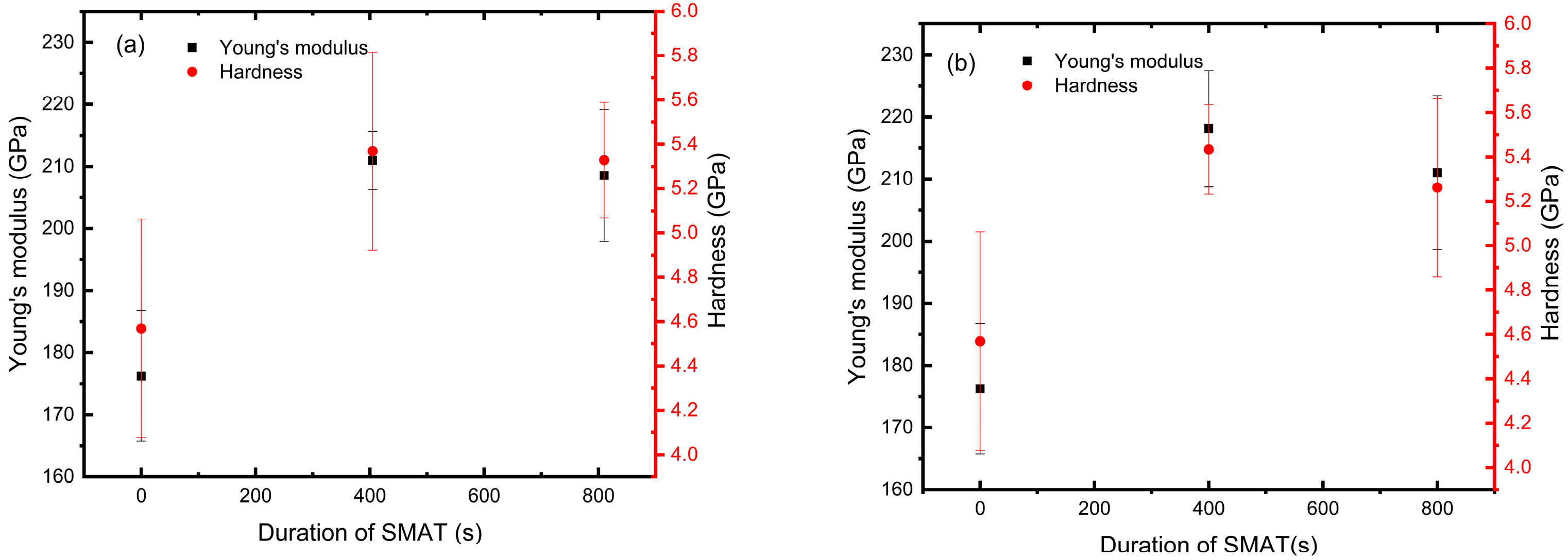

3.4. Nano Indentation

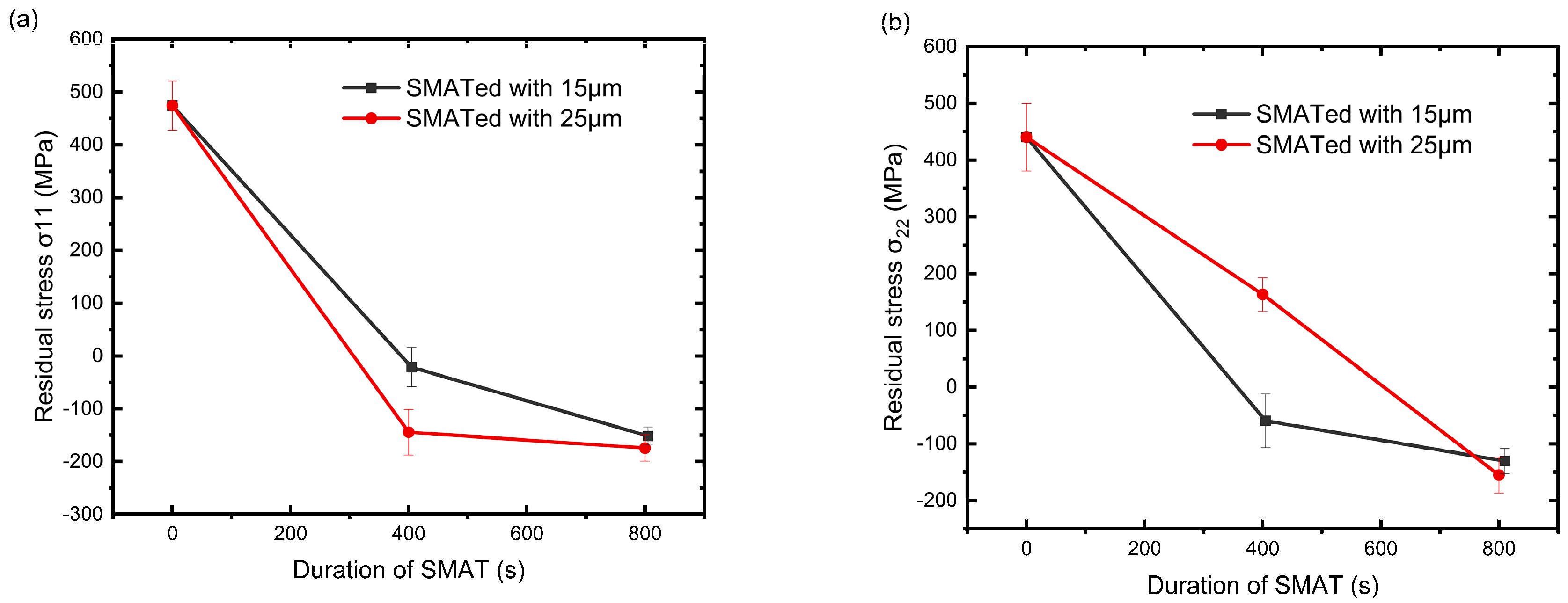

3.5. Residual Stresses

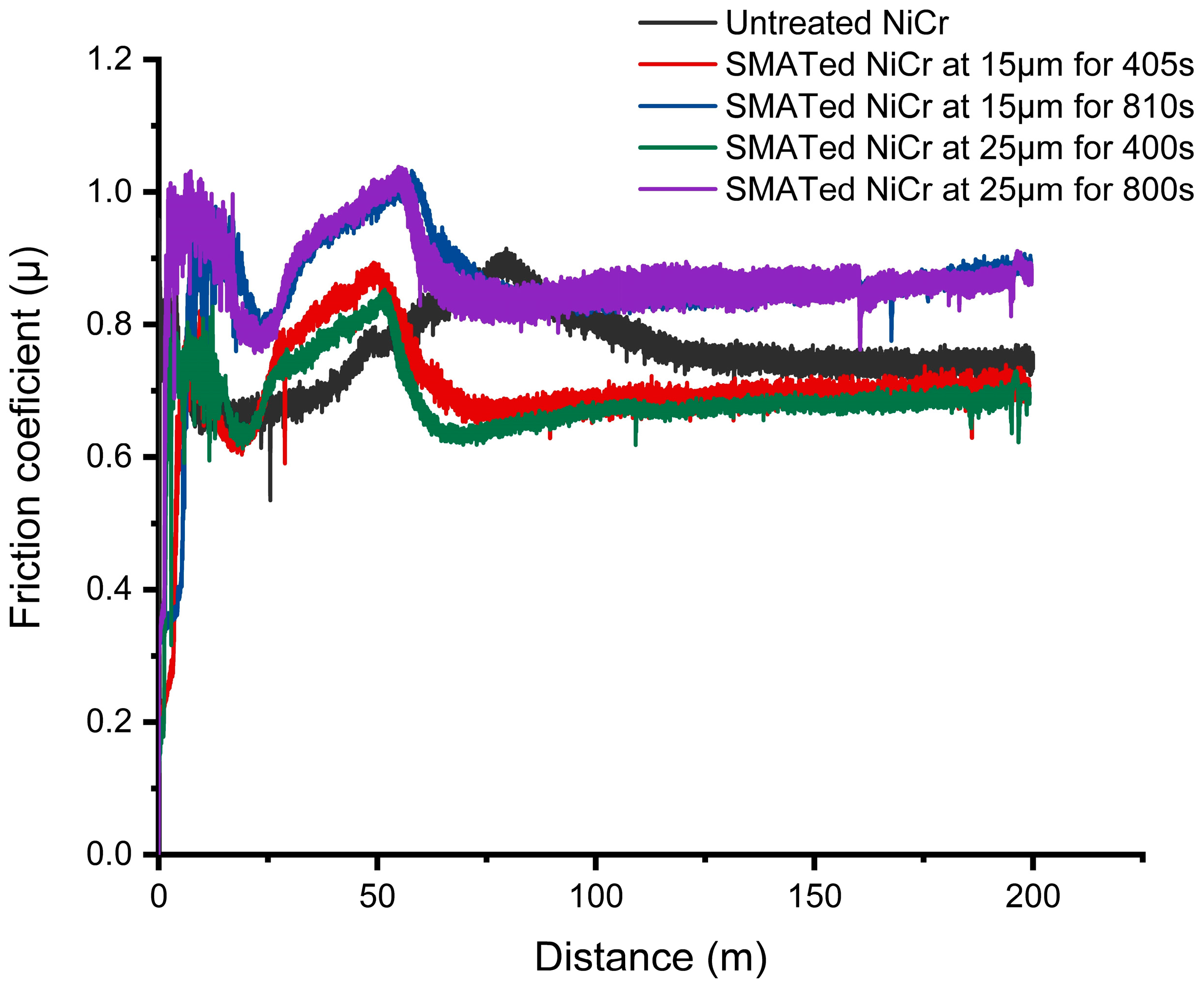

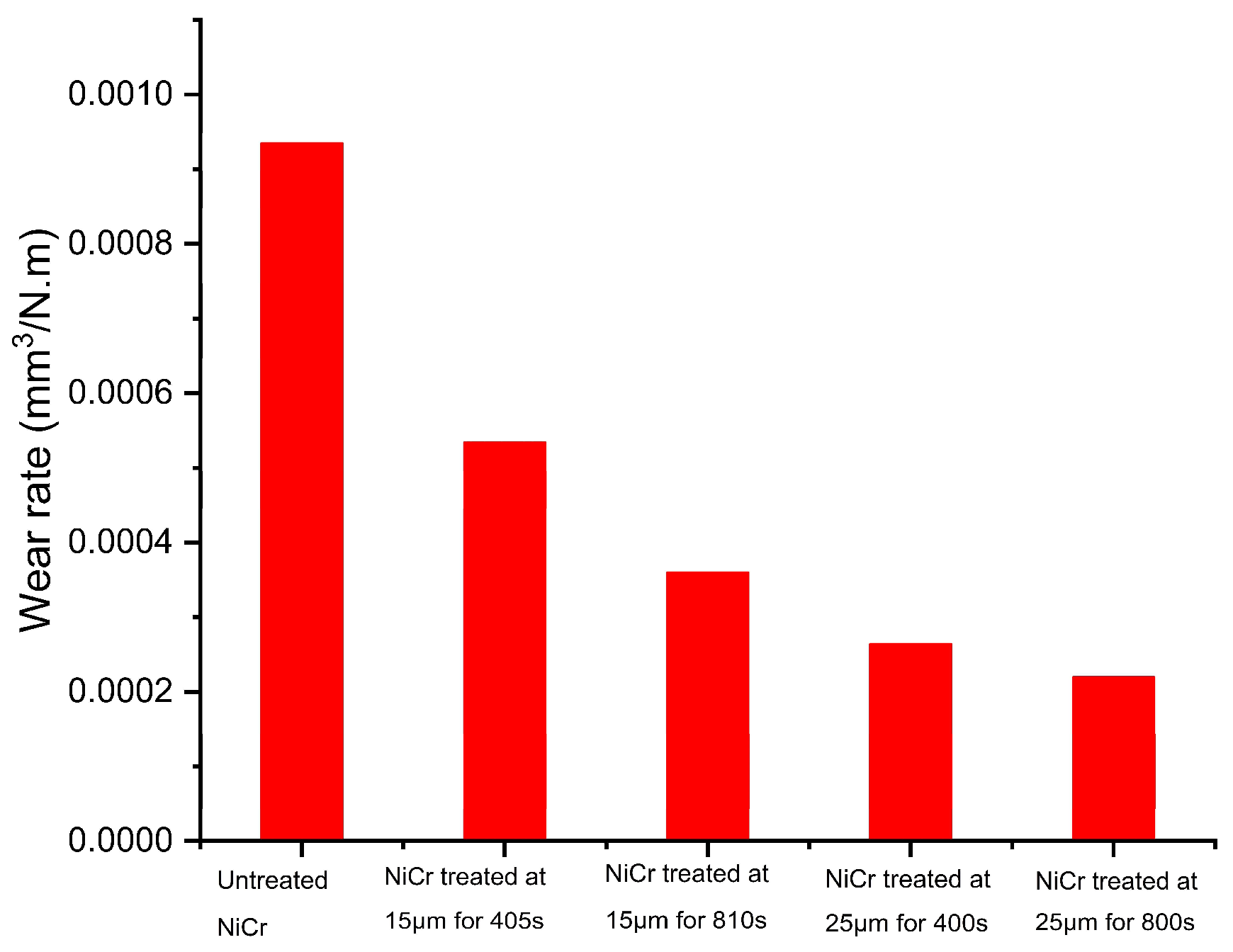

3.6. Friction and Wear Resistance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vicenzi, J.; Marques, C.M.; Bergmann, C.P. Hot and cold erosive wear of thermal sprayed NiCr-based coatings: Influence of porosity and oxidation. Surf. Coat. Technol. 2008, 202, 3688–3697. [Google Scholar] [CrossRef]

- Du, L.; Huang, C.; Zhang, W.; Li, T.; Liu, W. Preparation and wear performance of NiCr/Cr3C2–NiCr/hBN plasma sprayed composite coating. Surf. Coat. Technol. 2011, 205, 3722–3728. [Google Scholar] [CrossRef]

- Ivannikov, A.Y.; Kalita, V.I.; Komlev, D.I.; Radyuk, A.A.; Bagmutov, V.P.; Zakharov, I.N.; Parshev, S.N. The effect of electromechanical treatment on structure and properties of plasma sprayed Ni-20Cr coating. J. Alloy. Compd. 2016, 655, 11–20. [Google Scholar] [CrossRef]

- Lin, L.; Lia, G.-L.; Wang, H.-D.; Kang, J.-J.; Xu, Z.-L.; Wang, H.-J. Structure and wear behavior of NiCr-Cr3C2 coatings sprayed by supersonic plasma spraying and high velocity oxy-fuel technologies. Appl. Surf. Sci. 2015, 356, 383–390. [Google Scholar] [CrossRef]

- Sadeghimeresht, E.; Markocsan, N.; Joshi, S. Isothermal oxidation behavior of HVAF-sprayed Ni and NiCr coatings in H2-H2O environment. Surf. Coat. Technol. 2017, 317, 17–25. [Google Scholar] [CrossRef]

- Bolelli, G.; Berger, L.M.; Börner, T.; Koivuluoto, H.; Matikainen, V.; Lusvarghi, L.; Lyphout, C.; Markocsan, N.; Nylén, P.; Sassatelli, P.; et al. Sliding and abrasive wear behavior of HVOF-and HVAF-sprayed Cr3C2–NiCr hardmetal coatings. Wear 2016, 358, 32–50. [Google Scholar] [CrossRef]

- Zhou, W.; Zhou, K.; Li, Y.; Deng, C.; Zeng, K. High temperature wear performance of HVOF-sprayed Cr3C2-WC-NiCoCrMo and Cr3C2-NiCr hardmetal coatings. Appl. Surf. Sci. 2017, 416, 33–44. [Google Scholar] [CrossRef]

- Deesom, D.; Charoenrut, K.; Moonngam, S.; Banjongprasert, C. Fabrication and properties of NiCr/CNTs nanocomposite coatings prepared by High Velocity Oxy-Fuel Spraying. Surf. Coat. Technol. 2016, 306, 240–244. [Google Scholar] [CrossRef]

- Lin, J.; Wang, Z.; Lin, P.; Cheng, J.; Zhang, X.; Hong, S. Effects of post annealing on the microstructure, mechanical properties and cavitation erosion behavior of arc-sprayed FeNiCrBSiNbW coatings. Mater. Des. 2015, 65, 1035–1040. [Google Scholar] [CrossRef]

- Park, I.C.; Kim, S.J. Corrosion behavior in seawater of arc thermal sprayed Inconel 625 coatings with sealing treatment. Surf. Coat. Technol. 2017, 325, 729–737. [Google Scholar] [CrossRef]

- Luo, X.T.; Li, Y.J.; Li, C.X.; Yang, G.J.; Li, C.J. Effect of spray conditions on deposition behavior and microstructure of cold sprayed Ni coatings sprayed with a porous electrolytic Ni powder. Surf. Coat. Technol. 2016, 289, 85–93. [Google Scholar] [CrossRef]

- Chatha, S.S.; Sidhu, H.S.; Sidhu, B.S. High temperature hot corrosion behaviour of NiCr and Cr3C2–NiCr coatings on T91 boiler steel in an aggressive environment at 750 °C. Surf. Coat. Technol. 2012, 206, 3839–3850. [Google Scholar] [CrossRef]

- Khaled, M.M.; Yilbas, B.S. Corrosion properties of HVOF-coated steel in simulated concrete pore electrolyte and concentrated chloride environments. Surf. Coat. Technol. 2007, 202, 433–438. [Google Scholar] [CrossRef]

- Ahmed, N.; Bakare, M.S.; McCartney, D.G.; Voisey, K.T. The effects of microstructural features on the performance gap in corrosion resistance between bulk and HVOF sprayed Inconel 625. Surf. Coat. Technol. 2010, 204, 2294–2301. [Google Scholar] [CrossRef]

- Wenzelburger, M.; López, D.; Gadow, R. Methods and application of residual stress analysis on thermally sprayed coatings and layer composites. Surf. Coat. Technol. 2006, 201, 1995–2001. [Google Scholar] [CrossRef]

- Shukla, V.N.; Jayaganthan, R.; Tewari, V.K. Degradation behavior of HVOF-sprayed Cr3C2-25%NiCr cermet coatings exposed to high temperature environment. Mater. Today Proc. 2015, 2, 1805–1813. [Google Scholar] [CrossRef]

- Nayebpashaee, N.; Seyedein, S.H.; Aboutalebi, M.R.; Sarpoolaky, H.; Hadavi, S.M.M. Finite element simulation of residual stress and failure mechanism in plasma sprayed thermal barrier coatings using actual microstructure as the representative volume. Surf. Coat. Technol. 2016, 291, 103–114. [Google Scholar] [CrossRef]

- Selvadurai, U.; Hollingsworth, P.; Baumann, I.; Hussong, B.; Tillmann, W.; Rausch, S.; Biermann, D. Influence of the handling parameters on residual stresses of HVOF-sprayed WC-12Co coatings. Surf. Coat. Technol. 2015, 268, 30–35. [Google Scholar] [CrossRef]

- Rajasekaran, B.; Mauer, G.; Vaßen, R.; Röttger, A.; Weber, S.; Theisen, W. Thick tool steel coatings using HVOF spraying for wear resistance applications. Surf. Coat. Technol. 2010, 205, 2449–2454. [Google Scholar] [CrossRef]

- Pukasiewicz, A.G.M.; de Boer, H.E.; Sucharski, G.B.; Vaz, R.F.; Procopiak, L.A.J. The influence of HVOF spraying parameters on the microstructure, residual stress and cavitation resistance of FeMnCrSi coatings. Surf. Coat. Technol. 2017, 327, 158–166. [Google Scholar] [CrossRef]

- Katranidis, V.; Gu, S.; Allcock, B.; Kamnis, S. Experimental study of high velocity oxy-fuel sprayed WC-17Co coatings applied on complex geometries. Part A: Influence of kinematic spray parameters on thickness, porosity, residual stresses and microhardness. Surf. Coat. Technol. 2017, 311, 206–215. [Google Scholar] [CrossRef]

- Chatha, S.S.; Sidhu, H.S.; Sidhu, B.S. The effects of post-treatment on the hot corrosion behavior of the HVOF-sprayed Cr3C2–NiCr coating. Surf. Coat. Technol. 2012, 206, 4212–4224. [Google Scholar] [CrossRef]

- Liu, L.; Xu, H.; Xiao, J.; Wei, X.; Zhang, G.; Zhang, C. Effect of heat treatment on structure and property evolutions of atmospheric plasma sprayed NiCrBSi coatings. Surf. Coat. Technol. 2017, 325, 548–554. [Google Scholar] [CrossRef]

- Li, G.J.; Li, J.; Luo, X. Effects of high temperature treatment on microstructure and mechanical properties of laser-clad NiCrBSi/WC coatings on titanium alloy substrate. Mater. Charact. 2014, 98, 83–92. [Google Scholar] [CrossRef]

- Staia, M.H.; Suárez, M.; Chicot, D.; Lesage, J.; Iost, A.; Puchi-Cabrera, E.S. Cr2C3–NiCr VPS thermal spray coatings as candidate for chromium replacement. Surf. Coat. Technol. 2013, 220, 225–231. [Google Scholar] [CrossRef]

- Murthy, J.K.N.; Prasad, K.S.; Gopinath, K.; Venkataraman, B. Characterisation of HVOF sprayed Cr3C2-50(Ni20Cr) coating and the influence of binder properties on solid particle erosion behaviour. Surf. Coat. Technol. 2010, 204, 3975–3985. [Google Scholar] [CrossRef]

- Bergant, Z.; Trdan, U.; Grum, J. Effect of high-temperature furnace treatment on the microstructure and corrosion behavior of NiCrBSi flame-sprayed coatings. Corros. Sci. 2014, 88, 372–386. [Google Scholar] [CrossRef]

- Laika, A.; Chakravarthyb, D.P.; Kale, G.B. On characterisation of wire-arc–plasma-sprayed Ni on alumina substrate. Mater. Charact. 2005, 55, 118–126. [Google Scholar] [CrossRef]

- Gisario, A.; Puopolo, M.; Venettacci, S.; Veniali, F. Improvement of thermally sprayed WC–Co/NiCr coatings by surface laser processing. Int. J. Refract. Met. Hard Mater. 2015, 52, 123–130. [Google Scholar] [CrossRef]

- Janka, L.; Norpoth, J.; Eicher, S.; Ripoll, M.R.; Vuoristo, P. Improving the toughness of thermally sprayed Cr3C2-NiCr hardmetal coatings by laser post-treatment. Mater. Des. 2016, 98, 135–142. [Google Scholar] [CrossRef]

- Saedi, S.; Moghaddam, N.S.; Amerinatanzi, A.; Elahinia, M.; Karaca, H.E. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater. 2018, 144, 552–560. [Google Scholar] [CrossRef]

- Yu, J.; Wang, Y.; Zhou, F.; Wang, L.; Pan, Z. Laser remelting of plasma-sprayed nanostructured Al2O3–20 wt.% ZrO2 coatings onto 316L stainless steel. Appl. Surf. Sci. 2018, 431, 112–121. [Google Scholar] [CrossRef]

- Kromer, R.; Costil, S.; Verdy, C.; Gojon, S.; Liao, H. Laser surface texturing to enhance adhesion bond strength of spray coatings—Cold spraying, wire-arc spraying, and atmospheric plasma spraying. Surf. Coat. Technol. 2018, 352, 642–653. [Google Scholar] [CrossRef]

- Das, B.; Nath, A.K.; Bandyopadhyay, P.P. Online monitoring of laser remelting of plasma sprayed coatings to study the effect of cooling rate on residual stress and mechanical properties. Ceram. Int. 2018, 44, 7524–7534. [Google Scholar] [CrossRef]

- Kang, N.; Verdy, C.; Coddet, P.; Xie, Y.; Fu, Y.; Liao, H.; Coddet, C. Effects of laser remelting process on the microstructure, roughness and microhardness of in-situ cold sprayed hypoeutectic Al-Si coating. Surf. Coat. Technol. 2017, 318, 355–359. [Google Scholar] [CrossRef]

- Benafia, S.; Retraint, D.; Brou, S.Y.; Panicaud, B.; Poussard, J.G. Influence of Surface Mechanical Attrition Treatment on the oxidation behaviour of 316L stainless steel. Corros. Sci. 2018, 136, 188–200. [Google Scholar] [CrossRef]

- Wang, Z.; Diao, R.; Yuan, Z.; Yu, X.; Fu, T.; Zhao, Y.; Zhan, Z. Surface mechanical attrition treatment and corrosion resistance behavior of TA2 anodic oxide film. Int. J. Electrochem. Sci. 2018, 13, 4411–4423. [Google Scholar] [CrossRef]

- Nkonta, D.T.; Simescu-Lazar, F.; Drevet, R.; Aaboubi, O.; Fauré, J.; Retraint, D.; Benhayoune, H. Influence of the surface mechanical attrition treatment (SMAT) on the corrosion behavior of Co28Cr6Mo alloy in Ringer’s solution. J. Solid State Electrochem. 2018, 22, 1091–1098. [Google Scholar] [CrossRef]

- Chen, X.H.; Lu, J.; Lu, L.; Lu, K. Tensile properties of a nanocrystalline 316L austenitic stainless steel. Scr. Mater. 2005, 52, 1039–1044. [Google Scholar] [CrossRef]

- Roland, T.; Retraint, D.; Lu, K.; Lu, J. Generation of nanostructures on 316L stainless steel and its effect on mechanical behavior. Mater. Sci. Forum 2005, 490, 625–630. [Google Scholar] [CrossRef]

- Uusitalo, J.; Karjalainen, L.P.; Retraint, D.; Palosaari, M. Fatigue properties of steels with ultrasonic attrition treated surface layers. Mater. Sci. Forum 2009, 604–605, 239–248. [Google Scholar]

- Zhou, J.; Sun, Z.; Kanouté, P.; Retraint, D. Effect of surface mechanical attrition treatment on low cycle fatigue properties of an austenitic stainless steel. Int. J. Fatigue 2017, 103, 309–317. [Google Scholar] [CrossRef]

- Bernoulli, D.; Cao, S.C.; Lu, J.; Dao, M. Enhanced repeated frictional sliding properties in 304 stainless steel with a gradient nanostructured surface. Surf. Coat. Technol. 2018, 339, 14–19. [Google Scholar] [CrossRef]

- Chamgordani, S.A.; Miresmaeili, R.; Aliofkhazraei, M. Improvement in tribological behavior of commercial pure titanium (CP-Ti) by surface mechanical attrition treatment (SMAT). Tribol. Int. 2018, 119, 744–752. [Google Scholar] [CrossRef]

- Liu, Y.; Jin, B.; Li, D.J.; Zeng, X.Q.; Lu, J. Wear behavior of nanocrystalline structured magnesium alloy induced by surface mechanical attrition treatment. Surf. Coat. Technol. 2015, 261, 219–226. [Google Scholar] [CrossRef]

- Huang, R.; Han, Y. Structure evolution and thermal stability of SMAT-derived nanograined layer on Ti–25Nb–3Mo–3Zr–2Sn alloy at elevated temperatures. J. Alloy. Compd. 2013, 554, 1–11. [Google Scholar] [CrossRef]

- Liu, Y.; Jin, B.; Lu, J. Mechanical properties and thermal stability of nanocrystallized pure aluminum produced by surface mechanical attrition treatment. Mater. Sci. Eng. A 2015, 636, 446–451. [Google Scholar] [CrossRef]

- Zhou, J.; Retraint, D.; Sun, Z.; Kanouté, P. Comparative study of the effects of surface mechanical attrition treatment and conventional shot peening on low cycle fatigue of a 316L stainless steel. Surf. Coat. Technol. 2018, 349, 556–566. [Google Scholar] [CrossRef]

- Achache, S.; Lamri, S.; Alhussein, A.; Billard, A.; François, M.; Sanchette, F. Gum Metal thin films obtained by magnetron sputtering of a Ti-Nb-Zr-Ta target. Mater. Sci. Eng. A 2016, 673, 492–502. [Google Scholar] [CrossRef]

- Jelliti, S.; Richard, C.; Retraint, D.; Roland, T.; Chemkhi, M.; Demangel, C. Effect of surface nanocrystallization on the corrosion behavior of Ti–6Al–4V titanium alloy. Surf. Coat. Technol. 2013, 224, 82–87. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, Z.B. Strain-induced formation of a gradient nanostructured surface layer on an ultrahigh strength bearing steel. J. Mater. Sci. Technol. 2018, 34, 1676–1684. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y.; Wang, Y.; Yu, H.; Zhang, C. Fabrication of nanostructure in inner-surface of AISI 304 stainless steel pipe with surface plastic deformation. J. Mater. Sci. Technol. 2018, 34, 2125–2130. [Google Scholar] [CrossRef]

- Zhao, B.; Lv, Y.; Ding, Y.; Wang, L.; Lu, W. The grain refinement mechanisms of various phases in shot-peened Nickel-Aluminum bronze (NAB) alloy. Mater. Charact. 2018, 144, 77–85. [Google Scholar] [CrossRef]

- Ding, J.; Li, Q.; Li, J.; Xue, S.; Fan, Z.; Wang, H.; Zhang, X. Mechanical behavior of structurally gradient nickel alloy. Acta Mater. 2018, 149, 57–67. [Google Scholar] [CrossRef]

- Wang, T.G.; Zhao, S.S.; Hua, W.G.; Li, J.B.; Gong, J.; Sun, C. Estimation of residual stress and its effects on the mechanical properties of detonation gun sprayed WC–Co coatings. Mater. Sci. Eng. A 2010, 527, 454–461. [Google Scholar] [CrossRef]

- Suhonen, T.; Varis, T.; Dosta, S.; Torrell, M.; Guilemany, J.M. Residual stress development in cold sprayed Al, Cu and Ti coatings. Acta Mater. 2013, 61, 6329–6337. [Google Scholar] [CrossRef]

- Oladijo, O.P.; Venter, A.M.; Cornish, L.A.; Sacksn, N. X-ray diffraction measurement of residual stress in WC-Co thermally sprayed coatings onto metal substrates. Surf. Coat. Technol. 2012, 206, 4725–4729. [Google Scholar] [CrossRef]

| Spraying Parameters | Value |

|---|---|

| Arc current (A) | 135 |

| Arc voltage (V) | 33 |

| Spray distance (mm) | 125 |

| Spray speed (mm/s) | 500 |

| Pressure of compressed air (bar) | 8.25 |

| Nitrogen flow rate (m3/h) | 42–50 |

| Spray passes | 8 |

| Steps (mm) | 8 |

| Specimen Label | Nature of Balls | Diameter of Balls (mm) | Amplitude of Vibration (µm) | Treatment Duration (s) |

|---|---|---|---|---|

| NS | – | – | – | – |

| S 15-01 | 100Cr6 | 3 | 15 | 405 |

| S 15-02 | – | – | – | 810 |

| S 25-01 | – | – | 25 | 400 |

| S 25-02 | – | – | – | 800 |

| Parameters | Values |

|---|---|

| Ball material | 100Cr6 |

| Ball diameter (mm) | 6 |

| Load (N) | 5 |

| Radius (mm) | 6 |

| Linear speed (m/s) | 0.1 |

| Sliding distance (m) | 200 |

| Temperature (°C) | 23 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aoudia, K.; Lamri, S.; Achache, S.; Retraint, D.; Verdy, C.; Langlade, C.; Azem, S.; Sanchette, F. Structural and Mechanical Properties of Arc-Sprayed Ni–Cr Coating Post-Treated by Surface Mechanical Attrition Treatment (SMAT). Coatings 2018, 8, 424. https://doi.org/10.3390/coatings8120424

Aoudia K, Lamri S, Achache S, Retraint D, Verdy C, Langlade C, Azem S, Sanchette F. Structural and Mechanical Properties of Arc-Sprayed Ni–Cr Coating Post-Treated by Surface Mechanical Attrition Treatment (SMAT). Coatings. 2018; 8(12):424. https://doi.org/10.3390/coatings8120424

Chicago/Turabian StyleAoudia, Karima, Salim Lamri, Sofiane Achache, Delphine Retraint, Christophe Verdy, Cécile Langlade, Said Azem, and Frédéric Sanchette. 2018. "Structural and Mechanical Properties of Arc-Sprayed Ni–Cr Coating Post-Treated by Surface Mechanical Attrition Treatment (SMAT)" Coatings 8, no. 12: 424. https://doi.org/10.3390/coatings8120424

APA StyleAoudia, K., Lamri, S., Achache, S., Retraint, D., Verdy, C., Langlade, C., Azem, S., & Sanchette, F. (2018). Structural and Mechanical Properties of Arc-Sprayed Ni–Cr Coating Post-Treated by Surface Mechanical Attrition Treatment (SMAT). Coatings, 8(12), 424. https://doi.org/10.3390/coatings8120424