1. Introduction

Impingement of droplets on solid surfaces is a key physical factor in combustion, coating processes, inkjet printing, and spray cooling [

1,

2]. After the impingement of the droplets, characteristic behaviors, such as deposition, fingering, rebounding and splashing, are observed [

3,

4,

5]. In particular, the deposition and subsequent spreading without forming a crown shape is a basic behavior of droplet impingement on solid surfaces. Theoretical, empirical, and semi-empirical relations that describe this process have been proposed in previous research [

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21] to predict the maximum spreading factor β

m, defined as the ratio

dmax/

d0, where

dmax is the maximum spreading diameter and

d0 is the initial droplet diameter. Correlations between β

m, Weber number We (=ρ

lu2d0/σ

lg, where ρ

l,

u,

d0, and σ

lg represent the liquid density, impinging velocity, initial droplet diameter, and surface energy density of the liquid, respectively) and Reynolds number Re (=ρ

lud0/μ

l, where μ

l is the viscosity of the liquid) are mainly discussed considering the balance between the inertia, viscosity, and capillary effects [

3,

8,

9,

22,

23,

24]. However, it is important to note that the parameter

dmax in the existing models is not necessarily equivalent to the contact area diameter. Rather,

dmax in most existing models is defined as the distance between the top of both sides of the free surface at the maximum expansion, and thus,

dmax is the maximum diameter of the contact area only if the position of the droplet’s side surface does not exceed the position of the contact line. In the existing models, two definitions for β

m are mixed. This increases the difficulty of accurately modelling adhesion energy in the spreading process. In the spreading process, effect of the adhesion is calculated from surface tension in the horizontal direction at the contact line as follows: σ

lg(1 − cosθ). Recent studies have reported the effect and importance of the vertical component of the surface tension (σ

lgsinθ) on the wetting phenomena [

25,

26,

27,

28,

29]. This factor has long been neglected because of the resistance of the solid surface [

30]. For droplet impingement, the vertical component is a key factor for predicting the spreading contact area precisely. Recently, we derived an energy balance equation that includes the vertical component of the surface tension [

31]. From the previously derived model, two limiting solutions were obtained for the ratio between the maximum contact area diameter

dm and the initial droplet diameter

d0, β

m ≈ We

1/2 and β

m ≈ Re

1/5. The scaling of β

m ≈ Re

1/5 is theoretically certified in the case of the impingement behavior of high-viscosity liquid droplets [

31]. However, there is no available experimental data [

32] to support the solution β

m ≈ We

1/2. In recent numerical simulation [

33], the droplet impingement behavior over a wide range of We numbers was investigated using the phase field method, assuming a constant friction factor that depends on the kinds of liquid and solid materials. Finally, the new scaling law β

m ≈ (μ

lRe/μ

f)

1/2 is proposed. In the present study, we report the behavior of droplet impingement covering a wide range of liquid viscosities, surface tensions, and target surface wettabilities for superhydrophilic (SHPi), silicone rubber (SR), polycarbonate (PC), and superhydrophobic (SHPo) substrates, including the existing experimental data for a superamphiphobic substrate. As shown in this paper, our modified model can be universally used to predict the maximum spreading contact area diameter unlike other existing models. In particular, our model shows that constant parameters appearing in some previous models [

15,

17,

33] are not actually constant. The limits of applicability for recent existing models are discussed. This paper also reports an analytical result of the wetting behavior of low-viscosity liquid droplets, such as liquid helium. This modified model demonstrates that the impingement behavior of a superfluid will exhibit the scaling relation of β

m ≈ We

1/2.

2. Experiment

In the experiments with droplets, purified water (Wako Pure Chemical Industries, Ltd., Osaka, Japan; ρ

l = 998.2 kg m

−3, μ

l = 10

−3 Pa s and σ

lg = 72.8 × 10

−3 N·m

−1), pure ethanol (Kenei Pharmaceutical Co., Ltd., Osaka, Japan; purity = 99.5%, ρ

l = 789.2 kg m

−3, μ

l = 1.2 × 10

−3 Pa s and σ

lg = 21.1 × 10

−3 N·m

−1) and two types of silicon oils (Shin-Etsu Chemical Co., Ltd., Tokyo, Japan; ρ

l = 968.3 and 967.1 kg m

−3, μ

l = 0.306 and 3.062 Pa s and σ

lg = 21.1 × 10

−3 and 21.3 × 10

−3 N·m

−1, respectively) were used. The solids studied herein were as follows: a superhydrophilic (SHPi) substrate (3M Japan Ltd., Tokyo, Japan), polycarbonate (PC; Sumitomo Bakelite Co., Ltd., Tokyo, Japan), silicone rubber (SR; AS ONE Corporation, Osaka, Japan) and a superhydrophobic (SHPo) substrate (Toyo Aluminium K.K., Osaka, Japan). We used 3M

TM Scotchitint

TM and aluminum tape from Toyal Lotus

® (the so-called ‘lotus-effect’ tape) as superhydrophilic and superhydrophobic substrates, respectively. The wettability properties of the solid substrates are evaluated by measuring contact angle hysteresis (CAH) of θ

re − θ

ad [

34]. The value of CAH is obtained using the tilted plane method (sliding droplet) with purified water on each solid substrate [

35]. The values of CAH for SHPi, PC, SR, and SHPo are 2.0° ± 0.3° (two standard deviation (2 SD)), 25.4° ± 3.2° (2 SD), 17.9° ± 6.0° (2 SD), and 11.3° ± 2.6° (2 SD), respectively. Here, for the case of SHPi, rear contact line adheres to the solid substrate and does not move. Therefore, the value of CAH is evaluated using the value of θ

re − θ

ad when the front contact line begins moving. For the case of the superamphiphobic substrate, we referred to the results a previous study [

36]. The droplet was released from various heights using a microsyringe. We assumed that the droplet was in free fall in our experiments. The droplet volumes were in range 1.1–31.6 μL. Images of the droplet behavior after impacting on the solid surfaces were captured using a high-speed video camera (HX-5; NAC Image Technology, Ltd., Tokyo, Japan). From these images,

u,

d0, and

dm were measured. Here,

dm is the measured value of the maximum contact area diameter. In the experiments, the temperature and humidity were in the ranges 21.0–23.0 °C and 51.0%–55.0%, respectively.

3. Prediction of Maximum Spreading Contact Area Diameter

In our model [

31], the relationship between β

m, Re, and We for each release condition of a droplet is calculated using the following energy balance equation:

In this equation,

is the averaged contact angle (°) of the static contact angle θ

st and contact angle at maximum spreading θ

m. β

m is the ratio between the maximum contact area diameter

dm and the initial droplet diameter

d0.

hm is the droplet height. The subscript m indicates that the contact diameter reaches the maximum diameter. In an actual situation, the droplet is not strictly at equilibrium. Therefore, a value of a contact angle obtained via the sessile droplet experiment (apparent static contact angle) is used for θ

st. With respect to the values of θ

m, the measured values are used in Equation (1). However, the values of θ

m for each solid substrates are quite constant over the impingement velocities even if the droplet volume changes: θ

m = 128.2° ± 6.3°(2 SD) for water on SR, 161° ± 2.7°(2 SD) for water on SHPo, 44.8° ± 4.4°(2 SD) for water on SHPi, 66.4° ± 6.4°(2 SD) for ethanol on SR, 139.1° ± 11.8° (2 SD) for Oil 300 cs on SR, and 148.1° ± 12.3°(2 SD) for Oil 3000 cs on SR. A similar tendency was also reported by Lee et al. (2016) [

23]. In Equation (1), the first, second, and third terms on the left-hand side represent the non-dimensional kinetic energy

Ekine, the non-dimensional initial surface energy

Esurf and the non-dimensional gravitational potential energy

Egrav, respectively. On the right-hand side of Equation (1), the first and fourth terms represent the non-dimensional viscous dissipation energy

Evis and the non-dimensional deformed surface energy

Edef, respectively. The second and third terms represent the non-dimensional adhesion energy

Esprd. In the present study, some existing models (see the

Appendix A; the equations in the Appendix are expressed as Equations (A1) and (A2), etc., in the main text) are also used for the comparison of the experimental data, although the parameter

dmax in the existing models is not necessarily defined as the value of the contact area diameter.

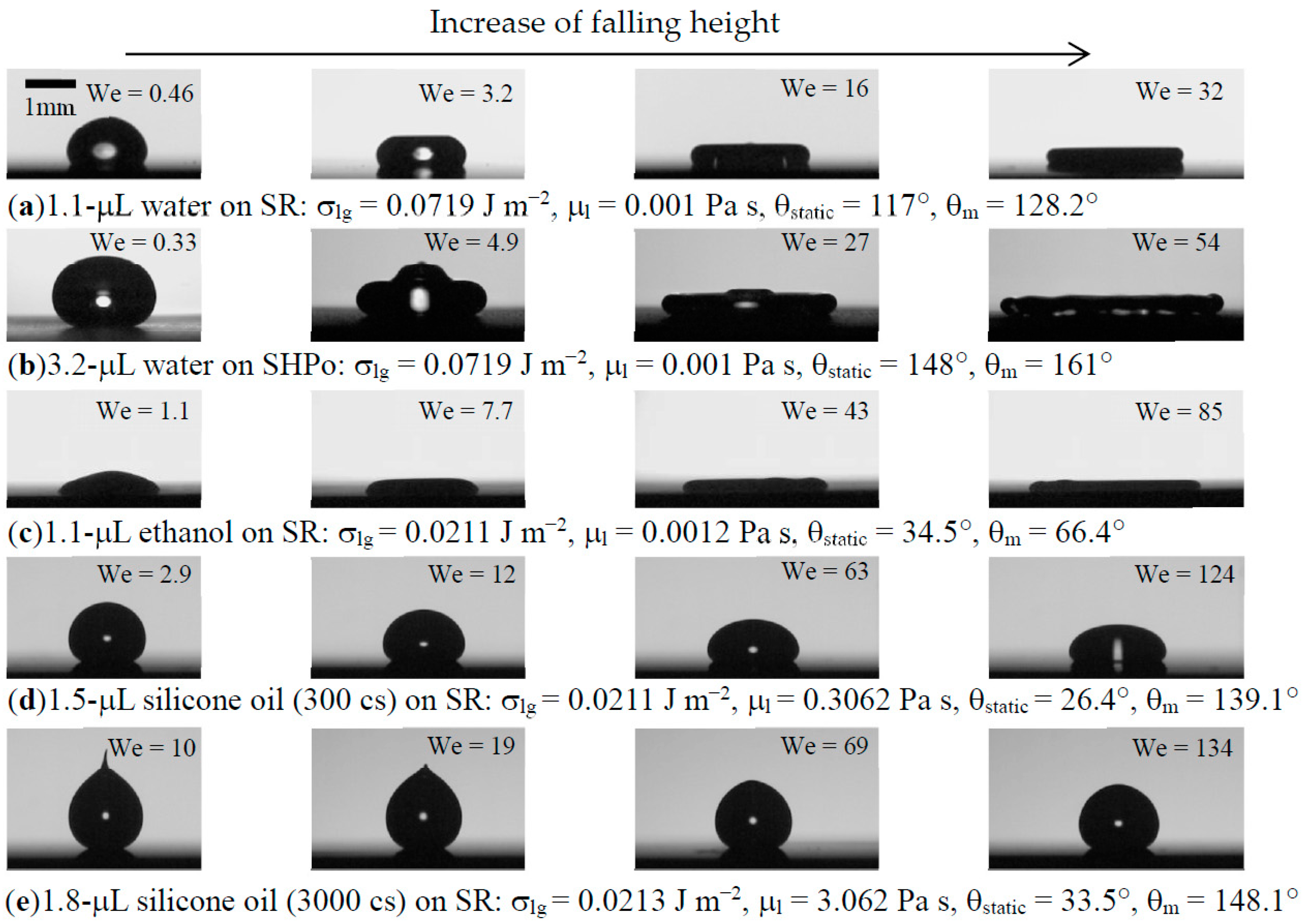

4. Result and Discussion

The images of the maximum spreading of droplets for water, ethanol, and silicone oils on solid substrates are shown in

Figure 1. We observed that the contact angles at maximum spreading (θ

m) for the high-viscosity liquid were considerably large in value in comparison with the static contact angles for the low-viscosity liquids. Additionally, the shape of the droplet near the contact line was almost similar to that observed in the hydrophobic case (

Figure 1a,b) rather than that observed in the hydrophilic case (

Figure 1c). The high-viscosity liquid exhibited a specific behavior: the contact angle was obtuse at maximum spreading even when the static contact angle was small (corresponding to the hydrophilic case), e.g. θ

m/θ

st = 4.4 for the silicone differential oil o3000 cs (hereinafter referred to as ‘Oil 3000 cs’) on SR, 1.1 for water on SR, and 1.9 for ethanol on SR. The relationships between β

m and We for each different liquid on different surfaces are shown in

Figure 2. Some existing models are compared with the experimental data. In our model, the surface deformation term in Equation (1) is modelled based on the experimental evidence of the specific behavior for a high-viscosity liquid as:

where

Sharm is the harmonic average of the surface areas for a spherical cap (

Ssph) and disc shape (

Sdisc) [

31].

f(

) is defined as:

Equation (2) indicates that the surface deformation of the droplet is mainly dependent on . Though the focus of this study is on the deposition process from the initiation of contact to the end of the spreading phase, the evaluation of surface deformation is important in analysing the rebound behavior of a droplet falling onto a superhydrophobic substrate. After reaching the maximum spreading diameter, the diameter of a droplet on a superhydrophobic substrate will retract. The surface deformation (Equation (2)) is relevant to the detailed consideration of this retraction process because the energy driving the retraction is supplied by the surface deformation. However, whether the droplet will rebound depends on the gravitational potential energy, adhesion energy, and viscous dissipation caused by fluid motion.

Figure 2 shows the relationship between β

m and We for the low- and high-viscosity liquids. In

Figure 2a–f, the red, blue and black solid lines represent the results obtained using our model (Equations (1) and (2)), the model proposed by Lee et al. [

17] (Equations (A3)) and the model proposed by Huang et al. (Equation (A9)), respectively. The green and pink dashed lines represent the results obtained using the model proposed by Laan et al. (Equation (A1)) and those obtained using the model proposed by Zhang et al. [

16] (Equations (A1) and (A2)), respectively. In

Figure 2g,h, the fitting parameters of

A in Equation (A1) and

B in Equation (A3) are evaluated using our model. The red solid horizontal lines of 1.24 and 7.6 in each figure are the values of

A and

B used in the original models. The red and blue solid lines in each figure represent the values of

A and

B, respectively, for the cases of Oil 3000 cs and Oil 300 cs, respectively. The red, black, blue, purple, and light green dashed lines correspond to the values of water on SR, water on PC, ethanol on SR, water on SHPo, and water on SHPi, respectively. From

Figure 2, we found that the model proposed by Lee et al. (Equation (A3)) [

17] and our model [

31] with the use of Equation (2) both showed good agreement with the experimental data.

However, for the high-viscosity liquid (Oil 3000 cs), Equation (A3) deviated from the experimental data. This deviation originated from the concept of Equation (A3): the value of β

0 in

is analytically evaluated. Strictly, the high-viscosity liquid under the conditions β

m < 1 and θ

m > 90°cannot be expressed by this model because β

0 approaches 1 as θ

m approaches 180° as shown in

Figure 3, which means that the lower limit of β

m = 1 exists. In addition, the fitting parameters A and B used in Equations (A1) and (A3), respectively, are not constant (see

Figure 2g,h). Actually, in the case of Oil 3000 cs, parameter B cannot be calculated because

is negative, thereby yielding an imaginary number in the numerator of

in Equation (A3). Such negative values can appear in some other cases. Notably, in

Figure 2b, the droplets in all cases rebounded after the maximum spreading diameter was reached. Here, the comparison of our model with other existing experimental data for the case of glycerol–water mixtures on superamphiphobic surfaces [

36] (

Figure 4a–f), ethanol and water on some different substrates, such as aluminum plate roughened by sand paper (Alro), as well as aluminum and parafilm [

23] (

Figure 4g,h) are performed. In the literature [

36], the maximum spreading diameter (

dmax) is defined by a distance between the top of both sides of free surface:

dc is defined as the maximum spreading contact area diameter in the literature. Therefore, we calibrated the extracted value using

dc ≈ 0.77

dmax from the image reported in the literature [

36]. This value of

dc is used herein.

Figure 4 shows the relationship between β

m and We for some existing data of low-to-high viscosities for glycerol–water mixtures [

36] (

Figure 4a–f), and the ethanol and water on Alro (rough) and Al, and parafilm [

23] (

Figure 4g,h). In

Figure 4a–f, the red, green, pink, blue, and black solid lines represent the results calculated by our model (Equations (1) and (2)), the model proposed by Zhang et al. [

16] (Equations (A1) and (A2)), the model proposed by Lee et al. [

17] (Equation (A3)) and the model proposed by Huang et al. [

24] (Equation (A9)), respectively. In

Figure 4g,h, the red and blue lines represent the results calculated using our model (Equations (1) and (2)) and the model proposed by Lee et al. [

17] (Equation (A3)), respectively. The dashed and solid lines denote the results obtained for ethanol and water, respectively. From

Figure 4, we observed that our model (Equations (1) and (2)) and that proposed by Lee et al. (Equation (A3)) show good agreement with the experimental results at a glance. However, the model proposed by Lee et al. does not catch the trend of the experimental data in the low-We region as the liquid viscosity of the glycerol–water mixture cases increases because this model potentially has a lower limit, i.e., β

m ≈1. Then, the data for the ethanol droplets on Al and parafilm deviate from the calculated results obtained from Equation (A3), as shown in

Figure 4g,h. Equation (A4) are developed based on a spherical cap droplet, which means that deviation may occur in the case of impingement of a low surface tension droplet, because the dynamic contact angle is not necessarily small.

Figure 5 shows the relation between β

m and Re for a purified water droplet with different volumes on SR and PC substrates. The experimental data are compared with our model and Equation (A3). The dashed and solid lines in both figures refer to the volumes of 1.1 μL and 31.6 μL, respectively. The red and blue lines represent the results evaluated by Equations (1) and (A3), respectively. From this figure, our model shows good agreement with the experimental data for ranges from low to high Re number. This may be because volume effects, such as gravitational potential, are included in Equation (1).

Figure 6a shows the relationship between β

mRe

−1/5 and the impact number

P (=WeRe

−2/5) of a water droplet (4.1 μL) on aluminum with a smooth surface (Al

sm); the data are extracted from the literature [

23]. In

Figure 6b, the energy transition for this case is depicted.

Rvis and

Rcap represent the non-dimensional viscous dissipation

Evis and the non-dimensional capillary energy

Ecap =

Esprd +

Edef, respectively, normalised by the non-dimensional initial impact energy

Eini =

Ekine +

Esurf +

Egrav in the following equations:

The lines A and C indicate that 99% of the initial impact energy is converted into

Evis and

Ecap, respectively. The line B shows that the

Eini value is equally converted into

Evis and

Ecap. The intersection of the two lines gives a transition point clearer than that given by the previous definition of

Er =

Evis/

Esprd [

31]. From

Figure 6a, in the low-impact number region where the capillary effect becomes dominant (

Figure 6b), we observed that the experimental data deviate from the green solid line (Equation (A1)). This model is developed based on the numerical results proposed by Eggers et al. [

2], where the effect of wettability on the spreading behavior was almost not considered because the contact angle was set to be constant (θ = 180°). In addition, the derivations of the scalings for β

m ≈ We

1/2 and β

m ≈ Re

1/5 were made via order estimation. Recently, Wang et al. simulated the droplet impingement behavior with a phase field method considering the friction factor μ

f, which controls the contact line velocity [

33]. In the simulation, the same result of the deviation from Equation (A1) was reported (

Figure 6a). This supports the validity of our model. However, our model indicates that the value of μ

f, calculated from Equation (A5), is not constant and takes a negative value in the low-

P region as shown in

Figure 7. This indicates that the validity of Equation (A5) is disputable because the equation is derived by rough order estimation.

Figure 8 shows the relationship between β

m and We for a low-viscosity liquid droplet, such as liquid helium. This analysis models the superfluid

4He on a cesium (Cs) coated substrate [

37,

38,

39]. The red solid line was plotted using our modified model with the properties of liquid helium (ρ

l = 145.2 kg m

−3, μ

l = 1.346 × 10

−6 Pa s, and σ

lg = 0.332 × 10

−3 N·m

−1 at

T = 1.5 K) [

40]. The advancing contact angle is 27.3°, based on measured data of liquid helium wettability on Cs-coated substrate in the literature [

39]. We use this as the value of θ

m. Liquid helium (

4He) on Cs-coated substrate does not wet the surface, and hence, has a finite contact angle, because the cesium surface exhibits the weak-binding substrate for liquid

4He [

37]. This behavior has been experimentally observed and theoretically modelled [

37,

38]. However, there are no data available for the static contact angle because there are few studies that investigates the liquid helium sessile droplet behavior in detail. Therefore, we set that the static contact angle θ

st of

4He on Cs is 3.6° by assuming that the similar ratio of θ

m/θ

st (ca. 7.5) for the case of water on SHPi (θ

m = 44.8° and θ

st = 6.0°) can be applied to that of the liquid helium on Cs case. The viscosity of liquid helium approaches zero as the temperature approaches 0 K [

41]. The results obtained using μ

l = 1.346 × 10

−8 Pa s are depicted with the solid green line in

Figure 8a. The scaling between β

m and We is almost β

m ≈ We

1/2 within the range We < 10

3 in

Figure 8a, as the viscosity of the liquid helium approaches zero (μ

l = 1.346 × 10

−8 Pa s). The black dashed line, solid green line, and solid red line nearly overlap in the range of We < 10

2. In

Figure 8b, the blue and red solid lines are the results for

Rcap and

Rvis for the case of μ

l = 1.346 × 10

−6 Pa s, respectively. Then, the light blue and orange solid lines are the results for

Rcap and

Rvis for the case of μ

l = 1.346 × 10

−8 Pa s, respectively. The intersection of

Rcap and

Rvis moves from

P1 toward

P2 as the viscosity approaches zero. In

Figure 8b, in the region We < 10

3 (β

m ≈ We

1/2 in

Figure 8a), we see that the conversion of energy to capillary energy (

Rcap) is dominant over the energy converted through viscous dissipation (

Rvis). In the case of the high-viscosity liquid (Oil 3000 cs),

Rvis is dominant compared with

Rcap in the area between Line B1 and Line C1.