Texturing Effect of Crater-Like Cavities Induced by High-Current Pulsed Electron Beam (HCPEB) Irradiation

Abstract

1. Introduction

2. Materials and Methods

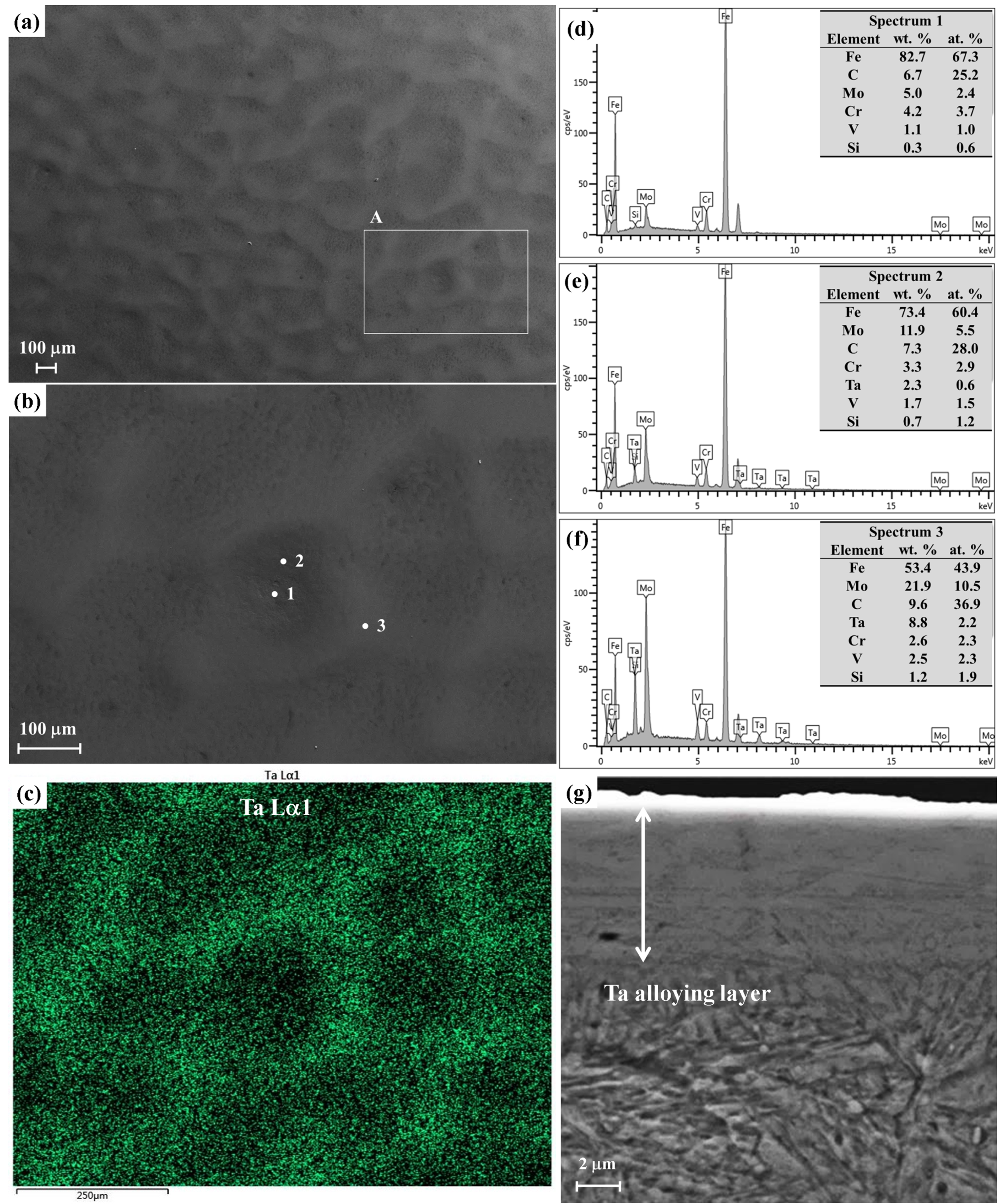

2.1. Preparation of HCPEB-Treated Ta Coating

2.2. Morphology Characterization

2.3. Nano-Indentation Tests

2.4. Friction Tests

3. Results

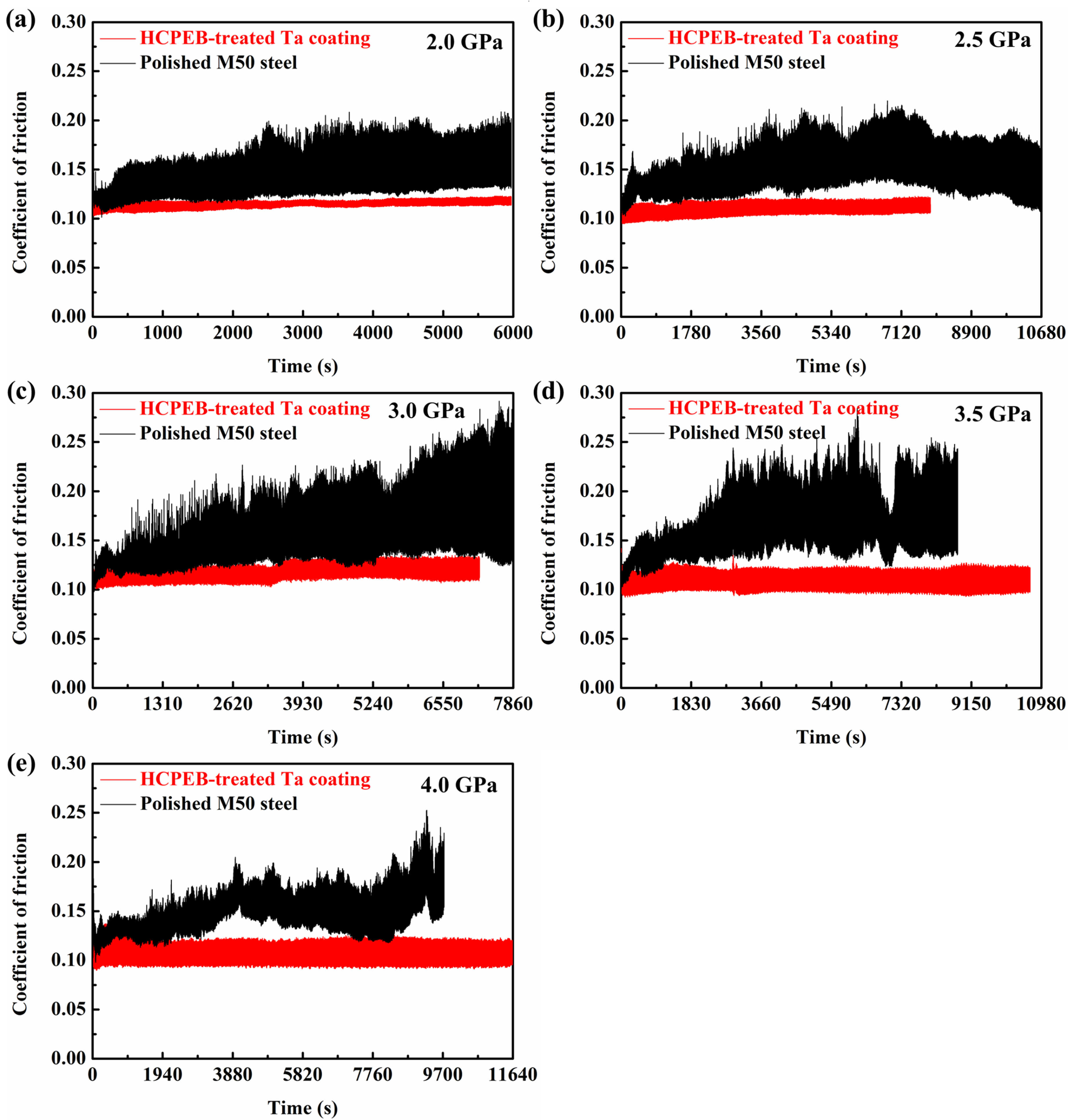

3.1. Coefficient of Friction

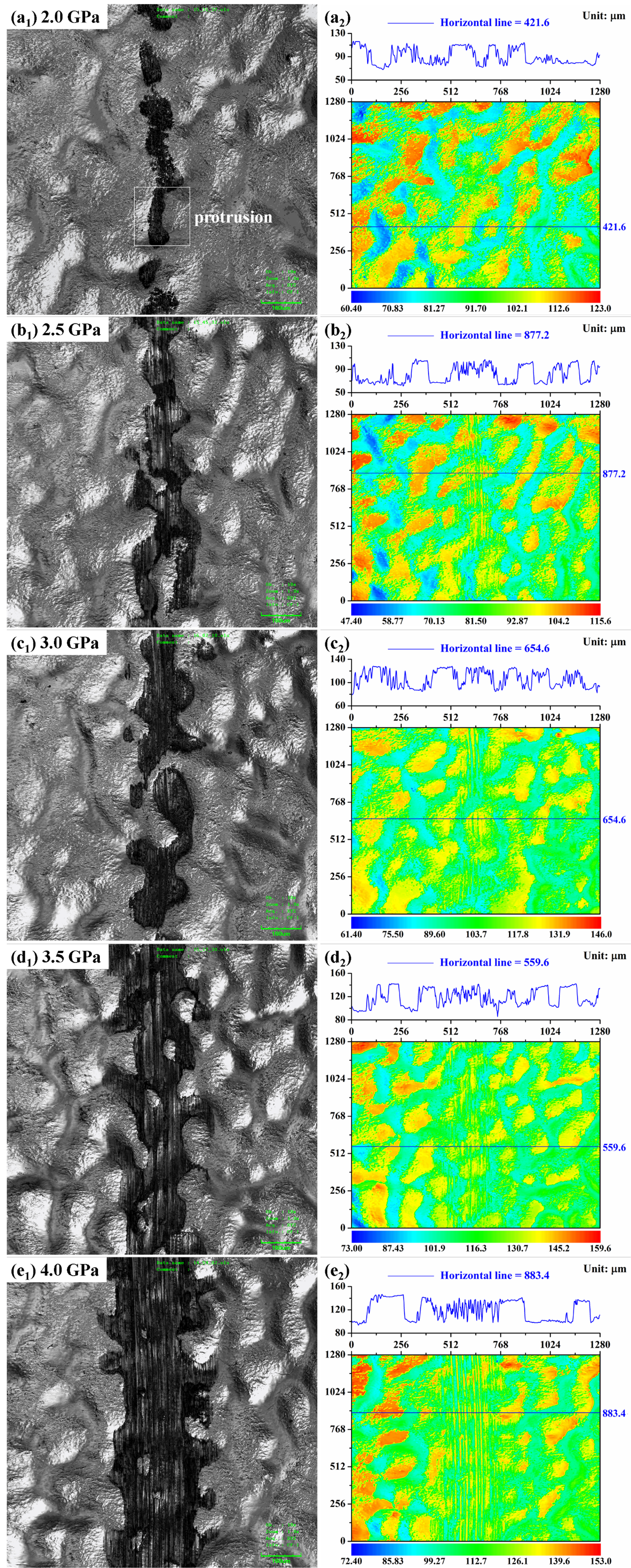

3.2. Wear Topography

3.2.1. Polished M50 Steel

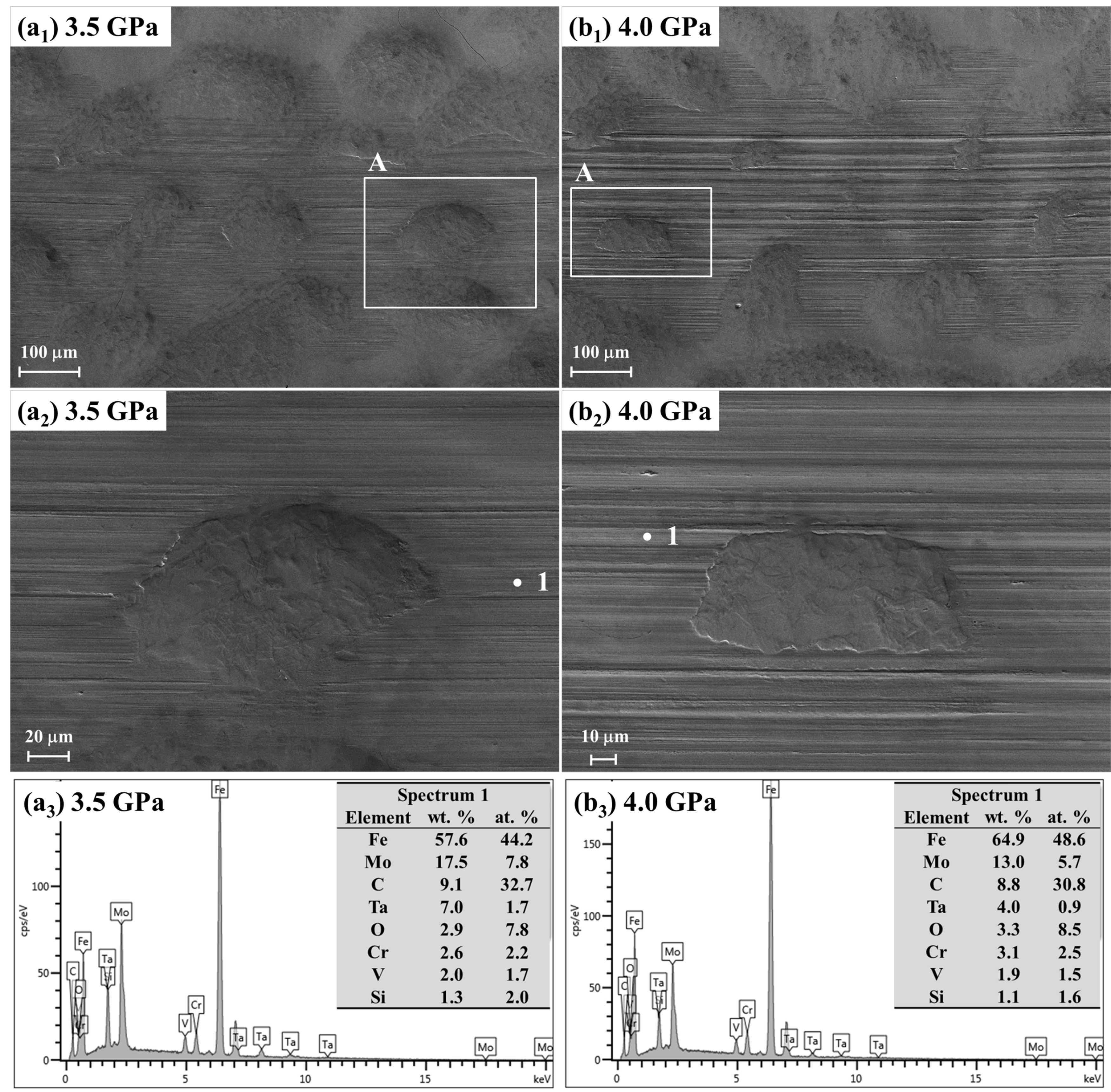

3.2.2. HCPEB-Treated Ta Coating

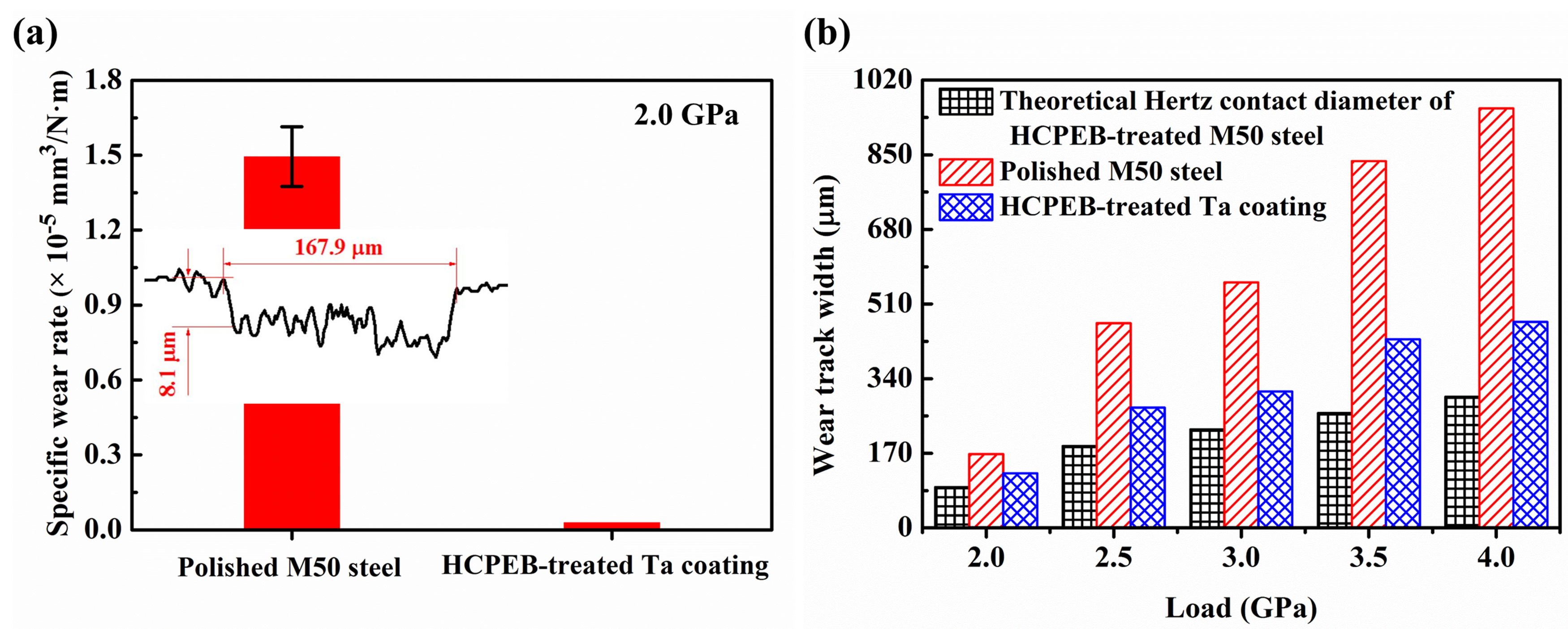

3.3. Specific Wear Rate

4. Discussion

4.1. Improved Boundary Tribological Performance

4.2. Texturing Effect from the Crater-Like Cavities

4.3. HCPEB: a Potential Surface Texturing Technique

5. Conclusions

- (1)

- Polished M50 steel underwent severe wear due to tribo-oxidation under any testing load, accompanied by a considerably fluctuant COF of above 0.16 on average at a steady friction stage. After depositing and alloying the Ta coating, the COF became significantly lower, far more stable, and considerably less fluctuant. The wear track width of the HCPEB-treated Ta coating was almost only half that of M50 steel at 2.5–4.0 GPa. In particular, the wear rate of the HCPEB-treated Ta coating was nearly zero after sliding a distance of 596.6 m under 2.0 GPa, while it was about 1.49 × 10−5 mm3/N·m (a rectangle-like profile of 167.9 μm × 8.1 μm) for the bare M50 steel. The COF of HCPEB-treated Ta coating was almost load-independent, stably remaining at 0.11 on average with small fluctuation, whereas the wear loss increased with raising the load. These friction tests demonstrate that proper surface modification is promising to overcome the wear problems caused by the inadequate lubricity of pure, low-viscosity fuel.

- (2)

- The presence of crater-like cavities makes the HCPEB-treated Ta coating tribologically resemble a high-quality textured surface. The analysis of the wear topographies indicates that the substantial improvement in the boundary tribological performance was mainly due to the texturing effect (additional fluid hydrodynamic pressure) originating from the crater-like cavities, strongly suggesting that HCPEB irradiation can be used to fabricate texture on tribological surfaces such as coatings/films.

Author Contributions

Funding

Conflicts of Interest

References

- Proskurovsky, D.I.; Rotshtein, V.P.; Ozur, G.E. Use of low-energy, high-current electron beams for surface treatment of materials. Surf. Coat. Technol. 1997, 96, 117–122. [Google Scholar] [CrossRef]

- Proskurovsky, D.I.; Rotshtein, V.P.; Ozur, G.E.; Markov, A.B.; Nazarov, D.S.; Shulov, V.A.; Ivanov, Y.F.; Buchheit, R.G. Pulsed electron-beam technology for surface modification of metallic materials. J. Vac. Sci. Technol. A 1998, 16, 2480–2488. [Google Scholar] [CrossRef]

- Proskurovsky, D.I.; Rotshtein, V.P.; Ozur, G.E.; Ivanov, Y.F.; Markov, A.B. Physical foundations for surface treatment of materials with low energy, high current electron beams. Surf. Coat. Technol. 2000, 125, 49–56. [Google Scholar] [CrossRef]

- Rotshtein, V.P.; Proskurovsky, D.I.; Ozur, G.E.; Ivanov, Y.F.; Markov, A.B. Surface modification and alloying of metallic materials with low-energy high-current electron beams. Surf. Coat. Technol. 2004, 180–181, 377–381. [Google Scholar] [CrossRef]

- Hao, S.; Xu, Y.; Zhang, Y.; Zhao, L. Improvement of surface microhardness and wear resistance of WC/Co hard alloy by high current pulsed electron beam irradiation. Int. J. Refract. Met. Hard Mater. 2013, 41, 553–557. [Google Scholar] [CrossRef]

- Samih, Y.; Marcos, G.; Stein, N.; Allain, N.; Fleury, E.; Dong, C.; Grosdidier, T. Microstructure modifications and associated hardness and corrosion improvements in the AISI 420 martensitic stainless steel treated by high current pulsed electron beam (HCPEB). Surf. Coat. Technol. 2014, 259, 737–745. [Google Scholar] [CrossRef]

- Chai, L.; Chen, B.; Wang, S.; Zhang, Z.; Murty, K.L. Microstructural, textural and hardness evolution of commercially pure Zr surface-treated by high current pulsed electron beam. Appl. Surf. Sci. 2016, 390, 430–434. [Google Scholar] [CrossRef]

- Guo, G.; Tang, G.; Ma, X.; Sun, M.; Ozur, G.E. Effect of high current pulsed electron beam irradiation on wear and corrosion resistance of Ti6Al4V. Surf. Coat. Technol. 2013, 229, 140–145. [Google Scholar] [CrossRef]

- Hao, S.; Zhao, L.; Zhang, Y.; Wang, H. Improving corrosion and wear resistance of FV520B steel by high current pulsed electron beam surface treatment. Nucl. Instrum. Methods Phys. Res. Sect. B 2015, 356–357, 12–16. [Google Scholar] [CrossRef]

- Gao, B.; Hao, S.; Zou, J.; Wu, W.; Tu, G.; Dong, C. Effect of high current pulsed electron beam treatment on surface microstructure and wear and corrosion resistance of an AZ91HP magnesium alloy. Surf. Coat. Technol. 2007, 201, 6297–6303. [Google Scholar] [CrossRef]

- Zhang, C.; Lv, P.; Cai, J.; Zhang, Y.; Xia, H.; Guan, Q. Enhanced corrosion property of W–Al coatings fabricated on aluminum using surface alloying under high-current pulsed electron beam. J. Alloy. Compd. 2017, 723, 258–265. [Google Scholar] [CrossRef]

- Cai, J.; Guan, Q.; Yang, S.; Yang, S.; Wang, Z.; Han, Z. Microstructural characterization of modified YSZ thermal barrier coatings by high-current pulsed electron beam. Surf. Coat. Technol. 2014, 254, 187–194. [Google Scholar] [CrossRef]

- Lv, P.; Sun, X.; Cai, J.; Zhang, C.; Liu, X.; Guan, Q. Microstructure and high temperature oxidation resistance of nickel based alloy GH4169 irradiated by high current pulsed electron beam. Surf. Coat. Technol. 2017, 309, 401–409. [Google Scholar] [CrossRef]

- Cai, J.; Guan, Q.; Hou, X.; Wang, Z.; Su, J.; Han, Z. Isothermal oxidation behaviour of thermal barrier coatings with CoCrAlY bond coat irradiated by high-current pulsed electron beam. Appl. Surf. Sci. 2014, 317, 360–369. [Google Scholar] [CrossRef]

- Xu, F.; Tang, G.; Guo, G.; Ma, X.; Ozur, G.E. Influence of irradiation number of high current pulsed electron beam on the structure and properties of M50 steel. Nucl. Instrum. Methods Phys. Res. Sect. B 2010, 268, 2395–2399. [Google Scholar] [CrossRef]

- An, J.; Shen, X.X.; Lu, Y.; Liu, Y.B. Microstructure and tribological properties of Al–Pb alloy modified by high current pulsed electron beam. Wear 2006, 261, 208–215. [Google Scholar] [CrossRef]

- Ivanov, Y.; Matz, W.; Rotshtein, V.; Günzel, R.; Shevchenko, N. Pulsed electron-beam melting of high-speed steel: Structural phase transformations and wear resistance. Surf. Coat. Technol. 2002, 150, 188–198. [Google Scholar] [CrossRef]

- Hao, Y.; Gao, B.; Tu, G.F.; Li, S.W.; Dong, C.; Zhang, Z.G. Improved wear resistance of Al–15Si alloy with a high current pulsed electron beam treatment. Nucl. Instrum. Methods Phys. Res. Sect. B 2011, 269, 1499–1505. [Google Scholar] [CrossRef]

- Zhang, C.; Cai, J.; Lv, P.; Zhang, Y.; Xia, H.; Guan, Q. Surface microstructure and properties of Cu–C powder metallurgical alloy induced by high-current pulsed electron beam. J. Alloy. Compd. 2017, 697, 96–103. [Google Scholar] [CrossRef]

- An, J.; Shen, X.X.; Lu, Y.; Liu, Y.B.; Li, R.G.; Chen, C.M.; Zhang, M.J. Influence of high current pulsed electron beam treatment on the tribological properties of Al–Si–Pb alloy. Surf. Coat. Technol. 2006, 200, 5590–5597. [Google Scholar] [CrossRef]

- Zhang, F.G.; Zhu, X.P.; Lei, M.K. Surface characterization and tribological properties of WC–Ni cemented carbide irradiated by high intensity pulsed electron beam. Vacuum 2017, 137, 119–124. [Google Scholar] [CrossRef]

- Dong, C.; Wu, A.; Hao, S.; Zou, J.; Liu, Z.; Zhong, P.; Zhang, A.; Xu, T.; Chen, J.; Xu, J.; et al. Surface treatment by high current pulsed electron beam. Surf. Coat. Technol. 2003, 163–164, 620–624. [Google Scholar] [CrossRef]

- Rotshtein, V.P.; Ivanov, Y.F.; Markov, A.B.; Proskurovsky, D.I.; Karlik, K.V.; Oskomov, K.V.; Uglov, B.V.; Kuleshov, A.K.; Novitskaya, M.V.; Dub, S.N.; et al. Surface alloying of stainless steel 316 with copper using pulsed electron-beam melting of film–substrate system. Surf. Coat. Technol. 2006, 200, 6378–6383. [Google Scholar] [CrossRef]

- Cai, J.; Guan, Q.; Lv, P.; Hou, X.; Wang, Z.; Han, Z. Surface modification of CoCrAlY coating by high-current pulsed electron beam treatment under the “evaporation” mode. Nucl. Instrum. Methods Phys. Res. Sect. B 2014, 337, 90–96. [Google Scholar] [CrossRef]

- Rotshtein, V.P.; Ivanov, Y.F.; Proskurovsky, D.I.; Karlik, K.V.; Shulepov, I.A.; Markov, A.B. Microstructure of the near-surface layers of austenitic stainless steels irradiated with a low-energy, high-current electron beam. Surf. Coat. Technol. 2004, 180–181, 382–386. [Google Scholar] [CrossRef]

- Qin, Y.; Dong, C.; Wang, X.; Hao, S.; Wu, A.; Zou, J.; Liu, Y. Temperature profile and crater formation induced in high-current pulsed electron beam processing. J. Vac. Sci. Technol. A 2003, 21, 1934–1938. [Google Scholar] [CrossRef]

- Xu, F.; Guo, G.; Tang, G.; Ma, X.; Wang, L.; Ozur, G.E.; Yukimura, K. Microstructure modifications and corrosion behaviors of Cr4Mo4V steel treated by high current pulsed electron beam. Mater. Chem. Phys. 2011, 126, 904–908. [Google Scholar] [CrossRef]

- Zhang, K.; Zou, J.; Grosdidier, T.; Dong, C.; Yang, D. Improved pitting corrosion resistance of AISI 316L stainless steel treated by high current pulsed electron beam. Surf. Coat. Technol. 2006, 201, 1393–1400. [Google Scholar] [CrossRef]

- Gao, Y.; Qin, Y.; Dong, C.; Li, G. From crater eruption to surface purification of raw silicon: A treatment by pulsed electron beam. Appl. Surf. Sci. 2014, 311, 413–421. [Google Scholar] [CrossRef]

- Luo, D.; Tang, G.; Ma, X.; Gu, L.; Sun, M.; Wang, L. Various categories of defects after surface alloying induced by high current pulsed electron beam irradiation. Appl. Surf. Sci. 2015, 351, 1069–1074. [Google Scholar] [CrossRef]

- Zhang, K.; Zou, J.; Grosdidier, T.; Dong, C. Formation and evolution of craters in carbon steels during low-energy high-current pulsed electron-beam treatment. J. Vac. Sci. Technol. A 2009, 27, 1217–1226. [Google Scholar] [CrossRef]

- Zou, J.; Zhang, K.; Dong, C.; Qin, Y.; Hao, S.; Grosdidier, T. Selective surface purification via crater eruption under pulsed electron beam irradiation. Appl. Phys. Lett. 2006, 89, 770. [Google Scholar] [CrossRef]

- Hao, S.; Zhao, L.; He, D. Surface microstructure and high temperature corrosion resistance of arc-sprayed FeCrAl coating irradiated by high current pulsed electron beam. Nucl. Instrum. Methods Phys. Res. Sect. B 2013, 312, 97–103. [Google Scholar] [CrossRef]

- Hamilton, D.; Walowit, J.; Allen, C. A theory of lubrication by microirregularities. J. Basic Eng. 1966, 88, 177–185. [Google Scholar] [CrossRef]

- Anno, J.N.; Walowit, J.; Allen, C. Microasperity lubrication. J. Lubr. Technol. 1968, 90, 351–355. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Brizmer, V.; Kligerman, Y.; Etsion, I. A laser surface textured parallel thrust bearing. Tribol. Trans. 2003, 46, 397–403. [Google Scholar] [CrossRef]

- Wang, X.; Kato, K.; Adachi, K.; Aizawa, K. Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water. Tribol. Int. 2003, 36, 189–197. [Google Scholar] [CrossRef]

- Lu, X.; Khonsari, M.M. An experimental investigation of dimple effect on the Stribeck curve of journal bearings. Tribol. Lett. 2007, 27, 169. [Google Scholar] [CrossRef]

- Brizmer, V.; Kligerman, Y. A laser surface textured journal bearing. J. Tribol. 2012, 134, 031702. [Google Scholar] [CrossRef]

- Ryk, G.; Kligerman, Y.; Etsion, I. Experimental investigation of laser surface texturing for reciprocating automotive components. Tribol. Trans. 2002, 45, 444–449. [Google Scholar] [CrossRef]

- Ryk, G.; Etsion, I. Testing piston rings with partial laser surface texturing for friction reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Etsion, I.; Kligerman, Y.; Halperin, G. Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol. Trans. 1999, 42, 511–516. [Google Scholar] [CrossRef]

- Zhou, L.; Kato, K.; Vurens, G.; Talke, F. The effect of slider surface texture on flyability and lubricant migration under near contact conditions. Tribol. Int. 2003, 36, 269–277. [Google Scholar] [CrossRef]

- Bernoulli, D.; Müller, U.; Schwarzenberger, M.; Hauert, R.; Spolenak, R. Magnetron sputter deposited tantalum and tantalum nitride thin films: An analysis of phase, hardness and composition. Thin Solid Films 2013, 548, 157–161. [Google Scholar] [CrossRef]

- Schneider, A.; Ware, R.E.; Janoski, E.J. Isomerization of endo-tetrahydrodicyclopentadiene to a missile fuel diluent. U.S. Patent 4,086,284, 25 April 1978. [Google Scholar]

- Luo, D.; Tang, G.; Ma, X.; Gu, L.; Wang, L.; Wu, T.; Ma, F. The microstructure of Ta alloying layer on M50 steel after surface alloying treatment induced by high current pulsed electron beam. Vacuum 2017, 136, 121–128. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Andriotis, O.G.; Manuyakorn, W.; Zekonyte, J.; Katsamenis, O.L.; Fabri, S.; Howarth, P.H.; Davies, D.E.; Thurner, P.J. Nanomechanical assessment of human and murine collagen fibrils via atomic force microscopy cantilever-based nanoindentation. J. Mech. Behav. Biomed. Mater. 2014, 39, 9–26. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Varatharajan, B.; Williams, F. Chemistry of JP-10 ignition. AIAA J. 2001, 39, 2351–2356. [Google Scholar] [CrossRef]

- Chenoweth, K.; Van Duin, A.C.; Dasgupta, S.; Goddard Iii, W.A. Initiation mechanisms and kinetics of pyrolysis and combustion of JP-10 hydrocarbon jet fuel. J. Phys. Chem. A 2009, 113, 1740–1746. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.W.; Vandeputte, A.G.; Yee, N.W.; Green, W.H.; Bonomi, R.E.; Magoon, G.R.; Wong, H.-W.; Oluwole, O.O.; Lewis, D.K.; Vandewiele, N.M. JP-10 combustion studied with shock tube experiments and modeled with automatic reaction mechanism generation. Combust. Flame 2015, 162, 3115–3129. [Google Scholar] [CrossRef]

- Chung, H.S.; Chen, C.S.H.; Kremer, R.A.; Boulton, J.R.; Burdette, G.W. Recent developments in high-energy density liquid hydrocarbon fuels. Energy Fuels 1999, 13, 641–649. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, L.; Wang, L.; Zou, J.-J. Review on synthesis and properties of high-energy-density liquid fuels: Hydrocarbons, nanofluids and energetic ionic liquids. Chem. Eng. Sci. 2018, 180, 95–125. [Google Scholar] [CrossRef]

- Yang, F.; Guo, Y.; Xing, Y.; Li, D.; Fang, W.; Lin, R. Densities and viscosities of binary mixtures of JP-10 with n-octane or n-decane at several temperatures. J. Chem. Eng. Data 2008, 53, 2237–2240. [Google Scholar] [CrossRef]

- Türker, L.; Variş, S.; Bayar, Ç.Ç. A theoretical study of JP-10 hydroperoxidation. Fuel 2013, 104, 128–132. [Google Scholar] [CrossRef]

- Xing, Y.; Yang, X.; Fang, W.; Guo, Y.; Lin, R. Measurement on vapor pressure, density and viscosity for binary mixtures of JP-10 and methylcyclohexane. Fluid Phase Equilib. 2011, 305, 192–196. [Google Scholar] [CrossRef]

- Qin, W.; Fu, L.; Zhu, J.; Yang, W.; Li, D.; Zhou, L. Tribological properties of self-lubricating Ta-Cu films. Appl. Surf. Sci. 2018, 435, 1105–1113. [Google Scholar] [CrossRef]

- Hsieh, P.Y.; Bruno, T.J. A perspective on the origin of lubricity in petroleum distillate motor fuels. Fuel Process. Technol. 2015, 129, 52–60. [Google Scholar] [CrossRef]

- Margaroni, D. Fuel lubricity. Ind. Lubr. Tribol. 1998, 50, 108–118. [Google Scholar] [CrossRef]

- Hu, W.; Xu, J.; Lu, X.; Hu, D.; Tao, H.; Munroe, P.; Xie, Z.-H. Corrosion and wear behaviours of a reactive-sputter-deposited Ta2O5 nanoceramic coating. Appl. Surf. Sci. 2016, 368, 177–190. [Google Scholar] [CrossRef]

- Sarraf, M.; Razak, B.A.; Nasiri-Tabrizi, B.; Dabbagh, A.; Kasim, N.H.A.; Basirun, W.J.; Bin Sulaiman, E. Nanomechanical properties, wear resistance and in-vitro characterization of Ta2O5 nanotubes coating on biomedical grade Ti–6Al–4V. J. Mech. Behav. Biomed. Mater. 2017, 66, 159–171. [Google Scholar] [CrossRef] [PubMed]

- Lv, Y.H.; Li, J.; Tao, Y.F.; Hu, L.F. High-temperature wear and oxidation behaviors of TiNi/Ti2Ni matrix composite coatings with TaC addition prepared on Ti6Al4V by laser cladding. Appl. Surf. Sci. 2017, 402, 478–494. [Google Scholar] [CrossRef]

- Hofer, A.M.; Mori, G.; Fian, A.; Winkler, J.; Mitterer, C. Improvement of oxidation and corrosion resistance of Mo thin films by alloying with Ta. Thin Solid Films 2016, 599, 1–6. [Google Scholar] [CrossRef]

- Chicardi, E.; Gotor, F.J.; Córdoba, J.M. Enhanced oxidation resistance of Ti(C,N)-based cermets containing Ta. Corros. Sci. 2014, 84, 11–20. [Google Scholar] [CrossRef]

- Xu, J.; Hu, W.; Xu, S.; Munroe, P.; Xie, Z.-H. Electrochemical properties of a novel β-Ta2O5 nanoceramic coating exposed to simulated body solutions. ACS Biomater. Sci. Eng. 2016, 2, 73–89. [Google Scholar] [CrossRef]

- Striebich, R.C.; Lawrence, J. Thermal decomposition of high-energy density materials at high pressure and temperature. J. Anal. Appl. Pyrolysis 2003, 70, 339–352. [Google Scholar] [CrossRef]

- Wakuda, M.; Yamauchi, Y.; Kanzaki, S.; Yasuda, Y. Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 2003, 254, 356–363. [Google Scholar] [CrossRef]

- Pettersson, U.; Jacobson, S. Friction and wear properties of micro textured DLC coated surfaces in boundary lubricated sliding. Tribol. Lett. 2004, 17, 553–559. [Google Scholar] [CrossRef]

- Li, J.; Xiong, D.; Wu, H.; Huang, Z.; Dai, J.; Tyagi, R. Tribological properties of laser surface texturing and molybdenizing duplex-treated Ni-base alloy. Tribol. Trans. 2010, 53, 195–202. [Google Scholar] [CrossRef]

- Hu, T.; Hu, L. Tribological properties of lubricating films on the Al−Si alloy surface via laser surface texturing. Tribol. Trans. 2011, 54, 800–805. [Google Scholar] [CrossRef]

- Segu, D.Z.; Hwang, P. Friction control by multi-shape textured surface under pin-on-disc test. Tribol. Int. 2015, 91, 111–117. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. A novel surface texture shape for directional friction control. Tribol. Lett. 2018, 66, 51. [Google Scholar] [CrossRef]

- Ye, J.; Zhang, H.; Liu, X.; Liu, K. Low wear steel counterface texture design: A case study using micro-pits texture and alumina–PTFE nanocomposite. Tribol. Lett. 2017, 65, 165. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, D.Y.; Hua, M.; Dong, G.N.; Chin, K.S. A study on the tribological behavior of surface texturing on babbitt alloy under mixed or starved lubrication. Tribol. Lett. 2014, 56, 305–315. [Google Scholar] [CrossRef]

- Li, K.; Yao, Z.; Hu, Y.; Gu, W. Friction and wear performance of laser peen textured surface under starved lubrication. Tribol. Int. 2014, 77, 97–105. [Google Scholar] [CrossRef]

| Surface | Load P/GPa FN/N | Si3N4 ball Diameter D/mm | Sliding Speed v/mm·s−1 | Sliding Radius r/mm | Cycle Number n | |

|---|---|---|---|---|---|---|

| Bare M50 steel (Ra: 0.05–0.08 μm) | 2.0 | 9.1 | 3.96 | 100 | 9.5 | 10,000 |

| 2.5 | 45.6 | 6.35 | 100 | 17.0 | 10,000 | |

| 3.0 | 78.9 | 6.35 | 100 | 12.5 | 10,000 | |

| 3.5 | 125.2 | 6.35 | 100 | 14.0 | 10,000 | |

| 4.0 | 187.5 | 6.35 | 100 | 15.5 | 10,000 | |

| HCPEB-treated Ta coating | 2.0 | 9.1 | 3.96 | 100 | 9.5 | 10,000 |

| 2.5 | 45.6 | 6.35 | 100 | 12.5 | 10,000 | |

| 3.0 | 78.9 | 6.35 | 100 | 11.5 | 10,000 | |

| 3.5 | 125.2 | 6.35 | 100 | 17.0 | 10,000 | |

| 4.0 | 187.5 | 6.35 | 100 | 18.5 | 10,000 | |

| Hertz Contact Radius/Diameter a/b (μm) | Normal Load FN/P (N/GPa) | Ball Diameter D/mm | Si3N4 Ball | HCPEB-Treated M50 Steel Disc | ||

|---|---|---|---|---|---|---|

| Elastic Modulus E1/GPa | Poisson Ratio μ1 | Elastic Modulus E2/GPa | Poisson Ratio μ2 | |||

| 46.61/93.22 | 9.1/2.0 | 3.96 | 295 | 0.26 | 210 | 0.3 |

| 93.36/186.72 | 45.6/2.5 | 6.35 | ||||

| 112.08/224.16 | 78.9/3.0 | 6.35 | ||||

| 130.73/261.46 | 125.2/3.5 | 6.35 | ||||

| 149.57/299.14 | 187.5/4.0 | 6.35 | ||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, B.; Tang, G.; Zhao, X.; Wang, L.; Gu, L. Texturing Effect of Crater-Like Cavities Induced by High-Current Pulsed Electron Beam (HCPEB) Irradiation. Coatings 2018, 8, 355. https://doi.org/10.3390/coatings8100355

Wu B, Tang G, Zhao X, Wang L, Gu L. Texturing Effect of Crater-Like Cavities Induced by High-Current Pulsed Electron Beam (HCPEB) Irradiation. Coatings. 2018; 8(10):355. https://doi.org/10.3390/coatings8100355

Chicago/Turabian StyleWu, Bo, Guangze Tang, Xiaoli Zhao, Liqin Wang, and Le Gu. 2018. "Texturing Effect of Crater-Like Cavities Induced by High-Current Pulsed Electron Beam (HCPEB) Irradiation" Coatings 8, no. 10: 355. https://doi.org/10.3390/coatings8100355

APA StyleWu, B., Tang, G., Zhao, X., Wang, L., & Gu, L. (2018). Texturing Effect of Crater-Like Cavities Induced by High-Current Pulsed Electron Beam (HCPEB) Irradiation. Coatings, 8(10), 355. https://doi.org/10.3390/coatings8100355