Superhydrophobic Fabrics with Mechanical Durability Prepared by a Two-Step Plasma Processing Method

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Plasma Treatment

- A plasma etching step to create micro-nanotexture at the following conditions: O2 flow: 100 sccm, power: 400 W, pressure: 10 mT for 12 min. At these conditions, other polymers (cyclo-olefin polymer COP, polystyrene PS, etc.) are etched with an etch rate of 100–200 nm/min. Shorter etching duration have also been tested but the resulting topography was not sufficient for superhydrophobicity.

- A plasma hydrophobization step for 2 min using C4F8 (10 mT, 50 W, 16 sccm). The resulting low surface energy (hydrophobic) layer thickness is 20 nm on a flat surface, while on a rough surface will be noticeably thinner but it is expected to alter the surface chemistry from hydrophilic to hydrophobic. For this reason, we consider that the proposed method is not categorized as an additive manufacturing method (bottom-up). Additionally, during the etching step, material is removed and therefore the thickness of the fibers on the treated fabrics will be lower than on the untreated ones.

2.3. Characterization Methods

3. Results and Discussion

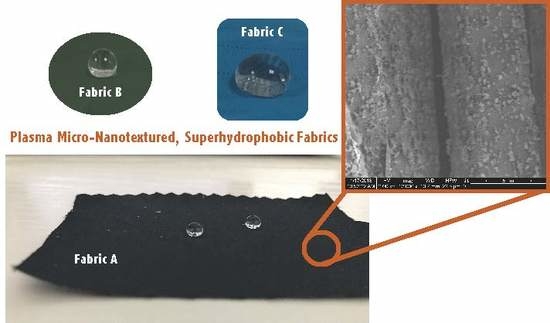

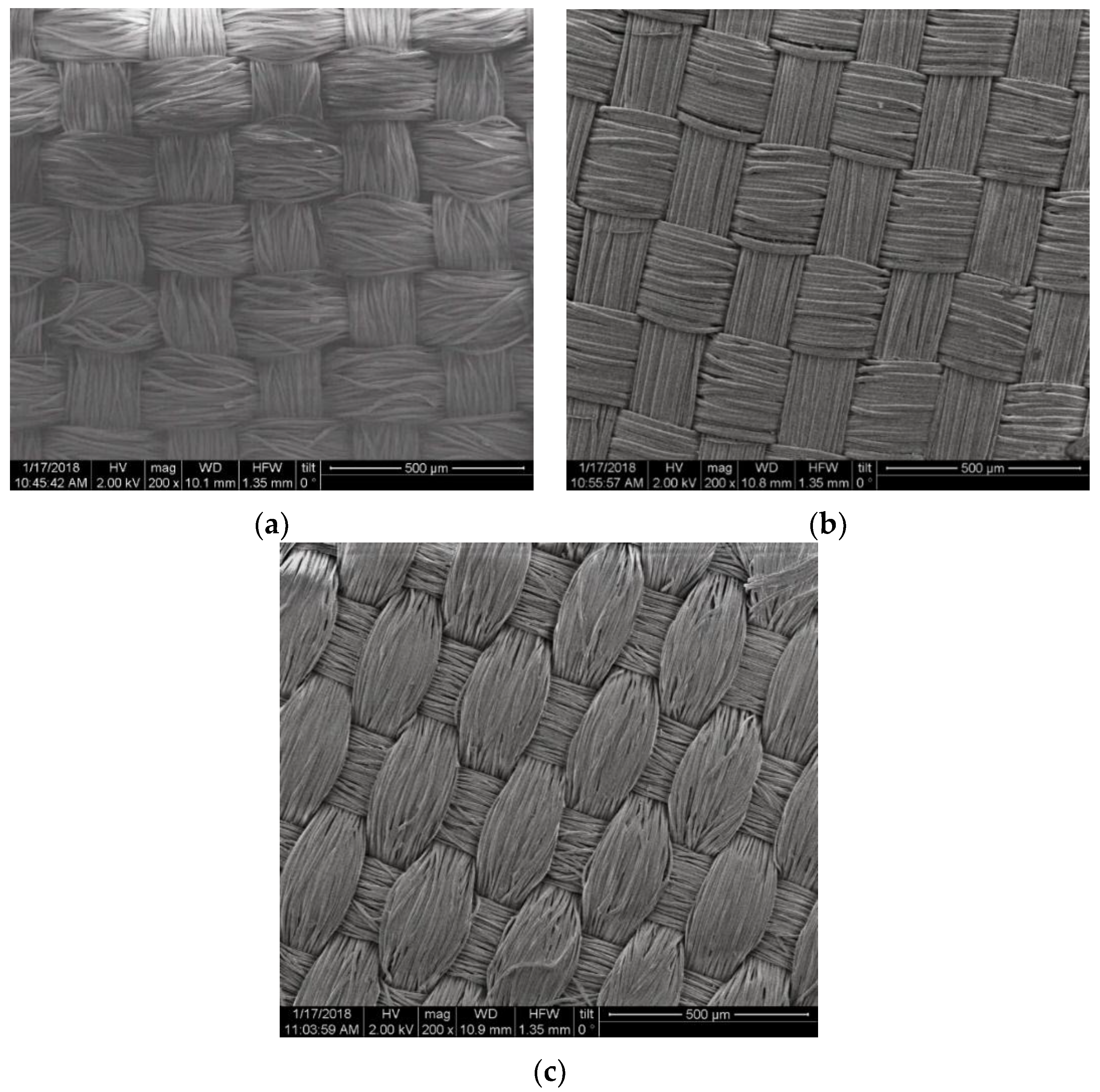

3.1. Fabrics Topography after the Plasma Micro-Nanotexturing

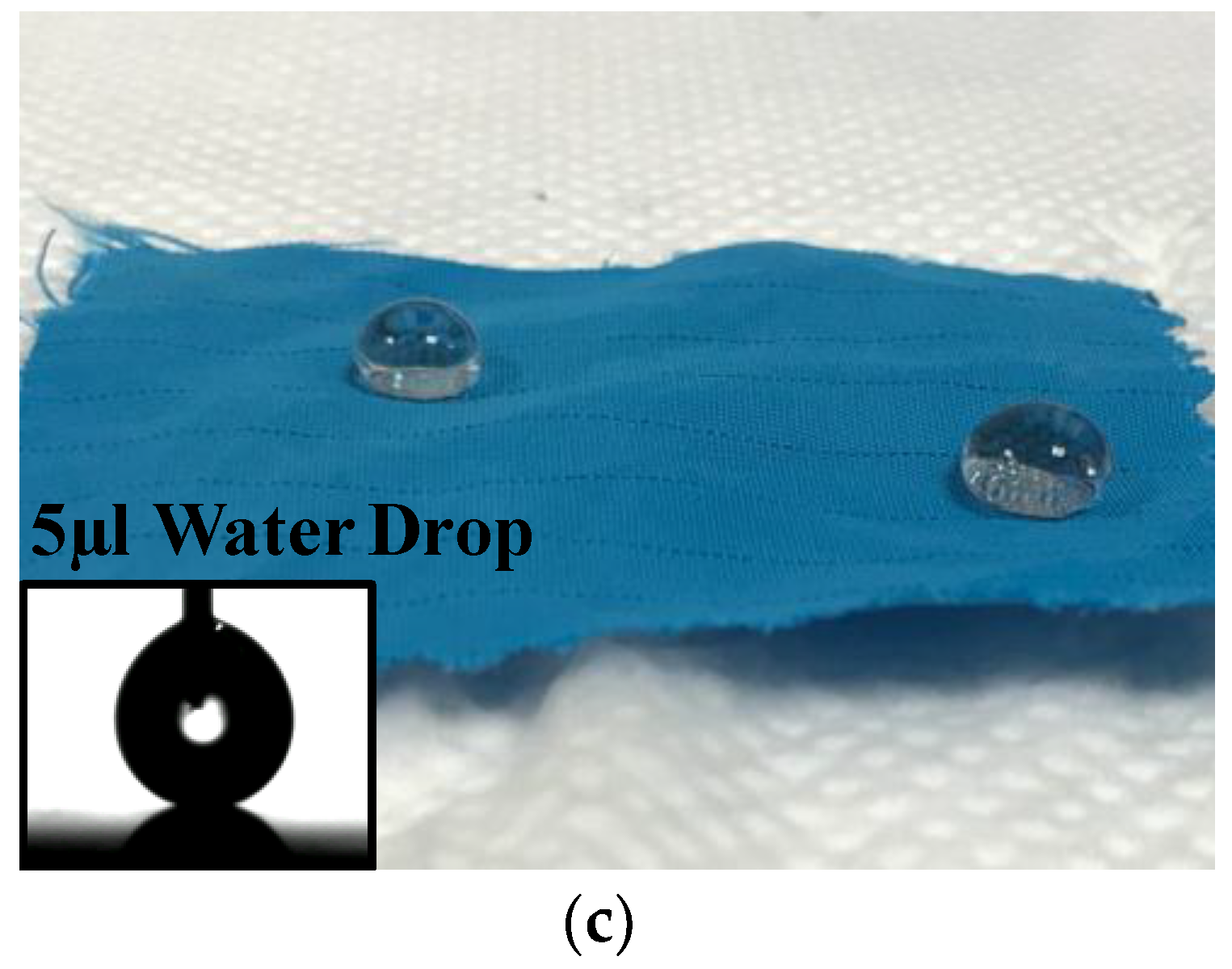

3.2. Wetting Properties

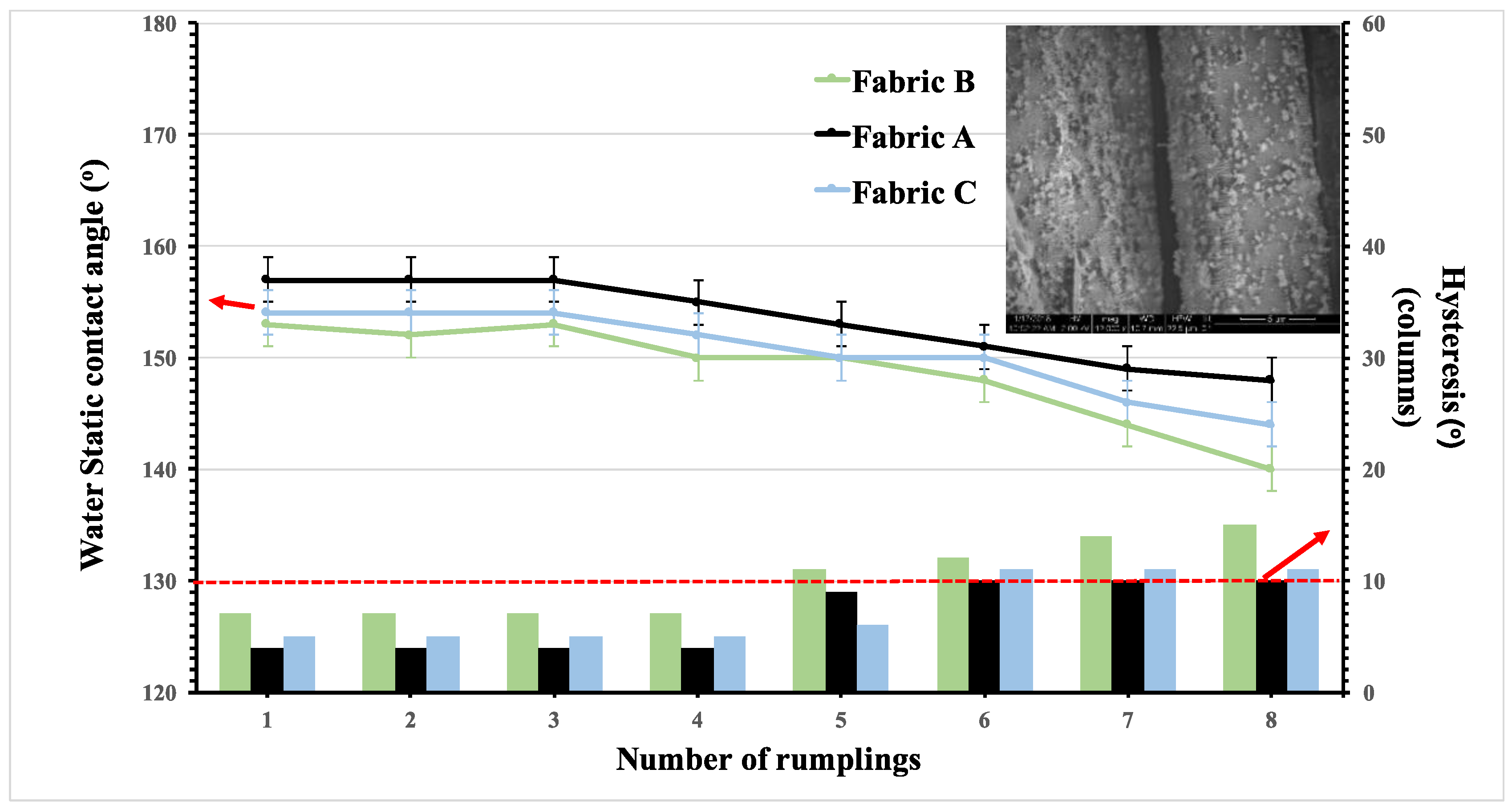

3.3. Mechanical Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhou, X.; Zhang, Z.; Xu, X.; Guo, F.; Zhu, X.; Men, X.; Ge, B. Robust and durable superhydrophobic cotton fabrics for oil/water separation. ACS Appl. Mater. Interfaces 2013, 5, 7208–7214. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Xue, Y.; Ding, J.; Feng, L.; Wang, X.; Lin, T. Durable, self-healing superhydrophobic and superoleophobic surfaces from fluorinated-decyl polyhedral oligomeric silsesquioxane and hydrolyzed fluorinated alkyl silane. Angew. Chem. Int. Ed. 2011, 50, 11433–11436. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Ma, B.; Pan, T.; Chen, S.; Sun, J. Silver-Nanoparticle-Colored Cotton Fabrics with Tunable Colors and Durable Antibacterial and Self-Healing Superhydrophobic Properties. Adv. Funct. Mater. 2016, 26, 569–576. [Google Scholar] [CrossRef]

- Bayer, I. On the Durability and Wear Resistance of Transparent Superhydrophobic Coatings. Coatings 2017, 7, 12. [Google Scholar] [CrossRef]

- Zeng, C.; Wang, H.; Zhou, H.; Lin, T. Self-cleaning, superhydrophobic cotton fabrics with excellent washing durability, solvent resistance and chemical stability prepared from an SU-8 derived surface coating. RSC Adv. 2015, 5, 61044–61050. [Google Scholar] [CrossRef]

- Bartlet, K.; Movafaghi, S.; Dasi, L.P.; Kota, A.K.; Popat, K.C. Antibacterial activity on superhydrophobic titania nanotube arrays. Colloids Surf. B Biointerfaces 2018, 166, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Ellinas, K.; Kefallinou, D.; Stamatakis, K.; Gogolides, E.; Tserepi, A. Is There a Threshold in the Antibacterial Action of Superhydrophobic Surfaces? ACS Appl. Mater. Interfaces 2017, 9, 39781–39789. [Google Scholar] [CrossRef] [PubMed]

- Ellinas, K.; Tserepi, A.; Gogolides, E. Durable superhydrophobic and superamphiphobic polymeric surfaces and their applications: A review. Adv. Colloid Interface Sci. 2017, 250, 132–157. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Zhao, Y.; Wang, H.; Lin, T. Recent Development in Durable Super-Liquid-Repellent Fabrics. Adv. Mater. Interfaces 2016, 3, 1600402. [Google Scholar] [CrossRef]

- Xue, C.H.; Bai, X.; Jia, S.T. Robust, Self-Healing Superhydrophobic Fabrics Prepared by One-Step Coating of PDMS and Octadecylamine. Sci. Rep. 2016, 6, 27262. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Wang, H.; Niu, H.; Fang, J.; Zhao, Y.; Lin, T. Superstrong, Chemically Stable, Superamphiphobic Fabrics from Particle-Free Polymer Coatings. Adv. Mater. Interfaces 2015, 2, 1–8. [Google Scholar] [CrossRef]

- Deng, B.; Cai, R.; Yu, Y.; Jiang, H.; Wang, C.; Li, J.; Li, L.; Yu, M.; Li, J.; Xie, L.; et al. Laundering durability of superhydrophobic cotton fabric. Adv. Mater. 2010, 22, 5473–5477. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Wang, H.; Niu, H.; Gestos, A.; Wang, X.; Lin, T. Fluoroalkyl silane modified silicone rubber/nanoparticle composite: A super durable, robust superhydrophobic fabric coating. Adv. Mater. 2012, 24, 2409–2412. [Google Scholar] [CrossRef] [PubMed]

- Zimmermann, J.; Reifler, F.A.; Fortunato, G.; Gerhardt, L.C.; Seeger, S. A simple, one-step approach to durable and robust superhydrophobic textiles. Adv. Funct. Mater. 2008, 18, 3662–3669. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, L.; Levänen, E. Superhydrophobic surfaces for the reduction of bacterial adhesion. RSC Adv. 2013, 3, 12003–12020. [Google Scholar] [CrossRef]

- Vilčnik, A.; Jerman, I.; Vuk, A.Š.; Koželj, M.; Orel, B.; Tomšič, B.; Simončič, B.; Kovač, J. Structural properties and antibacterial effects of hydrophobic and oleophobic sol-gel coatings for cotton fabrics. Langmuir 2009, 25, 5869–5880. [Google Scholar] [CrossRef] [PubMed]

- Shen, L.; Wang, B.; Wang, J.; Fu, J.; Picart, C.; Ji, J. Asymmetric Free-Standing Film with Multifunctional Anti-Bacterial and Self-Cleaning Properties. ACS Appl. Mater. Interfaces 2012, 4, 4476–4483. [Google Scholar] [CrossRef] [PubMed]

- Shateri Khalil-Abad, M.; Yazdanshenas, M.E. Superhydrophobic antibacterial cotton textiles. J. Colloid Interface Sci. 2010, 351, 293–298. [Google Scholar] [CrossRef] [PubMed]

- Kota, A.K.; Kwon, G.; Choi, W.; Mabry, J.M.; Tuteja, A. Hygro-responsive membranes for effective oilg-water separation. Nat. Commun. 2012, 3, 1025–1028. [Google Scholar] [CrossRef] [PubMed]

- Karmouch, R.; Ross, G.G. Superhydrophobic wind turbine blade surfaces obtained by a simple deposition of silica nanoparticles embedded in epoxy. Appl. Surf. Sci. 2010, 257, 665–669. [Google Scholar] [CrossRef]

- Karmouch, R.; Coudé, S.; Abel, G.; Ross, G.G. Icephobic PTFE coatings for wind turbines operating in cold climate conditions. In Proceedings of the 2009 IEEE Electrical Power & Energy Conference (EPEC), Montreal, QC, Canada, 22–23 October 2009; pp. 1–6. [Google Scholar]

- Zhang, W.; Brinn, C.; Cook, A.; Pascual-Marquez, F. Ice-Release and Erosion Resistant Materials for Wind Turbines. J. Phys. 2017, 926, 012002. [Google Scholar] [CrossRef]

- Dierer, S.; Oechslin, R.; Cattin, R. Wind turbines in icing conditions: Performance and prediction. Adv. Sci. Res. 2011, 6, 245–250. [Google Scholar] [CrossRef]

- Ellinas, K.; Pujari, S.P.; Dragatogiannis, D.A.; Charitidis, C.A.; Tserepi, A.; Zuilhof, H.; Gogolides, E. Plasma micro-nanotextured, scratch, water and hexadecane resistant, superhydrophobic, and superamphiphobic polymeric surfaces with perfluorinated monolayers. ACS Appl. Mater. Interfaces 2014, 6, 6510–6524. [Google Scholar] [CrossRef] [PubMed]

- Ellinas, K.; Tserepi, A.; Gogolides, E. From superamphiphobic to amphiphilic polymeric surfaces with ordered hierarchical roughness fabricated with colloidal lithography and plasma nanotexturing. Langmuir 2011, 27, 3960–3969. [Google Scholar] [CrossRef] [PubMed]

- Ellinas, K.; Chatzipetrou, M.; Zergioti, I.; Tserepi, A.; Gogolides, E. Superamphiphobic Polymeric Surfaces Sustaining Ultrahigh Impact Pressures of Aqueous High- and Low-Surface-Tension Mixtures, Tested with Laser-Induced Forward Transfer of Drops. Adv. Mater. 2015, 27, 2231–2235. [Google Scholar] [CrossRef] [PubMed]

- Dragatogiannis, D.A.; Koumoulos, E.; Ellinas, K.; Tserepi, A.; Gogolides, E.; Charitidis, C.A. Nanoscale Mechanical and Tribological Properties of Plasma Nanotextured COP Surfaces with Hydrophobic Coatings. Plasma Process. Polym. 2015, 12, 1271–1283. [Google Scholar] [CrossRef]

| Sample | Water Static Contact Angle (WSCA) Samples as Received (1) | Water Static Contact Angle (WSCA) after ONLY Plasma Deposition of Hydrophobic Film (2) | Water Static Contact Angle (WSCA) after Plasma Nanotexturing AND Plasma Deposition of Hydrophobic Film (3) |

|---|---|---|---|

| Fabric A | 108° (sticky) | 124° (sticky) | 157°± 3° [4°] (slippery) |

| Fabric B | 120° (sticky) | 128° (sticky) | 153°± 3° [7°] (slippery) |

| Fabric C | superhydrophilic | – | 154°± 2° [5°] (slippery) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ellinas, K.; Tserepi, A.; Gogolides, E. Superhydrophobic Fabrics with Mechanical Durability Prepared by a Two-Step Plasma Processing Method. Coatings 2018, 8, 351. https://doi.org/10.3390/coatings8100351

Ellinas K, Tserepi A, Gogolides E. Superhydrophobic Fabrics with Mechanical Durability Prepared by a Two-Step Plasma Processing Method. Coatings. 2018; 8(10):351. https://doi.org/10.3390/coatings8100351

Chicago/Turabian StyleEllinas, Kosmas, Angeliki Tserepi, and Evangelos Gogolides. 2018. "Superhydrophobic Fabrics with Mechanical Durability Prepared by a Two-Step Plasma Processing Method" Coatings 8, no. 10: 351. https://doi.org/10.3390/coatings8100351

APA StyleEllinas, K., Tserepi, A., & Gogolides, E. (2018). Superhydrophobic Fabrics with Mechanical Durability Prepared by a Two-Step Plasma Processing Method. Coatings, 8(10), 351. https://doi.org/10.3390/coatings8100351