Electrodeposition of Copper/Carbonous Nanomaterial Composite Coatings for Heat-Dissipation Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Copper/ND Composite Coatings

2.3. Characterization of Copper/ND Composite Coatings

3. Results and Discussion

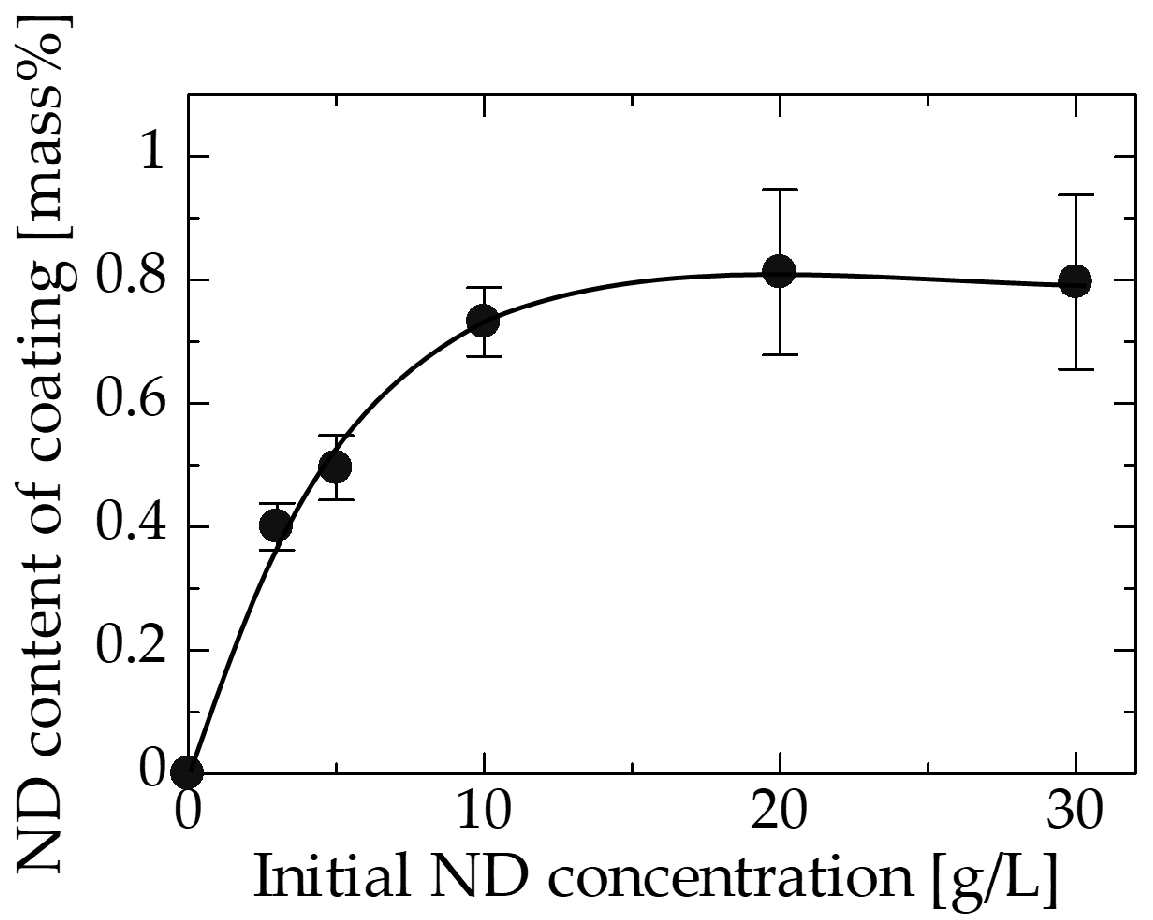

3.1. Effect of Initial ND Concentration of the Coating Bath

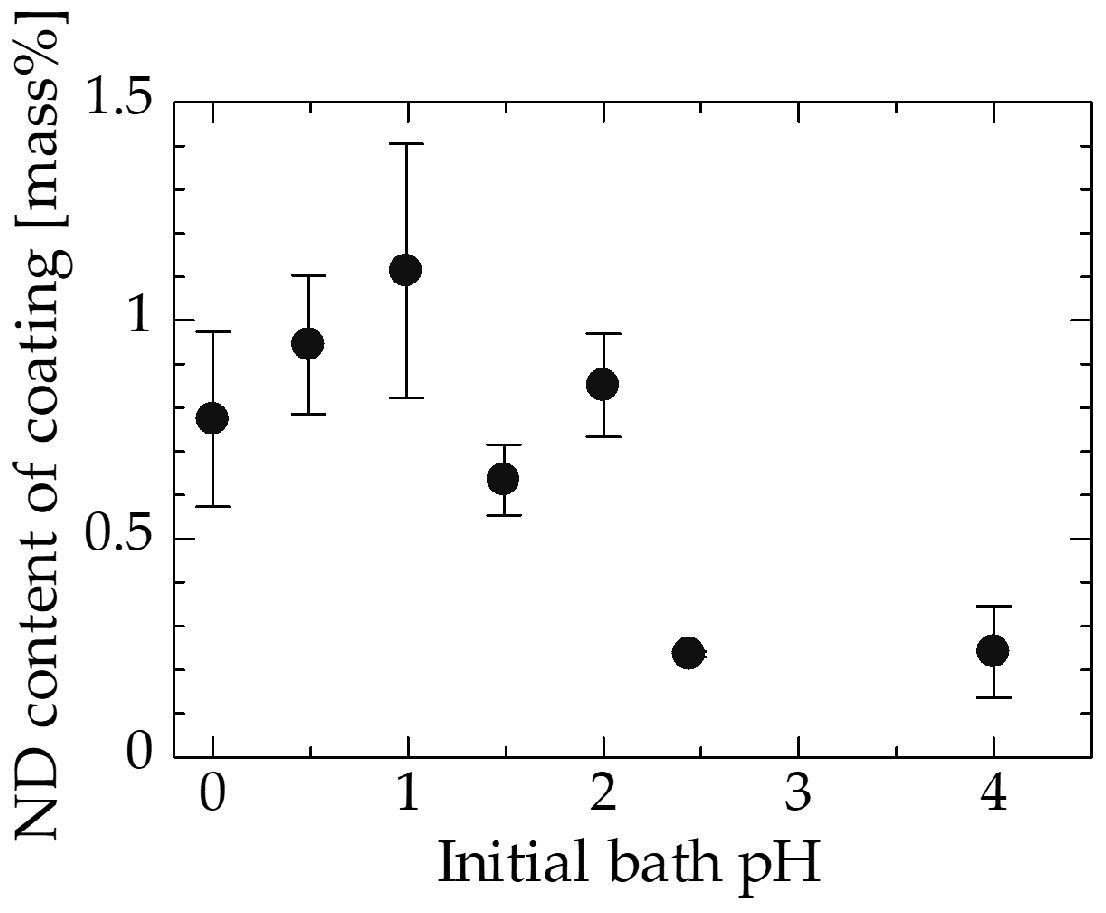

3.2. Effect of Initial pH of the Coating Bath

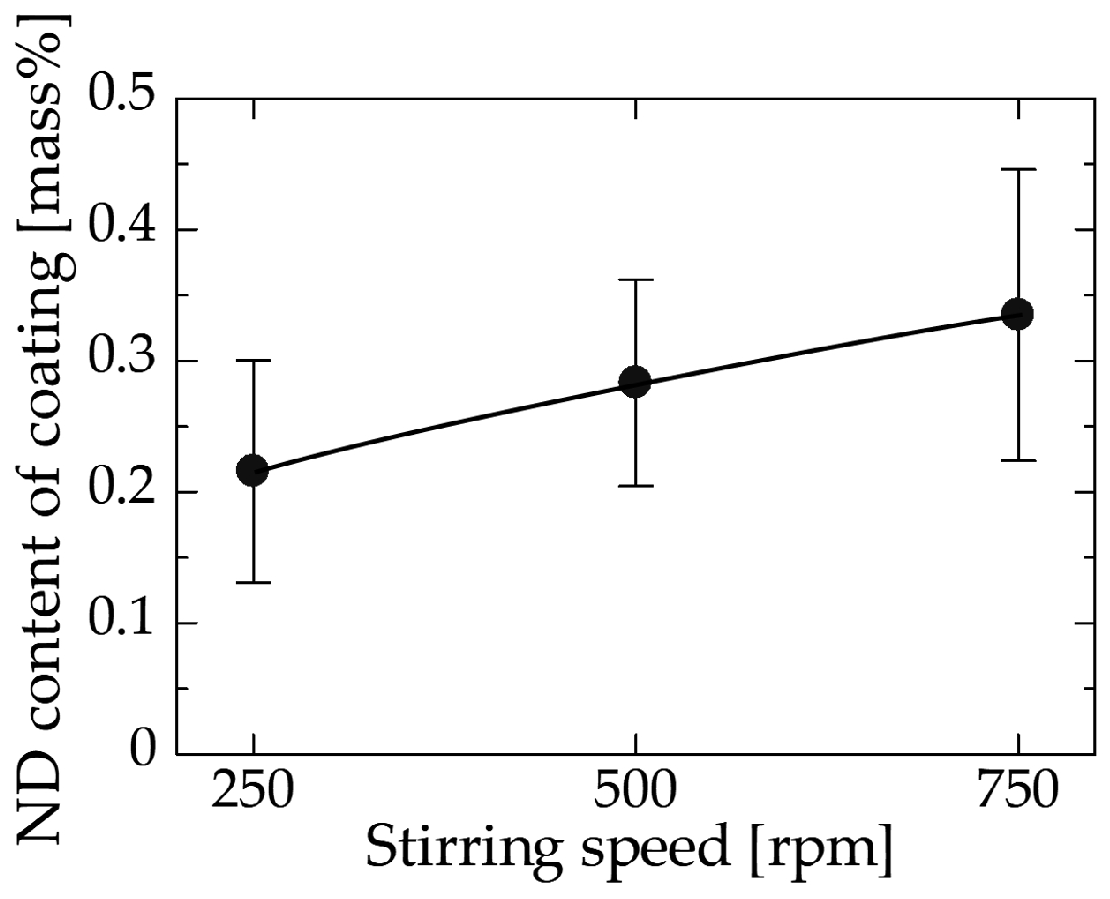

3.3. Effect of the Stirring Speed of the Coating Bath

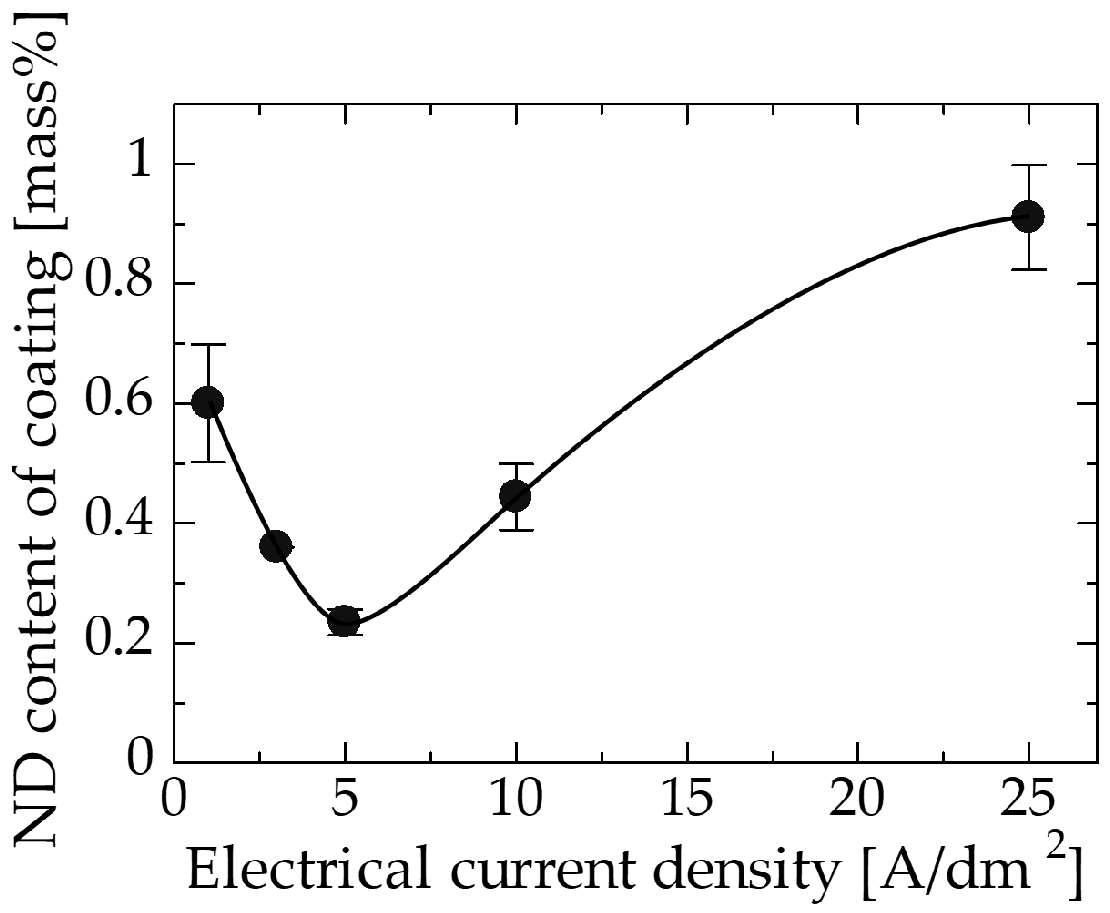

3.4. Effect of the Current Density during Electrodeposition

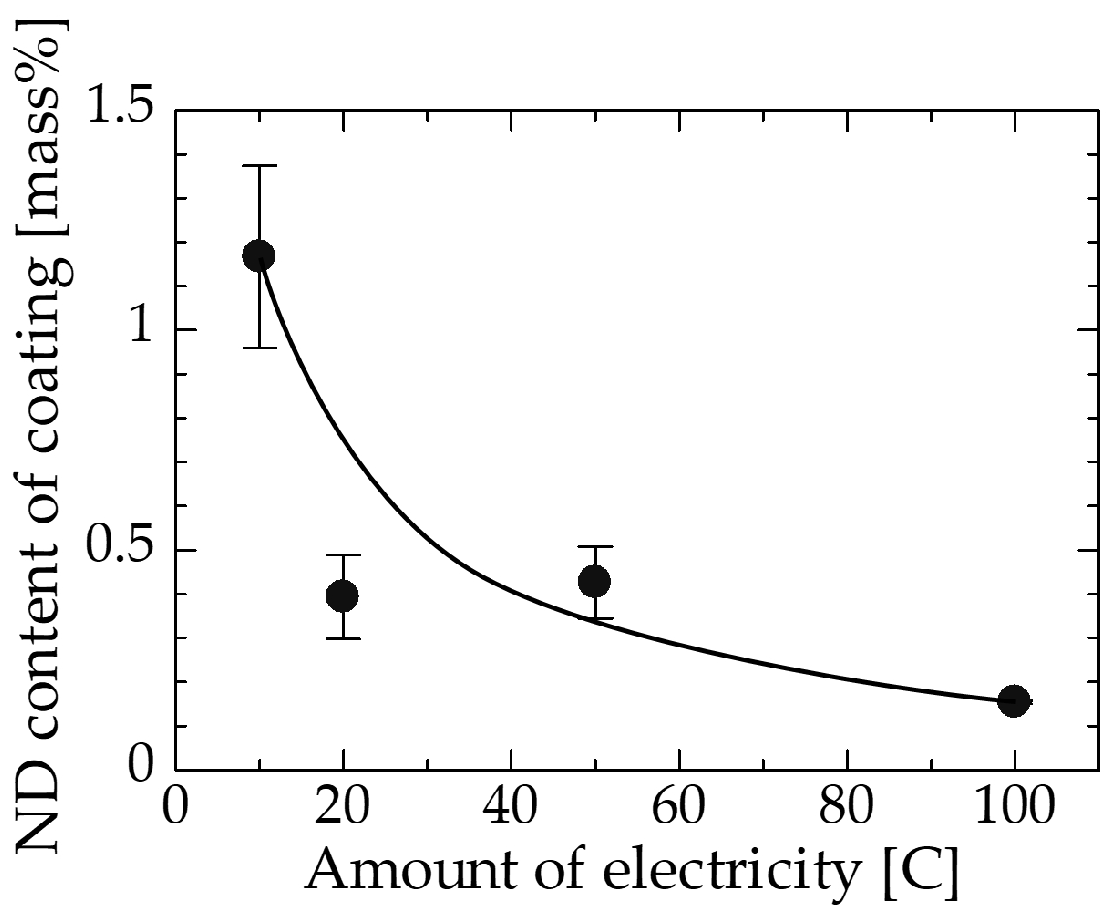

3.5. Effect of the Amount of Electricity Used for Electrodeposition

3.6. Effect of the Surface Modification of NDs

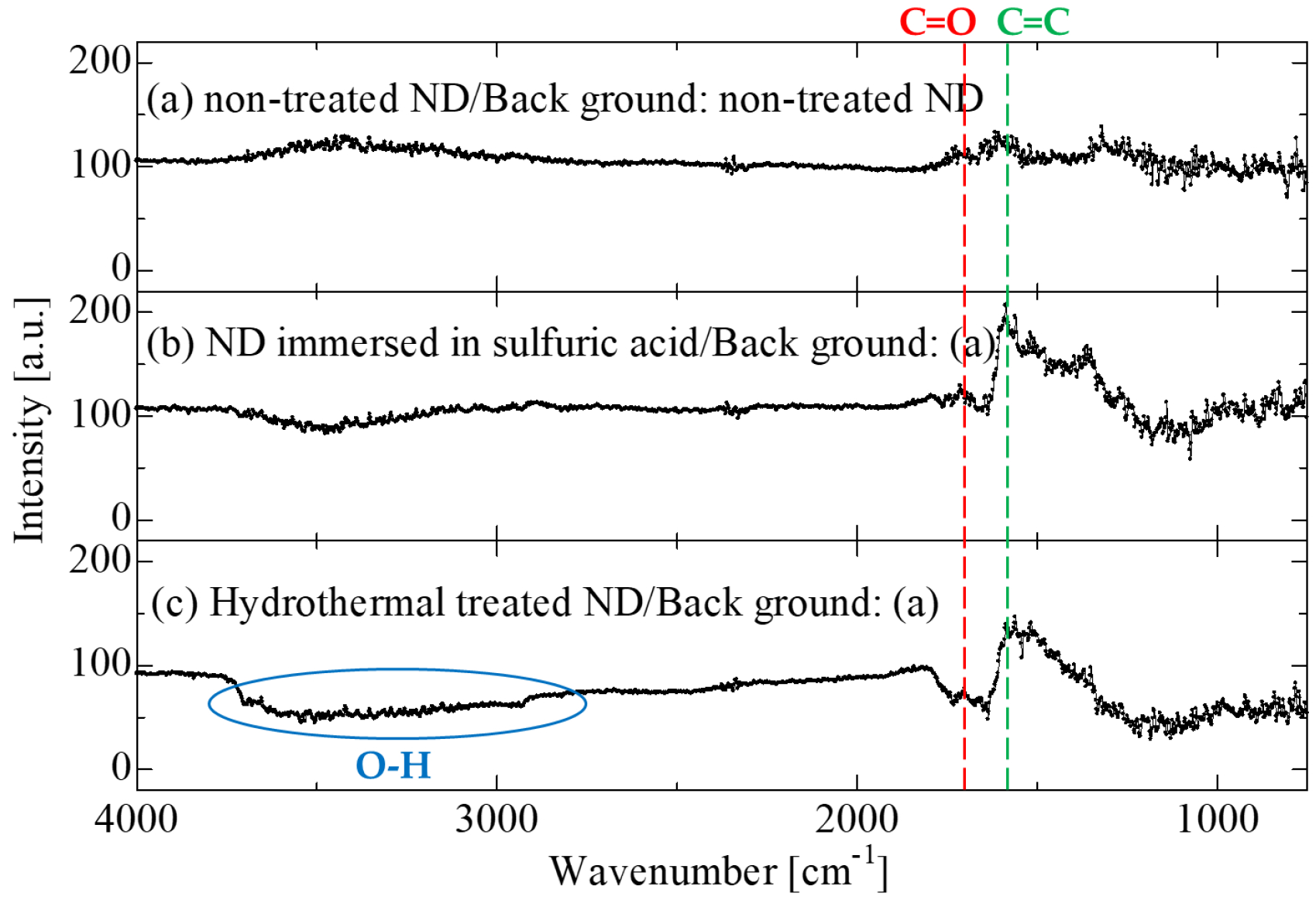

3.6.1. Characterization of Surface-Modified NDs

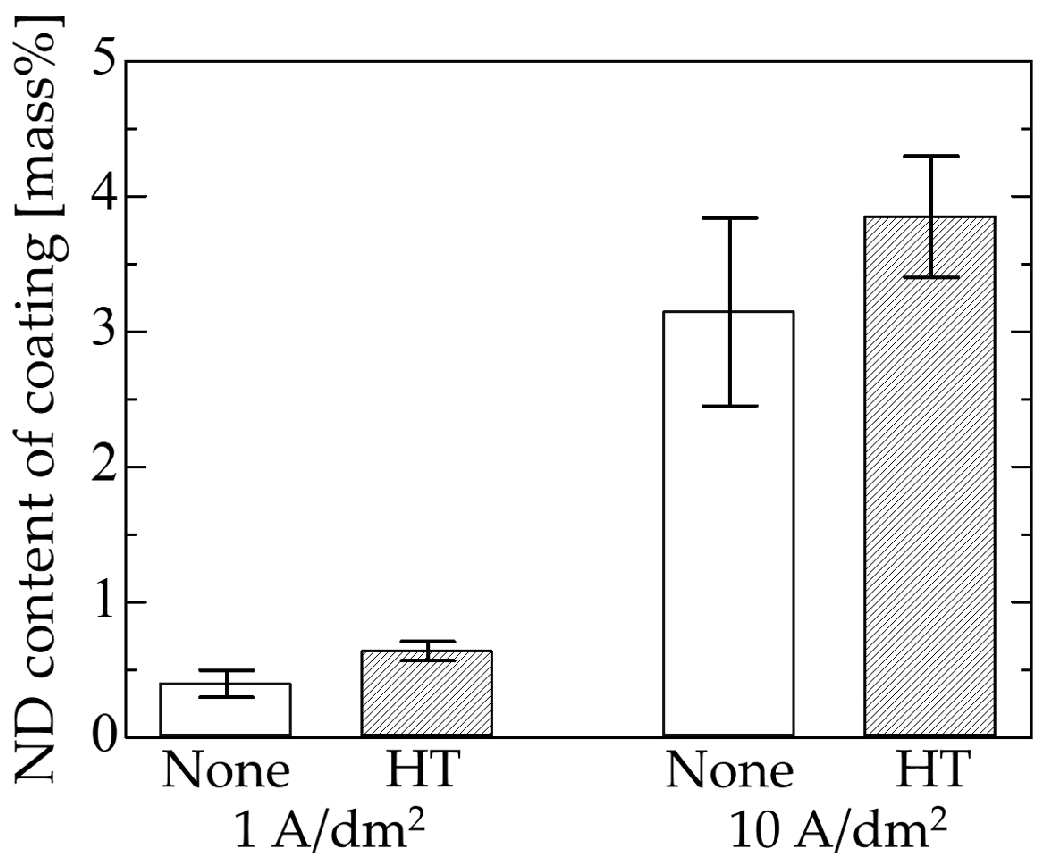

3.6.2. Effect of Surface Modification on the ND Content of Coatings

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Anandan, S.S.; Ramalingam, V. Thermal management of electronics: A review of literature. Therm. Sci. 2008, 12, 5–26. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Fan, C.; Yao, H.; Chen, X.; Liu, Y. Study on the preparation of a high-efficiency carbon fiber dissipating coating. Coatings 2017, 7, 94. [Google Scholar] [CrossRef]

- Silvain, J.F.; Veillère, A.; Lu, Y. Copper-carbon and aluminum-carbon composites fabricated by powder metallurgy processes. J. Phys. Conf. Ser. 2014, 525, 012015. [Google Scholar] [CrossRef]

- Koráb, J.; Štefánik, P.; Kavecký, Š.; Šebo, P.; Korb, G. Thermal conductivity of unidirectional copper matrix carbon fibre composites. Compos. Part A 2002, 33, 577–581. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, H.; Wen, G.; Wang, E.; Fang, X.; Liu, G.; Zhou, W. Copper–graphite–copper sandwich: Superior heat spreader with excellent heat-dissipation ability and good weldability. RSC Adv. 2016, 6, 25128–25136. [Google Scholar] [CrossRef]

- Ngo, Q.; Cruden, B.A.; Cassell, A.M.; Sims, G.; Meyyappan, M.; Li, J.; Yang, C.Y. Thermal interface properties of Cu-filled vertically aligned carbon nanofiber arrays. Nano Lett. 2004, 4, 2403–2407. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene, carbon nanotubes and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.; Yuan, J.; Sundén, B. Review on graphite foam as thermal material for heat exchangers. In Proceedings of the World Renewable Energy Congress 2011-Sweden, Energy End-Use Efficiency Issues (EEE), Linköping, Sweden, 8–13 May 2011; pp. 748–755. [Google Scholar]

- Santos, N.F.; Holz, T.; Santos, T.; Fernandes, A.J.S.; Vasconcelos, T.L.; Gouvea, C.P.; Archanjo, B.S.; Achete, C.A.; Silva, R.F.; Costa, F.M. Heat dissipation interfaces based on vertically aligned diamond/graphite nanoplatelets. ACS Appl. Mater. Interfaces 2015, 7, 24772–24777. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Han, X.H.; Sommers, A.; Park, Y.; Joen, C.T’; Jacobi, A. A review on application of carbonaceous materials and carbon matrix composites for heat exchangers and heat sinks. Int. J. Refrig. 2012, 35, 7–26. [Google Scholar] [CrossRef]

- Arpon, R.; Molina, M.J.; Saravanan, A.R.; Garcia-Cordovilla, C.; Louis, E.; Narciso, J. Thermal expansion behaviour of aluminium/SiC composites with bimodal particle distributions. Acta Mater. 2003, 51, 3145–3156. [Google Scholar] [CrossRef]

- Molina, M.J.; Narciso, J.; Weber, L.; Mortensen, A.; Louis, E. Thermal conductivity of Al–SiC composites with monomodal and bimodal particle size distribution. Mater. Sci. Eng. A 2008, 480, 483–488. [Google Scholar] [CrossRef]

- Molina, M.J.; Prieto, R.; Narciso, J.; Louis, E. The effect of porosity on the thermal conductivity of Al–12 wt % Si/SiC composites. Scr. Mater. 2009, 60, 582–585. [Google Scholar] [CrossRef]

- Qu, X.H.; Zhang, L.; Wu, M.; Ren, S.B. Review of metal matrix composites with high thermal conductivity for thermal management applications. Prog. Nat. Sci. Mater. Int. 2011, 21, 189–197. [Google Scholar] [CrossRef]

- Prieto, R.; Molina, M.J.; Narciso, J.; Louis, E. Fabrication and properties of graphite flakes/metal composites for thermal management applications. Scr. Mater. 2008, 59, 11–14. [Google Scholar] [CrossRef]

- Wang, L.; Gao, Y.; Xue, Q.; Liu, H.; Xu, T. Effects of nano-diamond particles on the structure and tribological property of Ni-matrix nanocomposite coatings. Mater. Sci. Eng. A 2005, 390, 313–318. [Google Scholar] [CrossRef]

- Burkat, G.K.; Fujimura, T.; Dolmatov, V.Y.; Orlova, E.A.; Veretennikova, M.V. Preparation of composite electrochemical nickel–diamond and iron–diamond coatings in the presence of detonation synthesis nanodiamonds. Diam. Relat. Mater. 2005, 14, 1761–1764. [Google Scholar] [CrossRef]

- Medelienė, V.; Stankevič, V.; Grigucevičienė, A.; Selskienė, A.; Bikulčiu, G. The study of corrosion and wear resistance of copper composite coatings with inclusions of carbon nanomaterials in the copper metal matrix. Mater. Sci. 2011, 17, 132–139. [Google Scholar] [CrossRef]

- Shakoor, A.R.; Waware, S.U.; Ali, K.; Kahraman, R.; Popelka, A.; Yusuf, M.M.; Hasan, A. Novel electrodeposited Ni-B/Y2O3 composite coatings with improved properties. Coatings 2017, 7, 161. [Google Scholar] [CrossRef]

- Praveen, B.M.; Venkatesha, T.V. Generation and corrosion behavior of Zn-Nano sized carbon black composite coating. Int. J. Electrochem. Sci. 2009, 4, 258–266. [Google Scholar]

- Pumera, M. Nanocarbon electrochemistry. In Electrochemistry. Volume 11, Nanosystems Electrochemistry; Wadhawan, J.D., Compton, R.G., Eds.; Royal Society of Chemistry: London, UK, 2012; pp. 104–123. [Google Scholar]

- Kuo, S.L.; Chen, Y.C.; Ger, M.D.; Hwu, W.H. Nano-particles dispersion effect on Ni/Al2O3 composite coatings. Mater. Chem. Phys. 2004, 86, 5–10. [Google Scholar] [CrossRef]

- Güler, E.S. Effects of electroplating characteristics on the coating properties. In Electrodeposition of Composite Materials; Mohamed, A.M.A., Golden, T.D., Eds.; InTech: Rijeka, Croatia, 2016; pp. 27–37. ISBN 978-953-51-2270-8. [Google Scholar]

- Shrestha, N.K.; Saji, T. Composite plating using an electro-active surfactant—A new approach to incorporate high amount of ceramic particles into a metal matrix. J. Surf. Finish. Soc. Jpn. 2006, 57, 489–496. [Google Scholar] [CrossRef]

- Arai, S.; Saito, T.; Endo, M. Cu–MWCNT composite films fabricated by electrodeposition. J. Electrochem. Soc. 2010, 157, D147–D153. [Google Scholar] [CrossRef]

- Gibson, N.; Shenderova, O.; Luo, T.J.M.; Moseenkov, S.; Bondar, V.; Puzyr, A.; Purtov, K.; Fitzgerald, Z.; Brenner, D.W. Colloidal stability of modified nanodiamond particles. Diam. Relat. Mater. 2009, 18, 620–626. [Google Scholar] [CrossRef]

- Xu, X.; Yu, Z.; Zhu, Y.; Wang, B. Influence of surface modification adopting thermal treatments on dispersion of detonation nanodiamond. J. Solid State Chem. 2005, 178, 688–693. [Google Scholar] [CrossRef]

- Kharissova, O.V.; Kharisov, B.I.; Ortiz, E.G.C. Dispersion of carbon nanotubes in water and non-aqueous solvents. RSC Adv. 2013, 3, 24812–24852. [Google Scholar] [CrossRef]

- Moraes, R.A.; Matos, C.F.; Castro, E.G.; Schreiner, W.H.; Oliveira, M.M.; Zarbin, A.J.G. The effect of different chemical treatments on the structure and stability of aqueous dispersion of iron- and iron oxide-filled multi-walled carbon nanotubes. J. Braz. Chem. Soc. 2011, 22, 2191–2201. [Google Scholar] [CrossRef]

- Cheng, J.; He, J.; Li, C.; Yang, Y. Facile approach to functionalize nanodiamond particles with V-shaped polymer brushes. Chem. Mater. 2008, 20, 4224–4230. [Google Scholar] [CrossRef]

- Aal, A.A.; Bahgat, M.; Radwan, M. Nanostructured Ni–AlN composite coatings. Surf. Coat. Technol. 2006, 201, 2910–2918. [Google Scholar] [CrossRef]

- Bahrololoom, M.E.; Sani, R. The influence of pulse plating parameters on the hardness and wear resistance of nickel–alumina composite coatings. Surf. Coat. Technol. 2005, 192, 154–163. [Google Scholar] [CrossRef]

- Guo, D.; Zhang, M.; Jin, Z.; Kang, R. Pulse plating of copper-ZrB2 composite coatings. J. Mater. Sci. Technol. 2006, 22, 514–518. [Google Scholar]

- Molina, J.M.; Saravanan, R.A.; Narciso, J.; Louis, E. Surface modification of 2014 aluminium alloy–Al2O3 particles composites by nickel electrochemical deposition. Mater. Sci. Eng. A 2004, 383, 299–306. [Google Scholar] [CrossRef]

- Krueger, A.; Lang, D. Functionality is key: Recent progress in the surface modification of nanodiamond. Adv. Funct. Mater. 2012, 22, 890–906. [Google Scholar] [CrossRef]

- Jiang, Z.; Liu, Y.; Sun, X.; Tian, F.; Sun, F.; Liang, C.; You, W.; Han, C.; Li, C. Activated carbons chemically modified by concentrated H2SO4 for the adsorption of the pollutants from wastewater and the dibenzothiophene from fuel oils. Langmuir 2003, 19, 731–736. [Google Scholar] [CrossRef]

- Matsubara, H. Fabrication of novel materials by the incorporation of nanodiamond into plated films. J. Surf. Sci. Soc. Jpn. 2009, 30, 279–286. [Google Scholar] [CrossRef]

| Exp. No. | Initial CuSO4 Concentration (M) | Initial ND Concentration (g/L) | Initial pH | Stirring Speed (rpm) | Current Density (A/dm2) | Amount of Electricity (C) | Surface Modification of ND |

|---|---|---|---|---|---|---|---|

| 1 | 0.1 | 0–30 | 2 | 500 | 1 | 20 | – |

| 2 | 1 | 3 | 0–4 | 500 | 0.1 | 20 | – |

| 3 | 0.1 | 3 | 2 | 250–750 | 1 | 20 | – |

| 4 | 1 | 20 | 2 | 500 | 1–25 | 20 | – |

| 5 | 0.1 | 3 | 2 | 500 | 1 | 10–100 | – |

| 6 | 0.1 | 3 | 2 or ≤ 0 1 | 500 | 1 or 10 | 20 | None or HT 2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goto, Y.; Kamebuchi, Y.; Hagio, T.; Kamimoto, Y.; Ichino, R.; Bessho, T. Electrodeposition of Copper/Carbonous Nanomaterial Composite Coatings for Heat-Dissipation Materials. Coatings 2018, 8, 5. https://doi.org/10.3390/coatings8010005

Goto Y, Kamebuchi Y, Hagio T, Kamimoto Y, Ichino R, Bessho T. Electrodeposition of Copper/Carbonous Nanomaterial Composite Coatings for Heat-Dissipation Materials. Coatings. 2018; 8(1):5. https://doi.org/10.3390/coatings8010005

Chicago/Turabian StyleGoto, Yasuki, Yota Kamebuchi, Takeshi Hagio, Yuki Kamimoto, Ryoichi Ichino, and Takeshi Bessho. 2018. "Electrodeposition of Copper/Carbonous Nanomaterial Composite Coatings for Heat-Dissipation Materials" Coatings 8, no. 1: 5. https://doi.org/10.3390/coatings8010005

APA StyleGoto, Y., Kamebuchi, Y., Hagio, T., Kamimoto, Y., Ichino, R., & Bessho, T. (2018). Electrodeposition of Copper/Carbonous Nanomaterial Composite Coatings for Heat-Dissipation Materials. Coatings, 8(1), 5. https://doi.org/10.3390/coatings8010005