Performance Investigation of an Exhaust Thermoelectric Generator for Military SUV Application

Abstract

:1. Introduction

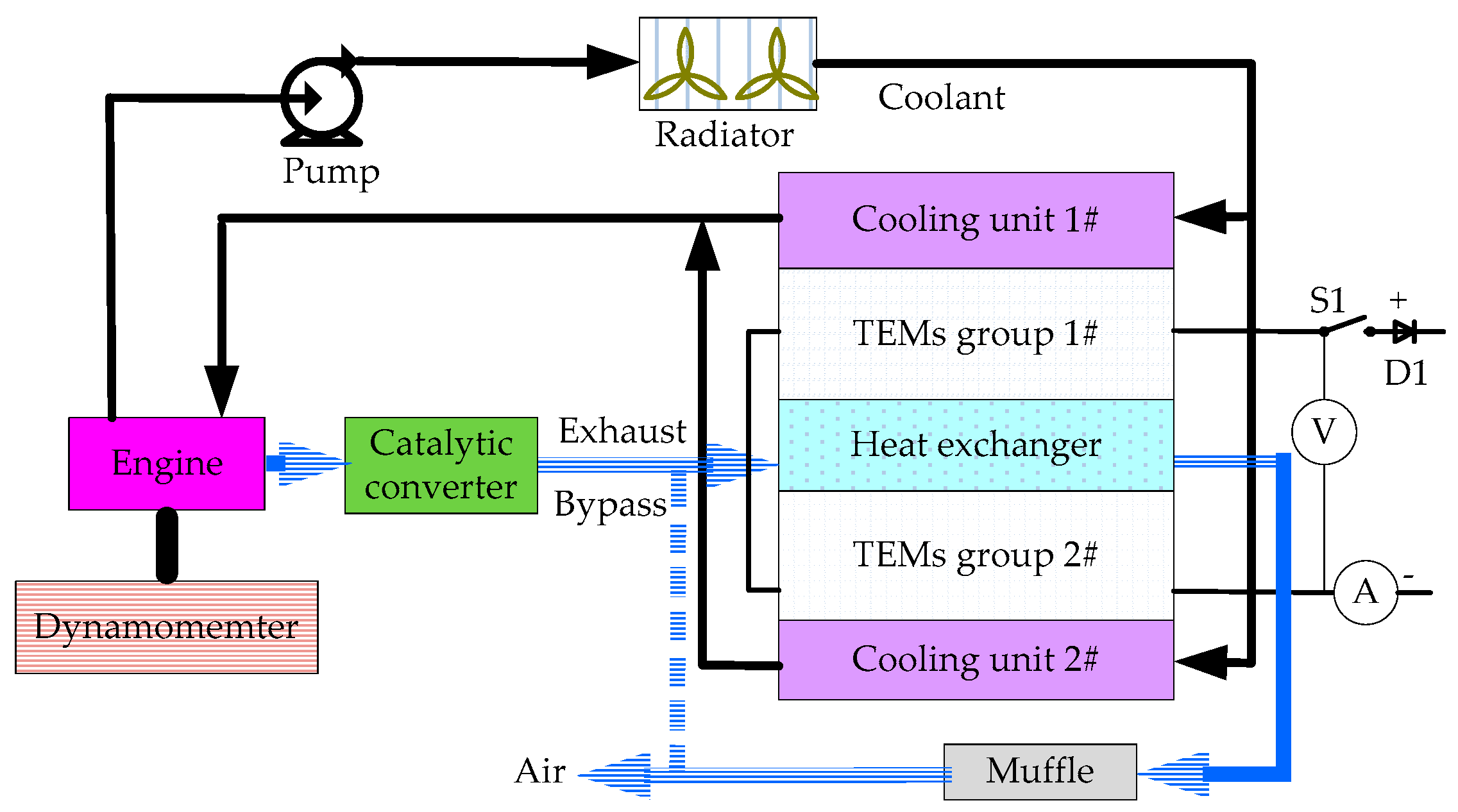

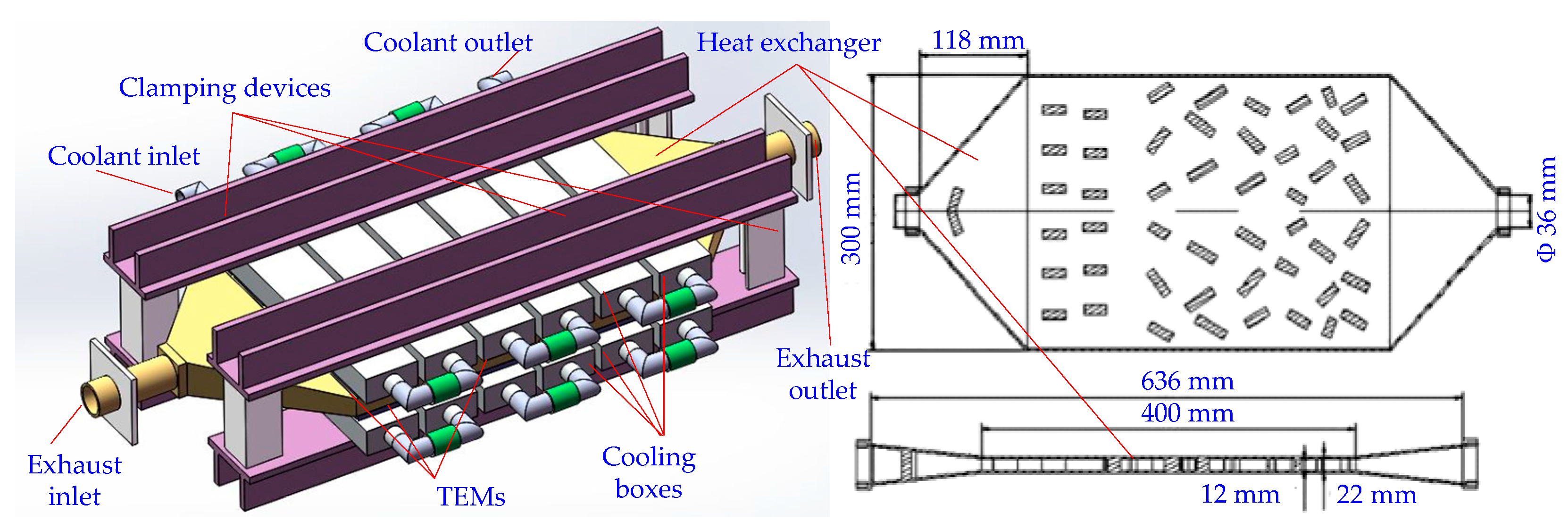

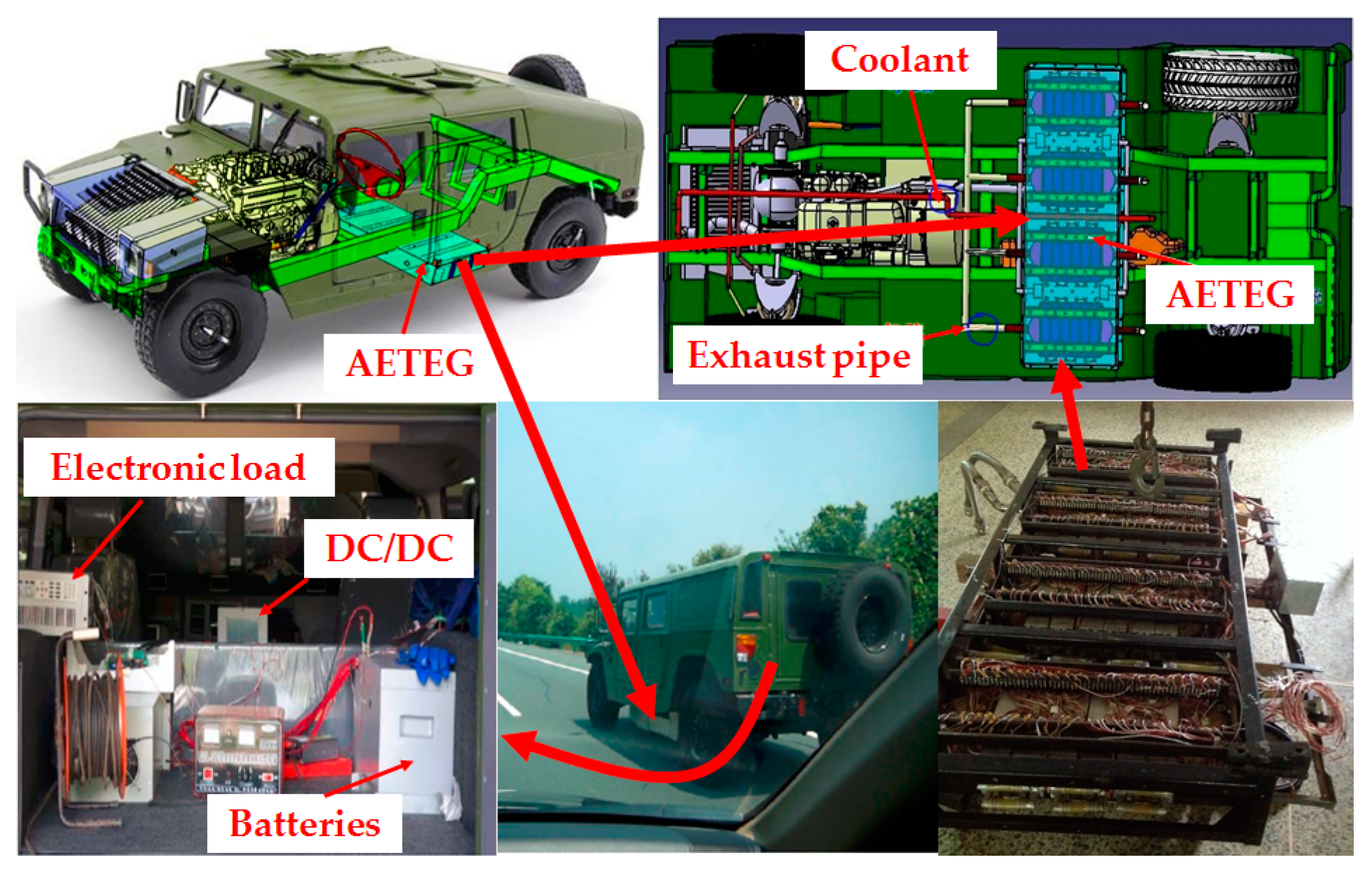

2. Experimental Setup of a TEG System

2.1. TEG Architecture

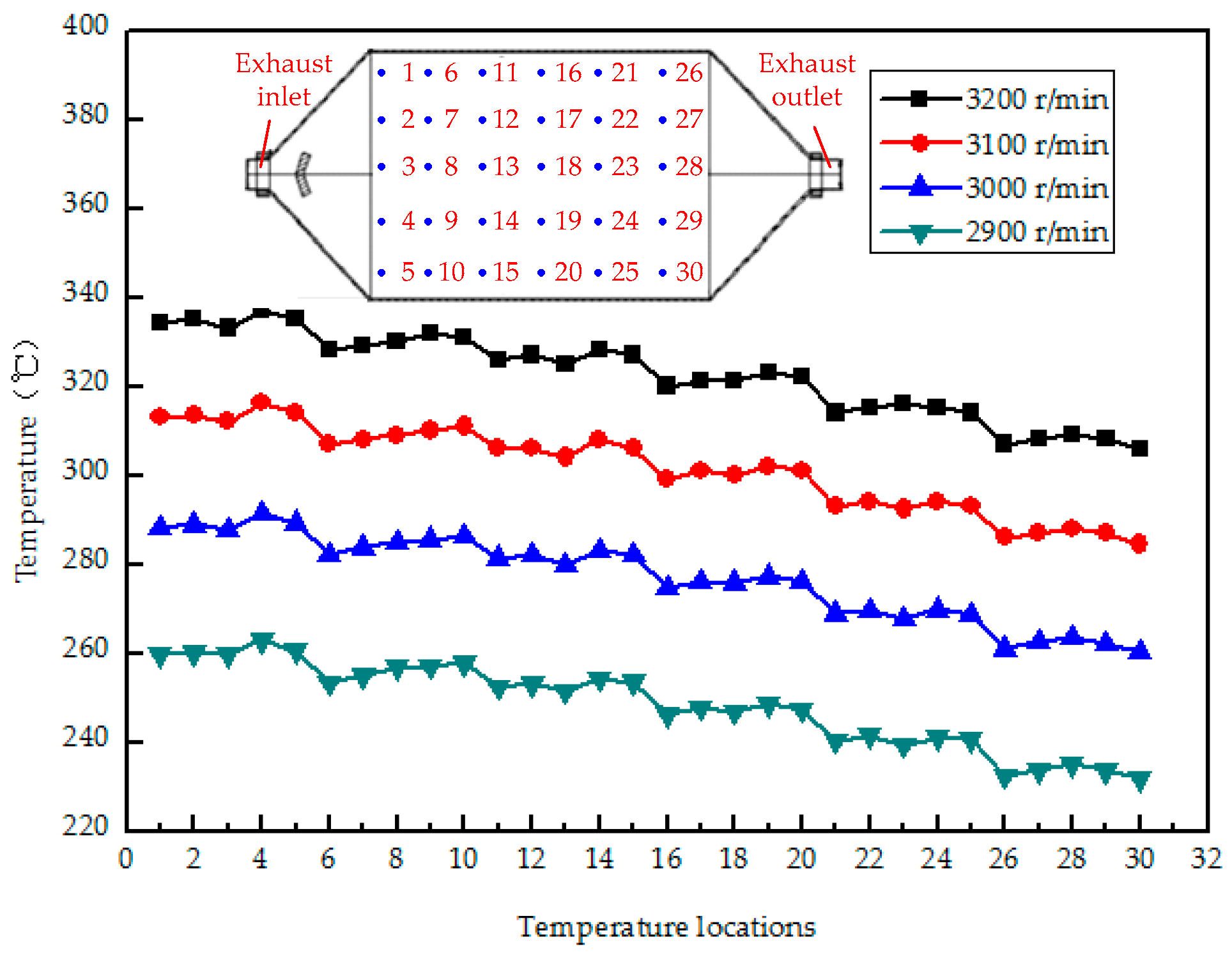

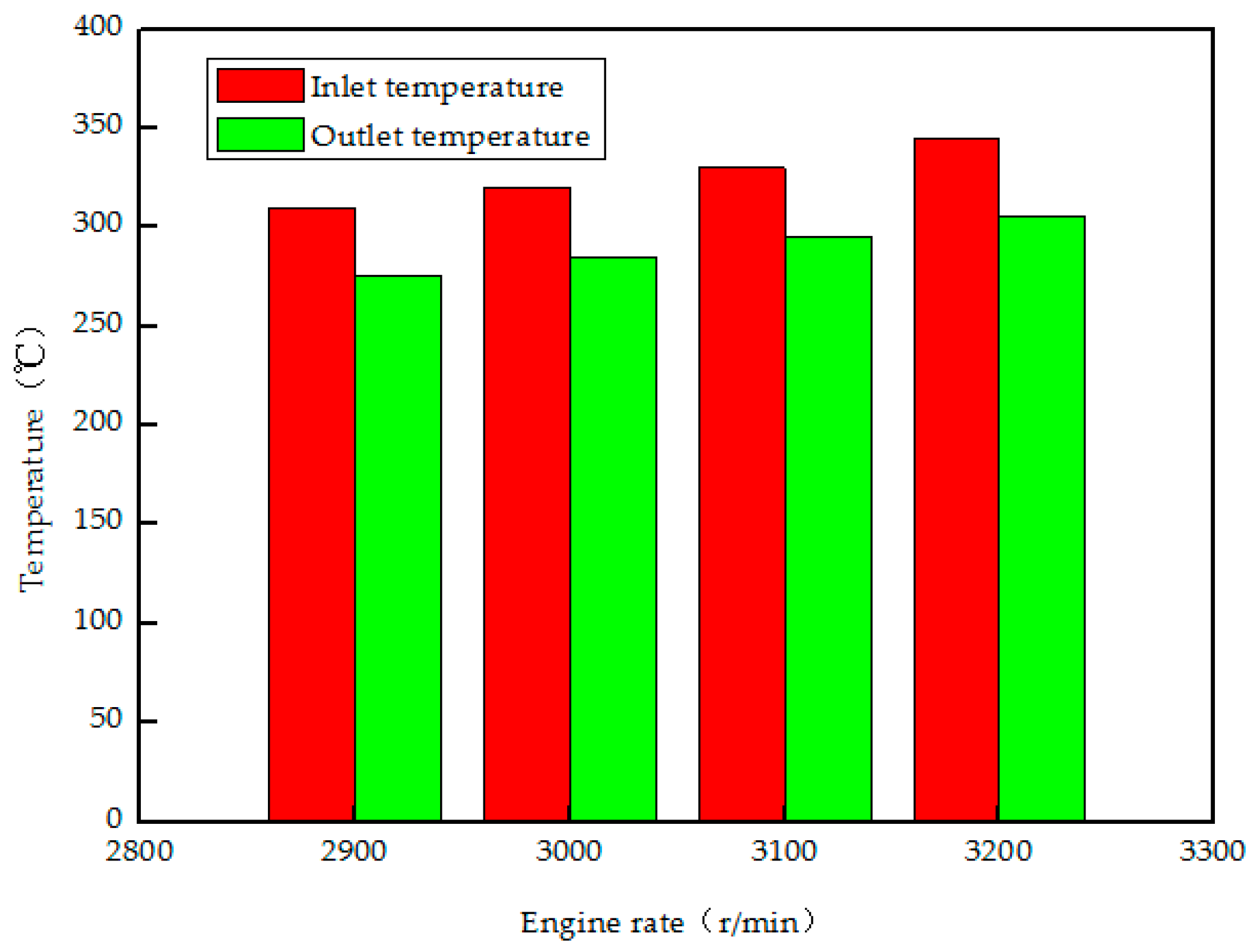

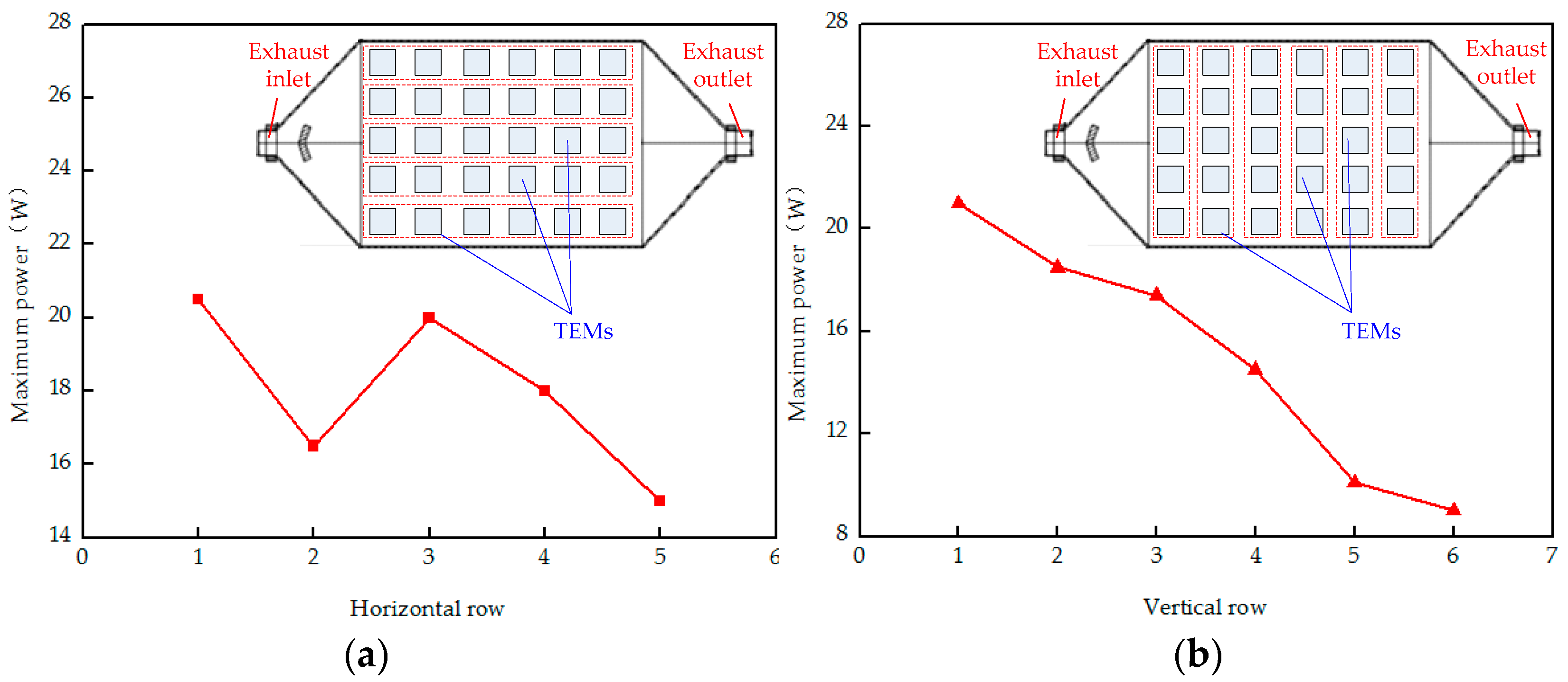

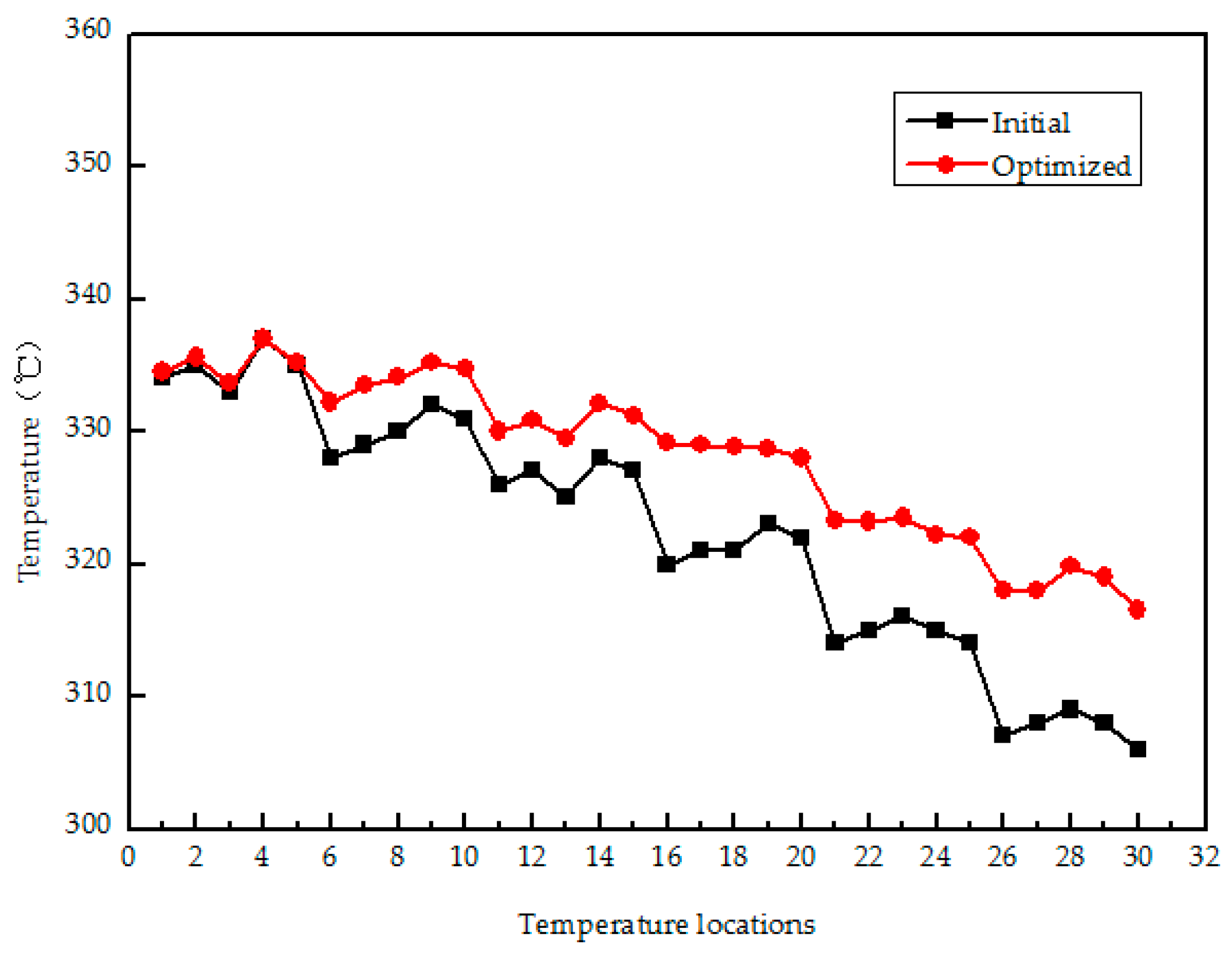

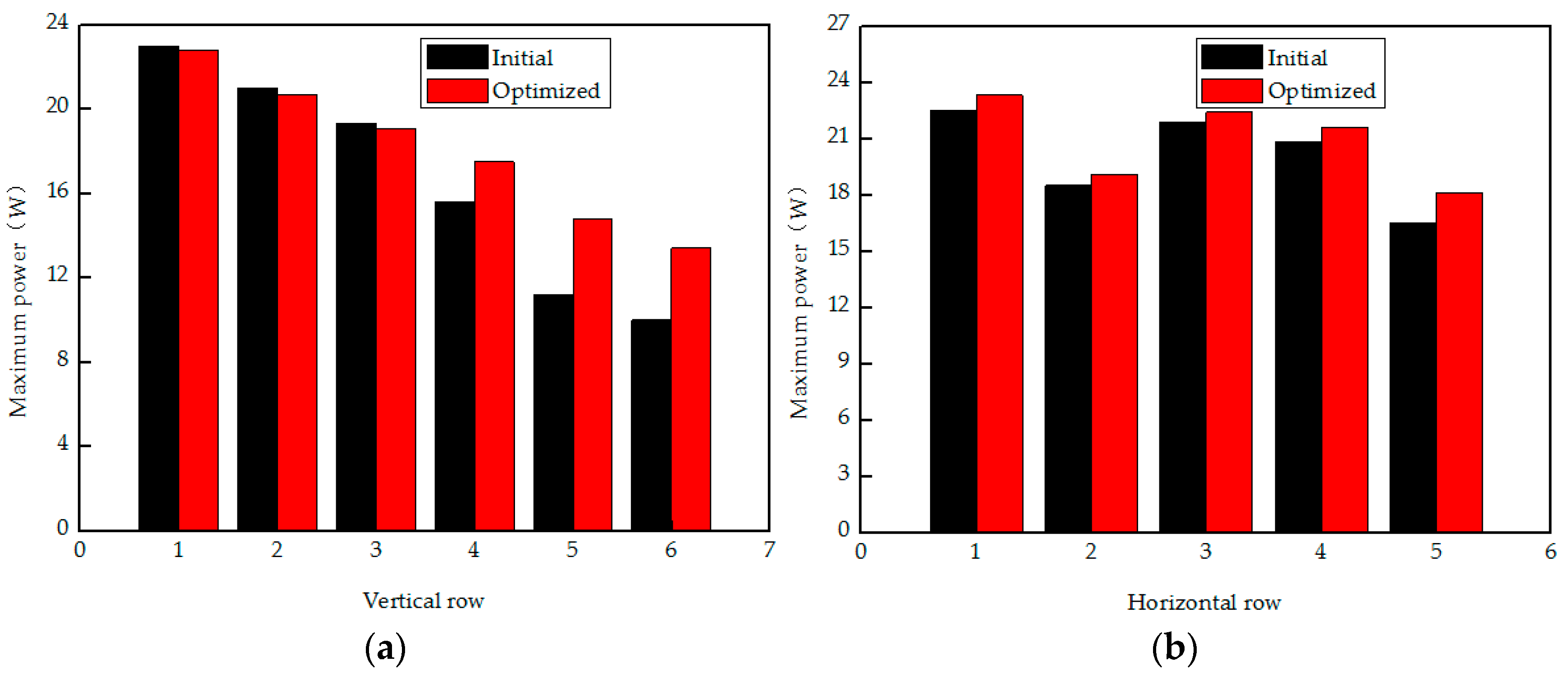

2.2. Temperature Distribution

2.3. Influence of Temperature Uniformity

3. Road Test of AETEG System

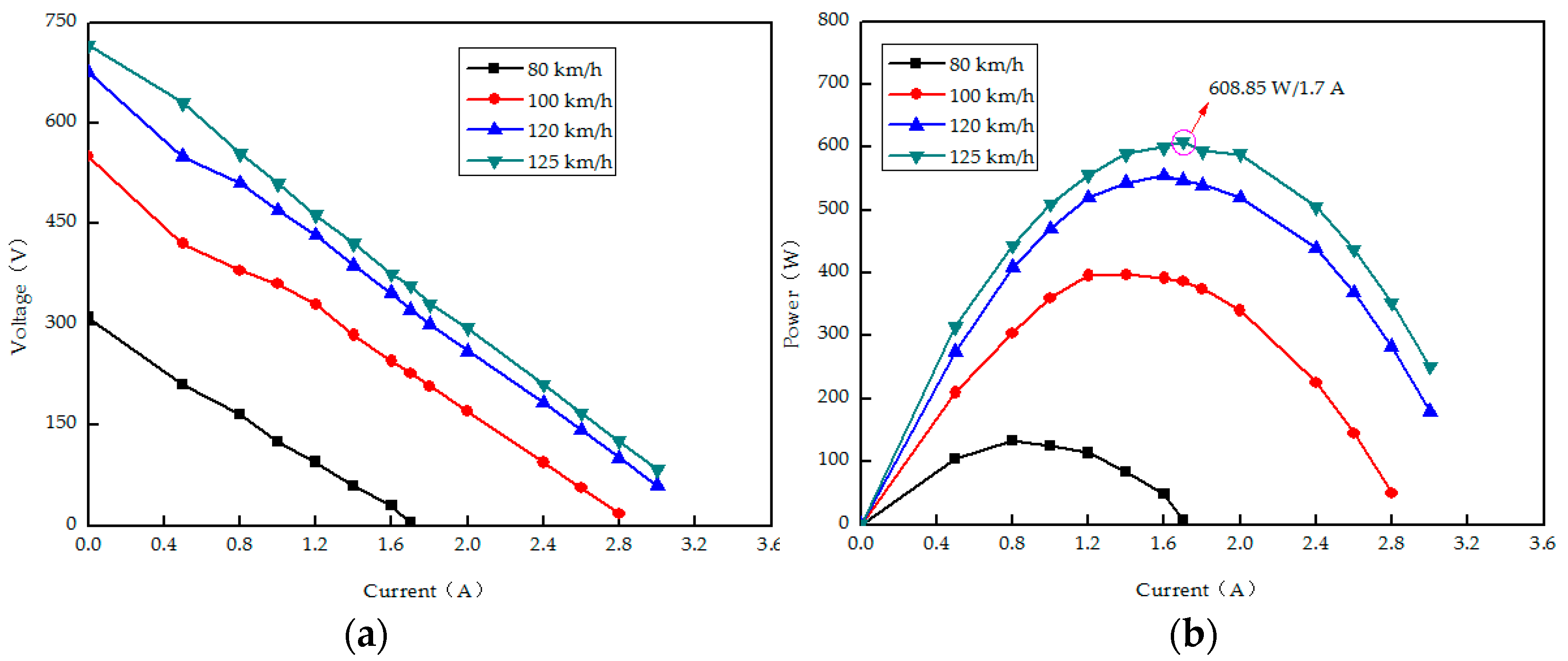

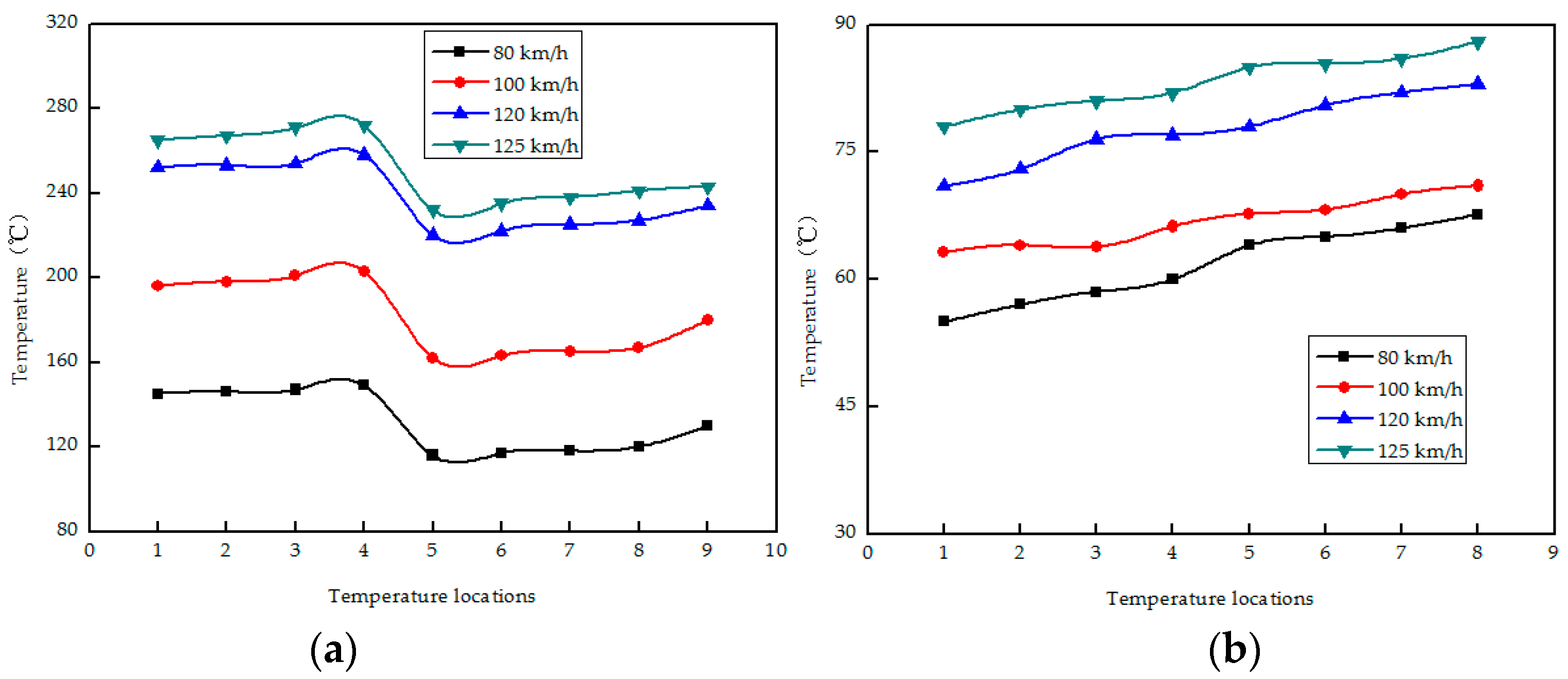

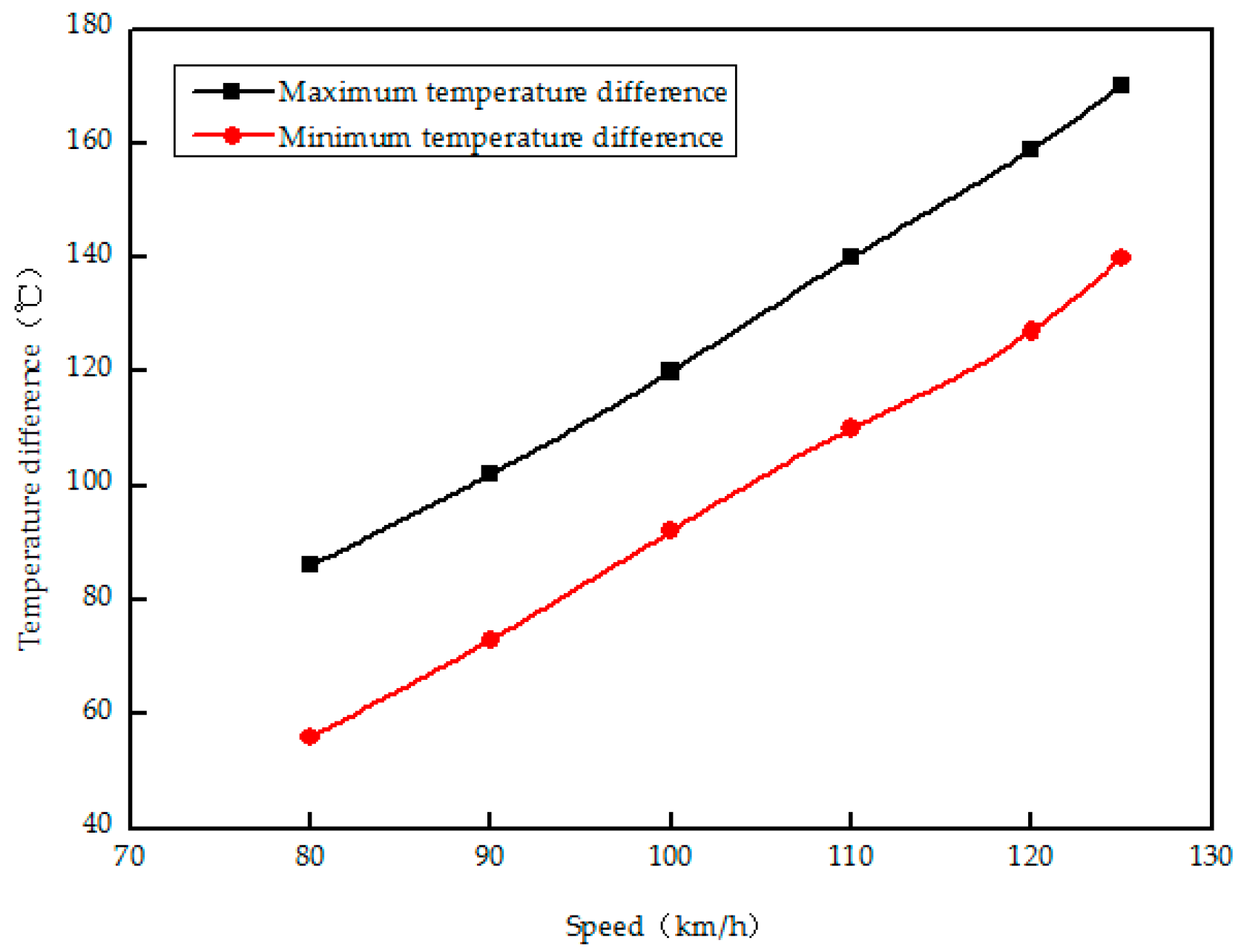

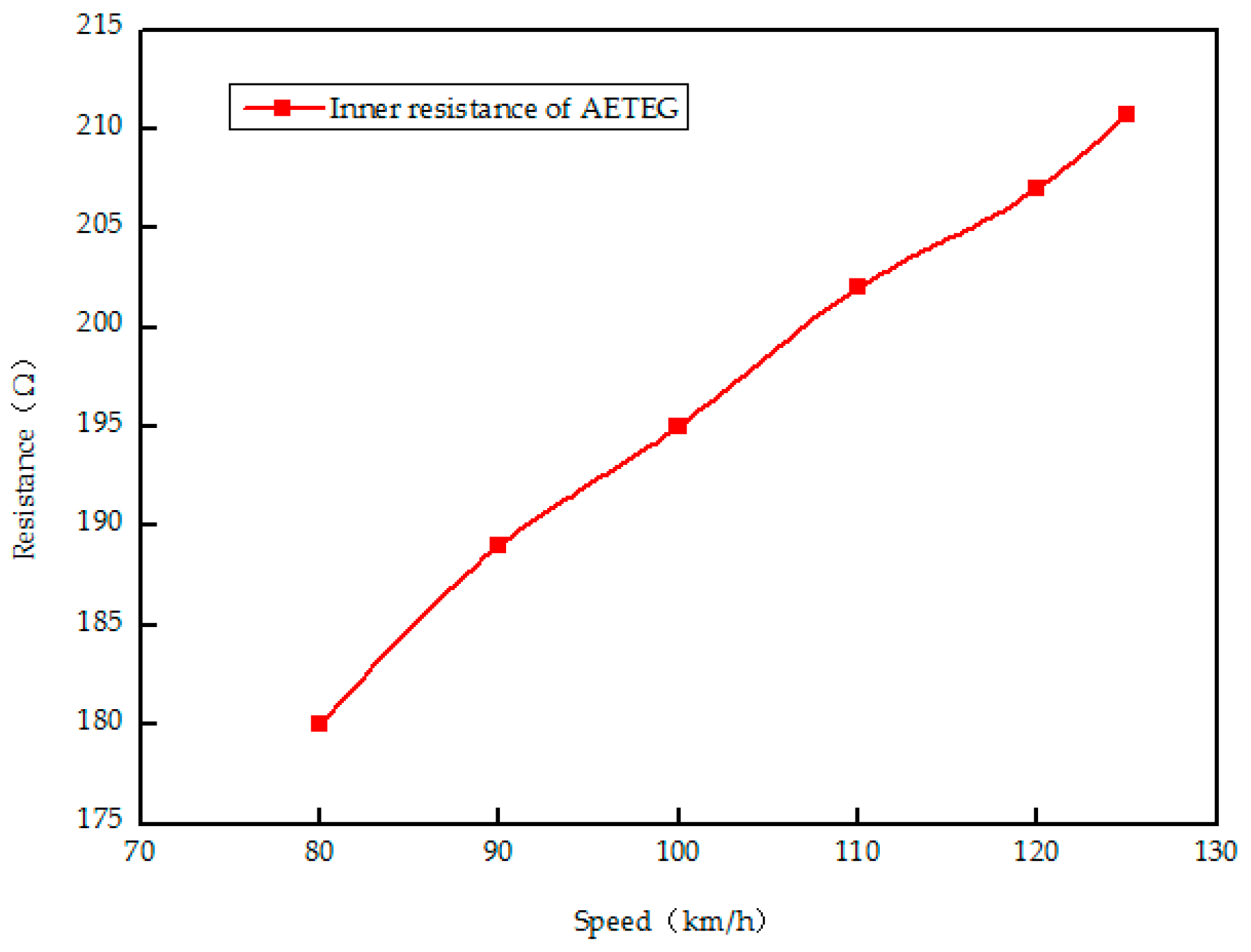

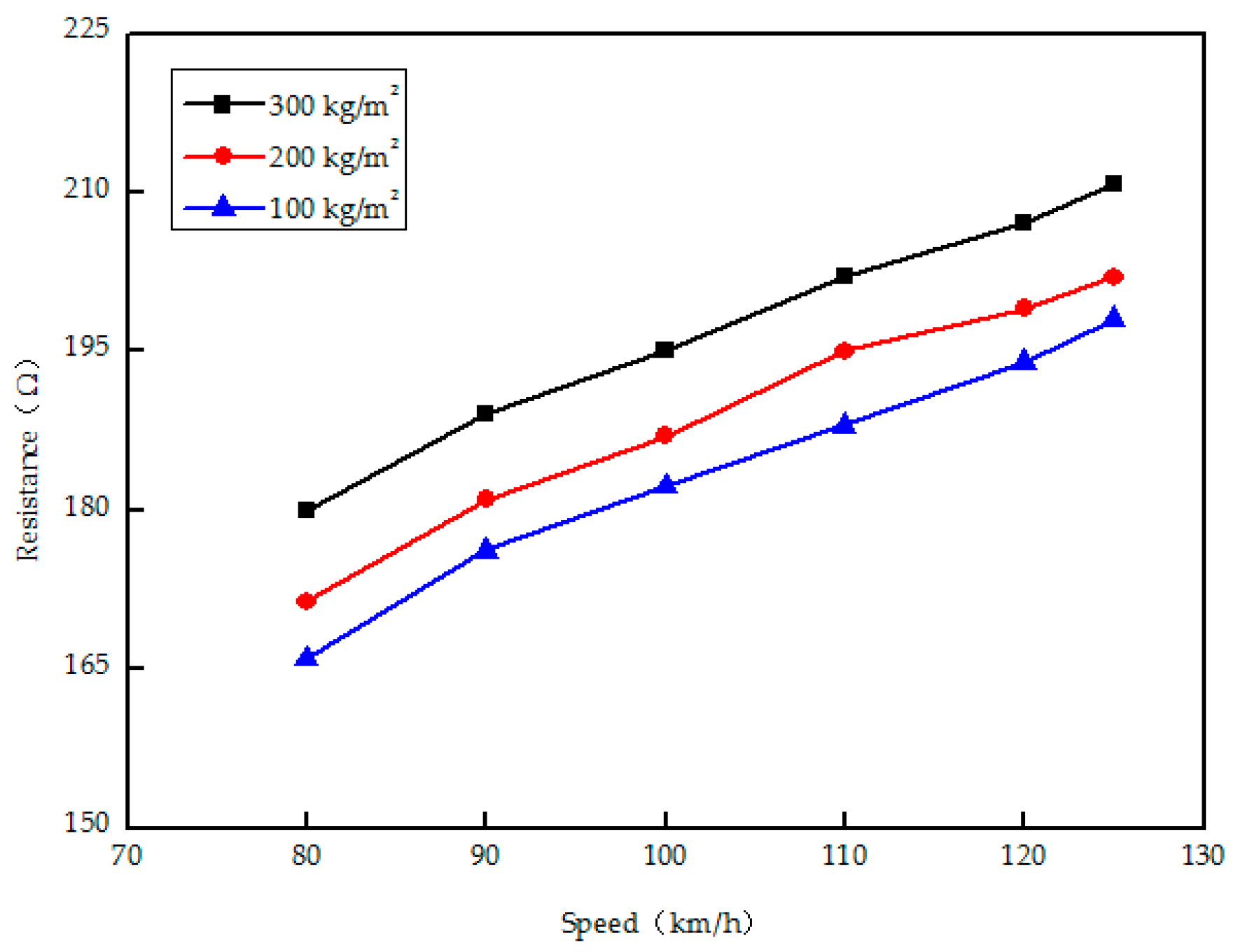

3.1. Influence of SUV Speed

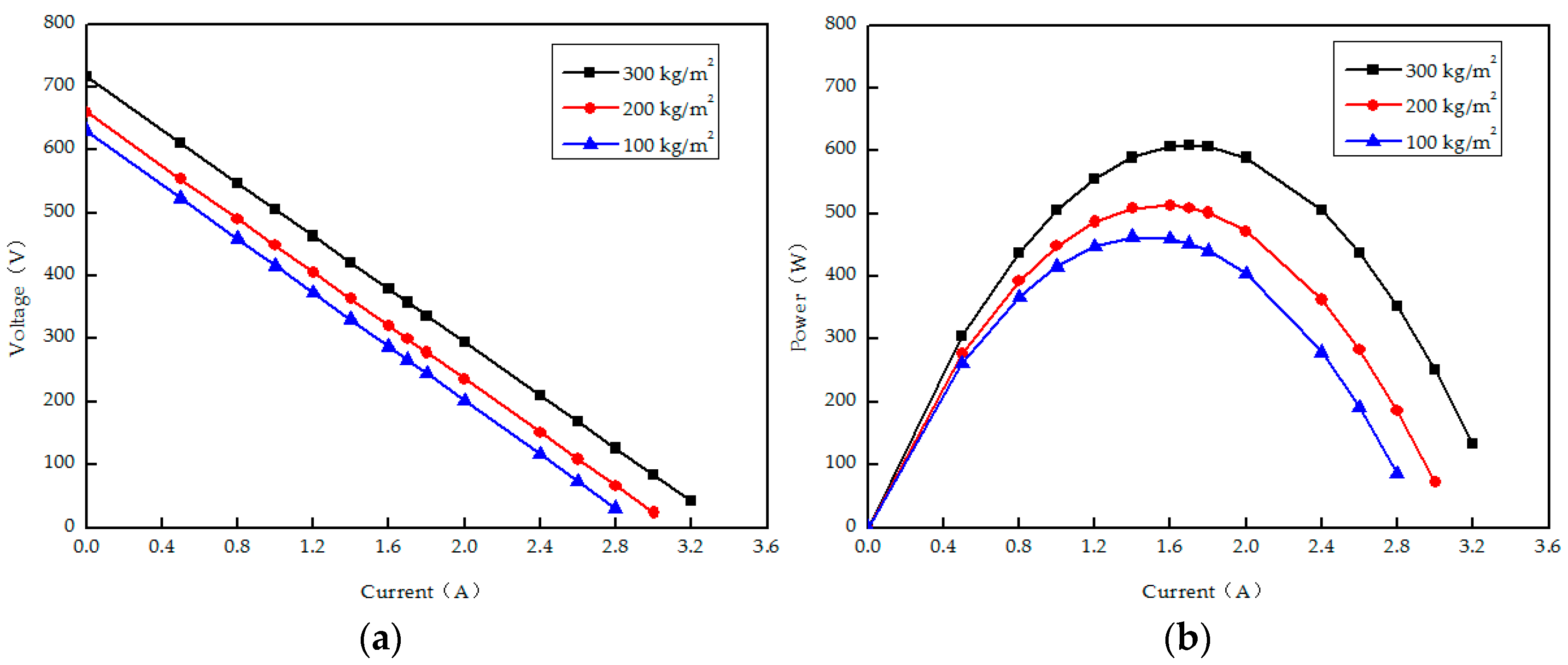

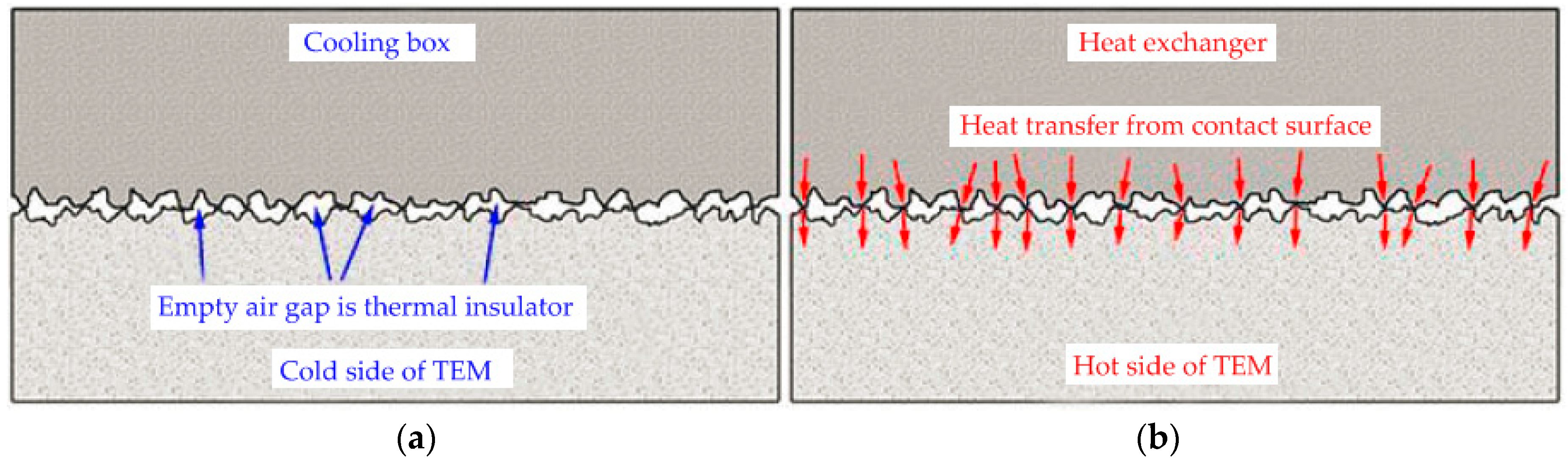

3.2. Influence of Clamping Pressure

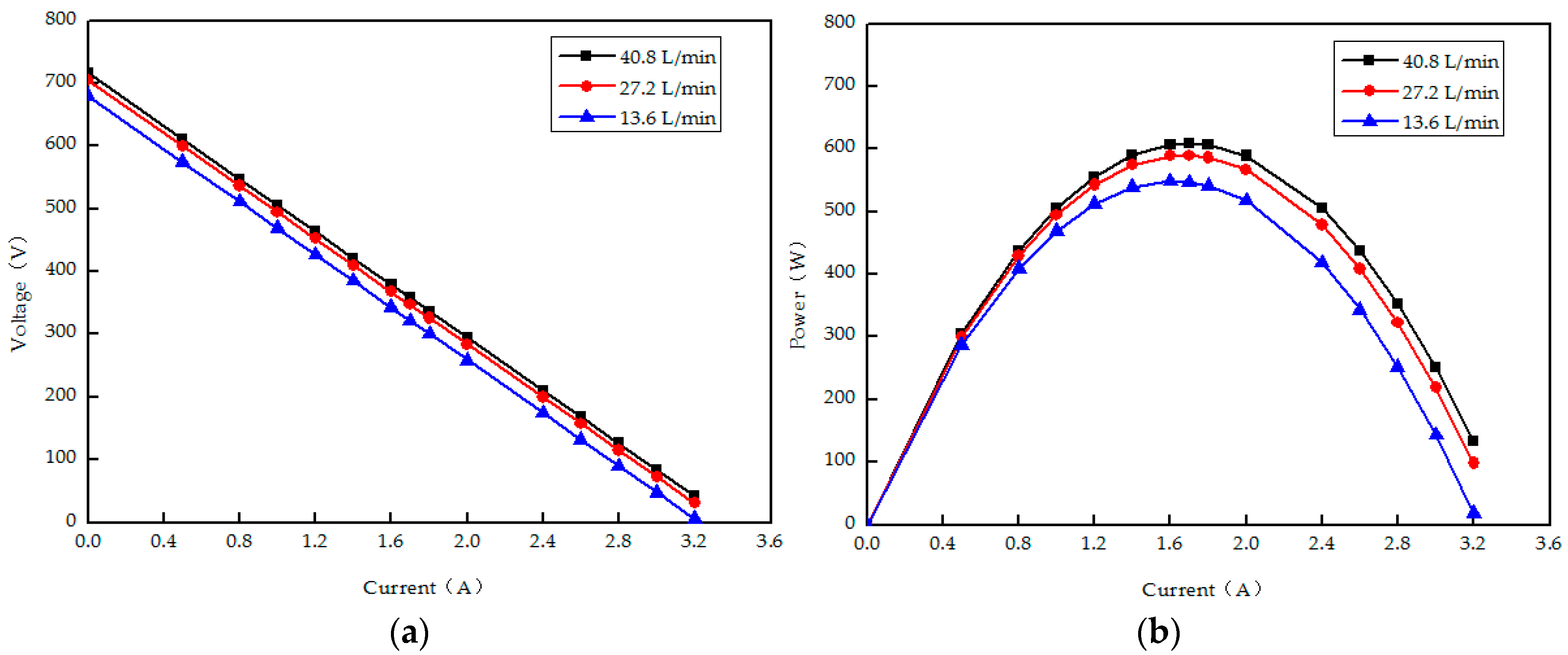

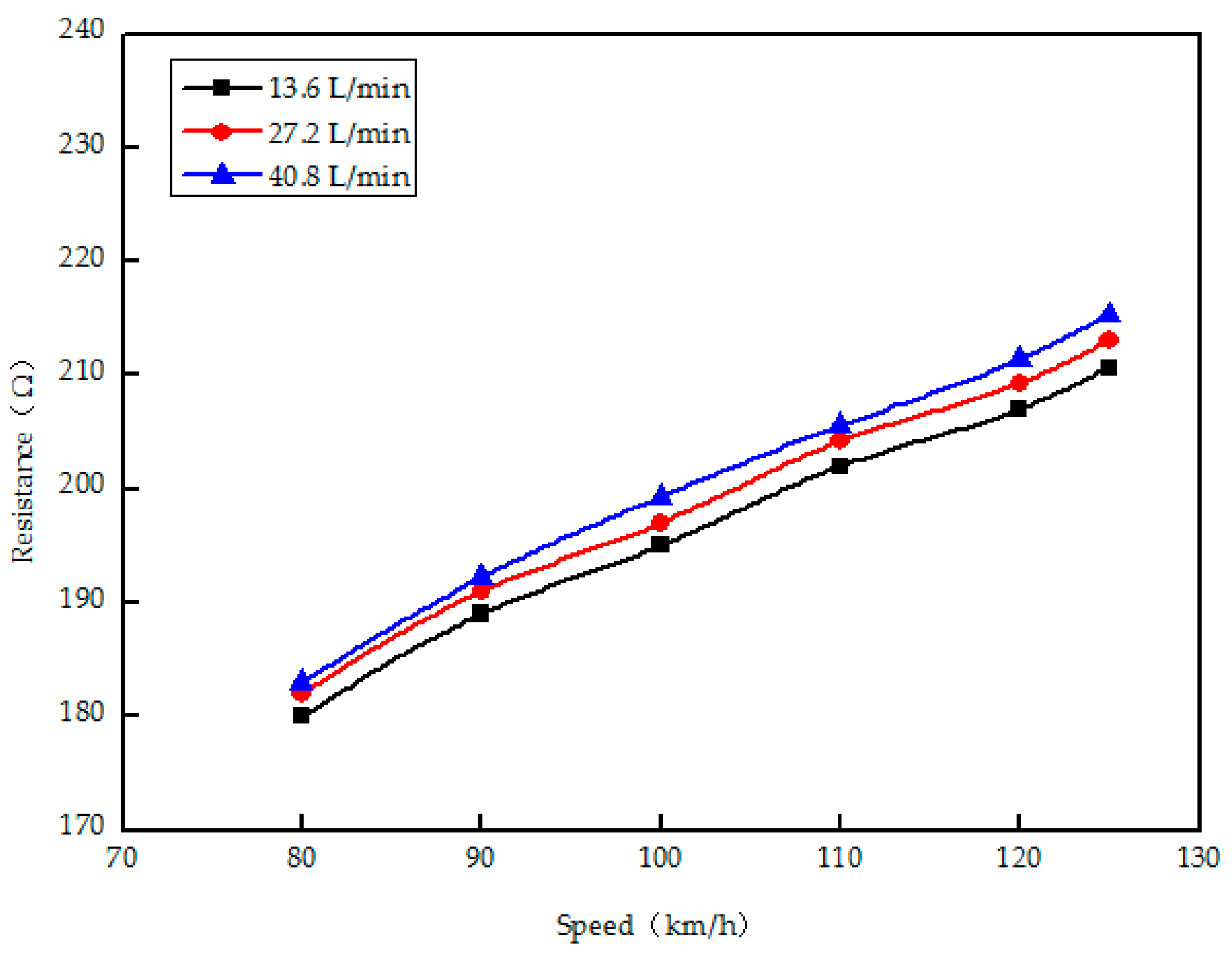

3.3. Influence of Engine Coolant Flow Rate

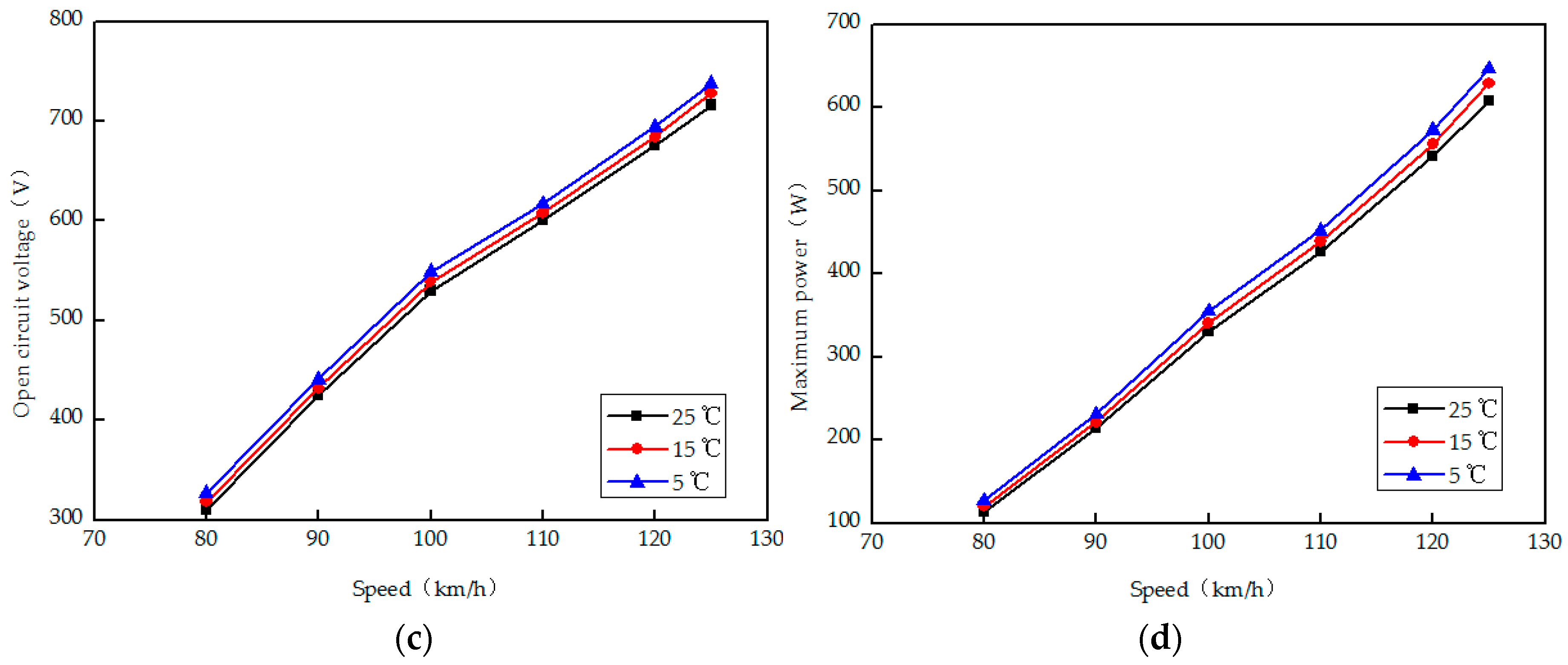

3.4. Influence of Ambient Temperature

3.5. System Efficiency

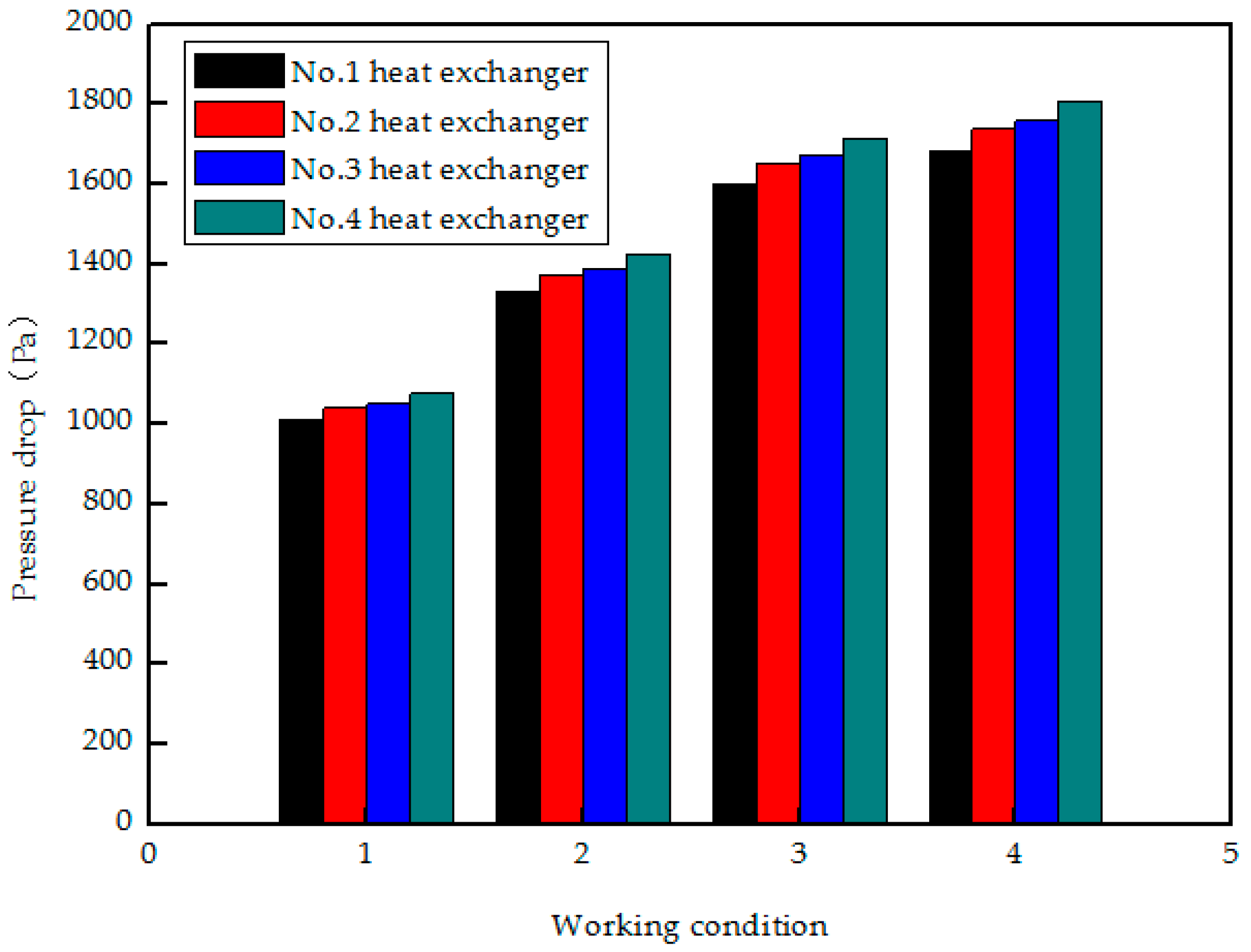

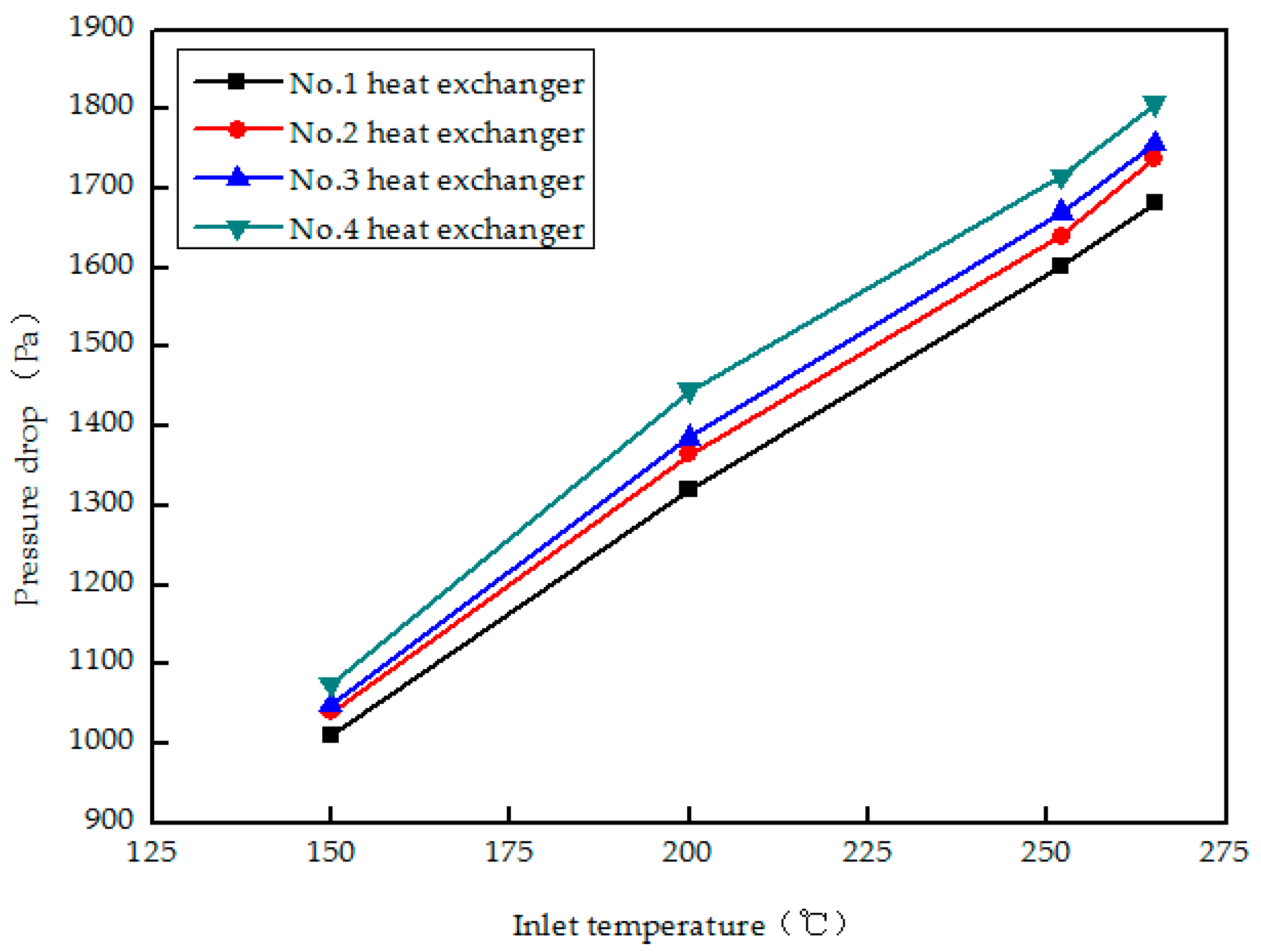

3.6. Backpressure

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Willars-Rodríguez, F.J.; Chávez-Urbiola, E.A.; Vorobiev, P.; Vorobiev, Y.V. Investigation of solar hybrid system with concentrating Fresnel lens, photovoltaic and thermoelectric generators. Int. J. Energy Res. 2017, 41, 377–388. [Google Scholar] [CrossRef]

- Demir, M.E.; Dincer, I. Performance assessment of a thermoelectric generator applied to exhaust waste heat recovery. Appl. Therm. Eng. 2017, 120, 694–707. [Google Scholar] [CrossRef]

- Li, W.K.; Peng, J.Y.; Xiao, W.L.; Wang, H.H.; Zeng, J.S.; Xie, J.; Huang, Q.B. The temperature distribution and electrical performance of fluid heat exchanger-based thermoelectric generator. Appl. Therm. Eng. 2017, 118, 742–747. [Google Scholar] [CrossRef]

- Meng, F.K.; Chen, L.G.; Feng, Y.L.; Xiong, B. Thermoelectric generator for industrial gas phase waste heat recovery. Energy 2017, 135, 83–90. [Google Scholar] [CrossRef]

- Kim, S.; Park, S.; Kim, S.K.; Rhi, S.H. A thermoelectric generator using engine coolant for light-duty internal combustion engine-powered vehicles. J. Electron. Mater. 2011, 40, 812–816. [Google Scholar] [CrossRef]

- Kim, T.Y.; Negash, A.A.; Cho, G. Waste heat recovery of a diesel engine using a thermoelectric generator equipped with customized thermoelectric modules. Energy Convers. Manag. 2016, 124, 280–286. [Google Scholar] [CrossRef]

- Bass, J.C.; Kushch, A.S.; Elsner, N.B. Thermoelectric generator development for heavy-duty truck applications. In Proceedings of the Annual Automotive Technology Development Contractors’ Coordination Meeting, Dearborn, MI, USA, 28–31 October 1991; pp. 743–748. [Google Scholar]

- Ikoma, K.; Munekiyo, M.; Furuya, K.; Kobayashi, M.; Izumi, T.; Shinohara, K. Thermoelectric module and generator for gasoline engine vehicles. In Proceedings of the 17th International Conference on Thermoelectrics-ICT1998, Nagoya, Japan, 24–28 May 1998; pp. 464–467. [Google Scholar]

- Lagrandeur, J.; Crane, D.; Mazar, S.; Eder, A. Automotive waste heat conversion to electric power using skutterudite, TAGS, PbTe and BiTe. In Proceedings of the 25th International Conference on Thermoelectrics ICT’06, Beijing, China, 6–8 August 2006; pp. 343–348. [Google Scholar]

- Thacher, E.F.; Helenbrook, B.T.; Karri, M.A.; Richter, C.J. Testing of an automobile exhaust thermoelectric generator in a light truck. J. Automob. Eng. 2007, 221, 95–107. [Google Scholar] [CrossRef]

- Hussain, Q.E.; Brigham, D.R.; Maranville, C.W. Thermoelectric exhaust heat recovery for hybrid vehicles. SAE Tech. Pap. 2009, 2, 1132–1142. [Google Scholar] [CrossRef]

- Hsu, C.T.; Huang, G.Y.; Chu, H.S.; Yu, B.; Yao, D.J. Experiments and simulations on low-temperature waste heat harvesting system by thermoelectric power generators. Appl. Energy 2011, 88, 1291–1297. [Google Scholar] [CrossRef]

- Kim, S.K.; Won, B.C.; Rhi, S.H.; Kim, S.H.; Yoo, J.H.; Jang, J.C. Thermoelectric power generation system for future hybrid vehicles using hot exhaust gas. J. Electron. Mater. 2011, 40, 778–783. [Google Scholar] [CrossRef]

- Liu, C.; Pan, X.; Zheng, X.; Yan, Y.; Li, W. An experimental study of a novel prototype for two-stage thermoelectric generator from vehicle exhaust. J. Energy Inst. 2016, 89, 271–281. [Google Scholar] [CrossRef]

- Domingues, A.; Santos, H.; Costa, M. Analysis of vehicle exhaust waste heat recovery potential using a Rankine cycle. Energy 2013, 49, 71–85. [Google Scholar] [CrossRef]

- Kumar, S.; Heister, S.D.; Xu, X.F.; Salvador, J.R.; Meisner, G.P. Thermoelectric generators for automotive waste heat recovery systems part II: Parametric evaluation and topological studies. J. Electron. Mater. 2013, 42, 944–955. [Google Scholar] [CrossRef]

- Kuhn, R.; Koeppen, O.; Kitte, J. Influence of an optimized thermoelectric generator on the back pressure of the subsequent exhaust gas system of a vehicle. J. Electron. Mater. 2014, 43, 1521–1526. [Google Scholar] [CrossRef]

- Martinez, A.; Vian, J.G.; Astrain, D.; Rodriguez, A.; Berrio, I. Optimization of the heat exchangers of a thermoelectric generation system. J. Electron. Mater. 2010, 39, 1463–1468. [Google Scholar] [CrossRef]

- Kempf, N.; Zhang, Y.L. Design and optimization of automotive thermoelectric generators for maximum fuel efficiency improvement. Energy Convers. Manag. 2016, 121, 224–231. [Google Scholar] [CrossRef]

- Bi, C.; Tang, G.H.; Tao, W.Q. Heat transfer enhancement in mini-channel heat sinks with dimples and cylindrical grooves. Appl. Therm. Eng. 2013, 55, 121–132. [Google Scholar] [CrossRef]

- David, B.; Ramousse, J.; Luo, L. Optimization of thermoelectric heat pumps by operating condition management and heat exchanger design. Energy Convers. Manag. 2012, 60, 125–133. [Google Scholar] [CrossRef]

- Wang, C.C.; Hung, C.I.; Chen, W.H. Design of heat sink for improving the performance of thermoelectric generator using two-stage optimization. Energy 2012, 39, 236–245. [Google Scholar] [CrossRef]

- Kubo, M.; Shinoda, M.; Furuhata, T.; Kitagawa, K. Optimization of the incision size and cold-end temperature of a thermoelectric device. Energy 2005, 30, 2156–2170. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Sahin, A.Z. Thermoelectric device and optimum external load parameter and slenderness ratio. Energy 2010, 35, 5380–5384. [Google Scholar] [CrossRef]

- Jang, B.; Han, S.; Kim, J.Y. Optimal design for micro-thermoelectric generators using Finite element analysis. Microelectron. Eng. 2011, 88, 775–778. [Google Scholar] [CrossRef]

- Su, C.Q.; Zhan, W.W.; Shen, S. Thermal optimization of the heat exchanger in the vehicular waste-heat thermoelectric generations. J. Electron. Mater. 2012, 41, 1693–1697. [Google Scholar] [CrossRef]

- Liu, X.; Deng, Y.D.; Zhang, K.; Xu, M.; Xu, Y.; Su, C.Q. Experiments and simulations on heat exchangers in thermoelectric generator for automotive application. Appl. Therm. Eng. 2014, 71, 364–370. [Google Scholar] [CrossRef]

- Wang, Y.P.; Cheng, W.; Tang, Z.B.; Xue, Y.; Deng, Y.D.; Su, C.Q. Optimization of fin distribution to improve the temperature uniformity of a heat exchanger in a thermoelectric generator. J. Electron. Mater. 2015, 44, 1724–1732. [Google Scholar] [CrossRef]

- Wang, Y.P.; Li, S.; Xue, Y.; Deng, Y.D.; Su, C.Q. Numerical and experimental investigation for heat transfer enhancement by dimpled surface heat exchanger in thermoelectric generator. J. Electron. Mater. 2016, 45, 1792–1802. [Google Scholar] [CrossRef]

- Gou, X.; Xiao, H.; Yang, S. Modeling, experimental study and optimization on low-temperature waste heat thermoelectric generator system. Appl. Energy 2010, 87, 3131–3136. [Google Scholar] [CrossRef]

- Quan, R.; Zhou, W.; Yang, G.Y.; Quan, S.H. A hybrid maximum power point tracking method for automobile exhaust thermoelectric generator. J. Electron. Mater. 2017, 46, 2676–2683. [Google Scholar] [CrossRef]

- Saqr, K.M.; Mansour, M.K.; Musa, M.N. Thermal design of automobile exhaust based thermoelectric generator: Objectives and challenges. Int. J. Automot. Technol. 2008, 9, 155–160. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Dimension of TEM | 56 mm × 56 mm × 6 mm |

| Materials of TEM | Bi2Te3 |

| Maximum operating temperature of TEM | 350 °C |

| Maximum conversion efficiency of TEM | 5% |

| Capacity of engine | 2.0 L (PSA RFN 10LH3X) |

| Maximum power of engine | 108 kW (6000 r/min) |

| Maximum torque of engine | 200 NM (4000 r/min) |

| Maximum power of dynamometer | 160 kW |

| Maximum speed of dynamometer | 6000 r/min |

| Maximum torque of dynamometer | 600 NM |

| Dimension of cooling box | 300 mm × 60 mm × 21 mm |

| Materials of cooling box | Aluminum |

| Materials of heat exchanger | Brass |

| Materials of clamping devices | Steel |

| Thickness of heat exchanger | 5 mm |

| Thickness of cooling box | 3 mm |

| Maximum power of pump | 750 W (220 VAC) |

| Rated power of radiator | 200 W (12 VDC) |

| Parameter | Value |

|---|---|

| Dimension | 4717 mm × 2210 mm × 19,835 mm |

| Frontal area | 5.17 m2 |

| Total weight | 3500 kg |

| Rolling resistance coefficient | 0.0135 |

| Wind resistance coefficient | 0.65 |

| Wheel radius | 0.37 m |

| Capacity of engine | 3.9 L (EQB150-20) |

| Type of engine | Four-cylinder diesel |

| Rated power of engine | 112 kW (2700 r/min) |

| Maximum torque of engine | 502 NM (1500 r/min) |

| Maximum revolution rate of engine | 3000 r/min |

| Ambient Temperature | Efficiency | |||

|---|---|---|---|---|

| 80 km/h | 100 km/h | 120 km/h | 125 km/h | |

| 5 °C | −0.49% | 0.92% | 1.02% | 1.03% |

| 15 °C | −0.47% | −0.90% | 0.99% | 1.00% |

| 25 °C | 0.45% | −0.86% | 0.96% | 0.97% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quan, R.; Liu, G.; Wang, C.; Zhou, W.; Huang, L.; Deng, Y. Performance Investigation of an Exhaust Thermoelectric Generator for Military SUV Application. Coatings 2018, 8, 45. https://doi.org/10.3390/coatings8010045

Quan R, Liu G, Wang C, Zhou W, Huang L, Deng Y. Performance Investigation of an Exhaust Thermoelectric Generator for Military SUV Application. Coatings. 2018; 8(1):45. https://doi.org/10.3390/coatings8010045

Chicago/Turabian StyleQuan, Rui, Guangyin Liu, Chengji Wang, Wei Zhou, Liang Huang, and Yadong Deng. 2018. "Performance Investigation of an Exhaust Thermoelectric Generator for Military SUV Application" Coatings 8, no. 1: 45. https://doi.org/10.3390/coatings8010045

APA StyleQuan, R., Liu, G., Wang, C., Zhou, W., Huang, L., & Deng, Y. (2018). Performance Investigation of an Exhaust Thermoelectric Generator for Military SUV Application. Coatings, 8(1), 45. https://doi.org/10.3390/coatings8010045