Titanium Aluminium Nitride and Titanium Boride Multilayer Coatings Designed to Combat Tool Wear

Abstract

:1. Introduction

2. Material and Methods

2.1. Substrate Preparation

2.2. Sputtering

2.3. Design of the Multilayer Coatings

2.4. XRD Characterisation

2.5. Laser Confocal Microscope

2.6. Scratch and Wear Tests

3. Results and Discussion

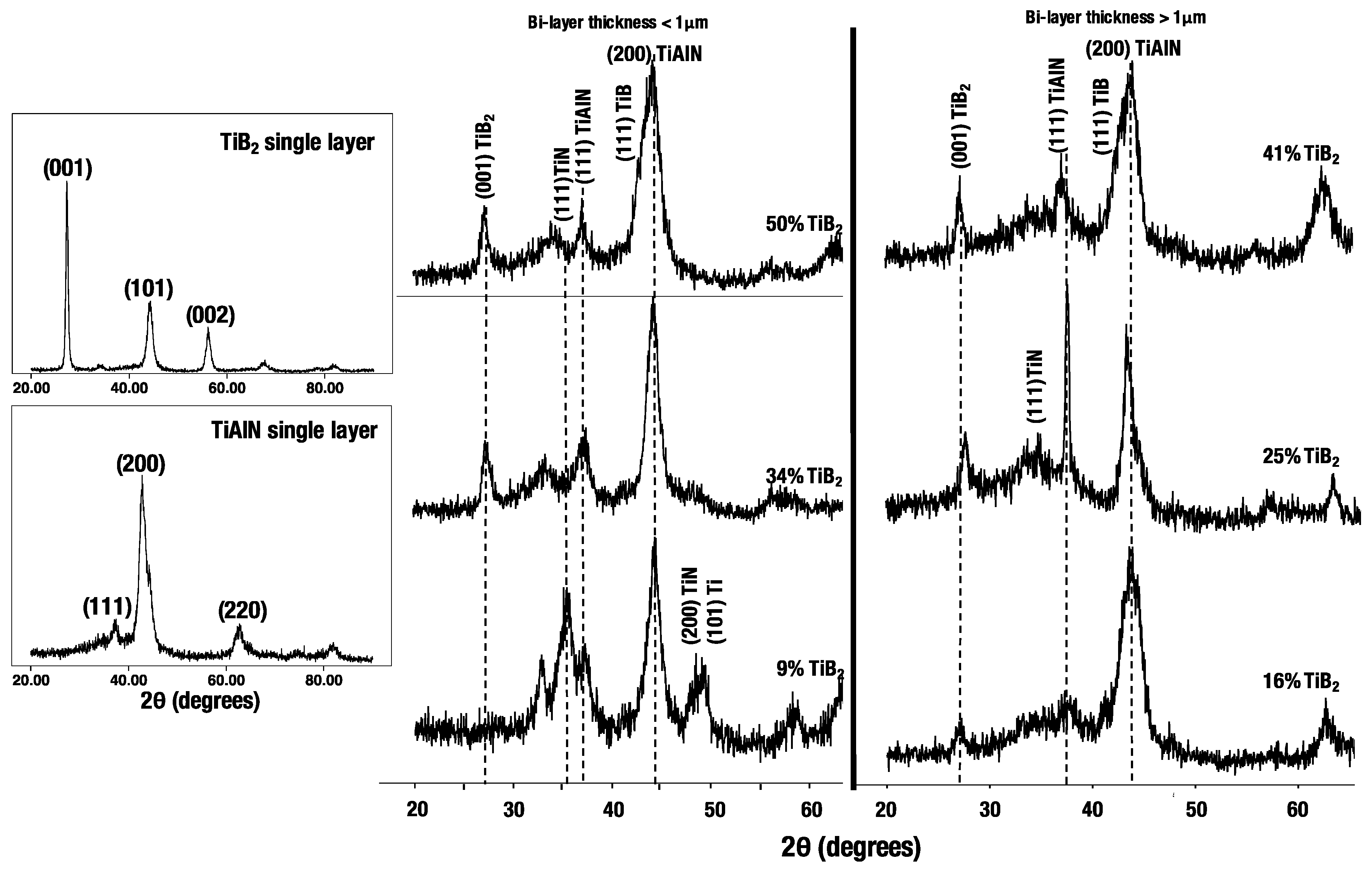

3.1. XRD Analysis

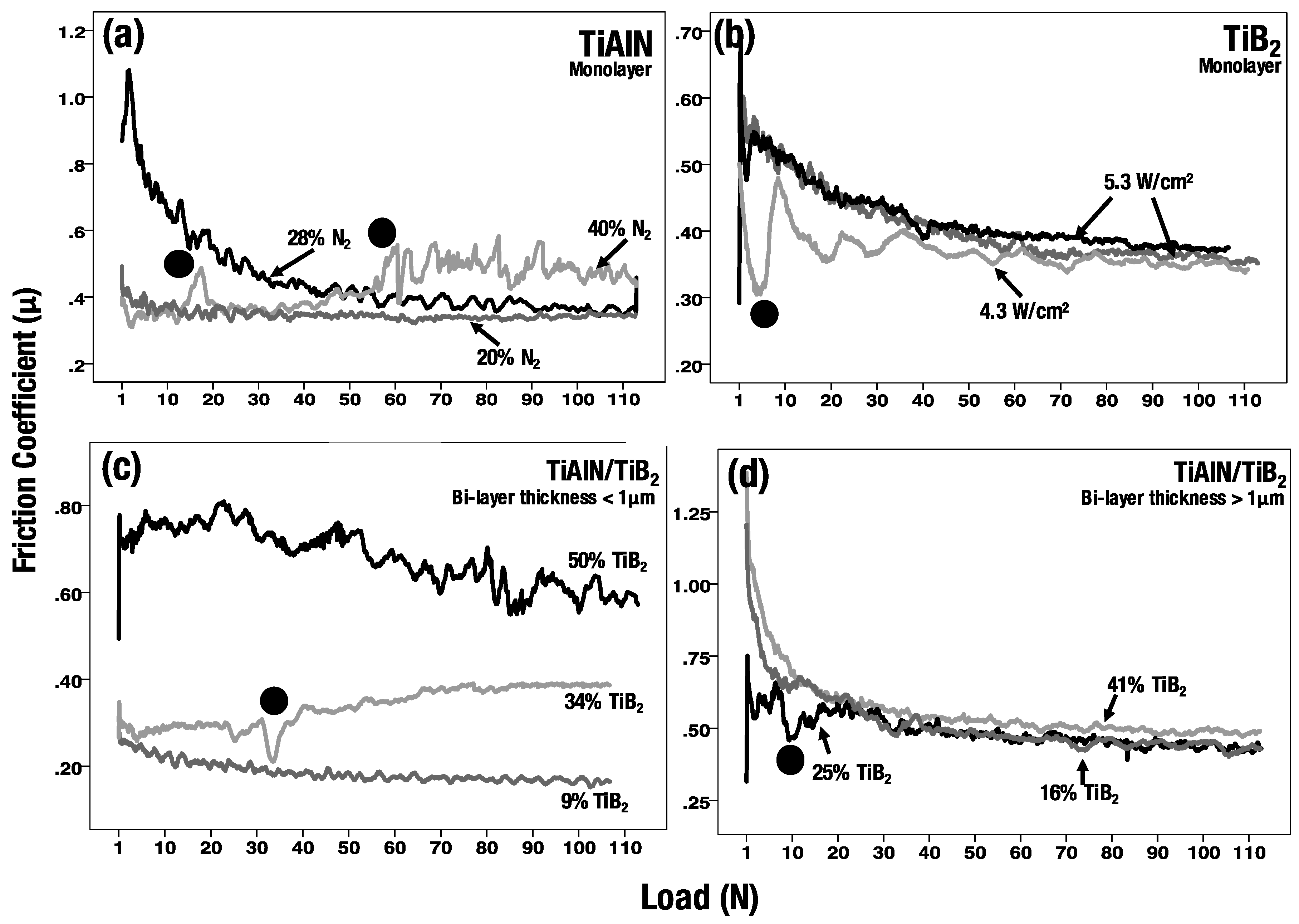

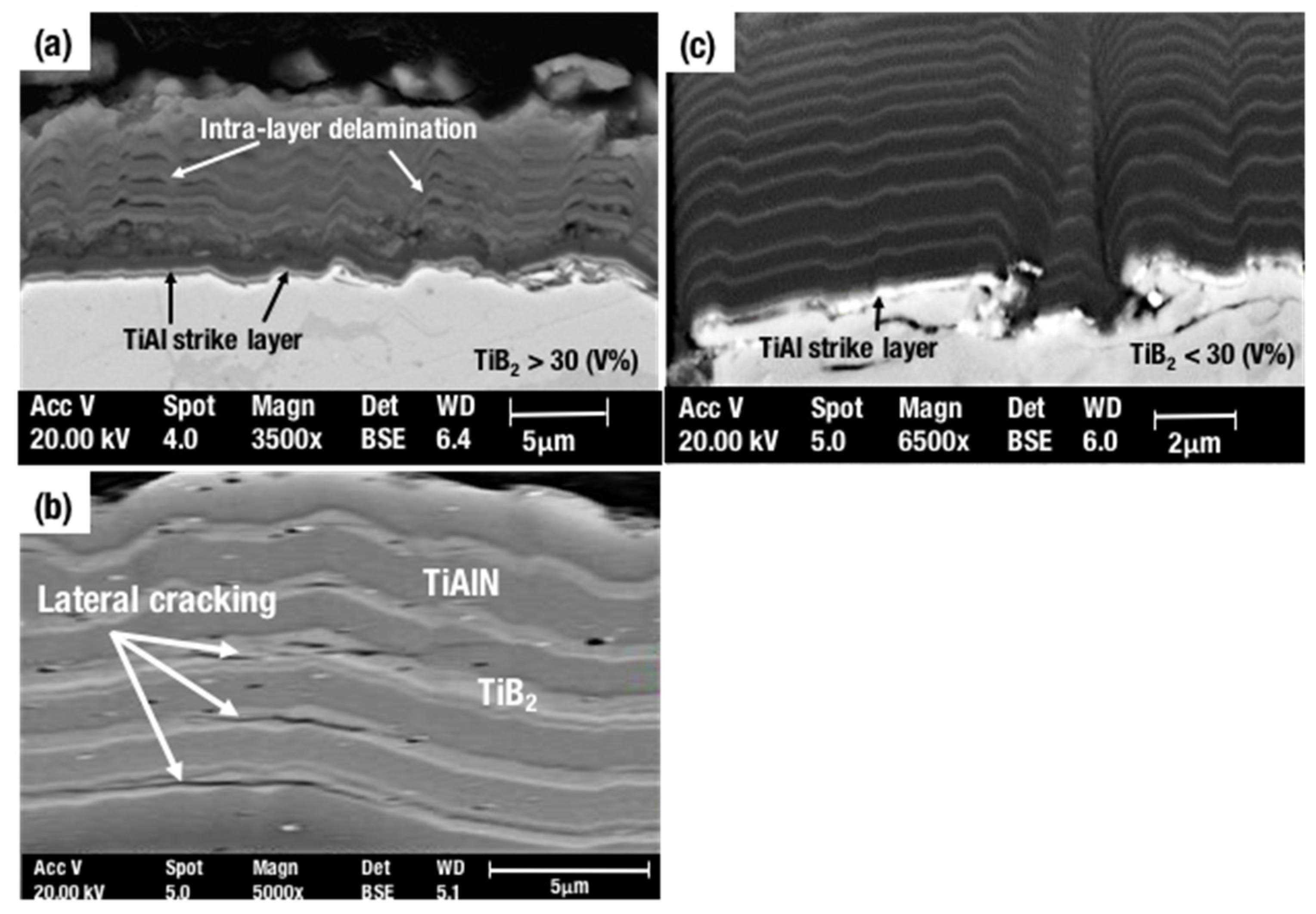

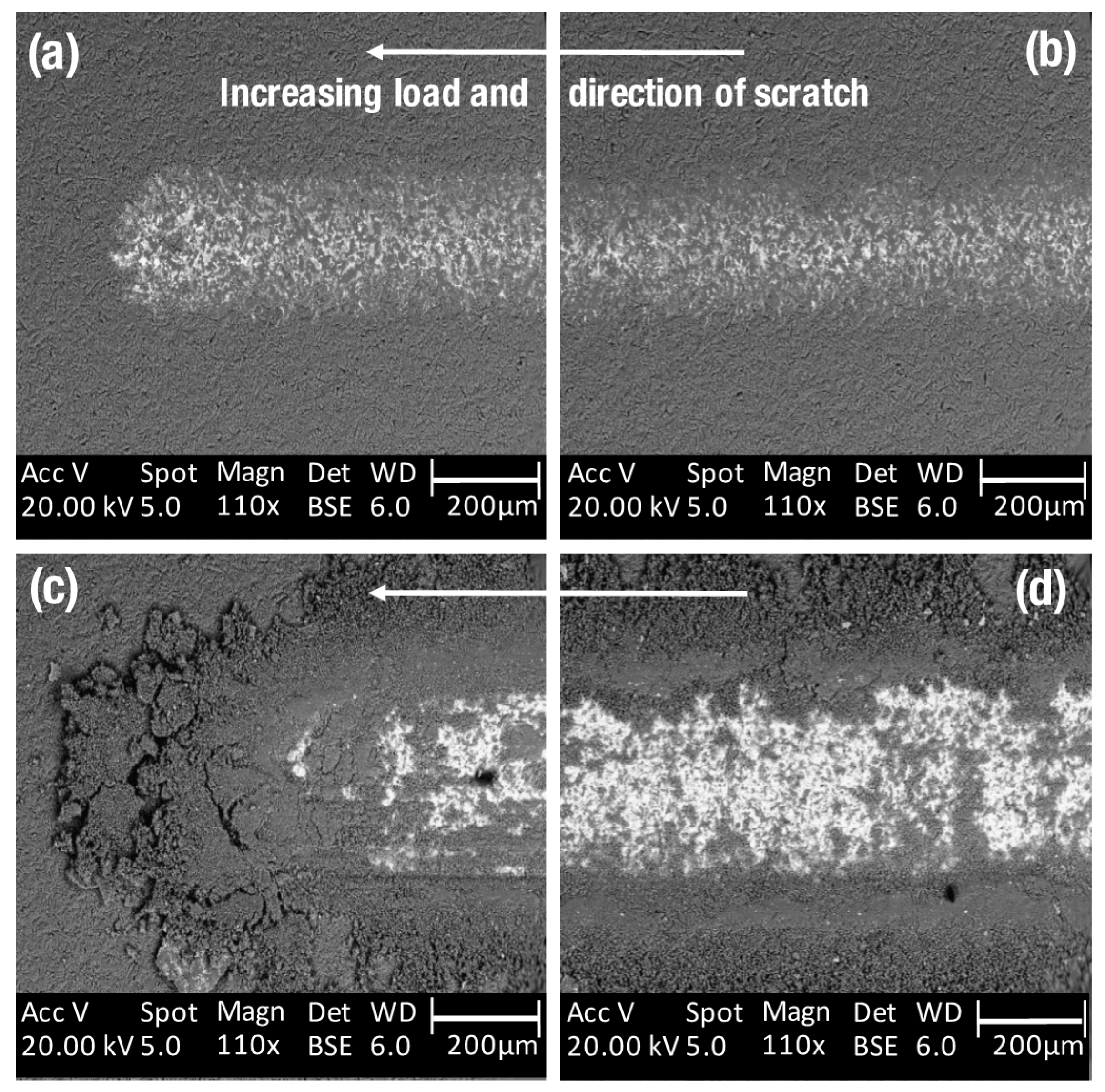

3.2. Tribological Characteristics

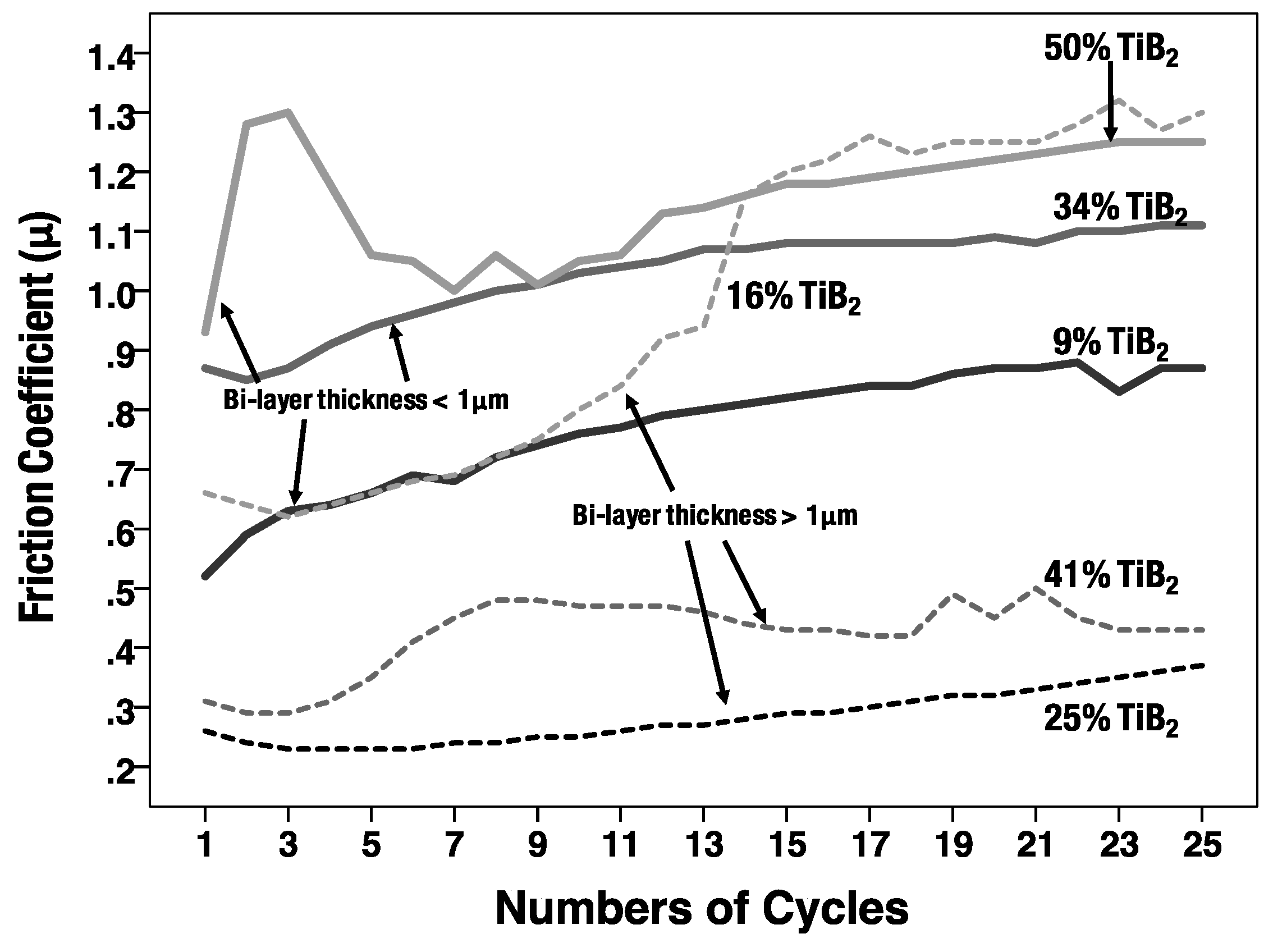

3.3. Multi-Pass, Bi-Directional Wear Studies

4. Conclusions

- X-ray diffraction showed the coatings to be predominately TiAlN orientated (200), with additional phases of TiN and Ti when the TiB2 content is 9%.

- Progressive-load scratch tests revealed a contrast in measured friction coefficients between multilayer coatings with bilayer thicknesses less-than and greater-than 1 μm. A coating containing 50% TiB2 and bilayer thicknesses <1 μm, the friction coefficients vary between 0.6 and 0.8 in contrast to around 0.2 for a coating containing 9% TiB2. For bilayer thicknesses >1 μm, the friction coefficients are around 0.5 over the entire load range of 110 N for all the TiB2 compositions measured.

- Bi-directional wear tests conducted at a constant load of 10 N show that the measured frictional coefficients are approximately 50% lower in coatings with a bilayer thickness >1 μm. This is due to the greater ability to distribute the stress within the layers.

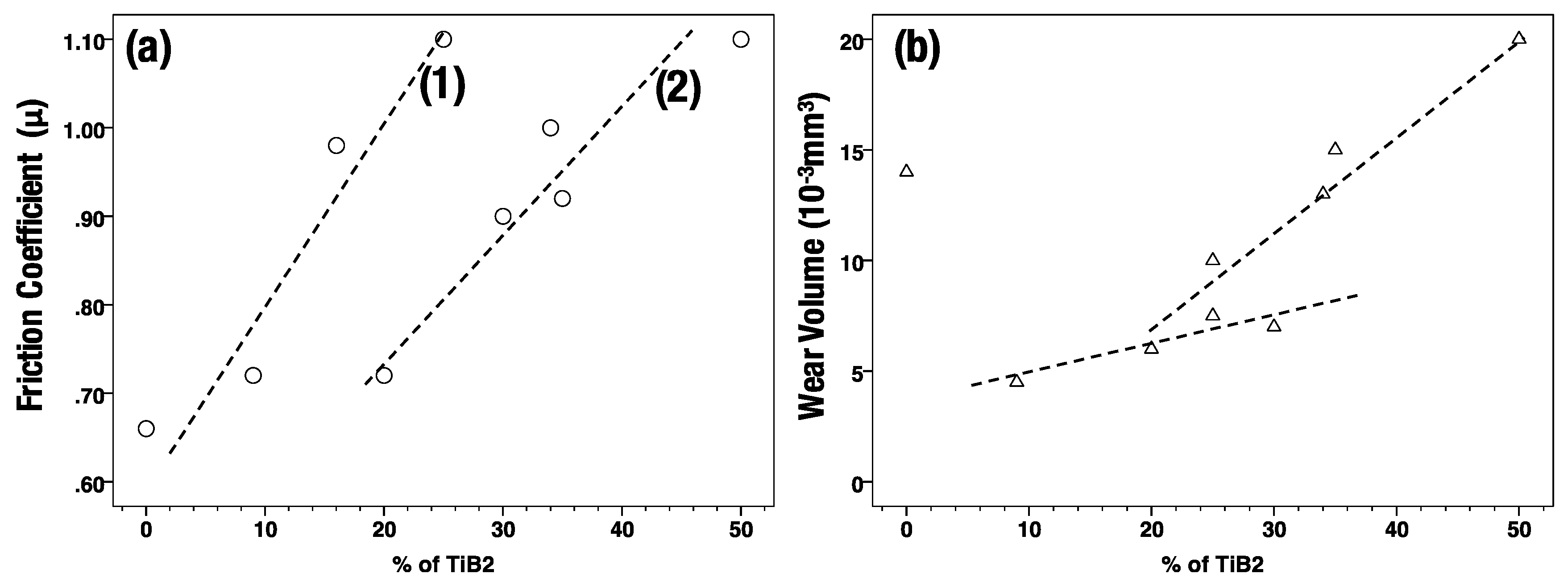

- There are two observed frictional coefficient regimes corresponding to a lower and high rate of material loss. At the lower regime, with TiB2 contents below 20%, material loss occurs mainly via delamination between the layers, whilst at compositions above this, material loss occurs via a break-up of material into finer particles that in combination with the load results in greater material loss.

- The measured wear scar volumes for a TiAlN/TiB2 multilayer coating containing 9% TiB2 is approximately three times lower than that measured on the substrate and half that of a monolayer TiAlN coating, thereby validating the increased wear resistance offered by this coating.

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Rao, J.; Rose, T.; Craig, M.; Nicholls, J.R. Wear Coatings for High Load Applications. Procedia CIRP 2014, 22, 277–280. [Google Scholar] [CrossRef]

- Nunes, V.; Silva, F.J.G.; Andrade, M.F.; Alexandre, R.; Baptista, A.P.M. Baptista, Increasing the lifespan of high-pressure die cast molds subjected to severe wear. Surf. Coat. Technol. 2017, 332, 319–331. [Google Scholar] [CrossRef]

- Prabakaran, V.; Sivakumaran, I.; Palimar, S.P. Experimental investigation of wear characteristics on TiCN-coated AISI 410 steel. Appl. Phys. A 2016, 122, 468. [Google Scholar] [CrossRef]

- Ikeda, T.; Satoh, H. Phase formation and characterization of hard coatings in the Ti-Al-N system prepared by the cathodic arc ion plating method. Thin Solid Films 1991, 195, 99–110. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Skrzypek, S.; Pakuła, D.; Mikuła, J.; Křiž, A. Influence of the PVD and CVD technologies on the residual macro-stresses and functional properties of the coated tool ceramics Manufacturing and processing Manufacturing and processing. J. Achiev. Mater. Manuf. Eng. 2009, 35, 162–168. [Google Scholar]

- Polvorosa, R.; Suarez, A.; de Lacalle, L.L.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Haubner, R.; Lessiak, M.; Pitonak, R.; Köpf, A.; Weissenbacher, R. Evolution of conventional hard coatings for its use on cutting tools. Int. J. Refract. Met. Hard Mater. 2017, 62, 210–218. [Google Scholar] [CrossRef]

- Rao, J.; Cruz, R.; Lawson, K.J.; Nicholls, J.R. Sputtered DLC-TiB2 multilayer films for tribological applications. Diam. Relat. Mater. 2005, 14, 1805–1809. [Google Scholar] [CrossRef]

- Baran, Ö.; Bidev, F.; Çiçek, H.; Kara, L.; Efeoğlu, İ.; Küçükömeroğlu, T. Investigation of the friction and wear properties of Ti/TiB2/MoS2 graded-composite coatings deposited by CFUBMS under air and vacuum conditions. Surf. Coat. Technol. 2014, 260, 310–315. [Google Scholar] [CrossRef]

- Gyawali, G.; Tripathi, K.; Joshi, B.; Lee, S.W. Mechanical and tribological properties of Ni-W-TiB2 composite coatings. J. Alloys Compd. 2017, 721, 757–763. [Google Scholar] [CrossRef]

- Smolik, J.; Gulde, M.; Walkowicz, J.; Suchanek, J. Influence of the structure of the composite: “Nitrided layer/PVD coating” on the durability of forging dies made of steel DIN-1.2367. Surf. Coat. Technol. 2004, 180–181, 506–511. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Lewis, D.B.; Luo, Q.; Münz, W.D.; Mayrhofer, P.H.; Mitterer, C.; Zhou, Z.; Rainforth, W.M. TiAlN based nanoscale multilayer coatings designed to adapt their tribological properties at elevated temperatures. Thin Solid Films 2005, 485, 160–168. [Google Scholar] [CrossRef]

- Fernández-Valdivielso, A.; López de Lacalle, L.N.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. Part C 2015, 230, 3725–3742. [Google Scholar] [CrossRef]

- Wong, M.S.; Lee, Y.C. Deposition and characterization of Ti–B–N monolithic and multilayer coatings. Surf. Coat. Technol. 1999, 120–121, 194–199. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Aramesh, M.; Attia, H.M.; Kishawy, H.A.; Balazinski, M. Observation of a unique wear morphology of cBN inserts during machining of titanium metal matrix composites (Ti-MMCs); leading to new insights into their machinability. Int. J. Adv. Manuf. Technol. 2017, 92, 519–530. [Google Scholar] [CrossRef]

- Munro, R.G. Material properties of titanium diboride. J. Res. Natl. Inst. Stand. Technol. 2000, 105, 709–720. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.D.; Yan, J.Y.; Zhang, S.; Xue, F.Y.; Liu, G.Q.; Li, D.J. Influence of modulation periods and modulation ratios on the structure and mechanical properties of nanoscale TiAlN/TiB2 multilayers prepared by IBAD. Vacuum 2012, 86, 949–952. [Google Scholar] [CrossRef]

- Yan, J.Y.; Sun, Y.D.; Li, D.J.; Liu, M.Y.; Dong, L.; Cao, M.; Gao, C.K.; Wang, N.; Deng, X.Y.; Gu, H.Q.; et al. High-temperature stability of TiAlN/TiB2 multilayers grown on Al2O3 substrates using IBAD. Surf. Coat. Technol. 2013, 229, 105–108. [Google Scholar] [CrossRef]

- Holleck, H.; Lahres, M.; Woll, P. Multilayer coatings—Influence of fabrication parameters on constitution and properties. Surf. Coat. Technol. 1990, 41, 179–190. [Google Scholar] [CrossRef]

- Holleck, H.; Schier, V. Multilayer PVD coatings for wear protection. Surf. Coat. Technol. 1995, 76–77, 328–336. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Prakash, M.S.; Jain, A.; Rajam, K.S. Structure, hardness and thermal stability of TiAlN and nanolayered TiAlN/CrN multilayer films. Vacuum 2005, 77, 169–179. [Google Scholar] [CrossRef]

- Cruz, R.; Rao, J.; Rose, T.; Lawson, K.; Nicholls, J.R. DLC-ceramic multilayers for automotive applications. Diam. Relat. Mater. 2006, 15, 2055–2060. [Google Scholar] [CrossRef]

- Rodríguez, C. Cutting Edge Preparation of Precision Cutting Tools by Applying Micro-Abrasive Jet Machining and Brushing; Kassel University Press GmbH: Kassel, Germany, 2009. [Google Scholar]

- Babu, S. A Material Based Approach to Creating Wear Resistant Surfaces for Hot Forging. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2004. [Google Scholar]

- Kim, C.K.; Shim, W.J. Analysis of contact force and thermal behaviour of lip seals. Tribol. Int. 1997, 30, 113–119. [Google Scholar]

- Fei, C.H.E.N.; Wang, T.M.; Chen, Z.N.; Feng, M.A.O.; Qiang, H.A.N.; Cao, Z.Q. Microstructure, mechanical properties and wear behaviour of Zn-Al-Cu-TiB2 in situ composites. Trans. Nonferr. Met. Soc. China 2015, 25, 103–111. [Google Scholar] [CrossRef]

- Kumar, S.; Chakraborty, M.; Sarma, V.S.; Murty, B.S. Tensile and wear behaviour of in situ Al–7Si/TiB2 particulate composites. Wear 2008, 265, 134–142. [Google Scholar] [CrossRef]

- Chen, J.S.; Wang, J.L. Diffusion Barrier Properties of Sputtered TiB2 between Cu and Si. J. Electrochem. Soc. 2000, 147, 1940–1944. [Google Scholar] [CrossRef]

- Shenoy, V.B.; Schwartzman, A.F.; Freund, L.B. Crack patterns in brittle thin films. Int. J. Fract. 2001, 109, 29–45. [Google Scholar] [CrossRef]

- Kimura, A.; Hasegawa, H.; Yamada, K.; Suzuki, T. Effects of Al content on hardness, lattice parameter and microstructure of Ti1–xAlxN films. Surf. Coat. Technol. 1999, 120–121, 438–441. [Google Scholar] [CrossRef]

- Cheng, Y.; Tay, B.; Lau, S.; Shi, X.; Chua, H. Deposition of (Ti, Al)N films by filtered cathodic vacuum arc. Thin Solid Films 2000, 379, 76–82. [Google Scholar] [CrossRef]

- Bujak, J.; Walkowicz, J.; Kusiński, J. Influence of the nitrogen pressure on the structure and properties of (Ti,Al)N coatings deposited by cathodic vacuum arc PVD process. Surf. Coat. Technol. 2004, 180, 150–157. [Google Scholar] [CrossRef]

- Obrosov, A.; Gulyaev, R.; Ratzke, M.; Volinsky, A.A.; Bolz, S.; Naveed, M.; Weiß, S. XPS and AFM Investigations of Ti-Al-N Coatings Fabricated Using DC Magnetron Sputtering at Various Nitrogen Flow Rates and Deposition Temperatures. Metals 2017, 7, 52. [Google Scholar] [CrossRef]

- Oliveira, J.C.; Manaia, A.; Cavaleiro, A. Hard amorphous Ti-Al-N coatings deposited by sputtering. Thin Solid Films 2008, 516, 5032–5038. [Google Scholar] [CrossRef]

- Wang, X.; Kwon, P.Y.; Schrock, D. Friction coefficient and sliding wear of AlTiN coating under various lubrication conditions. Wear 2013, 304, 67–76. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H. Tribological oxidation behaviour of PVD hard coatings. Tribol. Int. 2009, 42, 1758–1764. [Google Scholar] [CrossRef]

- Ramadoss, R.; Kumar, N.; Pandian, R.; Dash, S.; Ravindran, T.R.; Arivuoli, D.; Tyagi, A.K. Tribological properties and deformation mechanism of TiAlN coating sliding with various counterbodies. Tribol. Int. 2013, 66, 143–149. [Google Scholar] [CrossRef]

- Tillmann, W.; Vogli, E.; Momeni, S. Mechanical and tribological properties of Ti/TiAlN duplex coatings on high and low alloy tool steels. Vacuum 2009, 84, 387–392. [Google Scholar] [CrossRef]

- Yao, S.H.; Su, Y.L.; Kao, W.H.; Liu, T.H. Tribology and oxidation behavior of TiN/AlN nano-multilayer films. Tribol. Int. 2006, 39, 332–341. [Google Scholar] [CrossRef]

- Sun, Y.D.; Li, D.J.; Gao, C.K.; Wang, N.; Yan, J.Y.; Dong, L.; Cao, M.; Deng, X.Y.; Gu, H.Q.; Wan, R.X. The effect of annealing on hardness, residual stress, and fracture resistance determined by modulation ratios of TiB2/TiAlN multilayers. Surf. Coat. Technol. 2013, 228, S385–S388. [Google Scholar] [CrossRef]

| Bilayer Thickness Period | Sample ID | Coating Thickness (μm) | Bilayer Thickness λ (μm) | Volume Fraction TiB2 (%) | Critical Load (N) LC ± 0.25% | Friction Coefficient (μ) |

|---|---|---|---|---|---|---|

| λ < 1 μm | A1 | 6 | 0.3 | 50 | 25 | 0.60 |

| A2 | 5.5 | 0.35 | 30 | 48 | 0.40 | |

| A3 | 8 | 0.4 | 34 | 40 | 0.35 | |

| A4 | 5.5 | 0.5 | 35 | 45 | 0.40 | |

| A5 | 6.5 | 0.7 | 9 | 70 | 0.20 | |

| λ > 1 μm | B1 | 10 | 1.3 | 41 | 40 | 0.5 |

| B2 | 6.3 | 1.1 | 20 | 63 | 0.45 | |

| B3 | 18 | 2.7 | 25 | 8 | 0.45 | |

| B4 | 7 | 2.4 | 16 | 80 | 0.4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, J.; Sharma, A.; Rose, T. Titanium Aluminium Nitride and Titanium Boride Multilayer Coatings Designed to Combat Tool Wear. Coatings 2018, 8, 12. https://doi.org/10.3390/coatings8010012

Rao J, Sharma A, Rose T. Titanium Aluminium Nitride and Titanium Boride Multilayer Coatings Designed to Combat Tool Wear. Coatings. 2018; 8(1):12. https://doi.org/10.3390/coatings8010012

Chicago/Turabian StyleRao, Jeff, Amit Sharma, and Tim Rose. 2018. "Titanium Aluminium Nitride and Titanium Boride Multilayer Coatings Designed to Combat Tool Wear" Coatings 8, no. 1: 12. https://doi.org/10.3390/coatings8010012

APA StyleRao, J., Sharma, A., & Rose, T. (2018). Titanium Aluminium Nitride and Titanium Boride Multilayer Coatings Designed to Combat Tool Wear. Coatings, 8(1), 12. https://doi.org/10.3390/coatings8010012