Effect of Waveform and Heat Treatment Processes on the Performance of Electrodeposited Co-P Coating

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

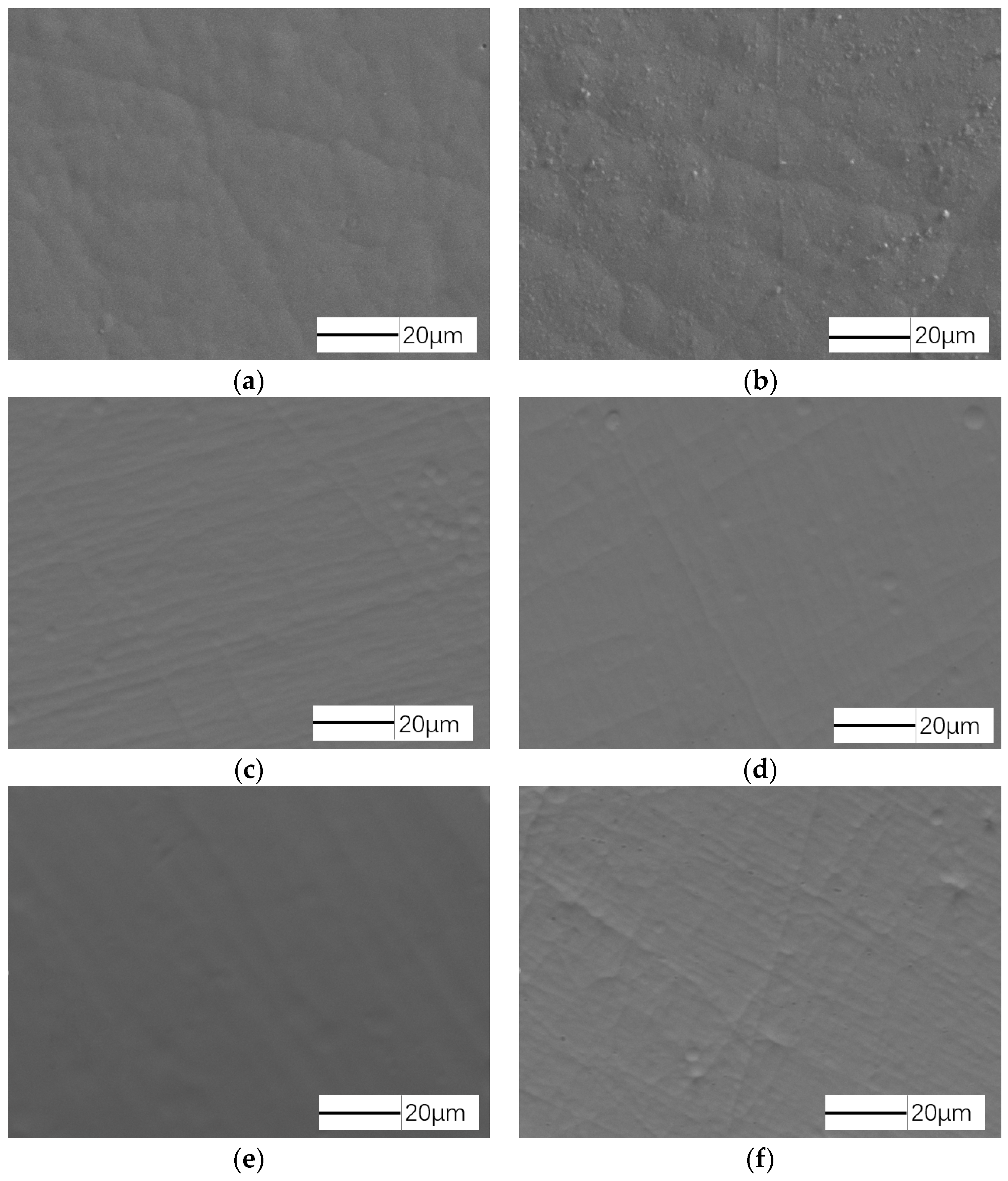

3.1. Surface Morphology of Co-P Coatings

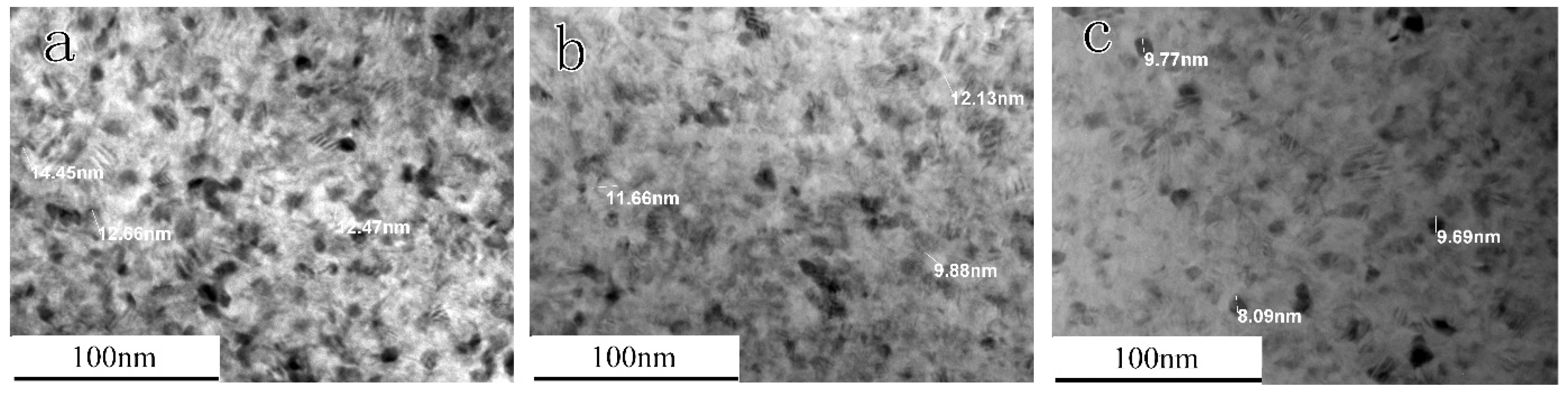

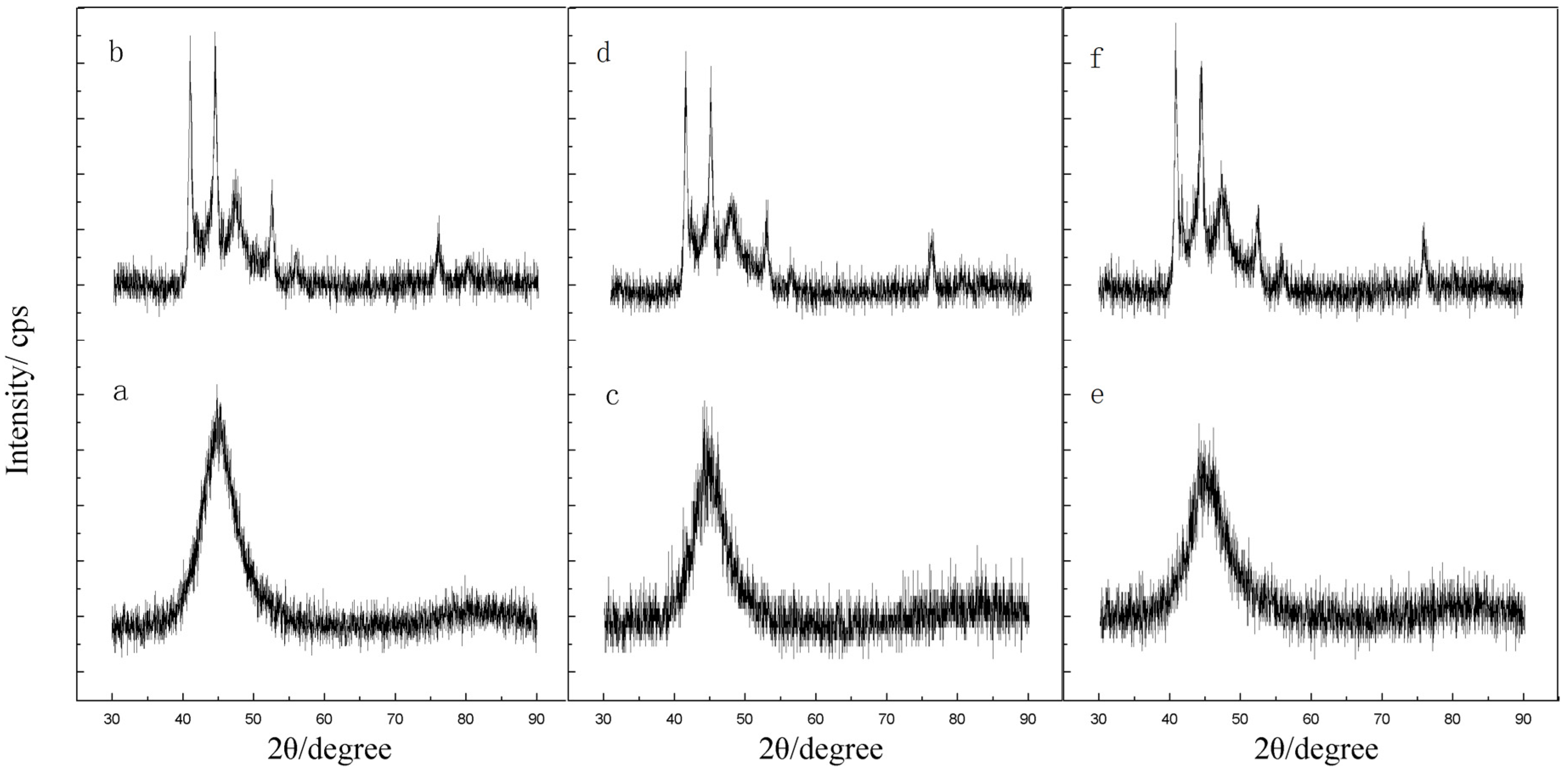

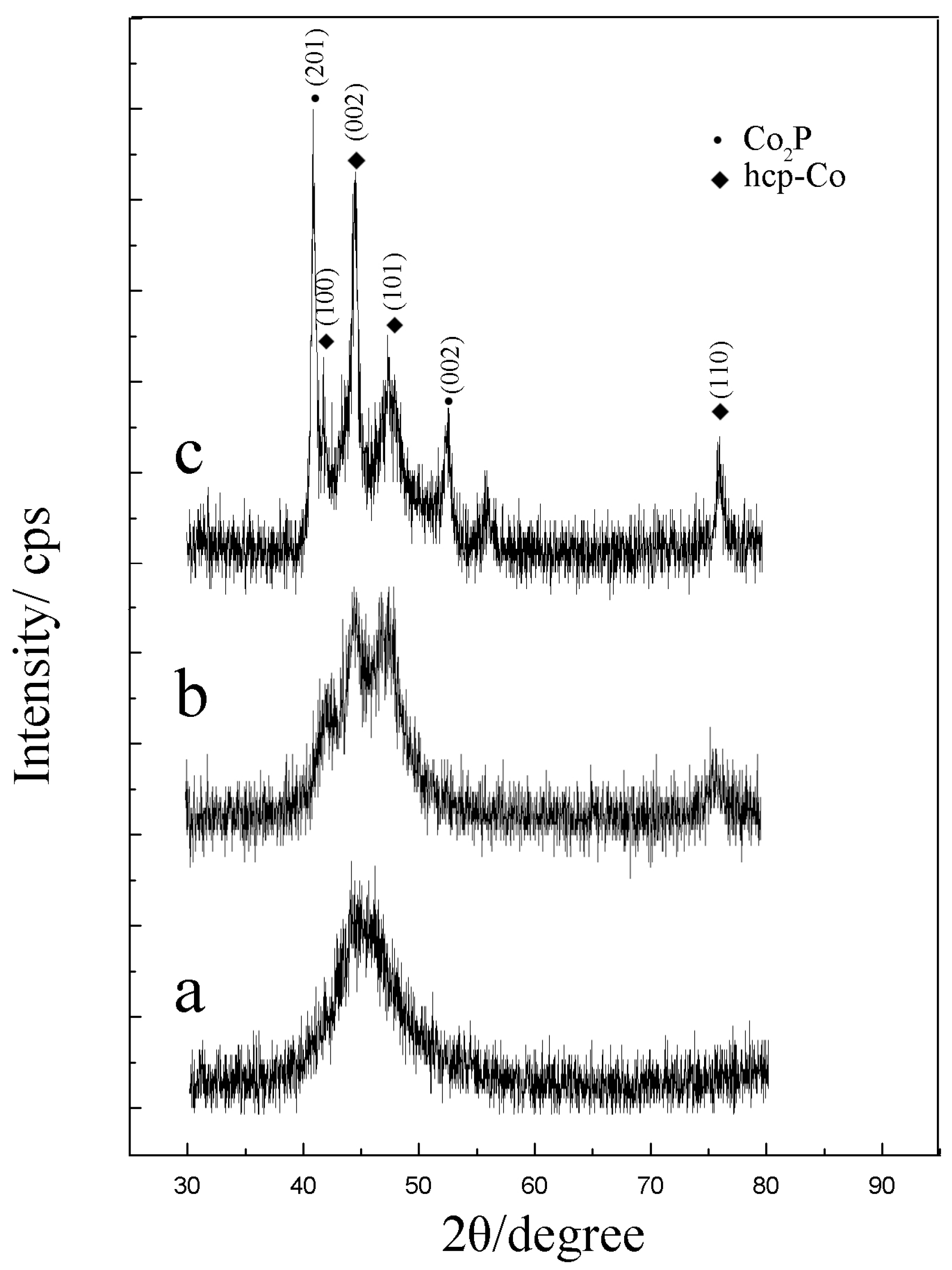

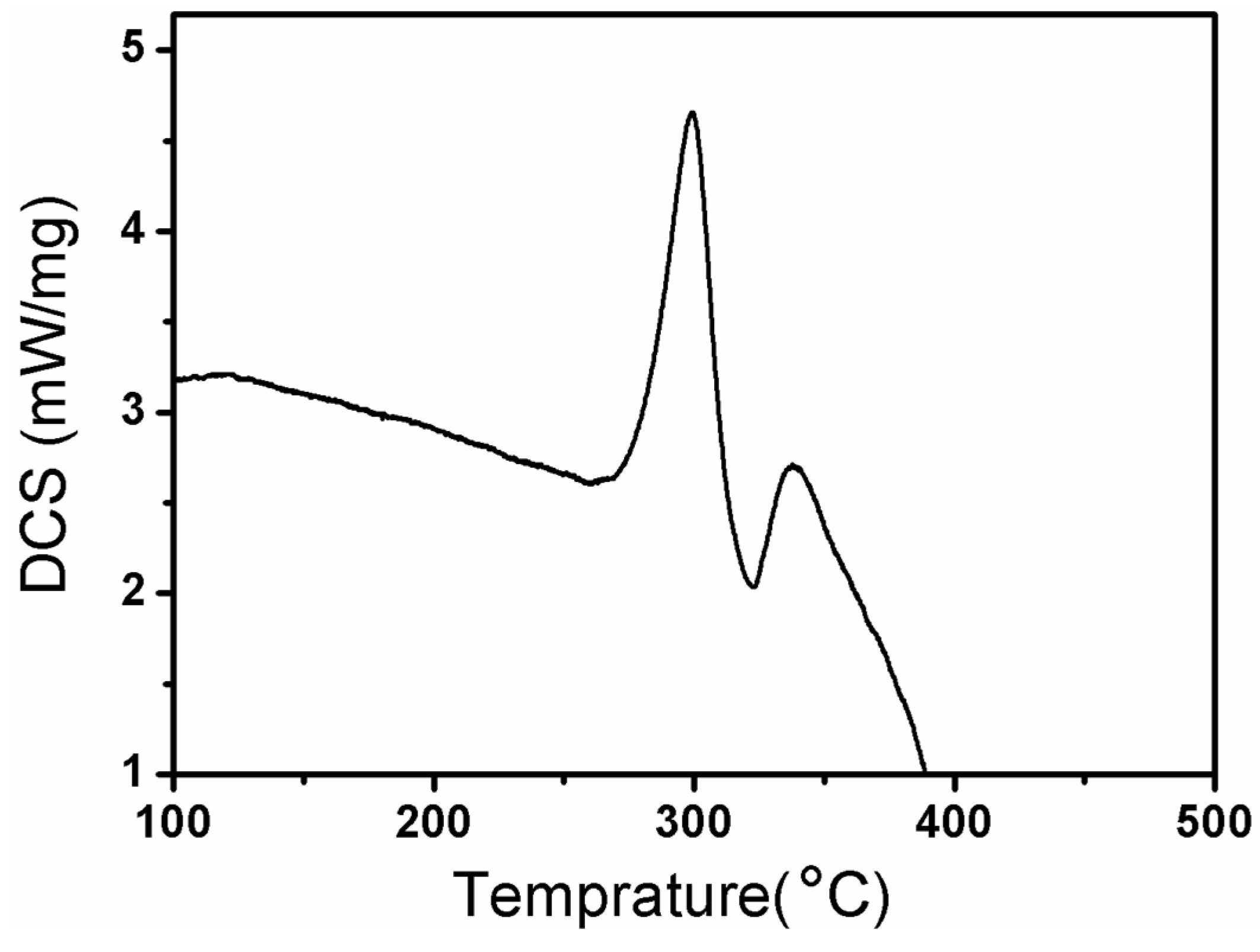

3.2. Effect of Heat Treatment on the Phase Structure of Co-P Coatings

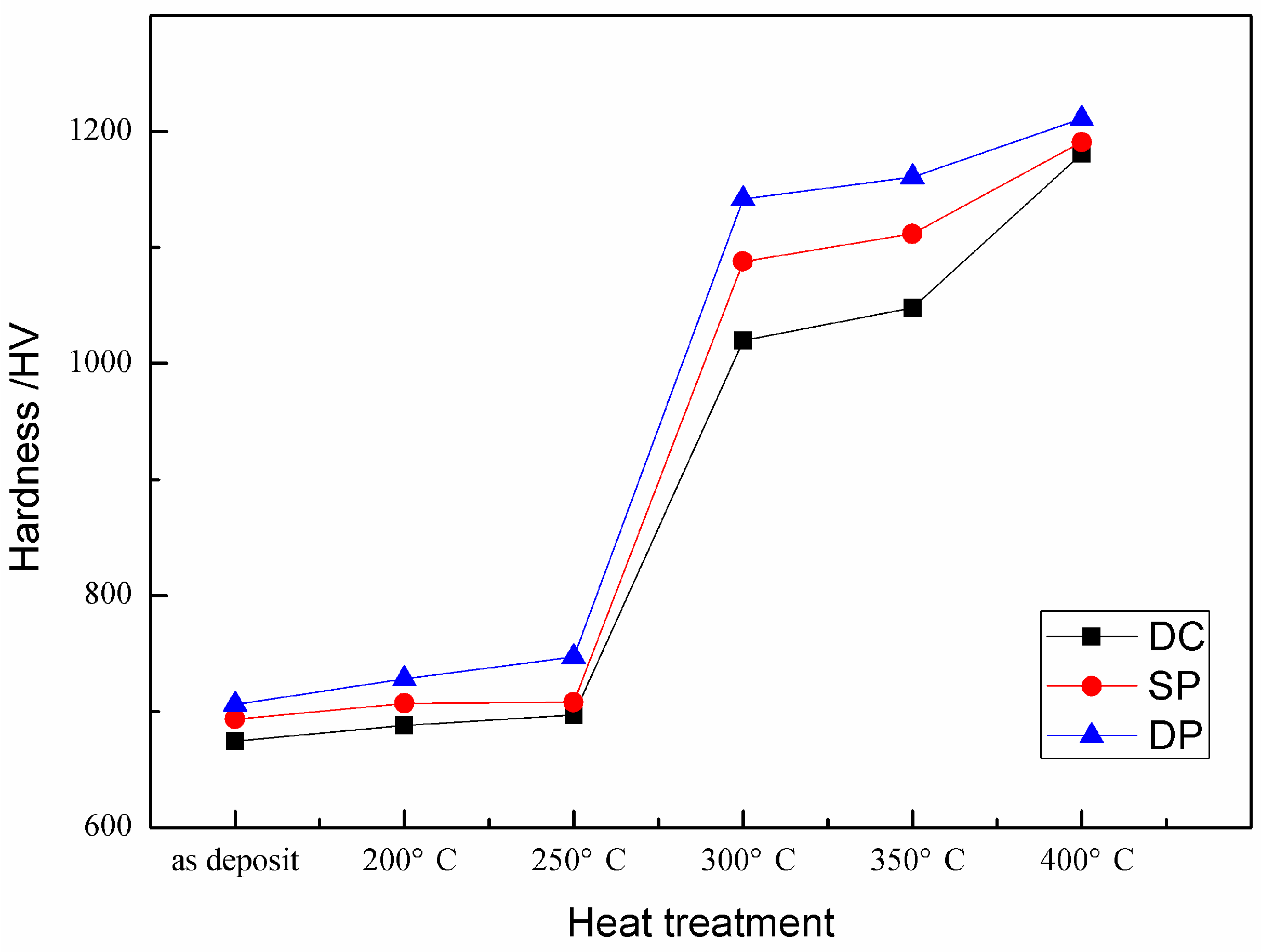

3.3. Effect of the Heat Treatment Temperature on Microhardness of Co-P Coatings

3.4. Effect of Heat Treatment on the Wear Resistance of Co-P Coatings

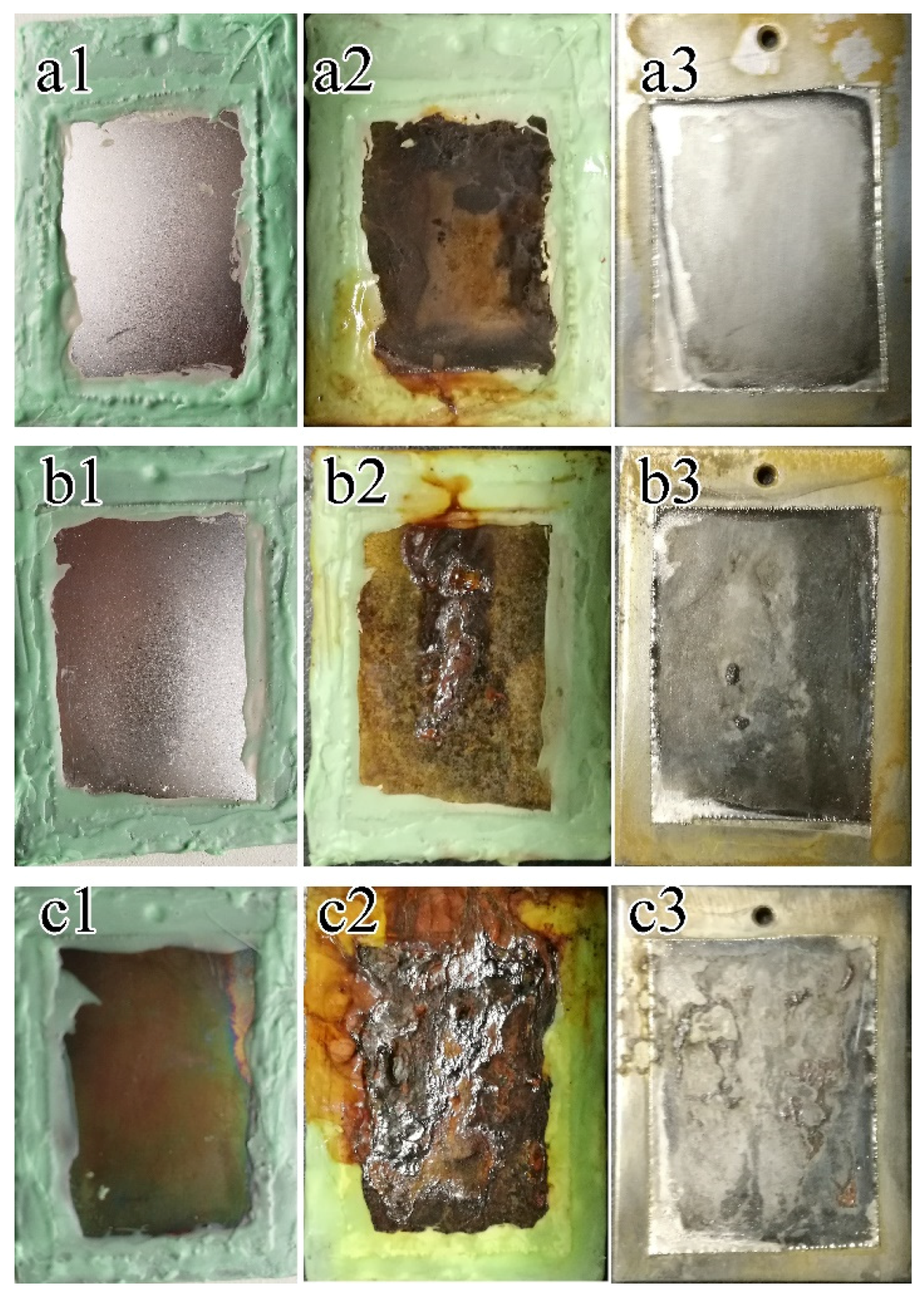

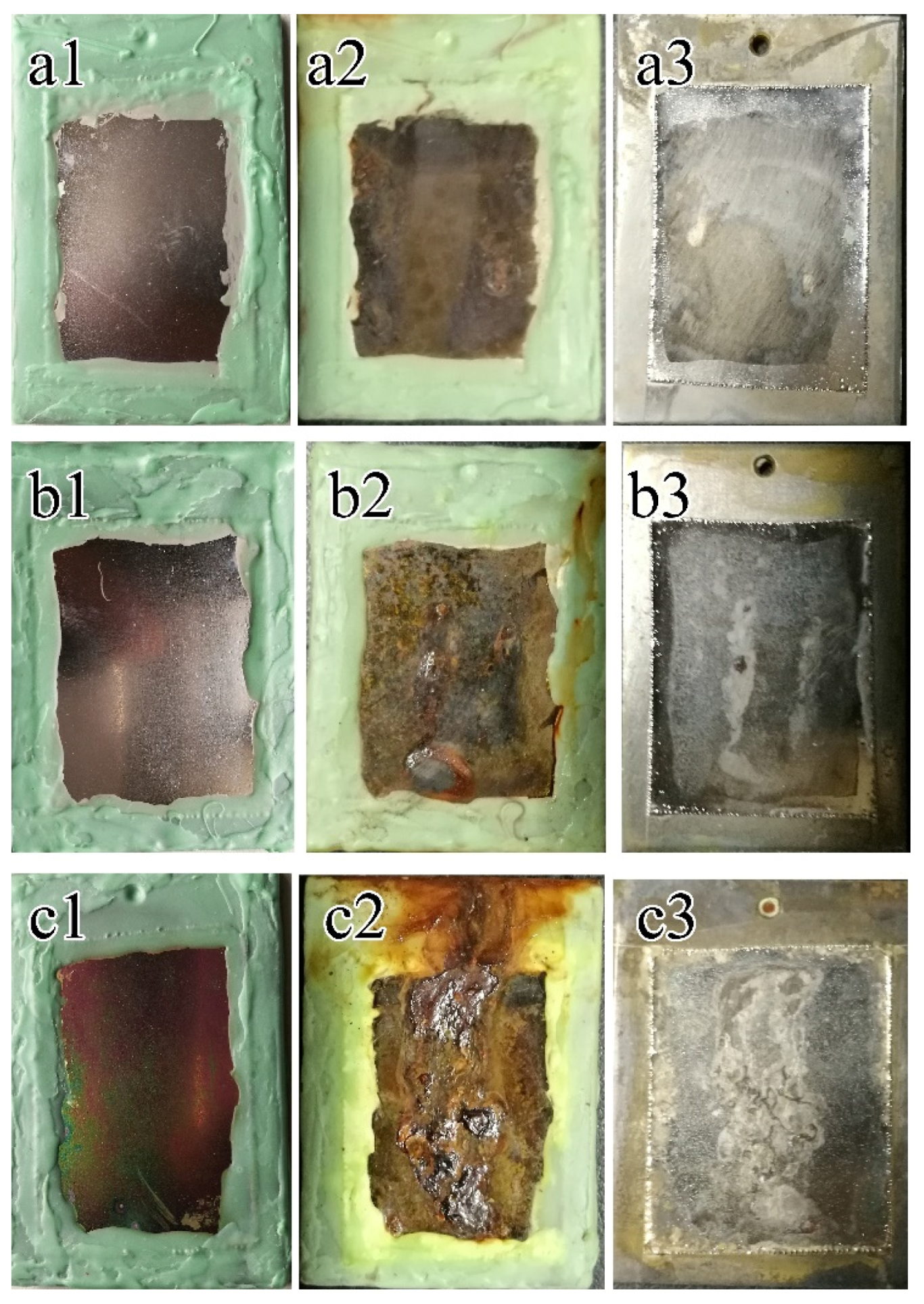

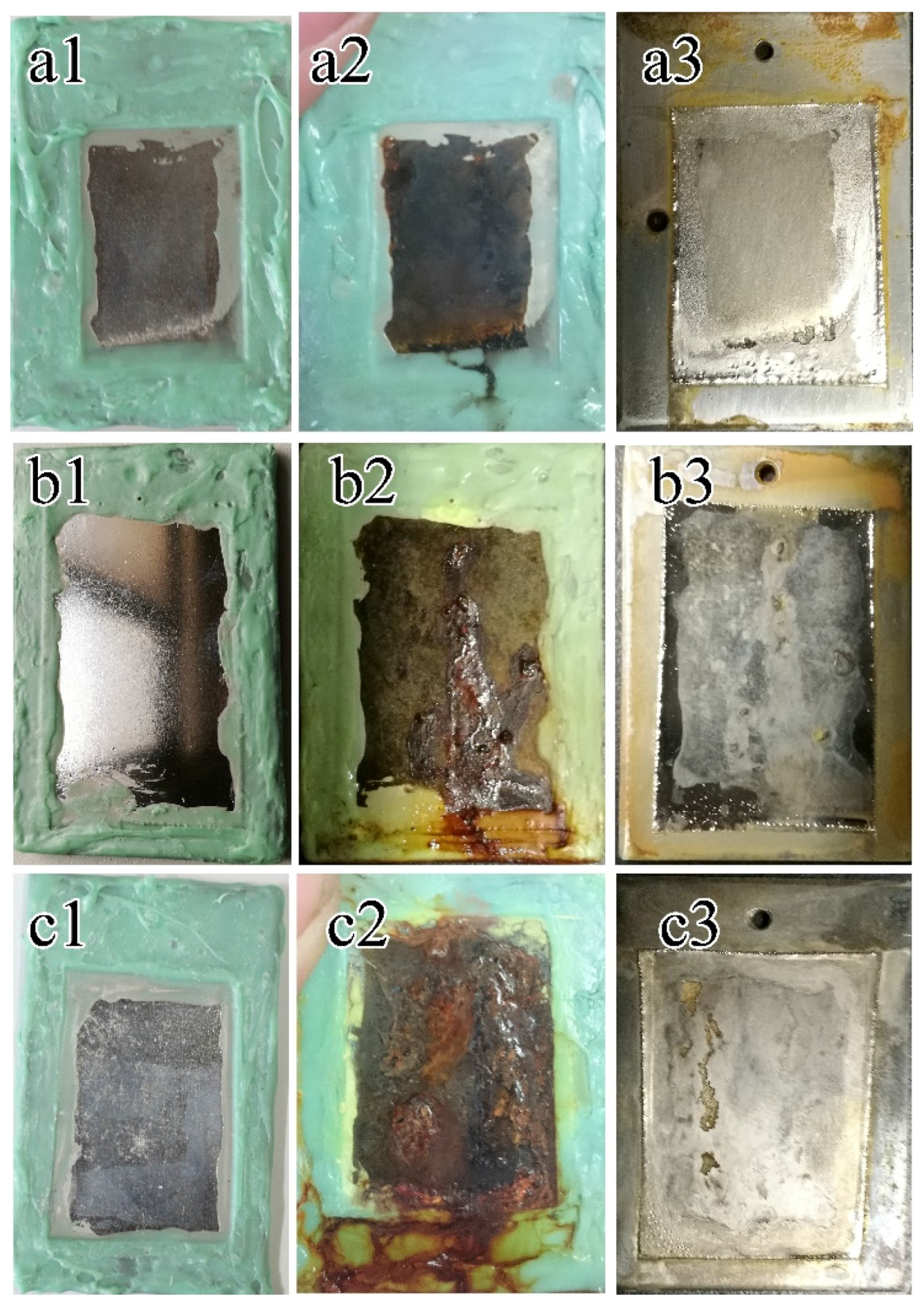

3.5. Effect of Heat Treatment on the Corrosion Resistance of Co-P Coatings

4. Conclusions

- Smooth and dense Co-P amorphous coatings could be deposited under direct, single pulse and double pulse current respectively on carbon steel substrate, with P content of 9.6, 8.9 and 9.1 wt %, respectively. The coating structure deposited under double pulse current was among the highest in terms of smoothness and density levels.

- Co-P coatings deposited under different currents transformed from an amorphous to hexagonal close packed structure at 299 °C. Co2P compounds were formed at 340 °C. Coatings deposited under DC, SP and DP currents became nanocrystalline structures after heat treatment at 400 °C and the grain size was 12–13 nm, 10–12 nm and 8–10 nm, respectively.

- Under all conditions, the microhardness of the coatings decreased progressively in the order: DP > SP > DC. Microhardness of the coatings deposited under DP was 706 HV; it rose to 1211 HV after heat treatment at 400 °C, which was higher than that of hard chromium.

- The wear rate of Co-P coatings was 4 × 10−6–5 × 10–6 mm3/N m, which was lower than that of hard chromium.

- After 1000 h of a neutral salt spray test, the Co-P coatings deposited under different currents with a thickness of ca. 40 μm showed no visible corrosion pits. However, coatings treated at 300 and 400 °C reached grade 7–8 and 4–5, respectively after 1000 h test. The results were better than those obtained for hard chromium.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Facchini, D.; Mahalanobis, N.; Gonzalez, F.; Palumbo, G. Electrodeposition of nanocrystalline cobalt alloy coatings as a hard chrome alternative. In Proceedings of the DoD Corrosion Conference, Washington, DC, USA, 12–14 August 2009. [Google Scholar]

- Hazra, S.; Sabiruddin, K.; Bandyopadhyay, P.P. Plasma and HVOF sprayed WC-Co coatings as hard chrome replacement solution. Surf. Eng. 2012, 28, 37–43. [Google Scholar] [CrossRef]

- Wasekar, N.P.; Sundararajan, G. Sliding wear behavior of electrodeposited Ni-W alloy and hard chrome coatings. Wear 2015, 342, 340–348. [Google Scholar] [CrossRef]

- Houdkova, S.; Zahalka, F.; Kasparova, M.; Berger, L.M. Comparative study of thermally sprayed coatings under different types of wear conditions for hard chromium replacement. Tribol. Lett. 2011, 43, 139–154. [Google Scholar] [CrossRef]

- Zhang, J.F.; Liu, M.; Zhou, K.S.; Deng, C.G.; Deng, C.M.; Song, J.B. Tribological behavior of HVOF cermet coatings as alternative to Cr-plating in artificial salt-fog atmosphere. Rare Metal Mater. Eng. 2016, 45, 2492–2497. [Google Scholar]

- Kong, D.J.; Wang, J.C.; Fu, G.Z.; Liu, H. Friction and wear performances of Ni-P coatings by chemical plating after crystallization treatment. Rare Metal Mater. Eng. 2015, 44, 1314–1319. [Google Scholar]

- Kosta, I.; Imaz, N.; Cinca, N.; García-Lecina, E.; Sarret, M.; Müller, C. Pulse plated CoP alloy as substitute for hard chromium electrodeposits. Trans. Inst. Metal Finish. 2012, 90, 252–258. [Google Scholar] [CrossRef]

- Prado, R.; Facchini, D.; Mahalanobis, N.; Gonzalez, F.; Palumbo, G. nCoP takes the hex out of crome plating products finishing. Prod. Finish. 2012, 77, 14–18. [Google Scholar]

- Zeinali-Rad, M.; Allahkaram, S.R.; Mahdavi, S. Effect of pH, surfactant, and heat treatment on morphology, structure, and hardness of electrodeposited Co-P coatings. J. Mater. Eng. Perform. 2015, 24, 3209–3217. [Google Scholar] [CrossRef]

- Ezhilselvi, V.; Seenivasan, H.; Bera, P.; Anandan, C. Characterization and corrosion behavior of Co and Co-P coatings electrodeposited from chloride bath. RSC Adv. 2014, 4, 46293–46304. [Google Scholar] [CrossRef]

- Kosta, I.; Sarret, M.; Müller, C. Structure, microhardness and corrosion behaviour of nanostructured CoP coatings obtained by direct current and pulse plating. Electrochim. Acta 2013, 114, 819–826. [Google Scholar] [CrossRef]

- Silva, M.D.; Wille, C.; Klement, U.; Choi, P.; Al-Kassab, T. Electrodeposited nanocrystalline Co-P alloys: Microstructural characterization and thermal stability. Mater. Sci. Eng. A 2007, 445–446, 31–39. [Google Scholar] [CrossRef]

- Choi, P.; Da Silva, M.; Klement, U.; Al-Kassab, T.; Kirchheim, R. Thermal stability of electrodeposited nanocrystalline Co-1.1 at. % P. Acta Mater. 2005, 53, 4473–4481. [Google Scholar] [CrossRef]

- Kosta, I.; Vallés, E.; Gómez, E.; Sarret, M.; Müller, C. Nanocrystalline CoP coatings prepared by different electrodeposition techniques. Mater. Lett. 2011, 65, 2849–2851. [Google Scholar] [CrossRef]

- Bera, P.; Seenivasan, H.; Rajam, K.S.; Grips, V.K.W. Characterization of amorphous Co-P alloy coatings electrodeposited with pulse current using gluconate bath. Appl. Surf. Sci. 2012, 258, 9544–9553. [Google Scholar] [CrossRef]

- Seenivasan, H.; Bera, P.; Rajam, K.; Parida, S.K. Characterization and hardness of Co-P coatings obtained from direct current electrodeposition using gluconate bath. Surf. Rev. Lett. 2013, 20, 549–555. [Google Scholar] [CrossRef]

- GB/T 10125-2012 Corrosion Tests in Artificial Atmospheres—Salt Spray Tests; General Administration of Quality Supervision, Inspection & Quarantine of the People’s Republic of China (AQSIQ); Standardization Administration of the People’s Republic of China: Beijing, China, 2012.

- GB/T 6461-2002 Methods for Corrosion Testing of Metallic and Other Inorganic Coatings on Metallic Substrates-Rating of Test Specimens and Manufactured Articles Subjected to Corrosion Tests; General Administration of Quality Supervision, Inspection & Quarantine of the People’s Republic of China (AQSIQ); Standardization Administration of the People’s Republic of China: Beijing, China, 2002.

- Jung, H.; Alfantazi, A. An electrochemical impedance spectroscopy and polarization study of nanocrystalline Co and Co-P alloy in 0.1M H2SO4 solution. Electrochim. Acta 2006, 51, 1806–1814. [Google Scholar] [CrossRef]

- Sheikholeslam, M.A.; Raeissi, K.; Enayati, M.H. Study on corrosion behaviour of nanocrystalline and amorphous Co-P electrodeposits. Trans. Inst. Metal Finish. 2010, 88, 324–329. [Google Scholar] [CrossRef]

- Chokshi, A.H.; Rosen, A.; Karch, J.; Gleiter, H. On the validity of the hall-petch relationship in nanocrystalline materials. Scr. Metall. 1989, 23, 1679–1683. [Google Scholar] [CrossRef]

- Ganavati, B.; Kukareko, V.A.; Tsybul’Skaya, L.S.; Perevoznikov, S.S. Structural state and tribological properties of Co-P coatings. Phys. Metals Metallogr. 2014, 115, 1037–1045. [Google Scholar] [CrossRef]

| Parameter | Value | ||

|---|---|---|---|

| DC | SP | DP | |

| j+peak (A dm−2) | 5 | +50 | +50 |

| Positive duty cycle | – | 10% | 10% |

| j−peak (A dm−2) | – | – | −5 |

| Negative duty cycle | – | – | 5% |

| Frequence | – | 5000 Hz | 5000 Hz |

| Temperature | 50 °C | ||

| Anode | Co plate (Co > 99%) | ||

| pH | 1.2–2.2 | ||

| Current | As Deposited (10−6 mm3/N m) | 300 °C Treated (10−6 mm3/N m) | 400 °C Treated (10−6 mm3/N m) |

|---|---|---|---|

| DC | 4.47 | 4.52 | 4.84 |

| SP | 4.83 | 4.82 | 4.00 |

| DP | 4.51 | 4.87 | 4.56 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Qian, J.; Hu, X. Effect of Waveform and Heat Treatment Processes on the Performance of Electrodeposited Co-P Coating. Coatings 2017, 7, 146. https://doi.org/10.3390/coatings7090146

Chen X, Qian J, Hu X. Effect of Waveform and Heat Treatment Processes on the Performance of Electrodeposited Co-P Coating. Coatings. 2017; 7(9):146. https://doi.org/10.3390/coatings7090146

Chicago/Turabian StyleChen, Xiaomei, Jiangang Qian, and Xiaotian Hu. 2017. "Effect of Waveform and Heat Treatment Processes on the Performance of Electrodeposited Co-P Coating" Coatings 7, no. 9: 146. https://doi.org/10.3390/coatings7090146

APA StyleChen, X., Qian, J., & Hu, X. (2017). Effect of Waveform and Heat Treatment Processes on the Performance of Electrodeposited Co-P Coating. Coatings, 7(9), 146. https://doi.org/10.3390/coatings7090146