Antimicrobial Films Based on Chitosan and Methylcellulose Containing Natamycin for Active Packaging Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Films

2.3. Film Thickness Measurement

2.4. Experimental Procedure for Kinetics of Natamycin Release

HPLC-DAD Analysis

2.5. Diffusion Coefficient (D) and Partition Coefficient (K) Measurement

2.6. Microbiological Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. Film Appearance Characterization

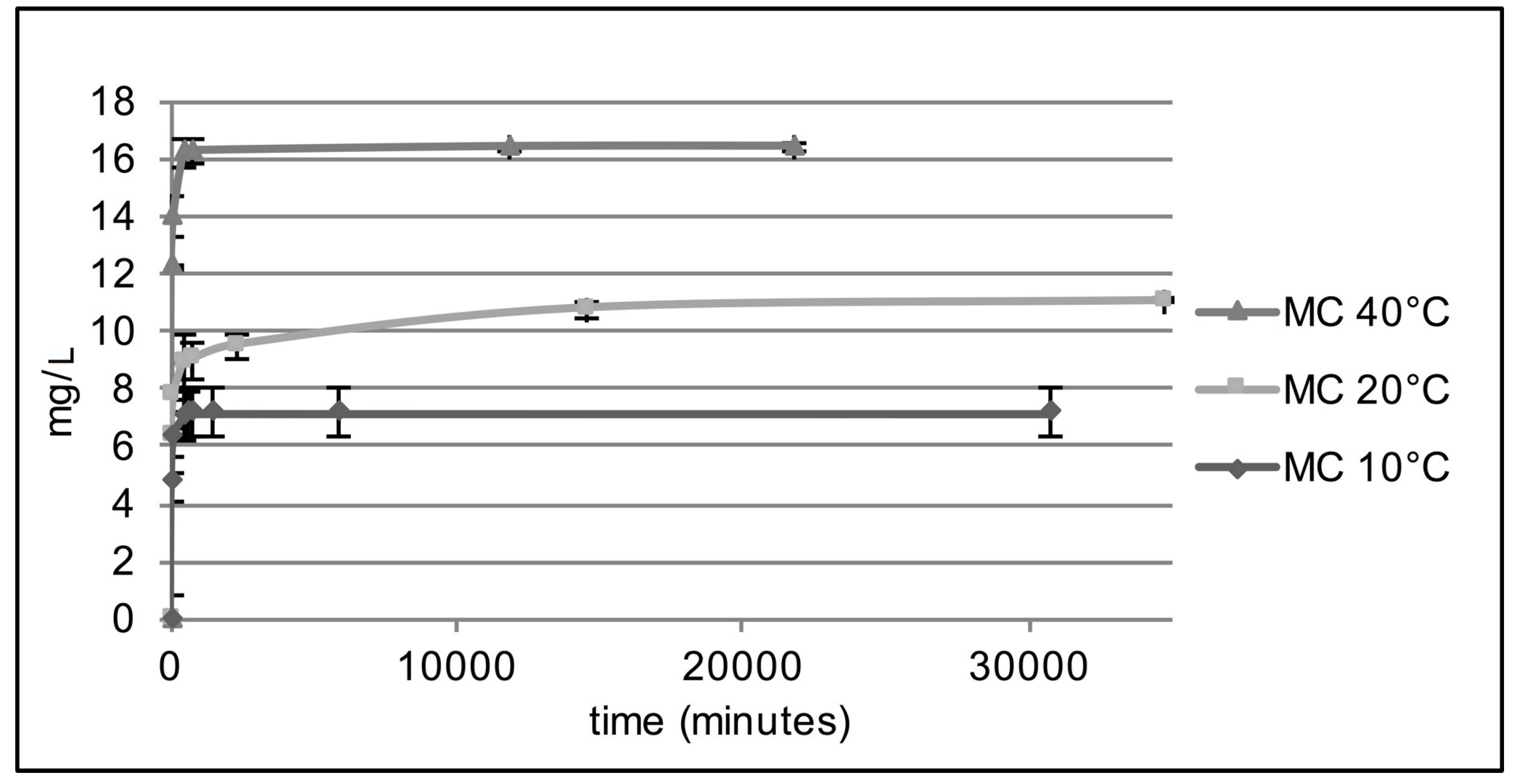

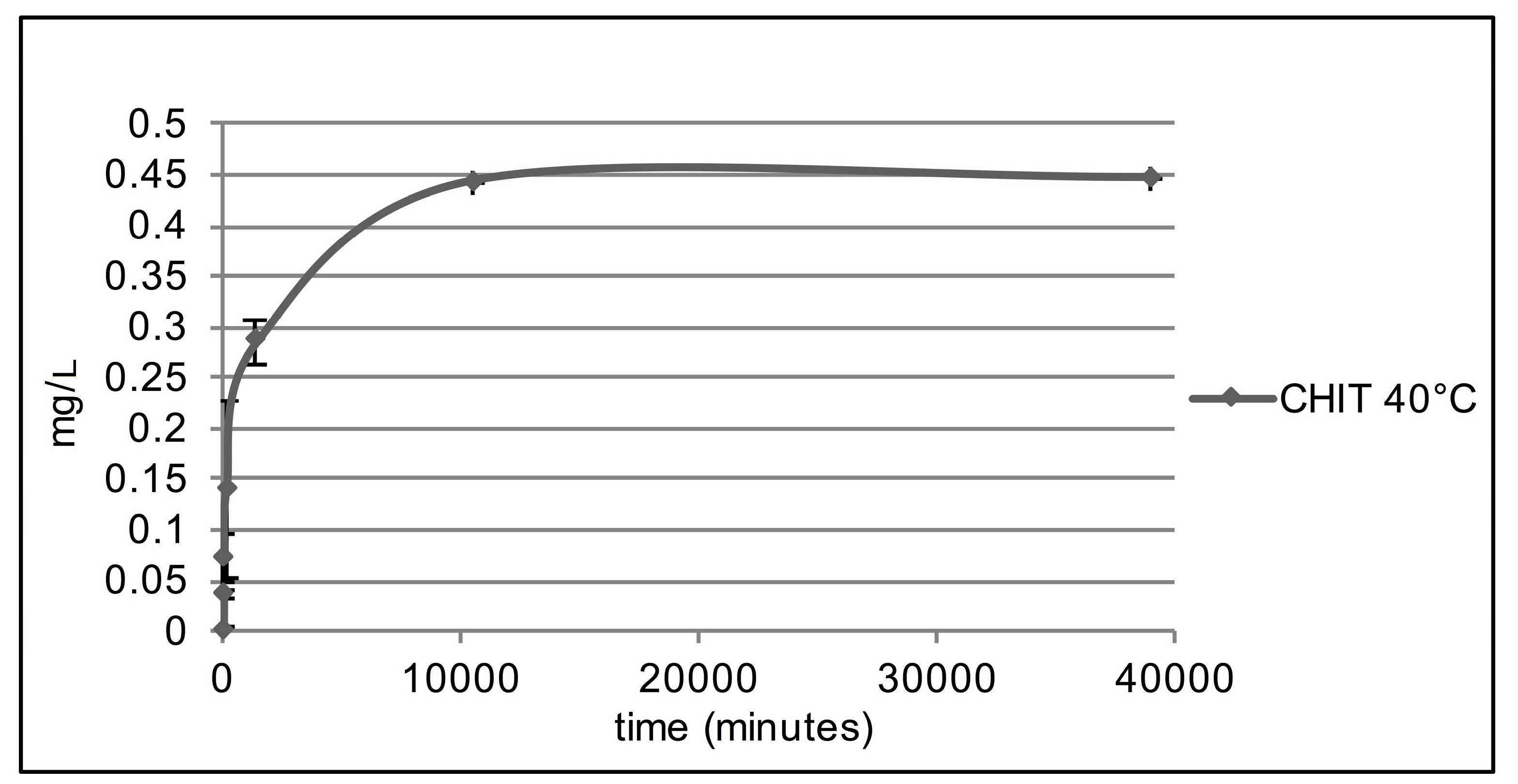

3.2. Natamycin Release Kinetics

3.3. Antimicrobial Activity of Films

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Appendini, P.; Hotchkiss, J.H. Review of antimicrobial food packaging. Innov. Food Sci. Emerg. 2002, 3, 113–126. [Google Scholar] [CrossRef]

- da Silva, M.A.; Iamanaka, B.T.; Taniwaki, M.H.; Kieckbusch, T.G. Evaluation of the antimicrobial potential of alginate and alginate/chitosan films containing potassium sorbate and natamycin. Packag. Technol. Sci. 2013, 26, 479–492. [Google Scholar] [CrossRef]

- Santiago-Silva, P.; Soares, N.F.F.; Nóbrega, J.E.; Júnior, M.A.W.; Barbosa, K.B.F.; Volp, A.C.P.; Zerdas, E.R.M.A.; Würlitzer, N.J. Antimicrobial efficiency of film incorporated with pediocin (ALTA_ 2351) on preservation of sliced ham. Food Control 2009, 20, 85–89. [Google Scholar] [CrossRef]

- Fajardo, P.; Martins, J.T.; Fuciños, C.; Pastrana, L.; Teixeira, J.A.; Vicente, A.A. Evaluation of a chitosan-based edible film as carrier of natamycin to improve the storability of Saloio cheese. J. Food Eng. 2010, 101, 349–356. [Google Scholar] [CrossRef]

- Imran, M.; Revol-Junelles, A.M.; Martyn, A.; Tehrany, E.A.; Jacquot, M.; Desobry, S. Active food packaging evolution: Transformation from micro- to nanotechnology. Crit. Rev. Food Sci. Nutr. 2010, 50, 799–821. [Google Scholar] [CrossRef] [PubMed]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-lactic acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. 2010, 9, 552–571. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Mastromatteo, M.; Conte, A.; Del Nobile, M.A. Advances in controlled release devices for food packaging applications. Trends Food Sci. Technol. 2010, 21, 591–598. [Google Scholar] [CrossRef]

- Rodríguez-Martínez, A.V.; Sendón, R.; Abad, M.J.; Gonzalez-Rodríguez, M.V.; Barros-Velazquez, J.; Aubourg, S.P.; Paseiro-Losada, P.; Rodríguez-Bernaldo de Quirós, A. Migration kinetics of sorbic acid from polylactic acid and seaweed based films into food stimulants. LWT Food Sci. Technol. 2016, 65, 630–636. [Google Scholar] [CrossRef]

- Siracusa, V.; Rocculi, P.; Romani, S.; Dalla Rosa, M. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Bourtoom, T. Edible protein films: Properties enhancement. Int. Food Res. J. 2009, 16, 1–9. [Google Scholar]

- Da Silva, M.A.; Bierhalz, A.C.K.; Kieckbusch, T.G. Modelling natamycin release from alginate/chitosan active films. Int. J. Food Sci. Technol. 2012, 47, 740–746. [Google Scholar] [CrossRef]

- Lago, M.A.; Sendón, R.; Rodríguez-Bernaldo de Quirós, A.; Sanches-Silva, A.; Costa, H.S.; Sánchez-Machado, D.I.; Soto Valdez, H.; Angulo, I.; Aurrekoetxea, G.P.; Torrieri, E.; et al. Preparation and characterization of antimicrobial films based on chitosan for active food packaging applications. Food Bioprocess Technol. 2014, 7, 2932–2941. [Google Scholar] [CrossRef]

- Abdollahi, M.; Rezaei, M.; Farzi, G. A novel active bionanocomposite film incorporating rosemary essential oil and nanoclay into chitosan. J. Food Eng. 2012, 111, 343–350. [Google Scholar] [CrossRef]

- Aider, M. Chitosan application for active bio-based films production and potential in the food industry: Review. LWT Food Sci. Technol. 2010, 43, 837–842. [Google Scholar] [CrossRef]

- Campos, C.A.; Gerschenson, L.N.; Flores, S.K. Development of edible films and coatings with antimicrobial activity. Food Bioprocess Technol. 2011, 4, 849–875. [Google Scholar] [CrossRef]

- No, H.K.; Meyers, S.P.; Prinyawiwatkul, W.; Xu, Z. Applications of chitosan for improvement of quality and shelf life of foods: A review. J. Food Sci. 2007, 72, 87–100. [Google Scholar] [CrossRef] [PubMed]

- Nasatto, P.L.; Pignon, F.; Silveira, J.L.M.; Duarte, M.E.R.; Noseda, M.D.; Rinaudo, M. Methylcellulose, a cellulose derivative with original physical properties and extended applications. Polymers 2015, 7, 777–803. [Google Scholar] [CrossRef]

- Ture, H.; Eroglu, E.; Ozen, B.; Soyer, F. Effect of biopolymers containing natamycin against Aspergillus niger and Penicillium roquefortii on fresh kashar cheese. Int. J. Food Sci. Technol. 2011, 46, 154–160. [Google Scholar] [CrossRef]

- Imran, M.; Klouj, A.; Revol-Junelles, A.M.; Desobry, S. Controlled release of nisin from HPMC, sodium caseinate, poly-lactic acid and chitosan for active packaging applications. J. Food Eng. 2014, 143, 178–185. [Google Scholar] [CrossRef]

- Dainelli, D.; Gontard, N.; Spyropoulosc, D.; Zondervan-van den Beukend, E.; Tobback, P. Active and intelligent food packaging: Legal aspects and safety concerns. Trends Food Sci. Technol. 2008, 19, S103–S112. [Google Scholar] [CrossRef]

- Cotter, P.D.; Hill, C.; Ross, R.P. Bacteriocins: Developing innate immunity for food. Nat. Rev. Microbiol. 2005, 3, 777–788. [Google Scholar] [CrossRef] [PubMed]

- Halami, P.M.; Chandrashekar, A. Enhanced production of pediocin C20 by anative strain of Pediococcus acidilatici C20 in an optimized food-grade medium. Process Biochem. 2005, 40, 1835–1840. [Google Scholar] [CrossRef]

- Ce´, N.; Norena, C.P.Z.; Brandelli, A. Antimicrobial activity of chitosan films containing nisin, peptide P34, and natamycin. CyTA-J. Food 2012, 10, 21–26. [Google Scholar] [CrossRef]

- Ollé Resa, C.; Gerschenson, L.; Jagus, R. Effect of natamycin on physical properties of starch edible films and their effect on Saccharomyces cerevisiae activity. Food Bioprocess Technol. 2013, 6, 3124–3133. [Google Scholar] [CrossRef]

- EU Parliament and Council Directive No 95/2/EC of 20 February 1995 on Food Additives Other Than Colours and Sweeteners. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=LEGISSUM%3Al21070a (accessed on 24 October 2017).

- EFSA Panel on Food Additives and Nutrient Sources added to Food (ANS). Scientific Opinion on the use of natamycin (E 235) as a food additive. EFSA J. 2009, 7, 1412. [Google Scholar]

- Davidson, P.M.; Sofos, J.N.; Branen, A.L. Antimicrobials in Food, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Kristo, E.; Koutsoumanis, K.; Biliaderis, C. Thermal, mechanical and water vapor barrier properties of sodium caseinate films containing antimicrobials and their inhibitory action on Listeria monocytogenes. Food Hydrocoll. 2008, 22, 373–386. [Google Scholar] [CrossRef]

- Cong, F.; Zhang, Y.; Dong, W. Use of surface coatings with natamycin to improve the storability of Hami melon at ambient temperature. Postharvest Biol. Technol. 2007, 46, 71–75. [Google Scholar] [CrossRef]

- Reps, A.; Drychowski, L.J.; Tomasik, J.; Winiewska, K. Natamycin in ripening cheeses. Pak.J. Nutr. 2002, 1, 243–247. [Google Scholar]

- Var, I.; Erginkaya, Z.; Güven, M.; Kabak, B. Effects of antifungal agent and packaging material on microflora of Kashar cheese during storage period. Food Control 2006, 17, 132–136. [Google Scholar] [CrossRef]

- Altieri, C.; Scrocco, C.; Sinigaglia, M.; Del Nobile, M.A. Use of chitosan to prolong mozzarella cheese shelf life. J. Dairy Sci. 2005, 88, 2683–2688. [Google Scholar] [CrossRef]

- Coma, V.; Martial-Gros, A.; Garreau, S.; Copinet, A.; Salin, F.; Deschamps, A. Edible antimicrobial films based on chitosan matrix. J. Food Sci. 2002, 67, 1162–1169. [Google Scholar] [CrossRef]

- Cerqueira, M.A.; Lima, A.M.; Souza, B.W.S.; Teixeira, J.A.; Moreira, R.A.; Vicente, A.A. Functional polysaccharides as edible coatings for cheese. J. Agric. Food Chem. 2009, 57, 1456–1462. [Google Scholar] [CrossRef] [PubMed]

- Gammariello, D.; Chillo, S.; Mastromatteo, M.; Di Giulio, S.; Attanasio, M.; Del Nobile, M.A. Effect of chitosan on the rheological and sensorial characteristics of Apulia spreadable cheese. J. Dairy Sci. 2008, 91, 4155–4163. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira, T.M.; de Fátima Ferreira Soares, N.; Pereira, R.M.; de Freitas Fraga, K. Development and evaluation of antimicrobial natamycin-incorporated film in Gorgonzola Cheese conservation. Packag. Technol. Sci. 2007, 20, 147–153. [Google Scholar] [CrossRef]

- Dos Santos Pires, A.C.; De Ferreira Soares, N.F.; De Andrade, N.J.; Mendes Da Silva, L.H.; Peruch Camilloto, G.; Campos Bernardes, P. Development and evaluation of active packaging for sliced mozzarella preservation. Packag. Technol. Sci. 2008, 21, 375–383. [Google Scholar] [CrossRef]

- Sánchez-González, L.; Cháfer, M.; González-Martínez, C.; Chiralt, A.; Desobry, S. Study of the release of limonene present in chitosan films enriched with bergamot oil in food stimulants. J. Food Eng. 2011, 105, 138–143. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No 10/2011 on Plastic Materials and Articles Intended to Come into Contact with Food. Available online: https://www.fsai.ie/uploadedFiles/Reg10_2011.pdf (accessed on 12 September 2017).

- Paseiro-Cerrato, R.; Otero-Pazos, P.; Rodríguez-Bernaldo de Quirós, A.; Sendón, R.; Angulo, I.; Paseiro-Losada, P. Rapid method to determine natamycin by HPLC-DAD in food samples for compliance with EU food legislation. Food Control 2013, 33, 262–267. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Oxford University Press Inc.: New York, NY, USA, 1975; pp. 69–88. [Google Scholar]

- Simoneau, C. Applicability of Generally Recognised Diffusion Models for the Estimation of Specific Migration in Support of EU Directive 2002/72/EC. Available online: http://ibebvi.studiorauw.eu/src/Frontend/Files/Labo/5/files/guideline%20modelling_70a.pdf (accessed on 24 October 2017).

- Chen, M.C.; Yeh, G.H.C.; Chiang, B.H. Antimicrobial and physicochemical properties of methylcellulose and chitosan films containing a preservative. J. Food Process. Preserv. 1996, 20, 379–390. [Google Scholar] [CrossRef]

- Nuijts, R.M.; Nuijts, R.M.M.A. Ocular Toxicity of Intraoperatively Used Drugs and Solutions; Kugler Publications: New Amsterdam, The Netherlands, 1995; pp. 19–20. [Google Scholar]

- Hanušova, K.; Štastná, M.; Votavová, L.; Klaudisová, K.; Dobiáš, J.; Voldrich, M. Polymer films releasing nisin and/or natamycin from polyvinyldichloride lacquer coating: Nisin and natamycin migration, efficiency in cheese packaging. J. Food Eng. 2010, 99, 491–496. [Google Scholar] [CrossRef]

- Agnihotri, S.A.; Mallikarjuna, N.N.; Aminabhavi, T.M. Recent advances on chitosan-based micro- and nanoparticles in drug delivery. J. Control. Release 2004, 100, 5–28. [Google Scholar] [CrossRef] [PubMed]

- Chung, D.; Chikindas, M.; Yan, K. Inhibition of Saccharomyces cerevisiae by slow release of propyl paraben from a polymer coating. J. Food Protect. 2001, 64, 1420–1424. [Google Scholar] [CrossRef]

- Silva, A.S.; Freire, J.M.C.; García, R.S.; Franz, R.; Losada, P.P. Time-temperature study of the kinetics of migration of dpbd from plastics into chocolate, chocolate spread and margarine. Food Res. Int. 2007, 40, 679–686. [Google Scholar] [CrossRef]

- Tehrany, E.A.; Desobry, S. Partition coefficients in food/packaging systems: A review. Food Addit. Contam. 2004, 21, 1186–1202. [Google Scholar] [CrossRef] [PubMed]

- Ouattara, B.; Simard, R.E.; Piett, G.; Begin, A.; Holley, R.A. Inhibition of surface spoilage bacteria in processed meats by application of antimicrobial films prepared with chitosan. Int. J. Food Microbiol. 2000, 62, 139–148. [Google Scholar] [CrossRef]

- Duan, J.; Park, S.I.; Daeschel, M.A.; Zhao, Y. Antimicrobial chitosan-lysozyme films and coatings for enhancing microbial safety of mozzarella cheese. J. Food Sci. 2007, 72, 359–362. [Google Scholar] [CrossRef] [PubMed]

- Del Nobile, M.T.; Gammariello, D.; Conte, A.; Attanasio, M. A combination of chitosan, coating and modified atmosphere packaging for prolonging Fior di latte cheese shelf life. Carbohyd. Polym. 2009, 78, 151–156. [Google Scholar] [CrossRef]

| Films | T | DP (cm2/s) | KP/S | RMSE (%) |

|---|---|---|---|---|

| chitosan + natamycin | 40 °C | 3.61 × 10–13 | 1054.11 | 0.63 |

| methylcellulose + natamycin | 10 °C | 7.30 × 10–10 | 271.64 | 5.38 |

| methylcellulose + natamycin | 20 °C | 1.14 × 10–9 | 127.85 | 4.59 |

| methylcellulose + natamycin | 40 °C | 3.20 × 10–8 | 3.74 | 10.93 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santonicola, S.; García Ibarra, V.; Sendón, R.; Mercogliano, R.; Rodríguez-Bernaldo de Quirós, A. Antimicrobial Films Based on Chitosan and Methylcellulose Containing Natamycin for Active Packaging Applications. Coatings 2017, 7, 177. https://doi.org/10.3390/coatings7100177

Santonicola S, García Ibarra V, Sendón R, Mercogliano R, Rodríguez-Bernaldo de Quirós A. Antimicrobial Films Based on Chitosan and Methylcellulose Containing Natamycin for Active Packaging Applications. Coatings. 2017; 7(10):177. https://doi.org/10.3390/coatings7100177

Chicago/Turabian StyleSantonicola, Serena, Verónica García Ibarra, Raquel Sendón, Raffaelina Mercogliano, and Ana Rodríguez-Bernaldo de Quirós. 2017. "Antimicrobial Films Based on Chitosan and Methylcellulose Containing Natamycin for Active Packaging Applications" Coatings 7, no. 10: 177. https://doi.org/10.3390/coatings7100177

APA StyleSantonicola, S., García Ibarra, V., Sendón, R., Mercogliano, R., & Rodríguez-Bernaldo de Quirós, A. (2017). Antimicrobial Films Based on Chitosan and Methylcellulose Containing Natamycin for Active Packaging Applications. Coatings, 7(10), 177. https://doi.org/10.3390/coatings7100177