Evaluation of Selected Properties of Alder Wood as Functions of Sanding and Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Surface Preparation of the Samples by Sanding

2.2. Determination of the Power Consumption during Sanding

2.3. Surface Roughness Measurement of the Samples

2.4. Coating of the Samples

2.5. Adhesion Test of the Coatings

2.6. Glossiness Measurement of the Samples

2.7. Processing of the Data

3. Results and Discussion

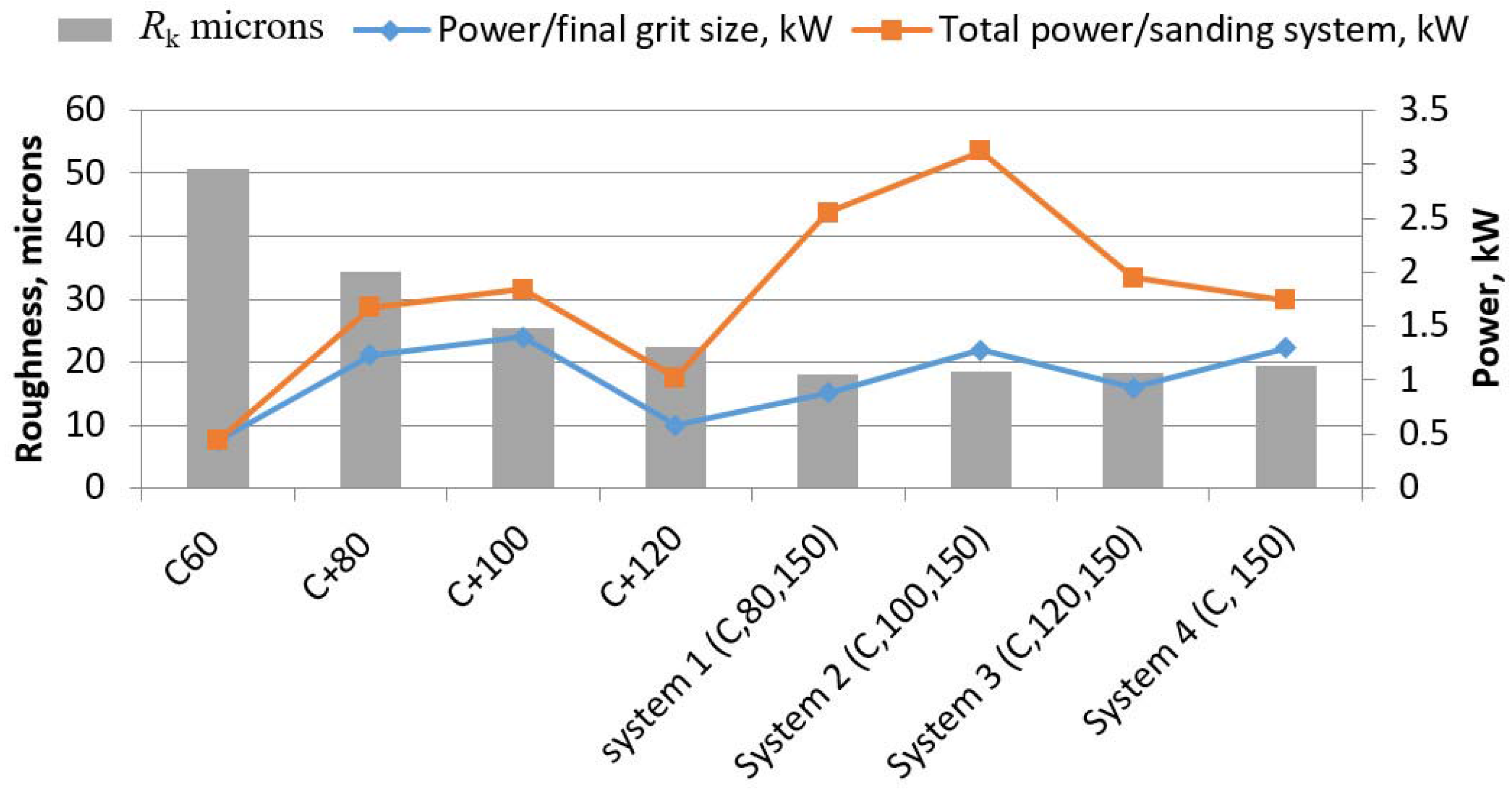

3.1. Variation of Power Consumption and Evaluation of Surface Roughness after Sanding

3.2. Evaluation of the Coating Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- European Commission Home Page. Available online: https://ec.europa.eu/jrc/en (accessed on 14 August 2017).

- Marschner, S.R.; Westin, S.H.; Arbree, A.; Moon, J.T. Measuring and modeling the appearance of finished wood. In Proceedings of the SIGGRAPH, Los Angeles, CA, USA, 31 July–4 August 2005; pp. 727–734. [Google Scholar]

- Varasquim, F.M.F.; Alves, M.C.; Goncalves, M.T.T.; Santiago, L.F.; Souza, A.J.D. Influence of belt speed, grit sizes and pressure on the sanding of Eucalyptus grandis wood. CERNE Lavras 2012, 18, 231–237. [Google Scholar] [CrossRef]

- Javorek, L.; Kúdela, J.; Svoreň, J.; Krajçoviçová, M. The influence of some factors on cutting force and surface roughness of wood after sanding. ProLigno 2015, 11, 516–524. [Google Scholar]

- Demirkir, C.; Aydin, I.; Çolak, S.; Çolakoğlu, G. Effects of plasma treatment and sanding process on surface roughness of wood veneers. Turk. J. Agric. For. 2014, 38, 663–667. [Google Scholar] [CrossRef]

- Sofuoglu, D.; Kurtoglu, A. Effects on machining conditions on surface roughness in planing and sanding of solid wood. Drv. Ind. 2015, 66, 265–272. [Google Scholar] [CrossRef]

- Gurau, L.; Irle, M. Surface Roughness Evaluation Methods for Wood Products: A Review. Curr. For. Rep. 2017, 3, 119. [Google Scholar] [CrossRef]

- Kilic, M.; Hoziroglu, S.; Burdurlu, E. Effect of machining on surface roughness of wood. Build. Environ. 2006, 41, 1074–1107. [Google Scholar] [CrossRef]

- Malkocoglu, A. Machining properties and surface roughness of various wood species planed in different conditions. Build. Environ. 2007, 42, 2562–2567. [Google Scholar] [CrossRef]

- Sandak, J.; Goli, G.; Cetera, P.; Sandak, A.; Cavalli, A.; Todaro, L. Machinability of minor wooden species before and after modification with thermos-vacuum tehnology. Materials 2017, 10, 121. [Google Scholar] [CrossRef] [PubMed]

- Varanda, L.D.; Alves, M.C.S.; Goncalves, M.T.T.; Santiago, L.F.F. Influência das varáveis no lixamento tubular na qualidade das peças de Eucalyptus grandis. CERNE Lavras 2010, 16, 23–32. [Google Scholar]

- Jaic, M.; Palija, T.; Đorđević, M. The Impact of Surface Preparation of Wood on the Adhesion of Certain Types of Coatings. Zastita Mater. 2014, 55, 163–169. [Google Scholar] [CrossRef]

- Ugulino, B.; Hernandez, R.E. Assessment of surface properties and solvent-borne coating performance of red oak wood produced by peripheral planning. Eur. J. Wood Prod. 2017, 75, 581–593. [Google Scholar] [CrossRef]

- Landry, V.; Blanchet, P.; Cormier, L.M. Water-based and solvent-based stains: Impact on the grain raising in yellow birch. BioResources 2013, 8, 1997–2009. Available online: http://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_08_2_1997_Landry_Water_Solvent_Stains (accessed on 31 August 2017). [CrossRef]

- Sönmez, A.; Budakçı, M.; Pelit, H. The effect of the moisture content of wood on the layer performance of water-borne varnishes. BioResources 2011, 6, 3166–3177. Available online: http://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_06_3_3166_sonmez_BP_Moisture_Wood_Varnishes (accessed on 31 August 2017).

- Nejad, M.; Shafaghi, R.; Ali, H.; Cooper, P. Coating perfomance on oil-heat treated wood for flooring. BioResources 2013, 8, 1881–1892. Available online: http://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_08_2_1881_Nejad_Coating_Performance_Flooring (accessed on 31 August 2017). [CrossRef]

- Cakicier, N.; Korkut, S.; Korkut, D. Varnish layer hardness, scratch resistance, and glossiness of various wood species as affected by heat treatment. BioResources 2011, 6, 1648–1658. Available online: http://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_06_2_1648_Cakicier_KS_Varnish_Hardness_Scratch_Heat_Treat (accessed on 31 August 2017).

- Slabejova, G.; Smidriakova, M. Gloss of transparent coating on beech wood surface. Acta Fac. Xylol. 2016, 58, 37–44. [Google Scholar] [CrossRef]

- Saeed, A.; Shabir, G. Synthesis of thermally stable high gloss water dispersible polyurethane/polyacrylate resins. Prog. Org. Coat. 2013, 76, 1135–1143. [Google Scholar] [CrossRef]

- Philipp, C. The future of wood coatings. Eur. Coat. J. 2010, 1, 1–6. [Google Scholar]

- Evans, P.D.; Haase, J.G.; Shakri, A.; Seman, B.M.; Kiguchi, M. The Search for Durable Exterior Clear Coatings for Wood. Coatings 2015, 5, 830–864. [Google Scholar] [CrossRef]

- Nejad, M.; Shafaghi, R.; Pershin, L.; Mostaghimi, J.; Cooper, P. Thermal spray coating: A new way of protecting wood. BioResources 2017, 12, 143–156. Available online: http://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_12_1_143_Nejad_Thermal_Spray_Coating_Protecting_Wood (accessed on 31 August 2017). [CrossRef]

- Bulian, F.; Collavini, F.; Matellon, A. Investigating the Effects of Weathering on Wood Coatings. FME Trans. 2017, 45, 405–411. [Google Scholar] [CrossRef]

- Budakçı, M.; Sönmez, A.; Pelit, H. The color changing effect of the moisture content of wood materials on water borne varnishes. BioResources 2012, 7, 5448–5459. Available online: http://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_07_4_5448_Budakci_Color_Moisture_Content_Varnish (accessed on 31 August 2017). [CrossRef]

- Salca, E.A.; Krystofiak, T.; Lis, B.; Mazela, B.; Proszyk, S. Some coating properties of black alder wood as function of varnish type and applications method. BioResources 2016, 11, 7580–7594. Available online: http://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_11_3_7580_Salca_Coating_Properties_Black_Alder_Wood (accessed on 31 August 2017). [CrossRef]

- Gurleyen, L.; Ayata, U.; Esteves, B.; Cakicier, N. Effects of heat treatment on the adhesion strength, pendulum hardness, surface roughness, color and glossiness of Scots pine laminated parquet with two different types of UV varnish application. Maderas Cienc. Tecnol. 2017, 19, 213–224. [Google Scholar] [CrossRef]

- APMR—Asociaţia Producătorilor de Mobilă din România Home Page. Available online: http://www.industriamobilei.ro/cele-mai-mari-destinatii-de-export-pentru-mobila-romaneasca-2016 (accessed on 1 August 2017).

- ISO 4287 (1998) Geometrical Product Specification (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; International Organization for Standardization: Geneva, Switzerland, 1998.

- ISO 13565–2 (1996) Geometrical Product Specification (GPS)—Surface Texture: PROFILE Method; Surfaces Having Stratified Functional Properties—Part 2: Height Characterization Using the Linear Material Ratio Curve; International Organization for Standardization: Geneva, Switzerland, 1996.

- Gurau, L.; Mansfield, H.; Irle, M. Processing Roughness of Sanded Wood Surfaces. Holz Roh-Werkst. 2005, 63, 43–52. [Google Scholar] [CrossRef]

- DIN 53211 (1974) Testing of Paints, Varnishes and Similar Products. Determination of the Flow Time by the DIN 4 Cup; German Institute for Standardization: Berlin, Germany, 1974.

- Paprzycki, O.; Proszyk, S.; Przybylak, A. Materials for The Exercises from The Technologies of The Finishing of Wood and Wood Based Materials Surfaces; Agriculture Academy: Poznan, Poland, 1985; p. 141. (In Polish) [Google Scholar]

- ISO 4624 (2003) Paints, Varnishes and Plastics. Pull-Off Test for Adhesion; German Institute for Standardization: Berlin, Germany, 2003.

- ISO 2813 (2014) Paints and Varnishes—Determination of Gloss Value at 20 Degrees, 60 Degrees and 85 Degrees; International Organization for Standardization: Geneva, Switzerland, 2014.

- De Moura, L.F.; Hernandez, R.E. Effects of abrasive mineral, grit size and feed speed on the quality of sanded surfaces of sugar maple wood. Wood Sci. Technol. 2006, 40, 517–530. [Google Scholar] [CrossRef]

- Vitosyte, J.; Ukvalbergiene, K.; Keturakis, G. The effects of surface roughness on adhesion strength of coated ash (Fraxinus excelsior L.) and birch (Betula L.) wood. J. Mater. Sci. 2012, 18, 347–351. [Google Scholar] [CrossRef]

- Wulf, M.; Netuschil, P.; Hora, G.; Schmich, P.; Cammenga, H.K. Investigation of the wetting characteristics of medium density fibreboards MDF by means of contact angle measurements. Holz Roh-Werkst. 1997, 55, 331–335. [Google Scholar] [CrossRef]

- De Meijer, M.; Thurich, K.; Militz, H. Comparative study on penetration characteristics of modern wood coatings. Wood Sci. Technol. 1998, 32, 347–365. [Google Scholar] [CrossRef]

- Demirci, Z.; Sonmez, A.; Budakci, M. Effect of thermal ageing on the gloss and adhesion strength of the wood varnish layers. BioResources 2013, 8, 1852–1867. Available online: http://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_08_2_1852_Demirci_Thermal_Ageing_Gloss_Adhesion (accessed on 31 August 2017). [CrossRef]

- Bekhta, P.; Proszyk, S.; Lis, B.; Krystofiak, T. Gloss of thermally densified alder (Alnus glutinosa Goertn.), beech (Fagus sylvatica L.), birch (Betula verrucosa Ehrh.), and pine (Pinus sylvestris L.) wood veneers. Eur. J. Wood Wood Prod. 2014, 72, 799–808. [Google Scholar] [CrossRef]

| Sanding Sequence and Grit Size | Calibration C 60 | |||

|---|---|---|---|---|

| 80 | 100 | 120 | 150 | |

| 150 | 150 | 150 | ||

| Sanding System | No.1 (C, 80, 150) | No.2 (C, 100, 150) | No.3 (C, 120, 150) | No.4 (C, 150) |

| Varnish Code | Varnish Type | VOC-EU (Volatile Organic Compounds), g/L | Density (g/cm3), 20 °C | Conventional Viscosity (s), 20 °C [31] | Organic Solvents (%) | Solid Content (%) |

|---|---|---|---|---|---|---|

| 1 | UV acrylic | 55.2 | 1.229 | 42 | 6.5 | 93.5 |

| 2 | water-borne (WB) | 55.2 | 1.024 | 65 | 5.4 | 27.9 |

| Processing Step | Ra (microns) | Rt (microns) | Rk (microns) | Rpk (microns) |

|---|---|---|---|---|

| Calibration (C) 60 | 16.5(2.6) * | 230.3(80.4) | 50.6(5.6) | 29.4(20.6) |

| C + 80 | 11.2(1.4) | 165.0(51.1) | 34.3(4.1) | 21.7(10.4) |

| C + 100 | 8.5(1.0) | 138.1(30.8) | 25.3(1.8) | 15.2(6.8) |

| C + 120 | 7.7(1.3) | 118.0(33.7) | 22.5(3.9) | 11.8(5.7) |

| system No.1 (C, 80, 150) | 6.0(0.4) | 86.0(23.0) | 18.1(1.4) | 10.4(2.8) |

| System No.2 (C, 100, 150) | 6.03(0.8) | 87.6(37.4) | 18.6(2.2) | 8.5(2.3) |

| System No. 3 (C, 120, 150) | 6.1(0.6) | 127.2(28.8) | 18.4(1.3) | 10.7(3.3) |

| System No. 4 (C, 150) | 6.2(0.9) | 100.9(21.1) | 19.4(2.4) | 9.1(3.5) |

| Sanding System | Varnish Type | Adherence (MPa) | Gloss 60 II | Gloss 60 ≠ |

|---|---|---|---|---|

| No. 1 | Uncoated | – | 3.1(0.1) * | 2.2(0.1) |

| UV | 1.41(0.02) | 35.6(3.8) | 19.9(2.2) | |

| WB | 1.20(0.01) | 27.6(3.8) | 18.2(2.3) | |

| No. 2 | Uncoated | – | 2.5(0.2) | 2.0(0.1) |

| UV | 1.29(0.1) | 26.5(11.8) | 17.5(4.1) | |

| WB | 1.24(0.01) | 31.9(3.3) | 21.3(2.7) | |

| No. 3 | Uncoated | – | 2.8(0.2) | 2.1(0.1) |

| UV | 1.22(0.01) | 42.5(2.2) | 27.0(2.4) | |

| WB | 1.22(0.2) | 25.8(3.5) | 16.8(1.7) | |

| No. 4 | Uncoated | – | 2.8(0.1) | 2.1(0.1) |

| UV | 1.39(0.1) | 37.4(1.4) | 22.8(1.9) | |

| WB | 1.43(0.1) | 24.5(4.8) | 15.0(0.9) |

| One-Way ANOVA Response | Source/Factor | Degrees of Freedom (DF) | Adjusted Sums of Squares (Adj SS) | Adjusted Mean Squares (Adj MS) | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Adherence, MPa | Sanding system | 3 | 0.1324 | 0.04415 | 0.11 | 0.956 |

| Varnish type | 2 | 22.6216 | 11.3108 | 725.04 | 0.000 | |

| Gloss 60 II | Sanding system | 3 | 87.8 | 29.28 | 0.12 | 0.946 |

| Varnish type | 2 | 11620 | 5810.09 | 191.78 | 0.000 | |

| Gloss 60 ≠ | Sanding system | 3 | 37.53 | 12.51 | 0.14 | 0.933 |

| Varnish type | 2 | 4337.2 | 2168.60 | 225.76 | 0.000 |

| Solution | Varnish Type | Sanding System | Gloss 60 ≠ Fit | Gloss 60 II Fit | Adherence (Mpa) Fit | Composite Desirability |

|---|---|---|---|---|---|---|

| 1 | UV | 3 | 23.2 | 37.3 | 1.27 | 0.79 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salca, E.-A.; Krystofiak, T.; Lis, B. Evaluation of Selected Properties of Alder Wood as Functions of Sanding and Coating. Coatings 2017, 7, 176. https://doi.org/10.3390/coatings7100176

Salca E-A, Krystofiak T, Lis B. Evaluation of Selected Properties of Alder Wood as Functions of Sanding and Coating. Coatings. 2017; 7(10):176. https://doi.org/10.3390/coatings7100176

Chicago/Turabian StyleSalca, Emilia-Adela, Tomasz Krystofiak, and Barbara Lis. 2017. "Evaluation of Selected Properties of Alder Wood as Functions of Sanding and Coating" Coatings 7, no. 10: 176. https://doi.org/10.3390/coatings7100176

APA StyleSalca, E.-A., Krystofiak, T., & Lis, B. (2017). Evaluation of Selected Properties of Alder Wood as Functions of Sanding and Coating. Coatings, 7(10), 176. https://doi.org/10.3390/coatings7100176