The Microstructure and Wear Resistance of a Copper Matrix Composite Layer on Copper via Nitrogen-Shielded Arc Cladding

Abstract

:1. Introduction

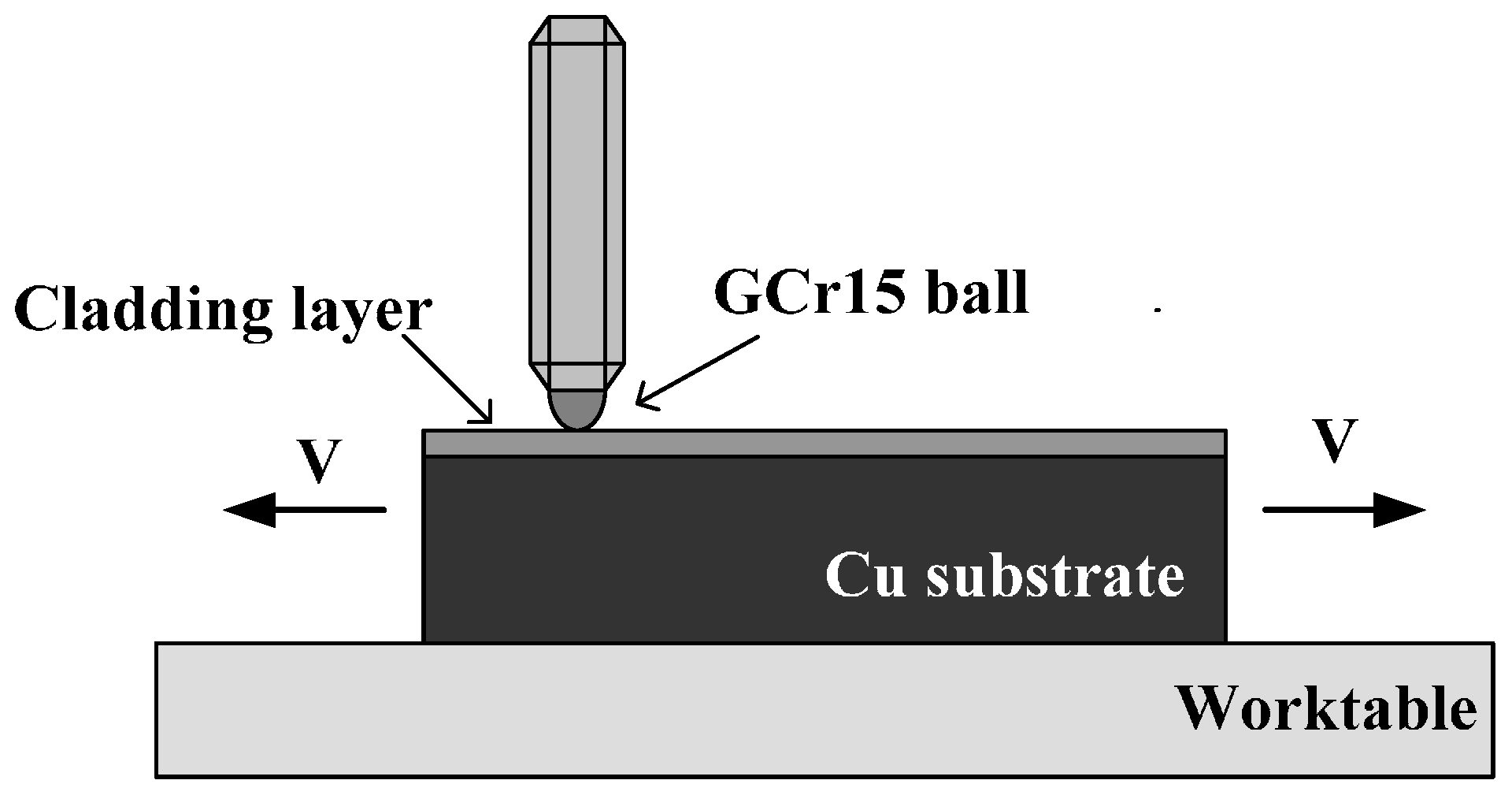

2. Materials and Methods

3. Results and Discussion

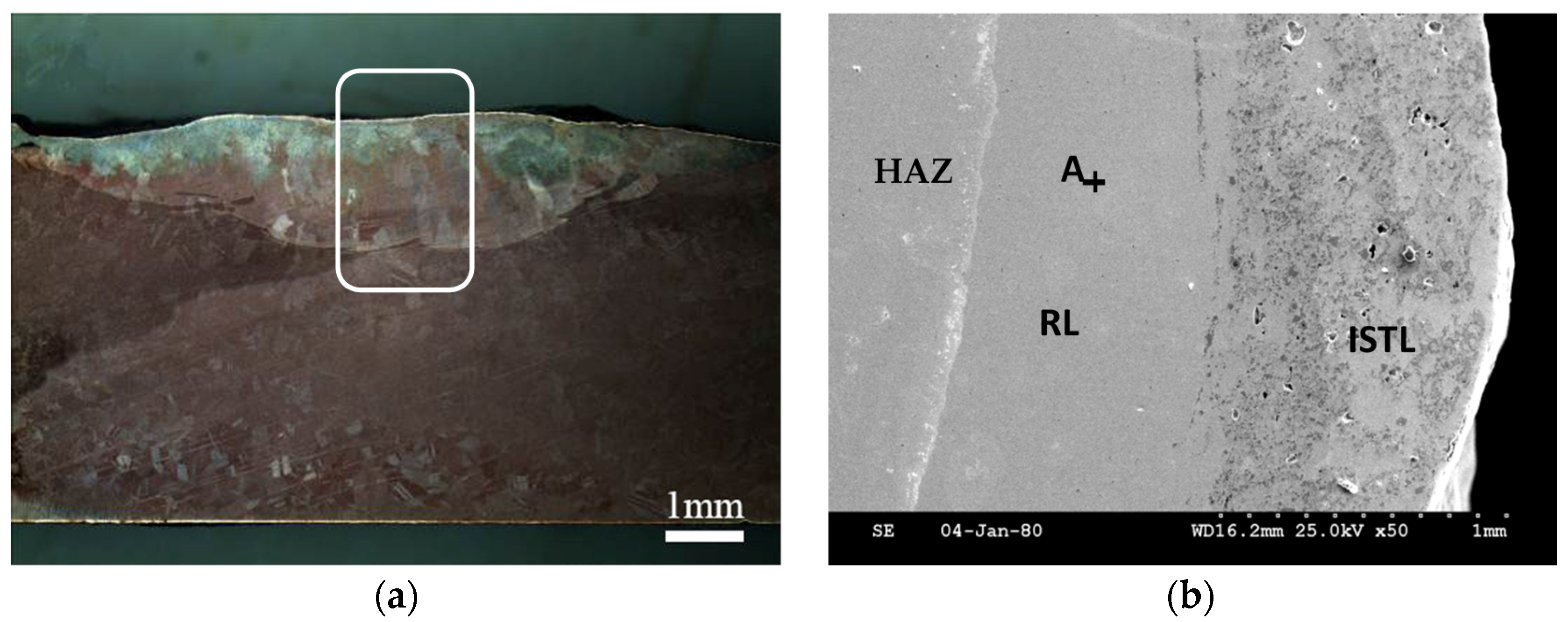

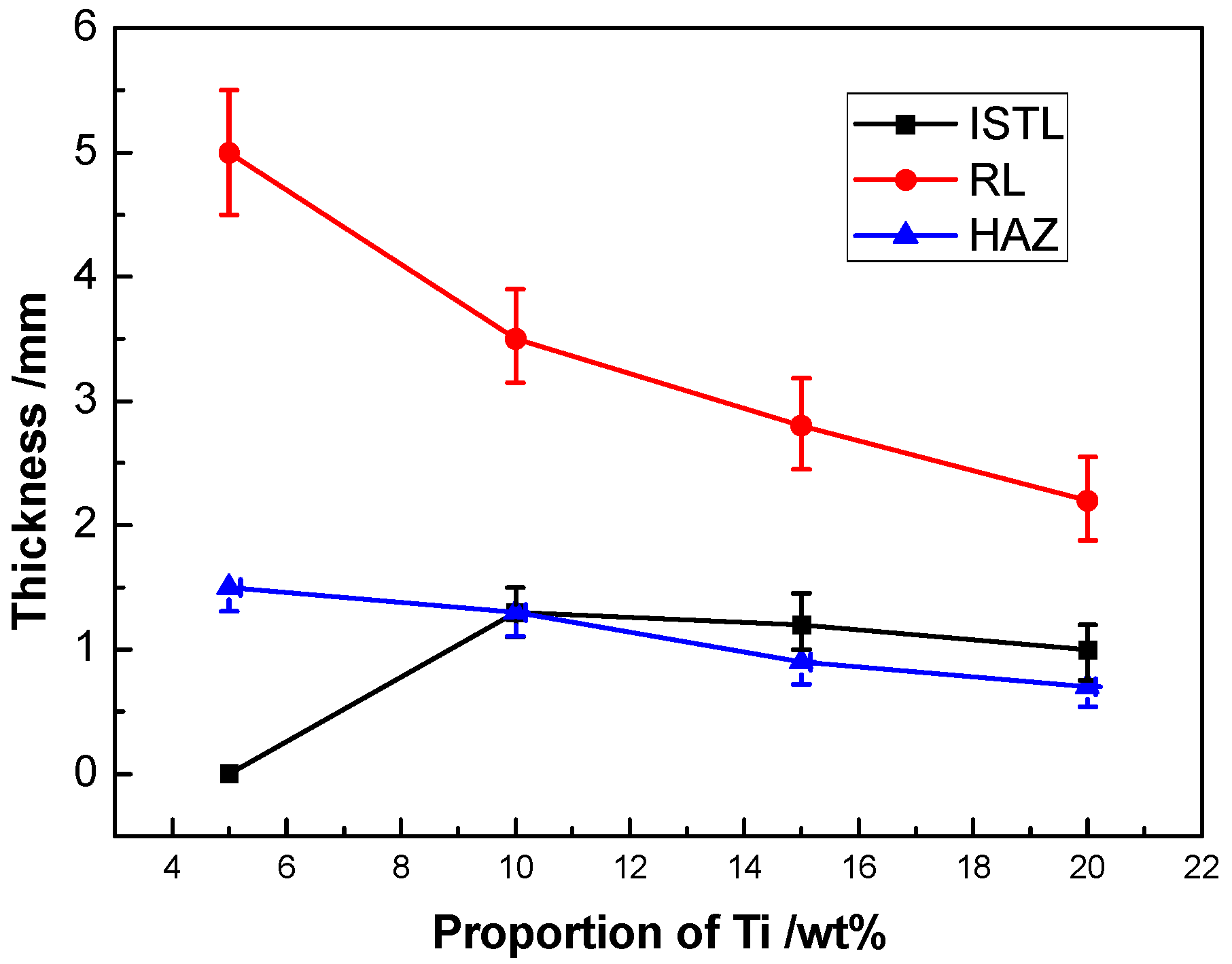

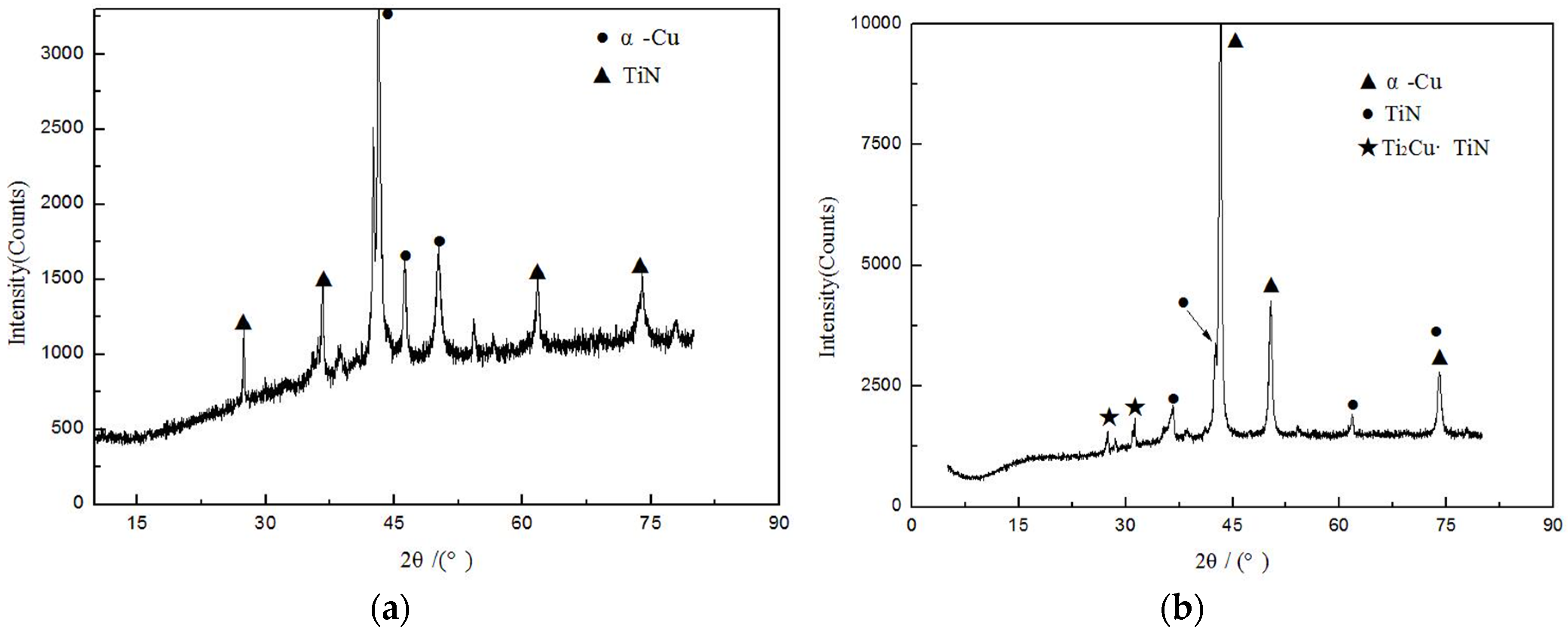

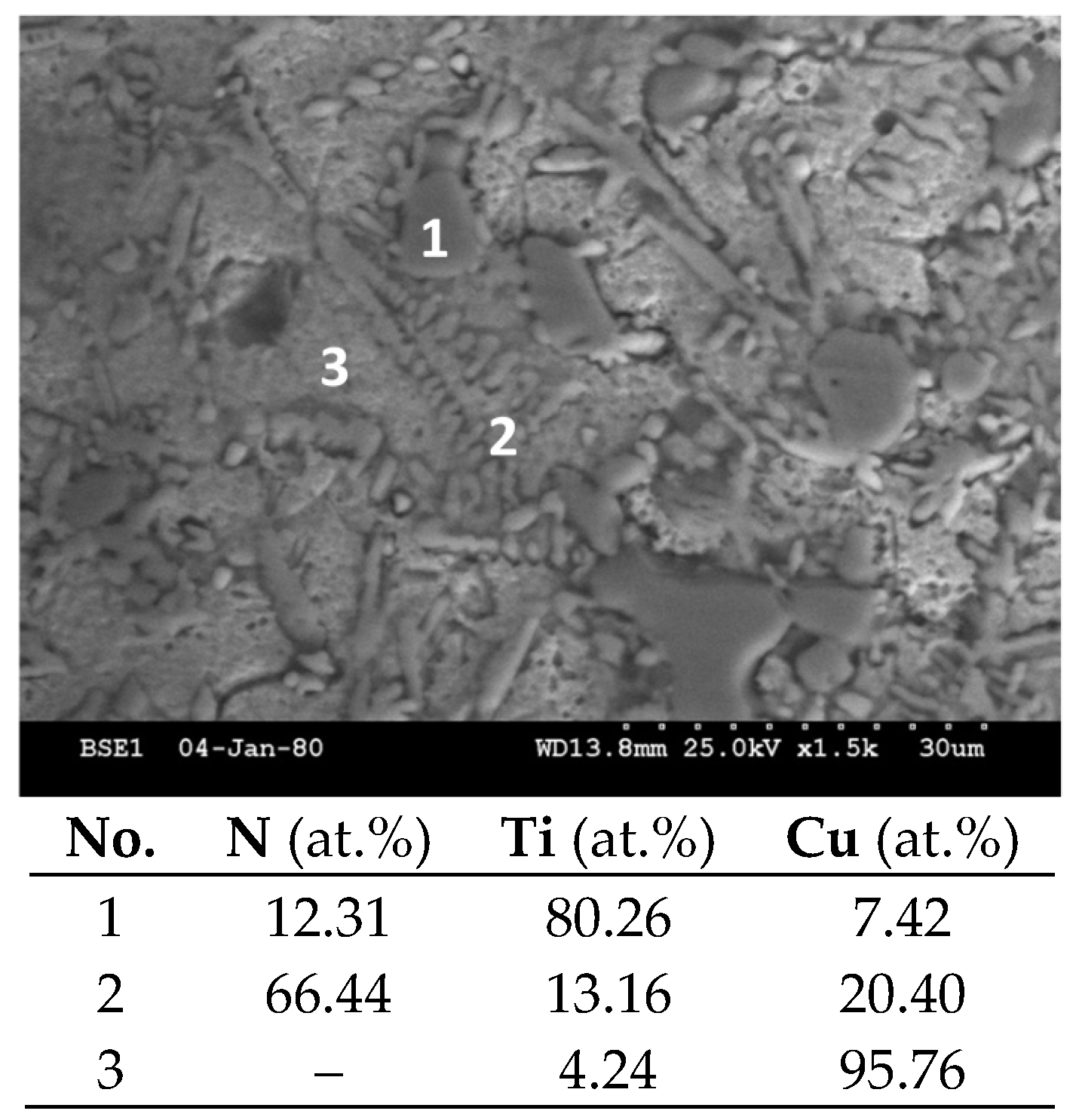

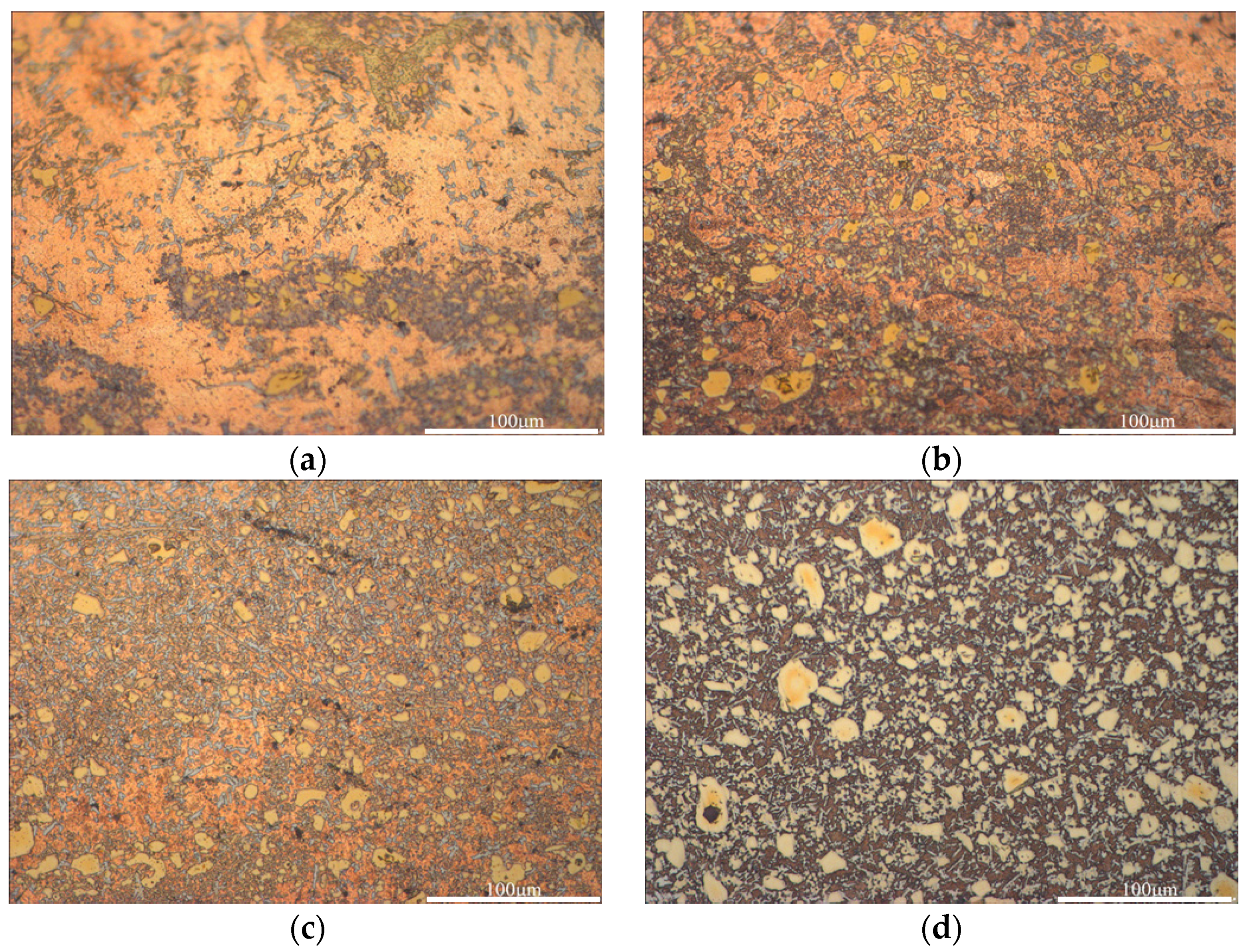

3.1. Morphology and Microstructure of the Cladding Layer

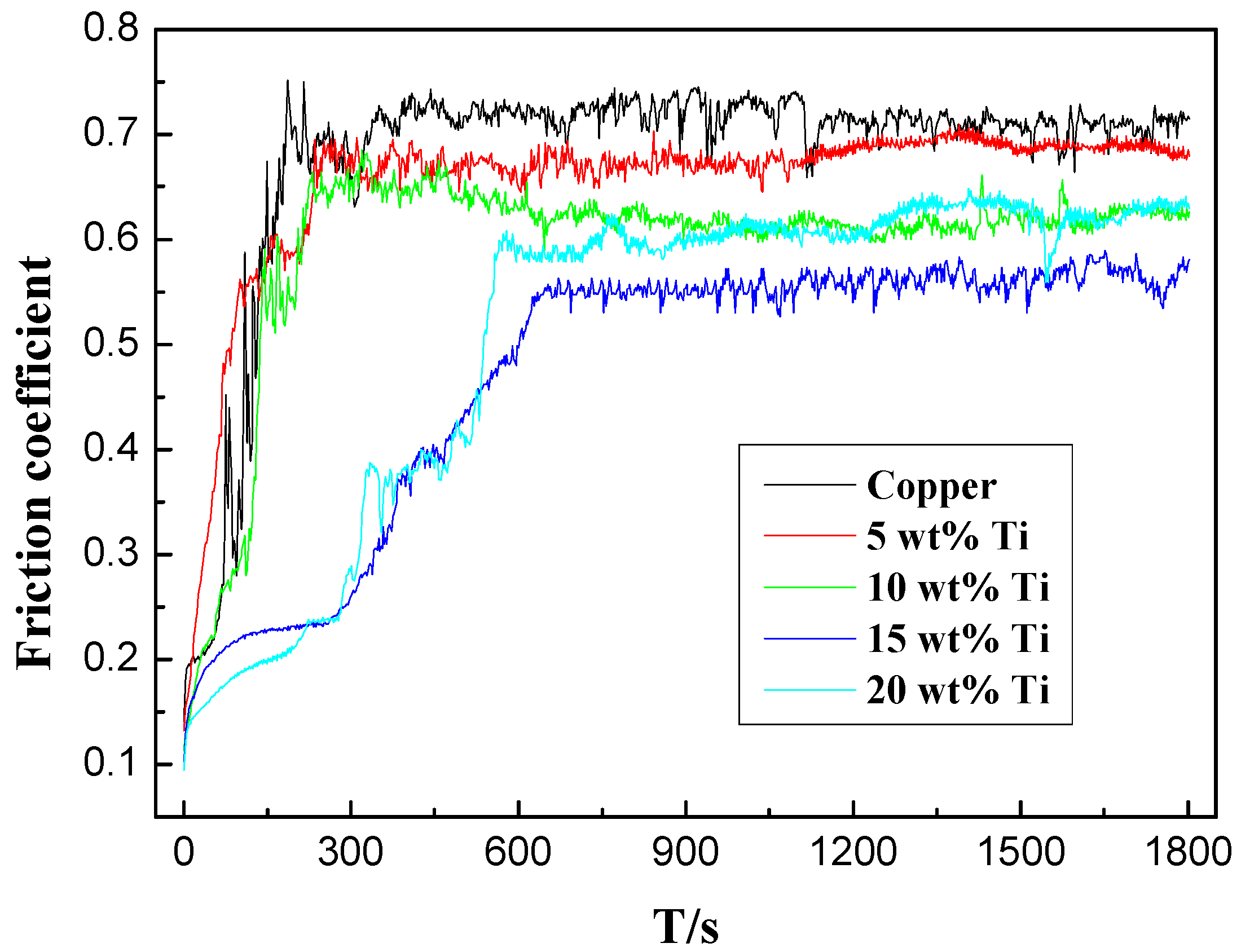

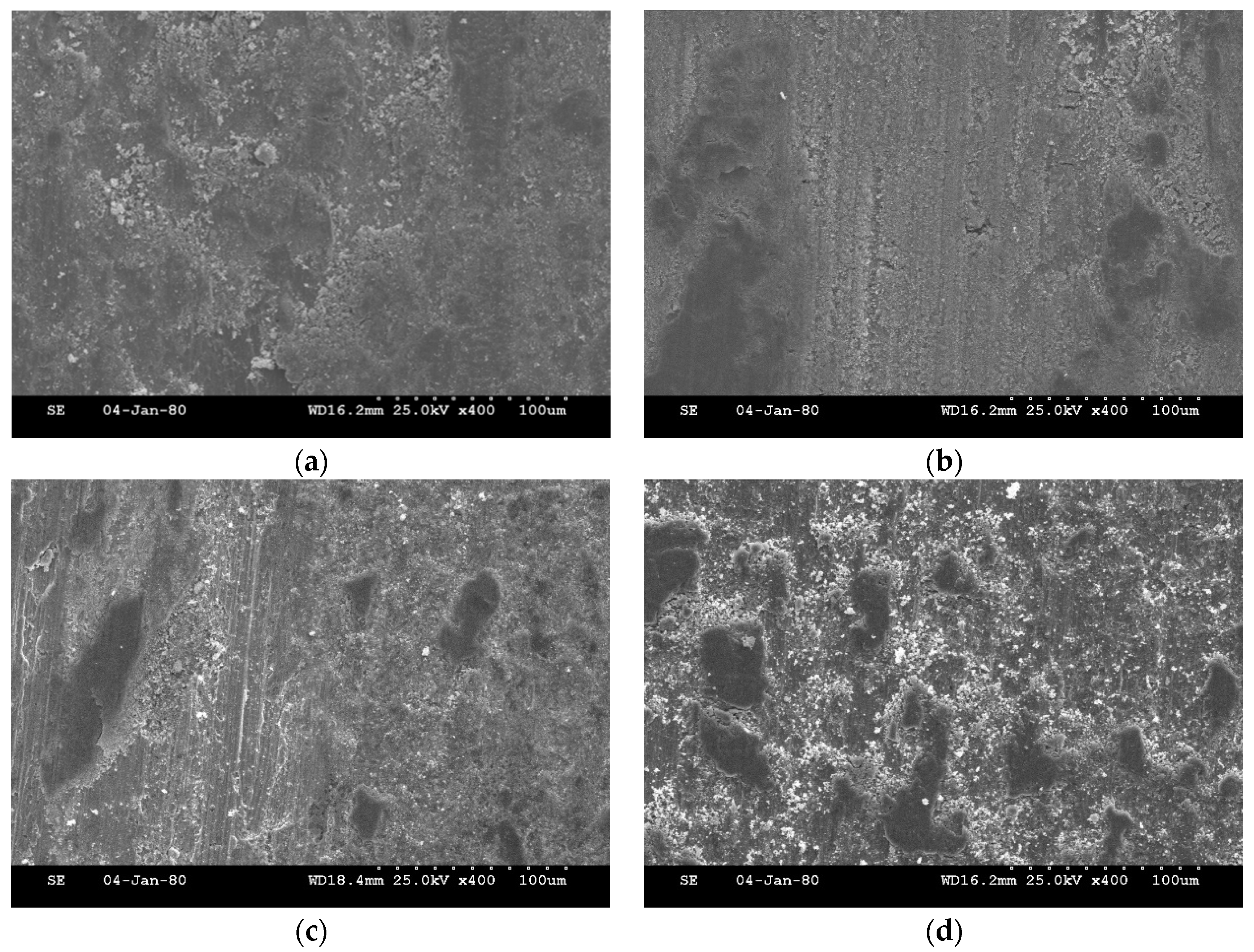

3.2. Micro-Hardness and Anti-Wear Performance of Cladding Layer

4. Conclusions

- The TiN·Ti2Cu- and TiN-reinforced copper matrix composite layer was in situ prepared on the surface of T3 copper successfully by means of N2 shielding gas tungsten arc cladding technology. The interface between the cladding layer and the substrate has a fine and uniform distribution without cracks and slags. As Ti increased, TiN·Ti2Cu and TiN increased as a result.

- The hardness of the cladding layer increased as the amount of reinforced phase generated in the layer increased. The hardness of the layer reached a maximum of 410 HV, 5.1 times greater than that of copper.

- The TiN·Ti2Cu- and TiN-reinforced phases improved the wear resistance of the cladding layers. The cladding layer with 15 wt % Ti had a longest launch stage of 638 s and a minimum fiction coefficient of 0.56.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, Y.Y.; Liang, Z.P.; Zhang, J.W. Microstructure and antiwear property of laser cladding Ni-Co duplex coating on copper. Material 2016, 9, 634–643. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Tu, Y.; Xi, M.Z.; Shi, L.K. Characterization on laser clad nickel based alloy coating on pure copper. Surf. Coat. Technol. 2008, 202, 5924–5928. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, P.L.; Yu, Z.S.; Lu, Q.H.; Yang, S.L.; Li, C.G. Microstructure and tribological properties oflaser-clad Ni-Cr/TiB2 composite coatings on copper with the addition of CaF2. Surf. Coat. Technol. 2012, 206, 4046–4053. [Google Scholar] [CrossRef]

- Dehm, G.; Bamberger, M. Laser cladding of Co-based hardfacing on Cu substrate. J. Mater. Sci. 2002, 37, 5345–5353. [Google Scholar] [CrossRef]

- Zhao, G.L.; Zou, Y.; Zou, Z.D. Research on in situ synthesised (Ti,V)C/Fe composite coating by laser cladding. Mater. Sci. Technol. 2015, 31, 1329–1334. [Google Scholar] [CrossRef]

- Meng, J.S.; Shi, X.P. Microstructure and properties of TiCp/Al composite coating by argon arc cladding. Trans. China Weld. Inst. 2011, 32, 73–76. [Google Scholar]

- Guo, G.L.; Yang, L. The investigation on wear resistance of Fe-based alloy coating by argon arc cladding. Appl. Mech. Mater. 2012, 217, 1247–1250. [Google Scholar] [CrossRef]

- Zhang, P.R.; Liu, Z.Q. Effect of sequential turning and burnishing on the surface integrity of Cr-Ni-based stainless steel formed by laser cladding process. Surf. Coat. Technol. 2015, 276, 327–335. [Google Scholar] [CrossRef]

- Liu, Y.H.; Qu, W.C. TiC reinforcement composite coating produced using graphite of cast iron by laser cladding. Materials 2016, 9, 815–825. [Google Scholar] [CrossRef]

- Candel, J.J.; Jimenez, J.A. Effect of laser irradiation on failure mechanism of TiCp reinforced titanium composite coating produced by laser cladding. J. Mater. Process. Technol. 2014, 214, 2325–2332. [Google Scholar] [CrossRef]

- Durakov, G.S.; Scheider, A. Effect of substrate temperature on microstructure and properties of the CuCr25 alloys produced by electron beam cladding. In Proceedings of International Symposium on Discharges and Electrical Insulation in Vacuum, Mumbai, India, 28 September–3 October 2014.

- Angelastro, A.; Campanelli, S.L.; Casalino, G.; Ludovico, A.D. Optimization of Ni-based WC/Co/Cr composite coatings produced by multilayer laser cladding. Adv. Mater. Sci. Eng. 2013, 1, 332–335. [Google Scholar] [CrossRef]

- Bataev, I.A.; Mul, D.O. Structure and tribological properties of steel after non-vacuum electron beam cladding of Ti, Mo and graphite powders. Mater. Charact. 2016, 112, 60–67. [Google Scholar] [CrossRef]

- Li, D.K.; Li, M.X. Effect of CeO2 on microstructure and properties of Fe-based coating produced by plasma arc cladding process. Trans. China Weld. Inst. 2011, 32, 109–112. [Google Scholar]

- Xia, D.; Xu, B.S. Experimental study on NiCrBSi multilayer coating cladded by micro—Plasma arc cladding process. Mater. Sci. Technol. 2009, 17, 645–648. [Google Scholar]

- Weng, F.; Yu, H.J.; Chen, C.Z. Microstructure and property of composite coatings on titanium alloy deposited by laser cladding with Co42+TiN mixed powders. J. Alloys Compd. 2016, 686, 74–81. [Google Scholar] [CrossRef]

- Alat, E.; Motta, A.; Comstock, R.J. Multilayer (TiN, TiAlN) ceramic coating for nuclear fuel cladding. J. Nuclear Mater. 2016, 478, 236–244. [Google Scholar] [CrossRef]

- Qi, Y.; Cao, Z.; Sheng, L.; Cao, R. Microstructure of Fe-based alloy composite coatings reinforced by Ti (C0.3N0.7) particles Tthrough laser cladding technology. J. Iron Steel Res. Int. 2013, 20, 78–82. [Google Scholar] [CrossRef]

- Liu, H.X.; Zhang, X.W. Microstructure and high temperature oxidation resistance of in-situ synthesized TiN/Ti3Al intermetallic composite coating on Ti6Al4V alloys by cladding process. J. Alloy. Compd. 2016, 670, 268–274. [Google Scholar] [CrossRef]

- Guo, B.G.; Zhou, J.S.; Zhang, S.T. Microstructure and tribological properties of in situ synthesized TiN/Ti3Al intermetallic matrix composite coatings on titanium by laser cladding and laser nitriding. Mater. Sci. Eng. A 2008, 480, 404–410. [Google Scholar] [CrossRef]

- Meng, J.S.; Ji, Z.S. Microstructure and technology research of In-situ synthesis TiN-TiB/Ni composite coating by arc cladding. Phys. Procedia 2013, 50, 253–260. [Google Scholar] [CrossRef]

- Mateusz, W.; Joanna, K.B. Copper metal matrix composites reinforced by titanium nitride particles. Key Eng. Mater. 2016, 682, 270–275. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Liu, X.; Zhou, Z.; Zhang, L.; Peng, Z. The Microstructure and Wear Resistance of a Copper Matrix Composite Layer on Copper via Nitrogen-Shielded Arc Cladding. Coatings 2016, 6, 67. https://doi.org/10.3390/coatings6040067

Li Y, Liu X, Zhou Z, Zhang L, Peng Z. The Microstructure and Wear Resistance of a Copper Matrix Composite Layer on Copper via Nitrogen-Shielded Arc Cladding. Coatings. 2016; 6(4):67. https://doi.org/10.3390/coatings6040067

Chicago/Turabian StyleLi, Yinan, Xianbao Liu, Zhikang Zhou, Lei Zhang, and Zilong Peng. 2016. "The Microstructure and Wear Resistance of a Copper Matrix Composite Layer on Copper via Nitrogen-Shielded Arc Cladding" Coatings 6, no. 4: 67. https://doi.org/10.3390/coatings6040067

APA StyleLi, Y., Liu, X., Zhou, Z., Zhang, L., & Peng, Z. (2016). The Microstructure and Wear Resistance of a Copper Matrix Composite Layer on Copper via Nitrogen-Shielded Arc Cladding. Coatings, 6(4), 67. https://doi.org/10.3390/coatings6040067