1. Introduction

Machining remains one of the most employed processes in the world’s metalworking context. The aeronautics, naval and automobile industries are, probably, the economic sectors that most demand this kind of process through the engineering of parts included directly and indirectly in aircrafts, ships, trucks, buses and cars. Machining processes are necessary when surface quality is one of the main requirements demanded by customers or designers. However, competitiveness is a key factor in such industries, requiring accurate and extremely efficient equipment. Indeed, the available equipment on the market has continued to grow, becoming increasingly sophisticated and allowing an improved accuracy [

1], answering to the need of the market for complex organic shapes and high surface quality.

Researchers have contributed significantly to this development, devoting their efforts to explaining many of the machining related phenomena, anticipating market needs and studying the best ways to increase production and improve products through tooling improvements, more accurate machining parameters, optimized machining trajectories, and so on.

With regards to the cutting process, mechanical work developed is converted into plastic deformation, creating friction between the tool and workpiece, resulting in heat generation [

2]. Increasing the tool temperature causes materials to become softer and wear increases rapidly, reducing the tool life and decreasing the machining efficiency and the accuracy attained. Some experiments suggest that tool temperature rises as speed machining increases [

3,

4] in continuous cutting processes. However, Palmai [

5], studying the interrupted cutting characteristics of the milling machining process, though not directly supported by experimental work, suggested that temperature can diminish as speed machining increases. Many studies have been carried out trying to optimize the parameters set for each material [

6,

7,

8]. Rawangwong et al. [

7], studying the main factors that affect the surface roughness of a semi-solid AA7075 alloy in face milling, suggested that feed rate ratio and cutting speed are the principal factors, whereas the depth of cut does not influence the surface quality. Furthermore, the same authors stated in the same work that higher cutting speed and lower feed rate tend to decrease the surface roughness. Zhang et al. [

8] concluded as well that cutting speed and feed rate are the main factors influencing the surface roughness, rather than the depth of cut, in the milling process. A similar study has been carried out by Sai et al. [

9] using as sample materials carbon steel and duplex stainless steel, concluding that a very slow cutting speed leads to build-up edge (BUE) formation, resulting in poor surface quality. They showed that a cutting speed of between 220 and 440 m/min achieved the best roughness surface values for small feed rate. An increase in the surface micro hardness and tensile residual stresses was also registered with higher values of cutting speed and feed rate.

The correlation among the parameters of surface integrity and fatigue life of machined components has also been studied. Li et al. [

10] focused on the Inconel 718 milling process, studying the relationship between tool wear, fatigue life and surface integrity, concluding that more tool wear generates low surface roughness, and, with tool wear up to

VB = 0.2 mm (

VB, width of the flank wear land), no fatigue took place in up to four million cycles on the machined samples. Furthermore, considering end mill tools provided with PVD coated inserts, the roughness in the step-over direction was more pronounced than in the feed direction.

Stability during a machining process is a key factor in obtaining lower surface roughness and accurate products. Regarding the milling process, Stepan et al. [

11] have studied the milling process stability using three different milling tools (conventional, variable helix and serrated milling tools). By means of semi-discretization and multi-frequency solution, the authors concluded that serrated milling tools provided the best contribution to cutting stability, despite this type of tool being used essentially in roughing operations, whereas the optimized variable helix end mill tools are more adequate for finishing operations, providing a better result in terms of stability than conventional ones.

The cost, quality and lead-time of the plastic products are directly influenced by the mould industry, which is based essentially on machining processes. When creating large mould cavities, milling operations are one of the most necessary means utilized [

12,

13], however, the surface roughness usually required by this industry cannot be achieved solely by this process [

14]. The need to involve hand polishing operations is required, despite the use of High Speed Machining (HSM) and sophisticated tool path trajectories created through Computer Aided Manufacturing (CAM) software. Souza et al. [

12] have stated that a correct selection of tool paths can save 88% of machining time and cut 40% of mould machining costs, when compared with a poor strategy option.

Denkena et al. [

15] recently studied the influence of cutting edge geometry in tough milling operations on hardened steel moulds, trying to overcome the thermo-mechanical stresses developed on tools. The main goal of these authors was to decrease tool friction and wear by changing the flank face geometry. Simulations were made, which allows the provision of tools with undercut geometries, whereby an increase in tool life and a decrease in induced residual stress on machined parts can be observed.

Coatings have proven to be an attractive way to extend tool life by increasing surface hardness, acting in addition to other crucial parameters concerning tool work such as: decreasing the friction between tool and part; creating a thermal barrier between the surface and the hard metal substrate and allowing a better surface temperature distribution by dissipating the heat generated during tool contact with chips and machined part [

16,

17]. Thus, tool coating requirements are large and of high importance. Tool manufacturers started using the conventional TiN, however, this coating was not sufficient to solve all the previously mentioned problems, hence, multilayered coatings started to be developed in order to improve tool performance. Nowadays, tools recently introduced on the market present three or more layers, each one with specific functions, in order to satisfy all the requirements.

2. Materials and Methods

The raw material chosen to be machined for this study was a CD4MCuN duplex stainless steel (material specification: ASTM A890, Werkstoff-Nr. 1.4517 or EN 10283, ARSOPI, Vale de Cambra, Portugal). It is composed of a dual phase microstructure of both austenite and ferrite in similar amounts. The chemical composition given by the supplier for this batch of steel was (wt %) C 0.03%, Si 0.41%, Mn 1.48%, P 0.02%, Cr 25.41%, Ni 6.08%, Mo 2.91%, Cu 3.30%, Nb 0.01%, V 0.02%, W 0.04%, N 0.19%, Co 0.08% and Fe 60.02% [

18]. It is sold in a heat treated state (quenched at 1135 °C and water cooled) and according to the supplier has a yield strength (0.2%) and an ultimate tensile strength of 489 MPa and 797 MPa, respectively (in accordance with ISO 6892-1 [

19]), as well as hardness of 267 HB (ISO 6506-1 [

20]). Among several different material properties, some of the most important are its high mechanical strength (approximately twice as much as the more common ASTM 304 and 316 stainless steels), good corrosion and pitting resistance, good toughness, good weldability and ease of fabrication. Typical applications are the construction of chemical equipment and tubbing, pressurized tanks and vessels, heat exchangers, cellulose and paper fabrication, sea water processing, etc. This duplex stainless steel is thought to be of interest due to the fact that numerous flanges and accessories, which require machining, are made from this material and information surrounding this topic is scarce. A round bar with a diameter of 60 and 300 mm in length was sufficient for all testing trials.

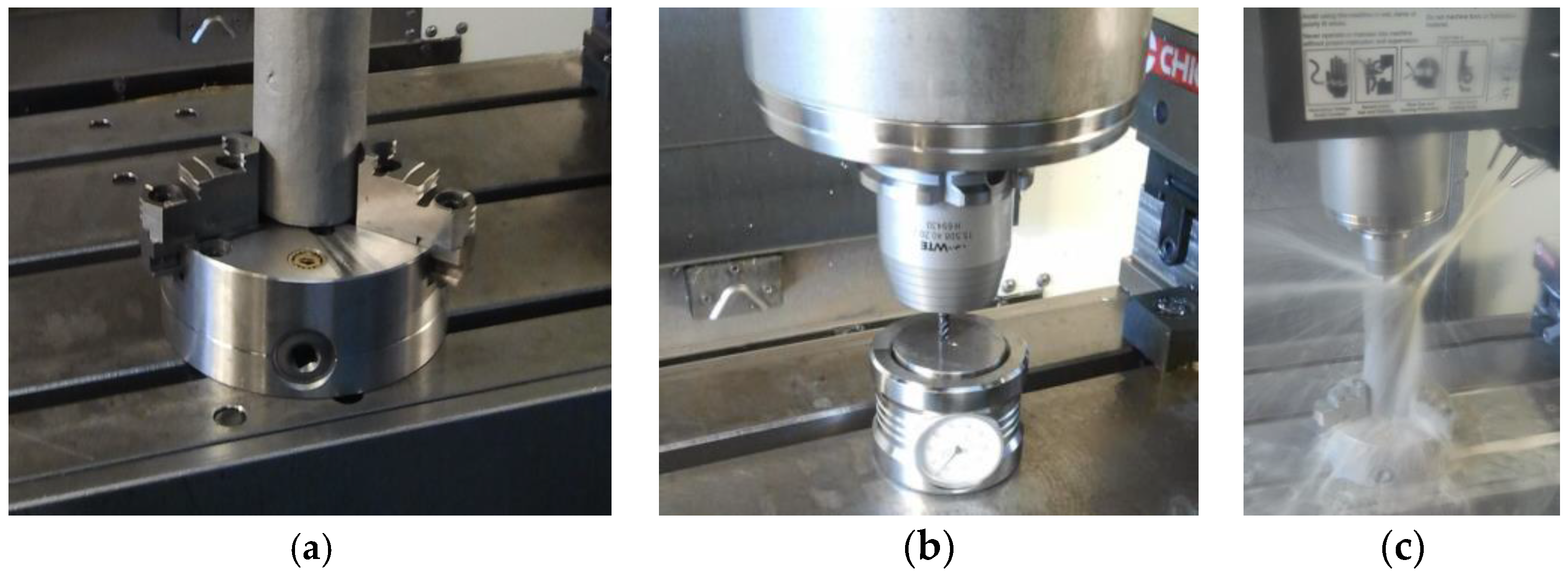

The machining operations were performed on a 3-axis CNC machine (brand/model: Haas VF2 vertical machining center, Hass Automation, Inc., Oxnard, CA, USA). A 3-jaw self-centering chuck (brand/model: Bison 3575, BISON-BIAL, S.A., Bielsk Podiaski, Poland) was mounted to the machine’s work table (in accordance with standard DIN 6350 [

21]), guaranteeing the exact same positioning of the round bar between each trial. The use of a hydraulic tool holder (brand/model: WTE DIN 69871-AD/B [

22], WTE Präzisionstechnik GmbH, Kempten, Germany) was necessary as this type of system minimized unwanted vibrations during testing.

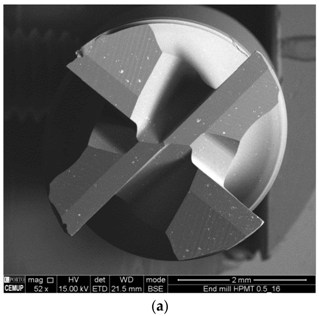

Figure 1 illustrates several components utilized during testing.

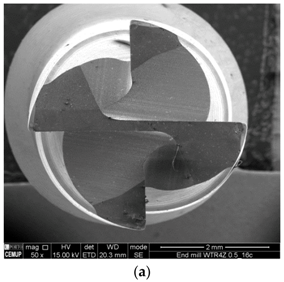

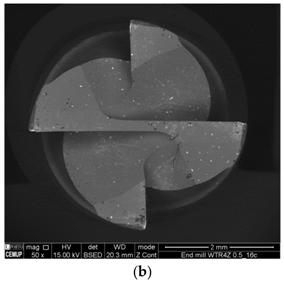

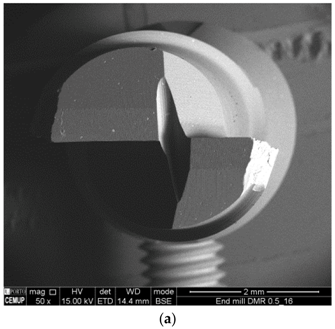

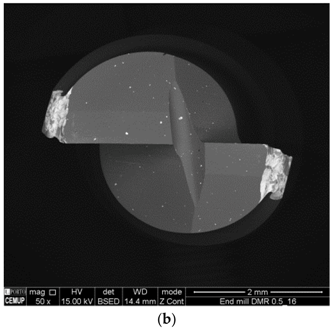

The comparative study is based on the wear analysis of four different milling tools advertised as being appropriate for milling duplex stainless steels. The milling tools used all have in common a cutting diameter of 4 mm, a 6 mm shank diameter and a coated hard metal substrate. Milling tools with a 4 mm shank diameter were initially tested, however, they proved to be too fragile, suffering premature breakage.

Table 1 lists the characteristics of all four different selected end mills.

For easier reading and referencing, tools will be referred to by their manufacturer’s name, followed by the number of cutting flutes and composition of coating (e.g., Dormer Z2 AlCrN) instead of their complete designation.

Besides analyzing the influence of coatings on wear behavior, the number of cutting flutes was also changed to investigate its effect on tool longevity. Usually, the amount of cutting flutes influences the ease of chip removal, so it is common sense to use tools with less cutting flutes in slotting operations and tools with more flutes in side milling operations. When chip removal is difficult, a buildup edge may appear on the tool.

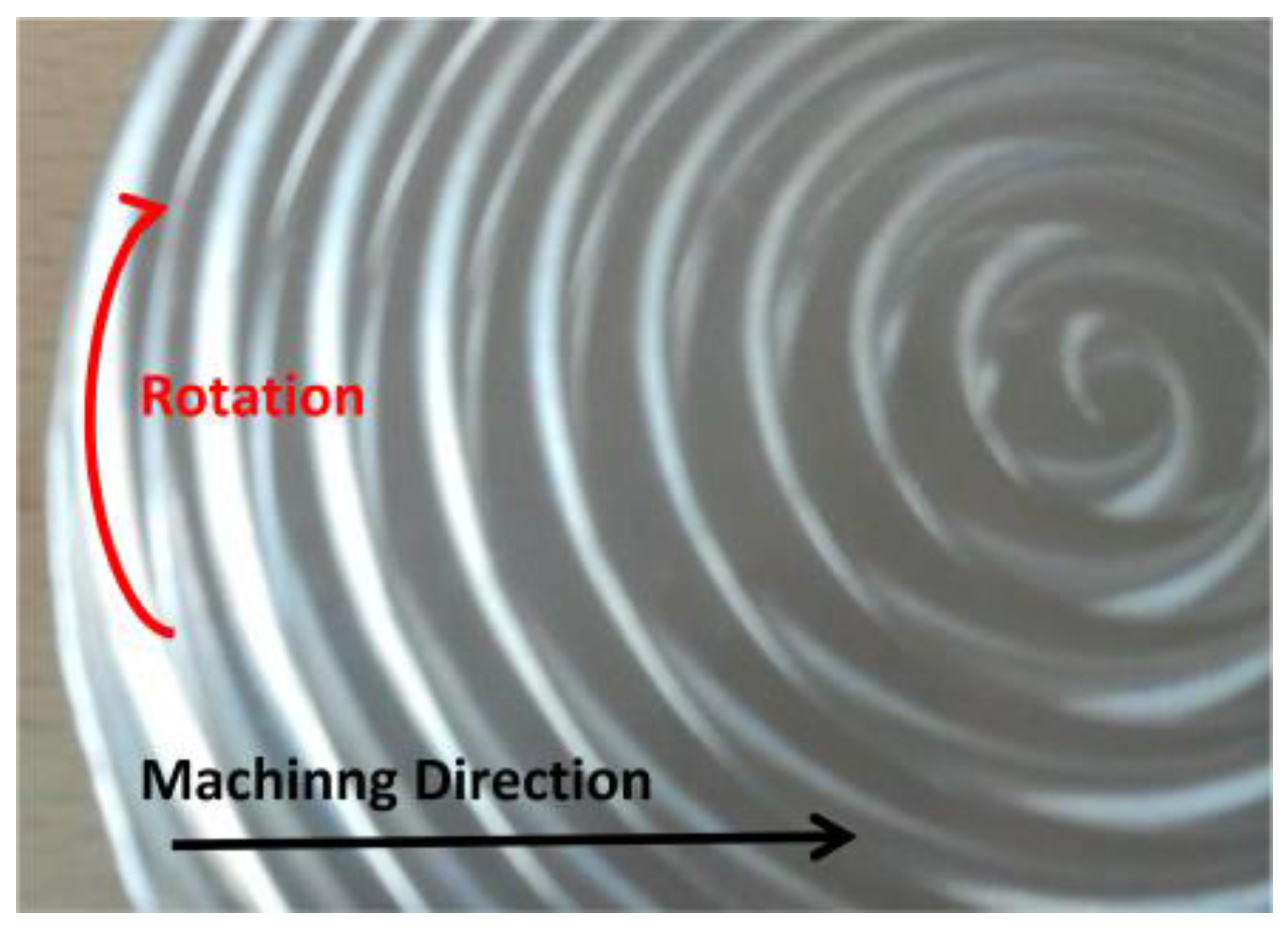

In order to evaluate the wear of each tool, a simple roughing machining strategy was created to ensure repeatability of test conditions. Based on the round format of the bar, a spiral path was created to optimize cutting length, as can be seen in

Figure 2. The tool begins side milling on the outer side of the stainless steel bar making its way to the center. A ramp plunge movement is used in the initial portion of the machining stage to create a gradual tool approach to the material, avoiding potential collisions.

All machining parameters remain the same throughout testing with the exception of the feed speed. As the number of cutting flutes changes from tool to tool, feed speeds are adjusted in order to ensure that feed per tooth speeds are similar. This allows similar cutting conditions on each cutting tooth, promoting equal working and wearing conditions. Spindle speed was established based on tool manufacturers’ recommendations and initial testing, ensuring a surface finish capable of being analyzed by the profilometer. Depth of cut and working engagement values were determined based on trial and error. Initial trials using 1 mm depth of cut were tested, however, this depth proved to be excessive for the combination of small tool diameter and high hardness steel, needing to be reduced to 0.5 mm. Recommended working engagement values are usually 60%–70% of tool diameter, so 3 mm was chosen for this parameter as smaller values may promote rougher surface finishing and decrease tool life span.

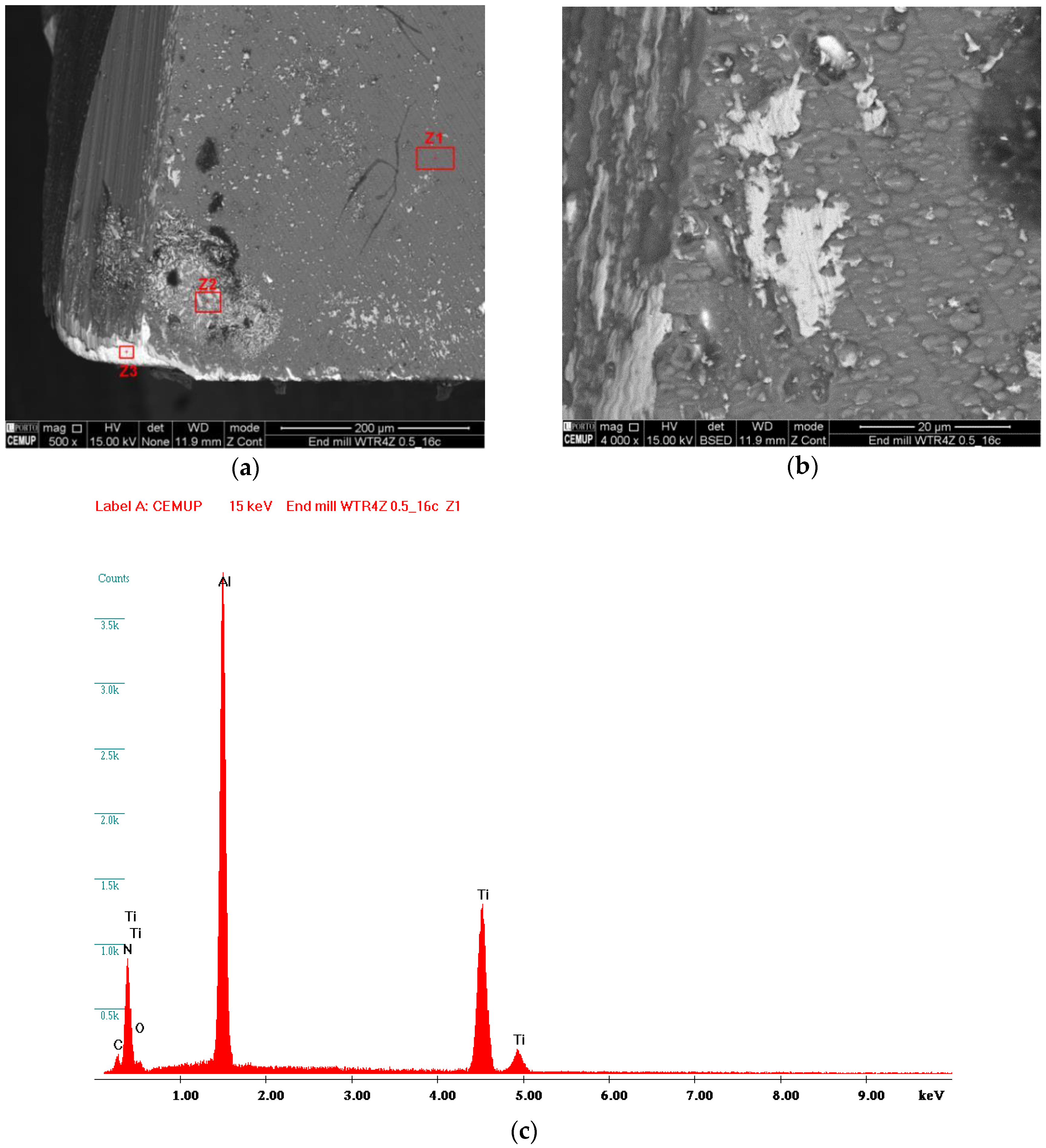

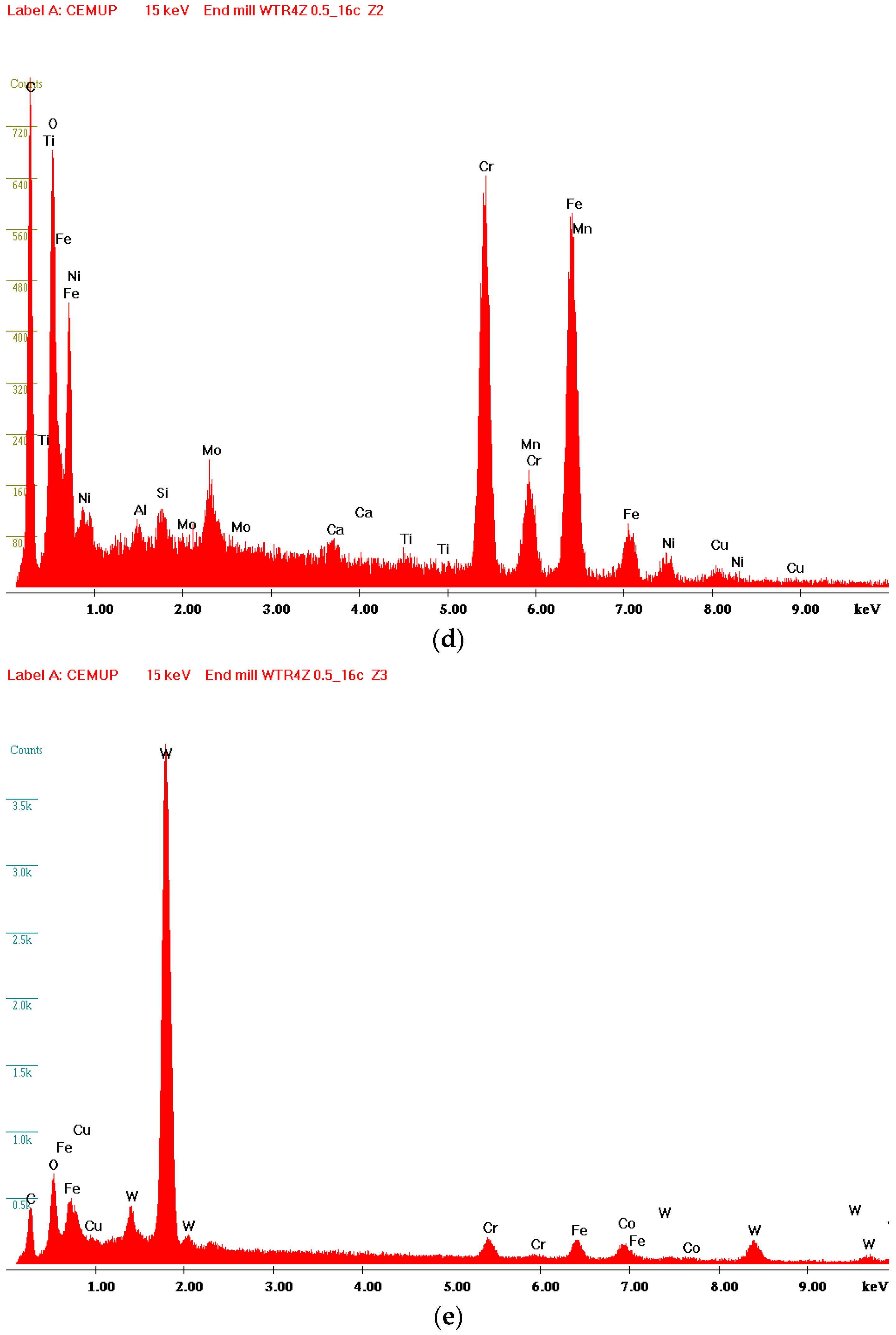

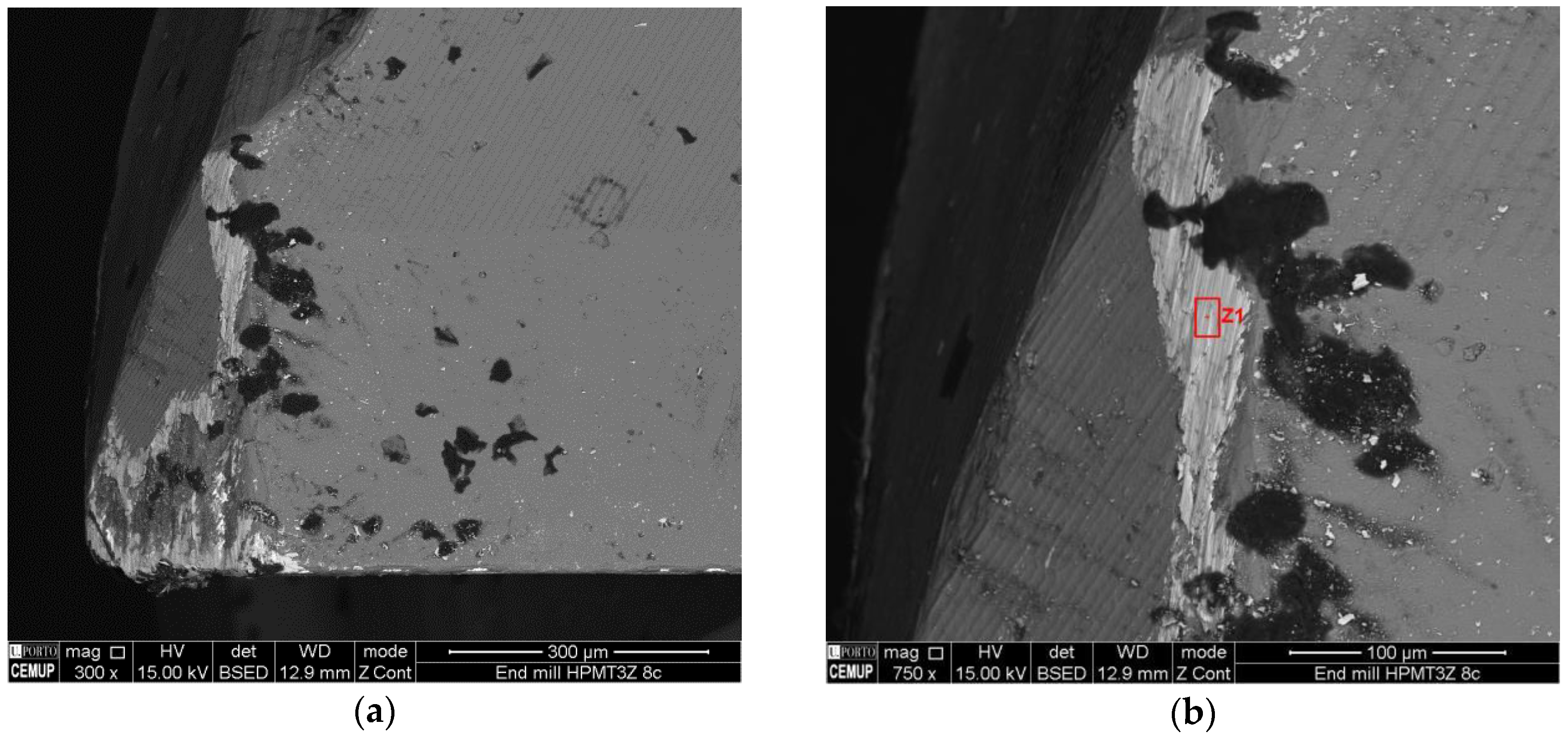

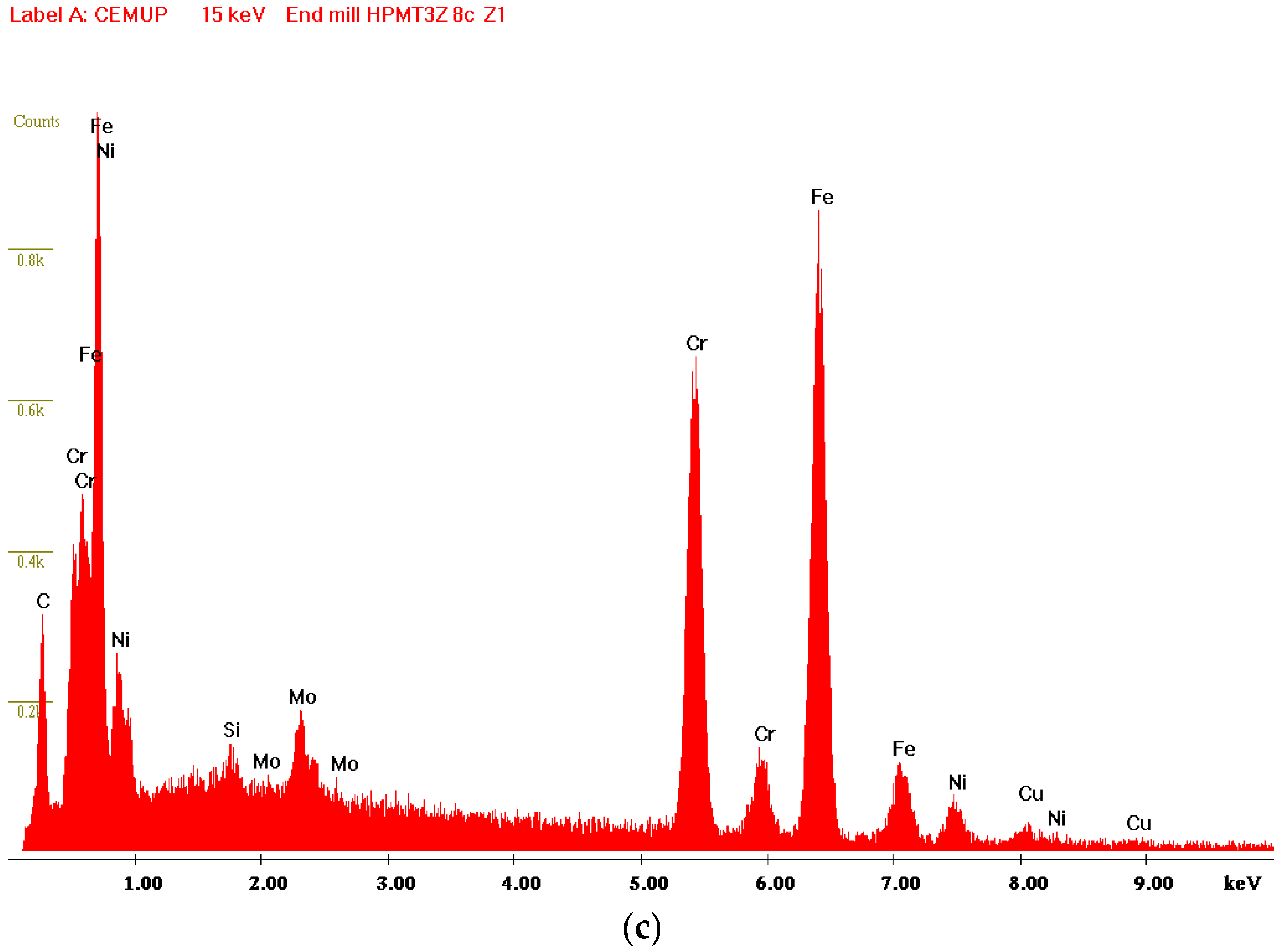

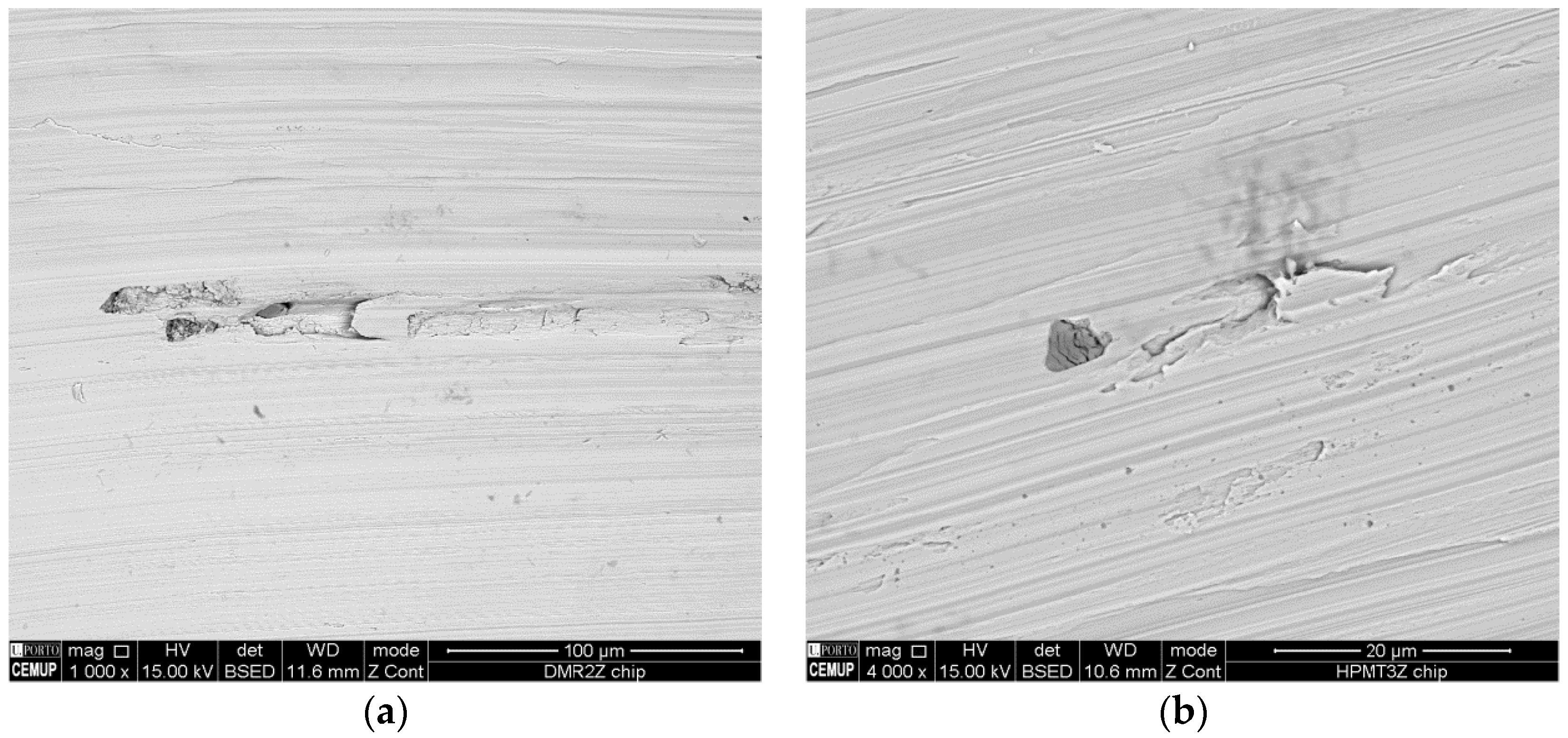

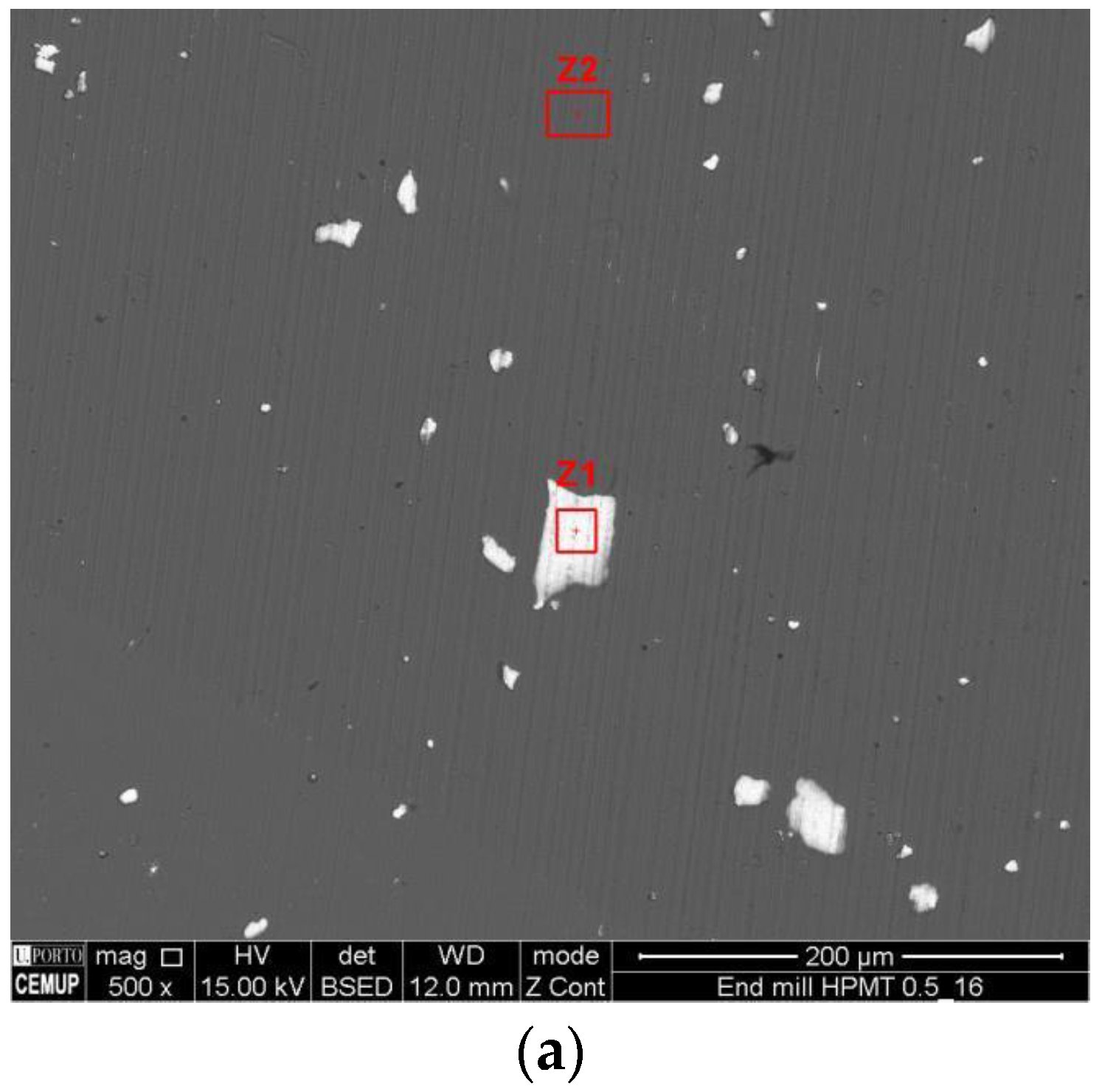

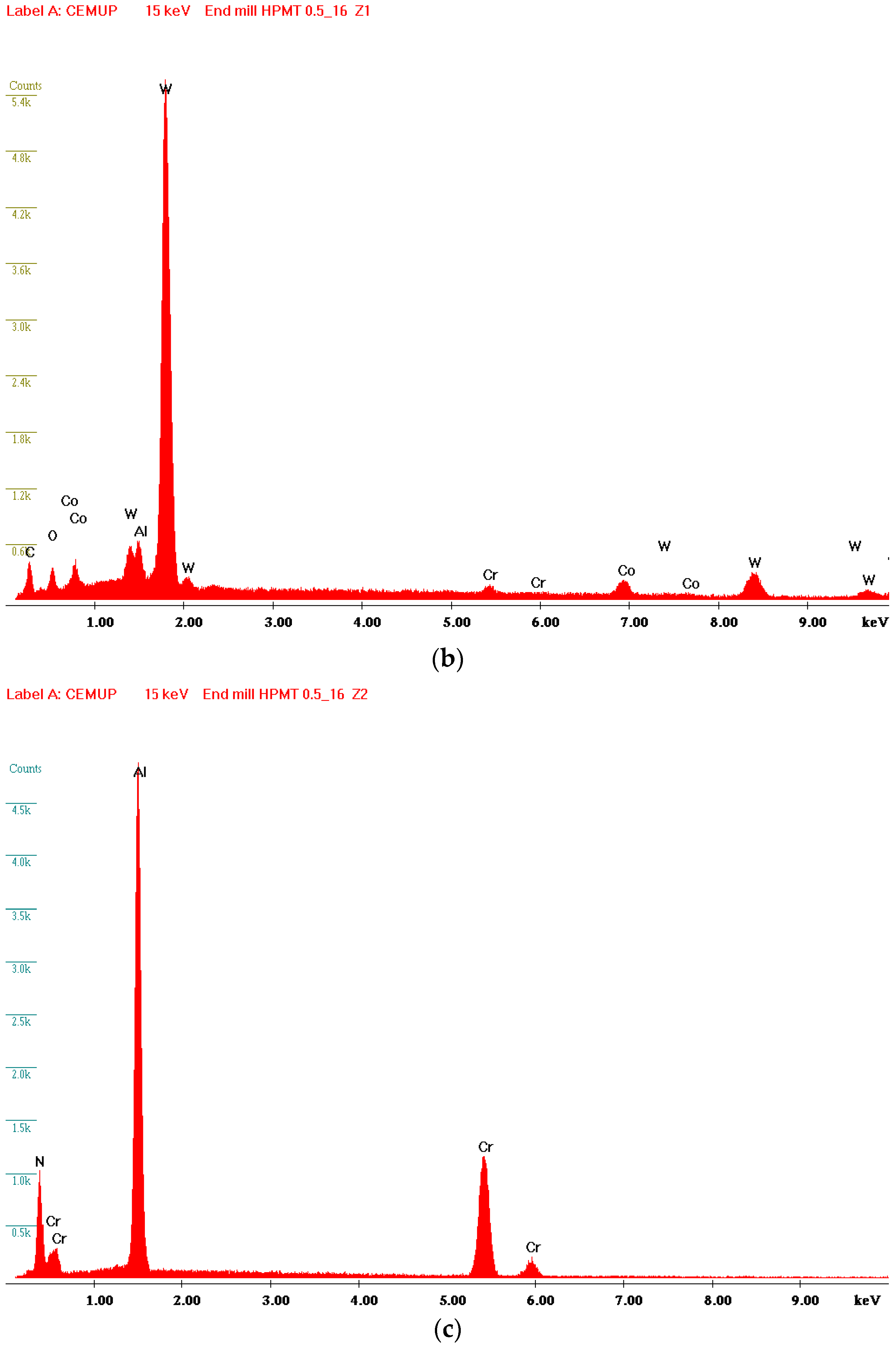

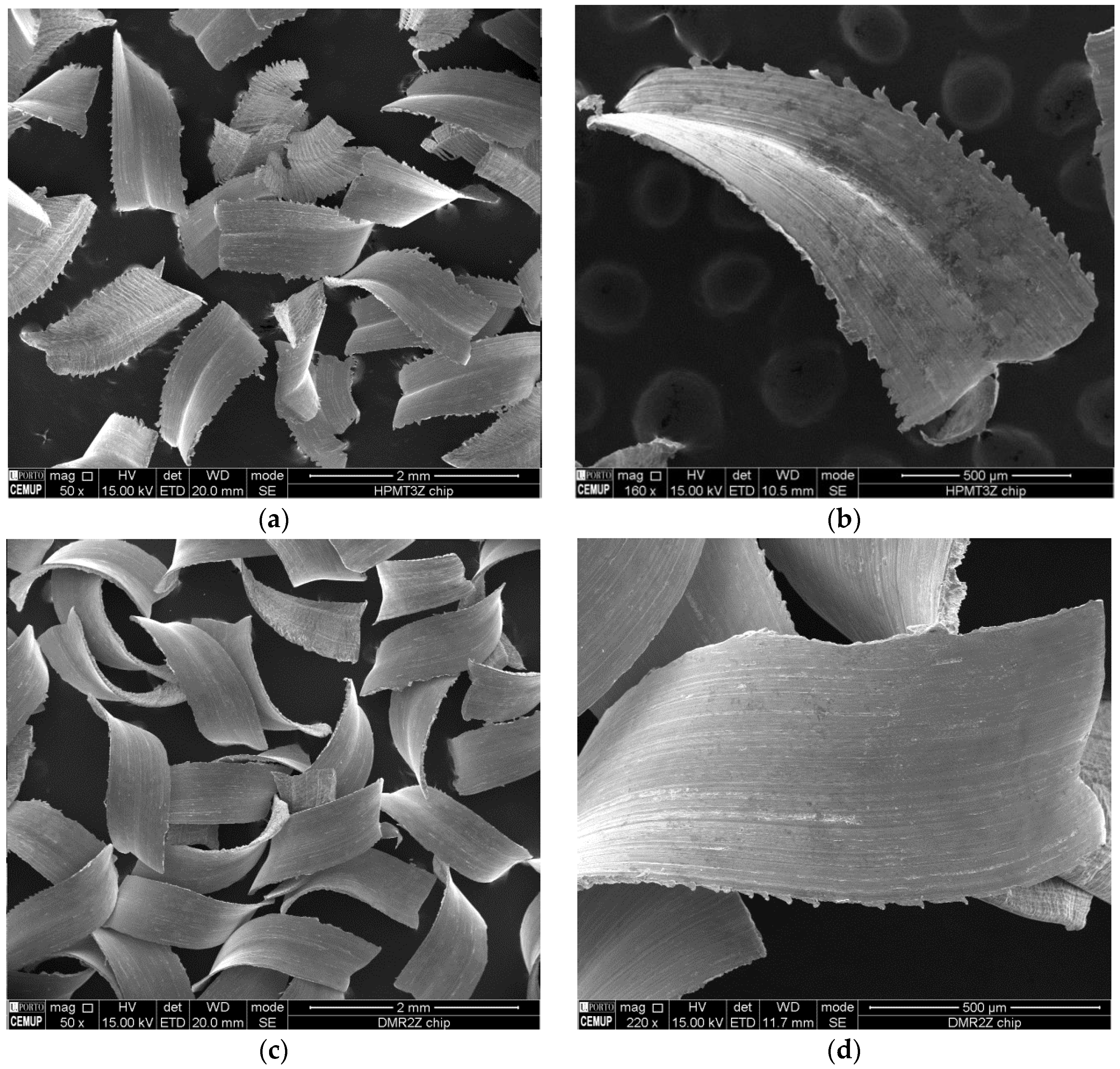

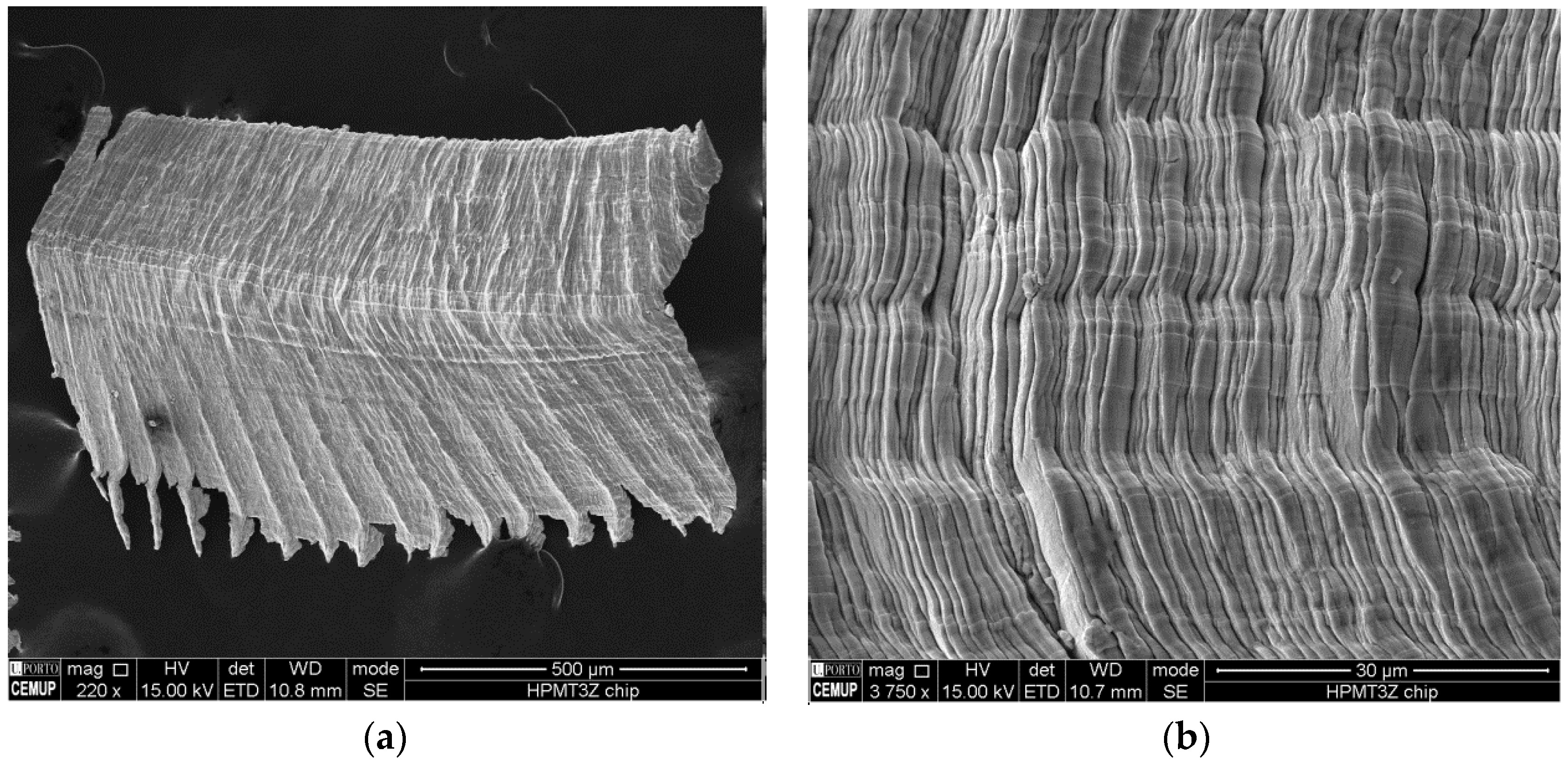

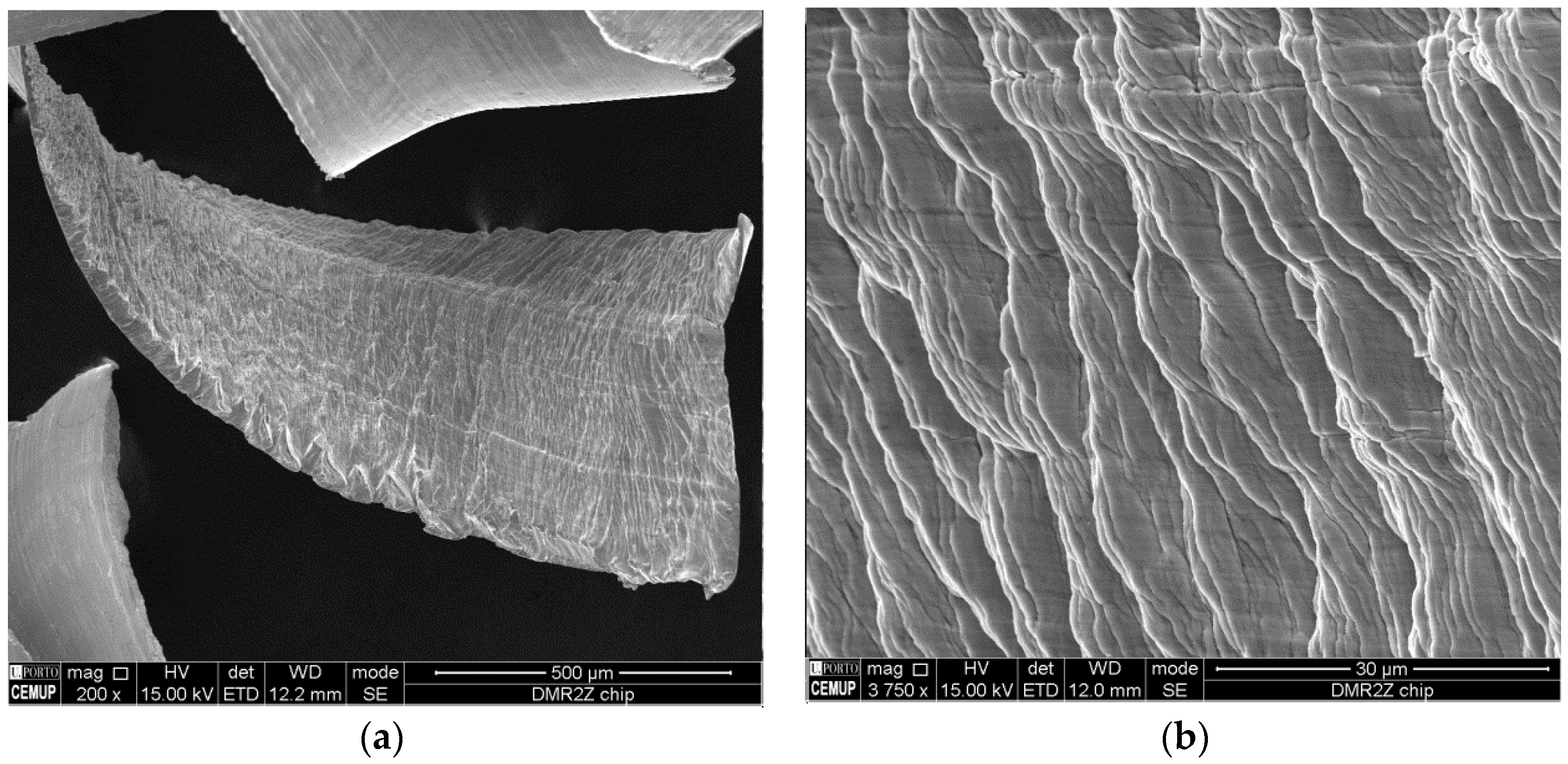

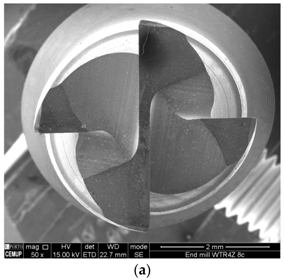

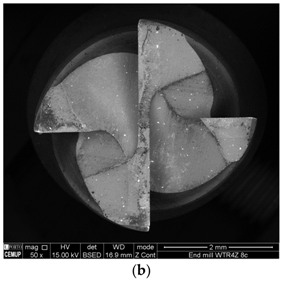

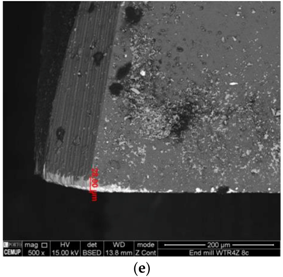

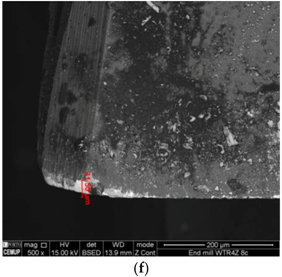

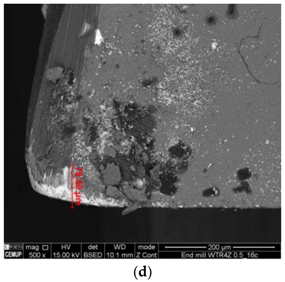

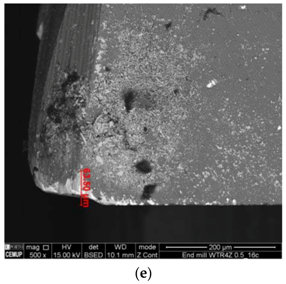

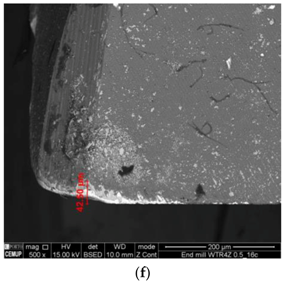

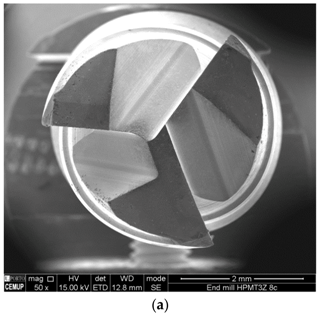

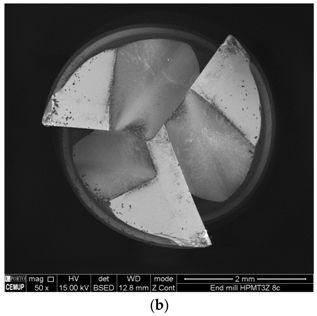

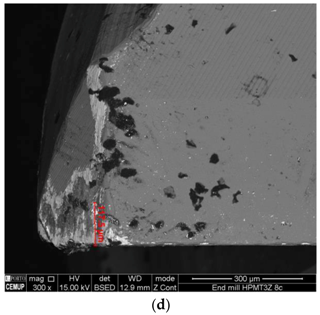

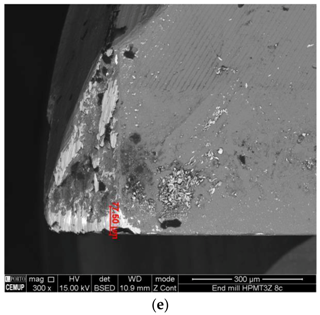

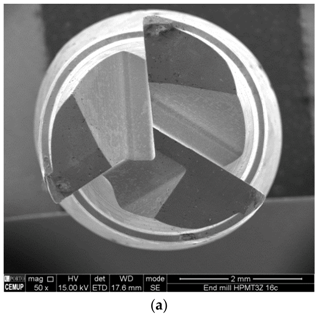

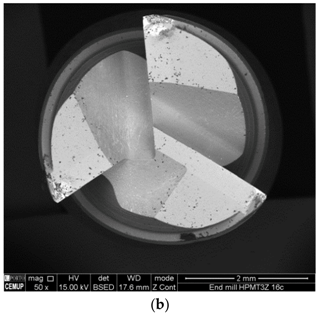

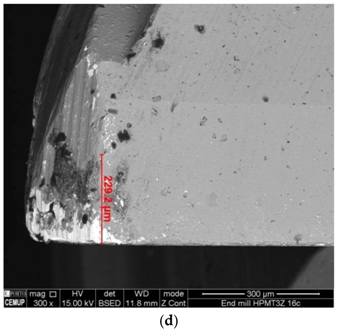

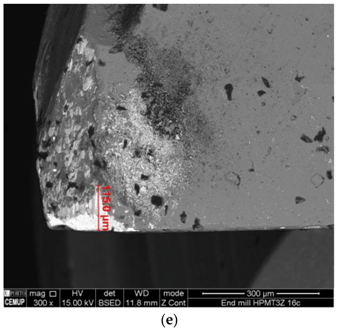

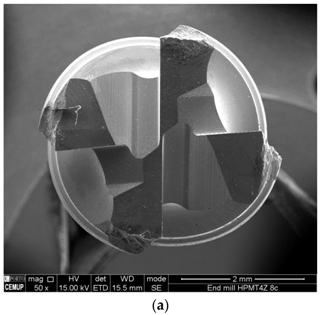

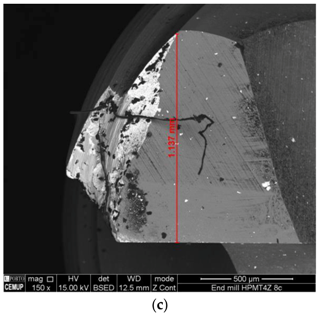

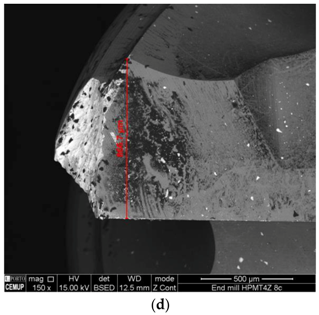

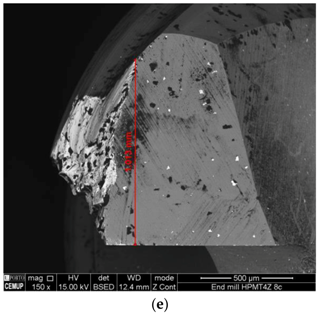

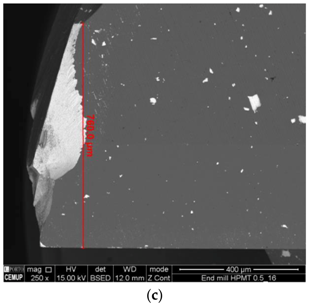

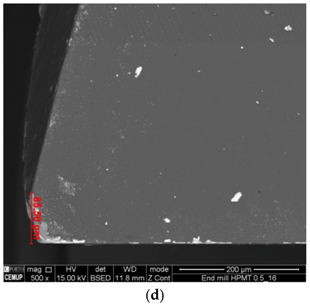

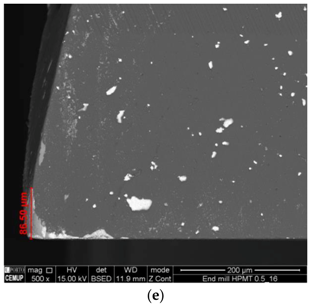

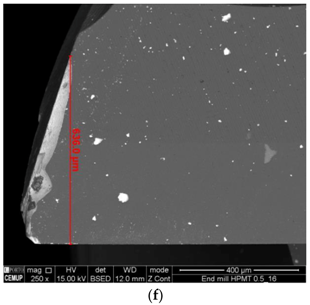

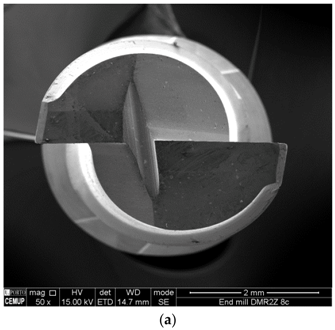

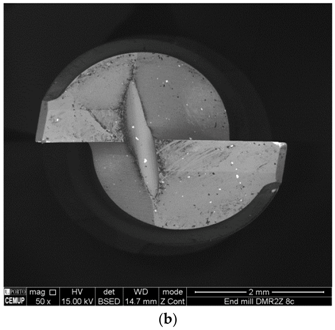

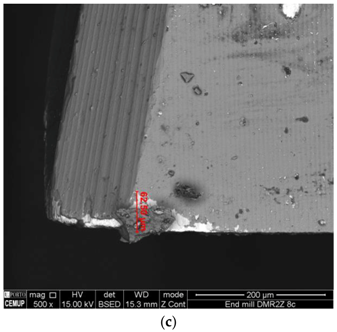

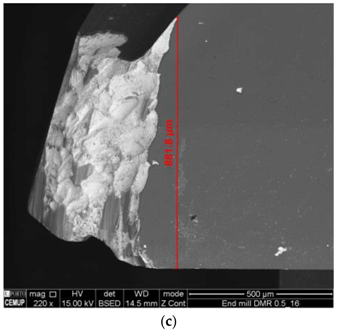

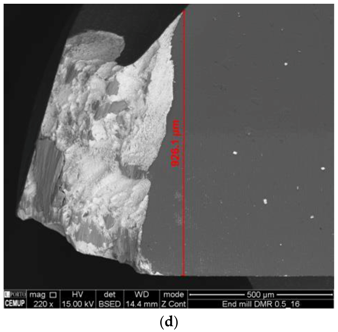

The surface wear of each tool was evaluated using a SEM microscope provided with an EDS (Energy-Dispersive X-ray Spectroscopy) system (EDAX X-ray micro-analysis). For this study, the equipment chosen was a FEI Quanta 400 FED SEM (FEI, Hillsboro, OR, USA). Several global and close up images of the worn edges were registered. Per tool, two global images are shown, one taken with secondary electron imaging and the other with retro diffused electron imaging. Whenever areas of discontinuities (promoted either by loss of coating or adhesion of external materials) were detected, an EDS analysis was made to determine the chemical composition of that unknown area. Close up images of each cutting flute were taken to evaluate and measure flank wear present on the cutting edges. These measurements are designated by the abbreviation VB.

Table 2 sums up all the machining parameters used with each tool. Cutting fluid emulsion was used during all machining operations, being composed of a mix of 5% oil in water.

The analysis of post-machined surface roughness was achieved using a surface profilometer (brand/model: Mahr Perthometer M2, MAHR, GmbH., Gottingen, Germany) provided with a diamond stylus tip with a 2 µm radius (ISO 4288:1996) [

23]. Two different roughness readings were taken, one in a radial orientation and the other in a tangential orientation, utilizing a cutoff value of 0.8 mm. Arithmetic mean surface roughness (

Ra), surface roughness depth (

Rz(DIN)) and maximum height of the roughness profile (

Rmax) were registered for each machined surface after each experimental run.

Ra is an arithmetical mean average and may not truly represent the roughness of the surface.

Rz is the sum of the height of the largest peak plus the depth of the deepest valley, inside the measured length.

Rmax is the height of the largest peak or the depth of the deepest valley encountered in the measured length. With radial readings it is possible to evaluate the surface roughness left by the tool feed marks (boundary lines between tool passes) while with tangential readings it is possible to verify the surface roughness in between these lines. For each tool trial, six measurements were taken (three in a radial direction and three in a tangential direction), allowing to determine a mean-value that better represents the overall roughness of the machined surface.

4. Discussion

In this section, a global analysis was done in order to establish which tools demonstrated superior performance and what lead to such results.

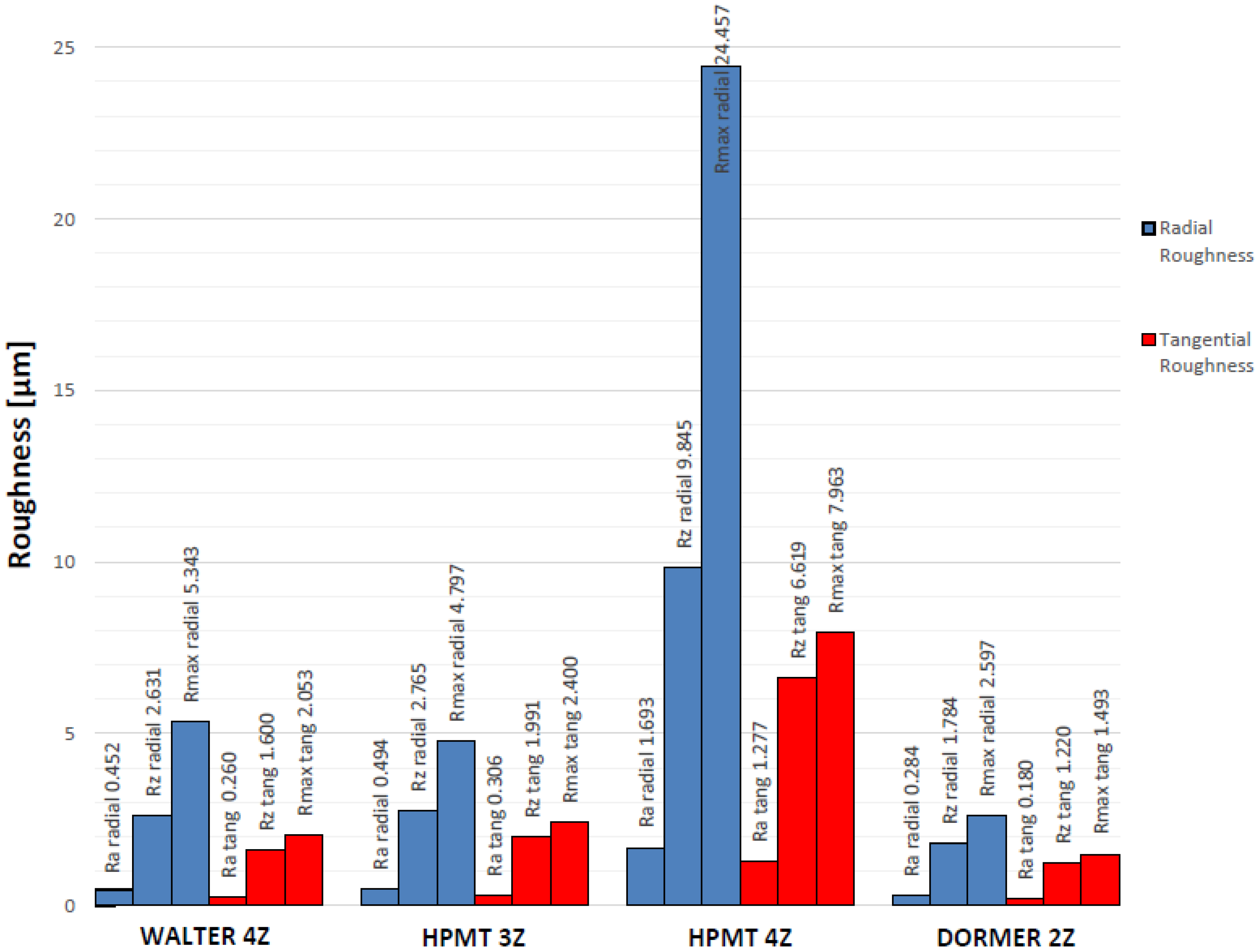

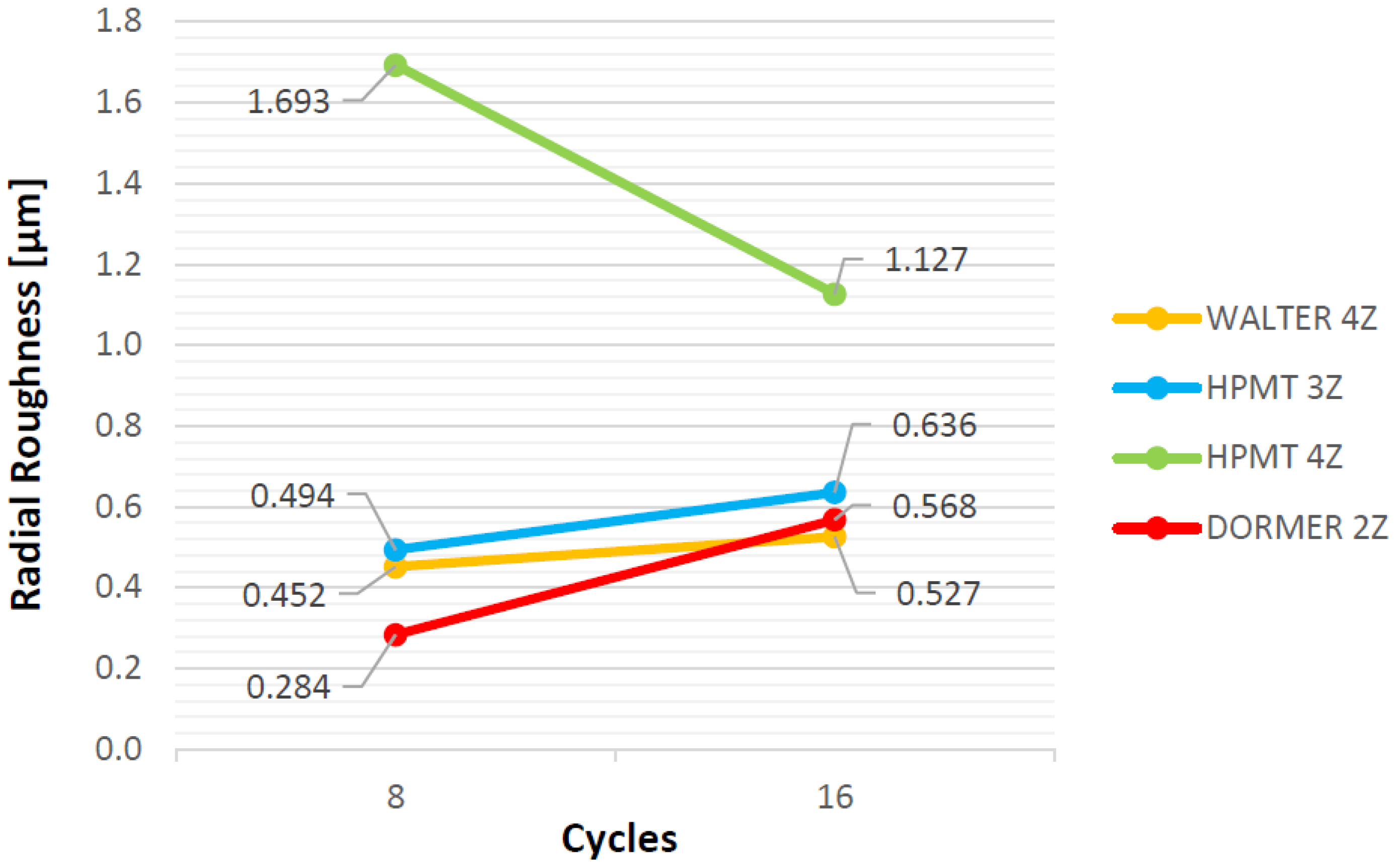

Depending on which tool was used and the length of the trial, several different roughness results were measured on each machined surface. The shorter 8 cycles trials presented lower roughness values, as expected. As seen in

Figure 10, the tool which produced the lowest surface roughness for the shorter cycle run was the DORMER 2Z AlCrN end mill, having, as well, the least difference between radial and tangential roughness values. This indicates a more uniform surface without noticeable feed marks. The

Rz values were also the smallest of all tests, indicating a low variation between surface peaks and valleys, which ensures longer part life with continued dimensional accuracy.

The WALTER 4Z TiAlN gave slightly higher roughness values for the 8 cycles when compared to the previous mentioned tool, however, it returned the most consistent global performance.

Regarding the HPMT 3Z AlCrN tool, reasonable roughness (including Rz) values were obtained, being the third best tool for the 8 cycles in terms of machining length.

End mill HPMT 4Z AlCrN performed poorly, returning very high values. This outcome was somewhat unexpected and, perhaps, may be a consequence of the excessive wear/damage suffered by the tool on the account of hardened material phases possibly present in the raw material. A possible manufacturing defect may also be speculated as the reason for such a rapid downfall.

Figure 10 also shows, in terms of radial roughness, an end mill which negatively stands out among the rest (HPMT 4Z AlCrN). While all other end mills showed similar

Ra results, HPMT 4Z AlCrN mill revealed higher

Ra radial roughness. As previously discussed, this tool suffered damage during the experimental trials, leading to a loss of material and edge sharpness of the cutting flutes. This phenomenon may explain the more noticeable feed mark embossments, leading to the larger radial

Rz and

Rmax roughness values.

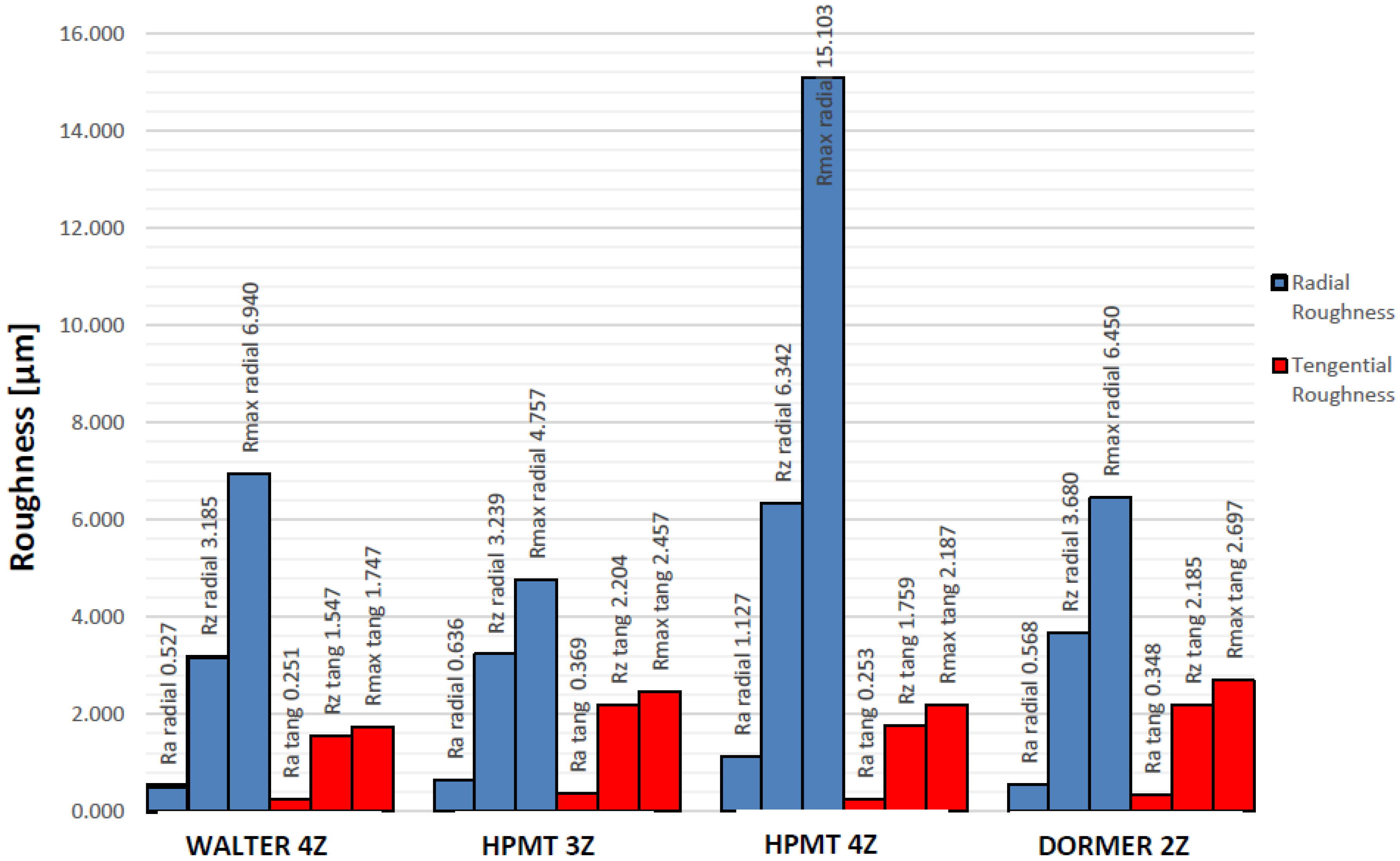

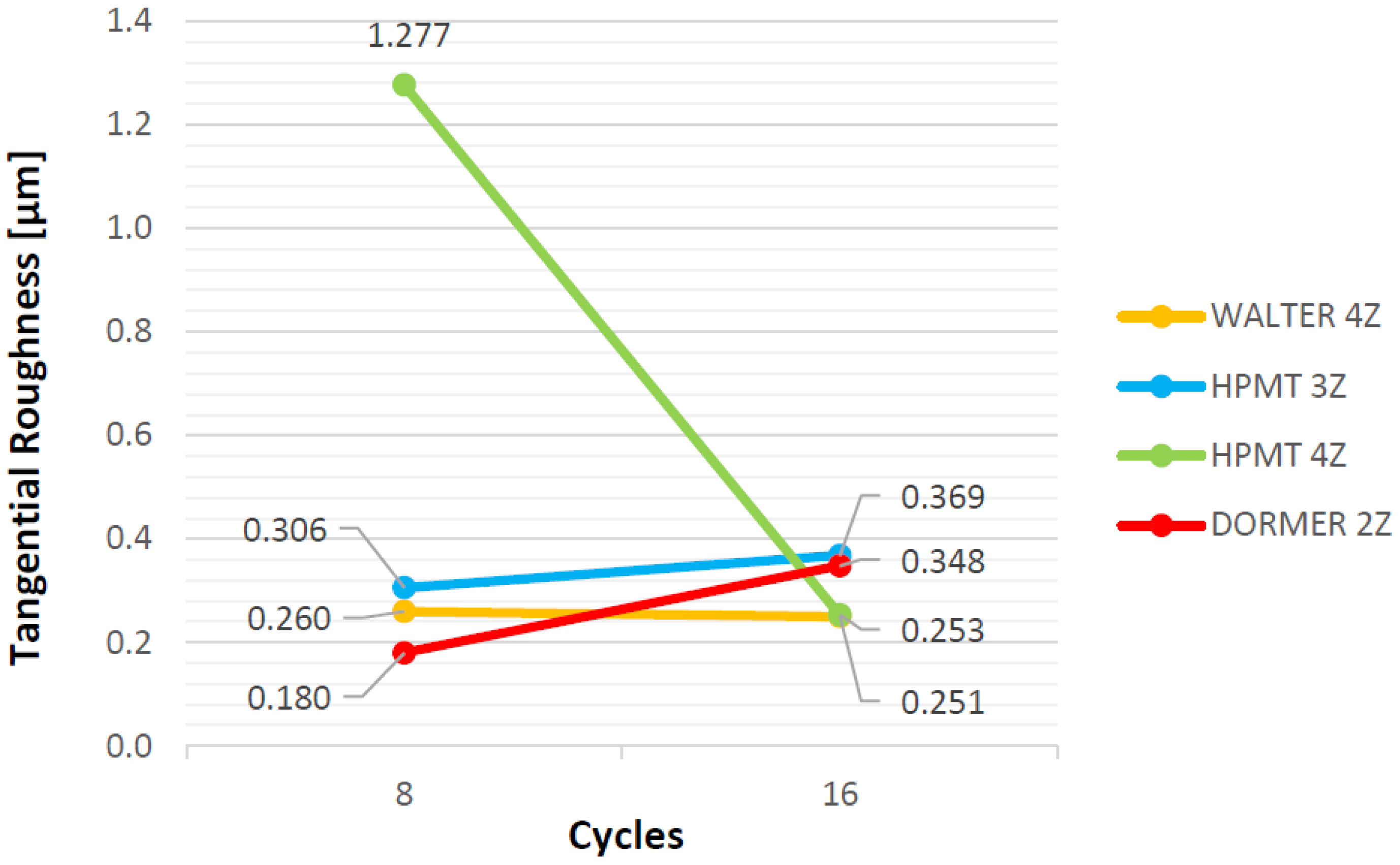

Tangential roughness values for the 16 cycles trials, shown in

Figure 11, clearly demonstrate that WALTER 4Z TiAlN and HPMT 4Z AlCrN obtained the best results. The remaining tools present similar and satisfactory tangential

Ra values, however, they exhibit higher

Rz values which lead to a more irregular surface in terms of peak height and valley depth.

All tools used in the experimental trials demonstrated similar types of wear, having some suffered more wear than others. In a broad way, it is possible to say that the main issues encountered were flank wear, chipping, cracking and breakage of the cutting edges. These issues manifested in different levels of severity. Tools with higher wear demonstrated poorer machined surfaces, while tools that suffered breakage created surfaces with noticeable feed marks.

The depth of cut used for all trials (0.5 mm) was more in tune with a finishing operation rather than a conventional roughing operation. The small material removal rate, aided with cutting fluid, allows a reduction of temperatures at the tool’s tip. The use of cutting fluids gives way to a large variation of temperature during machining, creating heat cycles which may lead to thermal fatigue. This fatigue may perhaps be the cause of, for instance, cutting edge fractures or other encountered defects. When adding the inherent vibration (created by the machining of tough materials) to the equation, the potential for tool chipping and crack propagation is increased, which then leads to a higher tool failure probability.

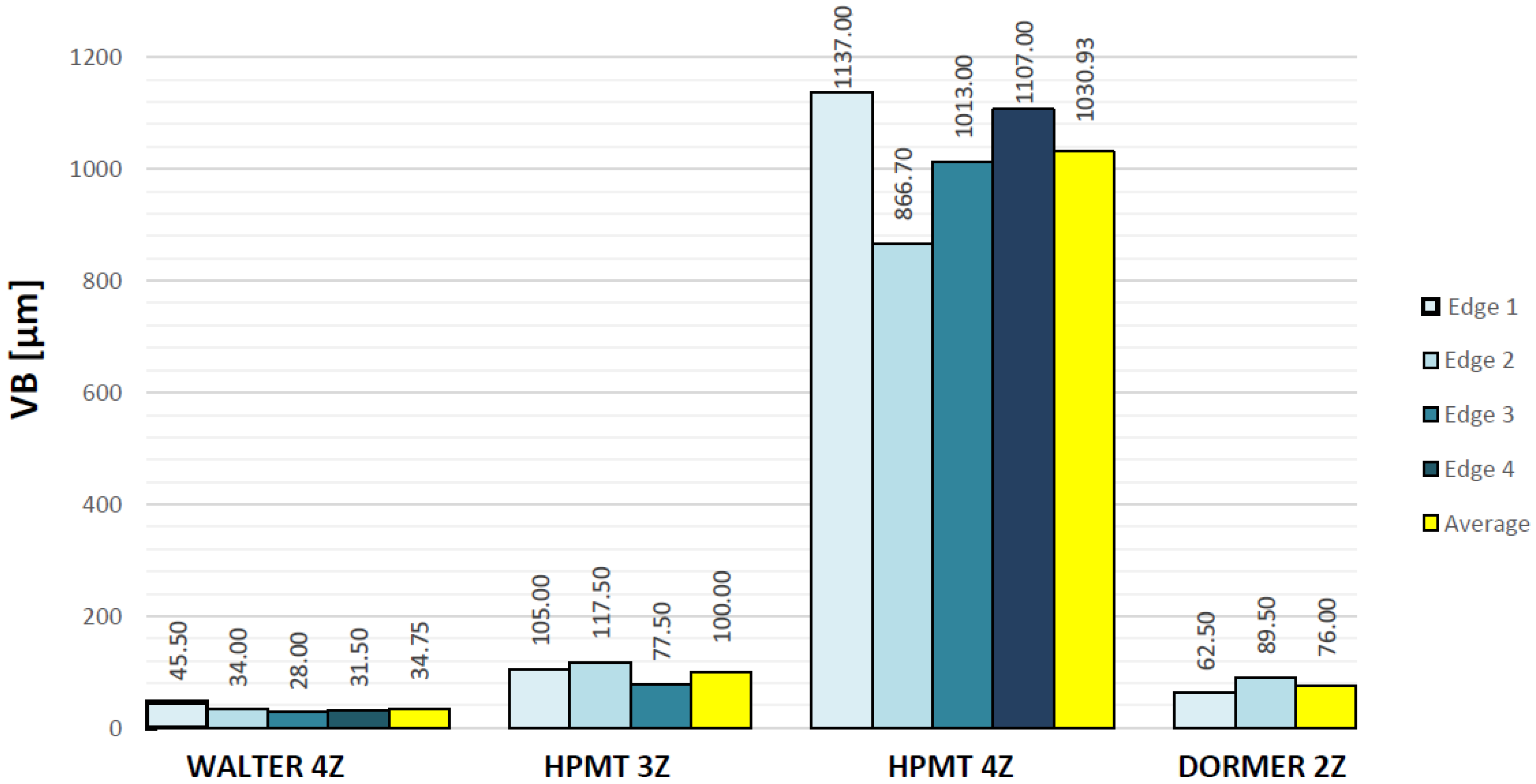

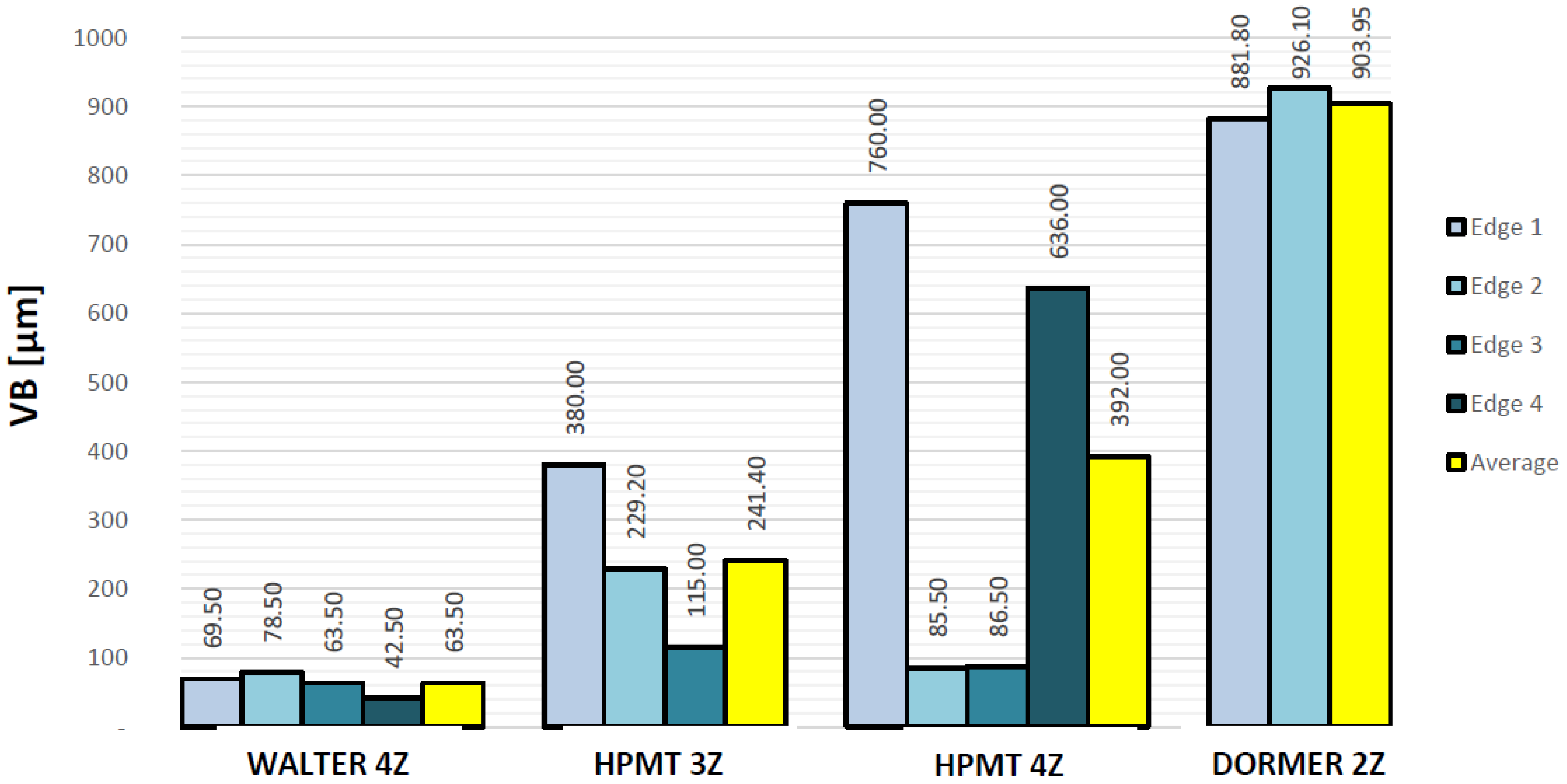

A comparison of flank wear suffered on each tool can be seen in

Figure 12 and

Figure 13. The WALTER 4Z TiAlN is the end mill with the lowest flank wear in the group having, as well, the smallest wear evolution when compared to the rest.

DORMER 2Z AlCrN came in second in terms of flank wear for the smaller cycle run, however, when compared to the results after 16 machining cycles, it is noticeable that this tool suffered severe cutting edge wear. As this tool only has two cutting flutes, it is at a disadvantage when compared to the others, demanding that each flute do extra work to achieve the same 15 m machining distance.

HPMT 3Z AlCrN achieved similar low VB values for the initial trial indicating low tool wear, and demonstrated the second best result after 16 cycles of machining. Although obtaining reasonable results, a large variation of flank wear between cutting flutes is present. Despite the fact that a low flank wear is present, this tool gave the highest surface roughness of all machined parts, delivering an inferior machined surface finish.

As stated previously, the HPMT 4Z AlCrN end mill suffered extended wear and damage during the first trial, exhibiting an overall significant degree of wear. SEM results for the lengthier trial show a large wear variation between cutting flutes. This variation may support the statement given previously which speculates that this tool dealt with different levels of hardness during its machining operation due to the presence of heterogeneities in the material.

Considering

Figure 12,

Figure 13,

Figure 14 and

Figure 15, it is possible to state that the WALTER 4Z TiAlN end mill:

Showed the overall best performance of the experiments;

Gave the second best/lowest radial and tangential surface roughness results for the 8 cycles trial and the best/lowest for the 16 cycles trial;

The quality of the machined surface is maintained independently of the increase in machining distance/working life of the tool. This can be seen by the registered low VB values of the cutting flutes and by the small slope of the line that correlates surface roughness between the first and second trials. This slope is the smallest among all the tools indicating a slower wear evolution and consequently longer tool life.

As can be seen in the previous figures, the coatings are valid essentially during the initial stage of the trials. Posteriorly, it is possible to observe deeply worn cutting edges, displaying coating detachment and requiring the hard metal substrate to work without any of the advantages conferred by the coating. Thus, it is important to observe the wear evolution from the 8 cycles to 16 cycles trials. The TiAlN coating displays better results in terms of flank wear, both in 8 and 16 cycles trials. All the AlCrN coatings demonstrate premature detachment and severe wear, mainly after 16 machining cycles. Hence, it can be stated that, when machining Duplex Stainless Steel, a TiAlN coating displays better results in terms of machining work than a AlCrN coating.

Hard metal grade seems to play an important role in wear evolution as some tools showed substrate wear and corresponding degradation in terms of flank wear.

The number of flutes is also an important issue to consider because when using the same feed speed on a tool with less cutting flutes, the number of tool rotations and corresponding impact increase, leading to a premature cutting edge wear.

The overall best tool (WALTER 4Z TiAlN) has a coating composed by titanium aluminium nitride. This coating was shown to be generally superior in terms of longevity and quality of machined surfaces. The aluminium oxide promotes high temperature resistance while the combination of elements promotes a hard and tough surface. In fact, the general consensus is that tools that are properly coated improve longevity and optimize cutting parameters.

5. Conclusions

All in all, it is possible to state that end mills with four cutting flutes maintained a better surface roughness, presenting the lowest Ra, Rz and Rmax results for the 16 cycles trials. They are an appropriate choice to perform side milling operations on the grade of Duplex Stainless Steel used in this study. Nonetheless, the other tested end mills showed interesting results (only slightly worse than the four-flute end mills), being more suitable for slotting or down milling operations. In these types of machining operations, having lesser cutting flutes gives the advantage of easily and effectively extracting chips from the tooling edges. This ease of extraction avoids potential material adhesion or build up on cutting edges, phenomena that worsens when machining materials with similar compositions as the ones here tested. On the downside, tools with only two or three cutting flutes tend to have a shorter working life owing to the fact that, to machine the same distance, each cutting knife has a higher work load when compared, for example, to four-flute end mills. The work load per tooth is independent of speed parameters, such as the feed per tooth speed of the machining center.

The duplex stainless steel used in the experiments proved to be very harsh on the cutting tools. Even though the machining distance used in the trials is considered to be relatively short, the tested tools suffered extended damage and wear, exemplifying how difficult it is to work and process these types of materials.

It seems to have been made clear that WALTER 4Z TiAlN end mill delivered the best results in terms of wear and almost always of machined surface quality. Worth mentioning as well is that, in spite of suffering large wear, the surface quality of parts machined with DORMER 2Z AlCrN end mill revealed very good results, being close to those of the other tools. However, this outcome can be attributed essentially to the quality of the tool substrate, made from a very good hard metal grade.

Thus, despite the large evolution registered by AlCrN coatings, this work shows that TiAlN is yet more effective in cutting tough materials, such as Duplex Stainless Steel grades, in end mill machining operations.