Morphology and Wear Resistance of Laser-Clad Fe-Cr-Nb-C Alloy Coatings

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Substrate and Raw Materials

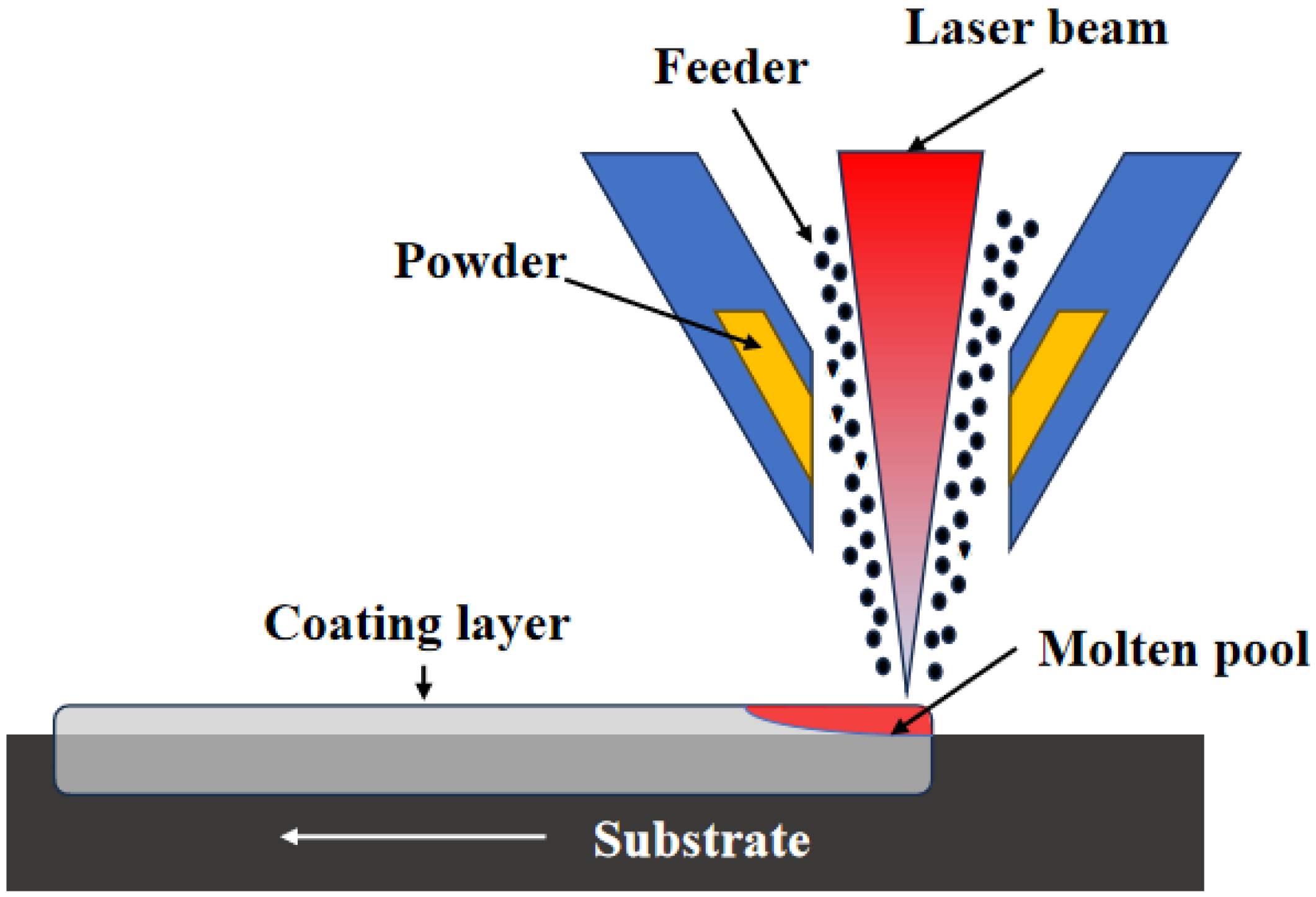

2.2. Experimental Procedures

2.3. Computational Methods

3. Results and Discussion

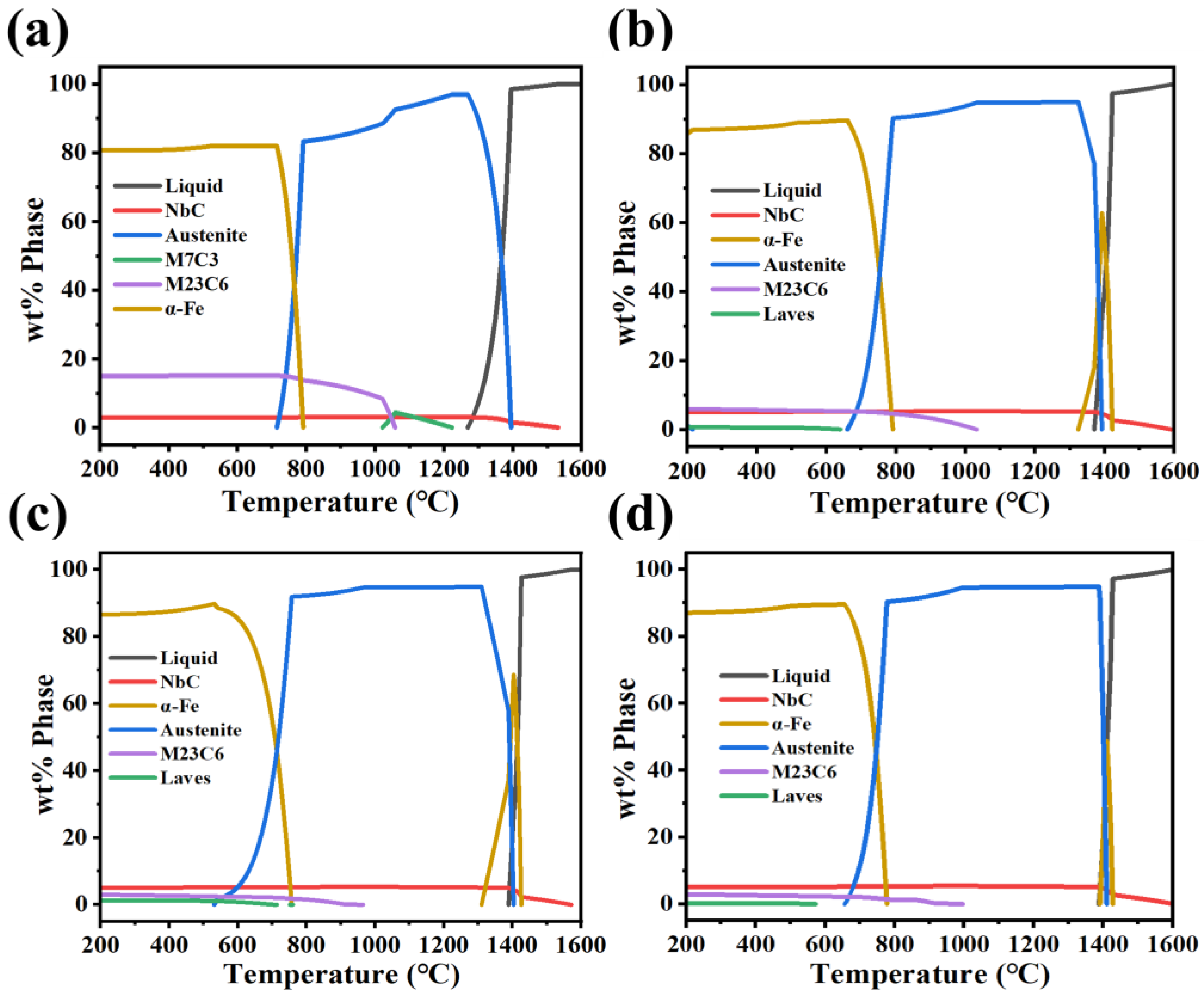

3.1. Coating Composition and Phase Analysis

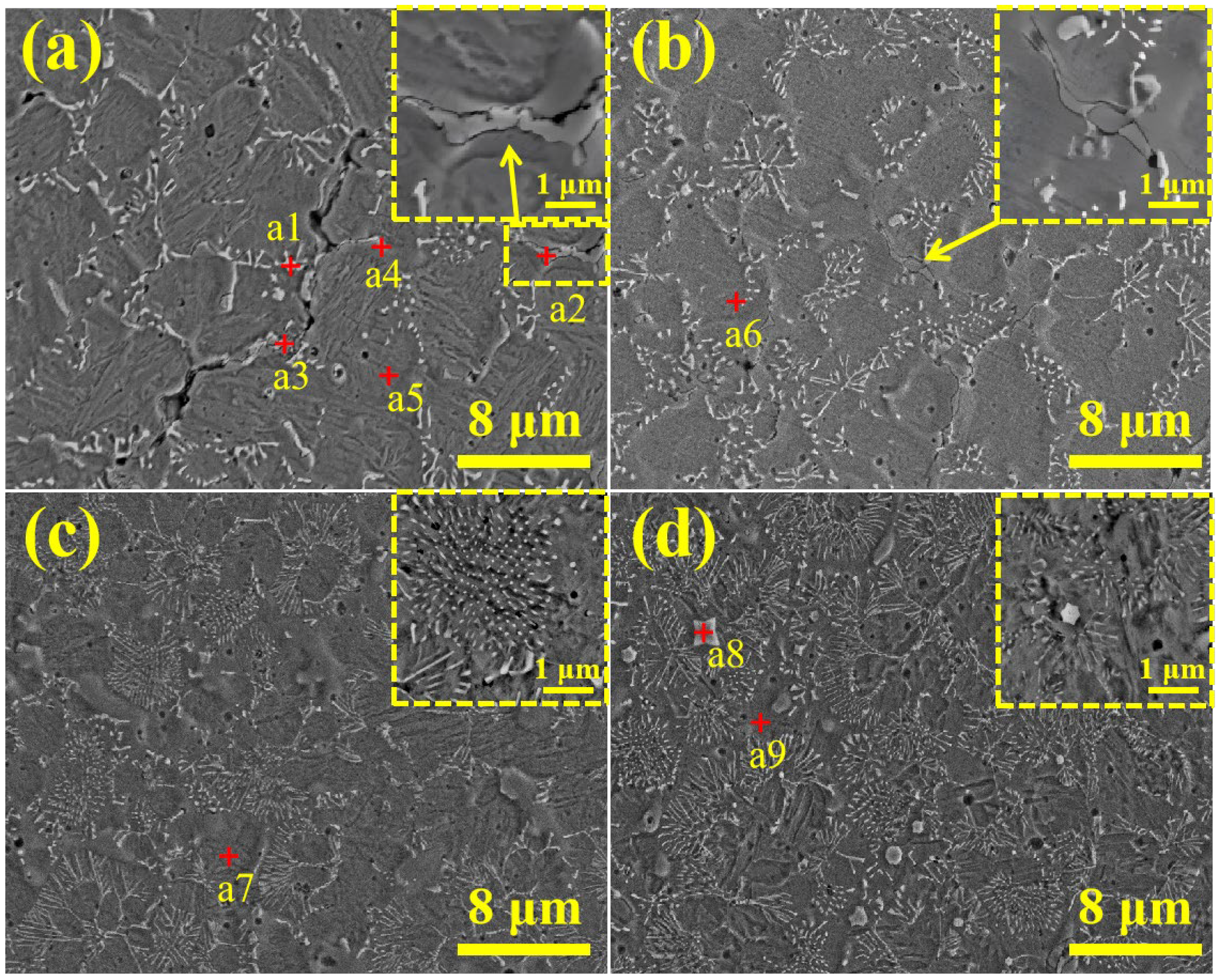

3.2. Microstructure of Coatings

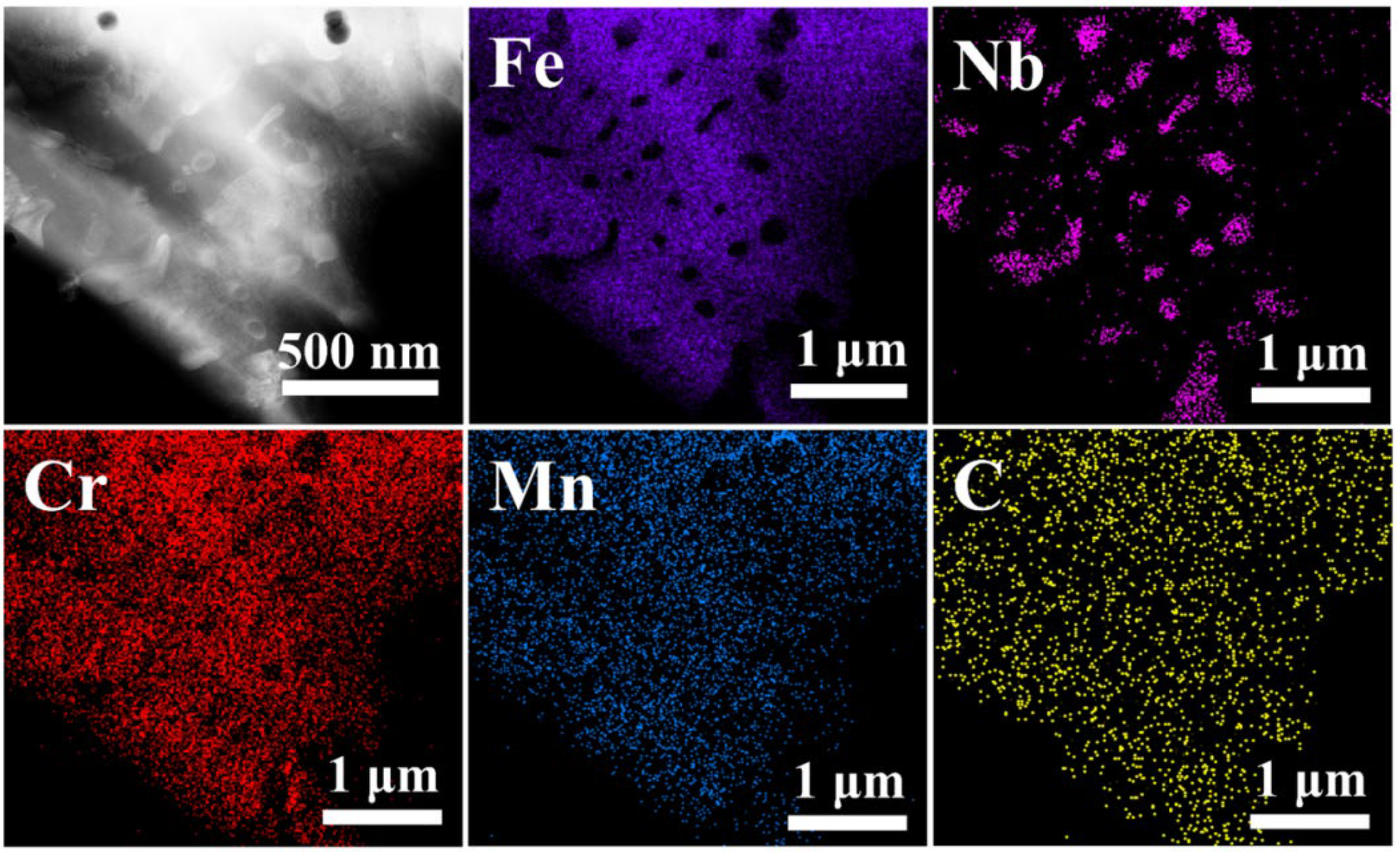

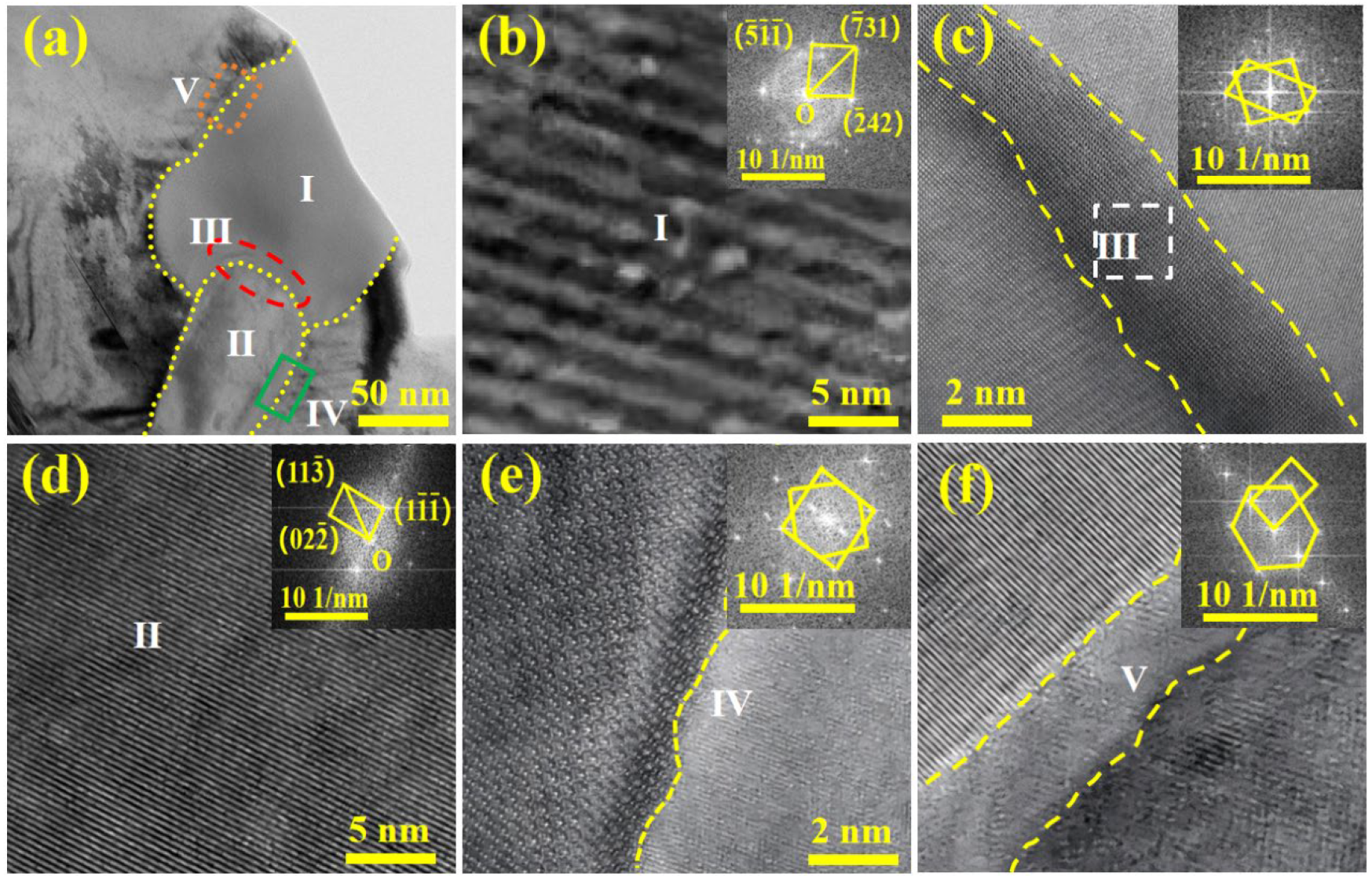

3.3. TEM Analysis

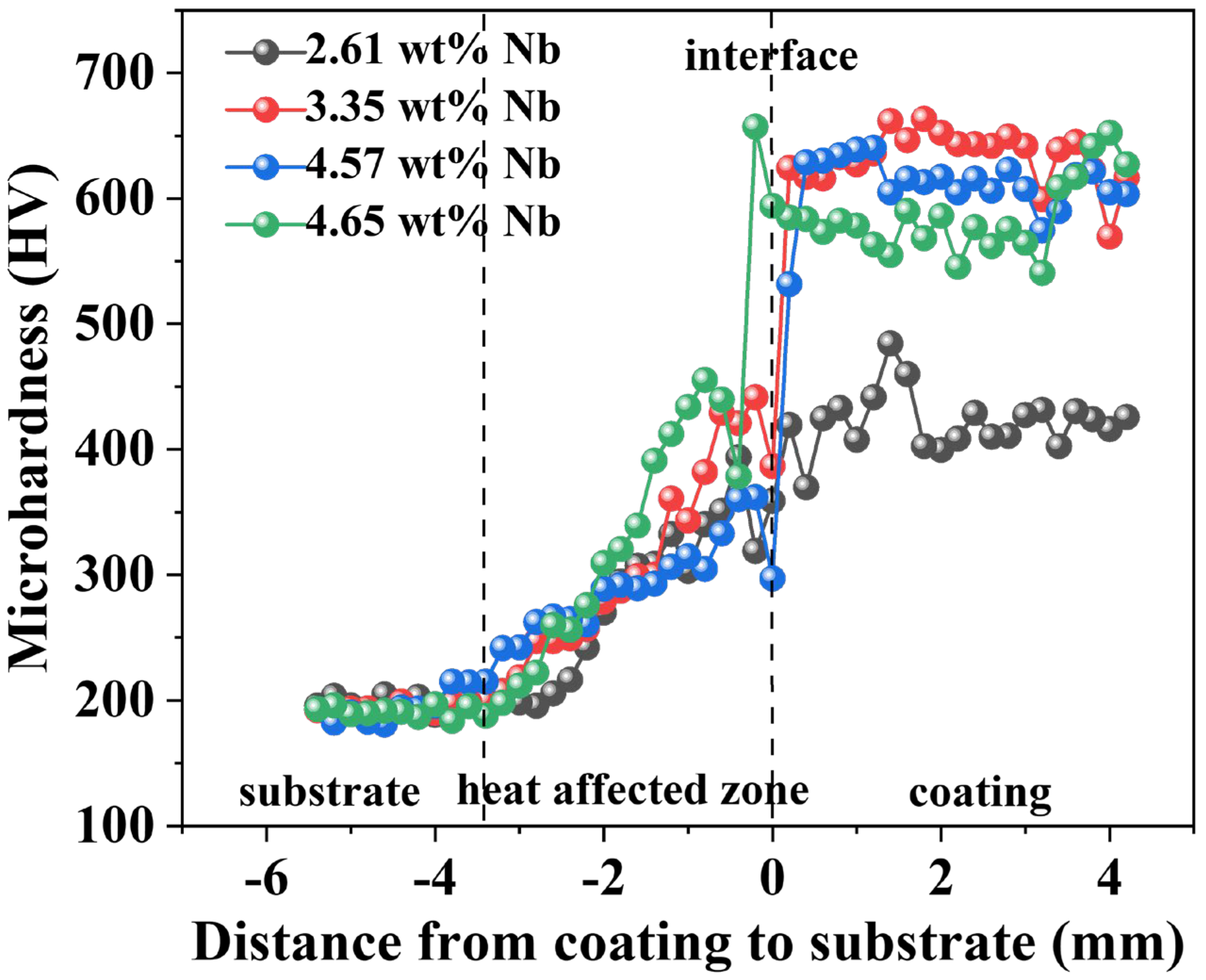

3.4. Microhardness Analysis

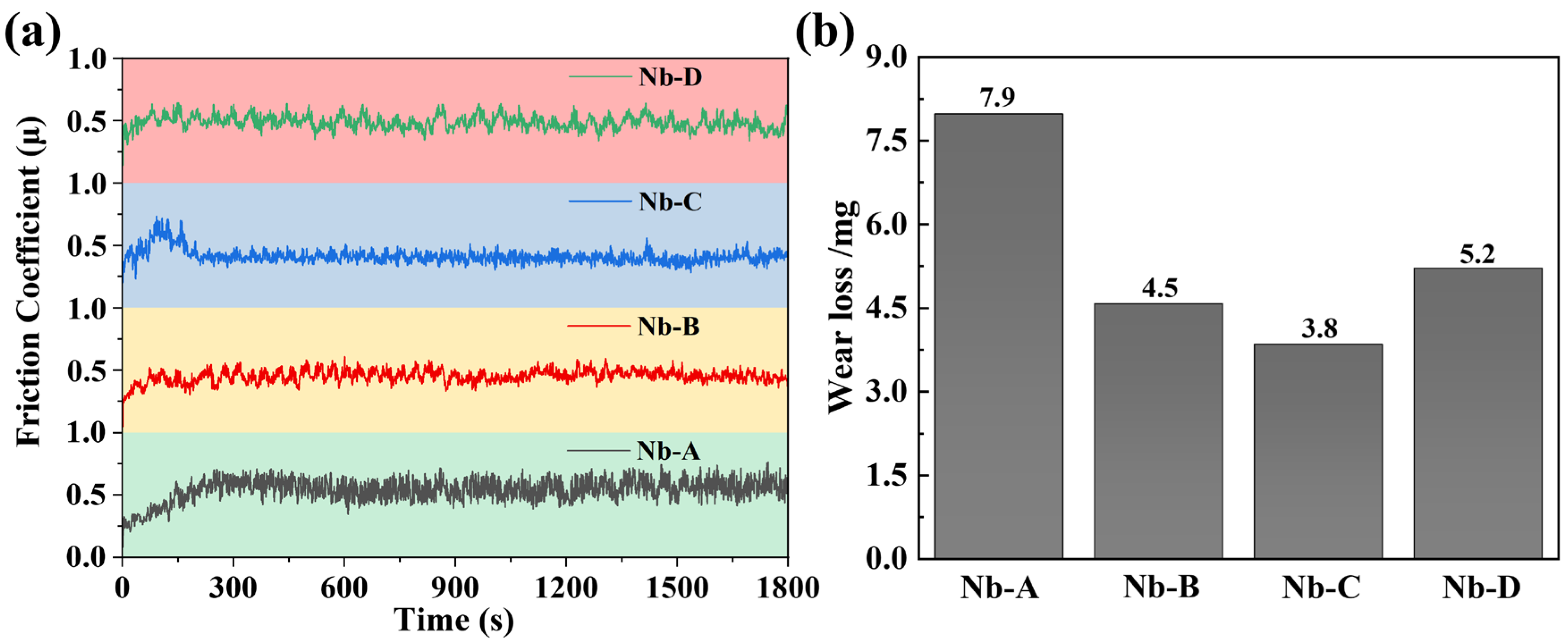

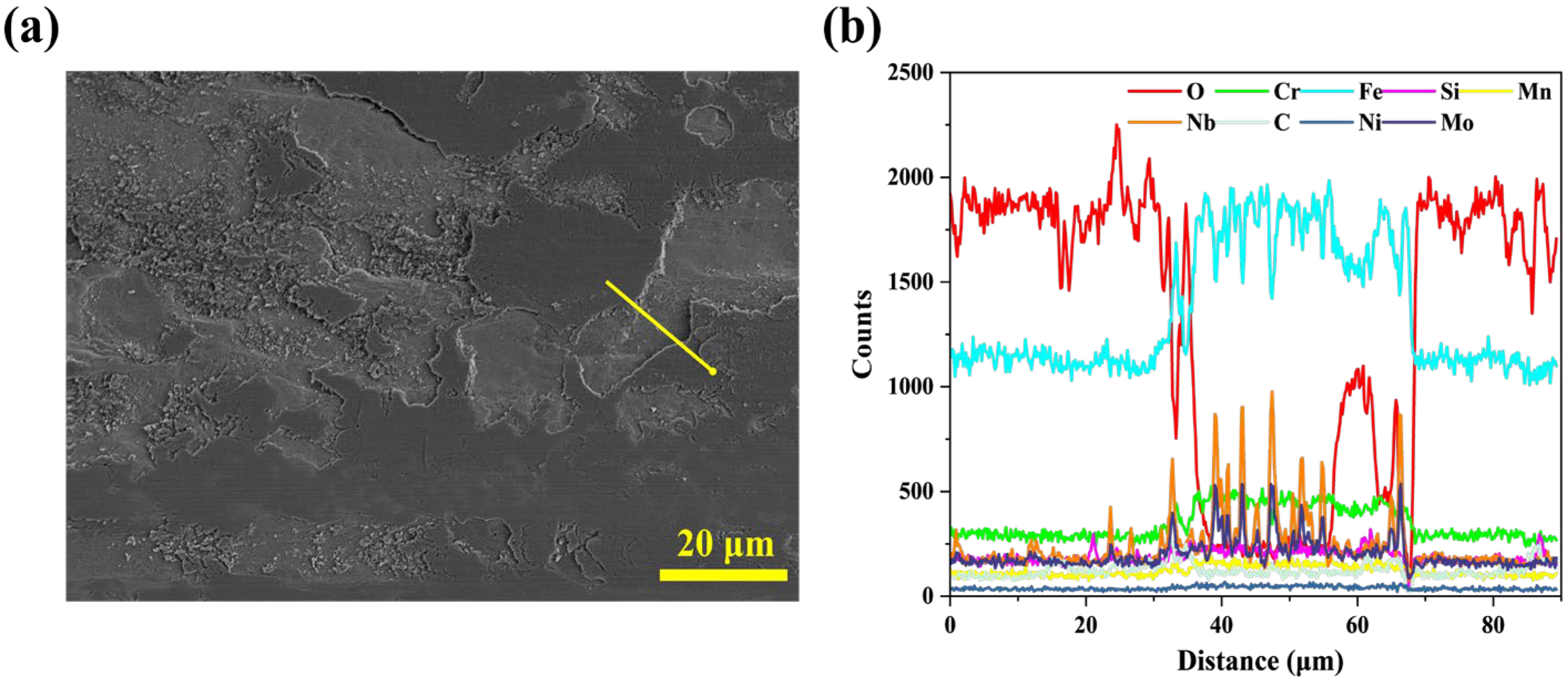

3.5. Tribological Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shang, F.; Chen, S.; Zhou, L.; Jia, W.; Cui, T.; Liang, J.; Liu, C.; Wang, M. Effect of laser energy volume density on wear resistance and corrosion resistance of 30Cr15MoY alloy steel coating prepared by laser direct metal deposition. Surf. Coat. Technol. 2021, 421, 127382. [Google Scholar] [CrossRef]

- Chen, S.; Ni, L.; Zhang, Y.; Wang, Y.; Cui, T.; Liang, J.; Chen, J.; Wang, M. Laser cladding of a novel Fe-based coating with high wear resistance, corrosion resistance and self-lubricating properties. Surf. Coat. Technol. 2024, 478, 130468. [Google Scholar] [CrossRef]

- Shang, F.; Chen, J.; Song, X.; Chen, S.; Liang, J.; Wang, M. Strength-ductility and corrosion resistance match mechanism of bainite/martensite dual phase 30Cr15MoY alloy steel. Mater. Sci. Eng. A. 2022, 832, 142477. [Google Scholar] [CrossRef]

- Shang, F.; Chen, S.; Zhang, C.; Liang, J.; Liu, C.; Wang, M. The effect of Si and B on formability and wear resistance of preset-powder laser cladding W10V5Co4 alloy steel coating. Opt. Laser Technol. 2021, 134, 106590. [Google Scholar] [CrossRef]

- Hou, Q.Y.; Wang, J.T. Influence of CeO2 on the microstructure and wear resistance of iron-based alloy coating studied by Rietveld refinement method. Surf. Coat. Technol. 2010, 204, 2677–2682. [Google Scholar] [CrossRef]

- Gao, B.; Xu, T.; Wang, L.; Liu, Y.; Liu, J.; Zhang, Y.; Sui, Y.; Sun, W.; Chen, X.; Li, X.; et al. Achieving a superior combination of tensile properties and corrosion resistance in AISI420 martensitic stainless steel by low-temperature tempering. Corros. Sci. 2023, 225, 111551. [Google Scholar] [CrossRef]

- Du, A.; Lattanzi, L.; Jarfors, A.E.W.; Zheng, J.; Wang, K.; Yu, G. Role of matrix alloy, reinforcement size and fraction in the sliding wear behaviour of Al-SiCp MMCs against brake pad material. Wear 2023, 530-531, 204969. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, S.; Zhang, H.Y.; Wang, R.; Zhang, H.F.; Zhang, C.H.; Wu, C.L.; Chen, H.T. Exploration of wear and slurry erosion mechanisms of laser clad CoCrFeNi + x (NbC) high entropy alloys composite coatings. Tribol. Int. 2024, 193, 109405. [Google Scholar] [CrossRef]

- Zhang, Y.; Ge, C.; Wu, Y.; Deng, Y.; Zhang, W.; Liu, X.; Liu, Y.; Chen, H. The impact of Nb on the microstructure and mechanical properties of Stellite 21 alloy coatings. Surf. Coat. Technol. 2024, 489, 131113. [Google Scholar] [CrossRef]

- Bolelli, G.; Colella, A.; Forlin, E.; Gehlen, L.R.; Lusvarghi, L.; Miconi, L.; Pintaude, G.; Puddu, P. Tribological performance of NbC-based hardmetal HVOF coatings with Fe-Cr-Mo matrix. Wear 2025, 564–565, 205680. [Google Scholar] [CrossRef]

- Pintaude, G. Strategies for the Development of Wear-Resistant Coatings: A Review. Soldag. Insp. 2021, 26, e2616. [Google Scholar] [CrossRef]

- Jokari, M.; Ali, Y.; Gallo, S.C.; Lin, W.; Gates, J. Effect of Cr:Fe ratio on the mechanical properties of (Cr,Fe)7C3 ternary carbides in abrasion-resistant white cast irons. J. Mater. Sci. 2023, 58, 7504–7521. [Google Scholar] [CrossRef]

- Yu, J.; Qiao, C.; Zhang, S.; Liu, Z.; Wróblewski, P. Tribological properties of laser-cladded Fe-based amorphous composite coatings under dry and lubricated sliding. Opt. Laser Technol. 2023, 166, 109583. [Google Scholar] [CrossRef]

- Zhu, C.; Fordyce, I.; Sun, S.D.; Annasamy, M.; Fabijanic, D.; Short, K.; Paradowska, A.; Leary, M.; Brandt, M.; Easton, M. Effect of Ti and TiC additions on the microstructure and wear resistance of high chromium white irons produced by laser directed energy deposition. Wear 2022, 510–511, 204519. [Google Scholar] [CrossRef]

- Li, J.; Zhu, Z.; Peng, Y.; Shen, G. A comparative study on microstructure evolution and wear resistance of different-sized tungsten carbide modified Fe-based laser cladding coatings. Opt. Laser Technol. 2022, 147, 107672. [Google Scholar] [CrossRef]

- Liu, L.; Lin, Y.; Peng, L.; Kang, X.; Wang, X. Progress in Microstructure Design and Control of High-Hardness Fe-Based Alloy Coatings via Laser Cladding. Coatings 2024, 14, 1351. [Google Scholar] [CrossRef]

- Ertugrul, O.; Enrici, T.M.; Paydas, H.; Saggionetto, E.; Boschini, F.; Mertens, A. Laser cladding of TiC reinforced 316L stainless steel composites: Feedstock powder preparation and microstructural evaluation. Powder Technol. 2020, 375, 384–396. [Google Scholar] [CrossRef]

- Xiao, Q.; Sun, W.L.; Yang, K.X.; Xing, X.F.; Chen, Z.H.; Zhou, H.N.; Lu, J. Wear mechanisms and micro-evaluation on WC particles investigation of WC-Fe composite coatings fabricated by laser cladding. Surf. Coat. Technol. 2021, 420, 127341. [Google Scholar] [CrossRef]

- Chen, L.; Yu, T.; Xu, P.; Zhang, B. In-situ NbC reinforced Fe-based coating by laser cladding: Simulation and experiment. Surf. Coat. Technol. 2021, 412, 127027. [Google Scholar] [CrossRef]

- Shifeng, W.; Guohua, L.; Jiawei, Z.; Kaian, L.; Shibin, Z. Preparation and Impact-Abrasive Wear Behavior of NbC-Reinforced Iron Matrix Composites. Adv. Eng. Mater. 2023, 25, 2301261. [Google Scholar] [CrossRef]

- Zhang, H.F.; Zhang, S.; Wu, H.; Wang, R.; Zhang, C.H.; Wu, C.L.; Chen, J.; Chen, H.T. Mechanical properties and corrosion resistance of laser cladding iron-based coatings with two types of NbC reinforcement. Surf. Coat. Technol. 2024, 479, 130558. [Google Scholar] [CrossRef]

- Tang, J.; Wang, K.; Fu, H. Laser Cladding In Situ Carbide-Reinforced Iron-Based Alloy Coating: A Review. Metals 2024, 14, 1419. [Google Scholar] [CrossRef]

- Tuominen, J.; Kiviö, J.; Balusson, C.; Raami, L.; Vihinen, J.; Peura, P. High-speed laser cladding of chromium carbide reinforced Ni-based coatings. Weld. World 2023, 67, 2175–2186. [Google Scholar] [CrossRef]

- Yuan, J.; Huang, Y.; Wang, L.; Jia, C.; Zhang, F.; Yang, L. Effect of the dissolution characteristic of tungsten carbide particles on microstructure and properties of Ni-WC/W2C reinforcement coating manufactured by TIG cladding. Int. J. Refract. Met. Hard Mater. 2023, 110, 106047. [Google Scholar] [CrossRef]

- Cao, Y.B.; Zhi, S.X.; Qi, H.B.; Zhang, Y.; Qin, C.; Yang, S.P. Evolution behavior of ex-situ NbC and properties of Fe-based laser clad coating. Opt. Laser Technol. 2020, 124, 105999. [Google Scholar] [CrossRef]

- Wu, C.; Ma, M.; Liu, W.; Zhong, M.; Zhang, W.; Zhang, H. Laser producing Fe-based composite coatings reinforced by in situ synthesized multiple carbide particles. Mater. Lett. 2008, 62, 3077–3080. [Google Scholar] [CrossRef]

- Zhang, H.; Yong, Y.; Wang, F.; Liang, Y.; Liu, L.; Liu, H.; Gao, Y. Progress on the Properties of Ceramic Phase-Reinforced High-Entropy Alloy Composite Coatings Produced via Laser Cladding. Coatings 2024, 14, 127. [Google Scholar] [CrossRef]

- Haoming, Y.; Dejun, K. Microstructure, Corrosive-Wear and Electrochemical Properties of TiC Reinforced Fe30 Coatings by Laser Cladding. J. Mater. Eng. Perform. 2025, 34, 7345–7355. [Google Scholar] [CrossRef]

- Cao, Y.B.; Zhi, S.X.; Gao, Q.; Tian, X.T.; Geng, T.; Guan, X.; Qin, C. Formation behavior of in-situ NbC in Fe-based laser cladding coatings. Mater. Charact. 2016, 119, 159–165. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, Y.; Shi, C.; Mao, D. Microscopic Analysis and Electrochemical Behavior of Fe-Based Coating Produced by Laser Cladding. Metals 2017, 7, 435. [Google Scholar] [CrossRef]

| Sample | Fe | Cr | Nb | Mo | C | Si | Mn |

|---|---|---|---|---|---|---|---|

| Nb-A | Balance | 9.55 | 3.00 | 1.39 | 1.01 | 0.77 | 2.33 |

| Nb-B | Balance | 9.55 | 4.00 | 1.39 | 1.01 | 0.72 | 2.33 |

| Nb-C | Balance | 9.55 | 5.00 | 1.39 | 1.01 | 0.66 | 2.33 |

| Nb-D | Balance | 9.55 | 6.00 | 1.39 | 1.02 | 0.61 | 2.33 |

| Position | Content of Components(wt%) | |||||

|---|---|---|---|---|---|---|

| Nb | Mn | Mo | Fe | Cr | C | |

| a1 | 51.73 | 0 | 0 | 20.71 | 8.64 | 18.92 |

| a2 | 0.84 | 0 | 0 | 46.8 | 39.93 | 12.43 |

| a3 | 0 | 0 | 0 | 50.38 | 35.27 | 14.35 |

| a4 | 2.28 | 0 | 0 | 74.97 | 11.57 | 11.18 |

| a5 | 0 | 1.62 | 0.68 | 85.63 | 5.84 | 6.23 |

| a6 | 0 | 1.64 | 0.64 | 85.63 | 5.94 | 6.06 |

| a7 | 0 | 1.62 | 0.69 | 8556 | 6.24 | 5.89 |

| a8 | 43.68 | 0 | 0 | 31.65 | 6.73 | 17.94 |

| a9 | 0 | 1.63 | 0.72 | 85.70 | 6.72 | 5.23 |

| Interface | [101]NbC || [001]α’-Fe | [010]NbC || [010]α’-;Fe | [111]NbC || [011]α’-Fe |

|---|---|---|---|

| dα’-Fe/nm | 2.87 | 2.87 | 4.05 |

| dNbC/nm | 3.32 | 2.35 | 4.07 |

| 1 | 1 | 0.986 | |

| δ% | 15.6 | 18.1 | 0.98 |

| Total δ% | |||

| Interface | [101]NbC || [110]Cr23C6 | [010]NbC || [100]Cr23C6 | [111]NbC || [111]Cr23C6 |

|---|---|---|---|

| dα’-Fe/nm | 7.55 | 5.34 | 9.25 |

| dNbC/nm | 6.63 | 4.69 | 8.12 |

| 1 | 1 | 1 | |

| δ% | 12.19 | 12.17 | 12.21 |

| Total δ% | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Zhou, H.; Liu, X.; Feng, Z.; Xiao, X.; Weng, L.; Yang, Y.; Jiang, Y. Morphology and Wear Resistance of Laser-Clad Fe-Cr-Nb-C Alloy Coatings. Coatings 2025, 15, 1055. https://doi.org/10.3390/coatings15091055

Chen M, Zhou H, Liu X, Feng Z, Xiao X, Weng L, Yang Y, Jiang Y. Morphology and Wear Resistance of Laser-Clad Fe-Cr-Nb-C Alloy Coatings. Coatings. 2025; 15(9):1055. https://doi.org/10.3390/coatings15091055

Chicago/Turabian StyleChen, Min, Haoran Zhou, Xuyang Liu, Zhongxue Feng, Xuan Xiao, Liu Weng, Yang Yang, and Yan Jiang. 2025. "Morphology and Wear Resistance of Laser-Clad Fe-Cr-Nb-C Alloy Coatings" Coatings 15, no. 9: 1055. https://doi.org/10.3390/coatings15091055

APA StyleChen, M., Zhou, H., Liu, X., Feng, Z., Xiao, X., Weng, L., Yang, Y., & Jiang, Y. (2025). Morphology and Wear Resistance of Laser-Clad Fe-Cr-Nb-C Alloy Coatings. Coatings, 15(9), 1055. https://doi.org/10.3390/coatings15091055