Abstract

Rail transport is an essential component of global logistics as it supports heavy loads and reduces transportation costs. However, rail tracks often suffer from wear, fatigue, and cracking, which increase maintenance costs and shortened service life. One potential approach to enhance the mechanical properties of rail surfaces is the application of laser cladding (LC) technology combined with deep rolling (DR), which increases the microhardness of the coating layer. This study aimed to examine the effects of four nickel-based cladding materials: Colmonoy 42, Colmonoy 56, Colmonoy 63, and NiCrBSi + 17WC. The experimental results showed that the laser cladding process significantly increased microhardness. Combined with the deep rolling process, Colmonoy 63 demonstrated the best response, achieving the highest microhardness of 943.47 HV, an increase of 24.78% compared to the rail treated with laser cladding. Therefore, the findings of this study indicated that combining the laser cladding process with deep rolling is an effective method for improving the surface properties of rails.

1. Introduction

Railway transportation plays a vital role in the global movement of passengers and freight due to its high load capacity, cost-effectiveness, and ability to reduce urban traffic congestion. These characteristics make it a sustainable option for urban development and have led to significant investments in modern railway systems worldwide, including in Thailand [1]. A commonly used material for rails is UIC 860 Grade 900A steel, a carbon–manganese alloy with a pearlitic microstructure that complies with European standards. The railhead, where direct contact with train wheels occurs, is especially important because it determines mechanical performance and overall service life [2]. However, as the use of rail transport continues to grow, rails are subjected to progressively higher loads, both in terms of the number of load cycles and the magnitude of the applied weight, which ultimately leads to damage. Rail degradation continues to be a major concern, compromising the safety and efficiency of railway operations. This deterioration is mainly caused by cyclic mechanical stresses such as bending, compression, shear, and contact fatigue. Over time, these stresses lead to surface wear, material loss, and the development of fatigue cracks at the railhead [3,4,5]. Rolling Contact Fatigue (RCF) and wear are the primary damage mechanisms, especially in curved sections and near platforms where contact stresses are highest. The resistance to RCF is strongly influenced by factors such as the stiffness mismatch between the wheel and rail and the rail’s microstructure [6]. In high-load rail systems, millions of wheel passes can cause deep subsurface damage if not properly managed [7,8]. In Thailand, current maintenance guidelines suggest replacing rails when the railhead thickness is reduced by 27% or when the wear depth exceeds 13 mm [9]. This wear is largely due to long-term metallurgical changes beneath the surface from repeated loading [8]. Therefore, strengthening rails can significantly enhance their resistance to wear. Despite the seriousness of this issue and its implications for rail safety, research on effective and economically viable solutions remains limited. Various coating techniques have been developed to mitigate material degradation in industrial applications, including thermal processes such as thermal spraying, High-Velocity Oxygen Fuel (HVOF), and High-Velocity Air Fuel (HVAF) [10]; laser-based techniques such as Laser Shot Peening and Laser Cladding; and other methods including Physical Vapor Deposition (PVD) [11], Chemical Vapor Deposition (CVD) [12], carburizing [13], and nitriding [14]. Among these techniques, Laser Cladding (LC) is particularly promising because it can produce coatings with high wear and corrosion resistance, refined microstructures, and strong metallurgical bonding with low dilution. This method is especially suitable for applications that require shock absorption, such as in the railway industry. Kusmoko et al. [15] reported that LC coatings achieved hardness values of 420–520 HV with reduced wear. Oberländer et al. [16] found that LC produces smoother surfaces and narrower heat-affected zones compared to Plasma Transferred Arc (PTA) and Atmospheric Plasma Spray (APS). Navas et al. [17] confirmed that LC results in dense, porosity-free coatings with strong adhesion and durability. Laser Cladding Deposition (LCD) uses a high-power laser to melt metallic powder and a thin surface layer of the substrate, forming a dense, crack-free coating with minimal thermal impact [18]. Coating thickness typically ranges from 50 μm to 2 mm. Powder-fed LC is considered the most practical and widely used method due to its energy efficiency and high-quality results. It has been employed to improve wear resistance and corrosion protection and to repair high-value components [19]. Cladding materials include cobalt-based alloys [20], nickel-based alloys [21,22], and composite systems [23]. Nickel-based coatings are especially notable for their excellent resistance to oxidation, creep, and fatigue at elevated temperatures [24], making them ideal for surface performance enhancement [25]. Studies by Wang et al. [21] and Soboleva et al. [22] demonstrated improved microstructure, hardness, and corrosion resistance. Additional research by Wang et al. [26] and Zhang et al. [27] confirmed that laser cladding can reduce wear and improve frictional properties in heavy-haul rail applications. Yildirimli et al. [28] demonstrate the feasibility of industrial-scale application of laser cladding to rail components, providing improved stiffness and wear resistance under real-world operating conditions. However, a key limitation of the laser cladding process is the formation of tensile residual stresses on the surface as a result of the thermal coating process. The high heat input during coating promotes these stresses, which can increase the likelihood of cracking and reduce the long-term fatigue life of the rail [29]. In contrast, inducing compressive residual stresses on the rail surface can suppress crack initiation and propagation, thereby extending rail service life [30]. One process that can effectively induce compressive residual stresses is deep rolling, a mechanical surface strengthening technique in which pressure from a roller or ball plastically deforms the surface and subsurface, thereby increasing hardness and fatigue resistance [31,32]. Previous studies have reported that deep rolling can also promote the formation of harder microstructures, such as martensite, and suppress fatigue crack growth [33,34], making it highly suitable for components subjected to continuous and repetitive loading, such as railway axles and railheads. The effectiveness of deep rolling depends on key process parameters, including pressure, feed rate, rolling speed, and number of passes, which directly influence the resulting surface integrity and mechanical performance [35,36]. Although deep rolling has been successfully applied to a variety of materials, including AISI 1020, AISI 1060, and several superalloys [31,37,38], its application in railway tracks remains relatively limited. Available data suggest that deep rolling can delay fatigue in railway axles through the induction of compressive residual stresses [32,39]. However, a major limitation is that deep rolling alone cannot provide sufficient strength to support the heavy loads experienced by rails.

To overcome this limitation, a combined approach is proposed in which laser cladding has the potential to form significantly increased hardness, while deep rolling is employed to introduce compressive residual stresses. This integration has the potential to mitigate the limitations of each individual method and to enhance the mechanical performance of rail steels. Accordingly, this study investigates the effects of applying deep rolling after laser cladding using four different nickel-based alloys. By empirically evaluating and mechanistically interpreting the microstructural evolution and microhardness responses in the coating and rail substrate, this work aims to provide fundamental insights into the potential and suitability of integrated thermal–mechanical processing technologies for future railway applications.

2. Materials and Methods

This study investigates the effects of Ni-based laser cladding (LC) and subsequent deep rolling (DR) on the microstructure and microhardness of UIC 860 grade 900A rail. The experimental procedure consisted of four main stages: specimen preparation, laser cladding, deep rolling, and mechanical characterization. Four different Ni-based cladding materials were employed to evaluate their individual and combined effects with deep rolling on the cladded layer.

2.1. Materials and Specimen

In this study, a commercial UIC 860 grade 900A rail (Panzhihua Iron & Steel Group Co., Ltd., Panzhihua, China), widely recognized in the railway industry for its exceptional strength, was employed. The chemical composition of the rail was analyzed using a FISCHERSCOPE XUV773 X-ray fluorescence (XRF, Helmut Fischer, Sindelfingen, Germany) with both the standard specification and measured values presented in Table 1. The rails were cut from their as-received condition to a length of 160 mm, while maintaining the original width of 70 mm. Four rail specimens were then prepared for the laser cladding process. Each specimen was cladded with a different Ni-based material: Colmonoy 42, Colmonoy 56, Colmonoy 63, and NiCrBSi + 17WC. The chemical compositions of these cladding materials, based on Wall Colmonoy’s standard [40] specifications, are shown in Table 2.

Table 1.

Chemical compositions of UIC860 grade 900A rail (wt.%).

Table 2.

Chemical compositions of cladding materials (wt.%).

2.2. Laser Cladding

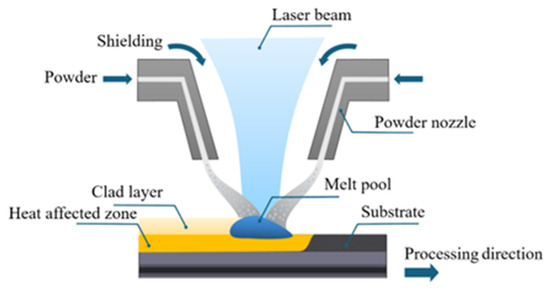

All rail specimens were subjected to laser cladding using a 6 kW diode laser (Laserline GmbH, Mülheim-Kärlich, Germany) that operated in continuous wave (CW) mode with a wavelength of 1000 nm. and a 400 mm. focusing system. For powder feeding, a ZY-PF2LC multi-nozzle powder feeding system (Jiangsu Zhiyuan Laser Equipment Technology Co., Ltd., Danyang, China) was utilized. This system sprayed powders using the direct blown method and employed Argon shielding gas to prevent oxidation during the cladding process. The laser cladding parameters were kept constant at 1.5 kW laser power; 0.6 m/min scanning speed; 22.5 g/min powder feed rate; and 3 mm spot size. The rail was cladded in the longitudinal direction. A schematic of the laser cladding process is illustrated in Figure 1, while Figure 2 shows (a) a schematic of the laser-cladded 160 mm rail section and (b) the actual laser cladding on a UIC860 grade 900A rail.

Figure 1.

Schematic diagram of laser cladding process.

Figure 2.

(a) Schematic of a laser clad 160 mm rail section; (b) laser cladding on UIC860 grade 900A rail.

2.3. Deep Rolling

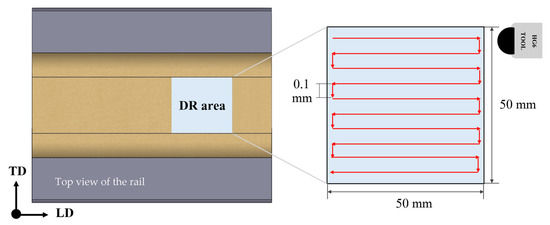

After cladding, the specimens were subjected to deep rolling on the cladding surface. The deep rolling process was performed using an (ECOROLL AG, Celle, Germany) equipped with a 6 mm diameter ball, which was pressed against the surface of the workpiece during the operation. TOTAL Lactuca LT3000 hydraulic oil (TotalEnergies, Pau, France) was employed as a lubricant, with the flow rate maintained at 2 L/min throughout the process to minimize friction and regulate temperature. The deep rolling was conducted on an HAAS VF2 Vertical Machining Center (HAAS Automation Inc., Oxnard, CA, USA). The parameters used for the deep rolling process are shown in Table 3. The area subjected to deep rolling measured 50 mm in width and 50 mm in length. A schematic diagram of the deep rolling process is presented in Figure 3, while Figure 4 shows the experimental arrangement for the deep rolling operation.

Table 3.

Deep rolling parameters.

Figure 3.

Schematic diagram of deep rolling process.

Figure 4.

Experimental arrangement for the deep rolling process.

2.4. Microstructure and Microhardness

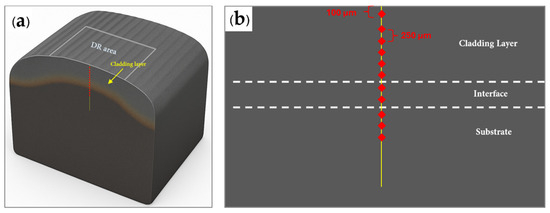

After completion of the laser cladding and deep rolling process, specimens were sectioned for microstructural and microhardness analyses. A microstructural observation was performed using a digital microscope (VHX-X1 series, Keyence, Osaka, Japan) and a scanning electron microscope (SEM, SU3800, Hitachi, Tokyo, Japan) to examine finer microstructural details. Samples were polished and etched using a 3:1 HCl:HNO3 solution (RCI Labscan Ltd., Bangkok, Thailand) to reveal grain boundaries. Phase identification in the clad microstructure was conducted using X-ray diffraction (XRD, Rigaku Corporation, Akishima, Tokyo, Japan) analysis. Microhardness was measured using a Vickers microhardness tester (AETALL, 7MHVS-1000A, Yantai, China) with a load of 1 kgf and a dwell time of 10 s. Indentations were made on the cross-sectional area of the rail at various depths, beginning at 100 µm below the top surface. Subsequent points were spaced 250 µm apart until substrate was reached, resulting in a total of 11 measurement points. The microhardness measurement positions are shown in Figure 5. The resulting data were analyzed to assess and compare the influence of each cladding material and the effects of deep rolling on microhardness and microstructure.

Figure 5.

Schematic of microhardness measurement positions: (a) cross-sectional view of the rail specimen and (b) points for microhardness measurement.

3. Results and Discussion

3.1. Microstructure Analysis

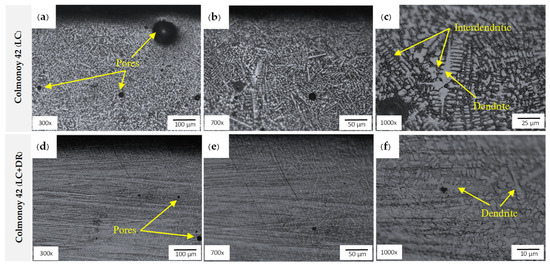

Figure 6, Figure 7, Figure 8, Figure 9, Figure 10 and Figure 11 demonstrate significant microstructural changes in Colmonoy 42, Colmonoy 56, Colmonoy 63, and NiCrBSi + WC nickel alloys (Wall Colmonoy Corporation, Madison Heights, MI, USA) under laser cladding (LC) before and after deep rolling (DR), providing insights into material behavior under different processing conditions.

Figure 6.

Digital microscope images of the clad layer of Colmonoy 42; (a–c) laser cladding; (d–f) laser cladding coupled with deep rolling.

Figure 7.

Digital microscope images of the clad layer of Colmonoy 56; (a–c) laser cladding; (d–f) laser cladding coupled with deep rolling.

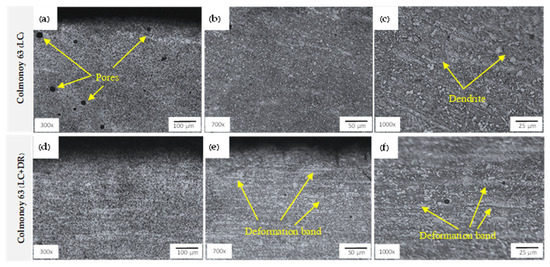

Figure 8.

Digital microscope images of the clad layer of Colmonoy 63; (a–c) laser cladding; (d–f) laser cladding coupled with deep rolling.

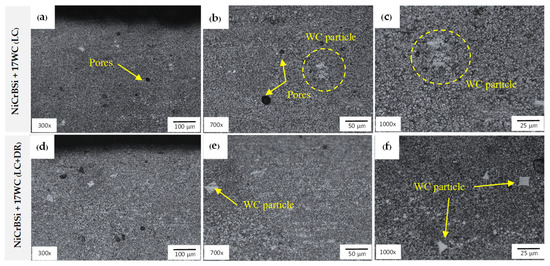

Figure 9.

Digital microscope images of the clad layer of NiCrBSi + 17WC; (a–c) laser cladding; (d–f) laser cladding coupled with deep rolling.

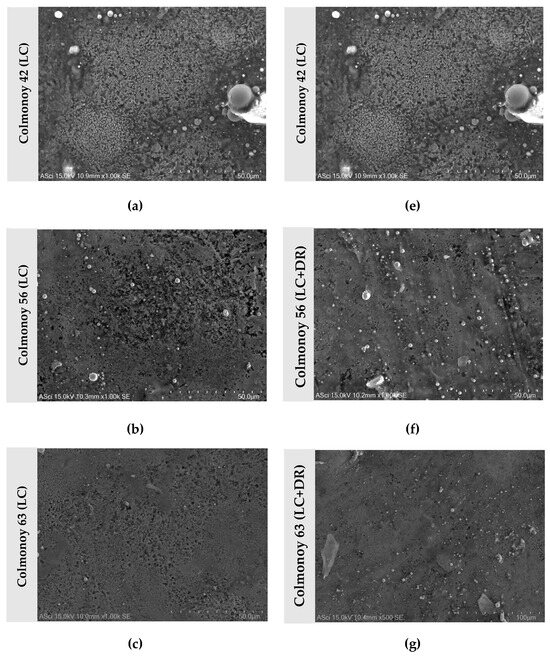

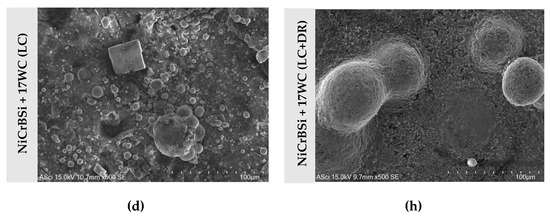

Figure 10.

SEM morphologies of the clad layer; (a–d) laser cladding; (e–h) laser cladding coupled with deep rolling.

Figure 11.

EDS Analysis of the clad layer of NiCrBSi + 17WC.

Figure 6a–c show the microstructure of Colmonoy 42 processed by laser cladding. In Figure 6a, large pores are observed in the cladding layer, which result from gas entrainment during the rapid cooling process following annealing, potentially leading to crack formation. Figure 6b,c clearly demonstrate the presence of columnar dendritic crystal structures, particularly in Figure 6b, where dense dendrite growth lines are aligned along the heat flow direction. This pattern results from directional solidification under rapid cooling. At higher magnification (1000×), Figure 6c reveals well-defined dendrite arms and interdendritic zones, indicating chemical compositional imbalance (microsegregation) during solidification. In contrast, Figure 6d–f, which represent the microstructure after laser cladding combined with deep rolling, show significant structural changes. A clear reduction in the size and number of pores is observed. Figure 6d and e exhibit a more uniform structure, where parallel deformation lines appear across the coating layer, resulting from compressive stress generated during the deep rolling process. In Figure 6f, dendrites are still present but are shorter, denser, and partially broken by deformation, indicating grain reorientation and refinement. These changes occur due to dislocation movement under compression, leading to a denser microstructure, reduced porosity, and increased surface hardness.

Colmonoy 56 treated with laser cladding, as shown in Figure 7a–c, exhibits a well-organized and uniform dendritic structure, though some pores are present due to the melting process. Figure 7c confirms that dendrites dominate the structure, indicating a high cooling rate during solidification. The prominent and widely distributed dendrites grow in the direction of heat flow, while the interdendritic zones may contain alloying elements or brittle phases that affect the overall coating strength. After deep rolling (Figure 7d–f), structural changes similar to those in Colmonoy 42 are observed. Porosity is significantly reduced, and Figure 7f shows that some dendrites are deformed or compressed, indicating plastic deformation. The interdendritic zones display more pronounced grain refinement, resulting in improved mechanical properties, including strength, toughness, and wear resistance. These observations are supported by previous studies [41,42], which confirm that grain-refined interdendritic zones exhibit finer distributions of precipitates and minor phases, creating a denser structure and reducing voids, pores.

Colmonoy 63, when subjected exclusively to laser cladding as shown in Figure 8a–c, exhibits a relatively coarse microstructure characterized by large grains and the presence of numerous pores throughout the coating (Figure 8a). The distribution of fine dendritic structures is notably non-uniform, contributing to a less refined overall morphology. However, following the application of deep rolling treatment (Figure 8d–f), substantial microstructural modifications are observed. Distinct deformation bands emerge (Figure 8e,f), and the dendrites are compressed by the DR rollers, leading to fragmentation and grain reorientation. This post-processing step effectively refines the microstructure and enhances the mechanical strength of the material, in agreement with findings reported in previous studies [43].

Finally, the NiCrBSi + 17WC cladding reinforced with WC ceramic particles is illustrated in Figure 9a–f. The microstructure observed after laser cladding exhibits a homogeneous distribution of WC particles throughout the coating layer, accompanied by the presence of visible porosity. Although the incorporation of WC contributes significantly to increased hardness, the influence of the deep rolling process remains limited. This is primarily due to the extreme hardness of WC, which restricts dislocation motion, thereby resulting in minimal structural modifications and limited grain refinement induced by deep rolling—unlike in coatings without reinforcement. These findings are consistent with previous studies [44], which have demonstrated that excessively hard ceramic reinforcements can hinder the efficacy of mechanical surface treatments.

Scanning electron microscopy (SEM) Figure 10 clearly demonstrates that combining deep rolling with laser cladding significantly enhances coating quality compared to laser cladding alone. While laser-cladded coatings typically exhibit rough morphologies, pores, and incomplete densification caused by rapid solidification, the subsequent deep rolling process smooths the surface, compresses pores, and improves particle distribution. These modifications strengthen the bonding between dendritic and interdendritic regions, thereby promoting greater structural integrity, densification, and hardness. Furthermore, point elemental analysis via energy-dispersive spectroscopy (EDS) (Figure 11) confirms the retention of WC reinforcement particles within the NiCrBSi matrix, which further contributes to hardness and microstructural stability. Although the improvements from deep rolling are less pronounced in ceramic-reinforced coatings, the results demonstrate that deep rolling effectively mitigates solidification-related defects, enhances compactness, and improves the mechanical reliability of the cladded layers.

Laser cladding—focusing only on the cladding layer—shows similar structural characteristics across all samples. The microstructures mainly consist of dendrites and columnar grains. These features agree with previous studies such as [45,46,47]. In addition, pores appear in the coating layer of all four materials, which is consistent with the findings of [48], where rail coatings processed by laser cladding were studied. However, when the rails undergo laser coupled with deep rolling, the microstructures change significantly. The grain boundaries become distorted or elongated, and the grains become finer. The compressive force from the rolling process leads to a noticeable reduction in pore size and quantity. These microstructural modifications result in a significant increase in surface hardness, in agreement with the findings in [49].

3.2. Phase Analysis by X-Ray Diffraction (XRD)

The identification of phase types in the cladding layer is carried out using X-ray diffraction (XRD) analysis. The results indicate the presence of both primary and secondary phases formed after laser deposition and after the combined process of laser deposition with deep rolling, as presented in Figure 12.

Figure 12.

Comparison of XRD spectra of the laser cladding (LC) and laser cladding coupled with deep rolling (LC+DR) under different cladding materials: (a) Colmonoy 42, (b) Colmonoy 56, (c) Colmonoy 63, (d) NiCrBSi+17WC and (e) UIC860 Grade900A Rail (non clad).

XRD analysis of the Ni-based alloy cladding reveals the presence of the primary phases γ-Ni (FCC) and α-Fe (BCC), which originate from the initial Fe-containing composition of the cladding powder. Overlapping signals between γ-Ni and Ni3Si are also observed, indicating the formation of intermetallic compounds that enhance the hardness and of the Ni-based cladding, thereby contributing to the strengthening of the coated rail surface. In addition, Cr5B3 is identified in association with certain γ-Ni planes.

Following the application of the deep rolling (DR) process to the cladding, the intensity and sharpness of the diffraction peaks increase significantly, particularly for the γ-Ni phase. This behavior indicates enhanced crystallinity, reduced porosity and surface roughness, and the development of preferred orientations as a result of plastic deformation and residual compressive stress induced by the DR process. DR does not generate new phases; instead, it alters the relative prominence of specific crystal planes, which is consistent with grain refinement and a reduction in lattice defects within the cladding.

3.3. Microhardness Analysis

3.3.1. Microhardness of Laser Cladding Process

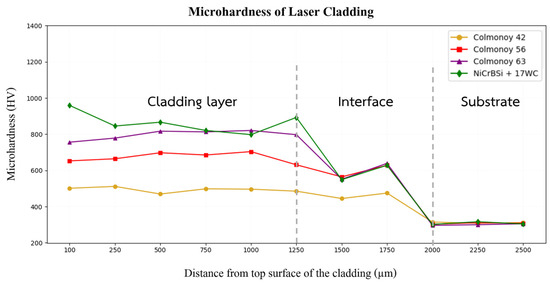

The results of microhardness measurements of the rails after the laser cladding process, measured in the depth direction from the cladding layer through the interface down to the substrate perpendicularly, are shown in Figure 13. This analysis aims to examine the trend of hardness variation among four nickel-based alloys: colmonoy 42, colmonoy 56, colmonoy 63 and NiCrBSi + 17WC.

Figure 13.

Microhardness profiles of the laser cladding under different cladding materials.

The microhardness measurements of the rails after the laser cladding process show that each cladding material gives different hardness values. Colmonoy 42 has a microhardness in the cladding layer of about 485 to 511 HV (493.9 ± 14.6 HV), which is 58% higher than the substrate. Colmonoy 56 gives higher microhardness than colmonoy 42, with values between 630 and 704 HV (672.6 ± 28.1 HV)), or approximately 2.19 times greater than that of the substrate. This difference is attributed to its chemical composition, which contains higher proportions of boron (B) and chromium (Cr), which help for hard phases in the cladding layer. In the same way, colmonoy 63 gives the highest microhardness among the colmonoy group, with the cladding layer reaching up to 820 HV and the average microhardness in the cladding layer is 797.1 ± 25.4 HV, or approximately 2.65 times of the substrate. These findings demonstrate the superior ability of Colmonoy 63 to form hard and wear resistant coatings. In addition, NiCrBSi + 17WC, a nickel alloy reinforced with tungsten carbide (WC)—a material known for their extremely high hardness —also gives interesting results. The average microhardness in the cladding layer was found to be as high as 863.8 ± 57.4 HV. The initial microhardness of the cladding layer is approximately 798 HV and increases to a maximum of 960 HV near the surface (around 100 µm). This continuous increase suggests a uniform and effective distribution of WC particles, leading to a improvement in the coating’s wear resistance [27].

From the microhardness profile of the laser cladding process shown in Figure 13, the thickness of the cladding layer can be estimated. The thickness of the cladding layer is approximately 1200–1300 µm, while the thickness of the interface zone is about 500 µm. In this region, microhardness decreases gradually until it approaches that of the substrate. Beyond a depth of 2000 µm, the microhardness remains stable, which clearly indicates the region of the substrate.

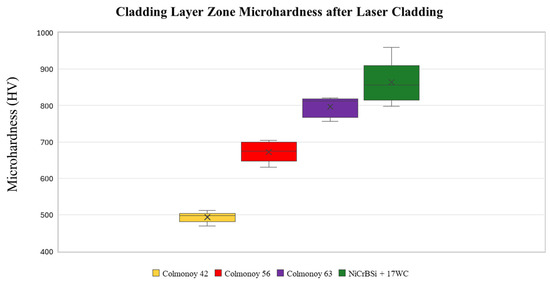

The results in the box plots in Figure 14 indicate that each cladding material provides distinctly different microhardness values. Colmonoy 42 provides the lowest but highly consistent microhardness values, while Colmonoy 56 and Colmonoy 63 provide progressively higher microhardness values and remain relatively stable in their results. The NiCrBSi + 17WC material shows the highest microhardness values, with greater data dispersion than the other materials. This comparison demonstrates that material selection has a direct effect on the coating properties.

Figure 14.

Cladding layer zone microhardness of the laser cladding under different cladding materials.

In conclusion, the microhardness results show that laser cladding can clearly increase the surface hardness of the rails [50,51], especially when using alloys with hard particles like WC. These properties make them suitable for rail applications where parts are exposed to high friction contact. The results also agree with the findings of [50], who also reported a significant increase in microhardness in nickel-based alloys materials treated using laser cladding processes.

3.3.2. Comparison Between Laser Cladding and Laser Cladding Coupled with Deep Rolling

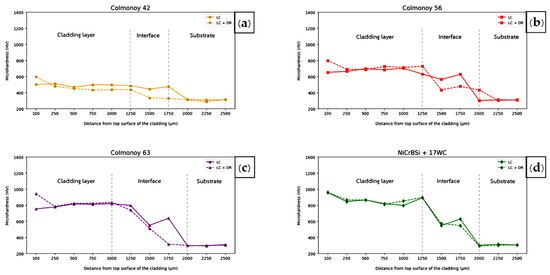

Figure 15a–d shows the comparison of microhardness of four nickel-based alloys, Colmonoy 42, Colmonoy 56, Colmonoy 63 and NiCrBSi + 17WC, under laser plating (LC) and laser cladding coupled with deep rolling (LC + DR) processes, by measuring perpendicular from the cladding surface to the substrate to evaluate the effect of deep rolling on the hardness distribution of each material.

Figure 15.

Comparison of microhardness profiles of the laser cladding (LC) and laser cladding coupled with deep rolling (LC+DR) under different cladding materials: (a) Colmonoy 42, (b) Colmonoy 56, (c) Colmonoy 63, and (d) NiCrBSi+17WC.

The results of microhardness measurements presented in Figure 15 demonstrate the influence of deep rolling on the surface properties of various cladding materials. In Figure 15a, Colmonoy 42 is used as the cladding material, with an average microhardness of the cladding layer zone of 472.3 ± 63.3 HV. The microhardness near the surface, at approximately 100 µm depth, shows a significant increase after deep rolling—from 501.6 HV to 597.8 HV—corresponding to a 19.12% improvement over the untreated specimen. This indicates that deep rolling enhances surface hardness through work hardening. A similar trend is observed in Figure 15b with Colmonoy 56, which exhibits an average microhardness of the cladding layer zone of 724.9 ± 40.4 HV. The microhardness increases from 652.8 HV after laser cladding to 799.3 HV following the deep rolling process, resulting in a 22.45% increase. This confirms that deep rolling effectively induces plastic deformation at the surface, contributing to enhanced hardness through strain hardening mechanisms. Figure 15c presents the results for Colmonoy 63, with an average microhardness of the cladding layer zone of 843.2 ± 59.3 HV, which exhibits the highest response among the tested materials. The surface microhardness at 100 µm depth rises from 756.1 HV to 943.47 HV after deep rolling, representing a 24.78% increase. This makes Colmonoy 63 the hardest among the Colmonoy group, suggesting a superior ability to respond to compressive forces during the deep rolling process and a strong work-hardening capacity. In contrast, Figure 15d shows the performance of a NiCrBSi coating reinforced with 17% tungsten carbide (WC) particles, with an average microhardness of the cladding layer zone of 863.8 ± 49.9 HV. This composite structure results in a distinct hardness profile compared to the other cladding materials. The microhardness at 100 µm depth increases only slightly from 959.23 HV to 961.63 HV after deep rolling. The presence of hard WC particles contributes to high initial hardness and limits plastic deformation under compressive force. As supported by previous research [38], the applied rolling pressure may be insufficient to induce further significant hardening in such intrinsically hard materials. Thus, while deep rolling improves hardness in most cases, its effect is relatively limited when applied to coatings with very high baseline hardness such as NiCrBSi + 17WC.

In addition, the results of microhardness measurements of the cladding layer zone after applying the laser cladding combined with deep rolling (LC+DR) process for different cladding materials are presented in Figure 16 as boxplot graphs. These boxplots clearly illustrate the distribution, variability, and outlier values of the microhardness, enabling a comprehensive and easily interpretable comparison of the microhardness distribution characteristics for each cladding material. It is observed that the LC+DR process increases the microhardness of the cladding layer, with variations in distribution depending on the type of coating material.

Figure 16.

Cladding layer zone microhardness of the laser cladding coupled with deep rolling (LC+DR) under different cladding materials.

From all experimental results, it can be concluded that the deep rolling process increases microhardness primarily at the surface of the cladding layer. The effect is most pronounced within the depth range not exceeding 200 µm, as shown in Table 4. Beyond this depth, the microhardness continuously decreases [35,36]. This behavior reflects the mechanisms of work hardening and compressive residual stress, which are characteristic of deep rolling and contribute to improved resistance to wear and cracking, consistent with the findings of previous research [52]. Additionally, the performance of deep rolling clearly depends on the alloy type. Colmonoy 63 shows the best response to deep rolling, while NiCrBSi + 17WC shows the lowest response, due to the high hardness of WC particles that inhibit compressive deformation.

Table 4.

Comparison of Top Surface Microhardness (100 µm).

4. Conclusions

- The laser cladding process of nickel alloys (Colmonoy 42, Colmonoy 56, Colmonoy 63, and NiCrBSi + 17WC) resulted in dendritic microstructures with pores, due to rapid solidification and gas entrapment within the coating.

- The microstructure after laser cladding followed by the deep rolling process exhibited noticeable changes, including a reduction in pore size and number, smoother and denser coating, more distinct deformation lines, and shorter, thicker, and more dispersed dendritic structures.

- Regarding NiCrBSi + 17WC, the presence of hard WC particles and a very hard matrix limited the effect of deep rolling. Only slight grain elongation and minor reductions in porosity and internal deformation were observed. The overall microstructure remained largely unchanged compared to only laser cladding.

- Laser cladding significantly enhanced the surface microhardness of rail steel. All four nickel-based cladding materials outperformed the unclad substrate, with NiCrBSi + 17WC showing the highest hardness at 962 HV, followed by Colmonoy 63, Colmonoy 56, and Colmonoy 42. When combined with deep rolling, most materials exhibited an additional 20–25% increase in hardness within the first 100 μm from the surface, due to the compressive stresses introduced. However, NiCrBSi + 17WC showed only a minimal increase of 0.25%, attributed to its already high intrinsic hardness and the low deformability of WC particles.

- Colmonoy 63 exhibited the best coating performance, with a hardness increase of 24.78% after the DR process due to the compressive force applied.

- Based on the current experiments, pore formation is likely caused by gas entrapment, vaporization of volatile elements, or insufficient melting during cladding. While some regions of the Colmonoy 56 layer are practically free of pores, a small amount of porosity is still observed in other areas, indicating that the overall pore formation is limited. A detailed investigation of pore formation will be conducted in future work.

Overall, the combined application of laser cladding and deep rolling proved effective in enhancing the microstructural quality and mechanical performance of nickel-based coatings on rail steel. While the improvements varied depending on the alloy composition, the results indicate that this hybrid approach can reduce defects and increase hardness, which may suggest a potential contribution to improved durability of the rails.

Author Contributions

Conceptualization, S.J. and A.B.; methodology, S.J., A.B. and C.W.; validation, A.B. and W.N.; formal analysis, S.J.; investigation, S.J.; resources, A.B. and W.N.; data curation, S.J., A.B. and C.W.; writing—original draft preparation, S.J. and C.W.; writing—review and editing, A.B. and W.N.; visualization, S.J.; supervision, A.B.; project administration, W.N.; funding acquisition, W.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially funded by Fundamental Fund-2024 Chiang Mai University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

This research was partially funded by Chiang Mai University, Thailand.

Conflicts of Interest

The authors declare no conflicts of interest regarding the publication of this manuscript.

References

- Mattos Ferreira, V.; Mecozzi, M.G.; Petrov, R.H.; Sietsma, J. Microstructure development of pearlitic railway steels subjected to fast heating. Mater. Des. 2022, 221, 110989. [Google Scholar] [CrossRef]

- Hong, S.; Shi, X.; Lin, J.; Wu, Y.; Li, J.; Zheng, Y. Microstructure and cavitation-silt erosion behavior of two HVOF-sprayed hardfacing coatings for hydro-turbine applications. Alex. Eng. J. 2023, 69, 483–496. [Google Scholar] [CrossRef]

- Cannon, D.F.; Edel, K.O.; Grassie, S.L.; Sawley, K. Rail defects: An overview. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 865–886. [Google Scholar] [CrossRef]

- Wang, W.J.; Guo, H.M.; Du, X.; Guo, J.; Liu, Q.Y.; Zhu, M.H. Investigation on the damage mechanism and prevention of heavy-haul railway rail. Eng. Fail. Anal. 2013, 35, 206–218. [Google Scholar] [CrossRef]

- Zhong, W.; Hu, J.J.; Shen, P.; Wang, C.Y.; Liu, Q.Y. Experimental investigation between rolling contact fatigue and wear of high-speed and heavy-haul railway and selection of rail material. Wear 2011, 271, 2485–2493. [Google Scholar] [CrossRef]

- Hu, Y.; Zhou, L.; Ding, H.H.; Tan, G.X.; Lewis, R.; Liu, Q.Y.; Guo, J.; Wang, W.J. Investigation on wear and rolling contact fatigue of wheel-rail materials under various wheel/rail hardness ratio and creepage conditions. Tribol. Int. 2020, 143, 106087. [Google Scholar] [CrossRef]

- Muster, H.; Schmedders, H.; Wick, K.; Pradier, H. Rail rolling contact fatigue. The performance of naturally hard and head-hardened rails in track. Wear 1996, 191, 54–64. [Google Scholar] [CrossRef]

- Christodoulou, P.I.; Kermanidis, A.T.; Haidemenopoulos, G.N. Fatigue and fracture behavior of pearlitic Grade 900A steel used in railway applications. Theor. Appl. Fract. Mech. 2016, 83, 51–59. [Google Scholar] [CrossRef]

- Department of Rail Transport. Railway Transport Standard No. MoT–C–009–2566: Maintenance Standard for Mainline Railway Tracks; Department of Rail Transport: Bangkok, Thailand, 2024. [Google Scholar]

- Berger, L.M. Application of hardmetals as thermal spray coatings. Int. J. Refract. Met. Hard Mater. 2015, 49, 350–364. [Google Scholar] [CrossRef]

- Zlamal, T.; Mrkvica, I.; Szotkowski, T.; Malotova, S. The influence of surface treatment of PVD coating on its quality and wear resistant. Coatings 2019, 9, 439. [Google Scholar] [CrossRef]

- You, Q.; Xiong, J.; Guo, Z.; Huo, Y.; Liang, L.; Yang, L. Study on coating performance of CVD coated cermet tools for 4340 steel cutting. Int. J. Refract. Met. Hard Mater. 2021, 98, 105554. [Google Scholar] [CrossRef]

- Adachi, S.; Ueda, N. Surface hardness improvement of plasma-sprayed AISI 316L stainless steel coating by low-temperature plasma carburizing. Adv. Powder Technol. 2013, 24, 818–823. [Google Scholar] [CrossRef]

- Wang, X.; Bai, S.; Li, F.; Li, D.; Zhang, J.; Tian, M.; Zhang, Q.; Tong, Y.; Zhang, Z.; Wang, G.; et al. Effect of plasma nitriding and titanium nitride coating on the corrosion resistance of titanium. J. Prosthet. Dent. 2016, 116, 450–456. [Google Scholar] [CrossRef] [PubMed]

- Kusmoko, A.; Dunne, D.; Li, H. A comparative study for wear resistance of Stellite 6 on nickel alloy substrate produced by laser cladding, HVOF and plasma spraying techniques. Int. J. Curr. Eng. Technol. 2014, 4, 32–36. [Google Scholar]

- Oberländer, B.C.; Lugscheider, E. Comparison of properties of coatings produced by laser cladding and conventional methods. Mater. Sci. Technol. 1992, 8, 642–649. [Google Scholar] [CrossRef]

- Navas, C.; Colaço, R.; de Damborenea, J.; Vilar, R. Abrasive wear behaviour of laser clad and flame sprayed-melted NiCrBSi coatings. Surf. Coat. Technol. 2006, 200, 6854–6862. [Google Scholar] [CrossRef]

- Liu, X.B.; Meng, X.J.; Liu, H.Q.; Shi, G.L.; Wu, S.H.; Sun, C.F.; Wang, M.D.; Qi, L.H. Development and characterization of laser clad high temperature self-lubricating wear resistant composite coatings on Ti–6Al–4V alloy. Mater. Des. 2014, 55, 404–409. [Google Scholar] [CrossRef]

- Vilar, R. Laser cladding. Laser Appl. 2001, 11, 64–79. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Wang, Y.; Yu, Y.; Hu, Z.; Zhao, Y. Microscopic characteristics and properties of Co-based coating by pulse current-assisted laser cladding on high carbon steel. Surf. Coat. Technol. 2024, 494, 131367. [Google Scholar] [CrossRef]

- Wang, R.; Ouyang, C.; Li, Q.; Bai, Q.; Zhao, C.; Liu, Y. Study of the microstructure and corrosion properties of a Ni-based alloy coating deposited onto the surface of ductile cast iron using high-speed laser cladding. Materials 2022, 15, 1643. [Google Scholar] [CrossRef]

- Soboleva, N.N.; Makarov, A.V.; Malygina, I.Y. NiCrBSi coating obtained by laser cladding and subsequent deformation processing. J. Phys. Conf. Ser. 2018, 946, 012004. [Google Scholar] [CrossRef]

- Zhang, X.S.; Wang, Q.Y.; Deng, Y.H.; Liu, L.Y.; Xi, Y.C.; Dong, L.J.; Gao, Q.Y.; Zhang, J.; Lin, Y.H. Synergistic effect of temperature and CO2 on corrosion behavior and mechanism of laser cladding Ni/WC composite coating. Corros. Commun. 2025, 9, 1–12. [Google Scholar] [CrossRef]

- Hu, Y.B.; Cheng, C.Q.; Cao, T.S.; Zhang, L.; Zhao, J. A study on the multiple stages of oxidation kinetics in a single crystal nickel-based superalloy. Corros. Sci. 2021, 188, 109512. [Google Scholar] [CrossRef]

- Xiao, H.; Sun, J.; Li, W.; Liu, S.B.; Fu, L.B.; Jiang, S.M. Effect of Pt on the microstructure and oxidation behavior of NiCrAlYSi+AlY coating on a Ni-based superalloy. Corros. Sci. 2022, 194, 109916. [Google Scholar] [CrossRef]

- Wang, W.J.; Hu, J.; Guo, J.; Liu, Q.Y.; Zhu, M.H. Effect of laser cladding on wear and damage behaviors of heavy-haul wheel/rail materials. Wear 2014, 311, 130–136. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Wang, L.; Jin, Y.; Wang, Z.; Shi, X. Effect of ceramic particles on Ni-based alloy coating fabricated via laser technology. Lubricants 2023, 11, 483. [Google Scholar] [CrossRef]

- Yildirimli, K.; Boschetti Pereira, H.; Goldenstein, H.; Fletcher, D.I.; Lee, Z.S.; Lewis, R. Scaling-up laser cladding of rails. Wear 2024, 540–541, 205227. [Google Scholar] [CrossRef]

- Roy, T.; Paradowska, A.; Abrahams, R.; Law, M.; Mutton, P.; Soodi, M.; Yan, W. Residual stress in laser cladded heavy-haul rails investigated by neutron diffraction. J. Mater. Process. Technol. 2020, 278, 116511. [Google Scholar] [CrossRef]

- Betsofen, S.Y.; Grigorovich, K.V.; Ashmarin, A.A.; Abdurashitov, A.Y.; Lebedev, M.A. Peculiarities of formation of residual stresses in welded joints and Stellite weld cladding on rail steel. Inorg. Mater. Appl. Res. 2020, 11, 634–640. [Google Scholar] [CrossRef]

- Rao, D.S.; Hebbar, H.S.; Komaraiah, M.; Kempaiah, U.N. Investigations on the effect of ball burnishing parameters on surface hardness and wear resistance of HSLA dual-phase steels. Mater. Manuf. Process. 2008, 23, 295–302. [Google Scholar] [CrossRef]

- Regazzi, D.; Cantini, S.; Cervello, S.; Foletti, S.; Pourheidar, A.; Beretta, S. Improving fatigue resistance of railway axles by cold rolling: Process optimisation and new experimental evidences. Int. J. Fatigue 2020, 137, 105603. [Google Scholar] [CrossRef]

- Meyer, D.; Kämmler, J. Surface integrity of AISI 4140 after deep rolling with varied external and internal loads. Procedia CIRP 2016, 45, 363–366. [Google Scholar] [CrossRef]

- Kloos, K.H.; Fuchsbauer, B.; Adelmann, J. Fatigue properties of specimens similar to components deep rolled under optimized conditions. Int. J. Fatigue 1987, 9, 35–42. [Google Scholar] [CrossRef]

- dos Santos, F.S.; Abrao, A.M.; Denkena, B.; Breidenstein, B.; Meyer, K. Influência da operação de roleteamento sobre a integridade superficial do aço ABNT 1020. Matéria 2020, 25, 12554. [Google Scholar]

- Abrão, A.M.; Denkena, B.; Breidenstein, B.; Mörke, T. Surface and subsurface alterations induced by deep rolling of hardened AISI 1060 steel. Prod. Eng. 2014, 8, 551–558. [Google Scholar] [CrossRef]

- Nagarajan, B.; Castagne, S. Microstructure study of nickel-based superalloys after deep cold rolling. Mater. Sci. Forum 2017, 879, 169–174. [Google Scholar] [CrossRef]

- Baisukhan, A.; Nakkiew, W. Effects of deep rolling on surface residual stress and microhardness of JIS SS400 MIG welding. Mater. Sci. Forum 2018, 939, 31–37. [Google Scholar] [CrossRef]

- Pertoll, T.; Buzzi, C.; Dutzler, A.; Leitner, M.; Seisenbacher, B.; Winter, G.; Boronkai, L. Experimental and numerical investigation of the deep rolling process focusing on 34CrNiMo6 railway axles. Int. J. Mater. Form. 2023, 16, 51. [Google Scholar] [CrossRef]

- Wall Colmonoy Corp. Colmonoy ® Alloys—Technical Data Sheet; Wall Colmonoy Corp.: Madison Heights, MI, USA, 2014. [Google Scholar]

- Du, B.; Yang, J.; Cui, C.; Sun, X. Effects of grain refinement on the microstructure and tensile behavior of K417G superalloy. Mater. Sci. Eng. A 2015, 623, 59–67. [Google Scholar] [CrossRef]

- Park, S.; Kayani, S.H.; Kim, H.; Jung, I.D.; Reddy, N.S.; Euh, K.; Seol, J.B.; Kim, J.G.; Sung, H. Effect of interdendritic precipitations on the mechanical properties of GBF- or EMS-processed Al–Zn–Mg–Cu alloys. Crystals 2021, 11, 1162. [Google Scholar] [CrossRef]

- Flemings, M.C. Dendrite fragmentation in semisolid casting: Could we do this better? Solid State Phenom. 2019, 285, 3–11. [Google Scholar] [CrossRef]

- Zhang, J.; Hou, S. Effects of CTCP modification on microstructure and wear behavior of CTCP-NiCrBSi/heat resistant steel composite layer. Materials 2018, 11, 2202. [Google Scholar] [CrossRef]

- Chen, S.; Feng, A.; Chen, C.; Song, X. Research on the process of laser cladding Ni60 coating on high-nickel cast iron surfaces. Processes 2024, 12, 647. [Google Scholar] [CrossRef]

- Lim, L.C.; Ming, Q.; Chen, Z.D. Microstructures of laser-clad nickel-based hardfacing alloys. Surf. Coat. Technol. 1998, 106, 183–192. [Google Scholar] [CrossRef]

- Qian, S.; Dai, Y.; Guo, Y.; Zhang, Y. Microstructure and wear resistance of multi-layer Ni-based alloy cladding coating on 316L SS under different laser power. Materials 2021, 14, 781. [Google Scholar] [CrossRef]

- Lewis, S.R.; Fretwell-Smith, S.; Goodwin, P.S.; Smith, L.; Lewis, R.; Aslam, M.; Fletcher, D.I.; Murray, K.; Lambert, R. Improving rail wear and RCF performance using laser cladding. Wear 2016, 366–367, 268–278. [Google Scholar] [CrossRef]

- Wang, X.; Xiong, X.; Huang, K.; Ying, S.; Tang, M.; Qu, X.; Ji, W.; Qian, C.; Cai, Z. Effects of deep rolling on the microstructure modification and fatigue life of 35Cr2Ni4MoA bolt threads. Metals 2022, 12, 1224. [Google Scholar] [CrossRef]

- Clare, A.; Oyelola, O.; Folkes, J.; Farayibi, P. Laser cladding for railway repair and preventative maintenance. J. Laser Appl. 2012, 24, 032004. [Google Scholar] [CrossRef]

- Lu, P.; Lewis, S.R.; Fretwell-Smith, S.; Engelberg, D.L.; Fletcher, D.I.; Lewis, R. Laser cladding of rail: The effects of depositing material on lower rail grades. Wear 2019, 438–439, 203045. [Google Scholar] [CrossRef]

- Zheng, K.; Lin, Y.; Cai, J.; Lei, C. Corrosion resistance and tribological properties of laser cladding layer of H13 die steel strengthened by ultrasonic rolling. Chin. J. Mech. Eng. 2022, 35, 137. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).