Advances and Prospects of Nanomaterial Coatings in Optical Fiber Sensors

Abstract

1. Introduction

2. Nanocoating Deposition Technology

2.1. Spin Coating

2.2. Dip Coating

2.3. Spray Coating

2.4. Physical Vapor Deposition (PVD)

2.5. Chemical Vapor Deposition (CVD)

2.6. Hydrothermal/Solvothermal Methods

2.7. Nanomaterial Self-Assembly Techniques

2.8. Atomic Layer Deposition

2.9. Pulsed Laser Deposition

2.10. Electrochemical Deposition

2.11. Electron Beam Evaporation

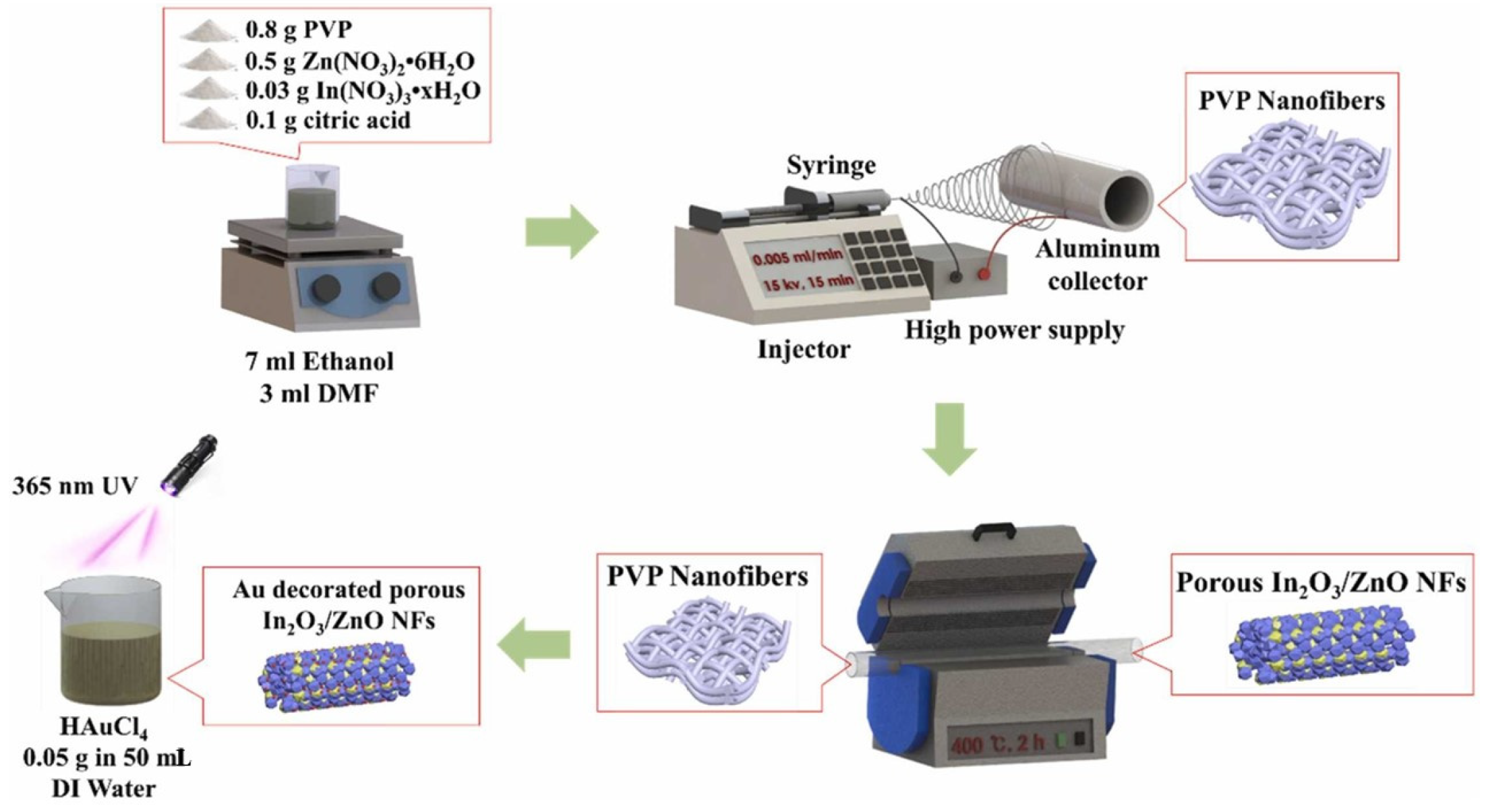

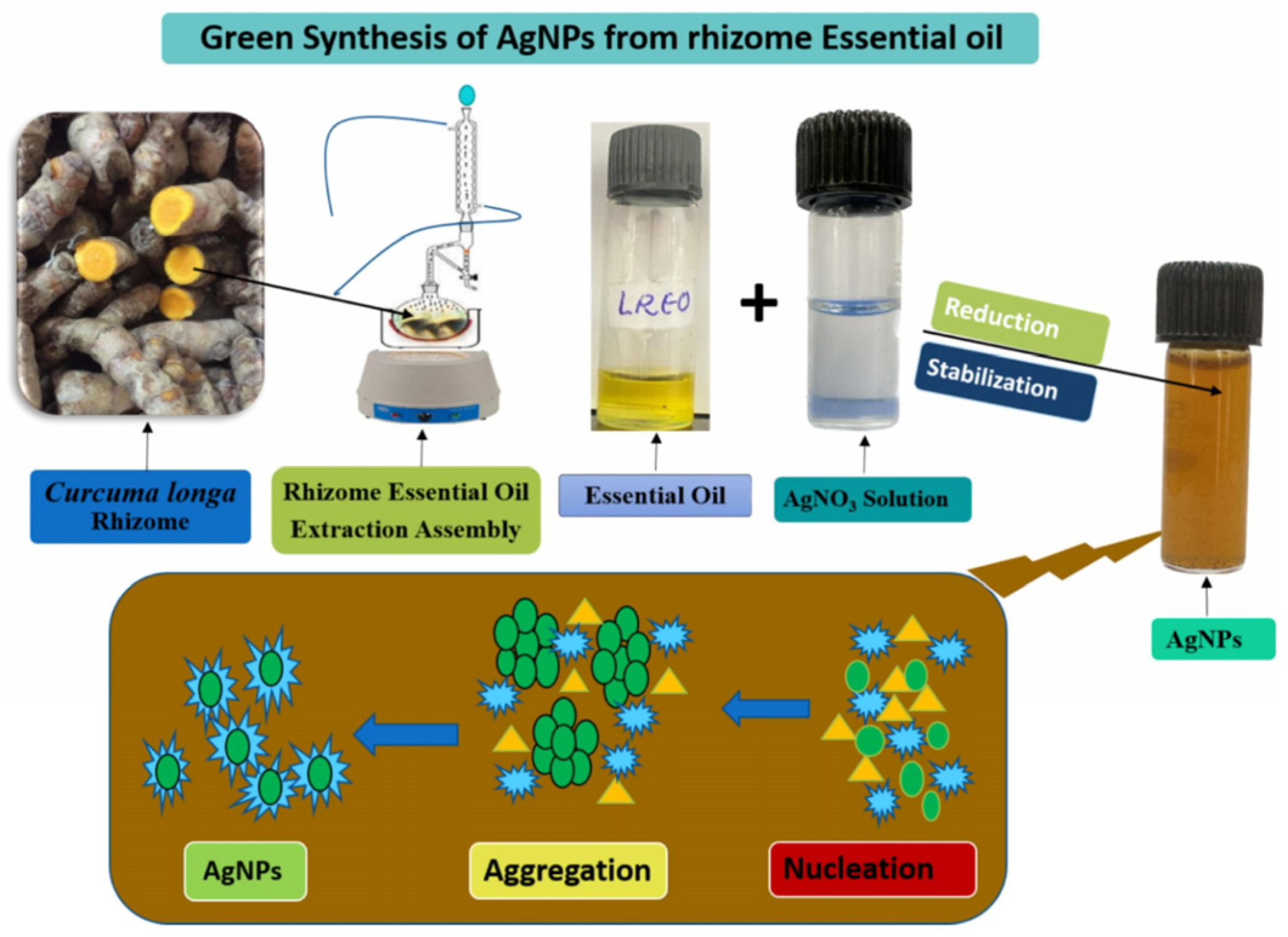

2.12. Electrospinning

2.13. Optical Tweezer Effect

3. Optic Fiber Sensor

3.1. Intensity-Modulated Optical Fiber Sensors

3.2. Phase-Modulated Optical Fiber Sensors

3.3. Wavelength-Modulated Optical Fiber Sensors

4. Applications in Various Fields

4.1. Relative Humidity (RH)

4.2. Gas Detection

4.3. Biosensors

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Llobet, E. Gas sensors Using Carbon Nanomaterials: A Review. Sens. Actuators B Chem. 2013, 179, 32–45. [Google Scholar] [CrossRef]

- Bai, J.; Zhou, B. Titanium Dioxide Nanomaterials for Sensor Applications. Chem. Rev. 2014, 114, 10131–10176. [Google Scholar] [CrossRef]

- Tong, H.; Ouyang, S.; Bi, Y.; Umezawa, N.; Oshikiri, M.; Ye, J. Nano-Photocatalytic Materials: Possibilities and Challenges. Adv. Mater. 2012, 24, 229–251. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, Z.; Pan, Y.; Dai, R.; Wu, Y.; Zhuang, Z.; Wang, D.; Peng, Q.; Chen, C.; Li, Y. Functionalization of Hollow Nanomaterials for Catalytic Applications: Nanoreactor Construction. Adv. Mater. 2019, 31, 1800426. [Google Scholar] [CrossRef]

- Sanlés-Sobrido, M.; Pérez-Lorenzo, M.; Rodríguez-González, B.; Salgueiriño, V.; Correa-Duarte, M.A. Highly Active Nanoreactors: Nanomaterial Encapsulation Based on Confined Catalysis. Angew. Chem. Int. Ed. 2012, 51, 3877–3882. [Google Scholar] [CrossRef]

- Mekuye, B.; Abera, B. Nanomaterials: An Overview of Synthesis, Classification, Characterization, and Applications. Nano Sel. 2023, 4, 486–501. [Google Scholar] [CrossRef]

- Dhall, S.; Nigam, A.; Harshavardhan, M.; Mukherjee, A.; Srivastava, P. A Comprehensive Overview of Methods Involved in Nanomaterial Production and Waste Disposal from Research Labs and Industries and Existing Regulatory Guidelines for Handling Engineered Nanomaterials. Environ. Chem. Ecotoxicol. 2024, 6, 269–282. [Google Scholar] [CrossRef]

- Pokropivny, V.; Skorokhod, V. Classification of Nanostructures by Dimensionality and Concept of Surface Forms Engineering in Nanomaterial Science. Mater. Sci. Eng. C 2007, 27, 990–993. [Google Scholar] [CrossRef]

- Jia, Z.; Shi, C.; Yang, X.; Zhang, J.; Sun, X.; Guo, Y.; Ying, X. QD-Based Fluorescent Nanosensors: Production Methods, Optoelectronic Properties, and Recent Food Applications. Compr. Rev. Food Sci. Food Saf. 2023, 22, 4644–4669. [Google Scholar] [CrossRef]

- Rafiq, K.; Sadia, I.; Abid, M.Z.; Waleed, M.Z.; Rauf, A.; Hussain, E. Scientific Insights into the Quantum Dots (QDs)-Based Electrochemical Sensors for State-of-the-Art Applications. ACS Biomater. Sci. Eng. 2024, 10, 7268–7313. [Google Scholar] [CrossRef]

- Díaz-Álvarez, M.; Martín-Esteban, A. Molecularly Imprinted Polymer-Quantum Dot Materials in Optical Sensors: An Overview of Their Synthesis and Applications. Biosensors 2021, 11, 79. [Google Scholar] [CrossRef]

- Cai, Y.; Li, M.; Wang, M.; Li, J.; Zhang, Y.-n.; Zhao, Y. Optical Fiber Sensors for Metal Ions Detection Based on Novel Fluorescent Materials. Front. Phys. 2020, 8, 598209. [Google Scholar] [CrossRef]

- Ryu, S.; Lee, P.; Chou, J.B.; Xu, R.; Zhao, R.; Hart, A.J.; Kim, S.-G. Extremely Elastic Wearable Carbon Nanotube Fiber Strain Sensor for Monitoring of Human Motion. ACS Nano 2015, 9, 5929–5936. [Google Scholar] [CrossRef]

- Wang, R.; Sun, L.; Zhu, X.; Ge, W.; Li, H.; Li, Z.; Zhang, H.; Huang, Y.; Li, Z.; Zhang, Y.F. Carbon Nanotube-Based Strain Sensors: Structures, Fabrication, and Applications. Adv. Mater. Technol. 2023, 8, 2200855. [Google Scholar] [CrossRef]

- Sun, P.; Bachilo, S.M.; Weisman, R.B.; Nagarajaiah, S. Carbon Nanotubes as Non-Contact Optical Strain Sensors in Smart Skins. J. Strain Anal. Eng. Des. 2015, 50, 505–512. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, X.-g.; Zhou, X.; Zhang, Y.-n. Review on the Graphene Based Optical Fiber Chemical and Biological Sensors. Sens. Actuators B Chem. 2016, 231, 324–340. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, L.; Qiao, D.; Liu, M.; Yang, H.; Meng, C.; Miao, T.; Xue, J.; Yao, Y. Progress on Optical Fiber Biochemical Sensors Based on Graphene. Micromachines 2022, 13, 348. [Google Scholar] [CrossRef]

- Zhu, C.; Gerald, R.E.; Huang, J. Metal-Organic Framework Materials Coupled to Optical Fibers for Chemical Sensing: A review. IEEE Sens. J. 2021, 21, 19647–19661. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Tissot, A.; Serre, C. Recent Progress on Mof-Based Optical Sensors for Voc Sensing. Chem. Sci. 2022, 13, 13978–14007. [Google Scholar] [CrossRef] [PubMed]

- Zhuo, Y.; Ma, P.; Jiao, P.; Yuan, X. Application of Long-Period Fiber Grating Sensors in Structural Health Monitoring: A Review. CivilEng 2024, 5, 559–575. [Google Scholar] [CrossRef]

- Zhong, X.; Xie, Q.; Liu, Y.; He, Y.; Zhong, N.; Zhang, Z.; Karimi-Maleh, H.; Peng, X.; Lichtfouse, E. Recent Advances in Optical Fiber Grating Sensors for Detection of Organic Substances. Chem. Eng. J. 2024, 492, 152260. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L.; Song, Y.; Wang, W.; Lin, C.; He, X. Functional Optical Fiber Sensors Detecting Imperceptible Physical/Chemical Changes for Smart Batteries. Nano-Micro Lett. 2024, 16, 154. [Google Scholar] [CrossRef]

- Jha, R.; Mishra, P.; Kumar, S. Advancements in Optical Fiber-Based Wearable Sensors for Smart Health Monitoring. Biosens. Bioelectron. 2024, 254, 116232. [Google Scholar] [CrossRef]

- Ma, S.; Xu, Y.; Pang, Y.; Zhao, X.; Li, Y.; Qin, Z.; Liu, Z.; Lu, P.; Bao, X. Optical Fiber Sensors for High-Temperature Monitoring: A Review. Sensors 2022, 22, 5722. [Google Scholar] [CrossRef]

- Zhu, C.; Gerald, R.E.; Huang, J. Progress Toward Sapphire Optical Fiber Sensors for High-Temperature Applications. IEEE Trans. Instrum. Meas. 2020, 69, 8639–8655. [Google Scholar] [CrossRef]

- Ascorbe, J.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Recent Developments in Fiber Optics Humidity Sensors. Sensors 2017, 17, 893. [Google Scholar] [CrossRef]

- Consales, M.; Buosciolo, A.; Cutolo, A.; Breglio, G.; Irace, A.; Buontempo, S.; Petagna, P.; Giordano, M.; Cusano, A. Fiber Optic Humidity Sensors for High-Energy Physics Applications at CERN. Sens. Actuators B Chem. 2011, 159, 66–74. [Google Scholar] [CrossRef]

- Luo, D.; Li, J.; Li, Y. A Review of Fiber-Optic Corrosion Sensor in Civil Engineering. AIP Conf. Proc. 2018, 1967, 020055. [Google Scholar] [CrossRef]

- Ren, L.; Jiang, T.; Jia, Z.-g.; Li, D.-s.; Yuan, C.-l.; Li, H.-n. Pipeline Corrosion and Leakage Monitoring Based on the Distributed Optical Fiber Sensing Technology. Measurement 2018, 122, 57–65. [Google Scholar] [CrossRef]

- Yang, Y.; Han, K. Damage Monitoring and Impact Detectionusing Optical Fiber Vibration Sensors. Smart Mater. Struct. 2002, 11, 337. [Google Scholar] [CrossRef]

- Chang, C.-C.; Sirkis, J.S. Optical Fiber Sensors Embedded in Composite Panels for Impact Detection. In Proceedings of the Smart Structures and Materials 1995: Smart Sensing, Processing, and Instrumentation, San Diego, CA, USA, 26 February–3 March 1995; pp. 502–513. [Google Scholar]

- Li, X.; Chen, N.; Zhou, X.; Gong, P.; Wang, S.; Zhang, Y.; Zhao, Y. A Review of Specialty Fiber Biosensors Based on Interferometer Configuration. J. Biophotonics 2021, 14, e202100068. [Google Scholar] [CrossRef]

- Wang, X.-d.; Wolfbeis, O.S. Fiber-Optic Chemical Sensors and Biosensors (2015–2019). Anal. Chem. 2019, 92, 397–430. [Google Scholar] [CrossRef]

- Gomes, B.R.; Araújo, R.; Sousa, T.; Figueira, R.B. Sol-Gel Coating Membranes for Optical Fiber Sensors for Concrete Structures Monitoring. Coatings 2021, 11, 1245. [Google Scholar] [CrossRef]

- Kumar, V.; Raghuwanshi, S.K.; Kumar, S. Advances in Nanocomposite Thin-Film-Based Optical Fiber Sensors for Environmental Health Monitoring—A Review. IEEE Sens. J. 2022, 22, 14696–14707. [Google Scholar] [CrossRef]

- Niu, H.; Zhang, S.; Chen, W.; Liu, Y.; Li, X.; Yan, Y.; Wang, S.; Geng, T.; Sun, W.; Yuan, L. Optical Fiber Sensors Based on Core-Offset Structure: A Review. IEEE Sens. J. 2021, 21, 22388–22401. [Google Scholar] [CrossRef]

- Soares, M.S.; Vidal, M.; Santos, N.F.; Costa, F.M.; Marques, C.; Pereira, S.O.; Leitão, C. Immunosensing Based on Optical Fiber Technology: Recent Advances. Biosensors 2021, 11, 305. [Google Scholar] [CrossRef] [PubMed]

- Pawar, D.; Kale, S.N. A Review on Nanomaterial-Modified Optical Fiber Sensors for Gases, Vapors and Ions. Microchim. Acta 2019, 186, 253. [Google Scholar] [CrossRef]

- Li, M.; Singh, R.; Wang, Y.; Marques, C.; Zhang, B.; Kumar, S. Advances in Novel Nanomaterial-Based Optical Fiber Biosensors—A Review. Biosensors 2022, 12, 843. [Google Scholar] [CrossRef]

- Lee, S.; Song, H.; Ahn, H.; Kim, S.; Choi, J.-r.; Kim, K. Fiber-Optic Localized Surface Plasmon Resonance Sensors Based on Nanomaterials. Sensors 2021, 21, 819. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Liu, Z.; Zhang, Y.; Li, S.; Zhang, Y.; Yang, X.; Zhang, J.; Yuan, L. Specialty Optical Fibers and 2d Materials for Sensitivity Enhancement of Fiber Optic Spr Sensors: A Review. Opt. Laser Technol. 2022, 152, 108167. [Google Scholar] [CrossRef]

- Chauhan, M.; Singh, V.K. Review on Recent Experimental SPR/LSPR Based Fiber Optic Analyte Sensors. Opt. Fiber Technol. 2021, 64, 102580. [Google Scholar] [CrossRef]

- Qi, M.; Zhang, N.M.Y.; Li, K.; Tjin, S.C.; Wei, L. Hybrid Plasmonic Fiber-Optic Sensors. Sensors 2020, 20, 3266. [Google Scholar] [CrossRef] [PubMed]

- Paliwal, N.; John, J. Lossy Mode Resonance (LMR) Based Fiber Optic Sensors: A Review. IEEE Sens. J. 2015, 15, 5361–5371. [Google Scholar] [CrossRef]

- Vikas; Mishra, S.K.; Mishra, A.K.; Saccomandi, P.; Verma, R.K. Recent Advances in Lossy Mode Resonance-Based Fiber Optic Sensors: A Review. Micromachines 2022, 13, 1921. [Google Scholar] [CrossRef]

- Krogman, K.C.; Druffel, T.; Sunkara, M.K. Anti-Reflective Optical Coatings Incorporating Nanoparticles. Nanotechnology 2005, 16, S338. [Google Scholar] [CrossRef]

- Jiang, C.-c.; Cao, Y.-k.; Xiao, G.-y.; Zhu, R.-f.; Lu, Y.-p. A review on the Application of Inorganic Nanoparticles in Chemical Surface Coatings on Metallic Substrates. RSC Adv. 2017, 7, 7531–7539. [Google Scholar] [CrossRef]

- Ferraz, M.; Monteiro, F.; Manuel, C. Hydroxyapatite Nanoparticles: A Review of Preparation Methodologies. J. Appl. Biomater. Biomech. 2004, 2, 74–80. [Google Scholar]

- Choi, B.; Park, W.; Park, S.-B.; Rhim, W.-K.; Han, D.K. Recent Trends in Cell Membrane-Cloaked Nanoparticles for Therapeutic Applications. Methods 2020, 177, 2–14. [Google Scholar] [CrossRef]

- Vollath, D.; Szabo, D. Coated Nanoparticles: A New Way to Improved Nanocomposites. J. Nanopart. Res. 1999, 1, 235–242. [Google Scholar] [CrossRef]

- Lee, H.; Song, M.Y.; Jurng, J.; Park, Y.-K. The Synthesis and Coating Process of TiO2 Nanoparticles Using CVD Process. Powder Technol. 2011, 214, 64–68. [Google Scholar] [CrossRef]

- Hachem, K.; Ansari, M.J.; Saleh, R.O.; Kzar, H.H.; Al-Gazally, M.E.; Altimari, U.S.; Hussein, S.A.; Mohammed, H.T.; Hammid, A.T.; Kianfar, E. Methods of Chemical Synthesis in the Synthesis of Nanomaterial and Nanoparticles by the Chemical Deposition Method: A Review. BioNanoScience 2022, 12, 1032–1057. [Google Scholar] [CrossRef]

- Hodes, G. Semiconductor and Ceramic Nanoparticle Films Deposited by Chemical Bath Deposition. Phys. Chem. Chem. Phys. 2007, 9, 2181–2196. [Google Scholar] [CrossRef]

- Mustafa, H.A.M.; Jameel, D.A. Modeling and the Main Stages of Spin Coating Process: A Review. J. Appl. Sci. Technol. Trends 2021, 2, 119–123. [Google Scholar] [CrossRef]

- Moreira, J.; Vale, A.C.; Alves, N.M. Spin-Coated Freestanding Films for Biomedical Applications. J. Mater. Chem. B 2021, 9, 3778–3799. [Google Scholar] [CrossRef] [PubMed]

- Birnie, D.P., III. Spin Coating Technique. In Sol-Gel Technologies for Glass Producers and Users; Springer: New York, NY, USA, 2004; pp. 49–55. [Google Scholar]

- Emslie, A.G.; Bonner, F.T.; Peck, L.G. Flow of a Viscous Liquid on a Rotating Disk. J. Appl. Phys. 1958, 29, 858–862. [Google Scholar] [CrossRef]

- Washo, B. Rheology and Modeling of the Spin Coating Process. IBM J. Res. Dev. 1977, 21, 190–198. [Google Scholar] [CrossRef]

- Uddin, M.; Chan, H.; Chow, C.; Chan, Y. Effect of Spin Coating on the Curing Rate of Epoxy Adhesive for the Fabrication of a Polymer Optical Waveguide. J. Electron. Mater. 2004, 33, 224–228. [Google Scholar] [CrossRef]

- Skrobis, K.J.; Denton, D.D.; Skrobis, A.V. Effect of Early Solvent Evaporation on the Mechanism of the Spin-Coating of Polymeric Solutions. Polym. Eng. Sci. 1990, 30, 193–196. [Google Scholar] [CrossRef]

- Komaraiah, D.; Radha, E.; Sivakumar, J.; Reddy, M.R.; Sayanna, R. Photoluminescence and Photocatalytic Activity of Spin Coated Ag+ Doped Anatase TiO2 Thin Films. Opt. Mater. 2020, 108, 110401. [Google Scholar] [CrossRef]

- Hong, Y.-K.; Kim, H.; Lee, G.; Kim, W.; Park, J.-I.; Cheon, J.; Koo, J.-Y. Controlled Two-Dimensional Distribution of Nanoparticles by Spin-Coating Method. Appl. Phys. Lett. 2002, 80, 844–846. [Google Scholar] [CrossRef]

- Sonker, R.K.; Yadav, B.C.; Gupta, V.; Tomar, M. Synthesis of CdS Nanoparticle by Sol-Gel Method as Low Temperature NO2 Sensor. Mater. Chem. Phys. 2020, 239, 121975. [Google Scholar] [CrossRef]

- Karimi, V.; Asemi, M.; Ghanaatshoar, M. Improving Photovoltaic Properties of ZTO-Based DSSCs Using Surface Modification of Zn2SnO4 Nanoparticles Prepared by Co-Precipitation Method. Mater. Sci. Semicond. Process. 2021, 127, 105664. [Google Scholar] [CrossRef]

- Zheng, L.; Ogino, K.; Xiaoqiang, L. Low-temperature Welding Engineering of ZnO Nanoparticles Films via Sol-Gel Method. Colloids Surf. A Physicochem. Eng. Asp. 2024, 698, 134506. [Google Scholar] [CrossRef]

- Giribaldi, A.; Giordani, C.; Latronico, G.; Bourgès, C.; Baba, T.; Piscino, C.; Marinova, M.; Mori, T.; Artini, C.; Rijckaert, H. Enhancing Thermoelectric Performance: The Impact of Carbon Incorporation in Spin-Coated Al-Doped ZnO Thin Films. Coatings 2025, 15, 107. [Google Scholar] [CrossRef]

- Puetz, J.; Aegerter, M. Dip Coating Technique. In Sol-Gel Technologies for Glass Producers and Users; Springer: New York, NY, USA, 2004; pp. 37–48. [Google Scholar]

- Grosso, D. How to Exploit the Full Potential of the Dip-Coating Process to Better Control Film Formation. J. Mater. Chem. 2011, 21, 17033–17038. [Google Scholar] [CrossRef]

- Scriven, L. Physics and Applications of Dip Coating and Spin Coating. MRS Online Proc. Libr. 1988, 121, 717–729. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Shao, Y.; Liao, C.; Wang, Y. Highly Sensitive Surface Plasmon Resonance Humidity Sensor Based on a Polyvinyl-Alcohol-Coated Polymer Optical Fiber. Biosensors 2021, 11, 461. [Google Scholar] [CrossRef] [PubMed]

- Nagoor Meeran, M.; Saravanan, S.P.; Shkir, M.; Karthik Kannan, S. Fabrication of Transition-Metal (Zn, Mn, Cu)-Based MOFs as Efficient Sensor Materials for Detection of H2 Gas by Clad Modified Fiber Optic Gas Sensor Technique. Opt. Fiber Technol. 2021, 65, 102614. [Google Scholar] [CrossRef]

- Zaremba, O.T.; Goldt, A.E.; Khabushev, E.M.; Anisimov, A.S.; Nasibulin, A.G. Highly Efficient Doping of Carbon Nanotube Films with Chloroauric Acid by Dip-Coating. Mater. Sci. Eng. B 2022, 278, 115648. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, X.; Gong, Y.; He, X.; Wei, Y.; Li, H. Tribocorrosion Behaviours of Cold-Sprayed Diamond–Cu Composite Coatings in Artificial Sea Water. Surf. Eng. 2018, 34, 392–398. [Google Scholar] [CrossRef]

- Chen, T.-C.; Chou, C.-C.; Yung, T.-Y.; Tsai, K.-C.; Huang, J.-Y. Wear Behavior of Thermally Sprayed Zn/15Al, Al and Inconel 625 Coatings on Carbon Steel. Surf. Coat. Technol. 2016, 303, 78–85. [Google Scholar] [CrossRef]

- Saad, K.S.K.; Saba, T.; Rashid, A.B. Application of PVD Coatings in Medical Implantology for Enhanced Performance, Biocompatibility, and Quality of Life. Heliyon 2024, 10, e35541. [Google Scholar] [CrossRef]

- Lin, J.; Du, J.; Xie, S.; Yu, F.; Fang, S.; Yan, Z.; Lin, X.; Zou, D.; Xie, M.; Ye, W. Durable Superhydrophobic Polyvinylidene Fluoride Membranes Via Facile Spray-Coating for Effective Membrane Distillation. Desalination 2022, 538, 115925. [Google Scholar] [CrossRef]

- Xue, N.; Li, W.; Shao, L.; Tu, Z.; Chen, Y.; Dai, S.; Ye, N.; Zhang, J.; Liu, Q.; Wang, J. Comparison of Cold-Sprayed Coatings of Copper-Based Composite Deposited on AZ31B Magnesium Alloy and 6061 T6 Aluminum Alloy Substrates. Materials 2023, 16, 5120. [Google Scholar] [CrossRef]

- Lei, S.; Zhang, Y.-r.; Wang, Y.-x.; Li, J.-l.; Jiang, X.; Chen, J.-m. Corrosion and Wear Behaviors of PVD CrN and CrSiN Coatings in Seawater. Trans. Nonferrous Met. Soc. China 2016, 26, 175–184. [Google Scholar]

- Sui, X.; Xu, R.; Liu, J.; Zhang, S.; Wu, Y.; Yang, J.; Hao, J. Tailoring the Tribocorrosion and Antifouling Performance of (Cr, Cu)-GLC Coatings for Marine Application. ACS Appl. Mater. Interfaces 2018, 10, 36531–36539. [Google Scholar] [CrossRef] [PubMed]

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. On Coating Techniques for Surface Protection: A Review. J. Manuf. Mater. Process. 2019, 3, 28. [Google Scholar] [CrossRef]

- Pang, X.; Zhang, Q.; Shao, Y.; Liu, M.; Zhang, D.; Zhao, Y. A Flexible Pressure Sensor Based on Magnetron Sputtered Mos2. Sensors 2021, 21, 1130. [Google Scholar] [CrossRef]

- Marques, S.M.; Carvalho, I.; Henriques, M.; Polcar, T.; Carvalho, S. PVD-Grown Antibacterial Ag-TiN Films on Piezoelectric PVDF Substrates for Sensor Applications. Surf. Coat. Technol. 2015, 281, 117–124. [Google Scholar] [CrossRef]

- Aslanidis, E.; Sarigiannidis, S.; Skotadis, E.; Tsoukalas, D. Vibration Sensors on Flexible Substrates Based on Nanoparticle Films Grown by Physical Vapor Deposition. Materials 2024, 17, 1522. [Google Scholar] [CrossRef]

- Dobkin, D.; Zuraw, M.K. Principles of Chemical Vapor Deposition; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Manawi, Y.M.; Ihsanullah; Samara, A.; Al-Ansari, T.; Atieh, M.A. A Review of Carbon Nanomaterials’ Synthesis Via the Chemical Vapor Deposition (CVD) method. Materials 2018, 11, 822. [Google Scholar] [CrossRef]

- Fan, S.; Chen, Y.; Wu, J.; Xiao, S.; Chen, G.; Chu, P.K. Structure, Superlubricity, Applications, and Chemical Vapor Deposition Methods of Graphene Solid Lubricants. Tribol. Int. 2024, 198, 109896. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, K.; Qi, Y.; Liu, Z. Chemical Vapor Deposition Method for Graphene Fiber Materials. Acta Phys.-Chim. Sin. 2022, 38, 2006046. [Google Scholar] [CrossRef]

- Deokar, G.; Jin, J.; Schwingenschlögl, U.; Costa, P.M. Chemical Vapor Deposition-Grown Nitrogen-Doped Graphene’s Synthesis, Characterization and Applications. npj 2D Mater. Appl. 2022, 6, 14. [Google Scholar] [CrossRef]

- JR, V.G.; Goto, T. Chemical Vapor Deposition Of Iridium, Platinum, Rhodium and Palladium. Mater. Trans. 2003, 44, 1717–1728. [Google Scholar] [CrossRef]

- Shekhirev, M.; Lipatov, A.; Torres, A.; Vorobeva, N.S.; Harkleroad, A.; Lashkov, A.; Sysoev, V.; Sinitskii, A. Highly Selective Gas Sensors Based on Graphene Nanoribbons Grown by Chemical Vapor Deposition. ACS Appl. Mater. Interfaces 2020, 12, 7392–7402. [Google Scholar] [CrossRef] [PubMed]

- Andrés, M.A.; Vijjapu, M.T.; Surya, S.G.; Shekhah, O.; Salama, K.N.; Serre, C.; Eddaoudi, M.; Roubeau, O.; Gascón, I. Methanol and Humidity Capacitive Sensors Based on Thin Films of MOF Nanoparticles. ACS Appl. Mater. Interfaces 2020, 12, 4155–4162. [Google Scholar] [CrossRef]

- Xu, M.; Li, Z.; Zhu, X.; Hu, N.; Wei, H.; Yang, Z.; Zhang, Y. Hydrothermal/Solvothermal Synthesis of Graphene Quantum Dots and Their Biological Applications. Nano Biomed. Eng. 2013, 5, 65–71. [Google Scholar] [CrossRef]

- Rajamathi, M.; Seshadri, R. Oxide and Chalcogenide Nanoparticles from Hydrothermal/Solvothermal Reactions. Curr. Opin. Solid. State Mater. Sci. 2002, 6, 337–345. [Google Scholar] [CrossRef]

- Djurisic, A.B.; Xi, Y.Y.; Hsu, Y.F.; Chan, W.K. Hydrothermal Synthesis of Nanostructures. Recent Pat. Nanotechnol. 2007, 1, 121–128. [Google Scholar] [CrossRef]

- Ndlwana, L.; Raleie, N.; Dimpe, K.M.; Ogutu, H.F.; Oseghe, E.O.; Motsa, M.M.; Msagati, T.A.; Mamba, B.B. Sustainable Hydrothermal and Solvothermal Synthesis of Advanced Carbon Materials in Multidimensional Applications: A Review. Materials 2021, 14, 5094. [Google Scholar] [CrossRef]

- Ling, L.; Cai, S.; Li, Q.; Sun, J.; Bao, X.; Xu, G. Recent Advances in Hydrothermal Modification of Calcium Phosphorus Coating on Magnesium Alloy. J. Magnes. Alloys 2022, 10, 62–80. [Google Scholar] [CrossRef]

- Khizir, H.A. Gas-Sensing Performance of TiO2 Nanorod Arrays Synthesized by Solvothermal Method. Zanco J. Pure Appl. Sci. 2025, 37, 29–37. [Google Scholar] [CrossRef]

- Lines, M.G. Nanomaterials for Practical Functional Uses. J. Alloys Compd. 2008, 449, 242–245. [Google Scholar] [CrossRef]

- Kim, F.; Kwan, S.; Akana, J.; Yang, P. Langmuir-Blodgett Nanorod Assembly. J. Am. Chem. Soc. 2001, 123, 4360–4361. [Google Scholar] [CrossRef]

- Wink, T.; Van Zuilen, S.; Bult, A.; Van Bennekom, W. Self-Assembled Monolayers for Biosensors. Analyst 1997, 122, 43R–50R. [Google Scholar] [CrossRef] [PubMed]

- Chechik, V.; Stirling, C.J. Gold-Thiol Self-Assembled Monolayers. In The Chemistry of Organic Derivatives of Gold and Silver; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 1999; pp. 551–640. [Google Scholar]

- Gooding, J.J.; Mearns, F.; Yang, W.; Liu, J. Self-Assembled Monolayers into the 21st Century: Recent Advances and Applications. Electroanal. An. Int. J. Devoted Fundam. Pract. Asp. Electroanal. 2003, 15, 81–96. [Google Scholar] [CrossRef]

- Song, L.; Xu, B.B.; Cheng, Q.; Wang, X.; Luo, X.; Chen, X.; Chen, T.; Huang, Y. Instant Interfacial Self-Assembly for Homogeneous Nanoparticle Monolayer Enabled Conformal “Lift-on” Thin Film Technology. Sci. Adv. 2021, 7, eabk2852. [Google Scholar] [CrossRef] [PubMed]

- Guzmán, E.; Rubio, R.G.; Ortega, F. A Closer Physico-Chemical Look to the Layer-by-Layer Electrostatic Self-Assembly of Polyelectrolyte Multilayers. Adv. Colloid. Interface Sci. 2020, 282, 102197. [Google Scholar] [CrossRef]

- Richardson, J.J.; Cui, J.; Bjornmalm, M.; Braunger, J.A.; Ejima, H.; Caruso, F. Innovation in Layer-by-Layer Assembly. Chem. Rev. 2016, 116, 14828–14867. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Zhang, H. Layer-by-Layer Assembly: From Conventional to Unconventional Methods. Chem. Commun. 2007, 1395–1405. [Google Scholar] [CrossRef]

- Quinn, J.F.; Johnston, A.P.; Such, G.K.; Zelikin, A.N.; Caruso, F. Next Generation, Sequentially Assembled Ultrathin Films: Beyond Electrostatics. Chem. Soc. Rev. 2007, 36, 707–718. [Google Scholar] [CrossRef]

- Kharlampieva, E.; Kozlovskaya, V.; Sukhishvili, S.A. Layer-by-Layer Hydrogen-Bonded Polymer Films: From Fundamentals to Applications. Adv. Mater. 2009, 21, 3053–3065. [Google Scholar] [CrossRef]

- De Villiers, M.M.; Otto, D.P.; Strydom, S.J.; Lvov, Y.M. Introduction to Nanocoatings Produced by Layer-by-Layer (LbL) Self-Assembly. Adv. Drug Deliv. Rev. 2011, 63, 701–715. [Google Scholar] [CrossRef]

- Wang, C.; Park, M.J.; Yu, H.; Matsuyama, H.; Drioli, E.; Shon, H.K. Recent Advances of Nanocomposite Membranes Using Layer-by-Layer Assembly. J. Membr. Sci. 2022, 661, 120926. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, J.; Groll, J.; Matsusaki, M. Layer-by-layer Assembly Methods and Their Biomedical Applications. Biomater. Sci. 2022, 10, 4077–4094. [Google Scholar] [CrossRef] [PubMed]

- Iler, R.K. Multilayers of Colloidal Particles. J. Colloid. Interface Sci. 1966, 21, 569–594. [Google Scholar] [CrossRef]

- Song, Z.; Yin, J.; Luo, K.; Zheng, Y.; Yang, Y.; Li, Q.; Yan, S.; Chen, X. Layer-by-Layer Buildup of Poly (L-glutamic acid)/Chitosan Film for Biologically Active Coating. Macromol. Biosci. 2009, 9, 268–278. [Google Scholar] [CrossRef]

- Doria, G.; Conde, J.; Veigas, B.; Giestas, L.; Almeida, C.; Assunção, M.; Rosa, J.; Baptista, P.V. Noble Metal Nanoparticles for Biosensing Applications. Sensors 2012, 12, 1657–1687. [Google Scholar] [CrossRef]

- Hasanzadeh, M.; Shadjou, N.; de la Guardia, M. Iron and Iron-Oxide Magnetic Nanoparticles as Signal-Amplification Elements in Electrochemical Biosensing. TrAC Trends Anal. Chem. 2015, 72, 1–9. [Google Scholar] [CrossRef]

- Guo, L.; Chen, G.; Kim, D.-H. Three-Dimensionally Assembled Gold Nanostructures for Plasmonic Biosensors. Anal. Chem. 2010, 82, 5147–5153. [Google Scholar] [CrossRef]

- Teeparuksapun, K.; Hedström, M.; Mattiasson, B. A Sensitive Capacitive Biosensor for Protein a Detection Using Human IgG Immobilized on an Electrode Using Layer-by-Layer Applied Gold Nanoparticles. Sensors 2021, 22, 99. [Google Scholar] [CrossRef] [PubMed]

- Nangare, S.; Patil, P. Chitosan Mediated Layer-by-Layer Assembly Based Graphene Oxide Decorated Surface Plasmon Resonance Biosensor for Highly Sensitive Detection of β-Amyloid. Int. J. Biol. Macromol. 2022, 214, 568–582. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhao, Y.; Ruan, Y.; Weng, X.; Milcovich, G. Dendritic Gold Nanoparticles Loaded on 3D Graphene-like Surface and Layer-by-Layer Assembly for Enhanced Glucose Biosensing. Biosensors 2025, 15, 246. [Google Scholar] [CrossRef] [PubMed]

- Johnson, R.W.; Hultqvist, A.; Bent, S.F. A Brief Review of Atomic Layer Deposition: From Fundamentals to Applications. Mater. Today 2014, 17, 236–246. [Google Scholar] [CrossRef]

- Si, M.; Lin, Z.; Chen, Z.; Sun, X.; Wang, H.; Ye, P.D. Scaled Indium Oxide Transistors Fabricated Using Atomic Layer Deposition. Nat. Electron. 2022, 5, 164–170. [Google Scholar] [CrossRef]

- Niazi, M.F.K.; Munoz-Rojas, D.; Evrard, D.; Weber, M. Comparative Study of the Environmental Impact of Depositing Al2O3 by Atomic Layer Deposition and Spatial Atomic Layer Deposition. ACS Sustain. Chem. Eng. 2023, 11, 15072–15082. [Google Scholar] [CrossRef]

- Li, S.; Zhao, W.; Shi, X.-L.; Wang, L.; Pan, S.; Cheng, G.; Liu, W.-D.; Li, M.; Guo, K.; Chen, Z.-G. Designing Cost-Performance Porous Thermoelectric Materials by Interface Engineering through Atomic Layer Deposition. J. Mater. Sci. Technol. 2025, 214, 194–203. [Google Scholar] [CrossRef]

- Mihailescu, I.N.; György, E. Pulsed Laser Deposition: An Overview. In International Trends in Optics and Photonics: ICO IV; Springer: Berlin/Heidelberg, Germany, 1999; pp. 201–214. [Google Scholar]

- Lunney, J.G. Pulsed Laser Deposition of Metal and Metal Multilayer Films. Appl. Surf. Sci. 1995, 86, 79–85. [Google Scholar] [CrossRef]

- Lowndes, D.H.; Geohegan, D.; Puretzky, A.; Norton, D.; Rouleau, C. Synthesis of Novel Thin-Film Materials by Pulsed Laser Deposition. Science 1996, 273, 898–903. [Google Scholar] [CrossRef]

- Haider, A.J.; Alawsi, T.; Haider, M.J.; Taha, B.A.; Marhoon, H.A. A Comprehensive Review on Pulsed Laser Deposition Technique to Effective Nanostructure Production: Trends and Challenges. Opt. Quantum Electron. 2022, 54, 488. [Google Scholar] [CrossRef]

- Mouloua, D.; LeBlanc-Lavoie, J.; Pichon, L.; Rajput, N.S.; El Marssi, M.; Jouiad, M.; El Khakani, M.A. Tuning the Optoelectronic Properties of Pulsed Laser Deposited “3D”-MoS 2 Films Via the Degree of Vertical Alignment of Their Constituting Layers. Adv. Opt. Mater. 2024, 12, 2302966. [Google Scholar] [CrossRef]

- Cremer, S.; Voß, L.; Braun, N.; Wolff, N.; Kienle, L.; Lotnyk, A. Growth and Microstructure of GeTe-Sb2Te3 Heterostructures Prepared by Pulsed Laser Deposition. Appl. Surf. Sci. 2024, 655, 159679. [Google Scholar] [CrossRef]

- Gurrappa, I.; Binder, L. Electrodeposition of Nanostructured Coatings and their Characterization—A Review. Sci. Technol. Adv. Mater. 2008, 9, 043001. [Google Scholar] [CrossRef] [PubMed]

- Beck, F. Electrodeposition of Polymer Coatings. Electrochim. Acta 1988, 33, 839–850. [Google Scholar] [CrossRef]

- Reid, J. Copper Electrodeposition: Principles and Recent Progress. Jpn. J. Appl. Phys. 2001, 40, 2650. [Google Scholar] [CrossRef]

- Falcón, J.M.; Aoki, I.V. Electrodeposition of ZnCo Alloy Coatings on Carbon Steel and their Corrosion Resistance. Surf. Coat. Technol. 2024, 481, 130603. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Lou, G.; Chen, Y.; Pang, H.; Song, Y.; Naqvi, S.M.R.; Zhou, K.; Tian, Z.; Nasir, M.A.; et al. High-Performance Ni-SiC Composite Coatings with Enhanced Infrared Emissivity Via Magnetic Field-Assisted Jet Electrodeposition. Surf. Coat. Technol. 2025, 513, 132500. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z. Electron Beam Evaporation Deposition. In Advanced Nano Deposition Methods; Wiley Online Library: Hoboken, NJ, USA, 2016; pp. 33–58. [Google Scholar]

- Sahu, D.R.; Lin, S.-Y.; Huang, J.-L. Improved Properties of Al-Doped ZnO film by Electron Beam Evaporation Technique. Microelectron. J. 2007, 38, 245–250. [Google Scholar] [CrossRef]

- George, J.; Menon, C. Electrical and Optical Properties of Electron Beam Evaporated ITO Thin Films. Surf. Coat. Technol. 2000, 132, 45–48. [Google Scholar] [CrossRef]

- Singh, C.P.; Singh, V.P.; Ranjan, H.; Pandey, S.K. Bipolar and Rectifying Resistive Switching Dynamics in E-Beam Evaporated SnOx Based Memristor. Ceram. Int. 2024, 50, 4092–4100. [Google Scholar] [CrossRef]

- Kant, S.; Kumari, N.; Kumar, M. Effect of Deposition Conditions on the Morphological, Optical, and Corrosion Behavior of Electron Beam Evaporated High-Performance HfO2 Thin Films. Appl. Phys. A 2025, 131, 631. [Google Scholar] [CrossRef]

- Teo, W.E.; Ramakrishna, S. A Review on Electrospinning Design and Nanofibre Assemblies. Nanotechnology 2006, 17, R89. [Google Scholar] [CrossRef]

- Ji, D.; Lin, Y.; Guo, X.; Ramasubramanian, B.; Wang, R.; Radacsi, N.; Jose, R.; Qin, X.; Ramakrishna, S. Electrospinning of Nanofibres. Nat. Rev. Methods Primers 2024, 4, 1. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A Fascinating Fiber Fabrication Technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Zhao, J.; Cheng, H.; Feng, J.; Tang, T.; Qin, D. A Mo2C/CoO@N/CNFs Electrochemiluminescence Sensor Was Prepared Based on the Electrospinning Method for Rapid Detection of Azithromycin. Microchem. J. 2024, 205, 111241. [Google Scholar] [CrossRef]

- Luo, Y.; Shao, F.; Sun, Y.; Wang, H.; He, Y.; Wang, Y.; Xu, D. Synthesis of SnC@Au@Apta by Electrospinning as an Electrochemical Sensor for Detection of Tetracycline. Talanta 2025, 281, 126866. [Google Scholar] [CrossRef]

- Marago, O.M.; Jones, P.H.; Gucciardi, P.G.; Volpe, G.; Ferrari, A.C. Optical Trapping and Manipulation of Nanostructures. Nat. Nanotechnol. 2013, 8, 807–819. [Google Scholar] [CrossRef]

- Kolbow, J.D.; Lindquist, N.C.; Ertsgaard, C.T.; Yoo, D.; Oh, S.H. Nano-Optical Tweezers: Methods and Applications for Trapping Single Molecules and Nanoparticles. ChemPhysChem 2021, 22, 1409–1420. [Google Scholar] [CrossRef]

- Khazaeinezhad, R.; Kassani, S.H.; Nazari, T.; Jeong, H.; Kim, J.; Choi, K.; Lee, J.-U.; Kim, J.H.; Cheong, H.; Yeom, D.-I. Saturable Optical Absorption in MoS2 Nano-Sheet Optically Deposited on the Optical Fiber Facet. Opt. Commun. 2015, 335, 224–230. [Google Scholar] [CrossRef]

- Wang, R.; Kang, X.; Kong, D.; Jiang, M.; Ren, Z.; Hu, B.; He, Z. Highly Sensitive Metal Ion Sensing by Graphene Oxide Functionalized Micro-Tapered Long-Period Fiber Grating. Analyst 2022, 147, 3025–3034. [Google Scholar] [CrossRef]

- Shi, Z.; Shen, T.; Dou, L.; Gu, Z.; Zhu, R.; Dong, X.; Gu, F. Optical Trapping of Few-Layered Materials on Solid Substrates for In Situ and Dynamic Fabrication. Laser Photonics Rev. 2024, 18, 2400384. [Google Scholar] [CrossRef]

- Pendão, C.; Silva, I. Optical Fiber Sensors and Sensing Networks: Overview of the Main Principles and Applications. Sensors 2022, 22, 7554. [Google Scholar] [CrossRef]

- Gong, P.; Li, X.; Zhou, X.; Zhang, Y.; Chen, N.; Wang, S.; Zhang, S.; Zhao, Y. Optical Fiber Sensors for Glucose Concentration Measurement: A Review. Opt. Laser Technol. 2021, 139, 106981. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Fiber-Optic Sensors. In Structural Health Monitoring of Aerospace Composites; Academic Press: Cambridge, MA, USA, 2016; pp. 249–296. [Google Scholar]

- Elsherif, M.; Salih, A.E.; Muñoz, M.G.; Alam, F.; AlQattan, B.; Antonysamy, D.S.; Zaki, M.F.; Yetisen, A.K.; Park, S.; Wilkinson, T.D. Optical Fiber Sensors: Working Principle, Applications, and Limitations. Adv. Photonics Res. 2022, 3, 2100371. [Google Scholar] [CrossRef]

- Roriz, P.; Ramos, A.; Santos, J.L.; Simões, J.A. Fiber Optic Intensity-Modulated Sensors: A Review in Biomechanics. Photonic Sens. 2012, 2, 315–330. [Google Scholar] [CrossRef]

- Anwar Zawawi, M.; O’Keffe, S.; Lewis, E. Intensity-Modulated Fiber Optic Sensor for Health Monitoring Applications: A Comparative Review. Sens. Rev. 2013, 33, 57–67. [Google Scholar] [CrossRef]

- Teng, C.; Min, R.; Zheng, J.; Deng, S.; Li, M.; Hou, L.; Yuan, L. Intensity-Modulated Polymer Optical Fiber-Based Refractive Index Sensor: A Review. Sensors 2021, 22, 81. [Google Scholar] [CrossRef]

- Li, A.-W.; Shan, T.-Q.; Guo, Q.; Pan, X.-P.; Liu, S.-R.; Chen, C.; Yu, Y.-S. Research Progress of Optical Fiber Fabry-Perot Interferometer High Temperature Sensors. Chin. Opt. 2022, 15, 609–624. [Google Scholar] [CrossRef]

- Zhu, C.; Zheng, H.; Ma, L.; Yao, Z.; Liu, B.; Huang, J.; Rao, Y. Advances in Fiber-Optic Extrinsic Fabry–Perot Interferometric Physical and Mechanical Sensors: A Review. IEEE Sens. J. 2023, 23, 6406–6426. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Chu, S.; Fan, Z. A Highly Sensitive Photonic Crystal Fiber Temperature Sensor Based on Sagnac Interferometer with Full Liquid Filling. Opt. Quantum Electron. 2023, 55, 371. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, G.; Kumar, S.; Marques, C.; Min, R.; Li, X. recent Advancements in Resonant Fiber Optic Gyro—A Review. IEEE Sens. J. 2022, 22, 18240–18252. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, Y.; Lyu, W.; Lu, C.; Wei, L.; Yu, C. Non-Invasive Vital Signs Monitoring Based on Optical Fiber Mach-Zehnder Interferometer. In Proceedings of the 2024 24th International Conference on Transparent Optical Networks (ICTON), Bari, Italy, 14–18 July 2024; pp. 1–4. [Google Scholar]

- Lu, C.; Dong, X.; Wu, C. Characteristics of Critical-Wavelength-Existed Fiber-Optic Mach–Zehnder Interferometers and Their Sensing Applications. Photonics 2022, 9, 378. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.j.; Song, S.; Li, F. Overview of Fibre Optic Sensing Technology in the Field of Physical Ocean Observation. Front. Phys. 2021, 9, 745487. [Google Scholar] [CrossRef]

- Zhu, C.; Zhuang, Y.; Liu, B.; Huang, J. Review of Fiber Optic Displacement Sensors. IEEE Trans. Instrum. Meas. 2022, 71, 7008212. [Google Scholar] [CrossRef]

- Rao, Y. Study on Fiber-Optic Low-Coherence Interferometric and Fiber Bragg Grating Sensors. Photonic Sens. 2011, 1, 382–400. [Google Scholar] [CrossRef]

- Zhu, T.; Wu, D.; Liu, M.; Duan, D.-W. In-Line Fiber Optic Interferometric Sensors in Single-Mode Fibers. Sensors 2012, 12, 10430–10449. [Google Scholar] [CrossRef] [PubMed]

- Chiavaioli, F.; Baldini, F.; Tombelli, S.; Trono, C.; Giannetti, A. Biosensing with Optical Fiber Gratings. Nanophotonics 2017, 6, 663–679. [Google Scholar] [CrossRef]

- Riza, M.A.; Go, Y.I.; Harun, S.W.; Maier, R.R. FBG Sensors for Environmental and Biochemical Applications—A Review. IEEE Sens. J. 2020, 20, 7614–7627. [Google Scholar] [CrossRef]

- Kaur, B.; Kumar, S.; Kaushik, B.K. Recent Advancements in Optical Biosensors for Cancer Detection. Biosens. Bioelectron. 2022, 197, 113805. [Google Scholar] [CrossRef]

- Theodosiou, A. Recent Advances in Fiber Bragg Grating Sensing. Sensors 2024, 24, 532. [Google Scholar] [CrossRef]

- Ngiejungbwen, L.A.; Hamdaoui, H.; Chen, M.-Y. Polymer Optical Fiber and Fiber Bragg Grating Sensors for Biomedical Engineering Applications: A Comprehensive Review. Opt. Laser Technol. 2024, 170, 110187. [Google Scholar] [CrossRef]

- Bonopera, M. Fiber-Bragg-Grating-Based Displacement Sensors: Review of Recent Advances. Materials 2022, 15, 5561. [Google Scholar] [CrossRef]

- Cai, J.; Liu, Y.; Shu, X. Long-Period Fiber Grating Sensors for Chemical and Biomedical Applications. Sensors 2023, 23, 542. [Google Scholar] [CrossRef] [PubMed]

- Trono, C. Long Period Fiber Grating-Based Biosensing: Recent Trends and Future Perspectives. TrAC Trends Anal. Chem. 2024, 179, 117875. [Google Scholar] [CrossRef]

- Butov, O.V.; Tomyshev, K.; Nechepurenko, I.; Dorofeenko, A.V.; Nikitov, S.A. Tilted Fiber Bragg Gratings and Their Sensing Applications. Uspekhi Fiz. Nauk. 2022, 192, 1385–1398. [Google Scholar] [CrossRef]

- Guo, T.; Liu, F.; Guan, B.-O.; Albert, J. Tilted Fiber Grating Mechanical and Biochemical Sensors. Opt. Laser Technol. 2016, 78, 19–33. [Google Scholar] [CrossRef]

- Tosi, D. Review of Chirped Fiber Bragg Grating (CFBG) Fiber-Optic Sensors and Their Applications. Sensors 2018, 18, 2147. [Google Scholar] [CrossRef] [PubMed]

- Monzón-Hernández, D.; Luna-Moreno, D.; Martínez-Escobar, D. Fast Response Fiber Optic Hydrogen Sensor Based on Palladium and Gold Nano-Layers. Sens. Actuators B Chem. 2009, 136, 562–566. [Google Scholar] [CrossRef]

- Cho, Y.; Choi, Y.; Jang, Y.; Seong, H. Nanomaterial-Enhanced Biosensing: Mechanisms and Emerging Applications. Adv. Healthc. Mater. 2025, 2500189. [Google Scholar] [CrossRef]

- Shi, J.; Zhu, Y.; Zhang, X.; Baeyens, W.R.; García-Campaña, A.M. Recent Developments in Nanomaterial Optical Sensors. TrAC Trends Anal. Chem. 2004, 23, 351–360. [Google Scholar] [CrossRef]

- Li, F.; Li, X.-g.; Zhou, X.; Zhang, Y.-n.; Lv, R.-q.; Zhao, Y.; Xie, L.-s.; Nguyen, L.V.; Ebendorff-Heidepriem, H.; Warren-Smith, S.C. Simultaneous Measurement of Temperature and Relative Humidity Using Cascaded C-Shaped Fabry-Perot Interferometers. J. Light. Technol. 2022, 40, 1209–1215. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, X.; Zhang, J.; Liu, H. A Polyimide-Coated Fiber Bragg Grating Sensor for Multidepth Soil Humidity Measurement. IEEE Sens. J. 2024, 24, 7912–7920. [Google Scholar] [CrossRef]

- Rao, X.; Zhao, L.; Xu, L.; Wang, Y.; Liu, K.; Wang, Y.; Chen, G.Y.; Liu, T.; Wang, Y. Review of Optical Humidity Sensors. Sensors 2021, 21, 8049. [Google Scholar] [CrossRef] [PubMed]

- Tsai, Y.-T.; Wu, C.-W.; Tsai, L.; Chiang, C.-C. Application of Graphene Oxide-Based, Long-Period Fiber Grating for Sensing Relative Humidity. J. Light. Technol. 2021, 39, 4124–4130. [Google Scholar] [CrossRef]

- Al-Hayali, S.K.; Salman, A.M.; Al-Janabi, A.H. High Sensitivity Balloon-Like Interferometric Optical Fiber Humidity Sensor Based on Tuning Gold Nanoparticles Coating Thickness. Measurement 2021, 170, 108703. [Google Scholar] [CrossRef]

- Li, Z.; Dong, B.; Chen, E.; Li, Y.; Zhao, W.; Wang, Y.; Gao, C. High Sensitivity FBG Humidity Sensor Coated with Graphene and Polyimide Films. Opt. Fiber Technol. 2021, 66, 102635. [Google Scholar] [CrossRef]

- Ahmad, N.; Ali, A.H.; Al-Askery, A. Efficient Humidity Sensor Based on An Etched No-Core Fiber Coated with SiO2-Nanoparticles. In Proceedings of the 2024 Fourth International Conference on Advances in Electrical, Computing, Communication and Sustainable Technologies (ICAECT), Bhilai, India, 11–12 January 2024; pp. 1–6. [Google Scholar]

- Salim, A.A.; Ghoshal, S.K.; Amana, M.S.; Mufti, N.; Aziz, M.S.A.; Riyadh Waheed, S.; Abdulameer Kadhim, K.; Sarmin, N.H.; Bakhtiar, H. Humidity Sensing Characteristics of Rose Bengal Dye-Functionalized Plasmonic Silver Nanoparticles-Coated Novel Fiber-Optic Sensors. Opt. Fiber Technol. 2024, 88, 104025. [Google Scholar] [CrossRef]

- Cheng, T.; Li, B.; Zhang, F.; Chen, J.; Zhang, Q.; Yan, X.; Zhang, X.; Suzuki, T.; Ohishi, Y.; Wang, F. A Surface Plasmon Resonance Optical Fiber Sensor for Simultaneous Measurement of Relative Humidity and Temperature. IEEE Sens. J. 2022, 22, 3246–3253. [Google Scholar] [CrossRef]

- Han, Z.; Chao, J.; Xiping, Z.; Pei, W.; Tingshui, C.; Changning, L.; Simei, S. Simultaneous Humidity and Temperature Measurement Sensor Based on Two Cascaded Long-Period Fiber Gratings. Opt. Commun. 2023, 530, 129137. [Google Scholar] [CrossRef]

- Musgrove, A.L.; Cockerham, A.; Pazos, J.J.; Shahriar, S.; McMahon, M.; Touma, J.E.; Kuebler, S.M. Bio-Inspired Photonic and Plasmonic Systems for Gas Sensing: Applications, Fabrication, and Analytical Methods. J. Opt. Microsyst. 2024, 4, 020902. [Google Scholar] [CrossRef]

- Puttasakul, T.; Pintavirooj, C.; Sangma, C.; Sukjee, W. Hydrogel Based-Electrochemical Gas Sensor for Explosive Material Detection. IEEE Sens. J. 2019, 19, 8556–8562. [Google Scholar] [CrossRef]

- Gomes, J.B.; Rodrigues, J.J.; Rabêlo, R.A.; Kumar, N.; Kozlov, S. IoT-Enabled Gas Sensors: Technologies, Applications, and Opportunities. J. Sens. Actuator Netw. 2019, 8, 57. [Google Scholar] [CrossRef]

- Williams, J.; Pleil, J. Crowd-Based Breath Analysis: Assessing Behavior, Activity, Exposures, and Emotional Response of People in Groups. J. Breath. Res. 2016, 10, 032001. [Google Scholar] [CrossRef] [PubMed]

- Imbronito, A.V.; Okuda, O.S.; Maria de Freitas, N.; Moreira Lotufo, R.F.; Nunes, F.D. Detection of Herpesviruses and Periodontal Pathogens in Subgingival Plaque of Patients with Chronic Periodontitis, Generalized Aggressive Periodontitis, or Gingivitis. J. Periodontol. 2008, 79, 2313–2321. [Google Scholar] [CrossRef]

- Zuccarelli, R.; Rodríguez-Ruiz, M.; Lopes-Oliveira, P.J.; Pascoal, G.B.; Andrade, S.C.S.; Furlan, C.M.; Purgatto, E.; Palma, J.M.; Corpas, F.J.; Rossi, M.; et al. Multifaceted Roles of Nitric Oxide in Tomato Fruit Ripening: No-Induced Metabolic Rewiring and Consequences for Fruit Quality Traits. J. Exp. Bot. 2020, 72, 941–958. [Google Scholar] [CrossRef]

- Sauer, J.S.; Simkovsky, R.; Moore, A.N.; Camarda, L.; Sherman, S.L.; Prather, K.A.; Pomeroy, R.S. Continuous Measurements of Volatile Gases as Detection of Algae Crop Health. Proc. Natl. Acad. Sci. USA 2021, 118, e2106882118. [Google Scholar] [CrossRef]

- Maung, T.Z.; Bishop, J.E.; Holt, E.; Turner, A.M.; Pfrang, C. Indoor Air Pollution and the Health of Vulnerable Groups: A Systematic Review Focused on Particulate Matter (PM), Volatile Organic Compounds (VOCs) and Their Effects on Children and People with Pre-Existing Lung Disease. Int. J. Environ. Res. Public Health 2022, 19, 8752. [Google Scholar] [CrossRef]

- Ma, J.; McHugh, T.; Beckley, L.; Lahvis, M.; DeVaull, G.; Jiang, L. Vapor Intrusion Investigations and Decision-Making: A Critical Review. Environ. Sci. Technol. 2020, 54, 7050–7069. [Google Scholar] [CrossRef]

- Wang, L.; Gopalan, S.; Naidu, R. Advancements in Nanotechnological Approaches to Volatile Organic Compound Detection and Separation. Curr. Opin. Environ. Sci. Health 2024, 37, 100528. [Google Scholar] [CrossRef]

- Renganathan, B.; Gopakumar, C.K.; Priya, A.K.; Rao, S.K.; Sastikumar, D.; Silambarasan, M.; Kannapiran, N. Optimizing Gas Sensing Performance of CuO Nanoparticles via Sol-Gel Synthesis Approach for Efficient Detection of Ammonia Gas. Mater. Res. Bull. 2024, 170, 112556. [Google Scholar] [CrossRef]

- Liu, H.; Fang, C.; Zhao, J.; Zhou, Q.; Dong, Y.; Lin, L. The Detection of Acetone in Exhaled Breath Using Gas Pre-Concentrator by Modified Metal-Organic Framework Nanoparticles. Chem. Eng. J. 2024, 498, 155309. [Google Scholar] [CrossRef]

- Swargiary, K.; Jitpratak, P.; Pathak, A.K.; Viphavakit, C. Low-cost ZnO Spray-Coated Optical Fiber Sensor for Detecting VOC Biomarkers of Diabetes. Sensors 2023, 23, 7916. [Google Scholar] [CrossRef]

- Swargiary, K.; Metem, P.; Kulatumyotin, C.; Thaneerat, S.; Ajchareeyasoontorn, N.; Jitpratak, P.; Bora, T.; Mohammed, W.S.; Dutta, J.; Viphavakit, C. ZnO Nanorods Coated Single-Mode–Multimode–Single-Mode Optical Fiber Sensor for VOC Biomarker Detection. Sensors 2022, 22, 6273. [Google Scholar] [CrossRef] [PubMed]

- Prasanth, A.; Meher, S.; Alex, Z. Metal Oxide Thin Films Coated Evanescent Wave Based Fiber Optic VOC Sensor. Sens. Actuators A Phys. 2022, 338, 113459. [Google Scholar] [CrossRef]

- He, C.; Liu, L.; Korposh, S.; Correia, R.; Morgan, S.P. Volatile Organic Compound Vapour Measurements Using a Localised Surface Plasmon Resonance Optical Fibre Sensor Decorated with a Metal-Organic Framework. Sensors 2021, 21, 1420. [Google Scholar] [CrossRef]

- Swargiary, K.; Thaneerat, S.; Kongsawang, N.; Pathak, A.K.; Viphavakit, C. Highly Sensitive and Real-Time Detection of Acetone Biomarker for Diabetes Using a ZnO-Coated Optical Fiber Sensor. Biosens. Bioelectron. 2025, 271, 117061. [Google Scholar] [CrossRef] [PubMed]

- Bhise, G.D.; Karpe, S.B.; More, P.; Adhyapak, P.V. Optical Fibre Based Acetone Sensor Using Pd Modified WO3 Nanostructures. Opt. Laser Technol. 2022, 156, 108566. [Google Scholar] [CrossRef]

- Jaballah, S.; Benamara, M.; Dahman, H.; Ly, A.; Lahem, D.; Debliquy, M.; Mir, L.E. Effect of Mg-Doping ZnO Nanoparticles on Detection of Low Ethanol Concentrations. Mater. Chem. Phys. 2020, 255, 123643. [Google Scholar] [CrossRef]

- Chauhan, M.; Singh, V.K. Tapered MMF Sensor Fabrication Using SnO2-NPs for Alcohol Sensing Application. Opt. Fiber Technol. 2023, 75, 103167. [Google Scholar] [CrossRef]

- Tabassum, S.; Kumar, D.P.; Kumar, R. Copper Complex-Coated Nanopatterned Fiber-Tip Guided Mode Resonance Device for Selective Detection of Ethylene. IEEE Sens. J. 2021, 21, 17420–17429. [Google Scholar] [CrossRef]

- Yap, S.H.K.; Chan, K.K.; Yeh, C.-H.; Chien, Y.-H.; Yong, K.-T. Two-Dimensional MoS2 Nanosheet-Functionalized Optical Microfiber for Room-Temperature Volatile Organic Compound Detection. ACS Appl. Nano Mater. 2021, 4, 13440–13449. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.-n.; Liu, S.; Shi, B.; Wang, L.; Zhao, Y. Fiber Optic Room Temperature Ethanol Sensor Based on ZnSnO3/TiO2 with UV Radiation Sensitization. Sens. Actuators B Chem. 2024, 399, 134814. [Google Scholar] [CrossRef]

- Lopez, J.D.; Keley, M.; Dante, A.; Werneck, M.M. Optical Fiber Sensor Coated with Copper and Iron Oxide Nanoparticles for Hydrogen Sulfide Sensing. Opt. Fiber Technol. 2021, 67, 102731. [Google Scholar] [CrossRef]

- Prado, A.R.; Díaz, C.A.; Lyra Nunes, L.G.; Oliveira, J.P.; Guimarães, M.C.; Leal-Junior, A.; Ribeiro, M.R.; Pontes, M.J. Surface Plasmon Resonance-Based Optical Fiber Sensors for H2S in Situ Detection. Plasmonics 2021, 16, 787–797. [Google Scholar] [CrossRef]

- Chen, R.; Lan, G.; Wang, N.; Yan, W.; Yi, J.; Wei, W. Highly Sensitive Fiber-Optic SPR Sensor with Surface Coated TiO2/MWCNT Composite Film for Hydrogen Sulfide Gas Detection. J. Phys. D Appl. Phys. 2021, 55, 105108. [Google Scholar] [CrossRef]

- Lopez-Vargas, J.D.; Dante, A.; Allil, R.C.; Del Villar, I.; Matias, I.R.; Werneck, M.M. Ag@Fe3O4-Coated U-Shaped Plastic Optical Fiber Sensor for H2S Detection. Sens. Actuators B Chem. 2024, 401, 135054. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Y.; Li, C.; Yang, X. Copper-Multiwalled Carbon Nanotubes Decorated Fiber-Optic Surface Plasmon Resonance Sensor for Detection of Trace Hydrogen Sulfide Gas. Opt. Fiber Technol. 2023, 76, 103221. [Google Scholar] [CrossRef]

- Cai, Z.; Park, J.; Park, S. Room Temperature Selective Detection of NO2 Using Au-Decorated In2O3 Nanoparticles Embedded in Porous ZnO Nanofibers. J. Alloys Compd. 2023, 965, 171352. [Google Scholar] [CrossRef]

- Khomarloo, N.; Mohsenzadeh, E.; Bagherzadeh, R.; Latifi, M.; Debliquy, M.; Ly, A.; Lahem, D.; Gidik, H. Fabrication of Gas Sensors for Detecting NO and NO2 by Synthesizing rGO/ZnO Nanofibers. J. Text. Inst. 2025, 1–11. [Google Scholar] [CrossRef]

- Rahman, B.A.; Viphavakit, C.; Chitaree, R.; Ghosh, S.; Pathak, A.K.; Verma, S.; Sakda, N. Optical Fiber, Nanomaterial, and Thz-Metasurface-Mediated Nano-Biosensors: A Review. Biosensors 2022, 12, 42. [Google Scholar] [CrossRef]

- Eivazzadeh-Keihan, R.; Saadatidizaji, Z.; Mahdavi, M.; Maleki, A.; Irani, M.; Zare, I. Recent Advances in Gold Nanoparticles-Based Biosensors for Tuberculosis Determination. Talanta 2024, 275, 126099. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, S.; Liu, F.-Z.; Shuang, C.; Zhang, B.; Jha, R.; Kaushik, B.K. Etched Multicore Fiber Sensor Using Copper Oxide and Gold Nanoparticles Decorated Graphene Oxide Structure for Cancer Cells Detection. Biosens. Bioelectron. 2020, 168, 112557. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Y.; Lu, M.; Du, Y.; Chen, M.; Meng, S.; Ji, W.; Sun, C.; Peng, W. Near-Infrared Band Gold Nanoparticles-Au Film “Hot Spot” Model Based Label-Free Ultratrace Lead (II) Ions Detection Via Fiber SPR DNAzyme Biosensor. Sens. Actuators B Chem. 2021, 337, 129816. [Google Scholar] [CrossRef]

- Liu, F.; Singh, R.; Marques, C.; Zhang, B.; Kumar, S. Optical Fiber Biosensors with ZnO Nanowires and Nanoparticles of Fe3O4 and Au for Rapid Detection of Enrofloxacin Residues in Food. ACS Appl. Nano Mater. 2024, 7, 24417–24425. [Google Scholar] [CrossRef]

- Fu, Q.; Xie, Y.; Gao, F.; Singh, R.; Zhou, X.; Zhang, B.; Kumar, S. Four-Core Fiber-Based Multi-Tapered WaveFlex Biosensor for Rapid Detection of Vibrio Parahaemolyticus Using Nanoparticles-Enhanced Probes. Opt. Express 2024, 32, 25772–25788. [Google Scholar] [CrossRef]

- Borjikhani, P.; Granpayeh, N.; Zibaii, M.I. High Sensitivity Tapered Fiber Refractive Index Biosensor Using Hollow Gold Nanoparticles. Sci. Rep. 2025, 15, 1458. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, X.; Kumar, S.; Singh, R.; Zhang, B.; Bai, C.; Pu, X. Development of Glucose Sensor Using Gold Nanoparticles and Glucose-Oxidase Functionalized Tapered Fiber Structure. Plasmonics 2020, 15, 841–848. [Google Scholar] [CrossRef]

- Yang, Q.; Zhu, G.; Singh, L.; Wang, Y.; Singh, R.; Zhang, B.; Zhang, X.; Kumar, S. Highly Sensitive and Selective Sensor Probe Using Glucose Oxidase/Gold Nanoparticles/Graphene Oxide Functionalized Tapered Optical Fiber Structure for Detection of Glucose. Optik 2020, 208, 164536. [Google Scholar] [CrossRef]

- Xu, B.; Xiang, X.; Ding, L.; Luo, Z.; Zhao, J.; Huang, J.; Li, H.; Jiang, X. A Novel Large-Diameter Optical Fiber Glucose Biosensor Based on Glucose Oxidase–Graphene Oxide–Gold Nanoparticles. IEEE Sens. J. 2022, 23, 6832–6839. [Google Scholar] [CrossRef]

- Ujah, E.; Lai, M.; Slaughter, G. Ultrasensitive Tapered Optical Fiber Refractive Index Glucose Sensor. Sci. Rep. 2023, 13, 4495. [Google Scholar] [CrossRef]

- Li, G.; Xu, Q.; Singh, R.; Zhang, W.; Marques, C.; Xie, Y.; Zhang, B.; Kumar, S. Graphene Oxide/Multiwalled Carbon Nanotubes Assisted Serial Quadruple Tapered Structure-Based LSPR Sensor for Glucose Detection. IEEE Sens. J. 2022, 22, 16904–16911. [Google Scholar] [CrossRef]

- Wu, S.; Tan, Q.; Forsberg, E.; Hu, S.; He, S. In-Situ Dual-Channel Surface Plasmon Resonance Fiber Sensor for Temperature-Compensated Detection of Glucose Concentration. Opt. Express 2020, 28, 21046–21061. [Google Scholar] [CrossRef]

- Yu, H.; Chong, Y.; Zhang, P.; Ma, J.; Li, D. A D-Shaped Fiber SPR Sensor with a Composite Nanostructure of MoS2-Graphene for Glucose Detection. Talanta 2020, 219, 121324. [Google Scholar] [CrossRef]

- Zheng, W.; Han, B.; Siyu, E.; Sun, Y.; Li, X.; Cai, Y.; Zhang, Y.-n. Highly-Sensitive and Reflective Glucose Sensor Based on Optical Fiber Surface Plasmon Resonance. Microchem. J. 2020, 157, 105010. [Google Scholar] [CrossRef]

- Tam, T.V.; Hur, S.H.; Chung, J.S.; Choi, W.M. Novel Paper- and Fiber Optic-Based Fluorescent Sensor for Glucose Detection Using Aniline-Functionalized Graphene Quantum Dots. Sens. Actuators B Chem. 2021, 329, 129250. [Google Scholar] [CrossRef]

- Li, B.; Yan, X.; Zhang, X.; Wang, F.; Li, S.; Suzuki, T.; Ohishi, Y.; Cheng, T. No-Core Optical Fiber Sensor Based on Surface Plasmon Resonance for Glucose Solution Concentration and Temperature Measurement. Opt. Express 2021, 29, 12930–12940. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Huang, J.; Ding, L.; Cai, J. Graphene Oxide-Functionalized Long Period Fiber Grating for Ultrafast Label-Free Glucose Biosensor. Mater. Sci. Eng. C 2020, 107, 110329. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liang, T.; Wang, H.; Huang, Z.; Hu, Z.; Xie, K.; Zhang, W.; Wei, Y.; Wang, G.; Yan, J. Ultrasensitive Glucose Biosensor Using Micro-Nano Interface of Tilted Fiber Grating Coupled with Biofunctionalized Au Nanoparticles. IEEE Sens. J. 2022, 22, 4122–4134. [Google Scholar] [CrossRef]

- Xia, F.; Song, H.; Zhao, Y.; Zhao, W.-M.; Wang, Q.; Wang, X.-Z.; Wang, B.-T.; Dai, Z.-X. Ultra-High Sensitivity SPR Fiber Sensor Based on Multilayer Nanoparticle and Au Film Coupling Enhancement. Measurement 2020, 164, 108083. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, J.; Jiang, J.; Xu, T.; Wang, S.; Chang, P.; Zhang, Z.; Ma, J.; Liu, T. MoSe2-Au Based Sensitivity Enhanced Optical Fiber Surface Plasmon Resonance Biosensor for Detection of Goat-Anti-Rabbit IgG. IEEE Access 2019, 8, 660–668. [Google Scholar] [CrossRef]

- Tran Truc Phuong, N.; Anh, D.T.; Hoang Nhat Thao, N.; Kieu Thi Ta, H.; Tran, N.Q.M.; Ngoc Bach, T.; Thang Phan, B.; Tran, N.H.T. Application of Hybrid Au@Ag Nanostructures in Fiber Optic Biosensor for Rapid Detection of C-Reactive Protein. Opt. Mater. 2023, 143, 114184. [Google Scholar] [CrossRef]

- Lee, S.-L.; Kim, J.; Choi, S.; Han, J.; Seo, G.; Lee, Y.W. Fiber-Optic Label-Free Biosensor for SARS-CoV-2 Spike Protein Detection Using Biofunctionalized Long-Period Fiber Grating. Talanta 2021, 235, 122801. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Singh, R.; Chaudhary, S.; Zhang, B.; Kumar, S. 2-D Nanomaterials Assisted LSPR MPM Optical Fiber Sensor Probe for Cardiac Troponin I Detection. IEEE Trans. Instrum. Meas. 2022, 71, 1–9. [Google Scholar] [CrossRef]

- Divagar, M.; Gayathri, R.; Rasool, R.; Shamlee, J.K.; Bhatia, H.; Satija, J.; Sai, V. Plasmonic Fiberoptic Absorbance Biosensor (P-FAB) for Rapid Detection of SARS-CoV-2 Nucleocapsid Protein. IEEE Sens. J. 2021, 21, 22758–22766. [Google Scholar] [CrossRef]

- Bekmurzayeva, A.; Ashikbayeva, Z.; Myrkhiyeva, Z.; Nugmanova, A.; Shaimerdenova, M.; Ayupova, T.; Tosi, D. Label-Free Fiber-Optic Spherical Tip Biosensor to Enable Picomolar-Level Detection of CD44 Protein. Sci. Rep. 2021, 11, 19583. [Google Scholar]

- Chiavaioli, F.; Santano Rivero, D.; Del Villar, I.; Socorro-Leránoz, A.B.; Zhang, X.; Li, K.; Santamaría, E.; Fernández-Irigoyen, J.; Baldini, F.; Van den Hove, D.L. Ultrahigh Sensitive Detection of Tau Protein as Alzheimer’s Biomarker via Microfluidics and Nanofunctionalized Optical Fiber Sensors. Adv. Photonics Res. 2022, 3, 2200044. [Google Scholar] [CrossRef]

- Singh, L.; Singh, R.; Kumar, S.; Zhang, B.; Kaushik, B.K. Development of Collagen-IV Sensor Using Optical Fiber-Based Mach-Zehnder Interferometer Structure. IEEE J. Quantum Electron. 2020, 56, 7700208. [Google Scholar] [CrossRef]

- Song, H.; Wang, Q.; Zhao, W.-M. A novel SPR Sensor Sensitivity-Enhancing Method for Immunoassay by Inserting MoS2 Nanosheets between Metal Film and Fiber. Opt. Lasers Eng. 2020, 132, 106135. [Google Scholar] [CrossRef]

- Cennamo, N.; Pasquardini, L.; Arcadio, F.; Lunelli, L.; Vanzetti, L.; Carafa, V.; Altucci, L.; Zeni, L. SARS-CoV-2 Spike Protein Detection through a Plasmonic D-Shaped Plastic Optical Fiber Aptasensor. Talanta 2021, 233, 122532. [Google Scholar] [CrossRef] [PubMed]

- Cao, G.; Chang, P.; Zhang, A.; Liu, F.; Pan, H.; Wang, J.; Lin, S.; Yang, T. A Polydopamine Nanospheres Modified Fiber Optic SPR Biosensor for Specific Detection of C-Reactive Protein. Opt. Fiber Technol. 2023, 80, 103468. [Google Scholar] [CrossRef]

- Costa-Fernandez, J.M. Optical Sensors Based on Luminescent Quantum Dots. Anal. Bioanal. Chem. 2006, 384, 37–40. [Google Scholar] [CrossRef]

- Goicoechea, J.; Arregui, F.J.; Matias, I.R. Quantum Dots for Sensing. In Sensors Based on Nanostructured Materials; Springer: New York, NY, USA, 2009; pp. 131–181. [Google Scholar]

- Lang, X.; Singh, R.; Zeng, Q.; Li, J.; Tosi, D.; Nedoma, J.; Marques, C.; Zhang, B.; Kumar, S. Chitosan-Coated Iron (III) Oxide Nanoparticles and Tungsten Disulfide Quantum Dots-Immobilized Fiber-Based Waveflex Biosensor for Staphylococcus Aureus Bacterial Detection in Real Food Samples. Sens. Actuators Rep. 2024, 8, 100239. [Google Scholar] [CrossRef]

- Azargoshasb, T.; Navid, H.A.; Yadollahzadeh, S.; Aghbolaghi, R.; Parvizi, R.; Parsanasab, G.M. Carbon Quantum Dot Embedding Silica–Molecularly Imprinted Polymer Coated Optical Fiber as Ratiometric Biosensors Toward Dopamine Detection. IEEE Sens. J. 2024, 24, 4510–4522. [Google Scholar] [CrossRef]

- Ameta, R.K. Green Synthesis of Metal Based Nanomaterials and Their Sensing Application. In Comprehensive Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2024; Volume 105, pp. 251–274. [Google Scholar]

- Youssef, F.S.; Ismail, S.H.; Fouad, O.A.; Mohamed, G.G. Green Synthesis and Biomedical Applications of Zinc Oxide Nanoparticles. Review. Egypt. J. Vet. Sci. 2024, 55, 287–311. [Google Scholar] [CrossRef]

- Alanazi, M.M. Utilizing Cinnamomum Verum Extract for Green Synthesis of Silver Nanoparticles: Exploring Optical Properties, Morphology, and Potential Applications. J. King Saud. Univ. Sci. 2024, 36, 103312. [Google Scholar] [CrossRef]

- Ashikbayeva, Z.; Bekmurzayeva, A.; Myrkhiyeva, Z.; Assylbekova, N.; Atabaev, T.S.; Tosi, D. Green-Synthesized Gold Nanoparticle-Based Optical Fiber Ball Resonator Biosensor for Cancer Biomarker Detection. Opt. Laser Technol. 2023, 161, 109136. [Google Scholar] [CrossRef]

- Gangal, A.; Choudhary, K.; Duseja, M.; Shukla, R.K.; Kumar, S. Green Synthesis of Silver Nanoparticles from Plant Oil for Enzyme-Functionalized Optical Fiber Biosensor: Improved Sensitivity and Selectivity in Ascorbic Acid Detection. Opt. Laser Technol. 2025, 186, 112635. [Google Scholar] [CrossRef]

| Target Gas | Nanomaterial Coating | Deposition Method | Sensitivity | Response Time | Recovery Time | Reference |

|---|---|---|---|---|---|---|

| Ammonia, ethanol, and methanol vapors | Copper(II) Oxide (CuO) | Dip Coating | 26 counts/ppm (Ammonia) | 59 s (Ammonia) | 53 s (Ammonia) | [201] |

| Acetone | MIL-101 (Chromium) | PVD | --- | --- | ---- | [202] |

| Acetone, isopropyl alcohol (IPA) and ethanol | ZnO | Spray Coating | Acetone: 0.16 nm/% IPA: 0.08 nm/% Ethanol: 0.07 nm/% | Acetone: 10 min IPA: 9 min Ethanol: 8 min | --- | [203] |

| IPA | ZnO | Hydrothermal | 0.053 nm/%IPA vapor | 9 min | --- | [204] |

| Acetone, acetophenone, IPA, and ethanol | ZnO/AZO/ tin dioxide (SnO2) | PVD | --- | 17 s (SnO2 thin-film sensor monitors 250 ppm IPA) | 21 s (SnO2 thin-film sensor monitors 250 ppm IPA) | [205] |

| Acetone, ethanol, and methanol | Au | LbL | Acetone: 13.7 nm/% Ethanol: 15.5 nm/% Methanol: 6.7 nm/% | Acetone: 9.3 5 min Ethanol: 5.35 min Methanol: 2.39 min | Acetone: 3.85 min Ethanol: 2.12 min Methanol: 1.44 min | [206] |

| Acetone, methanol, ethanol, isopropanol, toluene, xylene | ZnO | Spray Coating | 0.116 nm/ppm (Acetone) | 26 s (Acetone) | 32 s (Acetone) | [207] |

| Ammonia, benzene, acetone, nitrogen oxides, ethanol, methanol, triethylamine, trimethylamine, toluene, formaldehyde | Palladium (Pd)-loaded tungsten trioxide (WO3) | Dip Coating | 80 normalized response/ppm (Acetone) | --- | --- | [208] |

| Ethanol | Magnesium (Mg)-doping ZnO | Spray Coating | --- | --- | --- | [209] |

| Isopropanol | SnO2 | Dip Coating | 22 counts/ppm | --- | --- | [210] |

| Ethylene | Copper (Cu) Complex-1 | CDSA | 60 pm/ppm | --- | --- | [211] |

| Acetone, ethyl acetate, cyclohexane, isopropanol | Molybdenum disulfide (MoS2) | Optical Tweezer Effect | Acetone: 0.0195 nm/ppm Ethyl acetate: 0.0143 nm/ppm Cyclohexane: 0.0072 nm/ppm Isopropanol: 0.0058 nm/ppm | 15 min | 5 min | [212] |

| Ethanol | TiO2 | Dip Coating | 3.85 pm/ppm | 20 s | 60 s | [213] |

| Nanocoating Materials | Deposition Method | Measurement Range | Sensitivity/Limit of Detection (LOD) | References |

|---|---|---|---|---|

| Au | CDSA | 0–10 mM | 0.9261 nm/mM | [228] |

| GO, Au | CDSA | 0–11 mM | 1.06 nm/mM | [229] |

| GO, Au | CDSA | 0–1 mL | 11.134 nm/(mg/mL) | [230] |

| Au | CDSA | 1.328–1.393 | 2032%/RIU | [231] |

| GO, multi-wall carbon nanotubes, Au | CDSA | 0–10 mM | 1.04 nm/mM | [232] |

| Ag, ZnO | PVD | 0.5 mM | 6.156 nm/mM | [233] |

| MoS2, graphene | CVD | 0–300 mg/dL | 6126.25 nm/RIU | [234] |

| Au | PVD | 0–0.5 mg/mL | 85.4nm/(mg/mL) | [235] |

| Aniline functionalized graphene QDs | --- | 0.05–20 mM | 2.1 μM | [236] |

| Ag | PVD | 5–25% | 2.882 nm/% | [237] |

| GO | Dip Coating | 0–4 mg/mL | 0.77 nm/(mg/mL) | [238] |

| Au | CDSA | 1nM-1mM | 2.5nM | [239] |

| Target Analyte | Nanocoating Material | Deposition Method | Measurement Range | LOD | Reference |

|---|---|---|---|---|---|

| Ig-G protein | Au | PVD | 0–16 μg/mL | 4.6 ng/mL | [240] |

| Ig-G protein | MoS2-Au | self-assemble | 0–1 mg/mL | 0.33 μg/mL | [241] |

| C-reactive protein | Ag-Au | CSDA | 0–2.5 mg/L | 2.4 × 10−5 mg/L | [242] |

| SARS-CoV-2 spike protein | Au | CSDA | 1 pg/mL–100 μg/mL | --- | [243] |

| Cardiac troponin I protein | GO-Au | CSDA | 0–1000 ng/mL | 96.2638 ng/mL | [244] |

| SARS-CoV-2 nucleocapsid protein | Au | CSDA | 0.1 ng/mL–100 ng/mL | 2.5 ng/mL | [245] |

| CD44 protein | Au | PVD | 0 Nm–100 nM | 17 pM | [246] |

| Tau protein | SnO2−x | PVD | 10−3–10 μg/mL | 1 pM | [247] |

| Collagen-IV | Au-ZnO | CSDA | 0–40 μg/mL | 1.6 μg/mL | [248] |

| Ig-G protein | MoS2 | electrostatic self-assembly | 0–22 μg/mL | 19.7 ng/mL | [249] |

| SARS-CoV-2 spike protein | Au | PVD | 25–1000 nM | 37 nM | [250] |

| C-reactive protein | Au, Cr, polydopamine | PVD, solution-based self-assembly | 0–78.6 μg/mL | 0.22 μg/mL | [251] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, W.; Chen, Y.; Liu, S.; Luo, L. Advances and Prospects of Nanomaterial Coatings in Optical Fiber Sensors. Coatings 2025, 15, 1008. https://doi.org/10.3390/coatings15091008

Qu W, Chen Y, Liu S, Luo L. Advances and Prospects of Nanomaterial Coatings in Optical Fiber Sensors. Coatings. 2025; 15(9):1008. https://doi.org/10.3390/coatings15091008

Chicago/Turabian StyleQu, Wenwen, Yanxia Chen, Shuangqiang Liu, and Le Luo. 2025. "Advances and Prospects of Nanomaterial Coatings in Optical Fiber Sensors" Coatings 15, no. 9: 1008. https://doi.org/10.3390/coatings15091008

APA StyleQu, W., Chen, Y., Liu, S., & Luo, L. (2025). Advances and Prospects of Nanomaterial Coatings in Optical Fiber Sensors. Coatings, 15(9), 1008. https://doi.org/10.3390/coatings15091008