Effects of Oxygen Gas Flow During Deposition on the Thermal Shock Life of YSZ Thermal Barrier Coatings Prepared by Electron Beam Physical Vapor Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Coatings

2.2. Thermal Shock Test 0

2.3. Characterization

3. Results and Discussion

3.1. Confirmation of Deposition Parameters

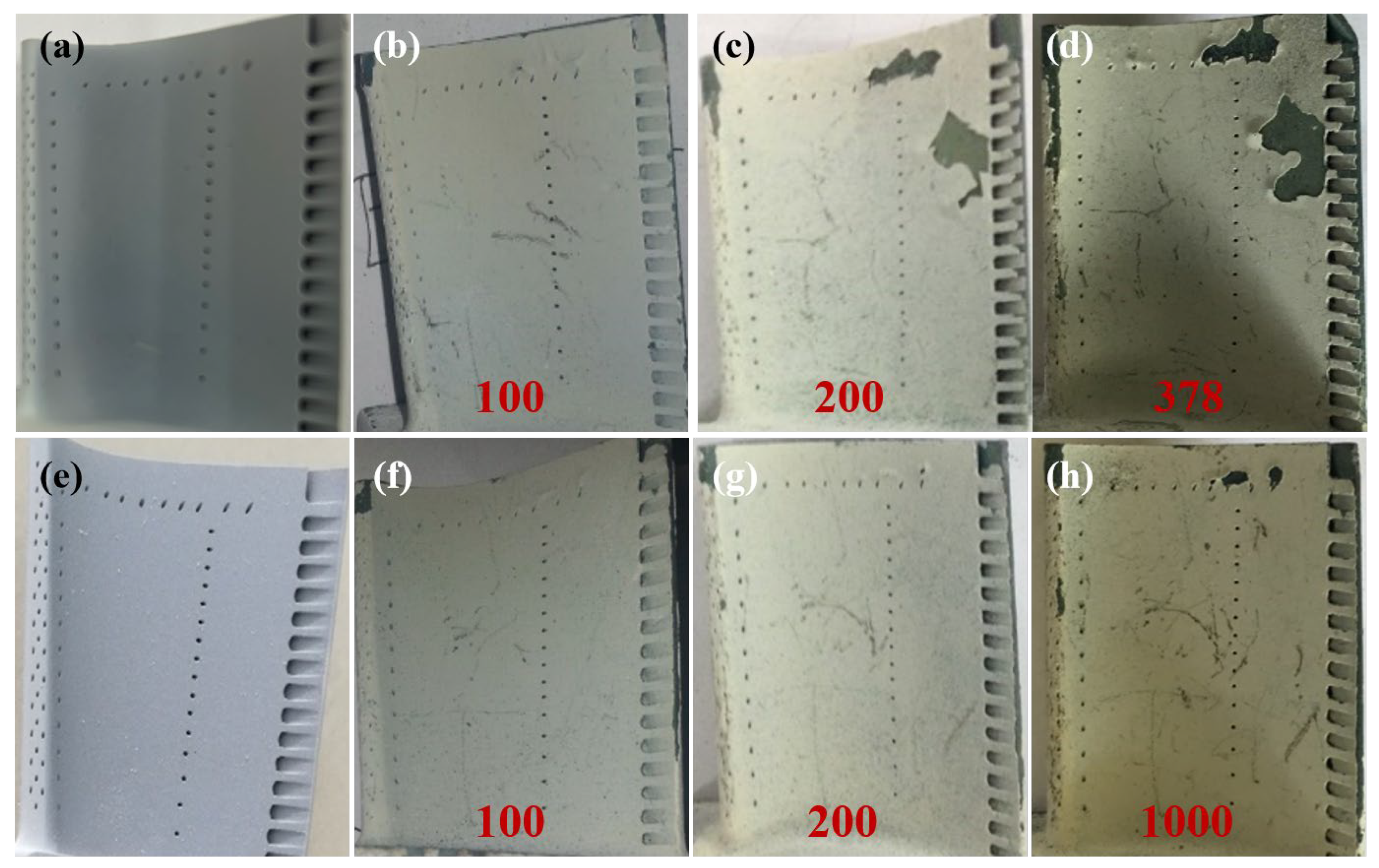

3.2. Thermal Shock Life

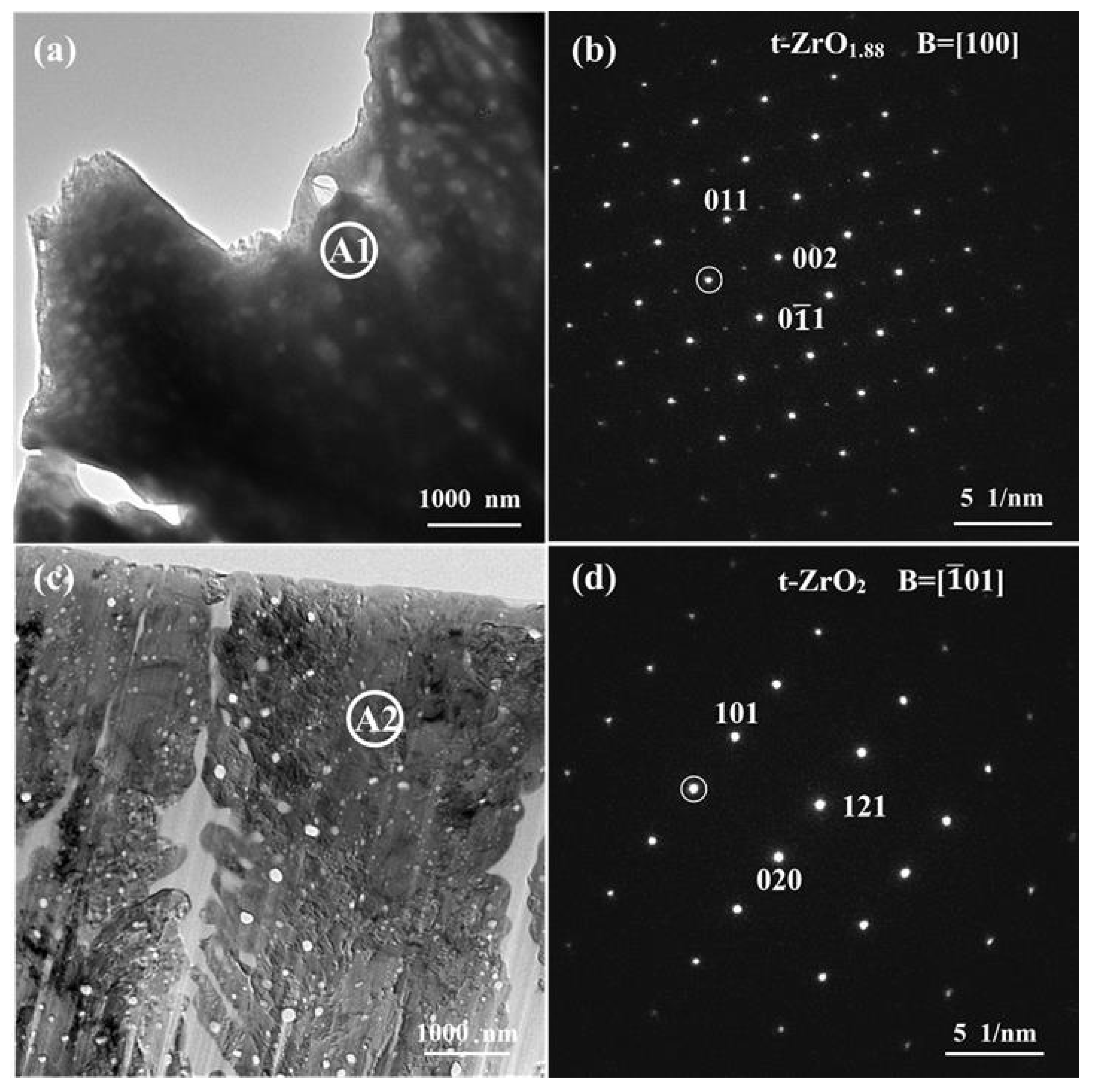

3.3. Crystallographic Texture Evolution

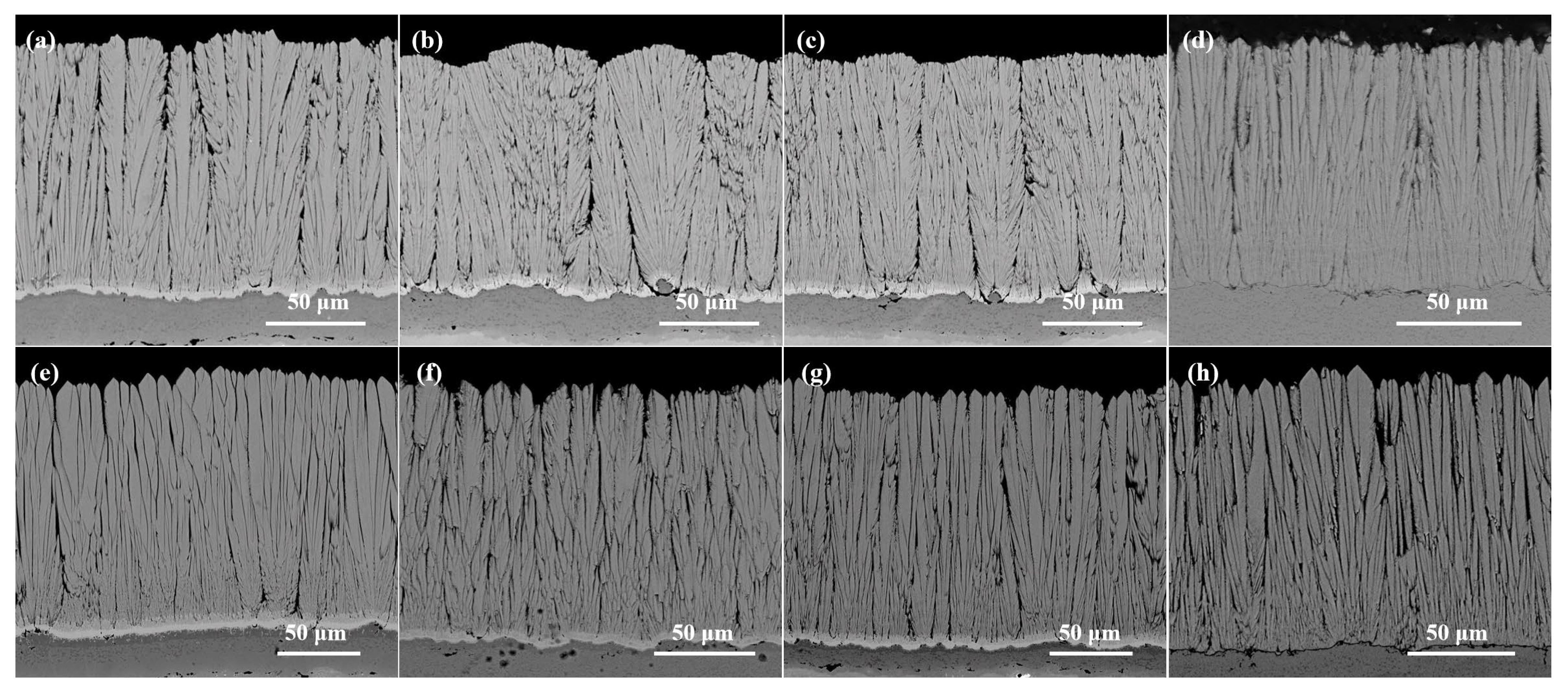

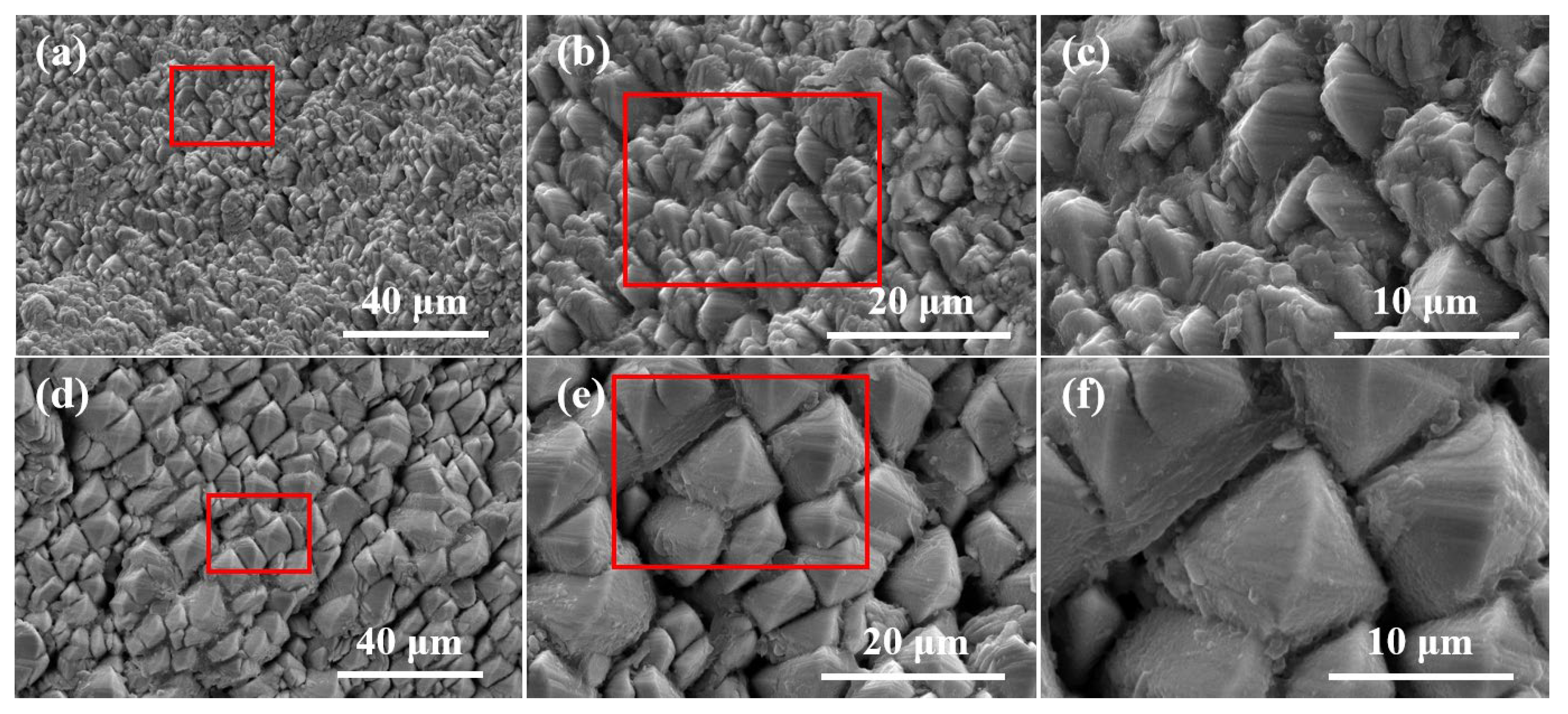

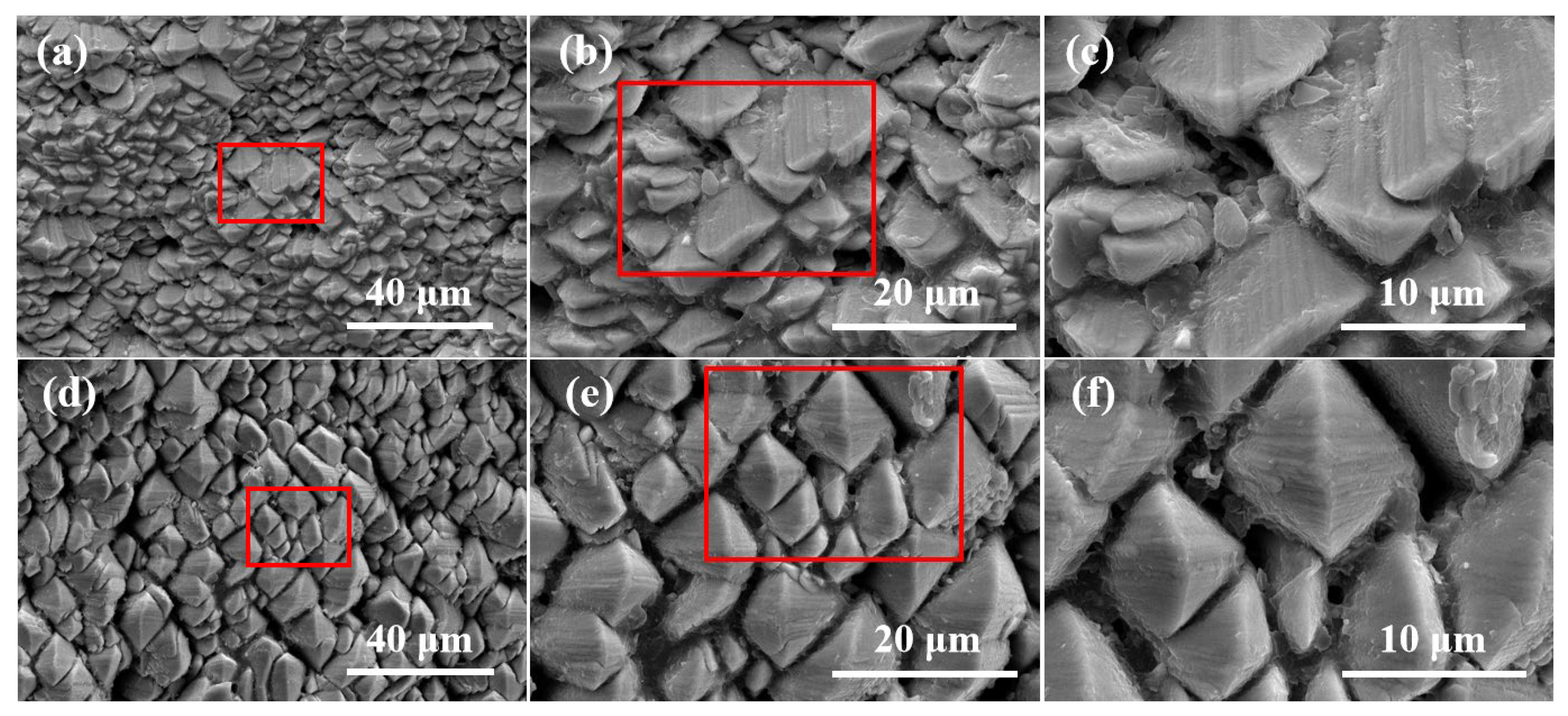

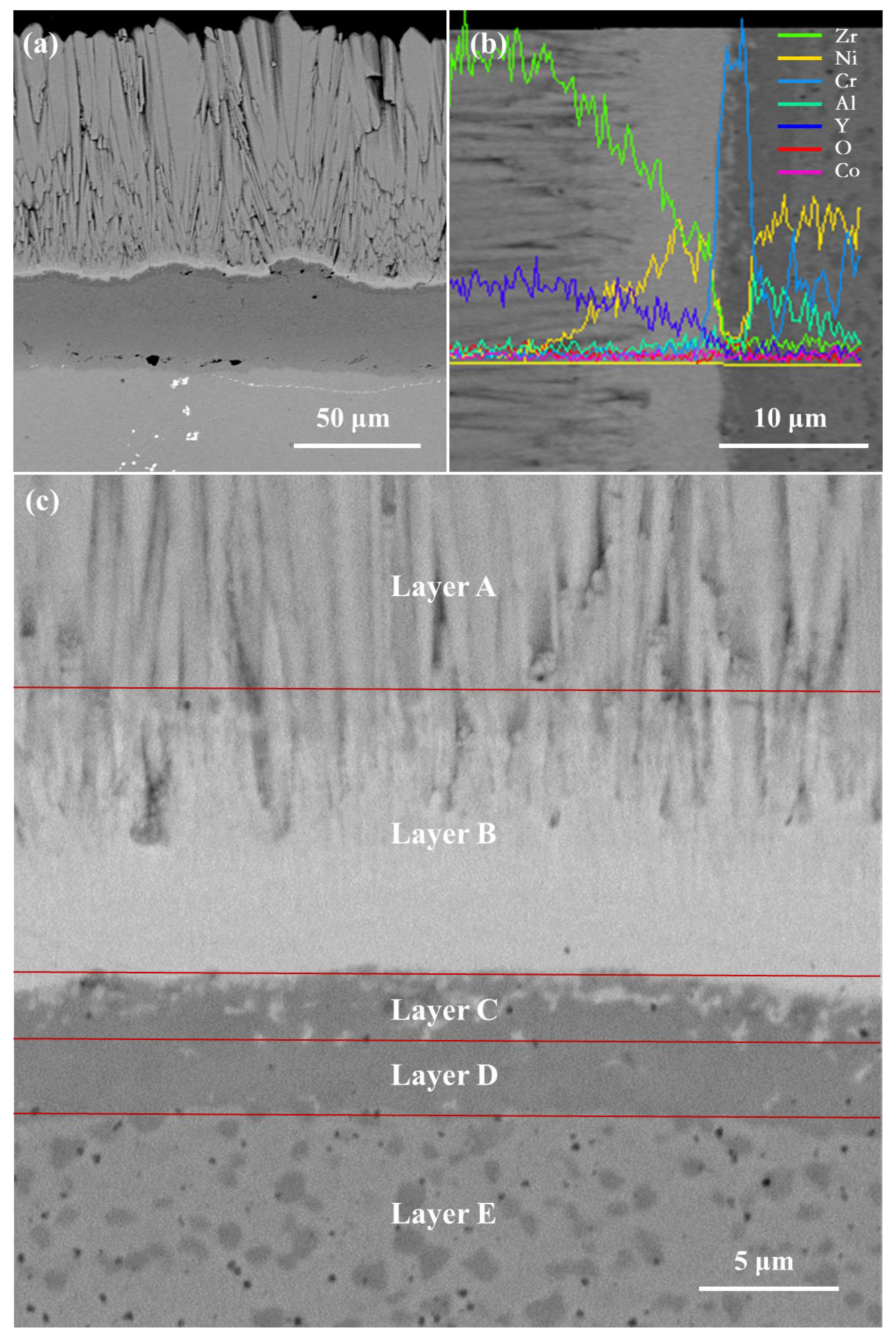

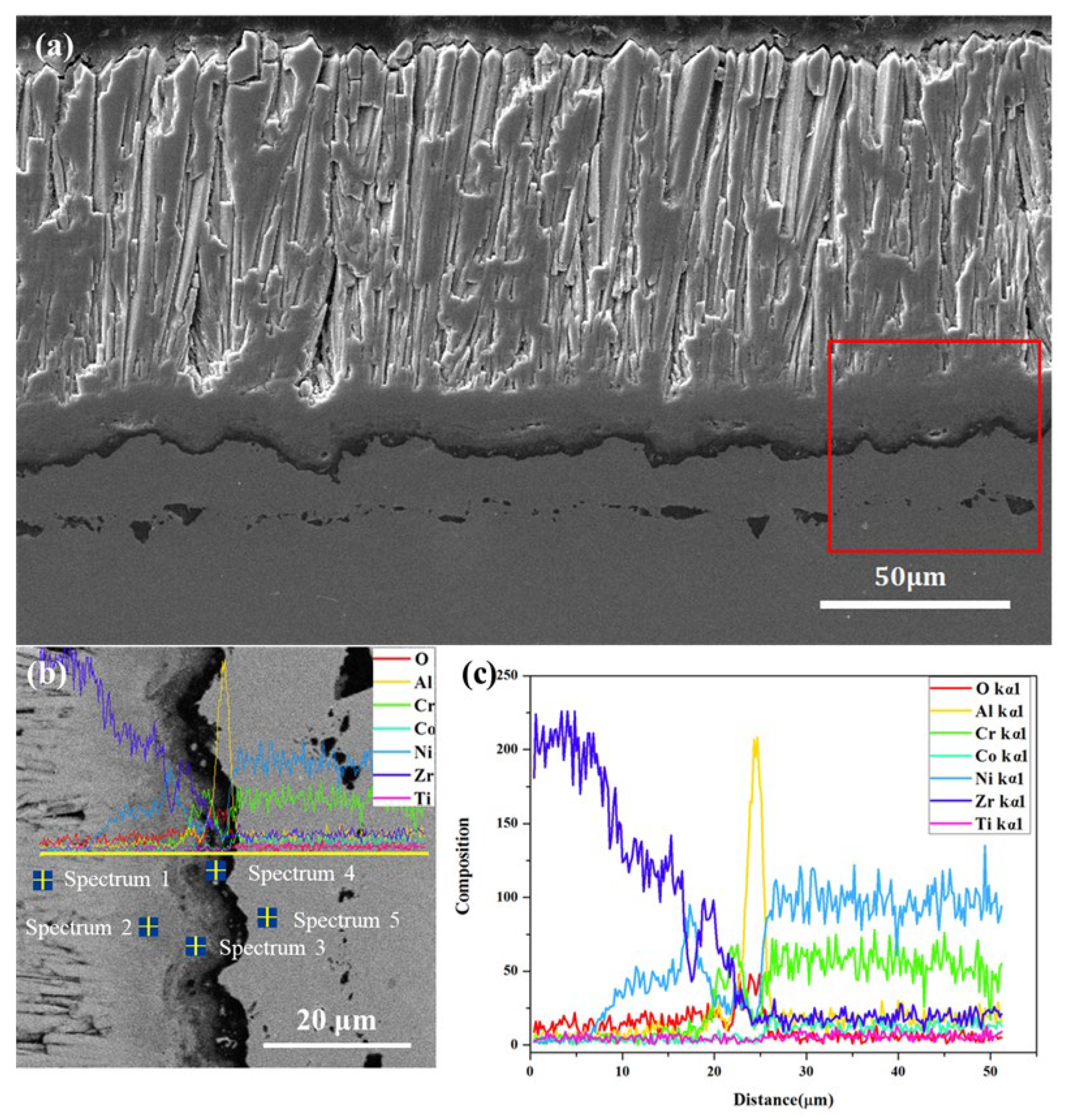

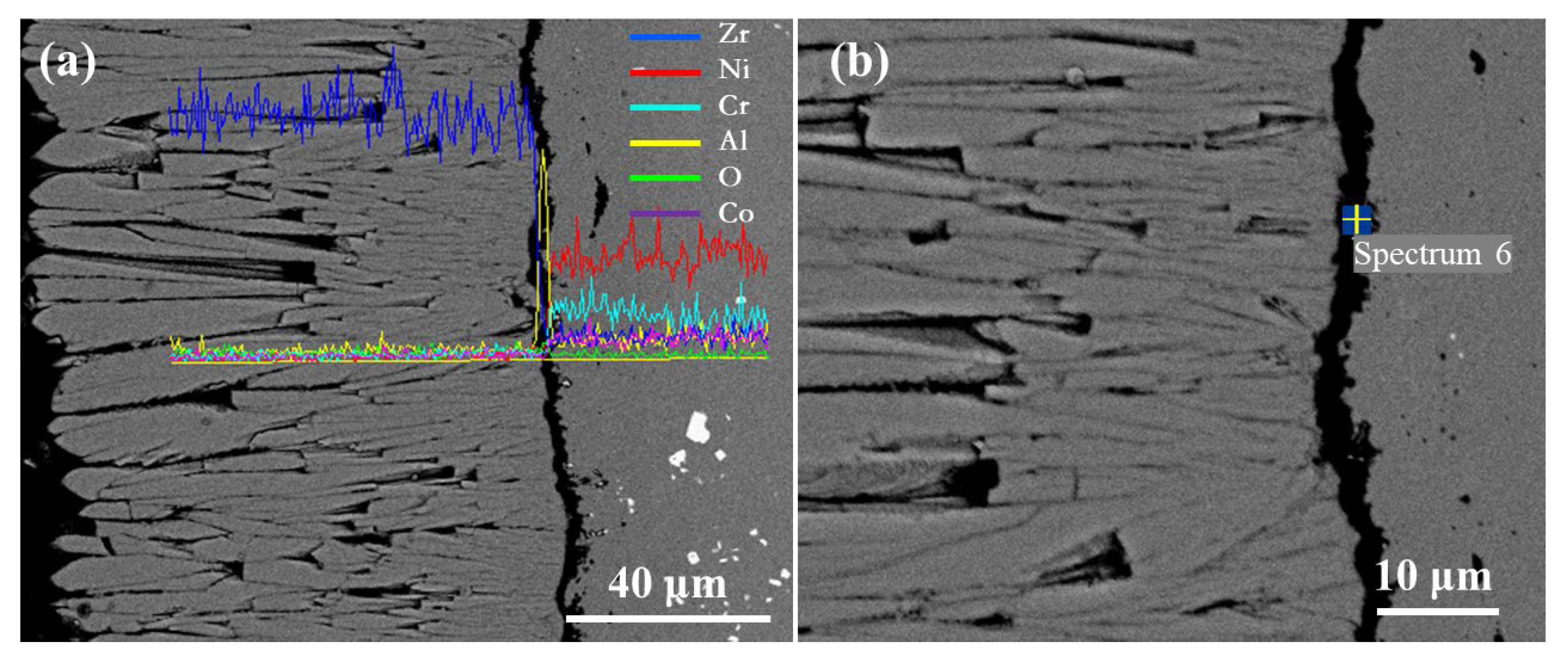

3.4. Microstructure Analysis of Surfaces and Cross-Sections

3.5. Influence of Oxygen Gas Flow

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Perepezko, J.H. The hotter the engine, the better. Science 2009, 326, 1068–1069. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Y.; Zhu, C.; Xiang, H.; Chen, H.; Sun, L.; Gao, Y.; Zhou, Y. Advances on strategies for searching for next generation thermal barrier coating materials. J. Mater. Sci. Technol. 2019, 35, 833–851. [Google Scholar] [CrossRef]

- Thakare, J.G.; Pandey, C.; Mahapatra, M.M.; Mulik, R.S. Thermal barrier coatings-a state of the art review. Met. Mater. Int. 2021, 27, 1947–1968. [Google Scholar] [CrossRef]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and economical aspects of current thermal barrier coating systems for gas turbine engines by thermal spray and EBPVD: A review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Mauer, G.; Vaßen, R. Coatings with columnar microstructures for thermal barrier applications. Adv. Eng. Mater. 2020, 22, 1900988. [Google Scholar] [CrossRef]

- Schulz, U.; Fritscher, K.; Leyens, C.; Peters, M. Influence of processing on microstructure and performance of electron beam physical vapor deposition (EB-PVD) thermal barrier coatings. J. Eng. Gas Turbines Power. 2002, 124, 229–234. [Google Scholar] [CrossRef]

- Movchan, B.A.; Demchishin, A.V. Study of structured properties of thick vacuum condensates of Nickel, Titanium, Tungsten, Aluminum oxide and zirconium dioxide. Fized Metall. Met. 1969, 28, 83–90. [Google Scholar]

- Messier, R.; Giri, A.P.; Roy, R.A. Revised structure zone model for thin film physical structure. J. Vac. Sci. Technol. A Vac. Surf. Film. 1984, 2, 500–503. [Google Scholar] [CrossRef]

- Thornton, J.A. High rate thick film growth. Annu. Rev. Mater. Sci. 1977, 7, 239–260. [Google Scholar] [CrossRef]

- Wada, K.; Yamaguchi, N.; Matsubara, H. Crystallographic texture evolution in ZrO2–Y2O3 layers produced by electron beam physical vapor deposition. Surf. Coat. Technol. 2004, 184, 55–62. [Google Scholar] [CrossRef]

- Yamaguchi, N.; Wada, K.; Kimura, K.; Matsubara, H. Microstructure Modification of Yttria-Stabilized Zirconia Layers Prepared by EB-PVD. J. Ceram. Soc. Jpn. 2003, 111, 883–889. [Google Scholar] [CrossRef][Green Version]

- Das, D.K.; Lakshmi, S.G.; Rao, D.S.; Banumathy, S.; Singh, A.K. Microstructure, texture and thermal cycling performance of EB-PVD TBCs deposited under different processing conditions. High Temp. Mater. Process. 2011, 30, 539–548. [Google Scholar] [CrossRef]

- Teng, X.; Peng, H.; Li, L.; Guo, H. Investigation on crystal orientations in EB-PVD YSZ coatings under different substrate rotation mode. J. Eur. Ceram. Soc. 2023, 43, 5373–5380. [Google Scholar] [CrossRef]

- Matsumoto, M.; Wada, K.; Yamaguchi, N.; Kato, T.; Matsubara, H. Effects of substrate rotation speed during deposition on the thermal cycle life of thermal barrier coatings fabricated by electron beam physical vapor deposition. Surf. Coat. Technol. 2008, 202, 3507–3512. [Google Scholar] [CrossRef]

- Rao, D.S.; Valleti, K.; Joshi, S.V.; Janardhan, G.R. Processing-structure-property relationships in electron beam physical vapor deposited yttria stabilized zirconia coatings. J. Vac. Sci. Technol. A 2011, 29, 031501. [Google Scholar] [CrossRef]

- Guo, F.; Zhou, R.; Shang, Y.; Zhang, H.; Pei, Y.; Li, S.; Gong, S. Development of deposition beam current dependent microstructure and nanomechanical properties in ZrO2-8wt% Y2O3 thermal barrier coatings produced by electron beam-physical vapor deposition technique. Mater. Chem. Phys. 2021, 272, 124998. [Google Scholar] [CrossRef]

- Rösemann, N.; Ortner, K.; Petersen, J.; Schadow, T.; Bäker, M.; Bräuer, G.; Rösler, J. Influence of bias voltage and oxygen flow rate on morphology and crystallographic properties of gas flow sputtered zirconia coatings. Surf. Coat. Technol. 2015, 276, 668–676. [Google Scholar] [CrossRef]

- Wada, K.; Yoshiya, M.; Yamaguchi, N.; Matsubara, H. Texture and microstructure of ZrO2-4mol% Y2O3 layers obliquely deposited by EB-PVD. Surf. Coat. Technol. 2006, 200, 2725–2730. [Google Scholar] [CrossRef]

- Wolfe, D.E.; Singh, J.; Miller, R.A.; Eldridge, J.I.; Zhu, D.M. Tailored microstructure of EB-PVD 8YSZ thermal barrier coatings with low thermal conductivity and high thermal reflectivity for turbine applications. Surf. Coat. Technol. 2005, 190, 132–149. [Google Scholar] [CrossRef]

- Schulz, U.; Fritscher, K.; Leyens, C.; Peters, M.; Kaysser, W.A. Thermocyclic Behavior of Differently Stabilized and structured EB-PVD thermal barrier coatings. Mater. Werkst. 1997, 28, 370–376. [Google Scholar] [CrossRef]

- Wen, M.; Jordan, E.H.; Gell, M. Effect of temperature on rumpling and thermally grown oxide stress in an EB-PVD thermal barrier coating. Surf. Coat. Technol. 2006, 201, 3289–3298. [Google Scholar] [CrossRef]

- Xiao, Q.; He, H.; Shao, S.; Shao, J.; Fan, Z. Influences of deposition rate and oxygen partial pressure on residual stress and microstructure of YSZ thin films. Thin Solid Film. 2009, 517, 4295–4298. [Google Scholar] [CrossRef]

- Schulz, U.; Miinzer, J.; Kaclen, U. Influence of Deposition Conditions on Density and Microstructure of EB–PVD TBCs. In 26th Annual Conference on Composites, Advanced Ceramics, Materials, and Structures: B: Ceramic Engineering and Science Proceedings; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2002; pp. 353–360. [Google Scholar]

| EB Power (kW) | Pressure (Torr) | Substrate Temperature (°C) | Rotation (rpm) | Oxygen Flow Rate (sccm) |

|---|---|---|---|---|

| 10 | 10−5 | 930 | 10 | 0 (BS1)//60 (BS2) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, K.; Xu, C.; Huang, Z.; Xia, J.; Zhang, L.; Zhang, X.; Li, T. Effects of Oxygen Gas Flow During Deposition on the Thermal Shock Life of YSZ Thermal Barrier Coatings Prepared by Electron Beam Physical Vapor Deposition. Coatings 2025, 15, 928. https://doi.org/10.3390/coatings15080928

Huo K, Xu C, Huang Z, Xia J, Zhang L, Zhang X, Li T. Effects of Oxygen Gas Flow During Deposition on the Thermal Shock Life of YSZ Thermal Barrier Coatings Prepared by Electron Beam Physical Vapor Deposition. Coatings. 2025; 15(8):928. https://doi.org/10.3390/coatings15080928

Chicago/Turabian StyleHuo, Keli, Chunhui Xu, Zhenwu Huang, Jie Xia, Ling Zhang, Xiaoshan Zhang, and Tiansheng Li. 2025. "Effects of Oxygen Gas Flow During Deposition on the Thermal Shock Life of YSZ Thermal Barrier Coatings Prepared by Electron Beam Physical Vapor Deposition" Coatings 15, no. 8: 928. https://doi.org/10.3390/coatings15080928

APA StyleHuo, K., Xu, C., Huang, Z., Xia, J., Zhang, L., Zhang, X., & Li, T. (2025). Effects of Oxygen Gas Flow During Deposition on the Thermal Shock Life of YSZ Thermal Barrier Coatings Prepared by Electron Beam Physical Vapor Deposition. Coatings, 15(8), 928. https://doi.org/10.3390/coatings15080928