The Influence of Direct Aging on TiB2/Al–Si–Mg Composites Fabricated by LPBF: Residual Stress, Mechanical Properties and Microstructure

Abstract

1. Introduction

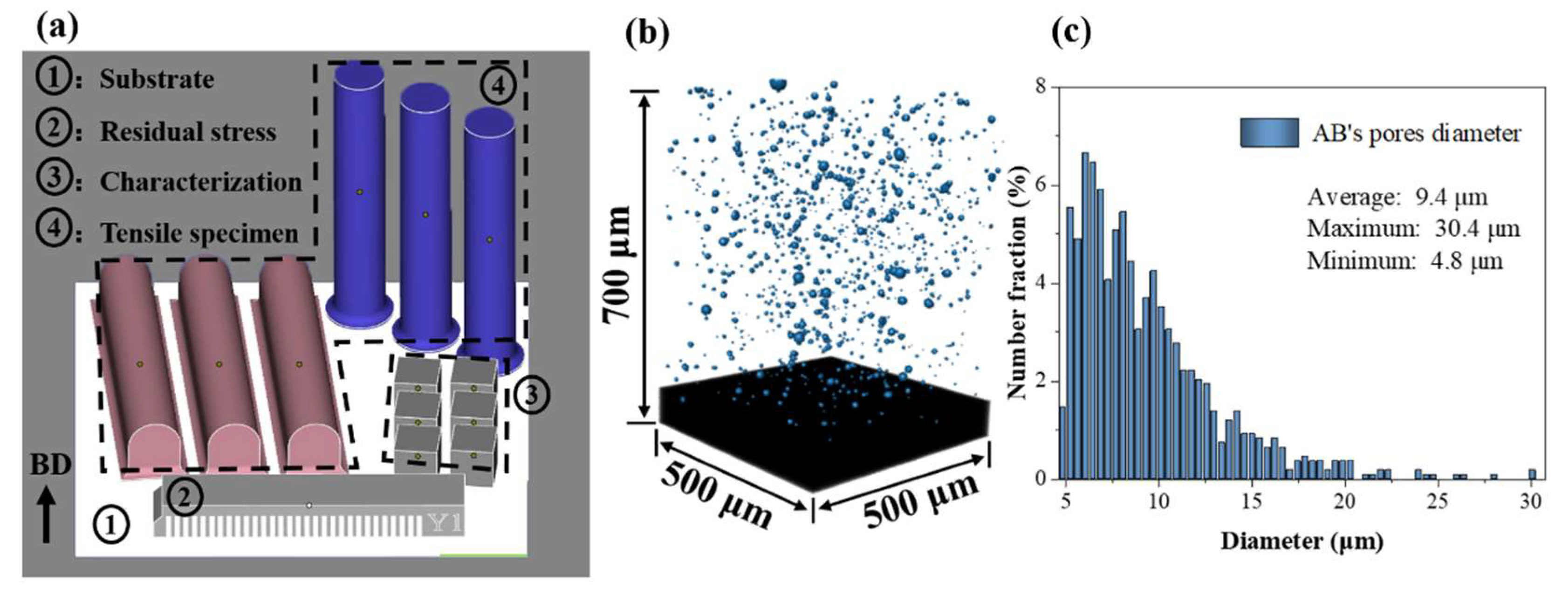

2. Materials and Methods

2.1. Materials Fabrication and Heat Treatment

2.2. Microstructure Characterization

2.3. Mechanical Tests

3. Results and Discussion

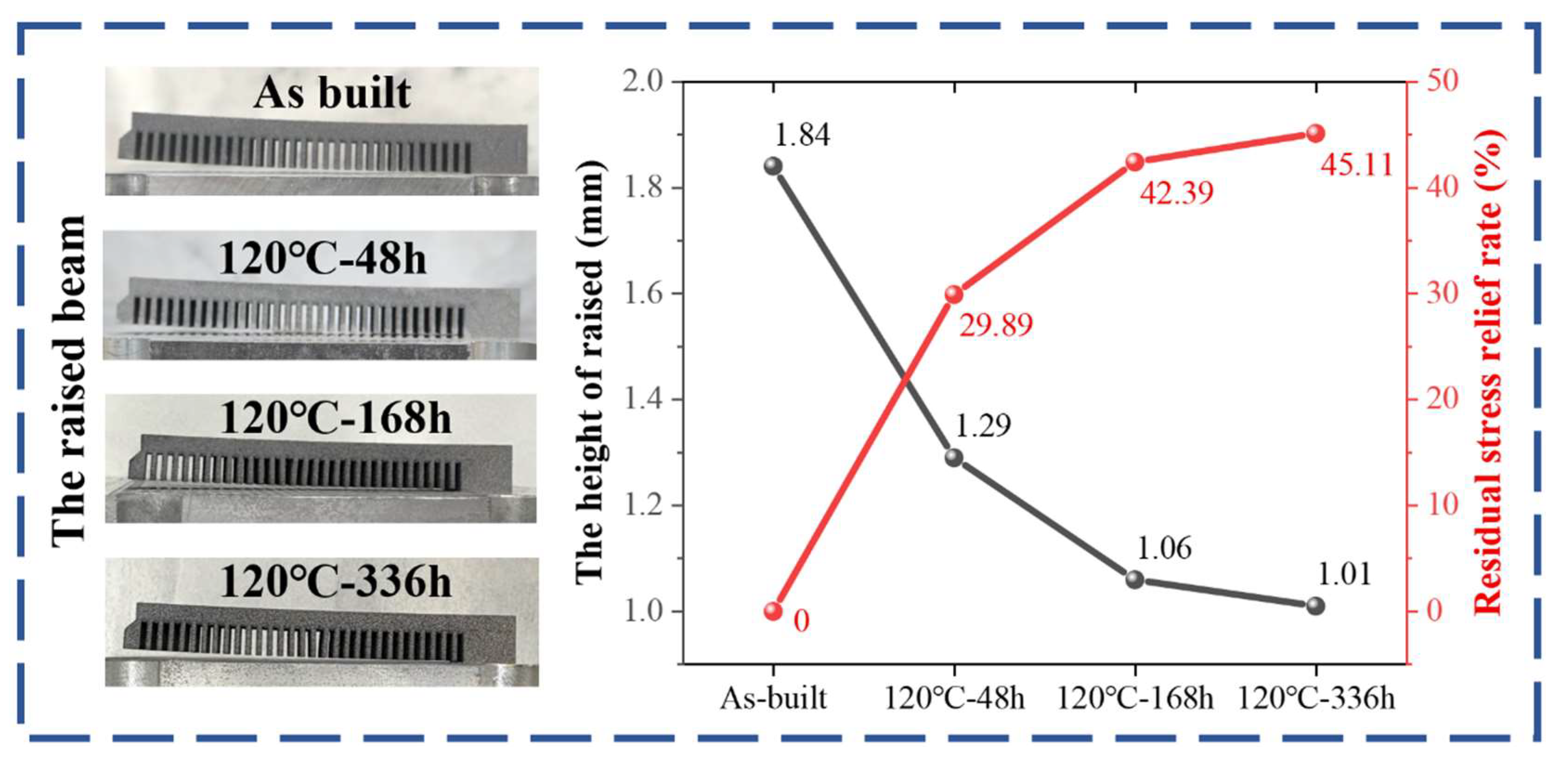

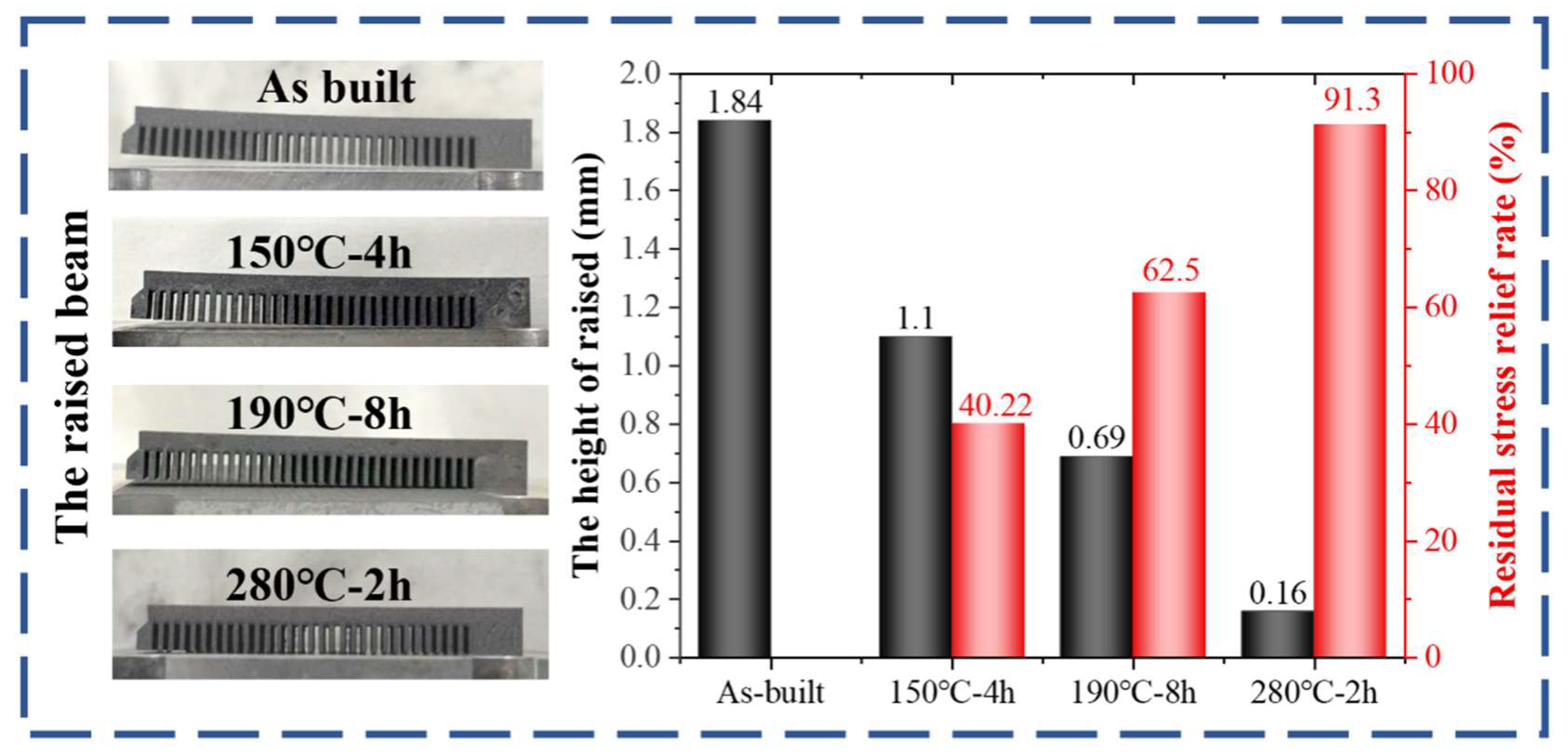

3.1. Effects of Direct Aging on Hardness and Residual Stresses

3.2. Effects of Direct Aging on Mechanical Properties

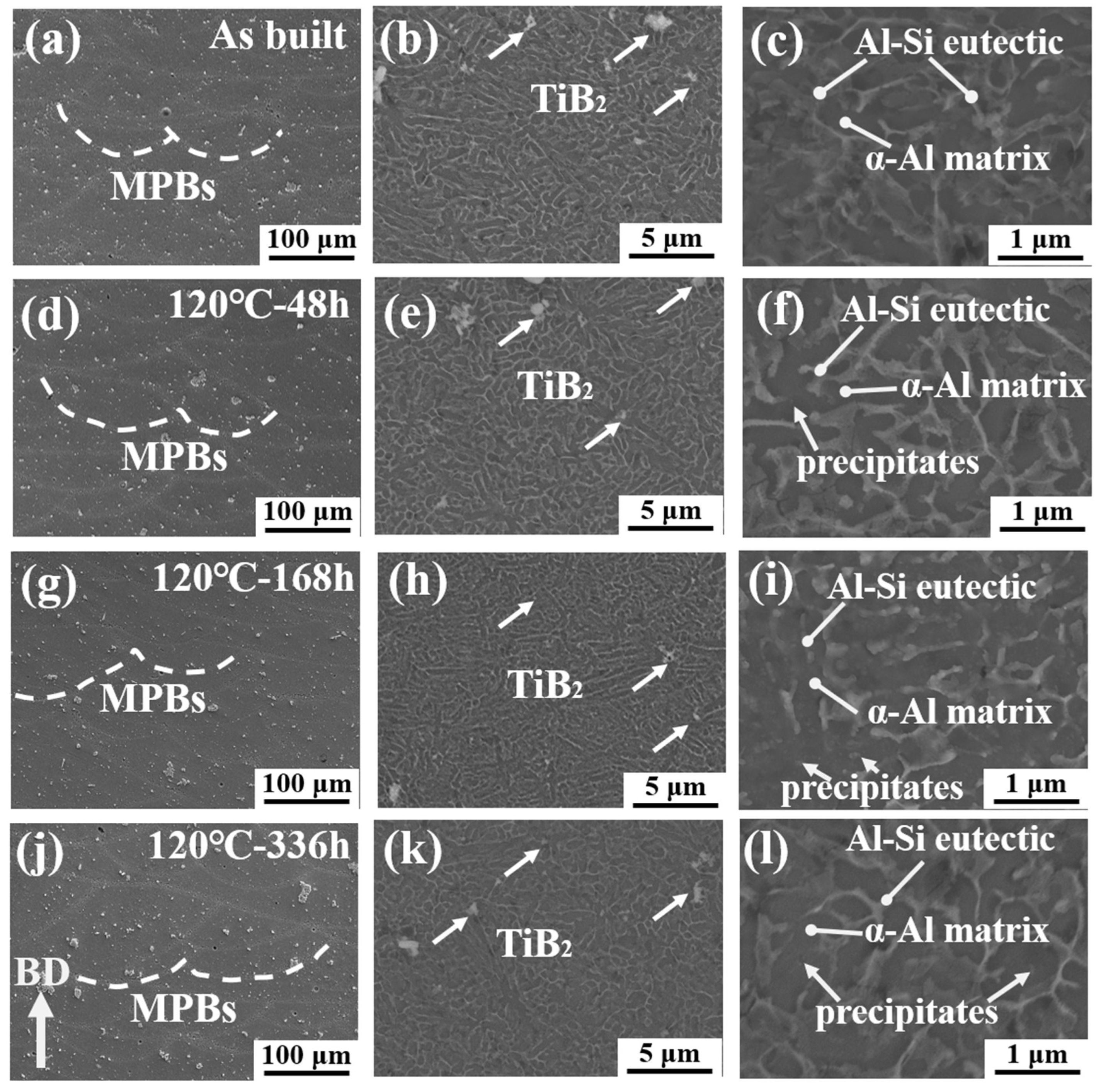

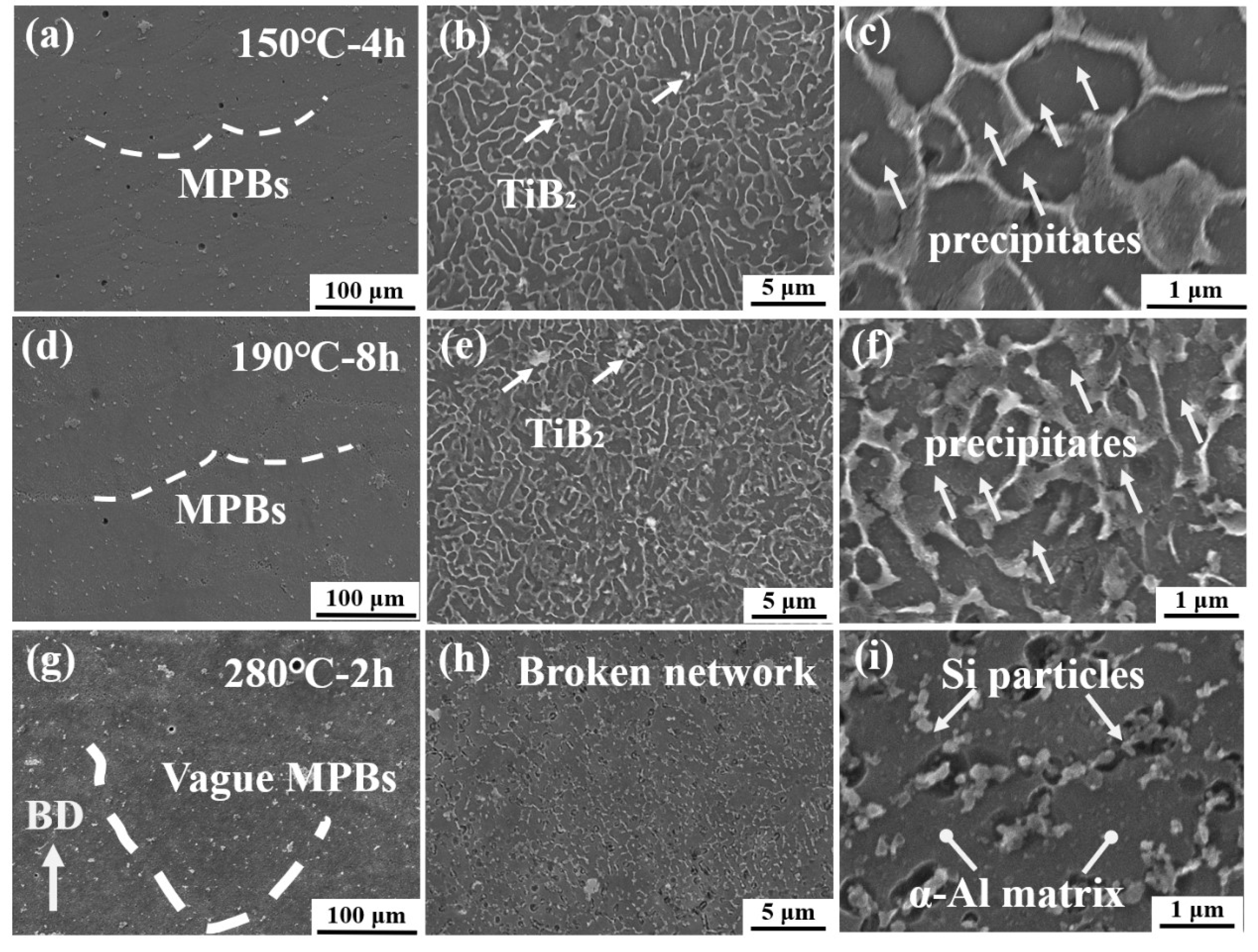

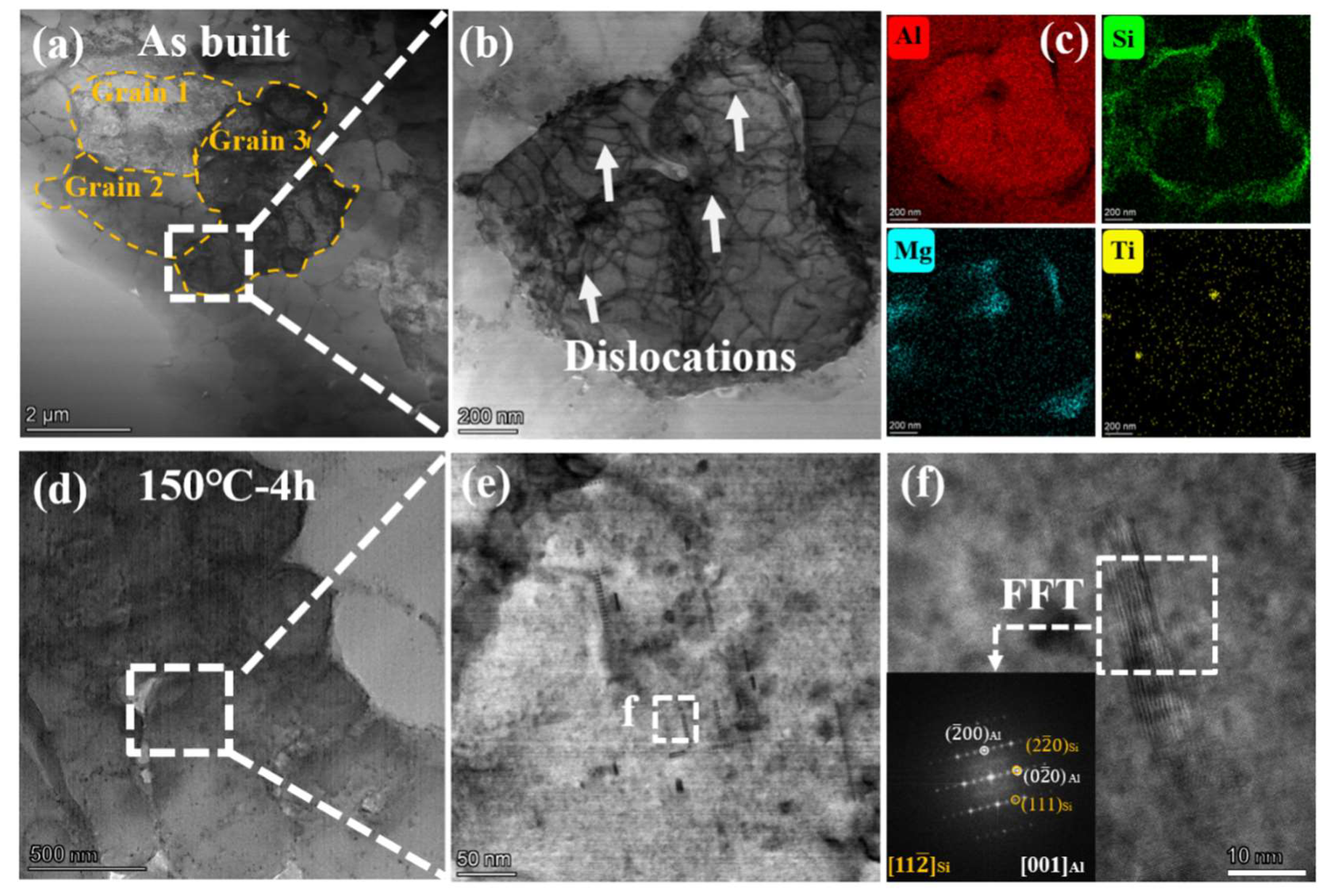

3.3. Effects of Direct Aging on Microstructure

3.4. Fracture Topography

4. Conclusions

- Stress relief level: Aging temperature dominates residual stress relief more than time. Treatments at 150 °C for 4 h and 190 °C for 8 h reduced stresses by 40% and 62%, respectively, while 120 °C for 336 h achieved 45.1% relief. Although 280 °C showed 91% stress relief, it disrupted the Al–Si eutectic network, compromising strength.

- Optimal aging conditions: Balancing performance and efficiency, 150 °C for 4 h (YS = 358 MPa, UTS = 503 MPa, EL = 9.2%) emerged as optimal strategy, followed by the 190 °C for 8 h treatment. Low-temperature aging (120 °C) improved strength but required impractical processing times.

- Microstructural evolution: As-built samples feature 0.5–1 μm non-equilibrium cellular structures strengthened by the Hall–Petch effect and load-bearing mechanism. Low-temperature aging preserves cellular structures while introducing nanoscale Si precipitates for precipitation strengthening, whereas high-temperature annealing degrades strength by disrupting the cellular network. All aged samples exhibit ductile–brittle mixed fracture.

- Industrial relevance: The 150 °C for 4 h and 190 °C for 8 h aging regimes offer superior balance of high strength (YS > 300 MPa, UTS > 450 MPa) and significant stress relief (40%–62%) within 8 h, outperforming conventional post-processing methods for cost-effective industrial applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, abg1487. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Song, L.B.; Macias, J.G.S.; Zhu, Y.X.; Huang, M.S.; Simar, A.; Li, Z.H. Review on the correlation between microstructure and mechanical performance for laser powder bed fusion AlSi10Mg. Addit. Manuf. 2022, 56, 102914. [Google Scholar] [CrossRef]

- Rometsch, P.A.; Zhu, Y.M.; Wu, X.H.; Huang, A.J. Review of high-strength aluminium alloys for additive manufacturing by laser powder bed fusion. Mater. Des. 2022, 219, 110779. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.H.; Hu, L.; Chen, T.T.; Ji, G.; Chen, H.; Wang, H.Z.; Wang, H.W.; Chen, Z. Nanoscale engineering of low-misfit TiB2/Al3(Sc,Zr)/α-Al multi-interface to improve strength-ductility synergy for direct energy deposited aluminum alloy. Addit. Manuf. 2024, 79, 103913. [Google Scholar] [CrossRef]

- Xiao, Y.K.; Bian, Z.Y.; Wu, Y.; Ji, G.; Li, Y.Q.; Li, M.J.; Lian, Q.; Chen, Z.; Addad, A.; Wang, H.W. Effect of nano-TiB2 particles on the anisotropy in an AlSi10Mg alloy processed by selective laser melting. J. Alloys Compd. 2019, 798, 644–655. [Google Scholar] [CrossRef]

- Xiao, Y.K.; Chen, H.; Bian, Z.Y.; Sun, T.T.; Ding, H.; Yang, Q.; Wu, Y.; Lian, Q.; Chen, Z.; Wang, H.W. Enhancing strength and ductility of AlSi10Mg fabricated by selective laser melting by TiB2 nanoparticles. J. Mater. Sci. Technol. 2022, 109, 254–266. [Google Scholar] [CrossRef]

- Dan, C.Y.; Cui, Y.C.; Wu, Y.; Chen, Z.; Liu, H.; Ji, G.; Xiao, Y.K.; Chen, H.; Wang, M.L.; Liu, J.; et al. Achieving ultrahigh fatigue resistance in AlSi10Mg alloy by additive manufacturing. Nat. Mater. 2023, 22, 1182–1188. [Google Scholar] [CrossRef]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.W.; Vleugels, J.; Van Humbeeck, J.; Kruth, J.P. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Li, S.S.; Yue, X.; Li, Q.Y.; Peng, H.L.; Dong, B.X.; Liu, T.S.; Yang, H.Y.; Fan, J.; Shu, S.L.; Qiu, F.; et al. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E.; Iuliano, L.; Galati, M. Experimental analysis of residual stresses on AlSi10Mg parts produced by means of Selective Laser Melting (SLM). In Proceedings of the 10th CIRP Conference on Intelligent Computation in Manufacturing Engineering—CIRP ICME ‘16, Ischia, Italy, 20–22 July 2016; Volume 62, pp. 452–457. [Google Scholar] [CrossRef]

- Dai, K.; Shaw, L. Thermal and stress modeling of multi-material laser processing. Acta Mater. 2001, 49, 4171–4181. [Google Scholar] [CrossRef]

- Marola, S.; Bosia, S.; Veltro, A.; Fiore, G.; Manfredi, D.; Lombardi, M.; Amato, G.; Baricco, M.; Battezzati, L. Residual stresses in additively manufactured AlSi10Mg Raman spectroscopy and X-ray diffraction analysis. Mater. Des. 2021, 202, 109550. [Google Scholar] [CrossRef]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M.; Bandini, M.; Guagliano, M. On the fatigue strength enhancement of additive manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater. Des. 2018, 145, 28–41. [Google Scholar] [CrossRef]

- Buchbinder, D.; Meiners, W.; Pirch, N.; Wissenbach, K.; Schrage, J. Investigation on reducing distortion by preheating during manufacture of aluminum components using selective laser melting. J. Laser Appl. 2014, 26, 012004. [Google Scholar] [CrossRef]

- Zhang, X.C.; Kang, J.W.; Rong, Y.M.; Wu, P.Y.; Feng, T. Effect of Scanning Routes on the Stress and Deformation of Overhang Structures Fabricated by SLM. Materials 2019, 12, 47. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Song, B.; Wei, Q.S.; Zhang, Y.J.; Shi, Y.S. Effects of annealing on the microstructure and mechanical properties of selective laser melted AlSi7Mg alloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2019, 739, 463–472. [Google Scholar] [CrossRef]

- Di Egidio, G.; Ceschini, L.; Morri, A.; Martini, C.; Merlin, M. A Novel T6 Rapid Heat Treatment for AlSi10Mg Alloy Produced by Laser-Based Powder Bed Fusion: Comparison with T5 and Conventional T6 Heat Treatments. Metall. Mater. Trans. B 2022, 53, 284–303. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, G.A.; Wu, Y.; Mathon, M.H.; Borbely, A.; Chen, D.; Ji, G.; Wang, M.L.; Zhong, S.Y.; Wang, H.W. Multi-scale study of microstructure evolution in hot extruded nano-sized TiB2 particle reinforced aluminum composites. Mater. Des. 2017, 116, 577–590. [Google Scholar] [CrossRef]

- Hovig, E.W.; Azar, A.S.; Mhamdi, M.; Sorby, K. Mechanical Properties of AlSi10Mg Processed by Laser Powder Bed Fusion at Elevated Temperature. In Tms 2020 149th Annual Meeting & Exhibition Supplemental Proceedings; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 395–404. [Google Scholar] [CrossRef]

- Batiot, B.; Rogaume, T.; Richard, F.; Luche, J.; Collin, A.; Guillaume, E.; Torero, J.L. Origin and Justification of the Use of the Arrhenius Relation to Represent the Reaction Rate of the Thermal Decomposition of a Solid. Appl. Sci. 2021, 11, 4075. [Google Scholar] [CrossRef]

- Tang, H.; Gao, C.; Zhang, Y.; Zhang, N.; Lei, C.; Bi, Y.; Tang, P.; Rao, J.H. Effects of direct aging treatment on microstructure, mechanical properties and residual stress of selective laser melted AlSi10Mg alloy. J. Mater. Sci. Technol. 2023, 139, 198–209. [Google Scholar] [CrossRef]

- Girelli, L.; Tocci, M.; Gelfi, M.; Pola, A. Study of heat treatment parameters for additively manufactured AlSi10Mg in comparison with corresponding cast alloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2019, 739, 317–328. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.Q.; Tan, Z.Q.; Xiong, D.B.; Guo, Q. Stress relaxation and the cellular structure-dependence of plastic deformation in additively manufactured AlSi10Mg alloys. Int. J. Plast. 2020, 127, 102640. [Google Scholar] [CrossRef]

- Li, C.; Zhang, W.X.; Yang, H.O.; Wan, J.; Huang, X.X.; Chen, Y.Z. Microstructural origin of high strength and high strain hardening capability of a laser powder b e d fuse d AlSi10Mg alloy. J. Mater. Sci. Technol. 2024, 197, 194–206. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Medrano, V.A.; Arrieta, E.; Merino, J.; Ruvalcaba, B.; Caballero, K.; Ramirez, B.; Diemann, J.; Murr, L.E.; Wicker, R.B.; Godfrey, D.; et al. A comprehensive and comparative study of microstructure and mechanical properties for post-process heat treatment of AlSi7Mg alloy components fabricated in different laser powder bed fusion systems. J. Mater. Res. Technol. 2023, 24, 6820–6842. [Google Scholar] [CrossRef]

- Ming, X.; Song, D.; Yu, A.; Tan, H.; Zhang, Q.; Zhang, Z.; Chen, J.; Lin, X. Effect of heat treatment on microstructure, mechanical and thermal properties of selective laser melted AlSi7Mg alloy. J. Alloys Compd. 2023, 945, 169278. [Google Scholar] [CrossRef]

- Gonela, K.K.; Vijayavarman, C.; Palanivel, M.; Mariappan, L.; Ramasubramanian, L.N.; Kannan, A.R. Effect of robotic weaving motion on mechanical and microstructural characteristics of wire arc additively manufactured NiTi shape memory alloy. Int. J. Mater. Res. Technol. 2023, 114, 947–954. [Google Scholar] [CrossRef]

- Motz, C.; Schöberl, T.; Pippan, R. Mechanical properties of micro-sized copper bending beams machined by the focused ion beam technique. Acta Mater. 2005, 53, 4269–4279. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Schwedt, A.; Goravanchi, P.; Prahl, U.; Bleck, W. Quantification of the effect of transformation-induced geometrically necessary dislocations on the flow-curve modelling of dual-phase steels. Int. J. Plast. 2013, 43, 128–152. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Xiao, Y.K.; Bian, Z.Y.; Wu, Y.; Ji, G.; Lian, Q.; Wang, H.Z.; Chen, Z.; Wang, H.W. Simultaneously minimizing residual stress and enhancing strength of selective laser melted nano-TiB2 decorated Al alloy via post-uphill quenching and ageing. Mater. Charact. 2021, 178, 111242. [Google Scholar] [CrossRef]

- Ahn, S.Y.; Moon, J.; Choi, Y.T.; Kim, E.S.; Jeong, S.G.; Park, J.M.; Kang, M.; Joo, H.; Kim, H.S. A precipitation-hardened AlSi10Mg alloy fabricated using selective laser melting. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2022, 844, 143164. [Google Scholar] [CrossRef]

- Zhu, H.; Sun, J.; Guo, Y.; Xu, X.; Huang, Y.; Jiang, Z.; Wu, G.; Li, J.; Liu, W. Effects of post heat treatment on the microstructure and mechanical properties of selective laser melted AlSi10Mg alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2024, 894, 146195. [Google Scholar] [CrossRef]

- Zhao, B.B.; Ye, B.; Wang, L.Y.; Bai, Y.; Yu, X.; Wang, Q.G.; Yang, W.Y. Effect of ageing and thermal exposure on microstructure and mechanical properties of a HPDC Al-Si-Cu-Mg alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2022, 849, 143463. [Google Scholar] [CrossRef]

- Mei, J.; Han, Y.; Sun, J.; Jiang, M.; Zu, G.; Song, X.; Zhu, W.; Ran, X. Improving the comprehensive mechanical property of the AlSi10Mg alloy via parameter adaptation of selective laser melting and heat treatment. J. Alloys Compd. 2024, 981, 173623. [Google Scholar] [CrossRef]

| Element | Si | Mg | Ti | B | Al |

|---|---|---|---|---|---|

| Powders | 7.00 | 1.35 | 1.32 | 0.62 | Balance |

| LPBF | 7.00 | 1.24 | 1.29 | 0.60 | Balance |

| Condition | Tensile Direction | YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|---|

| As-built | ⊥BD | 290 ± 5 | 475 ± 6 | 10.6 ± 1.2 |

| As-built | //BD | 255 ± 3 | 475 ± 6 | 9.0 ± 0.9 |

| 120 °C-48 h | ⊥BD | 345 ± 2 | 502 ± 1 | 10.0 ± 1.5 |

| 120 °C-48 h | //BD | 318 ± 5 | 509 ± 1 | 6.5 ± 1.1 |

| 120 °C-168 h | ⊥BD | 356 ± 3 | 509 ± 2 | 8.0 ± 0.5 |

| 120 °C-168 h | //BD | 330 ± 8 | 515 ± 5 | 5.3 ± 0.6 |

| 120 °C-336 h | ⊥BD | 361 ± 3 | 505 ± 3 | 8.5 ± 1.0 |

| 120 °C-336 h | //BD | 340 ± 7 | 513 ± 6 | 6.1 ± 0.3 |

| 150 °C-4 h | ⊥BD | 358 ± 5 | 503 ± 3 | 9.2 ± 0.3 |

| 150 °C-4 h | //BD | 325 ± 2 | 510 ± 2 | 7.0 ± 0.4 |

| 190 °C-8 h | ⊥BD | 320 ± 3 | 457 ± 5 | 7.9 ± 0.3 |

| 190 °C-8 h | //BD | 300 ± 5 | 459 ± 8 | 7.6 ± 0.5 |

| 280 °C-2 h | ⊥BD | 183 ± 5 | 285 ± 3 | 21.3 ± 0.8 |

| 280 °C-2 h | //BD | 176 ± 4 | 282 ± 3 | 18.3 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rong, P.; Fang, X.; Chang, Y.; Chen, Y.; Huang, D.; Li, Y. The Influence of Direct Aging on TiB2/Al–Si–Mg Composites Fabricated by LPBF: Residual Stress, Mechanical Properties and Microstructure. Coatings 2025, 15, 780. https://doi.org/10.3390/coatings15070780

Rong P, Fang X, Chang Y, Chen Y, Huang D, Li Y. The Influence of Direct Aging on TiB2/Al–Si–Mg Composites Fabricated by LPBF: Residual Stress, Mechanical Properties and Microstructure. Coatings. 2025; 15(7):780. https://doi.org/10.3390/coatings15070780

Chicago/Turabian StyleRong, Peng, Xin Fang, Yirui Chang, Yong Chen, Dan Huang, and Yang Li. 2025. "The Influence of Direct Aging on TiB2/Al–Si–Mg Composites Fabricated by LPBF: Residual Stress, Mechanical Properties and Microstructure" Coatings 15, no. 7: 780. https://doi.org/10.3390/coatings15070780

APA StyleRong, P., Fang, X., Chang, Y., Chen, Y., Huang, D., & Li, Y. (2025). The Influence of Direct Aging on TiB2/Al–Si–Mg Composites Fabricated by LPBF: Residual Stress, Mechanical Properties and Microstructure. Coatings, 15(7), 780. https://doi.org/10.3390/coatings15070780