1. Introduction

In underground mines worldwide, roadway excavation and coal seam extraction are most commonly carried out using mechanical excavation. This method enables high efficiency; however, its applicability depends on mining, geological conditions, and organizational and technical factors. Roadways are typically excavated from rocks characterized by high cohesion, uniaxial compressive strength, and favorable abrasive properties [

1,

2].

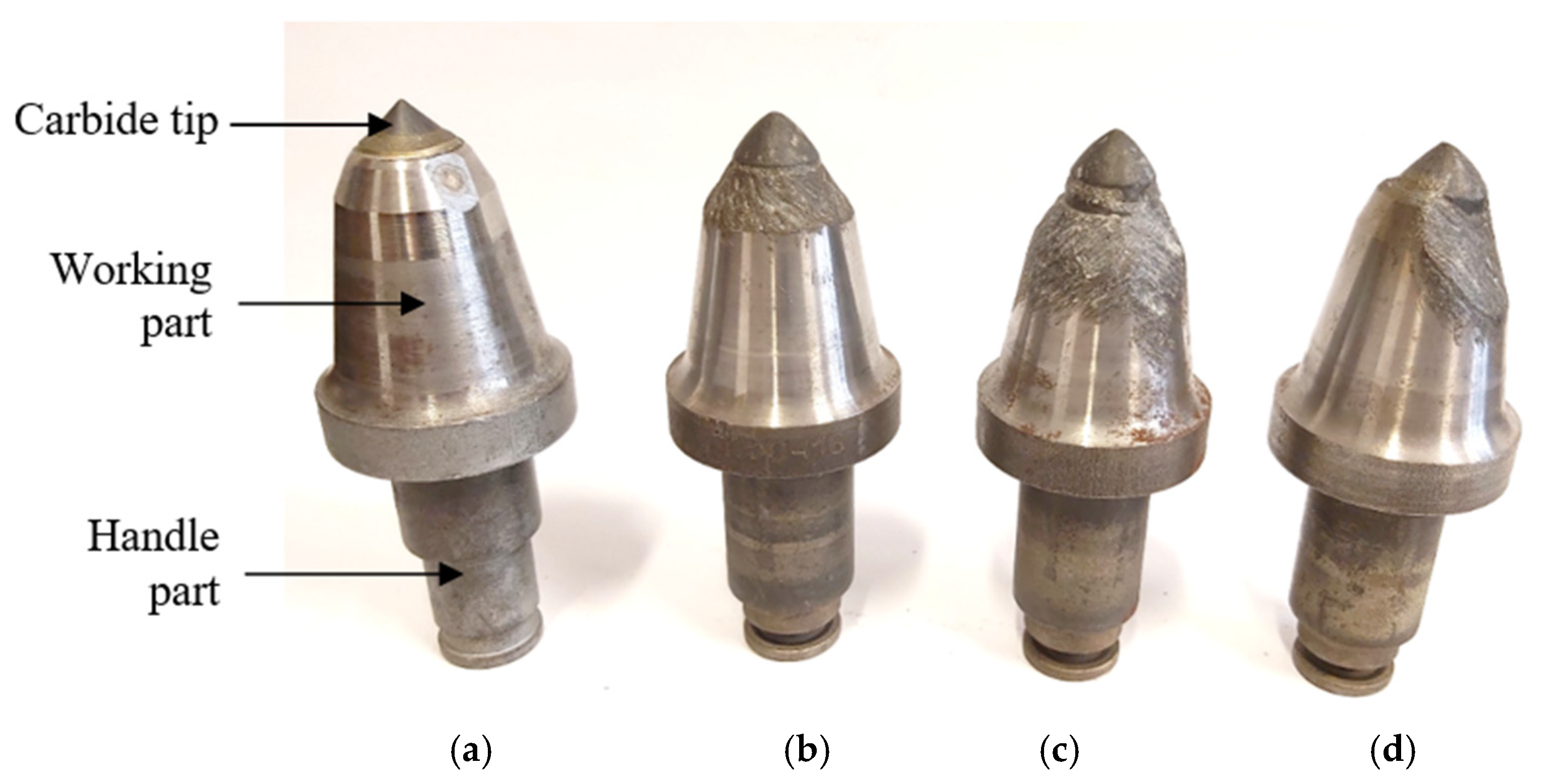

During excavation, the cutting tool is the component in direct contact with the undisturbed rock mass. One of the most significant factors affecting the cutting process is the wear of the tool’s working part (

Figure 1). The wear process of cutting tools is highly complex, making it impossible to isolate a single group of factors that predominantly influences its progression. According to Plinninger, Käsling, Thuro, and Kotwica [

3,

4,

5], the key parameters affecting tool wear include the following:

Geological, physical, and mechanical factors (rock properties [

6], rock cohesion, water saturation [

7], rock mass structure, direction, and magnitude of principal stresses within the rock formation);

Material and design-related factors (composition and structure of the material used for the tool body and tip);

Cutting-process parameters (cutting and feed speed, cutting depth);

Cooling conditions of the carbide tip (method, intensity, and type of cooling).

The mineral composition of the grains is crucial, as it influences the abrasive effect of the rock on the cutting pick. It is particularly relevant for the quartz grain content. Another important parameter is the equivalent quartz content, expressed as a percentage. Studies on specific pick wear conducted by Johnson and Fowell [

8], as well as Roxborough’s research [

9], have shown that for the same uniaxial compressive strength (UCS) of the rock, pick wear can vary by several times depending on the quartz content (higher abrasivity). The observed difference was exclusively in the form of increased wear. In the case of Johnson and Fowell, the wear increase was proportional, whereas Roxborough found an exponential relationship between wear and quartz content. This trend was further confirmed by the studies of Plinninger, Käsling, and Thuro [

3,

4].

Liu et al. [

10] highlighted the influence of pick types, structure, and working angle parameters on its wear. They also stated that the larger the height of the carbide tip and the cone angle of the pick tip, the easier it is to protect the head face of the pick body from interference with coal rock and to avoid carbide tip loss due to the wear of the pick body.

Cheluszka et al. [

11] also emphasized the importance of geometric parameters in conical picks. They pointed out that rotation is crucial for these tools, as the lack of rotation leads to asymmetric wear, resulting in reduced cutting efficiency, increased energy consumption, and a rise in dynamic overload, which affect the cutting machine. Therefore, they proposed modifications to the design of the picks and the method of securing the carbide tip in the working part of the tool to enhance their durability significantly.

Kadkhodaei et al. [

12] emphasized the significant influence of cutting process parameters on the forces acting on the cutting tool, and, consequently, on its wear. They also highlighted that these parameters affect the cutting machine’s energy consumption, dust generation, and maintenance requirements. Bilgin et al. [

1] conducted a detailed study on the impact of the depth of cut, friction angle between the tool and rock, and spacing between cuts.

All the parameters mentioned above influence the wear of tangential-rotary picks to varying degrees. Akintunde et al. [

13] listed the most common failures, which include the one-sided wear of the pick body, pull-out of the pick’s carbide tip, slimming of the steel body, and wear and deformation of the carbide tip. Additionally, the cracking and crushing of tungsten carbide (WC-Co) grains, cavity formation and pitting, coal intermixing, abrasive wear, long and deep cracks, rock channel formation, and corrosive degradation have been identified as key failure mechanisms.

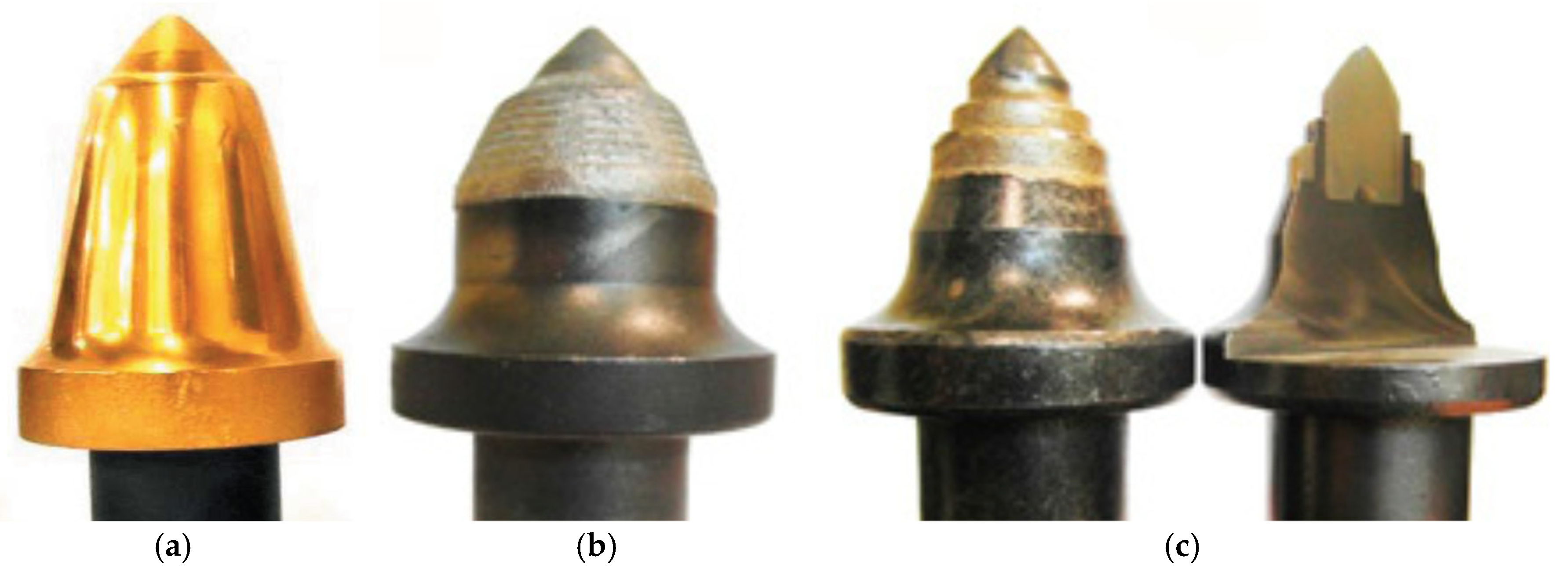

The wear process of cutting tools is associated with costs, and not only those directly related to their replacement. Each tool change results in machine downtime, thereby reducing its available operating time. More frequent downtimes negatively impact efficiency. Therefore, it is crucial for cutting tools to have the highest possible durability [

14,

15]. Heat treatment is most commonly applied to impart the required hardness to the working part of the cutting tool. However, this approach is often insufficient in ensuring the desired durability. Consequently, manufacturers employ various types of protective coatings to extend the service life of cutting tools (

Figure 2). Hardfacing is one of the most widely used techniques for prolonging the lifecycle of cutting components. Among the most efficient and versatile hardfacing methods are gas metal arc welding (GMAW) and its cored-wire variant flux-cored arc welding (FCAW) [

16]. Bołoz further identified additional solutions, such as rings made of sintered carbides, CAP-type carbides in picks with reduced-height bodies, as well as flat or round inserts composed of sintered carbide [

17].

Currently, end users—typically mine workers—do not have clear, standardized guidelines to follow when selecting cutting tools with appropriate protective coatings on the working parts. Therefore, the objective of this study is to develop a set of guidelines for the selection of conical picks with protective coatings that effectively enhance tool durability. The proposed selection method is based on two simple and readily measurable parameters: uniaxial compressive strength (UCS) and the rock abrasivity index (Wz). These parameters are systematically compiled and presented in a tabular format to ensure clarity and practical usability.

2. Research Material and Methods

The study was conducted on twelve rock samples collected from underground mining excavations in five Polish hard coal mines located in the cities of Bieruń, Jastrzębie-Zdrój, Jaworzno, Katowice, and Libiąż, all situated within the Upper Silesian Coal Basin (USCB) (

Figure 3). The USCB is located in southern Poland, spanning the regions of Upper Silesia and Lesser Poland and the Moravian-Silesian region of the Czech Republic. The place where the samples were taken for testing is not accidental, because hard black coal extraction has been conducted for nearly 250 years. Currently, 40 mines remain operational, including 34 on the Polish side of the basin [

18]. A summary of the analyzed material and the precise location of the deposits is provided in

Table 1.

After extracting the rock samples from the mining excavations, appropriate laboratory specimens were prepared, and tests were conducted according to a predetermined research plan and methodology. For the examined rocks, the chemical composition, uniaxial compressive strength (UCS), tensile strength using the Brazilian test method (BTS), and rock abrasivity using the proprietary AGH method (Wz) were determined.

2.1. Chemical Composition Analysis

The chemical composition of the samples was analyzed using wavelength-dispersive X-ray fluorescence (WD-XRF) with a ZSX Primus II Rigaku spectrometer (Rh anode). For measurement purposes, the samples were ground, homogenized, and subsequently pressed into pellets under a pressure of 15 Mg using an automatic press. A qualitative spectral analysis was performed by identifying spectral lines and assessing their potential coincidences. Based on this assessment, analytical lines were selected. A semi-quantitative analysis was conducted using the SQX calculation program (fundamental parameters method). The analysis covered the range from fluorine to uranium (F-U), and the concentrations of the detected elements were normalized to 100%.

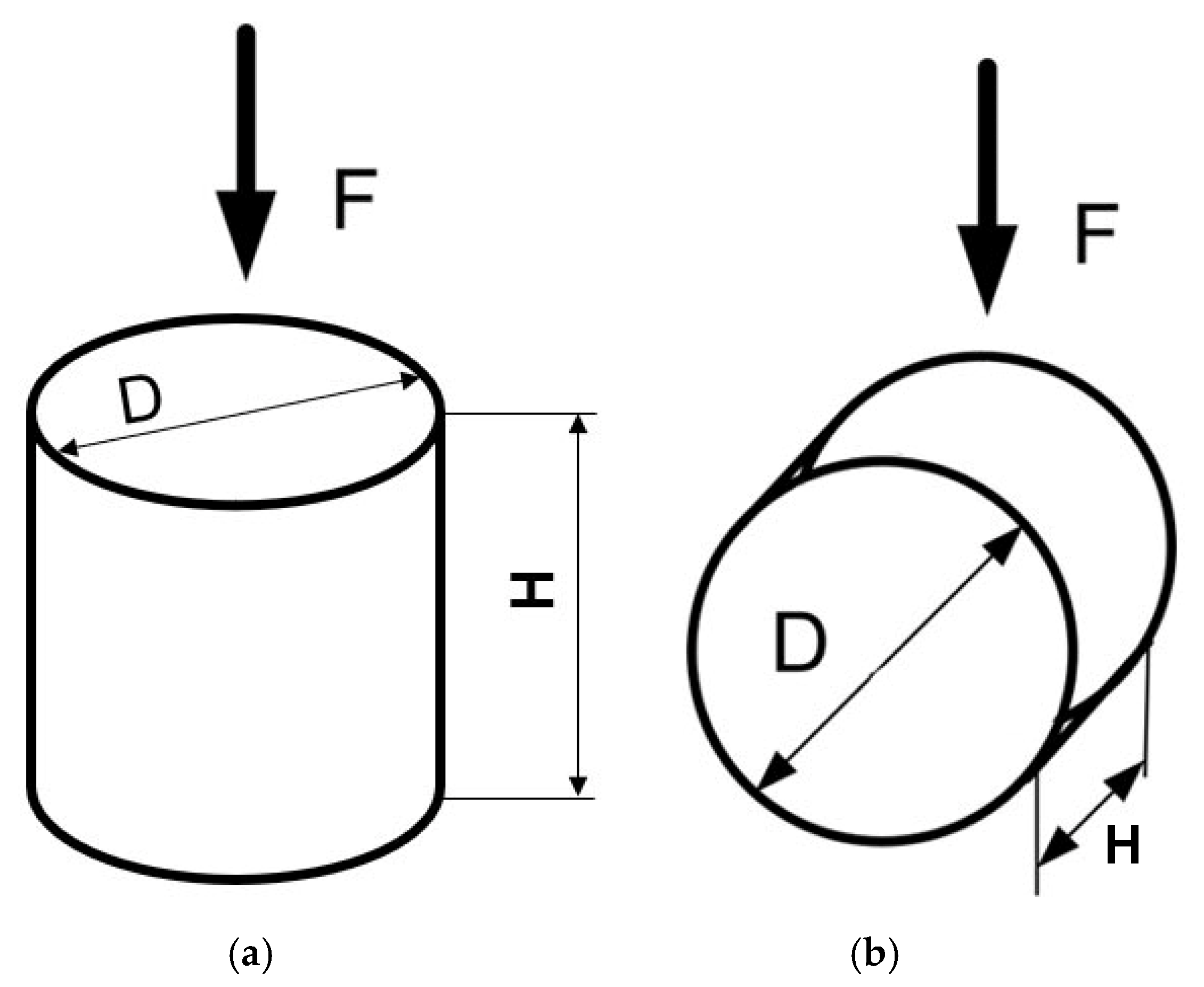

2.2. Strength Properties Analysis

Five cylindrical specimens were prepared to determine the uniaxial compressive strength (UCS) for each type of tested rock. Samples with a diameter and height of 50 ± 0.5 mm were prepared by EN 1926:2007 [

20]. The laboratory tests were conducted using an INSTRON 600DX testing machine by PN-G-04303:1997 [

21]. UCS is defined as the maximum stress a material can withstand under compressive loading conditions, and it was determined as the ratio of the fracture load F to the cross-sectional area A on which the force was applied (

Figure 4a).

where UCS—uniaxial compressive strength, MPa;

F—fracture load, N;

A—cross-sectional area before the test, m

2.

The Brazilian tensile strength test (BTS) was employed to determine the tensile strength. This method compressed a cylindrical specimen along its lateral surface using two opposing linear loads. Applying force perpendicular to the specimen’s axis (

Figure 4b) induced a fracture along a plane passing through the cylinder’s center, primarily due to tensile stresses [

22].

In this study, five cylindrical specimens were prepared for each type of examined rock with a diameter of 50 ± 0.5 mm and a thickness of 25 ± 0.5 mm, as the thickness-to-diameter ratio should be within the range of 0.5–0.6. The uniaxial tensile strength was determined using the following equation [

23]:

where BTS—uniaxial tensile strength, MPa;

F—fracture load, N;

D—diameter of the sample, m;

H—thickness of the sample, m.

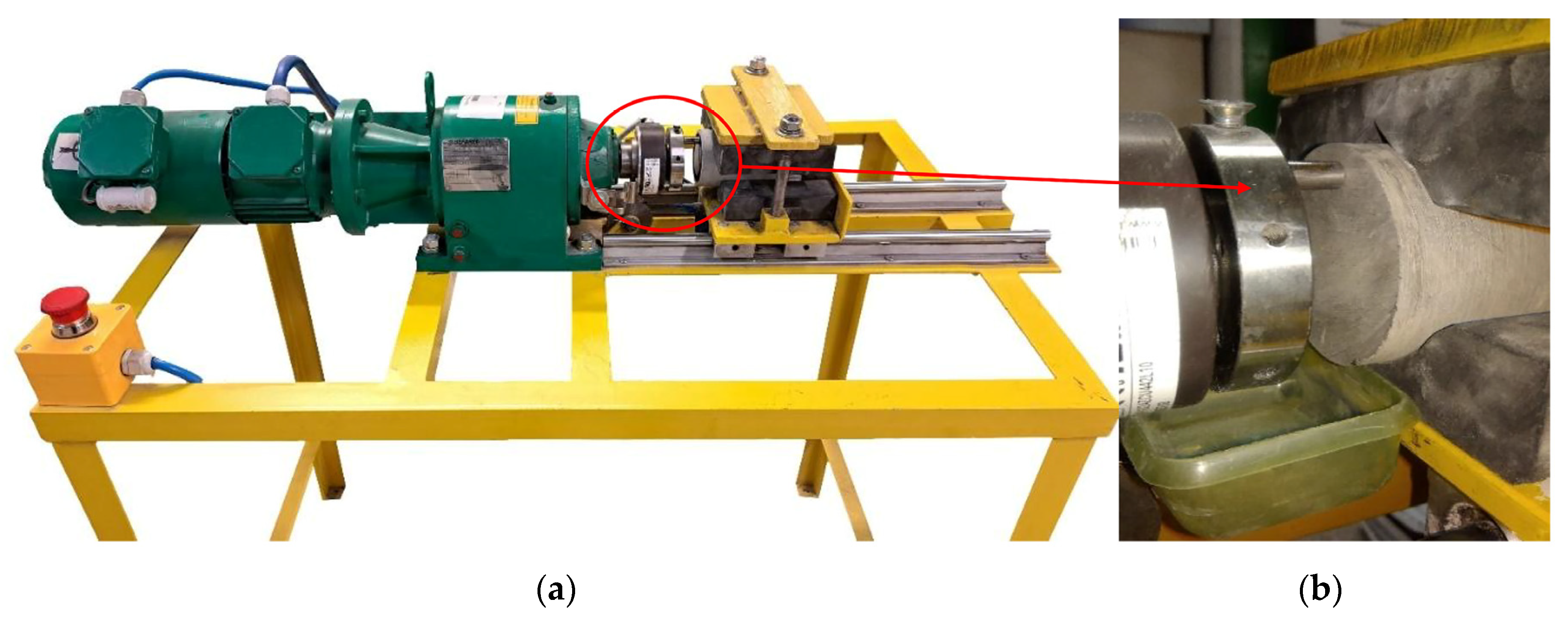

2.3. Rock Abrasivity Analysis

The rock abrasivity was evaluated using a proprietary method developed at the AGH University of Krakow [

24,

25]. This assessment was conducted on a laboratory testing stand, as shown in

Figure 5a. The method measured the mass loss of a standard steel pin that remained in contact with the rock sample while subjected to a constant normal force of 300 N. The steel pin moved uniformly in a circular path at a speed of 50 rpm for 8 min. The steel pin and the rock sample formed an abrasive pair (

Figure 5b). The movement of the steel pin was driven by a gear motor, while the normal force was applied using a simple gravity-based loading system with weights. Testing can be carried out on either cylindrical (core) or cubic rock samples.

The parameter that characterizes rock abrasivity is known as the abrasivity index. This index is defined as the ratio of the steel pin’s mass loss to the rock sample’s mass loss. It is calculated using the following formula:

where

Wz—abrasivity index;

mpab—mass of testing pin before test, g;

mpaa—mass of testing pin after test, g;

mpib—mass of rock sample before test, g;

mpia—mass of rock sample after test, g.

The assessment of rock abrasivity was based on the average value of the abrasivity index

Wz, calculated from a minimum of five measurements. The steel pin was weighed before and after testing using an ATN160G laboratory scale with internal calibration, manufactured by the AXIS company, featuring a reading unit of 0.0001 g and a verification unit of 0.001 g. Rock samples were weighed using an ACZ4200 laboratory scale, also by AXIS Sp. z o.o., with a reading unit of 0.01 g and a verification unit of 0.1 g. The tested rock was classified based on the value of the abrasivity index

Wz, in accordance with the classification presented in

Table 2.

3. Results

The study was conducted by the previously established research methodology described above. The chemical composition analysis selected a mechanical properties assessment, and an abrasivity evaluation was performed for twelve rocks. A detailed analysis of these properties is essential for establishing a consistent and coherent foundation for the selection of appropriate protective coatings for conical picks.

3.1. Chemical Composition

Providing the complete chemical composition of each of the twelve rocks would occupy an excessive portion of the article; therefore,

Table 3 presents selected components with the highest percentage share in the examined rocks.

The chemical composition analysis primarily focused on silicon dioxide (SiO2, silica), as its presence indicates the quartz content within the rock. This component constituted the most significant proportion in each analyzed sample. In the sandstones, silica content ranged from 66% (SJ2 fine-grained sandstone) to as high as 83.5% (SK2 medium-grained sandstone). Approximately 64% silica was detected in the ShJ3 clay shale. In mudstones, silica content varied from approximately 59% (ML2 and MJZ1 mudstones) to 62% (ML3 mudstone). The lowest silica content was observed in claystones, ranging from 50% (CK3 claystone) to 62.5% (CK4 claystone).

The second most significant component in the chemical composition of the analyzed rocks was aluminum oxide (Al2O3). Sandstones’ content ranged from approximately 6.5% (SK2 sandstone) to around 16.5% (SJ2 sandstone). In both claystones and mudstones, Al2O3 constituted approximately 28%. The highest aluminum oxide content was recorded in ShJ3 clay shale, reaching 29%.

Additionally, it is worth noting the presence of iron oxide (Fe2O3), which accounted for approximately 10% of CK3 claystone, and magnesium oxide (MgO), which reached 9% in the same sample. The remaining components were present in trace amounts, not exceeding 5%.

3.2. Strength Properties

The results of the strength properties assessment, presented in

Table 4, indicate significant variation in the properties of the examined rocks depending on their formation.

The analyzed rocks can be categorized into three groups based on bulk density. The highest bulk density, exceeding 2600 kg/m3, was observed in ML2 and MJZ1 mudstones, CK3 claystone, and SJ1 sandstone. Rocks with a bulk density above 2400 kg/m3 included SK1 and SK2 sandstones, CK4 claystone, and ML3 mudstone. The lowest bulk density, below 2300 kg/m3, was recorded in SB1, SJ2, and SL1 sandstones.

The analyzed rocks exhibited more significant variability regarding uniaxial compressive strength (UCS). The highest UCS value, nearly 65 MPa, was observed in SJ1 sandstone. The UCS values for the remaining sandstones ranged between 20 and 30 MPa. Claystones demonstrated UCS values of 25–28 MPa, while mudstones ranged from 12 to 18 MPa. The lowest UCS was recorded for clay shale, with a value of just under 10 MPa.

The tensile strength of the analyzed rocks, determined using the Brazilian test (BTS), followed a similar trend to uniaxial compressive strength. The highest tensile strength was observed in SJ1 sandstone (5.1 MPa), while the lowest BTS values were recorded for ShJ3 clay shale and ML3 mudstone (2.1 MPa).

3.3. Rock Abrasivity

According to the previously mentioned method (the AGH method) for assessing rock abrasivity, the abrasivity index

Wz was determined by calculating the mass loss of the steel pin and the mass loss of the tested rock sample. Five tests were performed for each rock type.

Table 5 presents the minimum, maximum, mean values, and standard deviations for both the wear of the steel pins and the rock samples, followed by the calculated values of the abrasivity index

Wz. Subsequently, each analyzed rock was classified according to

Table 2.

Although sandstones are generally considered highly abrasive rocks, the collected samples included sandstones with low, medium, and high abrasivity indices. The highest abrasivity index was recorded for the SK1 medium-grained sandstone, with an average abrasivity index Wz of 3.86 ± 0.08, classifying it as a highly abrasive rock. The SJ2 medium-grained sandstone was classified as a medium abrasive rock, with an abrasivity index of 2.34 ± 0.04. The remaining sandstones exhibited low abrasivity, with abrasivity index values ranging from 1.21 ± 0.10 ÷ 1.71 ± 0.08. Claystones were classified as rocks with insignificant abrasivity, while the abrasivity of mudstones and clay shale was considered negligible.

A significant portion of the collected rock samples consisted of sandstones with visually varying grain sizes. A trend indicated that sandstones with coarse grains had higher abrasivity index values.

4. Discussion

There are multiple methods for evaluating the quality of conical picks. These include assessing their geometric dimensions [

10,

11,

15], conducting metallographic examinations [

26,

27], and analyzing various factors influencing their wear [

28,

29,

30]. However, the primary concern for the end user (mine workers) is cutting efficiency. As mentioned in the introduction, each cutting tool replacement results in the stoppage of the cutting machine, directly affecting production output. Therefore, different durability indicators for picks are sometimes adopted.

Akintunde et al. [

13] described the premature failure of conical picks on the cutting head of a roadheader in a coal mine in Botswana. The failure posed a significant challenge, leading to frequent pick replacements, substantial losses, and ineffective machine operating time due to downtime. The authors defined pick durability using the indicator of coal tonnage per pick. Their study estimated that the efficiency of the picks ranged from approximately 150 to 350 tons per pick, significantly below the 400 tons per pick recommended by the manufacturer.

Prokopenko et al. [

31] proposed an alternative durability indicator, defined as the number of picks required per 1000 tons of excavated material. The highest durability was observed for picks manufactured by the Betek company, with a consumption rate of 1.6 picks per 1000 tons of broken rock mass. The authors emphasized that for low-quality picks, the consumption rate could increase to 14÷27 picks per 1000 tons of excavated material.

Krauze et al. [

32] developed the

C2 index to assess the pick’s durability, which was defined as the total mass loss of the picks about the volume of excavated rock. The lower the index value, the better the durability of the picks. However, this indicator was determined exclusively under laboratory conditions.

The present study evaluated pick durability based on specific pick consumption, defined as the number of picks consumed (replaced) per 1000 m

3 of excavated material. Consequently, data were collected from the mines that provided rock samples for analysis, including information about the excavation site, such as the excavation name, seam number, current tunnel length, and type of arch support, to calculate the excavation face area. Additionally, details on the type of roadheader used, and, crucially, the number of picks worn out since the beginning of excavation were recorded. These data were essential for determining specific pick consumption. The values were compiled along with UCS, BTS, the abrasivity index

Wz, and SiO

2 content in

Table 6.

The highest specific pick consumption reached 493 picks per 1000 m3 of excavated material. These picks were used for excavating SJ1 sandstone, which exhibited the highest UCS and BTS values. However, the abrasivity index for this sandstone was low, at only 1.47, with a SiO2 content of 66.1%. In this case, the UCS value significantly impacted the specific pick consumption. A similar level of specific pick consumption—457 picks per 1000 m3—was recorded for SL1 sandstone. This sandstone was characterized by a medium UCS value (20.8 MPa) and a low abrasivity index of 1.6, with a SiO2 content of 72.2%. Conversely, SK2 sandstone exhibited a high abrasivity index of 3.86 and a medium UCS value (29.4 MPa); the specific pick consumption was only 139 picks per 1000 m3 of excavated material.

Based on these findings, no clear trend can be identified regarding which of the examined parameters has the most significant impact on specific pick consumption. It suggests that cutting tool selection cannot be based solely on a single parameter. An attempt to address this issue was made by Sandvik Mining and Construction, which developed models considering the specific pick consumption as a function of UCS and CAI (Cerchar abrasivity index) [

33]. However, these models are intended for forecasting the quantity of tool wear under specific operating conditions, rather than for selecting picks based on the defined properties of the rock.

Unfortunately, picks are currently selected in Poland primarily based on UCS values. Therefore, a classification of rocks based on their uniaxial compressive strength and abrasive properties has been proposed (

Table 7). This classification aims to guide users (mine workers) in selecting the appropriate pick type for excavating a given rock.

In analyzing

Table 7 it is apparent that rocks classified in group Ia exhibit low UCS and negligible abrasive properties. Therefore, the user may employ a standard commercial pick without protection for the working part or a heat-treated pick with a hardness above 45 HRC. Rocks classified in group IIc should be excavated using picks with a coating or hardfacing layer with a hardness above 65 HRC.

On the other hand, rocks in category IIId are of high strength with excellent abrasive properties. Hence, it is recommended that the user selects a pick whose working part is reinforced with additional carbide rings or inserts around the cutting tip. These picks are significantly more expensive; however, their durability is considerably higher, and their operational lifespan is much longer. In such cases, it is advisable to consider alternative excavation methods, such as disc tools or explosives.

The proposed protection for the pick’s working part was developed based on an analysis of durability tests conducted on conical picks made from various materials. These tests were performed using a laboratory test stand to study the cutting process via milling or rotary drilling with a single cutting tool or cutting heads. The test stand belonged to the Department of Machinery Engineering and Transport at AGH University of Krakow, Poland. Most of the tests were commissioned by manufacturers of cutting tools, and some results of these studies have been published [

15,

34]. This proposal was developed to ensure that the rock’s uniaxial compressive strength and its abrasivity were considered when selecting the pick type and protecting its working part. There is a strong emphasis on requiring mineral extraction companies to consider not only the pick price when evaluating bids in public procurement processes [

35,

36].

5. Conclusions

The article provides valuable information for both manufacturers of cutting tools and end users, primarily in hard coal mines. It is suggested that the selection of picks with an appropriate protective coating be based on the strength and abrasivity properties of the rocks. Currently, the process relies mainly on uniaxial compressive strength (UCS), which is insufficient. It leads to rapid pick wear, thereby reducing the available operating time of the mining machine and ultimately diminishing the extraction output.

A classification of rocks is proposed based on their uniaxial compressive strength (UCS) and abrasiveness index (Wz), along with corresponding recommendations for the selection of picks with appropriate protective coatings. For rocks with parameters Wz ≤ 0.5 and UCS ≤ 80 MPa, as well as Wz ≤ 1.9 and UCS ≤ 50 MPa, picks without protective coatings or with only heat treatment are recommended, provided that the hardness of the working part exceeds 45 HRC. For rocks with Wz ≤ 0.5 and UCS ≥ 80 MPa, or Wz ≤ 1.9 and UCS ≥ 50 MPa, the use of picks with coatings or hardfacing that increases the hardness above 50 HRC is suggested. For rocks with Wz ≤ 3.9 and UCS ≤ 80 MPa, or Wz ≥ 3.9 and UCS ≤ 50 MPa, picks with coatings or hardfacing that raise the hardness above 65 HRC are recommended. In the case of rocks with Wz ≤ 1.9 and UCS ≥ 80 MPa, or Wz ≥ 3.9 and UCS ≥ 50 MPa, the recommended solution is the use of picks equipped with rings or inserts made of sintered carbide (WC-Co) or polycrystalline diamond (PCD). These parameters facilitate the selection of the cutting tool type and often aid in choosing the excavation method (e.g., mechanical excavation or blasting).

Furthermore, it is important to consider the costs of purchasing new cutting tools. Public mining enterprises procure picks for roadheaders and shearers through public tenders, the price of which is the most critical evaluation criterion. However, quality aspects also play a key role. In addition to criteria related to low cost and favorable financial terms, contracting authorities in the mining industry must also consider the quality aspects of the offers to ensure that the purchased cutters are highly durable and safe (e.g., minimized sparking).