Super-Hydrophobic Photothermal Copper Foam for Multi-Scenario Solar Desalination: Integrating Anti-Icing, Self-Cleaning, and Mechanical Durability

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Super-Hydrophobic Carbon Nanotubes (SHB-CNTs)

2.3. Preparation of Copper Foam with Micro-Nano Structure

2.4. Preparation of SDCF

2.5. Anti-Deicing Experiment

2.6. Characterization

3. Results and Discussion

3.1. Morphological Characterization of SDCF

3.2. Solar Desalination Capacity of the SDCF

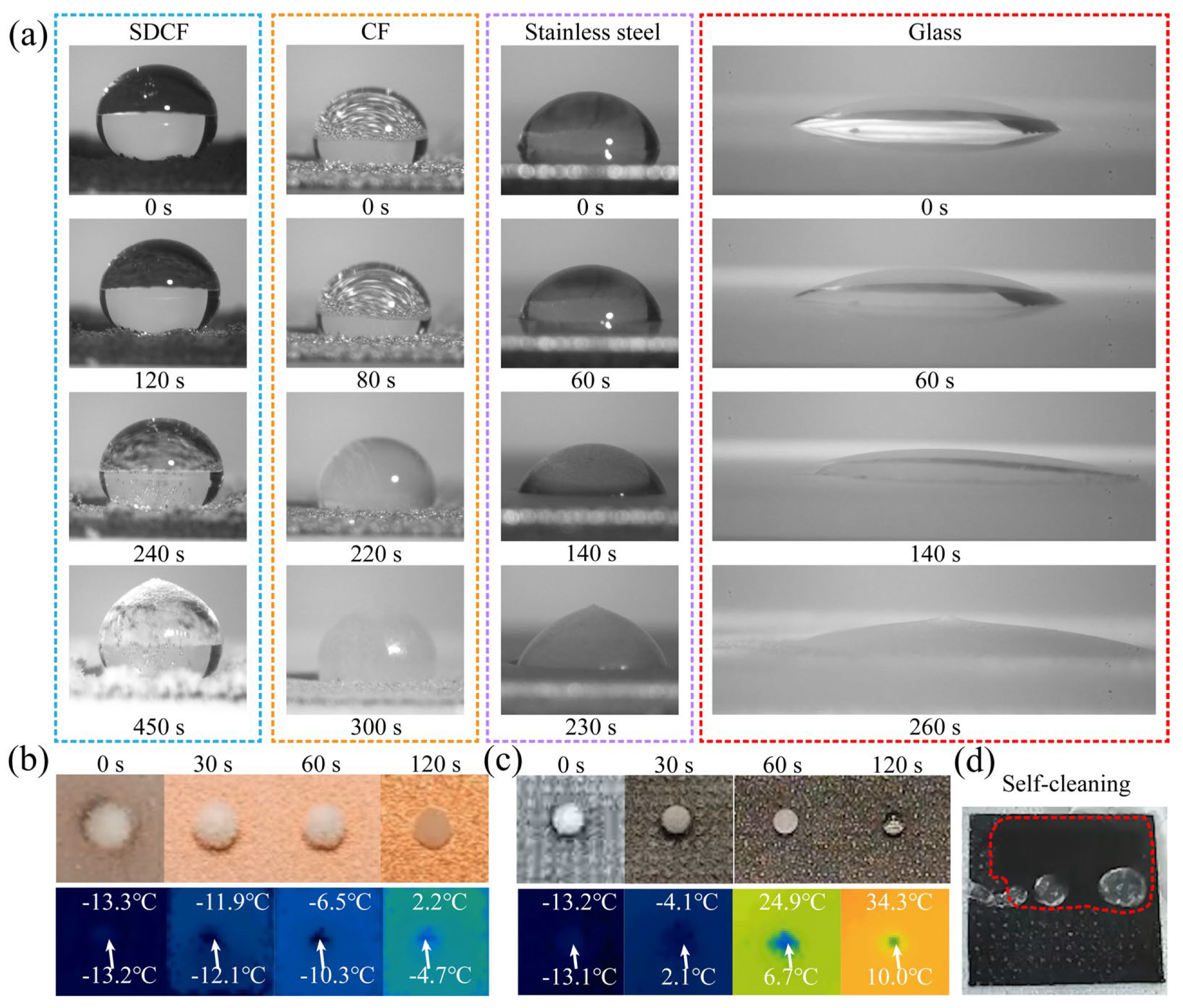

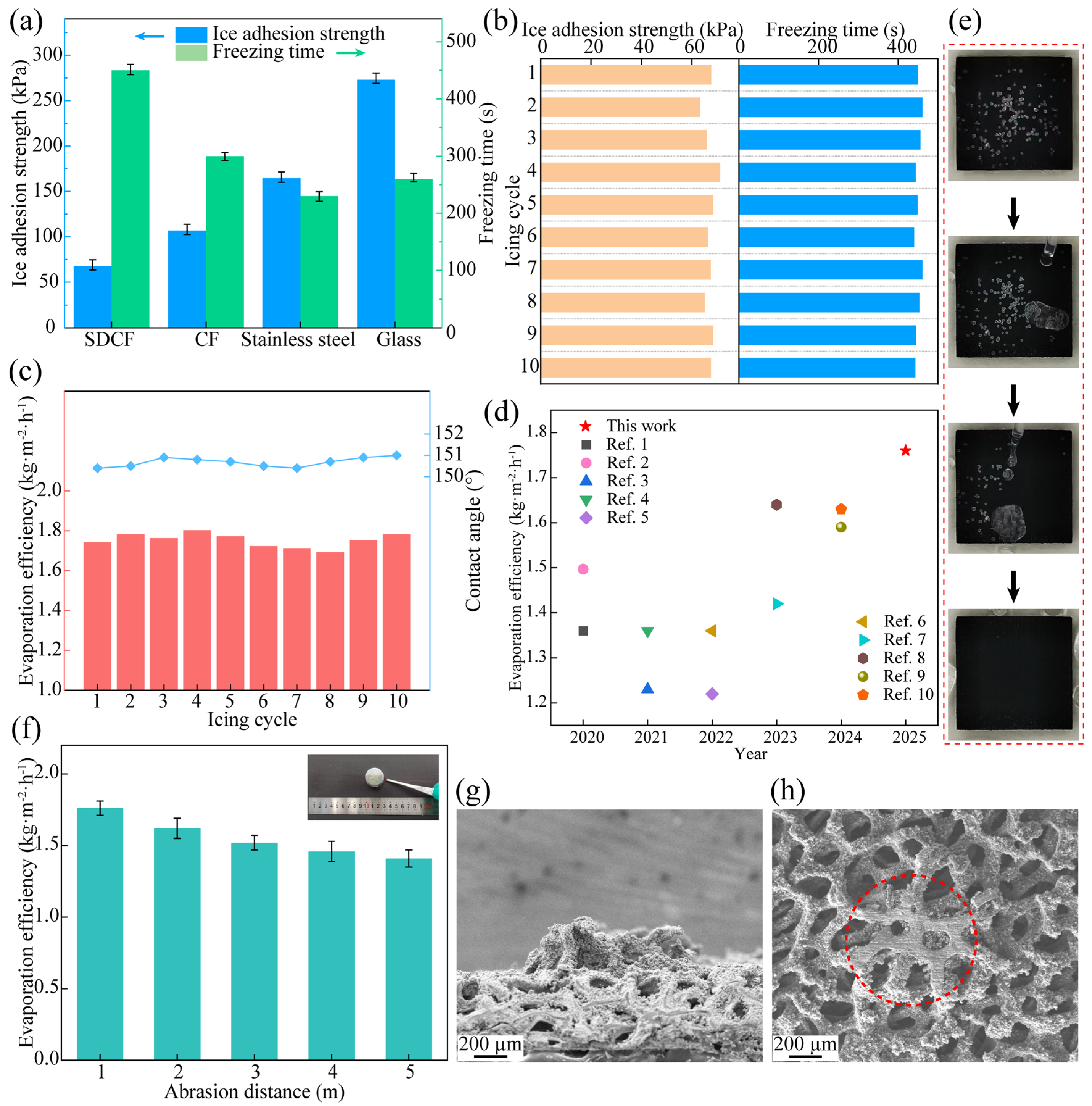

3.3. Anti-Deicing Performance and Durability of the SDCF

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, L.F.; Wang, P.F.; Che, H.N.; Chen, J.; Liu, B.; Ao, Y.H. Solar-driven interfacial water evaporation for wastewater purification: Recent advances and challenges. Chem. Eng. J. 2023, 477, 147158. [Google Scholar] [CrossRef]

- Nie, B.L.; Meng, Y.M.; Niu, S.M.; Gong, L.J.; Chen, Y.F.; Guo, L.J.; Li, X.; Wu, Y.C.; Li, H.J.; Zhang, W.W. Janus solar evaporators: A review of innovative technologies and diverse applications. Energy Environ. Sci. 2025, 18, 3502–3525. [Google Scholar] [CrossRef]

- Xiao, Y.; Guo, H.; Li, M.; He, J.; Xu, X.; Liu, S.; Wang, L.; James, T.D. Strategies for enhancing the photothermal conversion efficiency of solar-driven interfacial evaporation. Coord. Chem. Rev. 2025, 527, 216378. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Y.; Wang, H.; Liu, T.; Zheng, X.; Gao, S.; Lu, J. Recent advances in carbon-based materials for solar-driven interfacial photothermal conversion water evaporation: Assemblies, structures, applications, and prospective. Carbon Energy 2023, 5, e331. [Google Scholar] [CrossRef]

- Ivan, M.N.A.S.; Saha, S.; Saleque, A.M.; Ahmed, S.; Thakur, A.K.; Bai, G.; Miao, Z.; Saidur, R.; Tsang, Y.H. Progress in interfacial solar steam generation using low-dimensional and biomass-derived materials. Nano Energy 2024, 120, 109176. [Google Scholar] [CrossRef]

- Arunkumar, T.; Parbat, D.; Lee, S.J. Comprehensive review of advanced desalination technologies for solar-powered all-day, all-weather freshwater harvesting systems. Renew. Sustain. Energy Rev. 2024, 199, 114505. [Google Scholar] [CrossRef]

- Misra, U.; Barbhuiya, N.H.; Rather, Z.H.; Singh, S.P. Solar interfacial evaporation devices for desalination and water treatment: Perspective and future. Adv. Colloid Interface Sci. 2024, 327, 103154. [Google Scholar] [CrossRef]

- Zhan, Z.H.; Su, Y.; Xie, M.Z.; Li, Y.F.; Shuai, Y.; Wang, Z.L. Recent advances and challenges for bionic solar water evaporation. Mater. Today 2024, 80, 529–548. [Google Scholar] [CrossRef]

- Zhu, Z.; Xu, J.; Liang, Y.; Luo, X.; Chen, J.; Yang, Z.; He, J.; Chen, Y. Bioinspired Solar-Driven Osmosis for Stable High Flux Desalination. Environ. Sci. Technol. 2024, 58, 3800–3811. [Google Scholar] [CrossRef]

- Ma, J.; Sun, X.; Liu, Y.; Wang, L.; An, M.; Kim, M.; Yamauchi, Y.; Khaorapapong, N.; Yuan, Z. Bio-inspired 3D architectured aerogel evaporator for highly efficient solar seawater desalination. Nano Energy 2025, 137, 110781. [Google Scholar] [CrossRef]

- Bae, K.; Kang, G.; Cho, S.K.; Park, W.; Kim, K.; Padilla, W.J. Flexible thin-film black gold membranes with ultrabroadband plasmonic nanofocusing for efficient solar vapour generation. Nat. Commun. 2015, 6, 10103. [Google Scholar] [CrossRef] [PubMed]

- Qiao, P.; Wu, J.; Li, H.; Xu, Y.; Ren, L.; Lin, K.; Zhou, W. Plasmon Ag-Promoted Solar–Thermal Conversion on Floating Carbon Cloth for Seawater Desalination and Sewage Disposal. ACS Appl. Mater. Interfaces 2019, 11, 7066–7073. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Wang, W.; Li, D.; Xu, S.; Sun, Y.; Li, L.; Fan, K.; Xing, C.; Zhang, L.; Li, J. Multifunctional graphene/Ag hydrogel with antimicrobial and catalytic properties for efficient solar-driven desalination and wastewater purification. Chem. Eng. J. 2023, 478, 147249. [Google Scholar] [CrossRef]

- Fu, B.; Zhang, X.Y.; Robinson, N.; Zhang, Z.; Zhang, J.F.; Ji, J.P.; Xu, Y.M.; Zhang, K.D.; Dong, M.Y.; Kang, J.; et al. Multi-shelled hollow porous carbon nanospheres-based evaporator for highly efficient solar-driven desalination. Nano Energy 2024, 129, 110054. [Google Scholar] [CrossRef]

- Zhou, M.; Han, P.; Qi, G.; Gao, D.; Abdel-Ghafar, H.M.; Wang, Y.; Tao, S. Magnetic field induced the assembling of Photothermal evaporator for efficient solar-driven desalination. EcoMat 2023, 5, e12390. [Google Scholar] [CrossRef]

- Zhu, S.; Lei, Z.; Dou, Y.; Lou, C.-W.; Lin, J.-H.; Li, J. Sputter-deposited nickel nanoparticles on Kevlar fabrics with laser-induced graphene for efficient solar evaporation. Chem. Eng. J. 2023, 452, 139403. [Google Scholar] [CrossRef]

- Kang, H.S.; Zou, J.W.; Liu, Y.; Ma, L.; Feng, J.R.; Yu, Z.Y.; Chen, X.B.; Ding, S.J.; Zhou, L.; Wang, Q.Q. Synergistic Effect of Photothermal Conversion in MXene/Au@Cu2−xS Hybrids for Efficient Solar Water Evaporation. Adv. Funct. Mater. 2023, 33, 2303911. [Google Scholar] [CrossRef]

- Sun, J.; Farid, M.U.; Xi, W.; Lu, G.; Boey, M.W.; Ravi, S.K.; Sit, P.H.L.; An, A.K. Hydrogel-Based Photothermal-Catalytic Membrane for Efficient Cogeneration of Freshwater and Hydrogen in Membrane Distillation System. Adv. Funct. Mater. 2025, 24, 16768. [Google Scholar] [CrossRef]

- Zhou, P.; Zhu, Q.; Sun, X.; Liu, L.; Cai, Z.; Xu, J. Recent advances in MXene-based membrane for solar-driven interfacial evaporation desalination. Chem. Eng. J. 2023, 464, 142508. [Google Scholar] [CrossRef]

- Ihsanullah, I. Potential of MXenes in Water Desalination: Current Status and Perspectives. Nano-Micro Lett. 2020, 12, 72. [Google Scholar] [CrossRef]

- Wang, D.H.; Sun, Q.Q.; Hokkanen, M.J.; Zhang, C.L.; Lin, F.Y.; Liu, Q.; Zhu, S.P.; Zhou, T.F.; Chang, Q.; He, B.; et al. Design of robust superhydrophobic surfaces. Nature 2020, 582, 55–59. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Liu, M.J.; Zhang, X.Y.; Su, Z.Q. Construction of a biomimetic wood structure with cellulose nanofiber/molybdenum disulfide hybrid aerogel for highly-efficient solar-driven interfacial evaporation. Desalination 2023, 568, 117023. [Google Scholar] [CrossRef]

- Zhang, H.T.; Li, L.; He, N.; Wang, H.N.; Wang, B.S.; Dong, T.Y.; Jiang, B.; Tang, D.W. Bioinspired hierarchical evaporator via cell wall engineering for highly efficient and sustainable solar desalination. EcoMat 2022, 4, e12216. [Google Scholar] [CrossRef]

- Joo, B.S.; Lee, W.Y.; Lee, S.; Kim, J.H.; Kang, J.; Ko, H.Y.D.; Kang, G.M. Flower-shaped hierarchical CuO nanostructures for efficient solar desalination. Chem. Eng. J. 2025, 505, 159733. [Google Scholar] [CrossRef]

- Wu, S.; Xiong, G.; Yang, H.; Gong, B.; Tian, Y.; Xu, C.; Wang, Y.; Fisher, T.; Yan, J.; Cen, K.; et al. Multifunctional Solar Waterways: Plasma-Enabled Self-Cleaning Nanoarchitectures for Energy-Efficient Desalination. Adv. Energy Mater. 2019, 9, 1901286. [Google Scholar] [CrossRef]

- Li, W.Z.; Chu, D.K.; Wang, Q.W.; Yin, K.; Zhang, H.H.; Qu, S.S.; Yao, P. A salt pollution self-cleaning Al based solar desalination evaporator fabricated using a picosecond laser. J. Mater. Chem. C 2023, 11, 11234–11242. [Google Scholar] [CrossRef]

- Wang, Z.; Zhan, Z.; Chen, L.; Duan, G.; Cheng, P.; Kong, H.; Chen, Y.; Duan, H. 3D-Printed Bionic Solar Evaporator. Sol. RRL 2022, 6, 2101063. [Google Scholar] [CrossRef]

- Zheng, S.X.; Yang, M.Q.; Chen, X.; White, C.E.; Hu, L.B.; Ren, Z.J. Upscaling 3D Engineered Trees for Off-Grid Desalination. Environ. Sci. Technol. 2022, 56, 1289–1299. [Google Scholar] [CrossRef]

- Dong, X.Y.; Si, Y.; Chen, C.J.; Ding, B.; Deng, H.B. Reed Leaves Inspired Silica Nanofibrous Aerogels with Parallel-Arranged Vessels for Salt-Resistant Solar Desalination. ACS Nano 2021, 15, 12256–12266. [Google Scholar] [CrossRef]

- Zhou, P.; Fan, W.; Sun, Y.; Zhao, Y.; Sun, F.; Xu, J. Highly efficient hydrothermal management, shape-controlled 3D conical aerogels for solar high-salinity seawater desalination and water purification. Chem. Eng. J. 2024, 498, 155529. [Google Scholar] [CrossRef]

- Zhou, R.; Liao, L.; Chen, Z.; Zhong, L.; Xu, X.; Han, Y.; Zhong, Y.; Zheng, Y.; Yao, R. Fabrication of monolithic rGO/SiC(O) nanocomposite ceramics via precursor (polycarbosilane-vinyltriethoxysilane-graphene oxide) route. Ceram. Int. 2018, 44, 14929–14934. [Google Scholar] [CrossRef]

- Patil, A.J.; Jackson, O.; Fulton, L.B.; Hong, D.; Desai, P.A.; Kelleher, S.A.; Chou, D.T.; Tan, S.S.; Kumta, P.N.; Beniash, E. Anticorrosive Self-Assembled Hybrid Alkylsilane Coatings for Resorbable Magnesium Metal Devices. ACS Biomater. Sci. Eng. 2017, 3, 518–529. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.; Li, Y.; Wu, R.; Wang, X.; Qin, J.; Fu, Y.; Qin, M.; Wang, Z.; Zhang, Y.; Zhang, F. Bilayer Designed Paper-Based Solar Evaporator for Efficient Seawater Desalination. Nanomaterials 2022, 12, 3487–3496. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Lv, J.; Wang, B.; Zhang, L.; Zhong, Y.; Sui, X.; Xu, H.; Mao, Z. Robust, floatable, steam generator based on the graded porous polyimide film for efficient solar desalination. Polym. Adv. Technol. 2021, 32, 3436–3445. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, X.; Fan, D.; Yang, H.; Xu, H.; Min, H.; Yang, X. Biomass derived Janus solar evaporator for synergic water evaporation and purification. Sustain. Mater. Technol. 2020, 25, 180–189. [Google Scholar] [CrossRef]

- Li, J.; Zhou, X.; Jing, Y.; Sun, H.; Zhu, Z.; Liang, W.; Li, A. Ionic Liquid-Assisted Alignment of Corn Straw Microcrystalline Cellulose Aerogels with Low Tortuosity Channels for Salt-Assistance Solar Steam Evaporators. ACS Appl. Mater. Interfaces 2021, 13, 12181–12190. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, Z.; Liu, Y.; Yi, J.; Wang, Y.; Li, B.; Wang, W.; Peng, S.; Min, X.; Gui, Y.; et al. Full bagasse bio-waste derived 3D photothermal aerogels for high efficient solar steam generation. Cellulose 2021, 29, 927–939. [Google Scholar] [CrossRef]

- Meng, T.; Li, Z.; Wan, Z.; Zhang, J.; Wang, L.; Shi, K.; Bu, X.; Alshehri, S.M.; Bando, Y.; Yamauchi, Y.; et al. MOF-Derived nanoarchitectured carbons in wood sponge enable solar-driven pumping for high-efficiency soil water extraction. Chem. Eng. J. 2023, 452, 139193–139201. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Jiang, B.; Zhang, Q.; Ma, J.; Tang, D.; Song, Y. Highly Thermally Insulated and Superhydrophilic Corn Straw for Efficient Solar Vapor Generation. ACS Appl. Mater. Interfaces 2020, 12, 16503–16511. [Google Scholar] [CrossRef]

- Liu, C.; Wu, P. A durable hydrophobic photothermal membrane based on a honeycomb structure MXene for stable and efficient solar desalination. RSC Adv. 2024, 14, 10370–10377. [Google Scholar] [CrossRef]

- Zhou, J.; Xing, R.; Wu, Y.; Shen, M.; Wang, W.; Li, M.; Xiong, J.; Min, X. Full tea waste-based photothermal aerogel with vertical water transport channels for steady solar desalination. Ind. Crops Prod. 2024, 212, 118363–118371. [Google Scholar] [CrossRef]

- Qin, J.; Xu, W.; Li, Y.; Wang, X.; Wu, R.; Fu, Y.; Qin, M.; Zhang, Y.; Xu, C. Engineering salt-rejecting solar evaporator from naturally hierarchical tree root for sufficient clean water production. Ind. Crops Prod. 2023, 196, 116507–116514. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, C.; Yang, G.; Yuan, K.; Liu, L. Super-Hydrophobic Photothermal Copper Foam for Multi-Scenario Solar Desalination: Integrating Anti-Icing, Self-Cleaning, and Mechanical Durability. Coatings 2025, 15, 578. https://doi.org/10.3390/coatings15050578

Shao C, Yang G, Yuan K, Liu L. Super-Hydrophobic Photothermal Copper Foam for Multi-Scenario Solar Desalination: Integrating Anti-Icing, Self-Cleaning, and Mechanical Durability. Coatings. 2025; 15(5):578. https://doi.org/10.3390/coatings15050578

Chicago/Turabian StyleShao, Chen, Guojian Yang, Kang Yuan, and Liming Liu. 2025. "Super-Hydrophobic Photothermal Copper Foam for Multi-Scenario Solar Desalination: Integrating Anti-Icing, Self-Cleaning, and Mechanical Durability" Coatings 15, no. 5: 578. https://doi.org/10.3390/coatings15050578

APA StyleShao, C., Yang, G., Yuan, K., & Liu, L. (2025). Super-Hydrophobic Photothermal Copper Foam for Multi-Scenario Solar Desalination: Integrating Anti-Icing, Self-Cleaning, and Mechanical Durability. Coatings, 15(5), 578. https://doi.org/10.3390/coatings15050578