2.1. Material

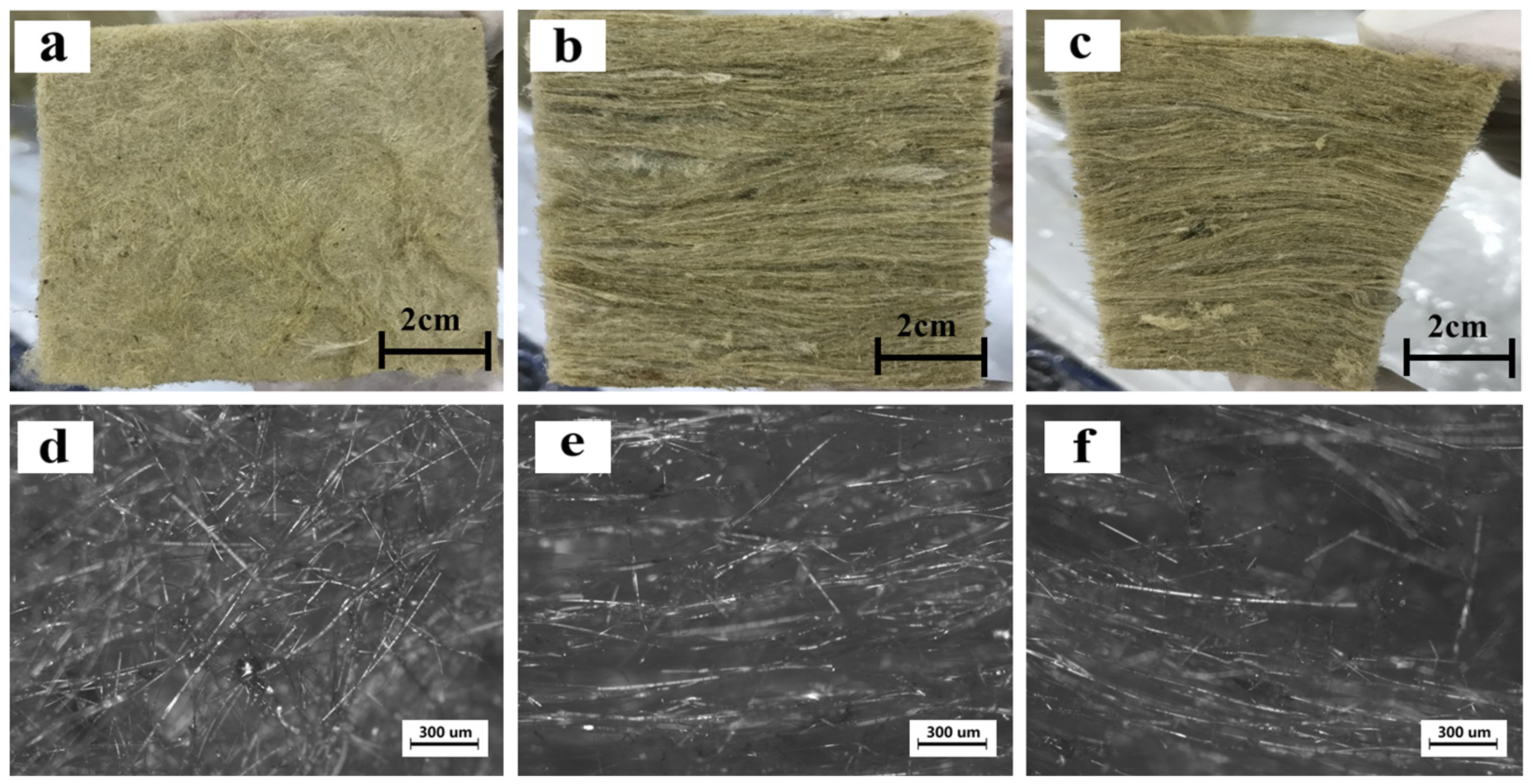

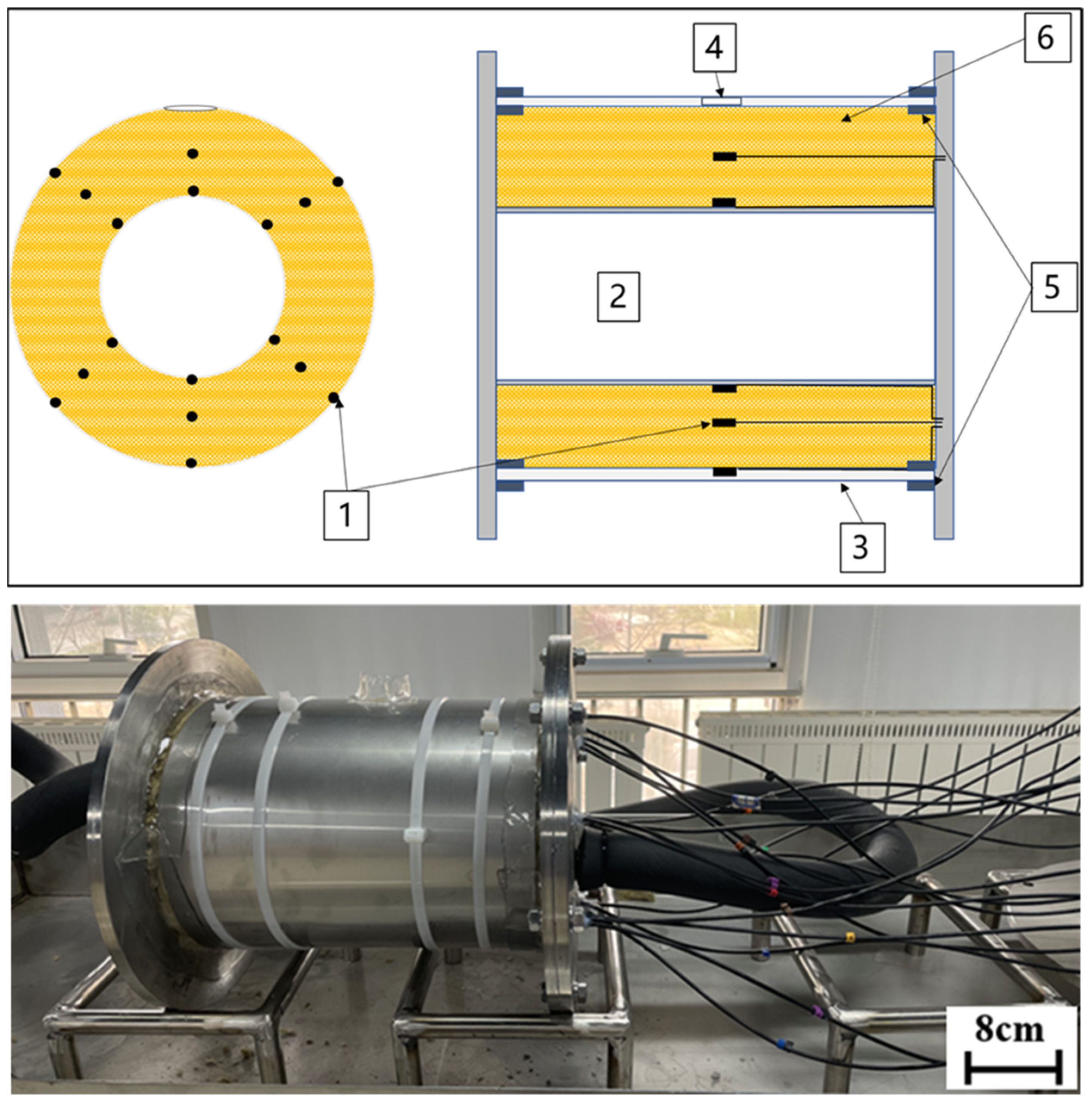

As shown in

Figure 1, rock wool pipe insulation material was selected for investigation. This insulation was a pipe shell—a hollow cylinder with a concentric ring cross-section featuring an inner diameter of 115 mm and a thickness of 50 mm. Generally, the inner surface fits over the metal pipe, while the outer surface is often covered with a waterproof or fireproof protective layer. Due to the forming process, fibers within the rock wool are aligned in specific directions, resulting in distinct pore structures. According to the cylindrical coordinate system, the rock wool pipe shell is divided into three orientations: the axial direction, which is parallel to the cylinder’s axis of symmetry; the radial direction, which is perpendicular to that axis; and the circumferential direction, which runs tangentially around the circumference.

Figure 2 combines macroscopic (

Figure 2a–c) and microscopic (

Figure 2d–f) images to reveal significant variations in the arrangement of rock wool fibers when viewed from different directions. These differences in fiber alignment result in distinct structural characteristics, which in turn affect the fluid flow through the material by altering both viscous resistance (arising from pore geometry and surface friction) and inertial resistance (resulting from flow deflection and localized acceleration at higher velocities). In the images, the viewing direction aligns with the previously defined orientations of the rock wool pipe shell, so the observed cross-sections are the planes perpendicular to each of these three orientations. In other words, when fluid flows along these orientations, it directly encounters the structural resistance depicted in

Figure 2. For instance, in images

Figure 2a,d (perpendicular to the radial orientation), the fibers appear randomly yet uniformly arranged, forming densely packed, layered pores; in contrast, the cross-sections perpendicular to the circumferential and axial orientations (shown in images

Figure 2b,c,e,f) exhibit more parallel fiber arrangements, with pores that vary in size and extend preferentially along the axial direction in b and e and along the circumferential direction in

Figure 2c,f.

Porosity is defined as the ratio of void volume to total volume of the porous medium. It is measured experimentally or provided by the manufacturer. In this study, the porosity of the rock wool used reached 95%.

2.2. Modelling

For the purpose of simulating the flow dynamics of water entering the pipeline insulation system, the following assumptions were adopted:

The porosity of the porous medium is uniform;

The fluid is incompressible;

The viscosity of the fluid is considered constant;

The influence of wall friction is neglected.

This study employed CFD simulations to analyze the multiphase flow within rock wool insulation surrounding a pipeline. The simulations were conducted using ANSYS Fluent, a comprehensive CFD software capable of modeling complex interactions in porous media. The methodology integrates fundamental theories of porous media flow, including Darcy’s law, the Forchheimer equation, and the Darcy-Forchheimer model, to accurately represent the resistance to flow within the insulation material. Key aspects of the methodology include the formulation of governing equations, incorporation of relevant physical models, determination of critical parameters, and validation against experimental data.

The Darcy–Forchheimer extended model was used to mathematically analyze the nonlinear flow characteristics of the porous medium. Its essence was to introduce an additional source term into the momentum equation based on the standard Navier–Stokes equation with the help of the relationship between the real flow velocity and the apparent flow velocity, and to prove the viscosity and inertia moment of the material by describing the source fluid. Different from the Darcy seepage model, there were nonlinear terms in the Darcy–Forchheimer extended model to describe the change of flow direction in the material. The equations of the continuity equation and the momentum equation are as follows:

The momentum equation:

where

is the porosity,

is the fluid density (kg/m

3),

is the velocity (m/s),

is the time (s),

is the pressure (Pa), and

is the shear stress (N/m

2).

In Formula (2), the source term

of the momentum equation reflects the definition of viscosity and inertial resistance caused by the influence of the porous material skeleton as follows:

where

represents dynamic viscosity(Pa·s), 1/

is the viscous resistance coefficient, and C

2 represents the inertial resistance coefficient.

The real flow rate and the apparent flow rate are related by porosity as follows:

where

is the apparent velocity of the fluid in the porous material, and

is the actual flow velocity in the porous material.

In the source term of the momentum equation, the viscous resistance term describes the seepage process in the porous material based on Darcy’s law, and the inertial resistance term is introduced to describe the velocity loss of the airflow in the porous material. The definitions of viscous resistance and inertial resistance are as follows:

Viscous resistance: When a fluid flows slowly in a porous medium, ignoring the convection and diffusion effects and assuming that there is no inertial resistance, the pressure gradient will be proportional to the fluid flow rate, which is a simplified form of Darcy’s law, and the pressure drop expressions in the x, y, and z directions are as follows:

Inertial resistance: When the fluid flows at high speed in a porous medium, C

2 in Equation (3) can be regarded as the inertial loss coefficient per unit length in the flow direction. If the fluid viscosity loss is not considered, the simplified momentum equation in the porous medium is expressed as follows:

Since the diffusion Darcy model is used to simulate the nonlinear flow characteristics of the fluid between the pores of the porous medium, the source term in the momentum equation reflects the viscosity and inertial resistance of the fluid flowing through the porous material. According to Equations (3), (5) and (6), a one-way simplified expression relationship can be obtained:

Thus,

where

is the length of the porous medium material through which the fluid flows.

Consequently, the viscous and inertial resistance coefficients of the porous medium can be directly derived from the pressure drop–velocity data obtained in Darcy flow experiments. These coefficients are then integrated into the mass-transfer model for the porous medium, ensuring that the CFD simulations closely reflect real operating conditions.

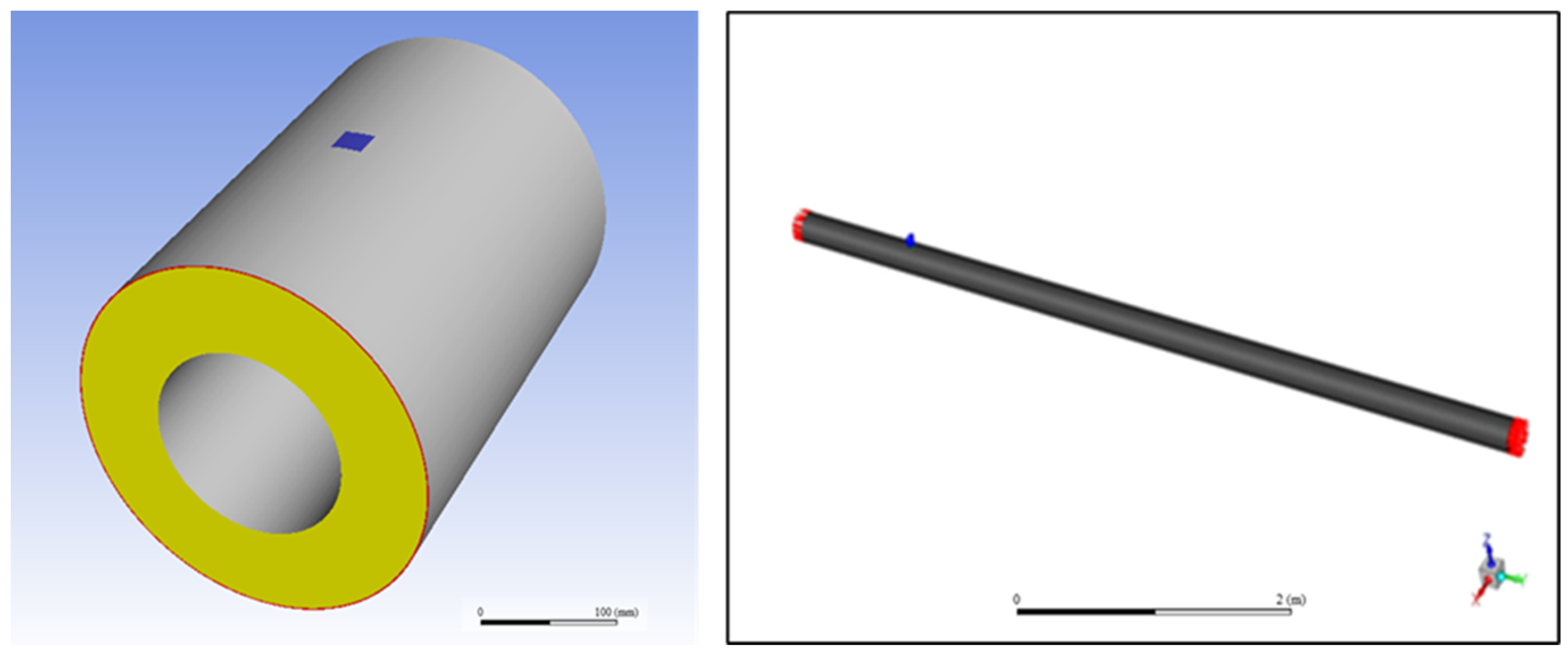

After obtaining the viscous and inertial drag coefficients through experiments and calculations, two three-dimensional simulation models were established: a small-scale model and a large-scale model. For the small one, according to the size of the actual rock wool insulation shell and the size of the experimental device, a hollow cylindrical model with an inner diameter of 115 mm, an outer diameter of 215 mm, a thickness of 50 mm, and a length of 300 mm was established as porous zone. In addition, two 1 mm-thick non-porous fluid domains were included on the inner and outer sides of the porous zone, respectively, to represent the gaps between the insulation and the metal pipe surface and between the insulation and the external protective layer. A 20 × 20 mm water inlet was left at the center of the horizontal top of the shell. For the large-scale model, the thicknesses of the fluid zones were established the same as the small one, but the length reached 6 m, and the inlet was located at a distance of 1 m from one outlet side, as illustrated in

Figure 3.

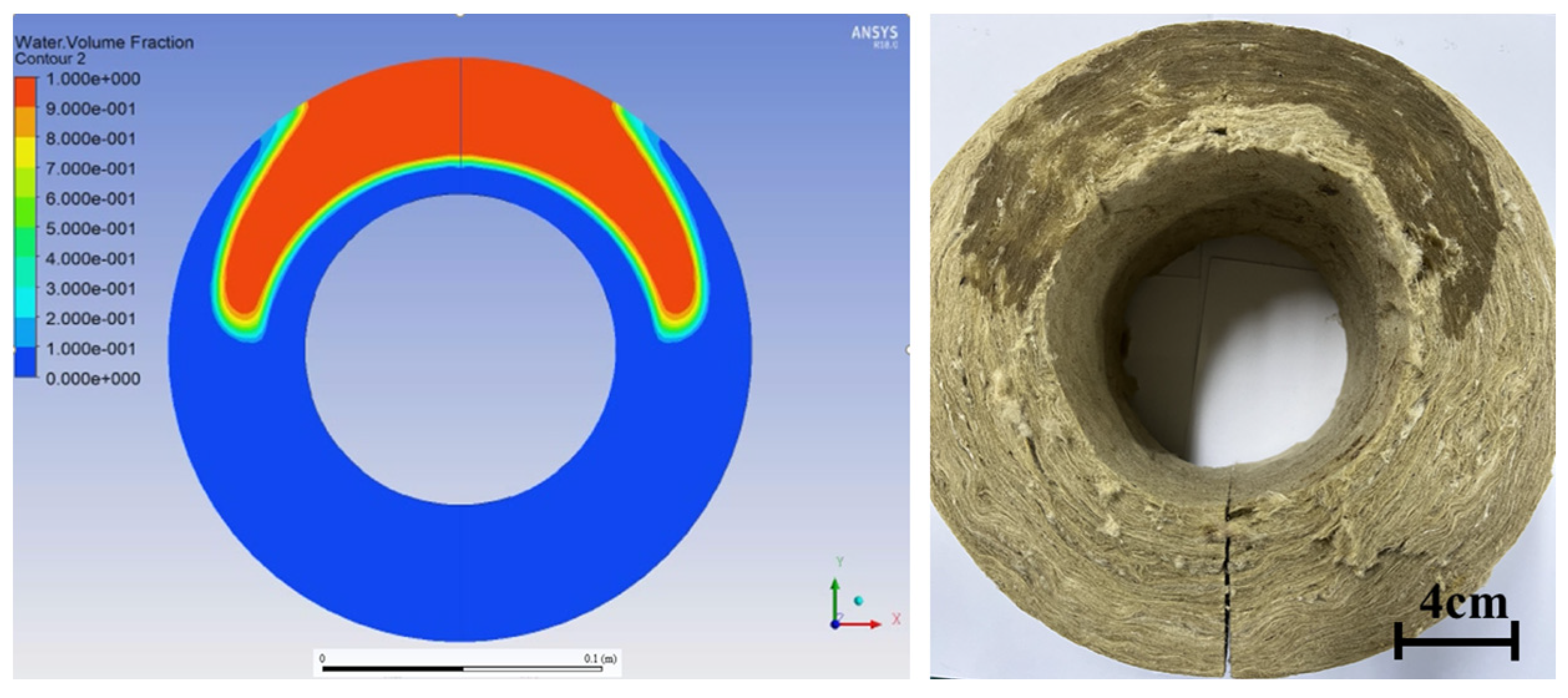

After completing the grid generation and quality inspection, a mesh sensitivity analysis was performed to ensure the accuracy and reliability of the simulation results. Different mesh densities were tested, and the results were compared to identify an optimal mesh that provides stable and accurate predictions of the fluid flow. Following this analysis, the CFD software ANSYS-FLUENT 17.0 was employed to simulate the environmental conditions of CUI using the volume of fluid (VOF) model to capture the flow process of both the liquid water and the air phases within insulated piping systems.

The k–ω SST turbulence model was selected, and transient simulations were performed with the influence of gravity taken into account. To ensure accurate near-wall resolution with the k–ω SST model, five uniform inflation layers were applied to all pipe walls, with the first layer thickness set to 0.02 mm and all layers having equal thickness (growth rate = 1). This mesh arrangement guarantees that the dimensionless wall distance y+ remains below 1 for all wall cells, placing them entirely within the viscous sublayer. Post-processing via Fluent’s Wall-Y+ contours confirmed that y+ never exceeded 1, demonstrating the adequacy of the mesh refinement and wall treatment. For the small-scale model, the inlet velocity was set at 0.005 m/s with a 100% liquid phase volume fraction. The top opening of the insulation layer faced vertically downward into the porous region, while all other boundaries were treated as no-slip walls. The computational domain was selected as the porous medium region, where the porosity was defined as 0.95 (matching the actual porosity of the rock wool insulation material). The experimentally determined viscous and inertial resistance coefficients were used as input parameters to define the porous medium properties. Since the model only involves mass transfer and does not account for temperature effects, a default temperature of 300 K was assumed. During the solution of the momentum and continuity equations, the pressure and velocity were coupled using the SIMPLE algorithm, and pressure discretization was carried out with the PRESTO scheme. Because the main parameters evolve over time, the calculation was performed as a transient simulation. After verifying time-independence, a time step of 0.05 s was chosen, with 20 iterations per time step to ensure convergence (with a convergence criterion set to a residual of less than 10−3 for both the continuity and momentum equations). The inlet boundary condition was maintained for 300 s, after which the flow was halted, and the subsequent redistribution of water was monitored. During the simulation, the velocity, pressure, and liquid water content were tracked over time to capture the transient flow behaviors.

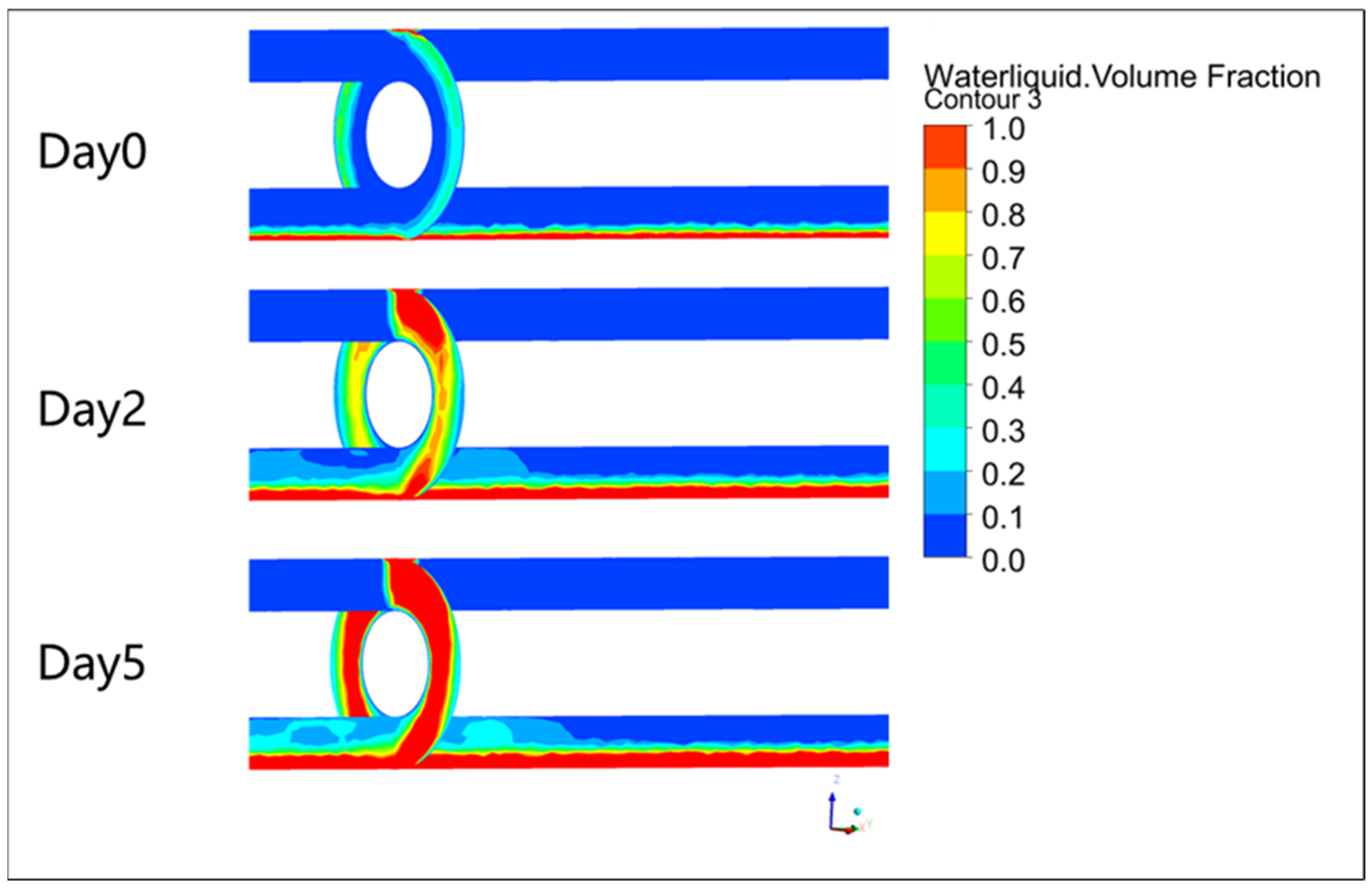

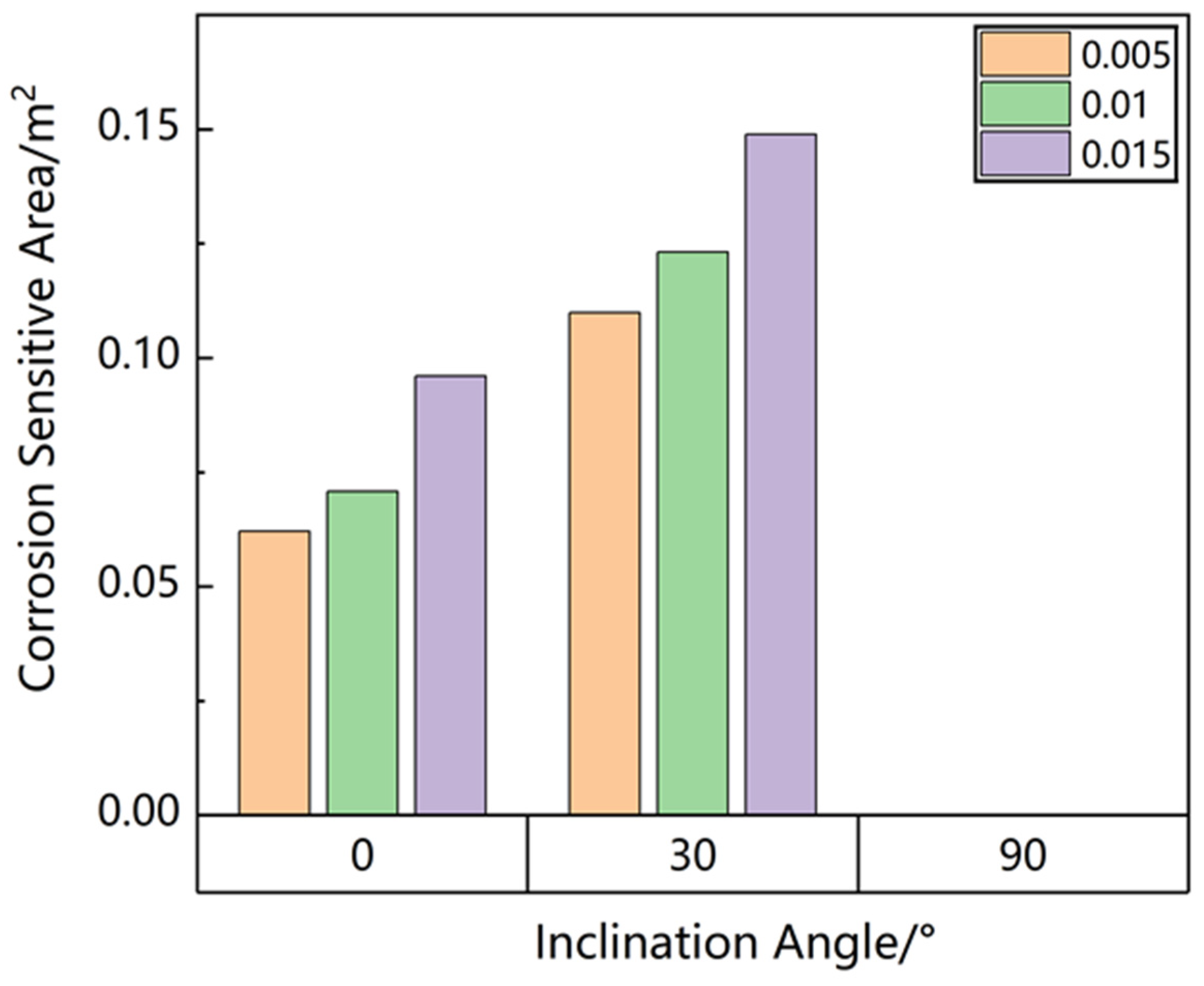

For the large-scale models, they were constructed based on the verified small-size models. A series of different conditions was investigated: inlet velocities were 0.005 m/s, 0.01 m/s, and 0.015 m/s; rock wool at three aging states (Day 0, Day 2, and Day 5, representing the new, relatively new, and old rock wool, which will be mentioned in the following experiments); different pipe inclination angles were 0° (horizontal), 30°, and 90° (vertical). These combinations aimed to mimic various real-world scenarios in which fluid flow through the pipe insulation could form corrosive conditions conducive to CUI. To optimize computational resources and address varying convergence rates under different flow conditions, an adaptive time-step scheme was used, with a minimum simulated duration of 3000 s for all cases.

2.3. Experiments

In this section, two experiments are presented: one is the data measurement of fluid flowing through rock wool material, and the other is the experiment simulating water entering the pipe insulation system as a verification experiment for the small-scale simulation model.

Due to the addition of hydrophobic agents in rock wool insulation—especially in newly produced material, where the high concentration of hydrophobic agents results in very strong surface hydrophobicity—liquids have difficulty penetrating and fully distributing within the insulation layer. This, in turn, affects the measurement of mass transfer resistance coefficients and the subsequent simulation of corrosion environments. Therefore, before investigating the porous mass transfer resistance coefficients of rock wool insulation, it is essential to fully consider the impact of its hydrophobicity on fluid behavior. In this study, a series of cyclic immersion-drying experiments on rock wool insulation were designed and conducted to simulate the gradual decay of hydrophobic performance that occurs after a period of service. This pre-treatment provided the necessary experimental materials for subsequent tests.

A semi-cylindrical sample with an inner diameter of 115 mm, a thickness of 50 mm, and a length of 300 mm was prepared in this experiment. During the immersion experiment, the sample was completely submerged in a rectangular water tank (1000 mm × 600 mm × 500 mm) filled with deionized water. Due to the strong hydrophobicity of the material—especially in newly produced rock wool with a high concentration of hydrophobic agents—the surface resists wetting, leading to the formation of air layers on both the surface and within localized regions. Consequently, the overall density of the sample becomes lower than that of water, causing it to float. To counter this, a weighting bracket was employed to press the sample at least 20 mm below the water surface. The design of the bracket ensured that the sample was completely submerged without being deformed. The water tank was also equipped with a thermostatic heating rod to maintain the water temperature.

The experimental procedure was as follows: The rock wool sample was fully immersed in deionized water heated to 90 °C and maintained at that constant temperature. Under the action of the weighting bracket, the sample remained stationary in the water for 24 h. After 24 h, the sample was removed and allowed to drain on a sieve for one hour, then transferred to a drying oven at 90 °C for 5 h (a duration verified to achieve complete drying), thus completing one immersion–drying cycle. Experiments were conducted for 1, 2, 3, 4, and 5 cycles, with three parallel tests for each cycle, resulting in three samples under identical conditions for subsequent flow and mass transfer experiments. Since each cycle involved one day of immersion, the samples were labeled as Day 1 through Day 5 according to the number of cycles performed, and Day 0 represented new rock wool.

This repeated immersion and drying process simulates the gradual decay of hydrophobic performance that occurs in real-world applications after prolonged use. The high-temperature water accelerates partial hydrolysis or deactivation of the hydrophobic agents, thereby rendering the material’s mass transfer characteristics more representative of those in insulation materials exposed to liquid media (such as rainwater, condensate, or steam) over extended periods.

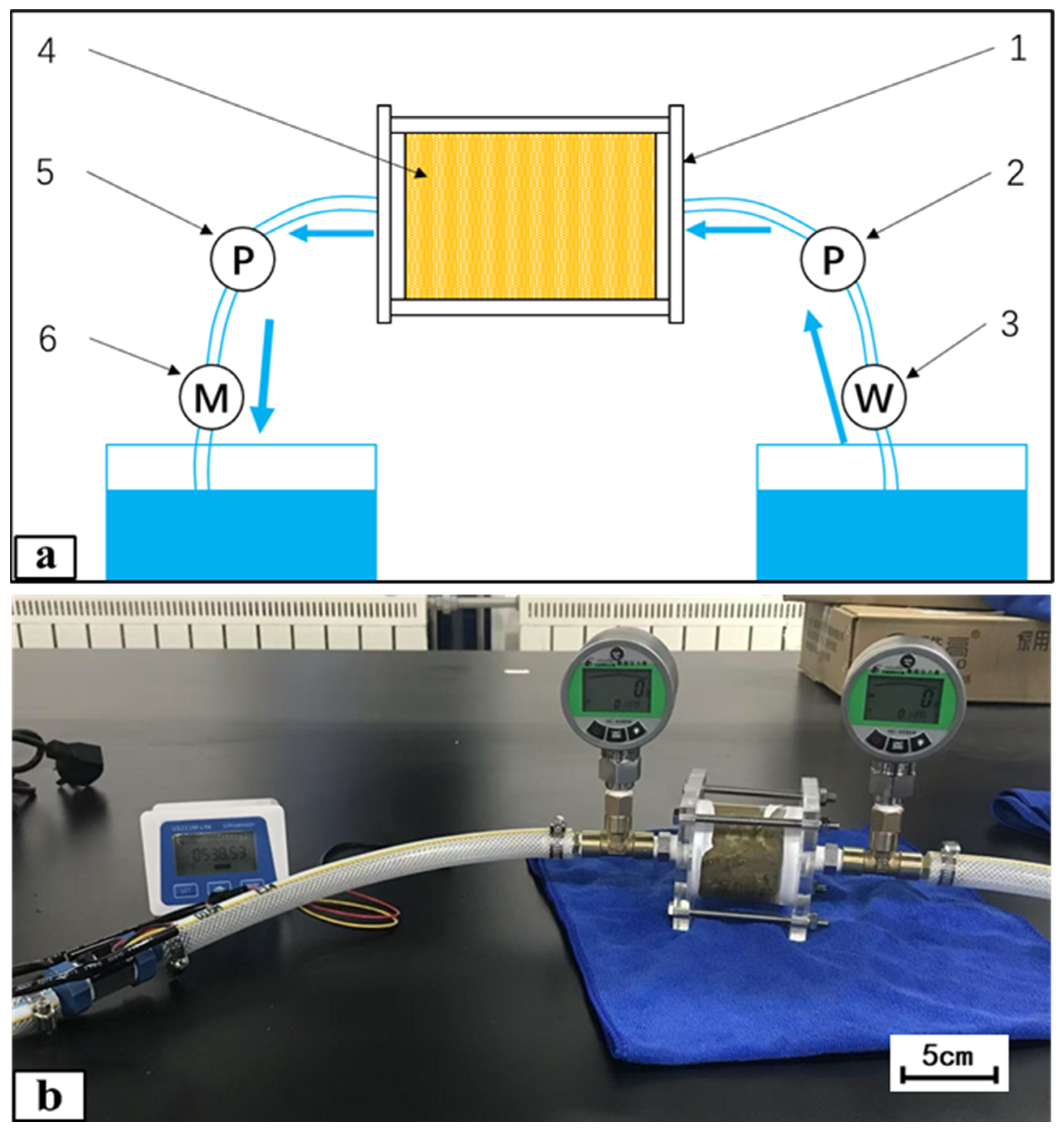

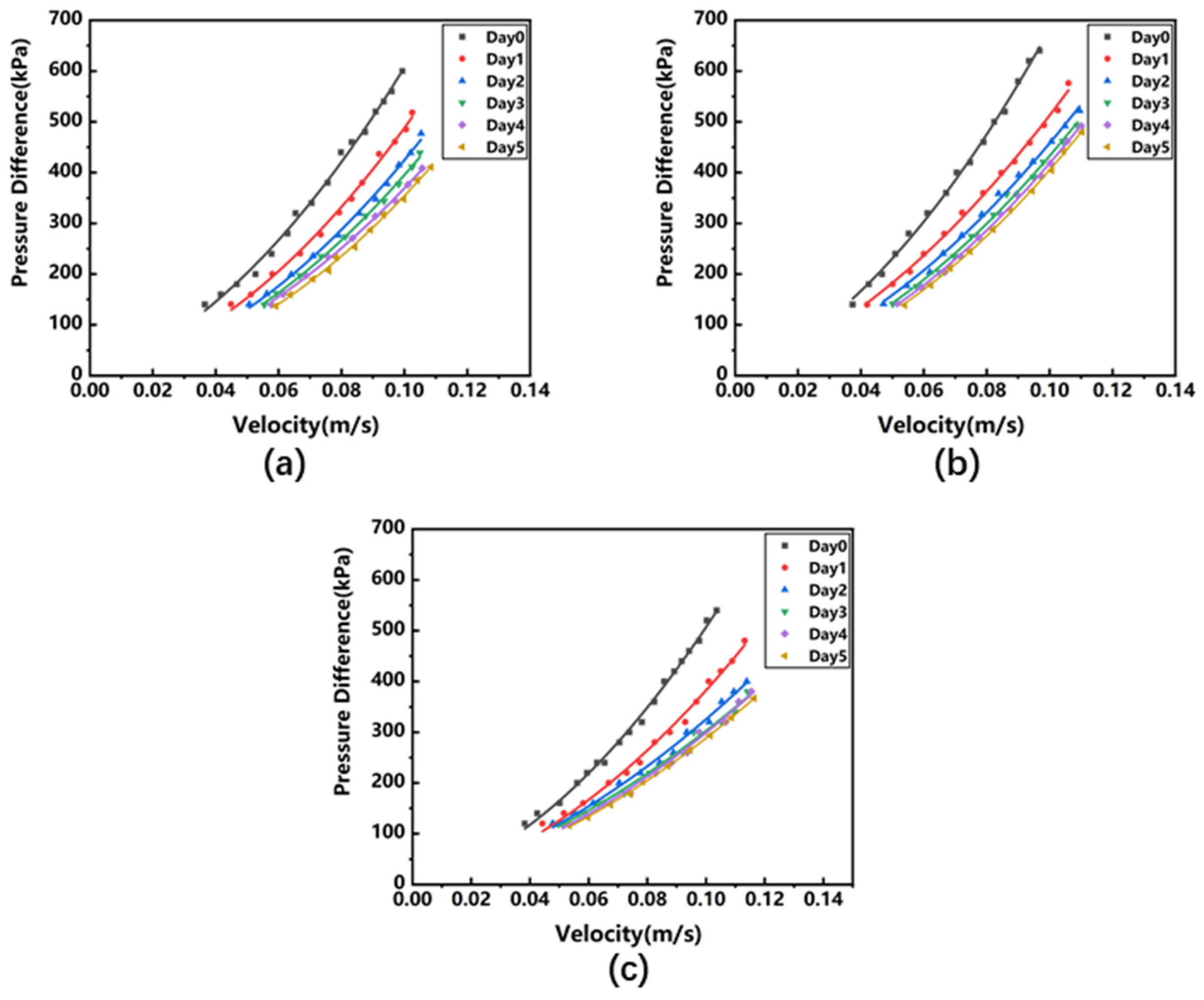

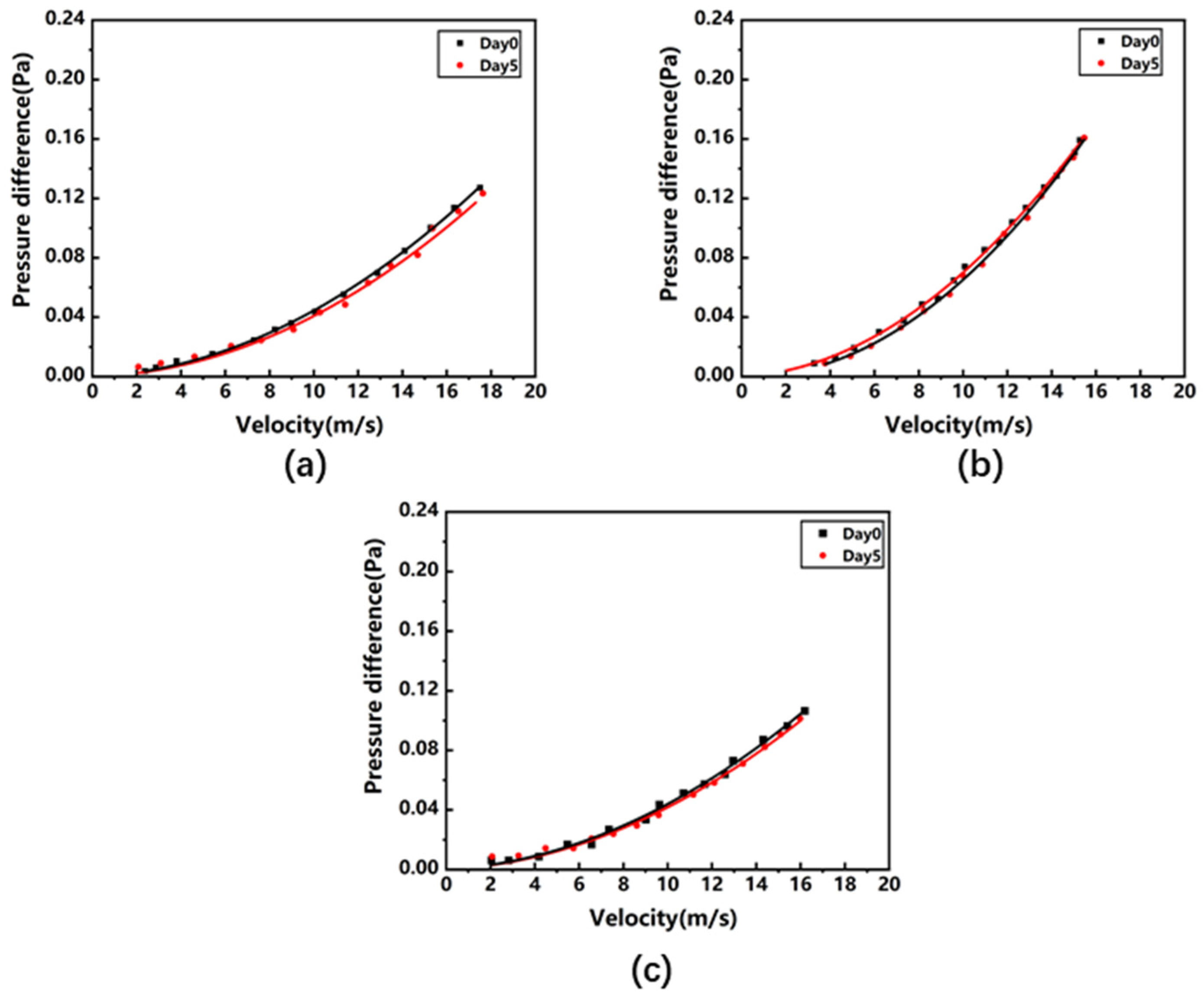

2.3.1. Porous Media Flow Experiments

Figure 4 illustrates a measurement apparatus for determining the mass transfer coefficients in porous media, specifically designed for rock wool insulation. The apparatus is based on the conventional Darcy experimental setup and is tailored to the geometric dimensions of the rock wool insulation shell (inner diameter 115 mm, outer diameter 215 mm, thickness 50 mm). The apparatus includes an acrylic tubular experimental container (transparent for easy observation) with an inner diameter of 50 mm (matching the insulation shell thickness), a length of 60 mm (slightly longer than the sample to allow for fluid accommodation), and a wall thickness of 3 mm. High-precision digital pressure gauges (denoted as P in the figure), with a range of 0–1.6 MPa and an accuracy of 0.1 grade (±1.6 kPa measurement error), are installed at both ends of the container to monitor pressure during flow. On the inlet side, a water pump draws water from a reservoir and injects it into the flow channel, creating a liquid flow system; at the outlet, a liquid flow meter measures the flow rate and converts it into flow velocity. Additionally, the connecting pipes are sufficiently long to ensure a stable flow state (with the inlet pipe length set at 1.2 m, and the outlet at 1 m, using PVC pipes with an inner diameter of 12 mm). Before introducing the rock wool sample, baseline (blank) tests were conducted with an empty container to record systematic pressure drops at various flow rates. These measurements reflect inherent losses due to structural changes and friction within the flow channel, independent of the porous sample. When experiments are performed with the rock wool sample in place, the measured pressure drop values are adjusted by subtracting these inherent system losses. This procedure yields the additional pressure drop attributed solely to the porous structure of the rock wool sample, allowing for a more accurate calculation of the viscous and inertial resistance coefficients. The rock wool experimental samples were prepared using a metal cylinder with an inner diameter of 50 mm, which was processed into a thin “cylindrical cutter” to directly encase and trim the material along the three orientations shown in

Figure 1. The circumferential orientation was obtained by cutting tangentially. As the sample diameter matched the inner diameter of the apparatus, the samples could be installed with a precise and seamless fit.

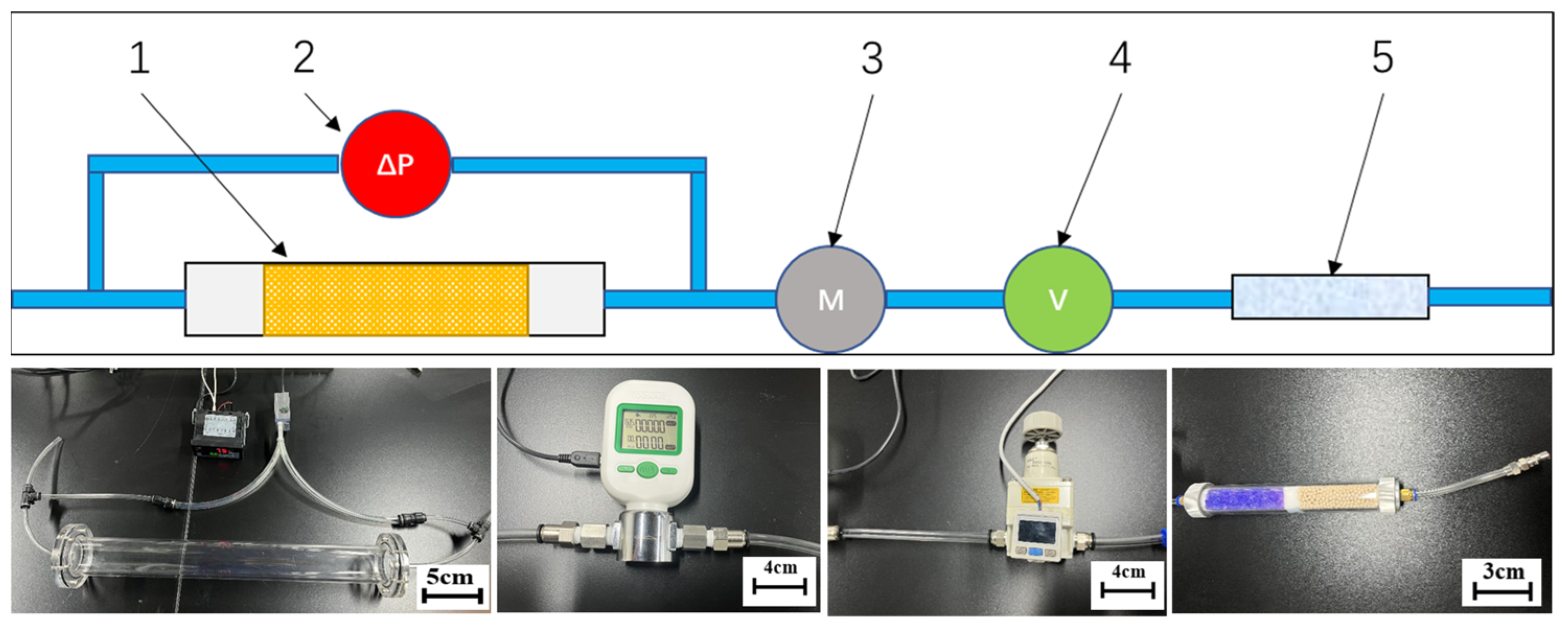

In order to study the flow characteristics of the gas phase in the rock wool porous medium domain, similar to the liquid phase flow experiment, a gas phase rock wool porous medium coefficient measurement experimental device, as shown in

Figure 5, was designed and built. According to the geometric dimensions of the rock wool insulation layer material (tube shell with an inner diameter of 115 mm, an outer diameter of 215 mm, and a thickness of 50 mm), an experimental device for measuring the porous medium mass transfer coefficient of the rock wool insulation material was designed. The device includes an acrylic tubular experimental container with an inner diameter of 50 mm, a length of 300 mm, and a thickness of 3 mm, which is used to fill the rock wool insulation material to form a porous medium channel. The channel length designed here is longer than that of the liquid phase flow device in order to ensure that the pressure difference value ∆p measured in the experiment can be within the measurement range that adapts to the instrument range by controlling the longer porous medium domain length ∆n. The two ends of the container are respectively connected to the two ends of the gas differential pressure sensor, and the pressure difference value at both ends of the experimental area can be directly monitored by the differential pressure sensor under gas experimental conditions. The gas pumped out by the external air pump will enter the porous medium test area from the inlet side through the dry clean pipe, pressure reducing valve, and gas flow meter in sequence. The function of the dry clean pipe is to absorb impurities and water vapor flowing through the gas, reduce experimental errors and protect subsequent instruments; the function of the pressure reducing valve is to adjust the pressure, stabilize the airflow, and control the gas flow (flow rate) in the experiment, which makes up for the deficiency that the air pump cannot accurately control the output; the gas flow meter monitors the gas flow in the pipeline to ensure whether the system state is stable or not, and the recorded data are used for the subsequent conversion of the gas flow rate in the porous medium domain. The cylindrical rock wool insulation material with a diameter of 50 mm is obtained from the axial, radial, and circumferential directions for the gas phase porous medium flow experiment. Unlike the liquid phase flow experiment that only uses one sample at a time, after debugging and verification, the gas phase flow experiment needs to use 5 pieces of experimental materials at a time to generate a sufficient gradient of pressure difference values distributed in the range of the pressure difference sensor at different flow rates.

In this series of experiments, both liquid and gas phases were introduced at varying inlet flow rates. By recording multiple sets of pressure differences and flow rates, the measurement devices provided the data necessary to determine the viscous and inertial resistance coefficients.

2.3.2. Model Validation Experiments

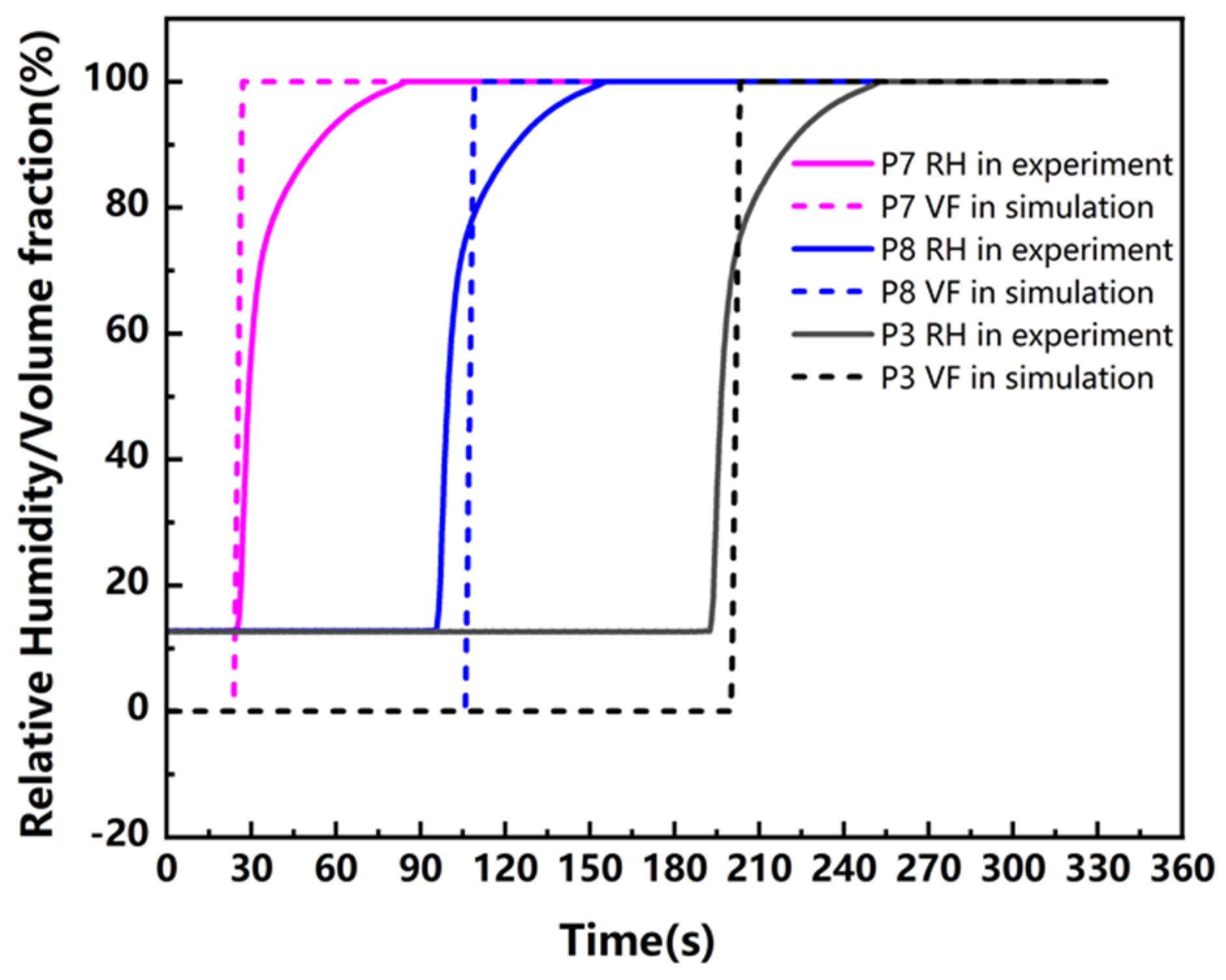

In order to verify the 3D simulation model of the liquid flow in rock wool insulation pipeline system, an experimental verification device was designed. As shown in

Figure 6, this device was mainly composed of a metal pipe, rock wool insulation, and jacketing layers. The metal pipe, with an outer diameter of 114.3 mm, was made of 316 L, which provided support for the insulation shell. The rock wool pipe insulation shell with 115 mm inner diameter and 50 mm thickness was installed on the pipe, and the jacketing made of 316 L was covered over the insulation to create a closed insulated piping system. A 20 mm × 20 mm hole was left above the jacket layer as the inlet for the fluid. On both sides of the device were flanges with holes for the sensor wires to pass through. In this experiment, relative humidity sensors were used to detect water flow within this insulated piping system. As illustrated in

Figure 6, the layout of the sensors is shown. Starting from the sensor at the top of the innermost circle and proceeding clockwise, the sensors are numbered 1 through 6. Similarly, for the middle layer, beginning with the top sensor and moving clockwise, the sensors are numbered 7 through 12. The outermost layer is numbered 13 through 18 in the same fashion. Note that the sensor located at the very top water inlet is omitted from the numbering.

In this experiment, old insulation (Day 5) was used. First, the sensors were activated to begin recording data. Liquid water was injected through the designated inlet at the top of the apparatus at a flow rate corresponding to a velocity of 0.005 m/s. The injection was stopped after 100 s, 200 s, and 300 s, respectively. The apparatus was then opened, and the rock wool insulation was cut along the inlet plane to observe the water distribution within the material, and the collected sensor data were analyzed. Because the processes of opening the apparatus and cutting the rock wool were irreversible, stopping the experiment at 100 s and 200 s effectively marked its conclusion. Therefore, in order to capture a continuous 300 s experiment and its intermediate stages, three separate experiments were conducted.