Analysis of Rammed Earth Wall Erosion in Traditional Village Dwellings in Zhuhai City

Abstract

1. Introduction

1.1. Background and Purpose

1.2. Literature Review

2. Materials and Methods

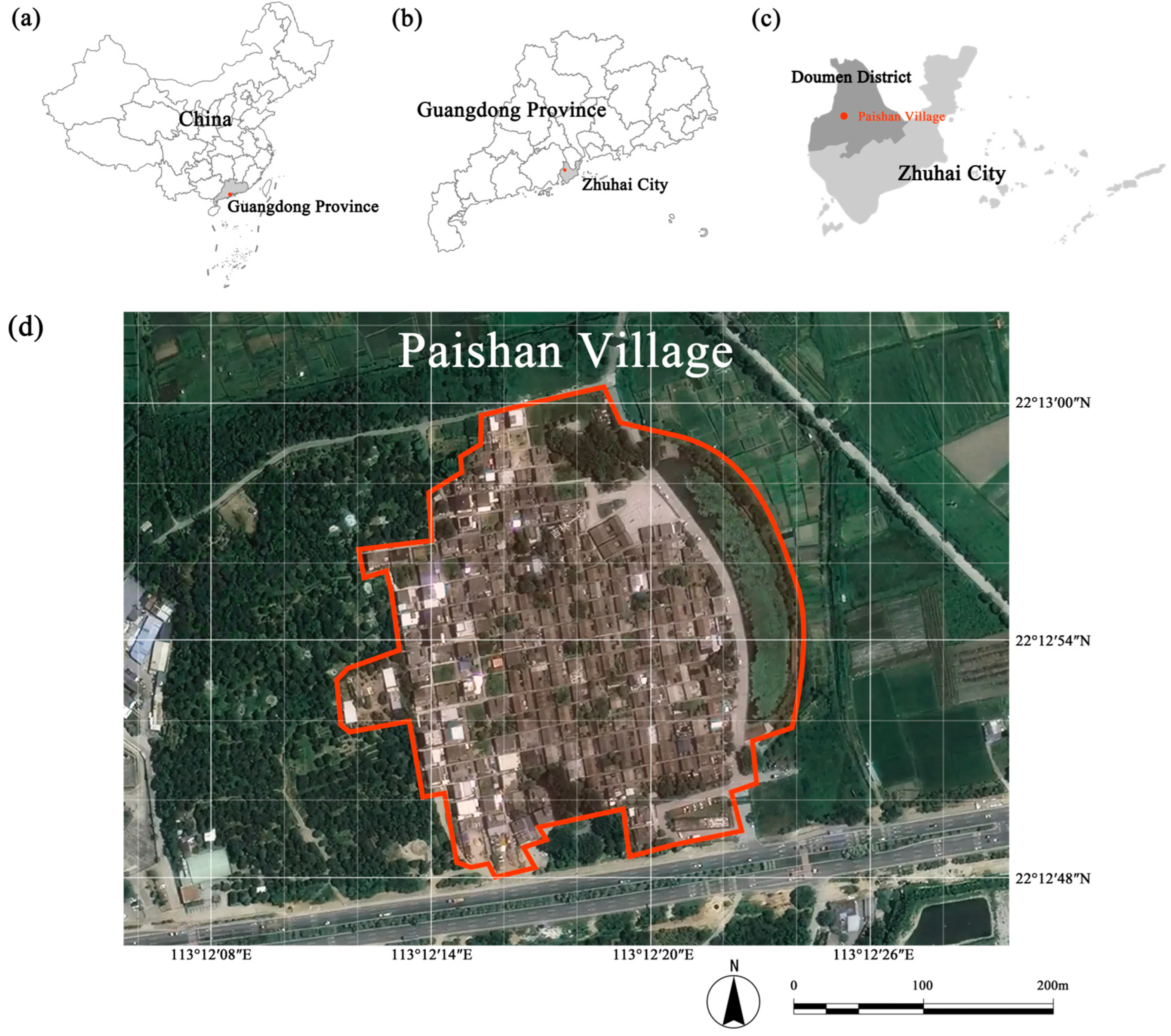

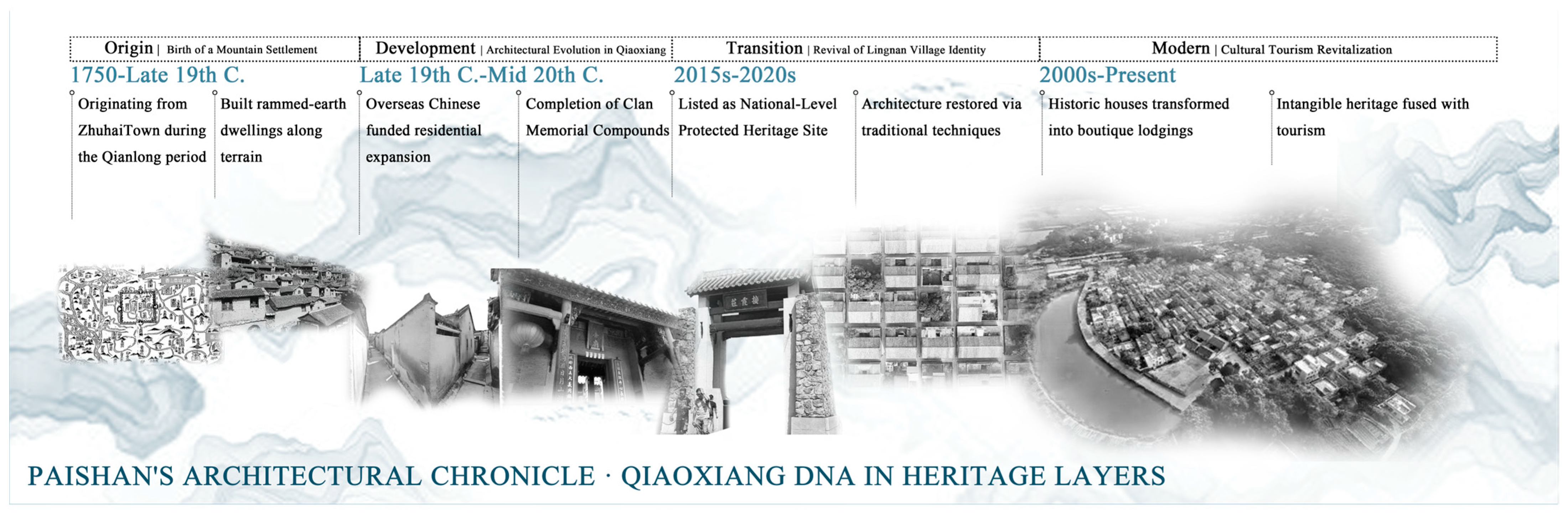

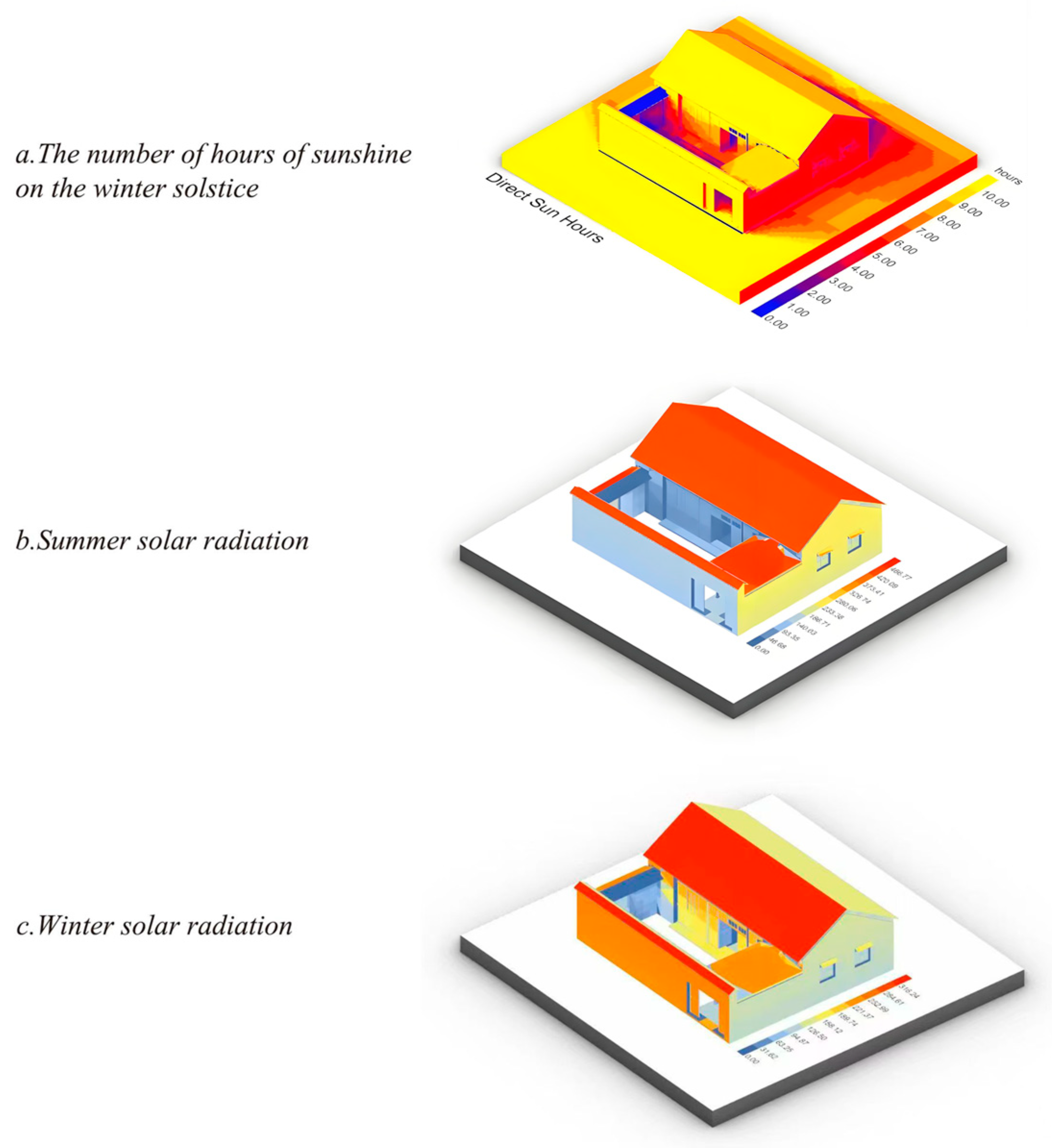

2.1. Study Area: Rammed Earth Dwellings in Paishan Village, Zhuhai City

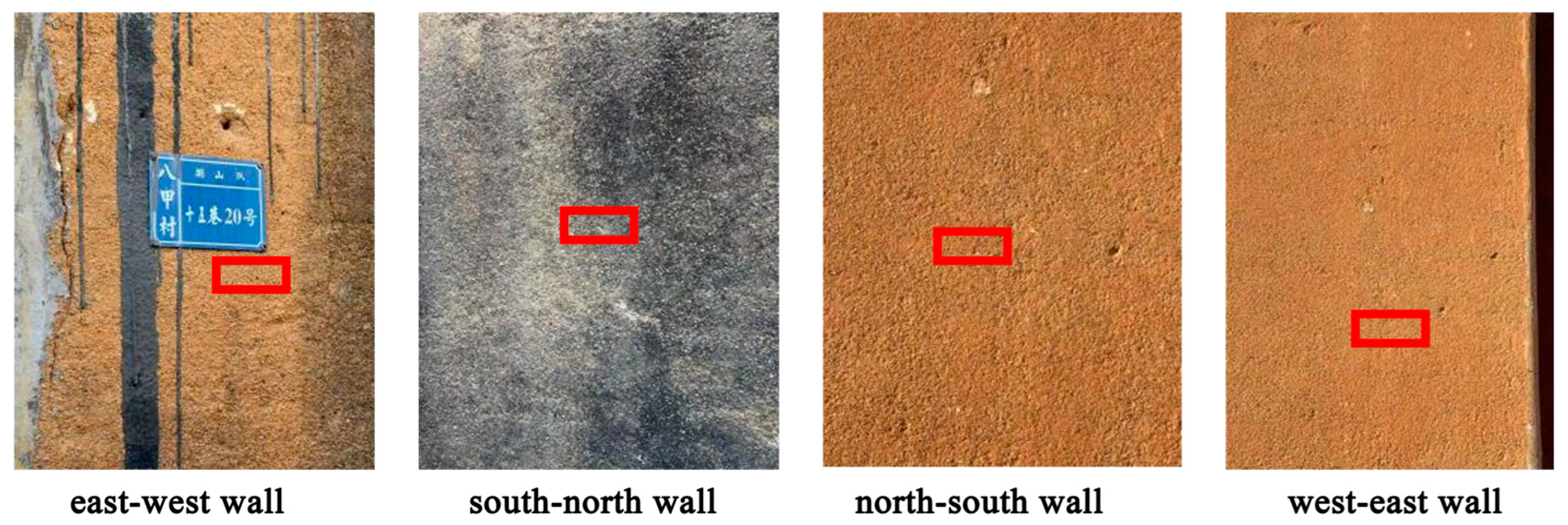

2.2. Sample Collection

2.3. Analytical Techniques

2.3.1. Mineralogical Characterization (XRD) Analysis

2.3.2. Ion Chromatography Detection

2.3.3. Scanning Electron Microscope (SEM)

3. Results

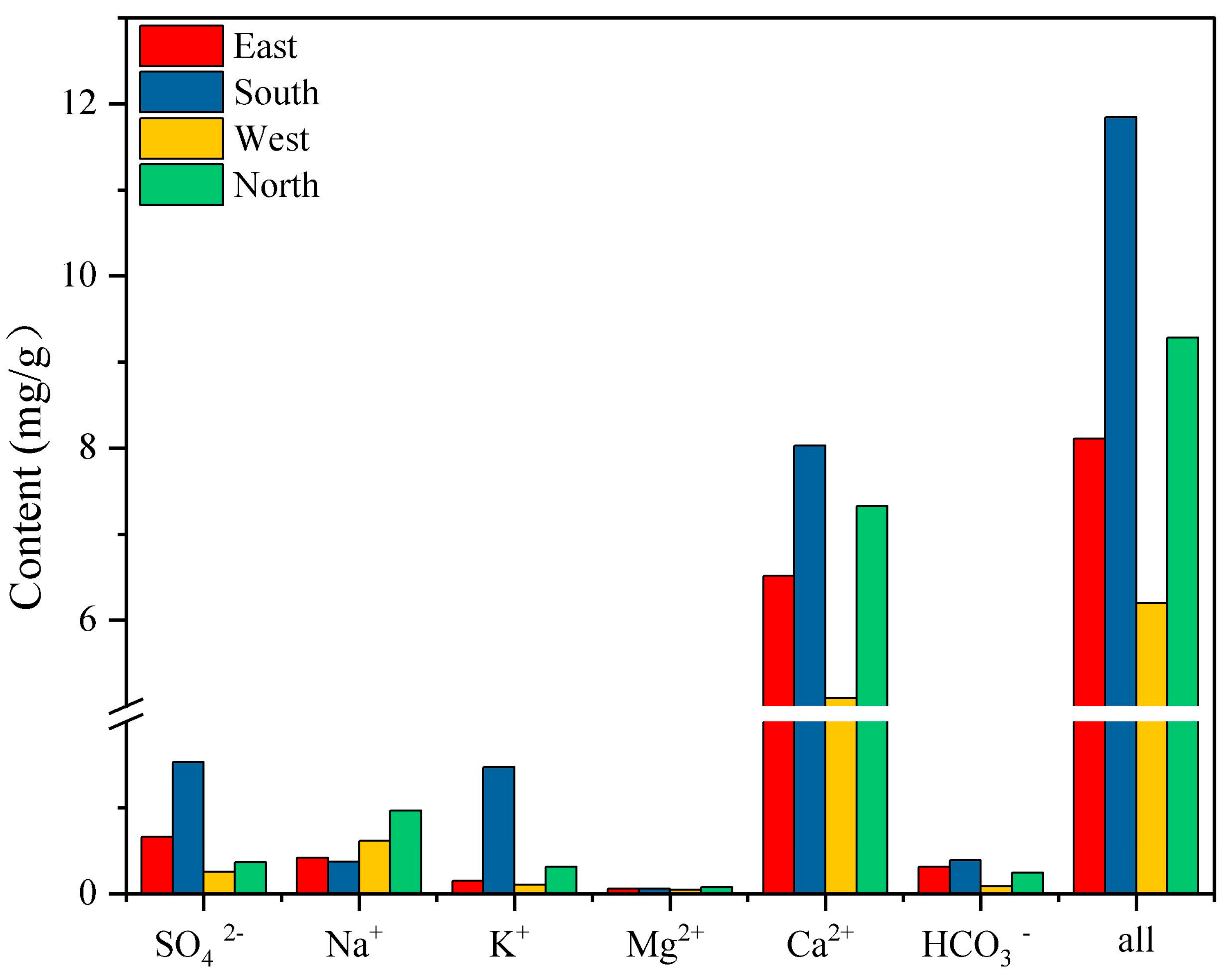

3.1. Ion Detection Results

3.1.1. Anion Content (SO42−, HCO3−)

3.1.2. Effect of Ion Distribution on Wall Corrosion Resistance

- (1)

- South wall (higher SO42−): sulfation may cause microcracks on the wall surface to expand, and peeling may occur in the long term. High HCO3− content helps to enhance structural stability in the short term but may cause loose structure due to humidity changes in the long term.

- (2)

- West wall (lower SO42−): The sulfate concentration is low, and the wall is relatively less affected by acid rain. However, due to the low HCO3− content, the cementing capacity of calcium carbonate is insufficient, and the durability of the wall is poor.

- (3)

- North wall (higher HCO3−): humidity has a greater impact, and HCO3− enrichment may be due to the dissolution of minerals by microbial activities, resulting in the wall being in a dynamic equilibrium of carbonate chemical reactions for a long time.

- (4)

- East wall (HCO3−-SO42− balance): short-term enhancement of structural density, and long-term changes in environmental factors may lead to calcium carbonate dissolution-precipitation cycles, making the wall structure tends to be loose.

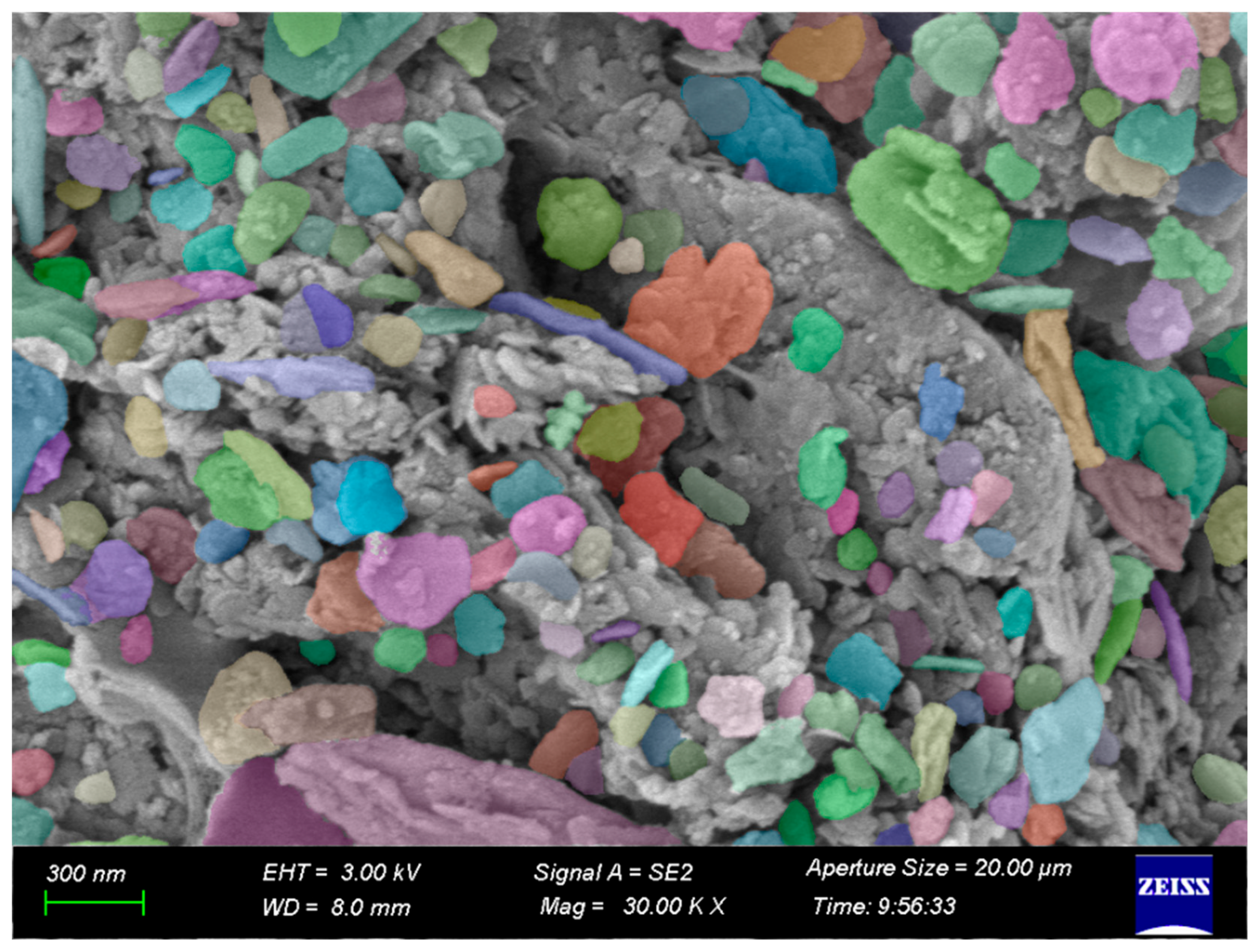

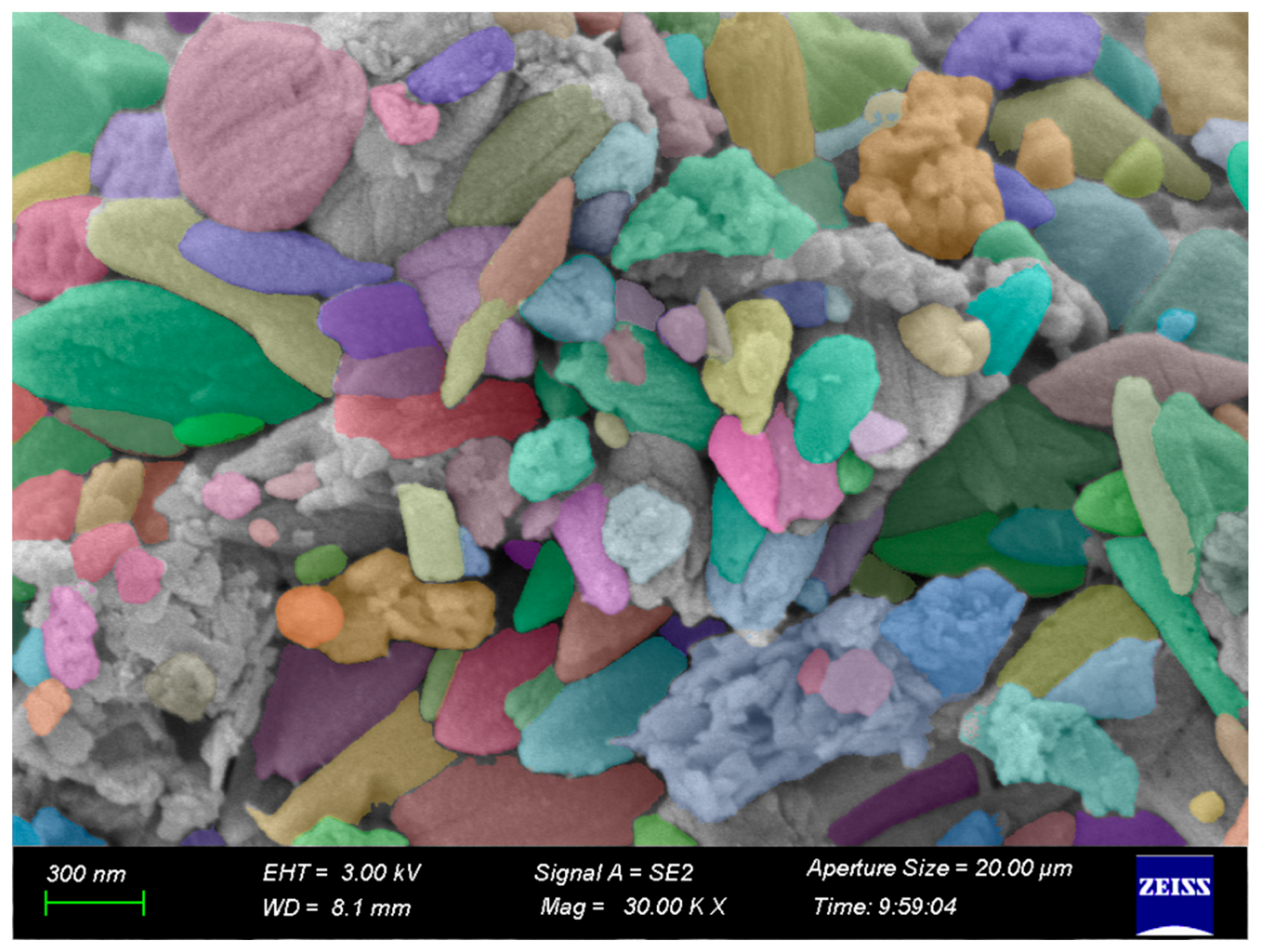

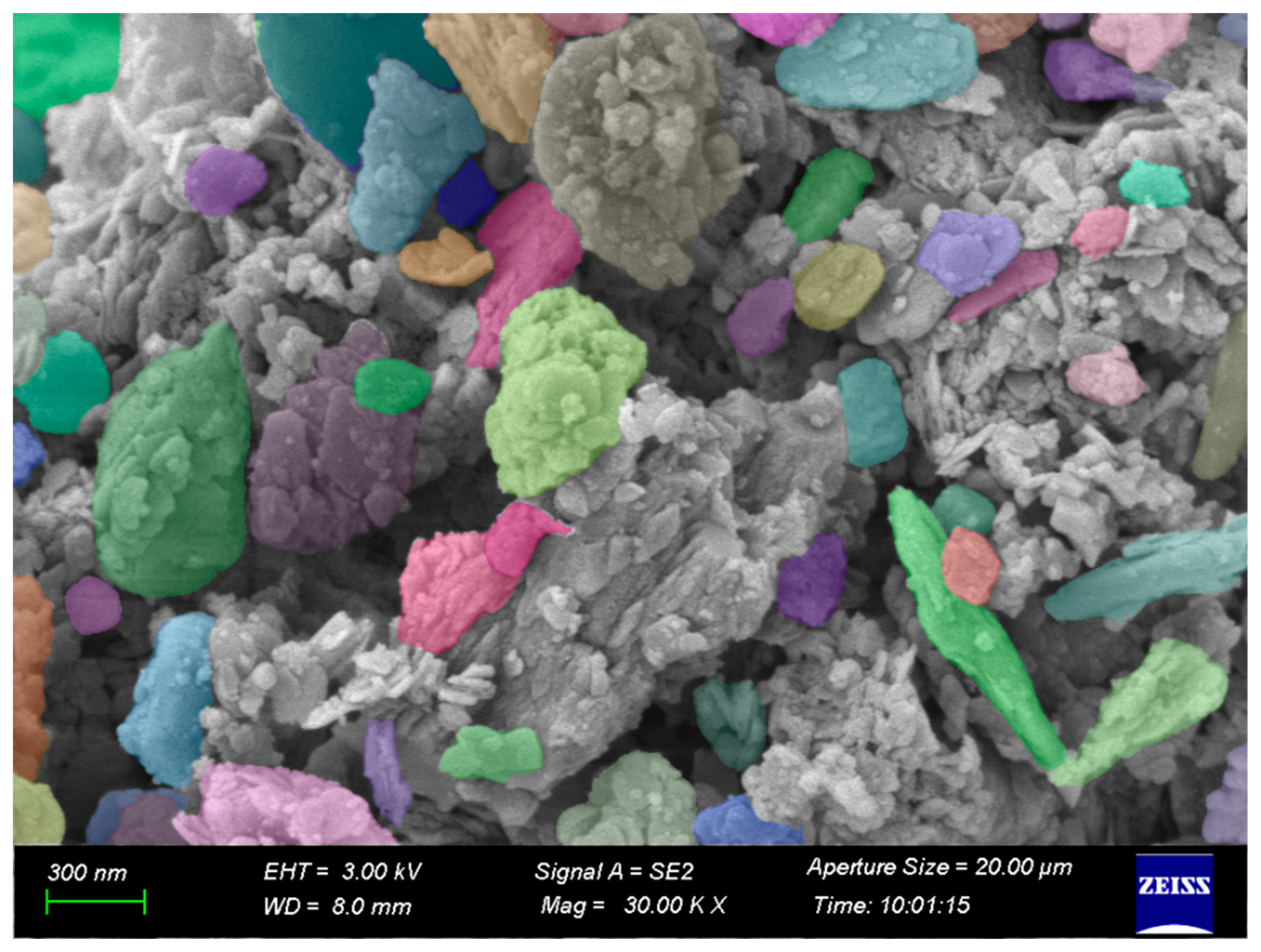

3.2. Comparison Results of Scanning Electron Microscope (SEM)

3.2.1. Comparative Analysis of SEM Images

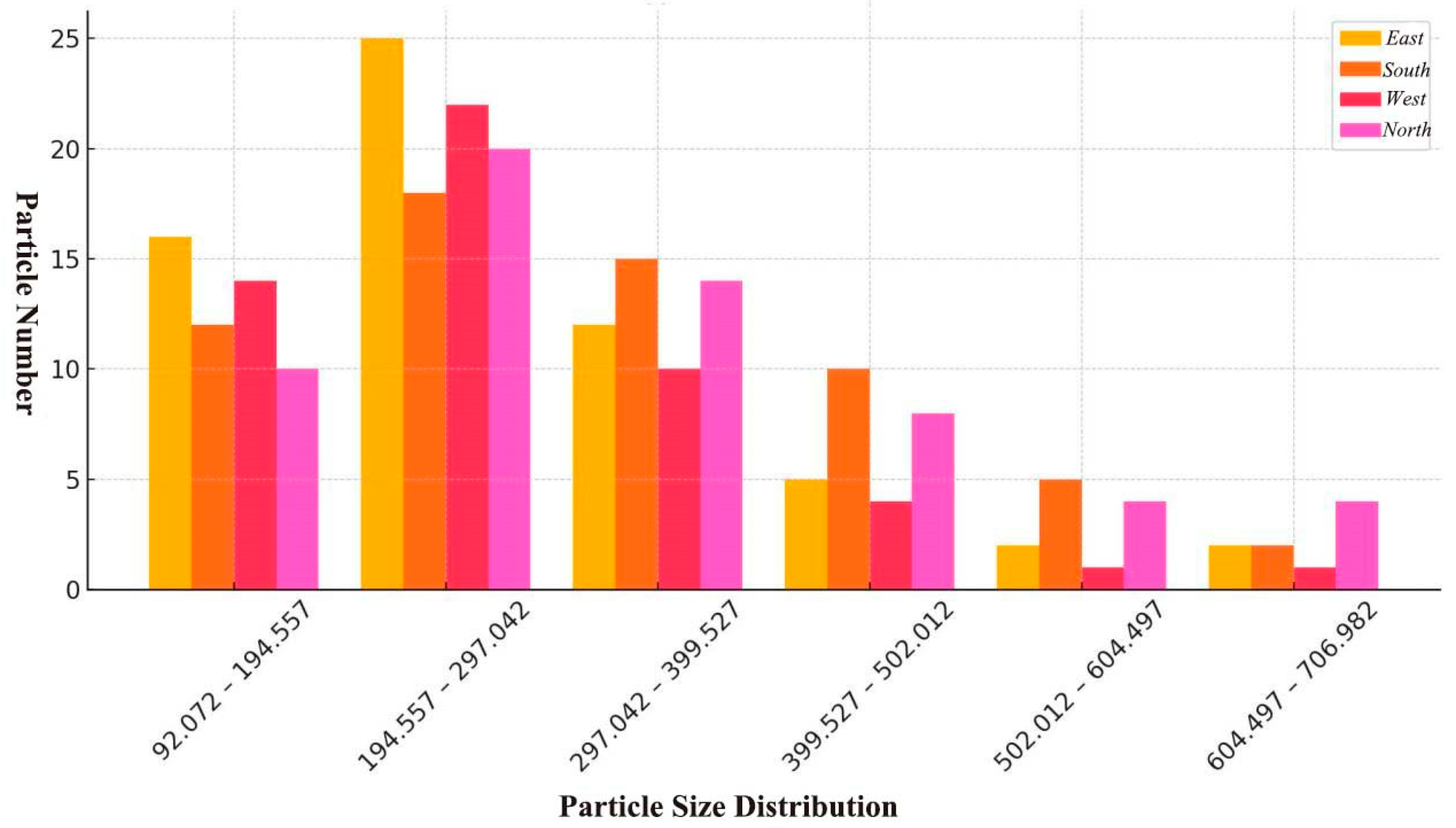

3.2.2. Particle Size Distribution Analysis

3.3. Comparative Analysis of Mineralogical Composition (XRD)

4. Discussion: Long-Term Impact on the Wall and Protection Strategy

4.1. South Wall: The Most Obvious Impact of Acid Rain

4.2. West Wall: Salt Spray Has a Greater Impact

4.3. North Wall: The Influence of Humidity and Biological Activity

4.4. East Wall: Carbonate Balance Has a Greater Impact

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Z.W. Analysis on the application of contemporary rammed earth materials in the design of the buildings. Urbanism Arch. 2023, 20, 143–146. [Google Scholar] [CrossRef]

- Liu, X.; Bai, W.F. Strategic research on the promotion and development of modern rammed earth building in China. Urbanism Arch. 2018, 2, 22–25. [Google Scholar] [CrossRef]

- Bai, W.F.; Chi, X.N.; Zhou, L. Research on preservation and activation of Kaiping Diaolou with rammed earth wall. New Archit. 2021, 4, 144–147. [Google Scholar]

- Liu, H.Q.; Li, Z.W. Research on the value of Traditional Chinese traditional building materials—Take rammed earth architecture as an example. Resid. Real Estate 2020, 32, 165–166. [Google Scholar]

- Zhang, H.Y.; Li, X.M.; Ren, K.B.; Yi, S.; Wang, Y.L. Stability analysis of rammed soil and masonry structure deterioration. J. Zhongyuan Univ. Technol. 2021, 32, 48–54. [Google Scholar] [CrossRef]

- Cui, K.; Chen, W.W.; Wang, X.D.; Han, W.F.; Zhu, Y.P. Tentative microscopic on degradation of rammed earth relics under coupled function of salinized and wetting-drying in arid region. J. Cent. South. Univ. 2013, 44, 2927–2933. [Google Scholar]

- Peng, X.Q.; Shi, W.J.; Hua, C.C. Study on the mechanism and loss of erosion by wind driven rain for rammed earth buildings. Adv. Eng. Sci. 2015, 47, 105–111. [Google Scholar] [CrossRef]

- Gu, T.Y.; Yang, X.Q.; Shi, D.H.; Yang, Y.G.; Ma, Y.P.; Zheng, X.X.; Wu, J.X.; Zhang, Y.X.; Song, G.D. Scientific analysis and research on rammed earth materials of the Shang Dynasty in Zhengzhou area:taking Zhengzhou Shang City and Zhengzhou Xiaoshuangqiao sites as examples. Sci. Conserv. Archaeol. 2024, 36, 89–100. [Google Scholar] [CrossRef]

- Zhou, Q.; Chen, W. Conservation intervention experience of the rammed earth historic monuments in spain. Archit. Herit. 2024, 1, 54–59. [Google Scholar] [CrossRef]

- Wang, M.L.; Li, S.H. Research on the Applicability of Passive Technology in Traditional Rammed Earth Buildings in Chaoshan. China Archit. J. 2022, S2, 42–48. [Google Scholar]

- Zhang, Q.; Guo, Q.; Zhang, H.; Wang, Y.; Li, P.; Zhang, B.; Tang, C.a. Surface weathering process of earthen heritage under dry-wet cycles: A case study of Suoyang City, China. J. Rock. Mech. Geotech. Eng. 2024. [Google Scholar] [CrossRef]

- Losini, A.E.; Woloszyn, M.; Chitimbo, T.; Pelé-Peltier, A.; Ouertani, S.; Rémond, R.; Doya, M.; Gaillard, D.; Force, M.S.; Outin, J. Extended hygrothermal characterization of unstabilized rammed earth for modern construction. Constr. Build. Mater. 2023, 409, 133904. [Google Scholar] [CrossRef]

- Du, X.Y.; Lin, H. Research on the characteristics of rammed earth buildings in the villages of Guangxi: A Case of Daxin County in Chongzuo. Urban. Arch. 2022, 19, 75–77. [Google Scholar] [CrossRef]

- Manzano-Fernández, S.; Mileto, C.; Vegas López-Manzanares, F.; Cristini, V. Conservation and In Situ Enhancement of Earthen Architecture in Archaeological Sites: Social and Anthropic Risks in the Case Studies of the Iberian Peninsula. Heritage 2024, 7, 2239–2264. [Google Scholar] [CrossRef]

- Petcu, C.; Dobrescu, C.F.; Dragomir, C.S.; Ciobanu, A.A.; Lăzărescu, A.V.; Hegyi, A. Thermophysical Characteristics of Clay for Efficient Rammed Earth Wall Construction. Materials 2023, 16, 6015. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.-C.; Vo, L.; Dotelli, G.; Woloszyn, M. Biopolymers impact on hygrothermal properties of rammed earth: From material to building scale. Build. Environ. 2023, 233, 110087. [Google Scholar] [CrossRef]

- Luo, Y.; Zhou, P.; Ni, P.; Peng, X.; Ye, J. Degradation of rammed earth under soluble salts attack and drying-wetting cycles: The case of Fujian Tulou, China. Appl. Clay Sci. 2021, 212, 106202. [Google Scholar] [CrossRef]

- Ou, C.Y. Research on the application of new rammed earth construction in the restoration and reconstruction of ancient villages. Residence 2023, 16, 159–162. [Google Scholar]

- Jiang, B.; Lu, R.; Jiang, M.; Wang, L.; Chun, L.; Wan, L. Experimental study on thermal and humidity properties of modified rammed earth buildings in winter. Build. Environ. 2024, 258, 111583. [Google Scholar] [CrossRef]

- Sánchez-Calvillo, A.; Rincón, L.; Hamard, E.; Faria, P. Bibliometric Analysis on Earthen Building: Approaches from the Scientific Literature and Future Trends. Buildings 2024, 14, 3870. [Google Scholar] [CrossRef]

- Lu, G.A.N.; Heng, C.; Yi, Y. The Livability Perception of Residents in Rural Areas and Its Influencing Factors: A Case Study of Doumen Town of Zhuhai. J. Landsc. Res. 2019, 11. [Google Scholar] [CrossRef]

- Zheng, B.; Liu, G.; Wang, H.; Cheng, Y.; Lu, Z.; Liu, H.; Zhu, X.; Wang, M.; Yi, L. Study on the Delimitation of the Urban Development Boundary in a Special Economic Zone: A Case Study of the Central Urban Area of Doumen in Zhuhai, China. Sustainability 2018, 10, 756. [Google Scholar] [CrossRef]

- Song, J.; Chen, Y.; Zheng, L.; Tang, Q. The evolution of traditional ancient towns in South China: Tangjiawan Ancient Town in Zhuhai city. J. Asian Archit. Build. Eng. 2024, 1–19. [Google Scholar] [CrossRef]

- Li, S.; Wang, M.; Shen, P.; Cui, X.; Bu, L.; Wei, R.; Zhang, L.; Wu, C. Energy Saving and Thermal Comfort Performance of Passive Retrofitting Measures for Traditional Rammed Earth House in Lingnan, China. Buildings 2022, 12, 1716. [Google Scholar] [CrossRef]

- Wang, W.; Luo, B. Lingnan Architecture Design Based on Ocean Climate Adaptability. J. Coast. Res. 2020, 107, 226–229. [Google Scholar] [CrossRef]

- Yan, L.; Chen, Y. Study of Roof Tiles in Lingnan Traditional Buildings and Roof Drainage Technologies. IOP Conference Series: Earth and Environmental Science. IOP Publ. 2021, 768, 012151. [Google Scholar] [CrossRef]

- Ji, H.; Wu, S.; Ye, B.; Wang, S.; Chen, Y.; Deng, J.-Y. Exploring the Implementation Path of Passive Heat-Protection Design Heritage in Lingnan Buildings. Buildings 2023, 13, 2954. [Google Scholar] [CrossRef]

- Tsai, S.-C.; Zhang, X.-F.; Chang, Y.-T. Toward Nearly Zero-Waste Architecture: Innovation, Application, and Practice of Construction Methods Using Natural Materials. Buildings 2024, 14, 1584. [Google Scholar] [CrossRef]

- Guo, Q.; Pei, Q.; Wang, Y.; Zhan, W.; Yang, S.; Sun, M.; Zhang, J.; Shi, Z. New Advances in the Protection and Research of Earthen Sites in China. Res. Prot. Grottoes Earthen Sites 2023, 3, 18–31. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, G.; Li, W.; Jiao, X. Characteristics and Sources of CBM Well-Produced Water in the Shouyang Block, China. Appl. Sci. 2024, 14, 4218. [Google Scholar] [CrossRef]

- Youssef, M. Passivation Mechanism of Pure Magnesium in Oleum and Sulfuric Acid Solutions/Author Mohamed Youssef. 2024. Available online: https://epub.jku.at/obvulihs/content/titleinfo/10095239 (accessed on 22 March 2025).

- Alam, B.Y.C.S.; Itoi, R.; Taguchi, S.; Yamashiro, R. Spatial Variation in Groundwater Types in the Mt. Karang (West Java, Indonesia) Volcanic Aquifer System Based on Hydro-Chemical and Stable Isotope (δD and δ18O) Analysis. Mod. Appl. Sci. 2014, 8, 87. [Google Scholar] [CrossRef]

- Rades, S.; Hodoroaba, V.D.; Salge, T.; Wirth, T.; Lobera, M.P.; Labrador, R.H.; Natte, K.; Behnke, T.; Gross, T.; Unger, W.E. High-resolution imaging with SEM/T-SEM, EDX and SAM as a combined methodical approach for morphological and elemental analyses of single engineered nanoparticles. RSC Adv. 2014, 4, 49577–49587. [Google Scholar] [CrossRef]

- Schulz, B.; Sandmann, D.; Gilbricht, S.S. SEM-Based Automated Mineralogy and Its Application in Geo- and Material Sciences. Minerals 2020, 10, 1004. [Google Scholar] [CrossRef]

- Wang, N.; Wang, Q.; Ye, W.M. Research Progress of Microbial Reinforcement Technology. J. Hydrogeol. Eng. Geol. 2024, 5, 231–244. [Google Scholar] [CrossRef]

- Chen, H.Y.; Zhao, X.F.; He, Z.D.; Fan, S.J. Variation characteristics and concept model of acid rain in Zhuhai city during 2000–2016. Acta Sci. Circumstantiae 2020, 40, 1998–2006. Available online: https://html.rhhz.net/hjkxxb/html/20191105011.htm (accessed on 22 March 2025).

- Zhang, Y.; Ye, W.M.; Chen, B.; Chen, Y.G.; Ye, B. Desiccation of NaCl-contaminated soil of earthen heritages in the Site of Yar City, northwest China. Appl. Clay Sci. 2016, 124, 1–10. [Google Scholar] [CrossRef]

- Zhu, C.H.; Li, N.; Ma, S. Research on Anti-seepage Measures for Rammed Earth Bases of Ancient Buildings Based on Model Tests. J. Rock Soil Mech. 2021, 42, 3281–3290. [Google Scholar] [CrossRef]

- Teng, F.; Sie, Y.C. Simulating field grouting to improve the shear strength of consolidated clay by microbially induced carbonate precipitation. Soils Found. 2025, 65, 101. [Google Scholar] [CrossRef]

- Ye, C.R.; Tao, Y.; Zhang, Y.R.; Cao, J.; Ke, T.; Wei, S.J.; De Philippis, R.; Chen, L.Z. Monosaccharide composition of primary cell wall polysaccharides as a development level indicator of biologic soil crusts. Catena 2020, 195, 104782. [Google Scholar] [CrossRef]

- Katharina, F.; Marija, M.; Gabriela, K. Preserving earthen architecture: Lessons learned from two case studies. J. Archaeol. Sci. 2024, 55, 104. [Google Scholar] [CrossRef]

| Wall Orientation | Average Particle Size (nm) | Particle Size Standard Deviation (nm) | P10 (nm) | P50 (nm) | P90 (nm) |

|---|---|---|---|---|---|

| East | 281.149 | 128.367 | 153.563 | 399.528 | 645.492 |

| South | 315.276 | 142.235 | 160.345 | 417.562 | 683.459 |

| West | 276.593 | 120.498 | 148.218 | 388.452 | 610.315 |

| North | 298.462 | 134.876 | 162.774 | 410.389 | 657.923 |

| Total Particles | 186 | |

|---|---|---|

| Particle size information | Average particle size | 185.841 nm |

| Particle size standard deviation | 74.159 nm | |

| P10 | 118.378 nm | |

| P50 | 276.216 nm | |

| P90 | 434.054 nm | |

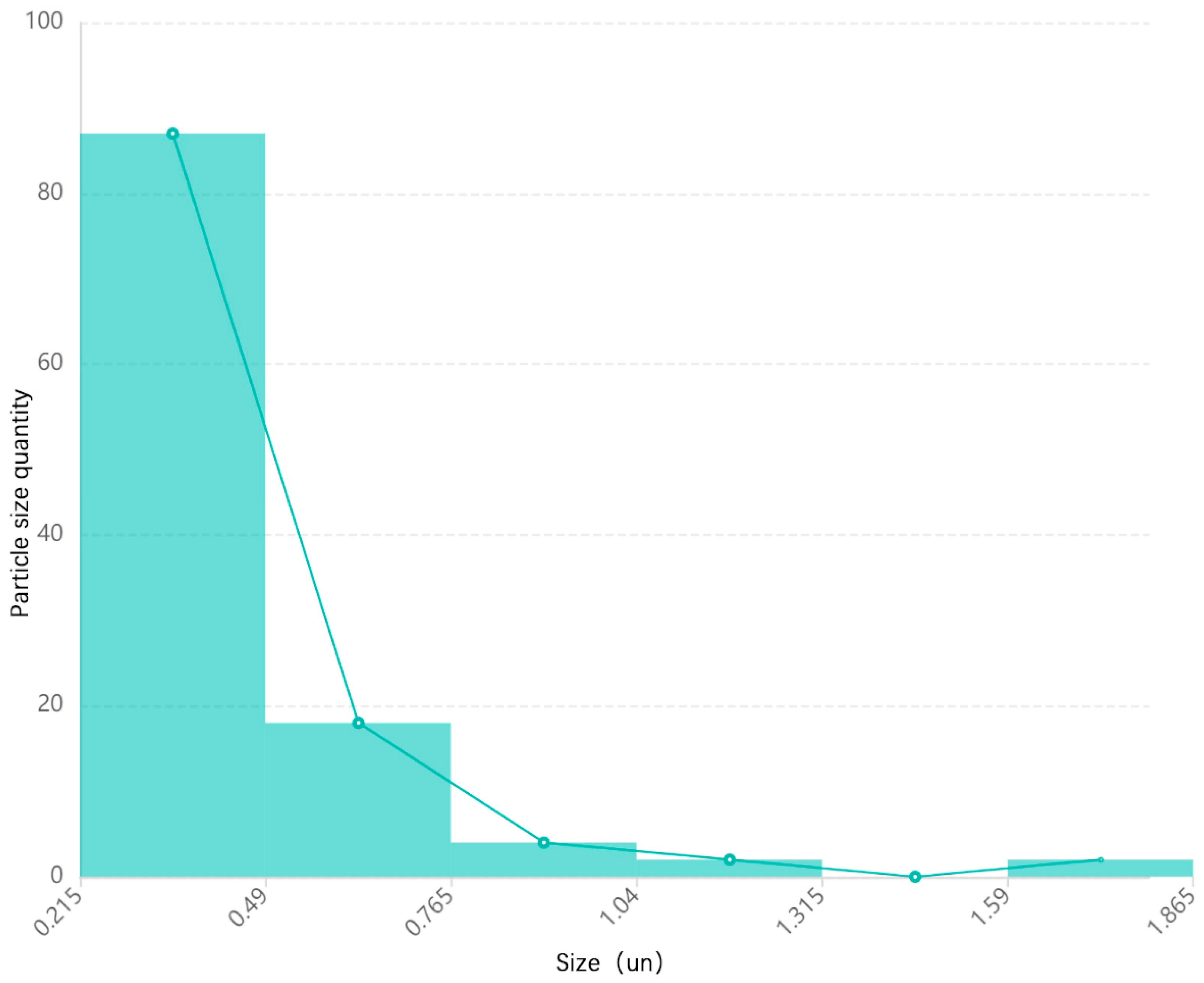

| Total Particles | 113 | |

|---|---|---|

| Particle size information | Average particle size | 0.431 µm |

| Particle size standard deviation | 0.253 µm | |

| P10 | 0.38 µm | |

| P50 | 1.039 µm | |

| P90 | 1.698 µm | |

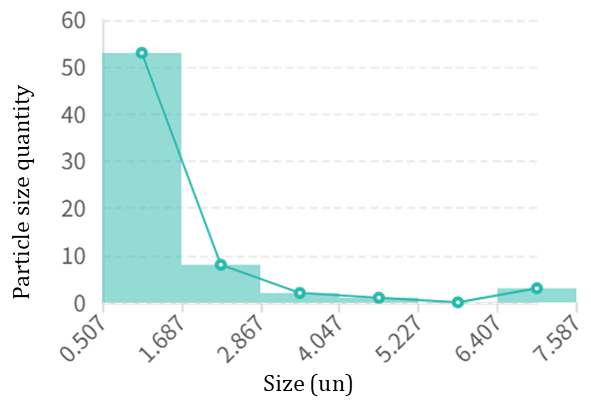

| Total Particles | 67 | |

|---|---|---|

| Particle size information | Average particle size | 1.488 µm |

| Particle size standard deviation | 1.388 µm | |

| P10 | 1.215 µm | |

| P50 | 4.048 µm | |

| P90 | 6.881 µm | |

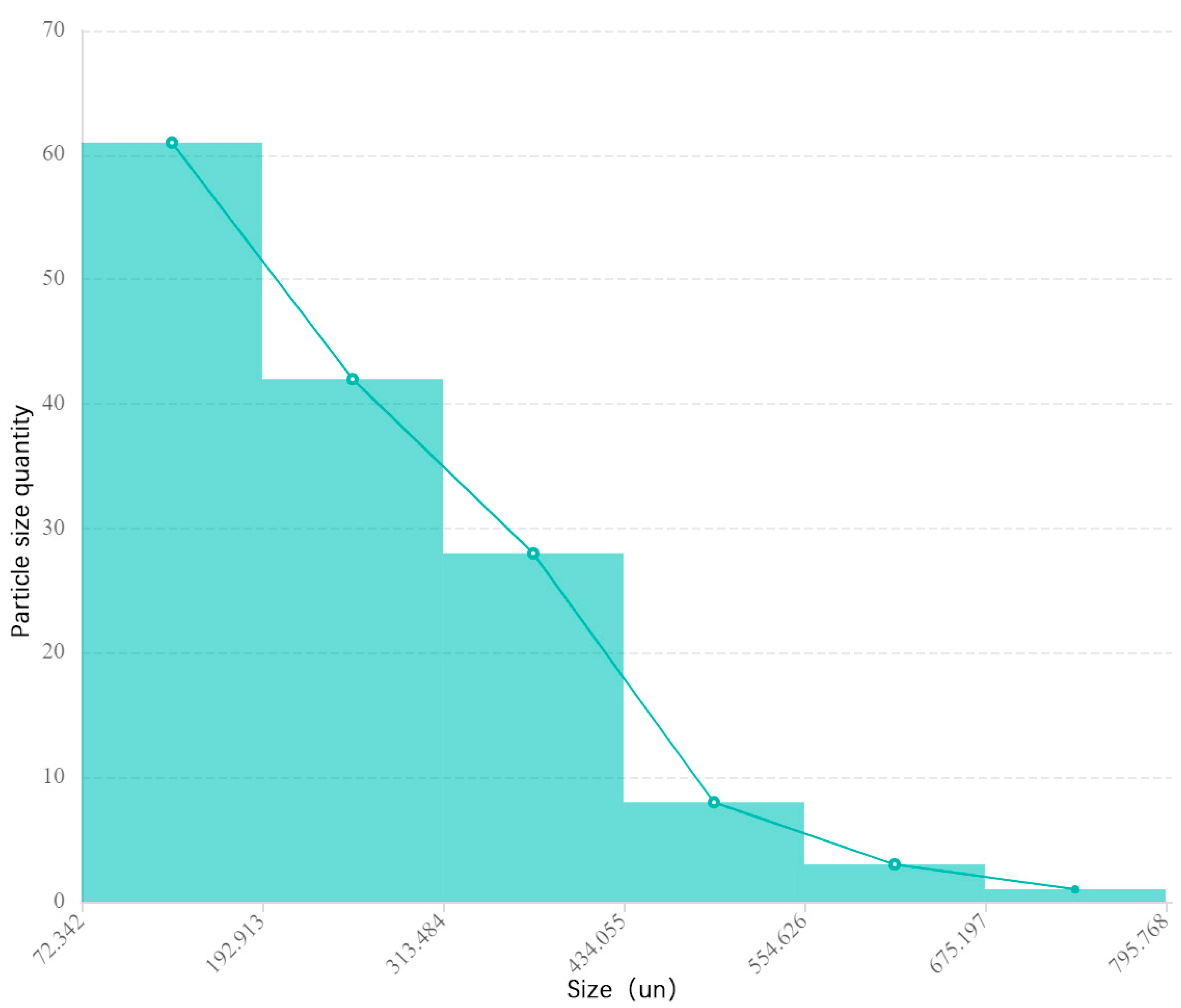

| Total Particles | 143 | |

|---|---|---|

| Particle size information | Average particle size | 245.012 nm |

| Particle size standard deviation | 129.568 nm | |

| P10 | 144.684 nm | |

| P50 | 434.054 nm | |

| P90 | 723.424 nm | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Song, J.; Zhang, J.; Huang, Y.; Yang, S. Analysis of Rammed Earth Wall Erosion in Traditional Village Dwellings in Zhuhai City. Coatings 2025, 15, 526. https://doi.org/10.3390/coatings15050526

Wang Y, Song J, Zhang J, Huang Y, Yang S. Analysis of Rammed Earth Wall Erosion in Traditional Village Dwellings in Zhuhai City. Coatings. 2025; 15(5):526. https://doi.org/10.3390/coatings15050526

Chicago/Turabian StyleWang, Yanjun, Junxin Song, Jiahao Zhang, Yue Huang, and Shuai Yang. 2025. "Analysis of Rammed Earth Wall Erosion in Traditional Village Dwellings in Zhuhai City" Coatings 15, no. 5: 526. https://doi.org/10.3390/coatings15050526

APA StyleWang, Y., Song, J., Zhang, J., Huang, Y., & Yang, S. (2025). Analysis of Rammed Earth Wall Erosion in Traditional Village Dwellings in Zhuhai City. Coatings, 15(5), 526. https://doi.org/10.3390/coatings15050526