Research Progress of Self-Healing Coatings on Ships Against Biological Pollution: A Review

Abstract

1. Introduction

2. Marine Biofouling

2.1. Forms of Biological Pollutions

2.2. The Process of Biological Pollution

2.3. Impact of Biological Pollution

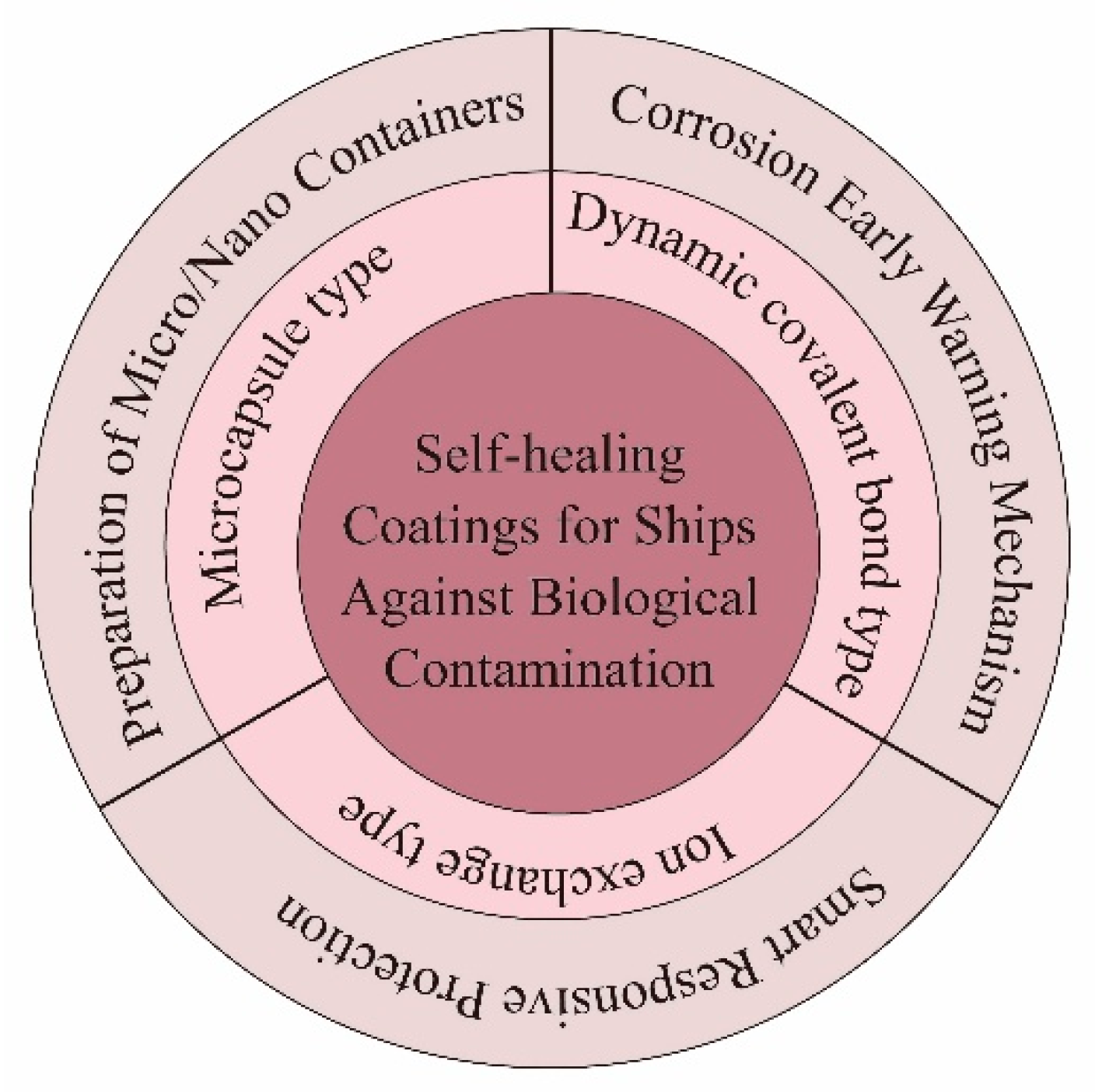

3. Current Research on Self-Healing Coatings for Ships

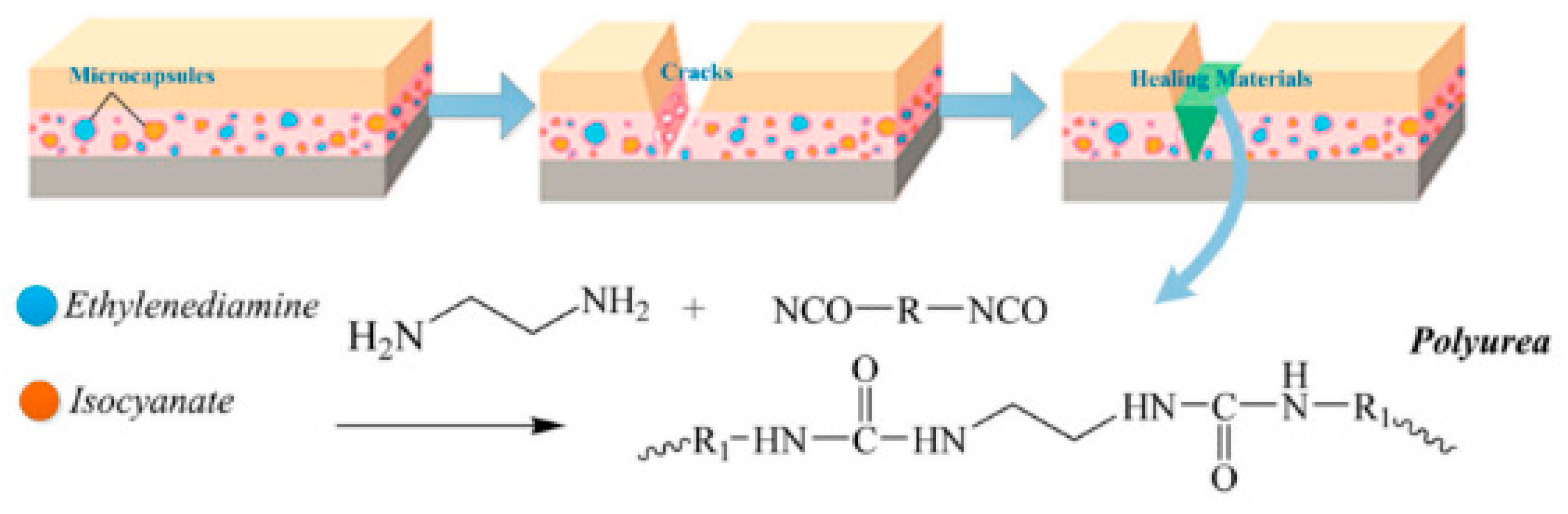

3.1. Microencapsulation Type

3.2. Ion-Exchange Type

3.3. Dynamic Covalent Bond Type

4. Construction and Protection of Self-Healing Coatings for Marine Applications

4.1. Preparation of Micro/Nano Containers

4.2. Corrosion Early Warning Mechanism

4.3. Smart Responsive Protection

5. Prospects and Outlook

- The amount of healing agent stored in microcapsules is limited, and in cases of severe coating damage, it may not be able to provide sufficient repair materials. Additionally, the randomness of microcapsule rupture makes it difficult to precisely control the release location and dosage of the healing agent, which may result in insufficient local repair. Particularly in the marine environment, high humidity and temperature fluctuations accelerate the degradation or failure of healing agents, weakening the coating’s long-term self-healing ability.

- Dynamic covalent bonds, although providing some self-healing capability, typically result in slower repair processes that are insufficient for larger cracks or deep damage. Moreover, the reversibility of dynamic covalent bonds is highly sensitive to environmental factors such as temperature and humidity, and excessive repair cycles may degrade material performance, shortening the effective lifespan of the coating. Simultaneously, the repair effect’s high sensitivity to environmental conditions (e.g., temperature, humidity, and pH) may cause instability in the repair effect under complex environmental conditions.

- Ionic exchange reactions are primarily used to repair surface damage, and their effectiveness for deep cracks or complex damage is often limited. Furthermore, ionic exchange reactions are relatively slow, and the repair process is time-consuming, which fails to meet the demands for rapid repairs of ship coatings. Additionally, the repair effect of ionic exchange coatings is also vulnerable to environmental factors such as seawater, humidity, and temperature, further limiting their practical application.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, S.; Bi, H.; Weinell, C.E.; Dam-Johansen, K. Submerged surfaces exposed to marine biofouling—Experimental investigation of cleaning parameters effectiveness. Prog. Org. Coat. 2022, 173, 107229. [Google Scholar] [CrossRef]

- Luoma, E.; Laurila-Pant, M.; Altarriba, E.; Nevalainen, L.; Helle, I.; Granhag, L.; Lehtiniemi, M.; Srebaliene, G.; Olenin, S.; Lehikoinen, A. A multi-criteria decision analysis model for ship biofouling management in the Baltic Sea. Sci. Total Environ. 2022, 852, 158316. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, D.R.; Lagerström, M.; Granhag, L.; Werner, S.; Larsson, A.I.; Ytreberg, E. A novel tool for cost and emission reduction related to ship underwater hull maintenance. J. Clean. Prod. 2022, 356, 131882. [Google Scholar] [CrossRef]

- Farkas, A.; Degiuli, N.; Martić, I.; Barbarić, M.; Guzović, Z. The impact of biofilm on marine current turbine performance. Renew. Energy 2022, 190, 584–595. [Google Scholar] [CrossRef]

- Kowach, G.R. The chemical physics of solid surfaces. Volume 10. Surface alloys and alloy surfaces edited by D. P. J. Am. Chem. Soc. 2004, 126, 979. [Google Scholar] [CrossRef]

- Prabhakar, J.M.; Varanasi, R.S.; da Silva, C.C.; Saood, S.; de Vooys, A.; Erbe, A.; Rohwerder, M. Chromium coatings from trivalent chromium plating baths: Characterization and cathodic delamination behaviour. Corros. Sci. 2021, 187, 109525. [Google Scholar] [CrossRef]

- Abdulaziz, A.-N.; Rizwan, H.R.; Abdulrahman, A.; Singh, D.D.N. Corrosion performance of hot-dip galvanized zinc-aluminum coated steel rebars in comparison to the conventional pure zinc coated rebars in concrete environment. Constr. Build. Mater. 2021, 274, 121921. [Google Scholar] [CrossRef]

- Pareek, S.; Jain, D.; Hussain, S.; Biswas, A.; Shrivastava, R.; Parida, S.K.; Kisan, H.K.; Lgaz, H.; Chung, I.-M.; Behera, D. A new insight into corrosion inhibition mechanism of copper in aerated 3.5 wt.% NaCl solution by eco-friendly Imidazopyrimidine Dye: Experimental and theoretical approach. Chem. Eng. J. 2019, 358, 725–742. [Google Scholar] [CrossRef]

- Zheng, H.; Li, Z.; Liu, L.; Meng, F.; Cui, Y.; Wang, F. Superhydrophobic composite coatings in bacterial culture media: Durable antibacterial activity and enhanced corrosion resistance. Compos. Commun. 2022, 30, 101041. [Google Scholar] [CrossRef]

- Zhang, F.; Ju, P.; Pan, M.; Zhang, D.; Huang, Y.; Li, G.; Li, X. Self-healing mechanisms in smart protective coatings: A review. Corros. Sci. 2018, 144, 74–88. [Google Scholar] [CrossRef]

- Luzzati, T.; Distefano, T.; Ialenti, S.; Andreoni, V. The circular economy and longer product lifetime: Framing the effects on working time and waste. J. Clean. Prod. 2022, 380, 134836. [Google Scholar] [CrossRef]

- Haines-Gadd, M.; Charnley, F.; Encinas-Oropesa, A. Self-healing materials: A pathway to immortal products or a risk to circular economy systems? J. Clean. Prod. 2021, 315, 128193. [Google Scholar] [CrossRef]

- Dang, H.; Lovell, C.R. Microbial Surface Colonization and Biofilm Development in Marine Environments. Microbiol. Mol. Biol. Rev. 2016, 80, 91–138. [Google Scholar] [CrossRef] [PubMed]

- Qian, P.Y.; Cheng, A.; Wang, R.; Zhang, R. Marine biofilms: Diversity, interactions and biofouling. Nat. Rev. Microbiol. 2022, 20, 671–684. [Google Scholar] [CrossRef]

- Karsenti, E. Towards an ‘oceans systems biology’. Mol. Syst. Biol. 2012, 8, 575. [Google Scholar] [CrossRef]

- Vorobev, A.; Dupouy, M.; Carradec, Q.; Delmont, T.O.; Annamale, A.; Wincker, P.; Pelletier, E. Transcriptome reconstruction and functional analysis of eukaryotic marine plankton communities via high-throughput metagenomics and metatranscriptomics. Genome Res. 2020, 30, 647–659. [Google Scholar] [CrossRef]

- Giuliano, B.; Mohamed, I.; Maurizio, Z.; Elisabetta, D.A.; Marcello, D.; Virginia, L.; Riccardo, S.; Stefano, M. Multi-kingdom characterization of living organisms by 13C CPMAS NMR spectroscopy reveals unique traits in bacteria, fungi, algae, and higher plants. Geoderma 2024, 448, 116978. [Google Scholar] [CrossRef]

- Hamidi, M.; Kozani, P.S.; Kozani, P.S.; Pierre, G.; Michaud, P.; Delattre, C. Marine Bacteria versus Microalgae: Who Is the Best for Biotechnological Production of Bioactive Compounds with Antioxidant Properties and Other Biological Applications? Mar. Drugs 2019, 18, 28. [Google Scholar] [CrossRef]

- Tong, C.Y.; Derek, C.J.C. The role of substrates towards marine diatom Cylindrotheca fusiformis adhesion and biofilm development. J. Appl. Phycol. 2021, 33, 2845–2862. [Google Scholar] [CrossRef]

- Michael, C. Who are the marine fungi. Environ. Microbiol. 2023, 25, 131–134. [Google Scholar] [CrossRef]

- Wu, G.; Lu, F.; Wu, G.; Wu, M. Insights into the physiology, biochemistry, and metabolic pathways of ethanol-resistant marine microalgae in phytoplankton. Algal Res. 2024, 81, 103580. [Google Scholar] [CrossRef]

- Tziveleka, L.A.; Tammam, M.A.; Tzakou, O.; Roussis, V.; Ioannou, E. Metabolites with Antioxidant Activity from Marine Macroalgae. Antioxidants 2021, 10, 1431. [Google Scholar] [CrossRef]

- Han, X.; Wang, Q.; Luo, X.; Tang, X.; Wang, Z.; Zhang, D.; Cao, S.; Li, P.; Li, G. Lemnalemnanes A-C, Three Rare Rearranged Sesquiterpenoids from the Soft Corals Paralemnalia thyrsoides and Lemnalia sp. Org. Lett. 2022, 24, 11–15. [Google Scholar] [CrossRef]

- Sun, S.; Xia, G.; Pang, H.; Zhu, J.; Li, L.; Zang, H. Phytochemical Analysis and Antioxidant Activities of Various Extracts from the Aerial Part of Anemone baicalensis Turcz.: In Vitro and In Vivo Studies. Molecules 2024, 29, 4602. [Google Scholar] [CrossRef]

- Mazzella, V.; Dell’Anno, A.; Etxebarria, N.; Gonzalez-Gaya, B.; Nuzzo, G.; Fontana, A.; Nunez-Pons, L. High microbiome and metabolome diversification in coexisting sponges with different bio-ecological traits. Commun. Biol. 2024, 7, 422. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, A.L.; Mitchell, J.; Girguis, P.; Bright, M. Novel Insights on Obligate Symbiont Lifestyle and Adaptation to Chemosynthetic Environment as Revealed by the Giant Tubeworm Genome. Mol. Biol. Evol. 2022, 39, msab347. [Google Scholar] [CrossRef]

- Liu, X.; Jin, H.; Xu, G.; Lai, R.; Wang, A. Bioactive Peptides from Barnacles and Their Potential for Antifouling Development. Mar. Drugs 2023, 21, 480. [Google Scholar] [CrossRef] [PubMed]

- Nalini, S.; Inbakandan, D.; Venkatnarayanan, S.; Mohammed Riyaz, S.U.; Dheenan, P.S.; Vinithkumar, N.V.; Sriyutha Murthy, P.; Parthasarathi, R.; Kirubagaran, R. PYRROLO isolated from marine sponge associated bacterium Halobacillus kuroshimensis SNSAB01—Antifouling study based on molecular docking, diatom adhesion and mussel byssal thread inhibition. Colloids Surf. B Biointerfaces 2019, 173, 9–17. [Google Scholar] [CrossRef]

- Liu, Y.N.; Liu, X.W. Nanoscale Spatiotemporal Dynamics of Microbial Adhesion: Unveiling Stepwise Transitions with Plasmonic Imaging. ACS Nano 2024, 18, 16002–16010. [Google Scholar] [CrossRef]

- Leclerc, M.; Wauthy, M.; Planas, D.; Amyot, M. How do metals interact with periphytic biofilms? Sci. Total Environ. 2023, 876, 162838. [Google Scholar] [CrossRef]

- Song, S.; Demirel, Y.K.; Atlar, M. An investigation into the effect of biofouling on the ship hydrodynamic characteristics using CFD. Ocean Eng. 2019, 175, 122–137. [Google Scholar] [CrossRef]

- Andersson, J.; Oliveira, D.R.; Yeginbayeva, I.; Leer-Andersen, M.; Bensow, R.E. Review and comparison of methods to model ship hull roughness. Appl. Ocean. Res. 2020, 99, 102119. [Google Scholar] [CrossRef]

- Valchev, I.; Coraddu, A.; Kalikatzarakis, M.; Geertsma, R.; Oneto, L. Numerical methods for monitoring and evaluating the biofouling state and effects on vessels’ hull and propeller performance: A review. Ocean. Eng. 2022, 251, 110883. [Google Scholar] [CrossRef]

- Choi, W.-S.; Min, G.-S.; Han, S.-S.; Yun, H.-C.; Terziev, M.; Dai, S.; Kim, D.; Song, S. Resistance and speed penalty of a naval ship with hull roughness. Ocean. Eng. 2024, 312, 119058–119082. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, L.; Wang, B.; Huang, L.; Wang, K.; Ma, R. Integrated optimization of speed schedule and energy management for a hybrid electric cruise ship considering environmental factors. Energy 2023, 282, 128795. [Google Scholar] [CrossRef]

- Fang, H.; Qin, S.; Sun, S.; Wang, L.; Feng, X.; Huang, B.; Wu, D. Numerical investigation on the cavity behavior and hydrodynamic performance of a planing air cavity ship. Ocean. Eng. 2021, 241, 110042. [Google Scholar] [CrossRef]

- Zhou, J.; Ren, J.; Bai, W. Survey on hydrodynamic analysis of ship–ship interaction during the past decade. Ocean. Eng. 2023, 278, 114361. [Google Scholar] [CrossRef]

- Ren, C.; Huang, Y.; Hao, W.; Zhang, D.; Luo, X.; Ma, L.; Wang, J.; Chowwanonthapunya, T.; Dong, C.; Li, X. Multi-action self-healing coatings with simultaneous recovery of corrosion resistance and adhesion strength. J. Mater. Sci. Technol. 2022, 101, 18–27. [Google Scholar] [CrossRef]

- Song, S.; Demirel, Y.K.; De Marco Muscat-Fenech, C.; Tezdogan, T.; Atlar, M. Fouling effect on the resistance of different ship types. Ocean. Eng. 2020, 216, 107736. [Google Scholar] [CrossRef]

- Bekas, D.G.; Tsirka, K.; Baltzis, D.; Paipetis, A.S. Self-healing materials: A review of advances in materials, evaluation, characterization and monitoring techniques. Compos. Part B Eng. 2016, 87, 92–119. [Google Scholar] [CrossRef]

- Mehta, N.K.; Bogere, M.N. Environmental studies of smart/self-healing coating system for steel. Prog. Org. Coat. 2009, 64, 419–428. [Google Scholar] [CrossRef]

- Hager, M.D.; Greil, P.; Leyens, C.; van der Zwaag, S.; Schubert, U.S. Self-healing materials. Adv. Mater. 2010, 22, 5424–5430. [Google Scholar] [CrossRef] [PubMed]

- Ataei, S.; Khorasani, S.N.; Neisiany, R.E. Biofriendly vegetable oil healing agents used for developing self-healing coatings: A review. Prog. Org. Coat. 2019, 129, 77–95. [Google Scholar] [CrossRef]

- Yuk, H.; Zhang, T.; Lin, S.; Parada, G.A.; Zhao, X. Tough bonding of hydrogels to diverse non-porous surfaces. Nat. Mater. 2016, 15, 190–196. [Google Scholar] [CrossRef] [PubMed]

- Chakma, P.; Konkolewicz, D. Dynamic Covalent Bonds in Polymeric Materials. Angew. Chem. Int. Ed. Engl. 2019, 58, 9682–9695. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Zhang, Y.; Liu, J.; Sun, Y.; Ge, Y.; Yan, X.; Wu, J. Preparation and Characterization of Ethylenediamine-Polyurea Microcapsule Epoxy Self-Healing Coating. Materials 2020, 13, 326. [Google Scholar] [CrossRef]

- Ni, X.; Li, C.; Lei, Y.; Shao, Y.; Zhu, Y.; You, B. Design of a Smart Self-Healing Coating with Multiple-Responsive Superhydrophobicity and Its Application in Antibiofouling and Antibacterial Abilities. ACS Appl. Mater. Interfaces 2021, 13, 57864–57879. [Google Scholar] [CrossRef]

- Kaiyun, W.; Taijiang, G.; Jiahao, D.; Jing, L.; Ren, L. Synthesis of robust polyaniline microcapsules via UV-initiated emulsion polymerization for self-healing and anti-corrosion coating. Prog. Org. Coat. 2022, 162, 106592. [Google Scholar] [CrossRef]

- Ma, C.; Wang, W.; Kong, D.; Li, W.; Chen, S. A novel all-organic microcapsule with excellent long-term antibacterial and anti-corrosion performances. J. Colloid. Interface Sci. 2023, 634, 553–562. [Google Scholar] [CrossRef]

- Liu, Y.; Zhan, Y.; Tian, L.; Zhao, J.; Sun, J. Study on the anticorrosion and antifouling performance of magnetically responsive self-healing polyurethane coatings. Prog. Org. Coat. 2024, 186, 108047. [Google Scholar] [CrossRef]

- Abi Nassif, L.; Rioual, S.; Farah, W.; Fauchon, M.; Toueix, Y.; Hellio, C.; Abboud, M.; Lescop, B. Electrophoretic deposition of zinc alginate coatings on stainless steel for marine antifouling applications. J. Environ. Chem. Eng. 2020, 8, 104246. [Google Scholar] [CrossRef]

- Dai, Z.; Cao, M.; Li, S.; Yao, J.; Wu, B.; Wang, Y.; Wang, H.; Dong, J.; Yi, J. A novel marine antifouling coating based on a self-polishing zinc-polyurethane copolymer. J. Coat. Technol. Res. 2021, 18, 1333–1343. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, Y.; Ni, C.; Yu, L. Preparation and evaluation of natural rosin-based zinc resins for marine antifouling. Prog. Org. Coat. 2021, 157, 106270. [Google Scholar] [CrossRef]

- Wang, B.; Wang, P.; He, B.; Liu, S.; Ye, Q.; Zhou, F. Fabrication of ionic liquid-functionalized polystyrene nanospheres via subsurface-initiated atom transfer radical polymerization for anti-fouling application. Prog. Org. Coat. 2022, 171, 107044. [Google Scholar] [CrossRef]

- Li, Q.; Yang, Q.; Cao, Z.; Le, X.; Meng, F.; Ren, Y.; Liu, Q.; Zhang, Q. Enhanced antifouling performance with a synergistic effect of self-renewal antifouling and contact bacteriostasis via the ionic exchange. Prog. Org. Coat. 2024, 192, 108471. [Google Scholar] [CrossRef]

- Chen, T.; Fang, L.; Li, X.; Gao, D.; Lu, C.; Xu, Z. Self-healing polymer coatings of polyurea-urethane/epoxy blends with reversible and dynamic bonds. Prog. Org. Coat. 2020, 147, 105876. [Google Scholar] [CrossRef]

- Ma, J.; Porath, L.E.; Haque, M.F.; Sett, S.; Rabbi, K.F.; Nam, S.; Miljkovic, N.; Evans, C.M. Ultra-thin self-healing vitrimer coatings for durable hydrophobicity. Nat. Commun. 2021, 12, 5210. [Google Scholar] [CrossRef]

- Yang, J.; Xue, B.; Zhou, Y.; Qin, M.; Wang, W.; Cao, Y. Spray-Painted Hydrogel Coating for Marine Antifouling. Adv. Mater. Technol. 2021, 6, 2000911. [Google Scholar] [CrossRef]

- Sun, J.; Duan, J.; Liu, X.; Dong, X.; Zhang, Y.; Liu, C.; Hou, B. Environmentally benign smart self-healing silicone-based coating with dual antifouling and anti-corrosion properties. Appl. Mater. Today 2022, 28, 101551. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Y.; Tian, S.; Qi, X.; Yang, J.; Li, Q.; Lin, C.; Zhang, J.; Zhang, L. A switchable zwitterionic ester and capsaicin copolymer for multifunctional marine antibiofouling coating. Chem. Eng. J. 2022, 436, 135072. [Google Scholar] [CrossRef]

- Wang, C.; Liu, W.; Chen, R.; Sun, G.; Yu, J.; Liu, Q.; Liu, J.; Li, Y.; Zhu, J.; Liu, P.; et al. Macrophage-Inspired marine antifouling coating with dynamic surfaces based on regulation of dynamic covalent bonds. J. Colloid. Interface Sci. 2024, 670, 223–233. [Google Scholar] [CrossRef]

- Richmond, M.D.; Seed, R. A review of marine macrofouling communities with special reference to animal fouling. Biofouling 2009, 3, 151–168. [Google Scholar] [CrossRef]

- Aldred, N.; Scardino, A.; Cavaco, A.; de Nys, R.; Clare, A.S. Attachment strength is a key factor in the selection of surfaces by barnacle cyprids (Balanus amphitrite) during settlement. Biofouling 2010, 26, 287–299. [Google Scholar] [CrossRef]

- Samadzadeh, M.; Boura, S.H.; Peikari, M.; Kasiriha, S.M.; Ashrafi, A. A review on self-healing coatings based on micro/nanocapsules. Prog. Org. Coat. 2010, 68, 159–164. [Google Scholar] [CrossRef]

- Krzak, M.; Tabor, Z.; Nowak, P.; Warszyński, P.; Karatzas, A.; Kartsonakis, I.A.; Kordas, G.C. Water diffusion in polymer coatings containing water-trapping particles. Part 2. Experimental verification of the mathematical model. Prog. Org. Coat. 2012, 75, 207–214. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Balaskas, A.C.; Koumoulos, E.P.; Charitidis, C.A.; Kordas, G. ORMOSIL-epoxy coatings with ceramic containers for corrosion protection of magnesium alloys ZK10. Prog. Org. Coat. 2013, 76, 459–470. [Google Scholar] [CrossRef]

- Pan, P.; Zhang, T.; Yue, Q.; Elzatahry, A.A.; Alghamdi, A.; Cheng, X.; Deng, Y. Interface Coassembly and Polymerization on Magnetic Colloids: Toward Core-Shell Functional Mesoporous Polymer Microspheres and Their Carbon Derivatives. Adv. Sci. 2020, 7, 2000443. [Google Scholar] [CrossRef]

- Li, P.; Fu, T.; Gao, X.; Zhu, W.; Han, C.; Liu, N.; He, S.; Luo, Y.; Ma, W. Adsorption and Reduction Transformation Behaviors of Cr(VI) on Mesoporous Polydopamine/Titanium Dioxide Composite Nanospheres. J. Chem. Eng. Data 2019, 64, 2686–2696. [Google Scholar] [CrossRef]

- Hu, X.; Lu, Y.; Shi, X.; Yao, T.; Dong, C.; Shi, S. Integrating in situ formation of nanozymes with mesoporous polydopamine for combined chemo, photothermal and hypoxia-overcoming photodynamic therapy. Chem. Commun. 2019, 55, 14785–14788. [Google Scholar] [CrossRef]

- Ni, X.; Gao, Y.; Zhang, X.; Lei, Y.; Sun, G.; You, B. An eco-friendly smart self-healing coating with NIR and pH dual-responsive superhydrophobic properties based on biomimetic stimuli-responsive mesoporous polydopamine microspheres. Chem. Eng. J. 2021, 406, 126725. [Google Scholar] [CrossRef]

- Ogurtsov, N.A.; Pud, A.A.; Kamarchik, P.; Shapoval, G.S. Corrosion inhibition of aluminum alloy in chloride mediums by undoped and doped forms of polyaniline. Synth. Met. 2004, 143, 43–47. [Google Scholar] [CrossRef]

- Assassi, F.; Benharrats, N. Synthesis, characterizations and application of polyaniline-paint as anticorrosion agent. Inorg. Nano-Met. Chem. 2021, 51, 805–813. [Google Scholar] [CrossRef]

- Qiu, S.; Chen, C.; Cui, M.; Li, W.; Zhao, H.; Wang, L. Corrosion protection performance of waterborne epoxy coatings containing self-doped polyaniline nano. Appl. Surf. Sci. 2017, 407, 213–222. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, A. Study on the synthesis of PANICNT nanocomposite and its anticorrosion mechanism in waterborne coatings. Prog. Org. Coat. 2021, 159, 106447. [Google Scholar] [CrossRef]

- Shchukina, E.; Wang, H.; Shchukin, D.G. Nanocontainer-based self-healing coatings: Current progress and future perspectives. Chem. Commun. 2019, 55, 3859–3867. [Google Scholar] [CrossRef] [PubMed]

- Ye, K.; Bi, Z.; Cui, G.; Zhang, B.; Li, Z. External self-healing coatings in anticorrosion applications: A review. Corros. Sci. 2020, 76, 279–298. [Google Scholar] [CrossRef]

- Li, Z.; Hu, J.; Li, Y.; Zheng, F.; Liu, J. Self-healing active anticorrosion coatings with polyaniline/cerium nitrate hollow microspheres. Surf. Coat. Technol. 2018, 341, 64–70. [Google Scholar] [CrossRef]

- Dong, J.; Pan, W.; Luo, J.; Liu, R. Synthesis of inhibitor-loaded polyaniline microcapsules with dual anti-corrosion functions for protection of carbon steel. Electrochim. Acta 2020, 364, 137299. [Google Scholar] [CrossRef]

- Dolatkhah, A.; Wilson, L.D. Saline-Responsive and Hydrogen Bond Gating Effects in Self-Healing Polyaniline. ACS Appl. Mater. Interfaces 2020, 2, 2311–2318. [Google Scholar] [CrossRef]

- Li, H.; Feng, Y.; Cui, Y.; Ma, Y.; Zheng, Z.; Qian, B.; Wang, H.; Semenov, A.; Shchukin, D. Polyurea/polyaniline hybrid shell microcapsules loaded with isophorone diisocyanate for synergetic self-healing coatings. Prog. Org. Coat. 2020, 145, 105684. [Google Scholar] [CrossRef]

- Aboudzadeh, M.A.; Shaplov, A.S.; Hernandez, G.; Vlasov, P.S.; Lozinskaya, E.I.; Pozo-Gonzalo, C.; Forsyth, M.; Vygodskii, Y.S.; Mecerreyes, D. Supramolecular ionic networks with superior thermal and transport properties based on novel delocalized di-anionic compounds. J. Mater. Chem. A 2015, 3, 2338–2343. [Google Scholar] [CrossRef]

- Aboudzadeh, M.A.; Zhu, H.; Pozo-Gonzalo, C.; Shaplov, A.S.; Mecerreyes, D.; Forsyth, M. Ionic conductivity and molecular dynamic behavior in supramolecular ionic networks; the effect of lithium salt addition. Electrochim. Acta 2015, 175, 74–79. [Google Scholar] [CrossRef]

- Bubel, S.; Menyo, M.S.; Mates, T.E.; Waite, J.H.; Chabinyc, M.L. Schmitt trigger using a self-healing ionic liquid gated transistor. Adv. Mater. 2015, 27, 3331–3335. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, L.; Pan, C.; Li, D. Review of recent achievements in self-healing conductive materials and their applications. J. Mater. Sci. 2017, 53, 27–46. [Google Scholar] [CrossRef]

- Yuan, J.; Mecerreyes, D.; Antonietti, M. Poly(ionic liquid)s: An update. Prog. Polym. Sci. 2013, 38, 1009–1036. [Google Scholar] [CrossRef]

- Lu, C.; Liu, Y.; Liu, X.; Wang, C.; Wang, J.; Chu, F. Sustainable Multiple- and Multistimulus-Shape-Memory and Self-Healing Elastomers with Semi-interpenetrating Network Derived from Biomass via Bulk Radical Polymerization. ACS Sustain. Chem. Eng. 2018, 6, 6527–6535. [Google Scholar] [CrossRef]

- Scheutz, G.M.; Lessard, J.J.; Sims, M.B.; Sumerlin, B.S. Adaptable Crosslinks in Polymeric Materials: Resolving the Intersection of Thermoplastics and Thermosets. J. Am. Chem. Soc. 2019, 141, 16181–16196. [Google Scholar] [CrossRef]

- Yi, J.; Huang, C.; Zhuang, H.; Gong, H.; Zhang, C.; Ren, R.; Ma, Y. Degradable polyurethane based on star-shaped polyester polyols (trimethylolpropane and ε-caprolactone) for marine antifouling. Prog. Org. Coat. 2015, 87, 161–170. [Google Scholar] [CrossRef]

- Chen, S.; Ma, C.; Zhang, G. Biodegradable polymer as controlled release system of organic antifoulant to prevent marine biofouling. Prog. Org. Coat. 2017, 104, 58–63. [Google Scholar] [CrossRef]

- Chen, S.; Ma, C.; Zhang, G. Biodegradable polymers for marine antibiofouling: Poly(ε-caprolactone)/poly(butylene succinate) blend as controlled release system of organic antifoulant. Polymer 2016, 90, 215–221. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, C.; Hong, Y.; Liu, R.; Zhou, X. Synthesis and application of self-crosslinking and flame retardant waterborne polyurethane as fabric coating agent. Prog. Org. Coat. 2019, 137, 105323. [Google Scholar] [CrossRef]

- Yonehara, Y.; Yamashita, H.; Kawamura, C.; Itoh, K. A new antifouling paint based on a zinc acrylate copolymer. Prog. Org. Coat. 2001, 42, 150–158. [Google Scholar] [CrossRef]

- Yousefi, E.; Dolati, A.; Najafkhani, H. Preparation of robust antistatic waterborne polyurethane coating. Prog. Org. Coat. 2020, 139, 105450. [Google Scholar] [CrossRef]

- Ni, C.; Feng, K.; Li, X.; Zhao, H.; Yu, L. Study on the preparation and properties of new environmentally friendly antifouling acrylic metal salt resins containing indole derivative group. Prog. Org. Coat. 2020, 148, 105824. [Google Scholar] [CrossRef]

- Yebra, D.M.; Kiil, S.; Dam-Johansen, K.; Weinell, C. Reaction rate estimation of controlled-release antifouling paint binders: Rosin-based systems. Prog. Org. Coat. 2005, 53, 256–275. [Google Scholar] [CrossRef]

- Curreri, A.M.; Mitragotri, S.; Tanner, E.E.L. Recent Advances in Ionic Liquids in Biomedicine. Adv. Sci. 2021, 8, 2004819. [Google Scholar] [CrossRef] [PubMed]

- Dong, D.; Tsao, C.; Hung, H.-C.; Yao, F.; Tang, C.; Niu, L.; Ma, J.; MacArthur, J.; Wu, A.S.K.; Jain, P.; et al. High-strength and fibrous capsule–resistant zwitterionic elastomers. Sci. Adv. 2021, 7, eabc5442. [Google Scholar] [CrossRef]

- Li, B.; Yuan, Z.; Jain, P.; Hung, H.-C.; He, Y.; Lin, X.; McMullen, P.; Jiang, S. De novo design of functional zwitterionic biomimetic material for immunomodulation. Sci. Adv. 2020, 6, eaba0754. [Google Scholar] [CrossRef]

- Nakahata, M.; Mori, S.; Takashima, Y.; Yamaguchi, H.; Harada, A. Self-Healing Materials Formed by Cross-Linked Polyrotaxanes with Reversible Bonds. Chem 2016, 1, 766–775. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, P.; Zhang, H.; Yan, C.; Zheng, Z.; Wu, B.; Yu, Y. A Transparent, Highly Stretchable, Autonomous Self-Healing Poly(dimethyl siloxane) Elastomer. Macromol. Rapid Commun. 2017, 38, 1700110. [Google Scholar] [CrossRef]

- Zou, Y.; Li, L.; Tan, B.; Ma, Y.; Fang, L.; Lu, C.; Xu, Z. Silane modified epoxy coatings with low surface tension to achieve self-healing of wide damages. Prog. Org. Coat. 2019, 133, 357–367. [Google Scholar] [CrossRef]

- Wojtecki, R.J.; Meador, M.A.; Rowan, S.J. Using the dynamic bond to access macroscopically responsive structurally dynamic polymers. Nat. Mater. 2011, 10, 14–27. [Google Scholar] [CrossRef] [PubMed]

- Kloxin, C.J.; Bowman, C.N. Covalent adaptable networks: Smart, reconfigurable and responsive network systems. Chem. Soc. Rev. 2013, 42, 7161–7173. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Urban, M.W. Self-healing polymeric materials. Chem. Soc. Rev. 2013, 42, 7446–7467. [Google Scholar] [CrossRef]

- Roy, N.; Bruchmann, B.; Lehn, J.M. DYNAMERS: Dynamic polymers as self-healing materials. Chem. Soc. Rev. 2015, 44, 3786–3807. [Google Scholar] [CrossRef]

- Garcia, F.; Smulders, M.M. Dynamic covalent polymers. J. Polym. Sci. A Polym. Chem. 2016, 54, 3551–3577. [Google Scholar] [CrossRef] [PubMed]

- Chang, K.; Jia, H.; Gu, S.-Y. A transparent, highly stretchable, self-healing polyurethane based on disulfide bonds. Eur. Polym. J. 2019, 112, 822–831. [Google Scholar] [CrossRef]

- Denissen, W.; Winne, J.M.; Du Prez, F.E. Vitrimers: Permanent organic networks with glass-like fluidity. Chem. Sci. 2016, 7, 30–38. [Google Scholar] [CrossRef]

- Guerre, M.; Taplan, C.; Winne, J.M.; Prez, F.E.D. Vitrimers: Directing chemical reactivity to control material properties. Chem. Sci. 2020, 11, 4855–4870. [Google Scholar] [CrossRef]

- Capelot, M.; Montarnal, D.; Tournilhac, F.; Leibler, L. Metal-catalyzed transesterification for healing and assembling of thermosets. J. Am. Chem. Soc. 2012, 134, 7664–7667. [Google Scholar] [CrossRef]

- Lahiri, S.K.; Zhang, P.; Zhang, C.; Liu, L. Robust Fluorine-Free and Self-Healing Superhydrophobic Coatings by H3BO3 Incorporation with SiO2-Alkyl-Silane@PDMS on Cotton Fabric. ACS Appl. Mater. Interfaces 2019, 11, 10262–10275. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Urban, M.W. Self-healing polymers. Nat. Rev. Mater. 2020, 5, 562–583. [Google Scholar] [CrossRef]

- Han, J.; Liu, T.; Hao, C.; Zhang, S.; Guo, B.; Zhang, J. A Catalyst-Free Epoxy Vitrimer System Based on Multifunctional Hyperbranched Polymer. Macromolecules 2018, 51, 6789–6799. [Google Scholar] [CrossRef]

- Jouyandeh, M.; Tikhani, F.; Hampp, N.; Yazdi, D.A.; Zarrintaj, P.; Ganjali, M.R.; Saeb, M.R. Highly curable self-healing vitrimer-like cellulose-modified halloysite nanotube/epoxy nanocomposite coatings. Chem. Eng. J. 2020, 396, 125196. [Google Scholar] [CrossRef]

- Bapat, A.P.; Sumerlin, B.S.; Sutti, A. Bulk network polymers with dynamic B–O bonds: Healable and reprocessable materials. Mater. Horiz. 2020, 7, 694–714. [Google Scholar] [CrossRef]

- Shabanian, S.; Khatir, B.; Nisar, A.; Golovin, K. Rational design of perfluorocarbon-free oleophobic textiles. Nat. Sustain. 2020, 3, 1059–1066. [Google Scholar] [CrossRef]

- Grandjean, P.; Clapp, R. Changing interpretation of human health risks from perfluorinated compounds. Public Health Rep. 2014, 129, 482–485. [Google Scholar] [CrossRef]

- Liao, M.; Wan, P.; Wen, J.; Gong, M.; Wu, X.; Wang, Y.; Shi, R.; Zhang, L. Wearable, Healable, and Adhesive Epidermal Sensors Assembled from Mussel-Inspired Conductive Hybrid Hydrogel Framework. Adv. Funct. Mater. 2017, 27, 1703852. [Google Scholar] [CrossRef]

- Gao, L.; Ma, S.; Ma, Z.; Zheng, Z.; Zhou, F.; Liang, Y. In situ covalent bonding in polymerization to construct robust hydrogel lubrication coating on surface of silicone elastomer. Colloids Surf. A Physicochem. Eng. Asp. 2020, 599, 124753. [Google Scholar] [CrossRef]

- Hawkins, M.L.; Fay, F.; Réhel, K.; Linossier, I.; Grunlan, M.A. Bacteria and diatom resistance of silicones modified with PEO-silane amphiphiles. Biofouling 2014, 30, 247–258. [Google Scholar] [CrossRef]

- Kerboua, B.; Bedia, E.A.A.; Benyoucef, A.T.E.S. Solution théorique améliorée pour étudier les interfaces des structures hybrides déformables, renfor. Matériaux Tech. 2008, 96, 49–63. [Google Scholar] [CrossRef]

- Qian, P.Y.; Lau, S.C.; Dahms, H.U.; Dobretsov, S.; Harder, T. Marine biofilms as mediators of colonization by marine macroorganisms: Implications for antifouling and aquaculture. Mar. Biotechnol. 2007, 9, 399–410. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Cao, Z.; Bai, T.; Carr, L.; Ella-Menye, J.R.; Irvin, C.; Ratner, B.D.; Jiang, S. Zwitterionic hydrogels implanted in mice resist the foreign-body reaction. Nat. Biotechnol. 2013, 31, 553–556. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Liu, Z.; Wu, X.; Guan, Q.; Chen, S.; Sun, L.; Guo, Y.; Wang, S.; Song, J.; Jeffries, E.M.; et al. A Highly Efficient Self-Healing Elastomer with Unprecedented Mechanical Properties. Adv. Mater. 2019, 31, 1901402. [Google Scholar] [CrossRef]

- Chafiq, M.; Chaouiki, A.; Ko, Y.G. Advances in COFs for energy storage devices: Harnessing the potential of covalent organic framework materials. Energy Storage Mater. 2023, 63, 103014. [Google Scholar] [CrossRef]

- Fenker, M.; Balzer, M.; Kappl, H. Corrosion protection with hard coatings on steel: Past approaches and current research efforts. Surf. Coat. Technol. 2014, 257, 182–205. [Google Scholar] [CrossRef]

- Chen, Z.; Scharnagl, N.; Zheludkevich, M.L.; Ying, H.; Yang, W. Micro/nanocontainer-based intelligent coatings: Synthesis, performance and applications—A review. Chem. Eng. J. 2023, 451, 138582. [Google Scholar] [CrossRef]

- Qian, B.; Zheng, Z.; Liu, C.; Li, M.; D’Sa, R.A.; Li, H.; Graham, M.; Michailidis, M.; Kantserev, P.; Vinokurov, V.; et al. Microcapsules Prepared via Pickering Emulsion Polymerization for Multifunctional Coatings. Prog. Org. Coat. 2020, 147, 105785. [Google Scholar] [CrossRef]

- Liu, T.; Li, W.; Zhang, C.; Wang, W.; Dou, W.; Chen, S. Preparation of highly efficient self-healing anticorrosion epoxy coating by integration of benzotriazole corrosion inhibitor loaded 2D-COF. J. Ind. Eng. Chem. 2021, 97, 560–573. [Google Scholar] [CrossRef]

- Li, Z.; Chen, H.; Xu, Q.; Li, X.; Ma, H.; Yuan, Q. Styrene and BPO poly (urea-melamine-formaldehyde) microcapsules prepared via in situ polymerization to promote the self-healing properties of epoxy composites. J. Coat. Technol. Res. 2022, 19, 1837–1850. [Google Scholar] [CrossRef]

- Zhang, C.; Li, W.; Guo, Z.; Sun, T.; Wang, W.; Chen, S. Controllable construction of mesoporous silica/2D-COF nanocomposites reinforced epoxy coatings with excellent self-repairing and long-lasting anticorrosion performances. Prog. Org. Coat. 2023, 177, 107441. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, C.; Guo, M. Fabrication of diisocyanate microcapsules for self-healing anti-corrosion coatings via integrating electrospraying and interfacial polymerization. Colloids Surf. A Physicochem. Eng. Asp. 2024, 695, 134247. [Google Scholar] [CrossRef]

- Liu, C.; Jin, Z.; Cheng, L.; Zhao, H.; Wang, L. Synthesis of nanosensors for autonomous warning of damage and self-repairing in polymeric coatings. Nanoscale 2020, 12, 3194–3204. [Google Scholar] [CrossRef] [PubMed]

- Lv, J.; Yue, Q.-x.; Ding, R.; Li, W.-h.; Wang, X.; Gui, T.-j.; Zhao, X.-d. Intelligent anti-corrosion and corrosion detection coatings based on layered supramolecules intercalated by fluorescent off-on probes. J. Taiwan Inst. Chem. Eng. 2021, 118, 309–324. [Google Scholar] [CrossRef]

- Liu, C.; Cheng, L.; Cui, L.; Qian, B.; Zeng, R. Corrosion self-diagnosing and self-repairing polymeric coatings based on zeolitic imidazolate framework decorated hydroxyapatite nanocontainer on steel. Chem. Eng. J. 2022, 431, 133476. [Google Scholar] [CrossRef]

- Gong, W.; Cheng, J.; Yan, W.; Zou, H.; Gao, C.; Liu, X.; Wang, L. Preparation and performance study of photo-initiated self-healing self-warning microencapsulated coated fabrics. Prog. Org. Coat. 2024, 192, 108530. [Google Scholar] [CrossRef]

- Cheng, L.; Jiao, D.; Cao, L.; Hou, P.; Deng, K.; Liu, C. Fluorescein-loaded nanoflowers driven smart anticorrosion coating for hierarchically visually monitoring of early failure process. Prog. Org. Coat. 2024, 194, 108579. [Google Scholar] [CrossRef]

- Hao, X.; Chen, S.; Qin, D.; Zhang, M.; Li, W.; Fan, J.; Wang, C.; Dong, M.; Zhang, J.; Cheng, F.; et al. Antifouling and antibacterial behaviors of capsaicin-based pH responsive smart coatings in marine environments. Mater. Sci. Eng. C Mater. Biol. Appl. 2020, 108, 110361. [Google Scholar] [CrossRef]

- Hao, X.; Yan, W.; Sun, Z.; Yang, J.; Bai, Y.; Qian, H.; Chowwanonthapunya, T.; Zhang, D. pH-Responsive Allicin-Based Coatings With Antibacterial and Antifouling Effects in Marine Environments. Front. Mater. 2022, 9, 852731. [Google Scholar] [CrossRef]

- Li, C.; Wang, P.; Zhang, D.; Wang, S. Near-Infrared Responsive Smart Superhydrophobic Coating with Self-Healing and Robustness Enhanced by Disulfide-Bonded Polyurethane. ACS Appl. Mater. Interfaces 2022, 14, 45988–46000. [Google Scholar] [CrossRef]

- Feng, H.; Wang, W.; Wang, T.; Zhang, L.; Li, W.; Hou, J.; Chen, S. Preparation of dynamic polyurethane networks with UV-triggered photothermal self-healing properties based on hydrogen and ion bonds for antibacterial applications. ACS Appl. Mater. Interfaces 2023, 133, 89–101. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Gui, T.; Guo, H.; Zhang, K.; Meng, F.; Zhan, X.; Liu, Q.; Zhang, Q. Carp-inspired self-regulating marine antifouling coating: Featuring robust controlled release of eugenol and high-efficiency self-healing performance. Chem. Eng. J. 2024, 486, 149929. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Y.; Zhong, J.; Yu, C. Superhydrophobic Coatings on Cellulose-Based Materials with Alkyl Ketene Dimer Pickering Emulsion: Fabrication and Properties. Coatings 2023, 13, 1829. [Google Scholar] [CrossRef]

- Watanabe, R.; Izaki, K.; Yamamoto, K.; Kadokawa, J.-I. Preparation of Nanochitin/Polystyrene Composite Particles by Pickering Emulsion Polymerization Using Scaled-Down Chitin Nanofibers. Coatings 2021, 11, 672. [Google Scholar] [CrossRef]

- Tischer, M.; Pradel, G.; Ohlsen, K.; Holzgrabe, U. Quaternary ammonium salts and their antimicrobial potential: Targets or nonspecific interactions? ChemMedChem 2012, 7, 22–31. [Google Scholar] [CrossRef] [PubMed]

- Almeida, L.P.; Coolen, J.W.P. Modelling thickness variations of macrofouling communities on offshore platforms in the Dutch North Sea. J. Sea Res. 2020, 156, 101836. [Google Scholar] [CrossRef]

- Li, X.; Li, X.; Zhao, Y.; Li, Q.; Wang, J.; Kang, M. Controllable preparation of isophorone diisocyanate microcapsules with silica/polyurea hybrid shells and application in self-healing epoxy coatings. Prog. Org. Coat. 2022, 163, 106638. [Google Scholar] [CrossRef]

- Hwang, J.-S.; Kim, J.-N.; Wee, Y.-J.; Yun, J.-S.; Jang, H.-G.; Kim, S.-H.; Ryu, H.-W. Preparation and characterization of melamine-formaldehyde resin microcapsules containing fragrant oil. Biotechnol. Bioprocess. Eng. 2006, 11, 332–336. [Google Scholar] [CrossRef]

- Bakry, A.M.; Abbas, S.; Ali, B.; Majeed, H.; Abouelwafa, M.Y.; Mousa, A.; Liang, L. Microencapsulation of Oils: A Comprehensive Review of Benefits, Techniques, and Applications. Compr. Rev. Food Sci. Food Safety 2016, 15, 143–182. [Google Scholar] [CrossRef]

- Ricardo, F.; Pradilla, D.; Luiz, R.; Alvarez Solano, O.A. A Multi-Scale Approach to Microencapsulation by Interfacial Polymerization. Polymers 2021, 13, 644. [Google Scholar] [CrossRef]

- Mytara, A.D.; Chronaki, K.; Nikitakos, V.; Papaspyrides, C.D.; Beltsios, K.; Vouyiouka, S. Synthesis of Polyamide-Based Microcapsules via Interfacial Polymerization: Effect of Key Process Parameters. Materials 2021, 14, 5895. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, H.; Gui, H.; Yao, C.; Zhang, G.; Liang, F. Solid-liquid phase change materials microcapsules: Synthesis strategies, thermal storage and beyond. Prog. Nat. Sci. Mater. Int. 2024, 34, 615–631. [Google Scholar] [CrossRef]

- Kandambeth, S.; Mallick, A.; Lukose, B.; Mane, M.V.; Heine, T.; Banerjee, R. Construction of crystalline 2D covalent organic frameworks with remarkable chemical (acid/base) stability via a combined reversible and irreversible route. J. Am. Chem. Soc. 2012, 134, 19524–19527. [Google Scholar] [CrossRef]

- Biswal, B.P.; Chandra, S.; Kandambeth, S.; Lukose, B.; Heine, T.; Banerjee, R. Mechanochemical synthesis of chemically stable isoreticular covalent organic frameworks. J. Am. Chem. Soc. 2013, 135, 5328–5331. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wu, Y.; Sun, Y.; Zhao, W.; Wang, L. 2D Nanomaterials Reinforced Organic Coatings for Marine Corrosion Protection: State of the Art, Challenges, and Future Prospectives. Adv. Mater. 2024, 36, 2312460. [Google Scholar] [CrossRef] [PubMed]

- Zou, C.; Li, Q.; Hua, Y.; Zhou, B.; Duan, J.; Jin, W. Mechanical Synthesis of COF Nanosheet Cluster and Its Mixed Matrix Membrane for Efficient CO2 Removal. ACS Appl. Mater. Interfaces 2017, 9, 29093–29100. [Google Scholar] [CrossRef]

- Patrick, J.F.; Robb, M.J.; Sottos, N.R.; Moore, J.S.; White, S.R. Polymers with autonomous life-cycle control. Nature 2016, 540, 363–370. [Google Scholar] [CrossRef]

- Kling, S.; Czigány, T. Damage detection and self-repair in hollow glass fiber fabric-reinforced epoxy composites via fiber filling. Compos. Sci. Technol. 2014, 99, 82–88. [Google Scholar] [CrossRef]

- Wang, J.P.; Wang, J.K.; Zhou, Q.; Li, Z.; Han, Y.; Song, Y.; Yang, S.; Song, X.; Qi, T.; Möhwald, H.; et al. Adaptive Polymeric Coatings with Self-Reporting and Self-Healing Dual Functions from Porous Core–Shell Nanostructures. Macromol. Mater. Eng. 2018, 303, 1700616. [Google Scholar] [CrossRef]

- Calvino, C.; Weder, C. Microcapsule-Containing Self-Reporting Polymers. Small 2018, 14, 1802489. [Google Scholar] [CrossRef]

- Rifaie-Graham, O.; Apebende, E.A.; Bast, L.K.; Bruns, N. Self-Reporting Fiber-Reinforced Composites That Mimic the Ability of Biological Materials to Sense and Report Damage. Adv. Mater. 2018, 30, 1705483. [Google Scholar] [CrossRef]

- Di Credico, B.; Griffini, G.; Levi, M.; Turri, S. Microencapsulation of a UV-responsive photochromic dye by means of novel UV-screening polyurea-based shells for smart coating applications. ACS Appl. Mater. Interfaces 2013, 5, 6628–6634. [Google Scholar] [CrossRef] [PubMed]

- van den Dungen, E.T.A.; Loos, B.; Klumperman, B. Use of a profluorophore for visualization of the rupture of capsules in self-healing coatings. Macromol. Rapid Commun. 2010, 31, 625–628. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Matthews, C.C.; Yang, K.; Odarczenko, M.T.; White, S.R.; Sottos, N.R. Autonomous Indication of Mechanical Damage in Polymeric Coatings. Adv. Mater. 2016, 28, 2189–2194. [Google Scholar] [CrossRef]

- Vidinejevs, S.; Aniskevich, A.N.; Gregor, A.; Sjöberg, M.; Alvarez, G. Smart polymeric coatings for damage visualization in substrate materials. J. Intell. Mater. Syst. Struct. 2012, 23, 1371–1377. [Google Scholar] [CrossRef]

- Mata, D.; Scharnagl, N.; Lamaka, S.V.; Malheiro, E.; Maia, F.; Zheludkevich, M.L. Validating the early corrosion sensing functionality in poly (ether imide) coatings for enhanced protection of magnesium alloy AZ31. Corros. Sci. 2018, 140, 307–320. [Google Scholar] [CrossRef]

- Lu, X.; Li, W.; Sottos, N.R.; Moore, J.S. Autonomous Damage Detection in Multilayered Coatings via Integrated Aggregation-Induced Emission Luminogens. ACS Appl. Mater. Interfaces 2018, 10, 40361–40365. [Google Scholar] [CrossRef]

- Robb, M.J.; Li, W.; Gergely, R.C.; Matthews, C.C.; White, S.R.; Sottos, N.R.; Moore, J.S. A Robust Damage-Reporting Strategy for Polymeric Materials Enabled by Aggregation-Induced Emission. ACS Cent. Sci. 2016, 2, 598–603. [Google Scholar] [CrossRef]

- Qiu, Z.; Zhao, W.; Cao, M.; Wang, Y.; Lam, J.W.Y.; Zhang, Z.; Chen, X.; Tang, B.Z. Dynamic Visualization of Stress/Strain Distribution and Fatigue Crack Propagation by an Organic Mechanoresponsive AIE Luminogen. Adv. Mater. 2018, 30, 1803924. [Google Scholar] [CrossRef]

- Davis, D.A.; Hamilton, A.; Yang, J.; Cremar, L.D.; Van Gough, D.; Potisek, S.L.; Ong, M.T.; Braun, P.V.; Martinez, T.J.; White, S.R.; et al. Force-induced activation of covalent bonds in mechanoresponsive polymeric materials. Nature 2009, 459, 68–72. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Barbee, M.H.; Cho, S.; Cho, S.; Shanker, R.; Kim, J.; Myoung, J.; Kim, M.P.; Baig, C.; et al. A Hierarchical Nanoparticle-in-Micropore Architecture for Enhanced Mechanosensitivity and Stretchability in Mechanochromic Electronic Skins. Adv. Mater. 2019, 31, 1808148. [Google Scholar] [CrossRef] [PubMed]

- Shree, S.; Dowds, M.; Kuntze, A.; Mishra, Y.K.; Staubitz, A.; Adelung, R. Self-reporting mechanochromic coating: A glassfiber reinforced polymer composite that predicts impact induced damage. Mater. Horiz. 2020, 7, 598–604. [Google Scholar] [CrossRef]

- Zhao, W.; He, Z.; Peng, Q.; Lam, J.W.Y.; Ma, H.; Qiu, Z.; Chen, Y.; Zhao, Z.; Shuai, Z.; Dong, Y.; et al. Highly sensitive switching of solid-state luminescence by controlling intersystem crossing. Nat. Commun. 2018, 9, 3044. [Google Scholar] [CrossRef] [PubMed]

- Pu, W.; Fu, D.; Wang, Z.; Gan, X.; Lu, X.; Yang, L.; Xia, H. Realizing Crack Diagnosing and Self-Healing by Electricity with a Dynamic Crosslinked Flexible Polyurethane Composite. Adv. Sci. 2018, 5, 1800101. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.; Bao, C.; Li, X.; Duan, F.; Friedrich, K.; Yang, J. Skin-Inspired, Fully Autonomous Self-Warning and Self-Repairing Polymeric Material under Damaging Events. Chem. Mater. 2019, 31, 2611–2618. [Google Scholar] [CrossRef]

- Hu, M.; Peil, S.; Xing, Y.; Döhler, D.; Caire da Silva, L.; Binder, W.H.; Kappl, M.; Bannwarth, M.B. Monitoring crack appearance and healing in coatings with damage self-reporting nanocapsules. Mater. Horiz. 2018, 5, 51–58. [Google Scholar] [CrossRef]

- Guo, Y.K.; Chen, L.; Xu, D.G.; Zhong, J.R.; Yue, G.Z.; Astruc, D.; Shuai, M.B.; Zhao, P.X. A dual functional epoxy material with autonomous damage indication and self-healing. RSC Adv. 2016, 6, 65067–65071. [Google Scholar] [CrossRef]

- Ma, S.; Huang, L.; Ma, L.; Shim, Y.; Islam, S.M.; Wang, P.; Zhao, L.D.; Wang, S.; Sun, G.; Yang, X.; et al. Efficient uranium capture by polysulfide/layered double hydroxide composites. J. Am. Chem. Soc. 2015, 137, 3670–3677. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Q.; Islam, S.M.; Liu, Y.; Ma, S.; Kanatzidis, M.G. Highly Selective and Efficient Removal of Heavy Metals by Layered Double Hydroxide Intercalated with the MoS42- Ion. J. Am. Chem. Soc. 2016, 138, 2858–2866. [Google Scholar] [CrossRef]

- Lv, F.; Xu, L.; Zhang, Y.; Meng, Z. Layered double hydroxide assemblies with controllable drug loading capacity and release behavior as well as stabilized layer-by-layer polymer multilayers. ACS Appl. Mater. Interfaces 2015, 7, 19104–19111. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, G.; Peng, X.; Li, L.; Feng, H.; Gao, B.; Huo, K.; Chu, P.K. Mitigation of Corrosion on Magnesium Alloy by Predesigned Surface Corrosion. Sci. Rep. 2015, 5, 17399. [Google Scholar] [CrossRef]

- Sene, S.; Bégu, S.; Gervais, C.; Renaudin, G.; Mesbah, A.; Smith, M.E.; Mutin, P.H.; van der Lee, A.; Nedelec, J.-M.; Bonhomme, C.; et al. Intercalation of Benzoxaborolate Anions in Layered Double Hydroxides: Toward Hybrid Formulations for Benzoxaborole Drugs. Chem. Mater. 2015, 27, 1242–1254. [Google Scholar] [CrossRef]

- Chen, H.; Wang, F.; Fan, H.; Hong, R.; Li, W. Construction of MOF-based superhydrophobic composite coating with excellent abrasion resistance and durability for self-cleaning, corrosion resistance, anti-icing, and loading-increasing research. Chem. Eng. J. 2021, 408, 127343. [Google Scholar] [CrossRef]

- Ramezanzadeh, M.; Ramezanzadeh, B.; Mahdavian, M.; Bahlakeh, G. Development of metal-organic framework (MOF) decorated graphene oxide nanoplatforms for anti-corrosion epoxy coatings. Carbon 2020, 161, 231–251. [Google Scholar] [CrossRef]

- Seidi, F.; Jouyandeh, M.; Taghizadeh, M.; Taghizadeh, A.; Vahabi, H.; Habibzadeh, S.; Formela, K.; Saeb, M.R. Metal-Organic Framework (MOF)/Epoxy Coatings: A Review. Materials 2020, 13, 2881. [Google Scholar] [CrossRef]

- Zhou, C.; Li, Z.; Li, J.; Yuan, T.; Chen, B.; Ma, X.; Jiang, D.; Luo, X.; Chen, D.; Liu, Y. Epoxy composite coating with excellent anticorrosion and self-healing performances based on multifunctional zeolitic imidazolate framework derived nanocontainers. Chem. Eng. J. 2020, 385, 123835. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, S.; Wu, Y.; Guan, T.; Sun, N.; Ren, B. Self-healing UV light-curable resins containing disulfide group: Synthesis and application in UV coatings. Prog. Org. Coat. 2019, 133, 289–298. [Google Scholar] [CrossRef]

- Hu, T.; Shi, H.; Fan, S.; Liu, F.; Han, E.-H. Cerium tartrate as a pigment in epoxy coatings for corrosion protection of AA 2024-T3. Prog. Org. Coat. 2017, 105, 123–131. [Google Scholar] [CrossRef]

- Nevejans, S.; Ballard, N.; Fernández, M.; Reck, B.; Asua, J.M. Flexible aromatic disulfide monomers for high-performance self-healable linear and cross-linked poly(urethane-urea) coatings. Polymer 2019, 166, 229–238. [Google Scholar] [CrossRef]

- Khayatan, N.; Rohwerder, M. A new insight into the rate determining step of cathodic delamination. Corros. Sci. 2022, 202, 110311. [Google Scholar] [CrossRef]

- Schoolaert, E.; Steyaert, I.; Vancoillie, G.; Geltmeyer, J.; Lava, K.; Hoogenboom, R.; De Clerck, K. Blend electrospinning of dye-functionalized chitosan and poly(epsilon-caprolactone): Towards biocompatible pH-sensors. J. Mater. Chem. B 2016, 4, 4507–4516. [Google Scholar] [CrossRef] [PubMed]

- Abou-Yousef, H.; Khattab, T.A.; Youssef, Y.A.; Al-Balakocy, N.; Kamel, S. Novel cellulose-based halochromic test strips for naked-eye detection of alkaline vapors and analytes. Talanta 2017, 170, 137–145. [Google Scholar] [CrossRef] [PubMed]

- Kamensky, K.M.; Hellum, A.M.; Mukherjee, R.; Naik, A.; Moisander, P.H. Underwater shear-based grooming of marine biofouling using a non-contact Bernoulli pad device. Biofouling 2020, 36, 951–964. [Google Scholar] [CrossRef]

- Ma, L.; Wang, J.; Zhang, D.; Huang, Y.; Huang, L.; Wang, P.; Qian, H.; Li, X.; Terryn, H.A.; Mol, J.M.C. Dual-action self-healing protective coatings with photothermal responsive corrosion inhibitor nanocontainers. Chem. Eng. J. 2021, 404, 127118. [Google Scholar] [CrossRef]

- Yan, W.; Ding, Y.; Zhang, R.; Luo, X.; Sheng, P.; Xue, P.; He, J. Dual-functional polymer blends with rapid thermo-responsive shape memory and repeatable self-healing properties. Polymer 2022, 239, 124436. [Google Scholar] [CrossRef]

- Xiong, C.; Li, M.; Han, Q.; Zhao, W.; Dai, L.; Ni, Y. Screen printing fabricating patterned and customized full paper-based energy storage devices with excellent photothermal, self-healing, high energy density and good electromagnetic shielding performances. J. Mater. Sci. Technol. 2022, 97, 190–200. [Google Scholar] [CrossRef]

- Yang, X.; Zhong, X.; Zhang, J.; Gu, J. Intrinsic high thermal conductive liquid crystal epoxy film simultaneously combining with excellent intrinsic self-healing performance. J. Mater. Sci. Technol. 2021, 68, 209–215. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, X.; Kang, J.; Yu, Z.; Tian, J.; Gong, Z.; Jia, A.; You, R.; Qian, K.; He, S.; et al. The active sites of Cu-ZnO catalysts for water gas shift and CO hydrogenation reactions. Nat. Commun. 2021, 12, 4331. [Google Scholar] [CrossRef]

- Kouklin, N. Cu-Doped ZnO Nanowires for Efficient and Multispectral Photodetection Applications. Adv. Mater. 2008, 20, 2190–2194. [Google Scholar] [CrossRef]

- Chen, R.; Luo, F.; Liu, Y.; Song, Y.; Dong, Y.; Wu, S.; Cao, J.; Yang, F.; N’Diaye, A.; Shafer, P.; et al. Tunable room-temperature ferromagnetism in Co-doped two-dimensional van der Waals ZnO. Nat. Commun. 2021, 12, 3952. [Google Scholar] [CrossRef]

- Vaiano, V.; Iervolino, G.; Rizzo, L. Cu-doped ZnO as efficient photocatalyst for the oxidation of arsenite to arsenate under visible light. Appl. Catal. B Environ. 2018, 238, 471–479. [Google Scholar] [CrossRef]

| Category | Year * | Denomination | Metabolic Substance |

|---|---|---|---|

| Microfouling Organisms | 2020 | Bacteria [18] | Organic acids like lactic acid and acetic acid. |

| 2021 | diatoms [19] | Polysaccharides, pigments (including pigments like xanthophylls, chlorophylls, and others), and UV-absorbing compounds similar to mycosporine amino acids. | |

| 2022 | fungi [20] | Carbohydrate, lipid, protein. | |

| 2024 | microalgae [21] | Plant sterols, aromatic substances (including phenolic acids, brominated phenols, root tannins, flavonoid derivatives, and related compounds), lipids, and nitrogen-containing compounds. | |

| Soft Macrofouling Organisms | 2020 | Large algae [22] | Phenolic compounds, encompassing bromophenols, phthalic acid tannins, and flavonoids; terpenoids, comprising steroids and carotenoids; thio-terpenoids; nitrogen-containing compounds, including proteins, nitrogenous bases, and chlorophyll analogs; as well as saccharides and complex carbohydrates. |

| 2024 | soft corals [23] | Hemiterpenes, diterpenes, steroids and fatty acids. | |

| 2024 | sea anemones [24] | Triterpenoid saponins, organic acids and coumarins. | |

| 2024 | sponges [25] | Steroidal compounds, terpenoids, cyclic peptides, alkaloids and pyrimidines. | |

| Hard macrofouling organisms | 2022 | tube worms [26] | Biological compounds such as carbohydrates, amino acids, vitamins and cofactors, among others. |

| 2024 | barnacles [27] | Chitin, calcite, chitinase and calcite hydrolase. |

| Antifouling Types | Year * | Compound | Main Characteristics and Requirements | Advantages | Disadvantages |

|---|---|---|---|---|---|

| 2020 | Microencapsulated polyurea with ethylenediamine as the central component [46] | High Self-healing Efficiency; Thermal Stability; High Core Content; Excellent Corrosion Resistance. | Enhanced Mechanical Properties; Improved Self-Healing Capability; Thermal Stability. | Poor Dispersion; Poor Degradability; High Cost. | |

| 2021 | ZnO-encapsulated MPDA microspheres responsive to UV, NIR, and acid/base stimuli [47] | Multiple Responsiveness; Superhydrophobicity Antibacterial and Antibiofouling Properties; Environmental Stability; Multifunctionality. | Effective Bacterial Inhibition; UV Resistance and Corrosion Resistance; Low Raw Material Cost. | UV Degradation; Slow Self-Healing Rate; Poor Compatibility. | |

| Microcapsules | 2022 | Tung oil-PGMA@PANI microcapsules [48] | Self-healing; Corrosion Inhibition; Mechanical Stability; Uniform Dispersion; Long-term Durability. | Improved Self-Healing Capability; Enhanced Corrosion Resistance; Controlled Release. | Limited Mechanical Strength; Potential for Incomplete Healing; Environmental Sensitivity. |

| 2023 | Salicylic acid@polyurea-formaldehyde [49] | Long-term Antibacterial Activity; Anti-corrosion; Controlled Release; and Environmental Durability. | Excellent long-term Antibacterial Properties; Controlled Release of Salicylic Acid; Enhanced Stability of Salicylic Acid. | Limited Mechanical Strength; Potential for Incomplete Release; Cost of Production. | |

| 2024 | Magnetically responsive microcapsules with self-healing properties [50] | Magnetically Responsive Self-healing; Corrosion-resistant; Antifouling; Well-dispersed Microcapsules for Enhanced Durability. | Controlled Release; Enhanced Durability and Protection; Eco-Friendly. | Complex Synthesis Process; High Production Costs; Limited Mechanical Strength. | |

| 2020 | Zinc alginate coatings applied through electrophoretic deposition [51] | Marine Antifouling; Zinc/calcium Ion Integration; Electrophoretic Deposition; Biocompatibility; Corrosion Resistance and Long-term Durability. | Improved Corrosion Resistance; Environmentally Friendly; Uniform Coating Thickness. | Limited Mechanical Strength; Thermal Instability; Limited Durability. | |

| 2021 | Polymeric salt-based zinc ions [52] | Self-polishing; Zinc-polyurethane Copolymer; Controlled Degradation; Marine Antifouling Efficiency; Biocide release; Long-term Durability. | Extended durability; Regulated marine fouling-resistant coatings; Enhanced stability. | High Production Costs; Limited Mechanical Strength; Potential Toxicity at High Concentrations. | |

| Ion Exchange | 2022 | Natural rosinbased zinc (RZn-x) resins [53] | Hydrolysis-Controlled Self-polishing; Antibacterial; Anti-algal; Environmentally Friendly; Long-term Durability. | Eco-Friendly and Renewable; Good Corrosion Resistance; Low Cost. | Limited Thermal Stability; Poor UV Resistance; Limited Mechanical Strength. |

| 2022 | IL-functionalized polystyrene nanospheres [54] | Ionic Liquid Functionalization; Antibacterial and Antifouling Properties; Wear Resistance; Self-Polishing Nanocomposite Coatings. | Enhanced Surface Properties; Increased Stability and Solubility; Enhanced Catalytic Activity. | Complex Synthesis Process; Potential Toxicity of Ionic Liquids; Limited Mechanical Strength. | |

| 2024 | Poly-ionic liquid-derived antimicrobial polyacrylate-3 coating [55] | Self-Renewing Antifouling; Ionic Exchange; Antibacterial and Anti-Algal Properties; Self-Cleaning; Optical Device Compatibility. | Effective Antimicrobial Properties; Durability and Long-lasting Protection; Flexibility and Adhesion. | High Production Cost; Environmental Sensitivity; Limited Mechanical Strength. | |

| 2020 | Dynamic disulfide bonds [56] | Self-Healing; Reversible Bonds; Shape-Memory Crack Closure; Enhanced Mechanical Properties; Phase Separation. | Thermally Responsive; Flexibility in Design; Enhanced Mechanical Properties. | Sensitivity to Reducing Agents; Limited Stability Under Harsh Conditions; Slower Reformation Rate. | |

| 2021 | Polydimethylsiloxane network fibers and reversible boronic ester linkages [57] | Ultra-Thin Self-Healing; Durable Hydrophobicity; Scratch Resistance; Superhydrophobicity; Scalable Fabrication; Environmentally Friendly. | Reversible Crosslinking; Improved Mechanical Properties; Durability. | Sensitivity to Environmental Factors; Lower Long-Term Mechanical Strength; Complexity in Synthesis. | |

| Dynamic Covalent Bonds | 2021 | Polyacrylamide multiarmed polyethylene glycol [58] | Spray-Paintable Hydrogel; Antifouling; Self-Polishing; High Adhesion; Mechanical Stability; Seawater Degradation. | Improved Stability; Functional Flexibility; Controlled Release and Gel Formation. | Complex Synthesis; Environmental Persistence; Cost. |

| 2022 | PDMS-based polymer [59] | Smart Self-Healing; Dual Antifouling and Anti-Corrosion; Silicone-Based; High Toughness; Environmentally Friendly; Strong Adhesion. | Flexibility and Elastomeric Properties; Thermal Stability; Optical Transparency. | Low Mechanical Strength; Low Adhesion; Cost. | |

| 2022 | Polydimethylsiloxane network [60] | Switchable Zwitterionic Ester; Antibacterial and Antifouling; Sustainable Capsaicin Release; Long-Term Performance; Environmental Adaptability. | Improved Mechanical Properties; Increased Durability; Enhanced Thermal Stability. | Brittleness at Low Crosslinking Densities; Difficult Processing; Difficult to Bond to Other Materials. | |

| 2024 | Polyurethane incorporating dimethylglyoxime [61] | Macrophage-Inspired Antifouling; Dynamic Surface; Free Radical Release; Self-Regenerating; Antibacterial and Antialgal. | Enhanced Metal Ion Binding; Improved Mechanical Properties; Enhanced Durability and Resistance. | Stability Issues; Processing Complexity; Cost. |

| Antifouling Strategies | Year * | Technology | Main Characteristics and Requirements | Advantages | Disadvantages |

|---|---|---|---|---|---|

| 2020 | Pickering Emulsion Polymerization [128] | Solid Particle Stabilization; High Emulsion Stability; Surface Modification; Multifunctional Coatings; Self-Healing and Antimicrobial Properties. | Environmentally friendly; Stable; Multifunctional. | High cost; Complex process; Limited monomer selection. | |

| 2021 | Covalent Organic Framework (COF) [129] | 2D Nanostructure; High Porosity; Chemical Stability; Low Interlayer Interactions; Functional Group Availability; Improved Dispersion. | High specific surface area and porosity; Strong structural designability; Excellent stability. | Stringent synthesis conditions; Poor processing performance; Relatively high cost. | |

| Microencapsulation Type | 2022 | In situ polymerization [130] | Core–Shell Structure; Controlled Polymerization; Stable Emulsification; High Encapsulation Efficiency; Thermal Stability; Versatility. | Strong interfacial bonding; Simple process; Wide application. | Limited monomer selection; Difficult reaction control; Relatively high cost. |

| 2023 | Covalent Organic Framework [131] | 2D Structure; High Dispersion; Physical Barrier; Epoxy Resin Reactivity; Corrosion Resistance; Compatibility with Nanomaterials. | High specific surface area and porosity; Strong structural designability; Excellent stability. | Stringent synthesis conditions; Poor processing performance; Relatively high cost. | |

| 2024 | Interfacial polymerization [132] | Core–Shell Structure; Rapid Polymerization; High Core Content; Controllable Shell Thickness; Good Dispersion; Thermal Stability. | Fast reaction rate; Easy to control; Wide application. | Limited monomer selection; High requirements for interfacial stability; Difficulties in large-scale production. | |

| 2020 | Damage probes and corrosion inhibitors [133] | Damage Detection; Corrosion Inhibition; Controlled Release; Dual Functionality; Efficient Loading; Long-Term Protection. | High sensitivity; Accurate positioning; Various types. | Relatively high cost; Complex process; Environmental impact. | |

| 2021 | Fluorescent probe [134] | Fluorescent On–Off Mechanism; Corrosion Sensitivity; Fluorescence Enhancement; Premature Exposure Protection; Targeted Release; High Selectivity. | High sensitivity; Accurate positioning; Various types. | Relatively high cost; Complex process; Environmental impact. | |

| Corrosion Early Warning Mechanism | 2022 | pH-sensitive molecules [135] | Corrosion Inhibition; pH-Responsive Release; Localized Protection; Targeted Release; Continuous Effectiveness. | High sensitivity; Environmental friendliness; Wide application. | Relatively high cost; Complex process; Environmental impact. |

| 2024 | Fluorescent agents and cations [136] | Fluorescent Visualization; Early Damage Detection; UV-Triggered Polymerization; Self-Healing Activation; Good Compatibility. | High sensitivity; Environmental friendliness; Wide application. | Background interference; Toxicity; Relatively high cost. | |

| 2024 | Fluorescent probe [137] | Fluorescence On–Off Behavior; pH and Metal Ion Sensitivity; Early Corrosion Detection; High Selectivity; Fluorescence Enhancement; Corrosion-Specific Response. | High sensitivity; Accurate positioning; Various types. | Relatively high cost; Complex process; Environmental impact. | |

| 2020 | pH variation [138] | pH-Responsive Release; Controlled CAP Release; Enhanced Antibacterial in Alkaline pH; Long-Term Stability; Dynamic Control of Antifouling. | Environmental responsiveness; Durability; Environmental friendliness. | High pH control requirements; Limited repair effectiveness; Complexity. | |

| 2021 | Near-infrared (NIR) response [70] | NIR-Responsive; Photothermal Effect; Repeatable Self-Healing; Thermal Response; Durability and Reversibility. | Precise control; No chemical stimulation required; Efficient local repair. | Relatively high cost; Strong dependence on NIR light source; Limited penetration ability. | |

| Smart Responsive Protection | 2022 | pH variation [139] | pH-Induced Release; Controlled Antibacterial Properties; Long-Term Stability; Responsive to pH Variation. | Environmental responsiveness; Durability; Environmental friendliness. | High pH control requirements; Limited repair effectiveness; Complexity. |

| 2022 | Near-infrared (NIR) response [140] | NIR-Induced Self-Healing; Photothermal Effect; Recovery of Superhydrophobicity; Repeatable Performance; Localized Healing. | Precise control; No chemical stimulation required; Efficient local repair. | Relatively high cost; Strong dependence on NIR light source; Limited penetration ability. | |

| 2023 | Ultraviolet (UV) light [141] | UV-Triggered Self-Healing; Photocatalytic Effect; Controlled Polymerization; Efficiency and Control; Repeatability. | Fast Response; Selective Activation; Reversibility. | Dependency on UV Light; Limited Depth of Penetration; Material Compatibility. | |

| 2024 | Disulfide bonds and hydrogen bonds [142] | Synergistic Self-Healing; Thermal Reversibility; Chain Mobility; Mechanical Reinforcement; Enhanced Adhesion. | Reversibility; Environmental resistance; Wide application. | Slower repair speed; Temperature sensitivity; Relatively high cost. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, W.; Qian, J.; Wang, X.; Liang, C.; Cui, L.; Tian, H.; Liaw, P.K. Research Progress of Self-Healing Coatings on Ships Against Biological Pollution: A Review. Coatings 2025, 15, 486. https://doi.org/10.3390/coatings15040486

Niu W, Qian J, Wang X, Liang C, Cui L, Tian H, Liaw PK. Research Progress of Self-Healing Coatings on Ships Against Biological Pollution: A Review. Coatings. 2025; 15(4):486. https://doi.org/10.3390/coatings15040486

Chicago/Turabian StyleNiu, Wenxu, Jiejun Qian, Xin Wang, Caiping Liang, Li Cui, Haobin Tian, and Peter K. Liaw. 2025. "Research Progress of Self-Healing Coatings on Ships Against Biological Pollution: A Review" Coatings 15, no. 4: 486. https://doi.org/10.3390/coatings15040486

APA StyleNiu, W., Qian, J., Wang, X., Liang, C., Cui, L., Tian, H., & Liaw, P. K. (2025). Research Progress of Self-Healing Coatings on Ships Against Biological Pollution: A Review. Coatings, 15(4), 486. https://doi.org/10.3390/coatings15040486