Experimental Investigation and Optimization of the Electrodeposition Parameters of Ni-Al2O3 Composite Coating Using the Taguchi Method

Abstract

1. Introduction

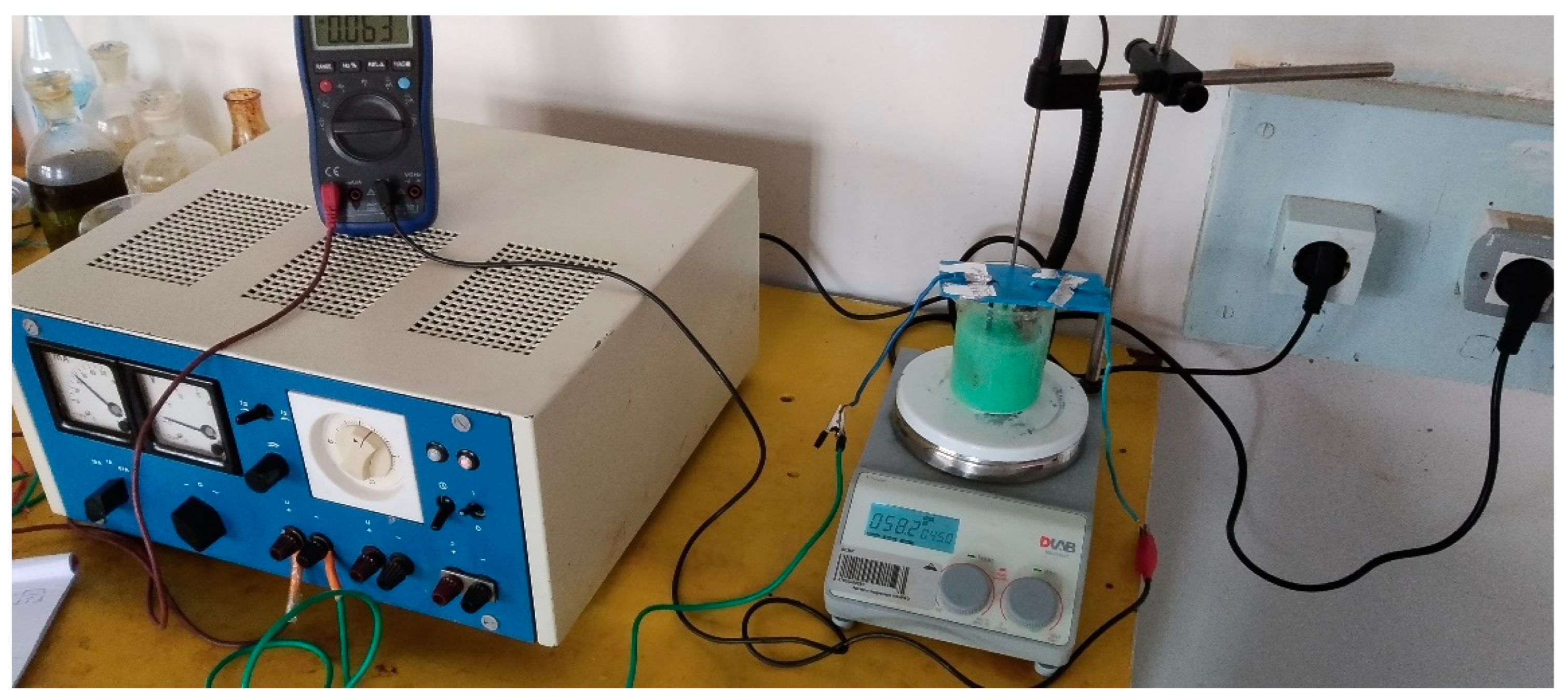

2. Materials and Methods

2.1. Materials

2.2. Substrate Preparation and Electrodeposition Parameters

2.3. Methods

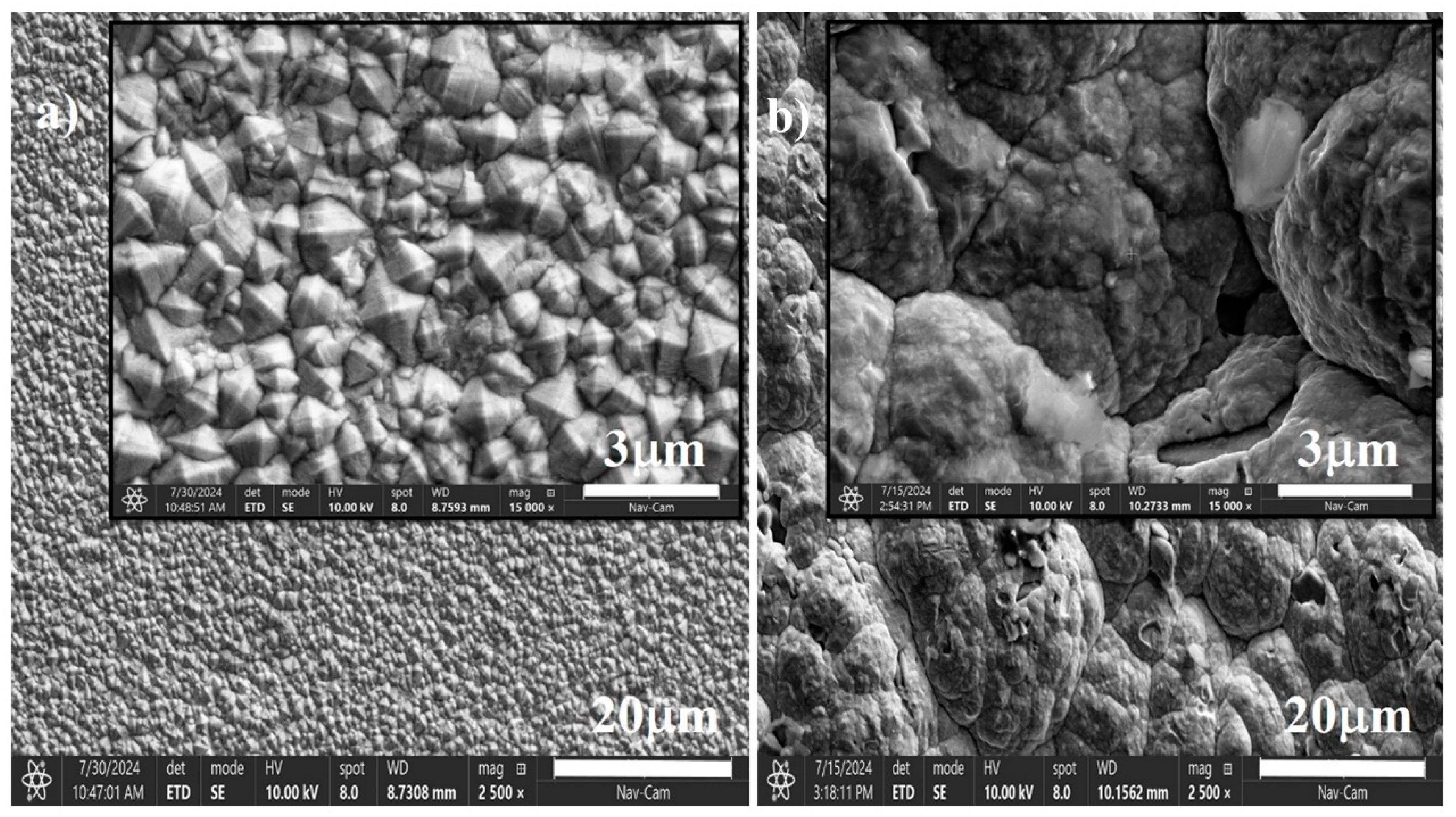

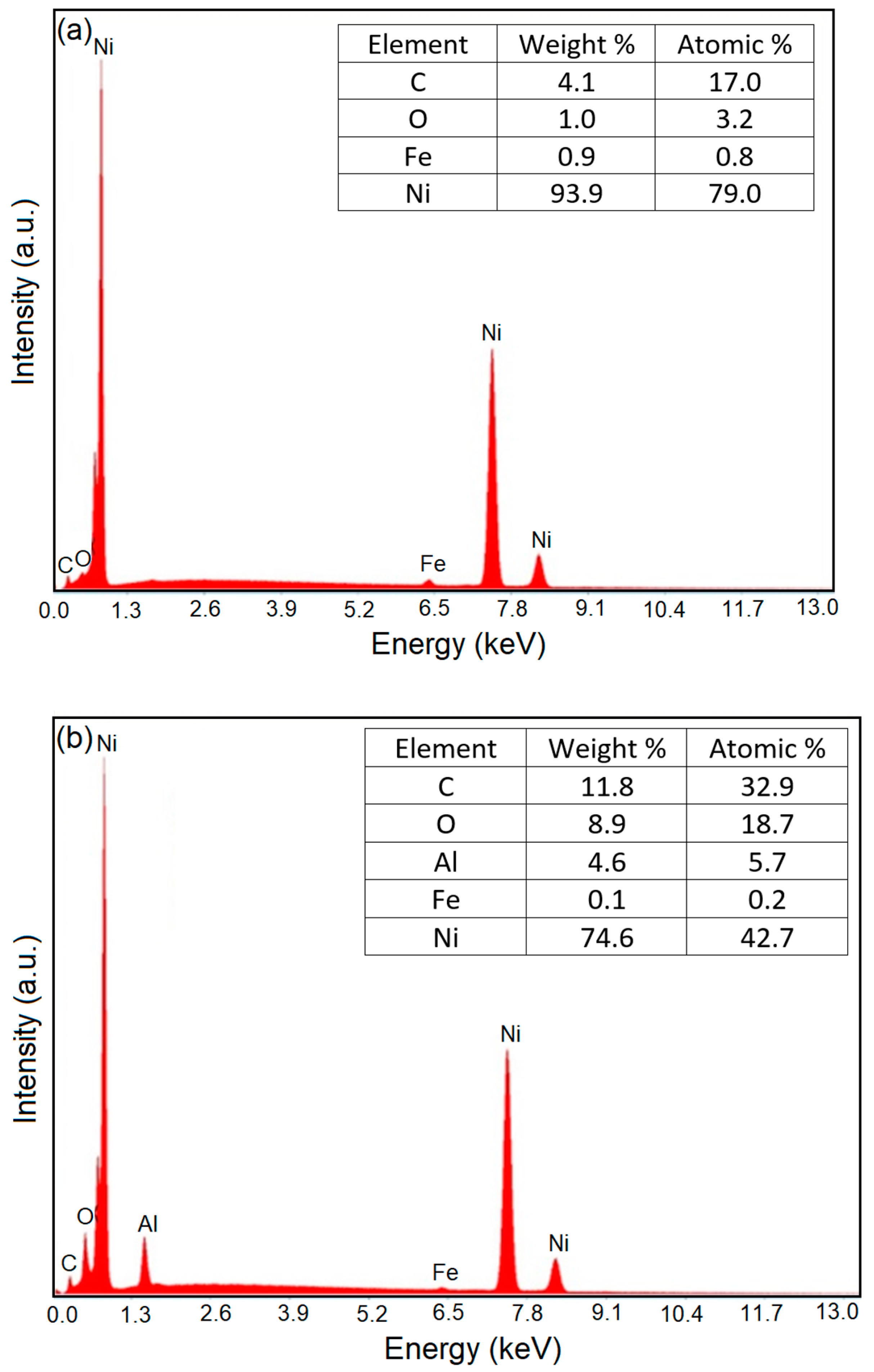

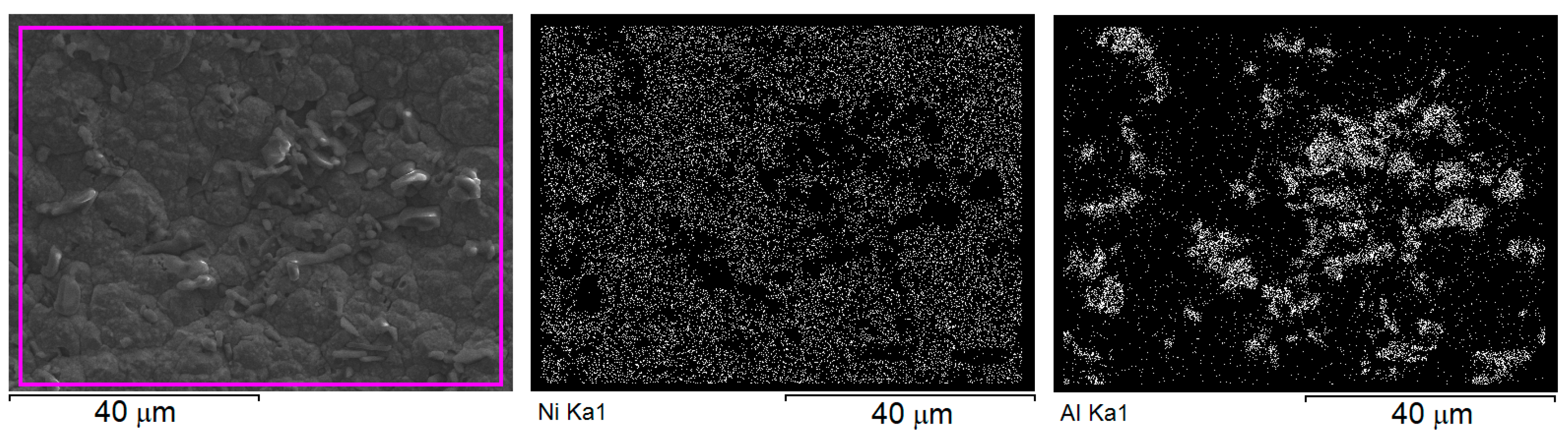

2.3.1. Morphology and SEM Examinations

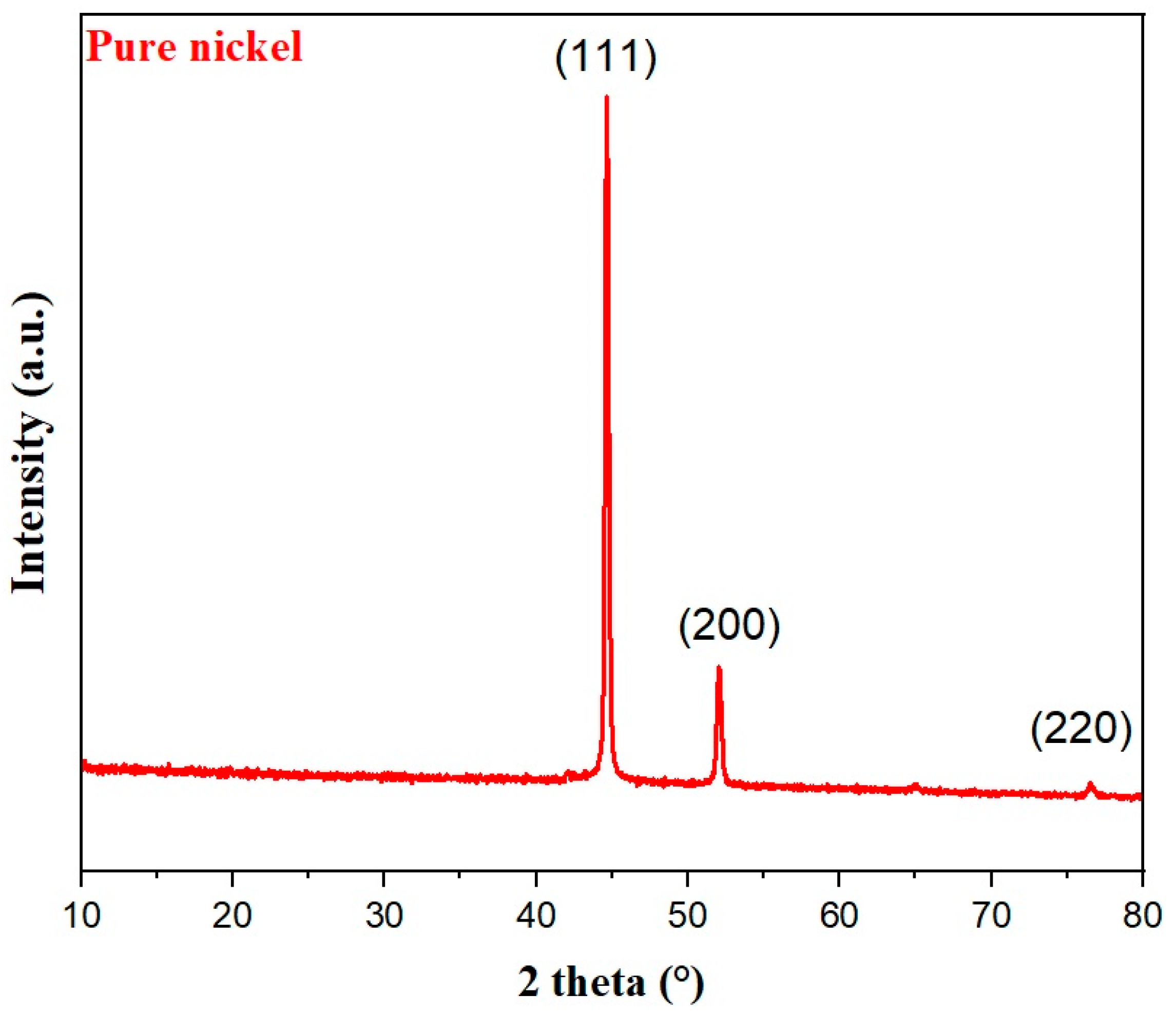

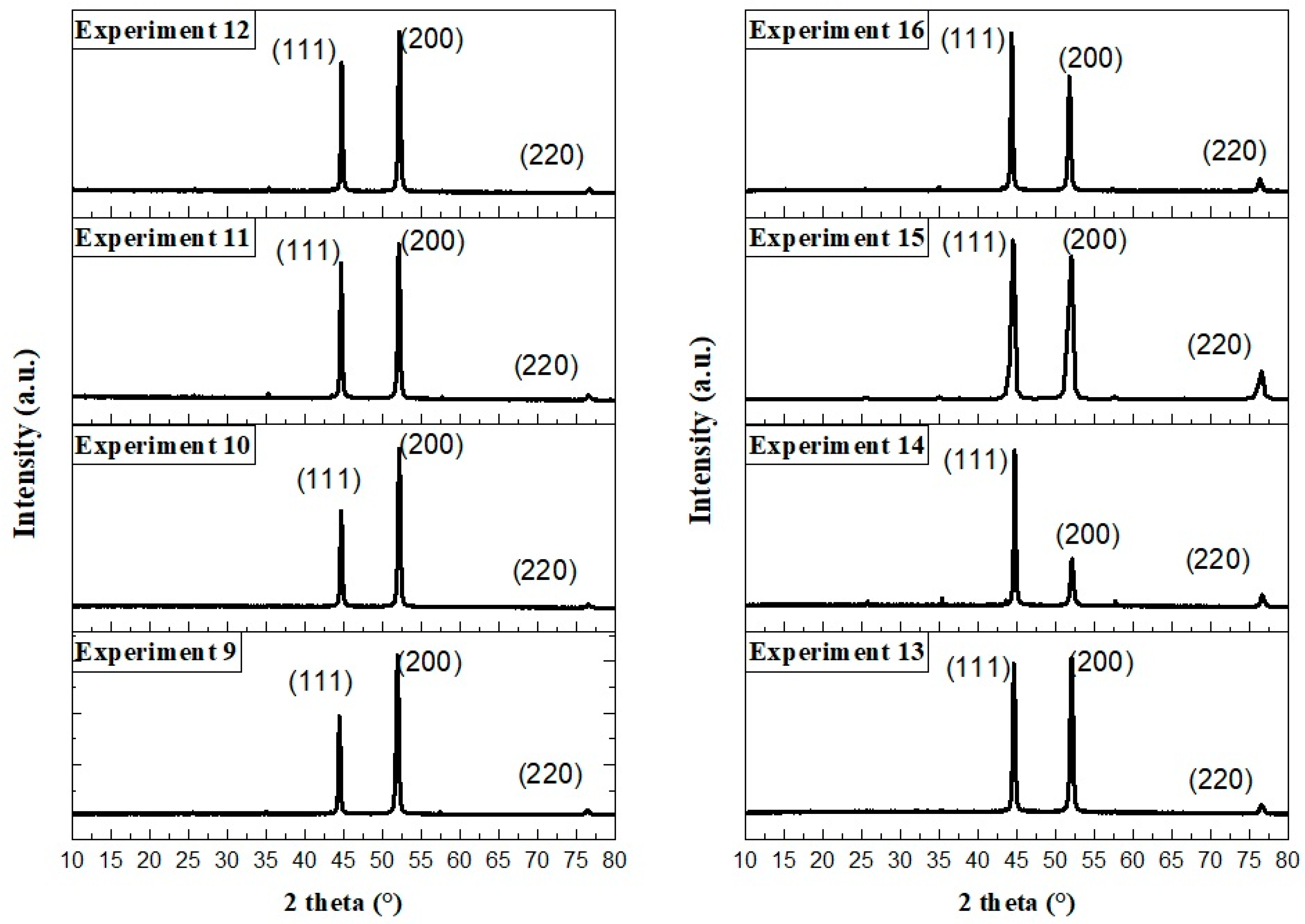

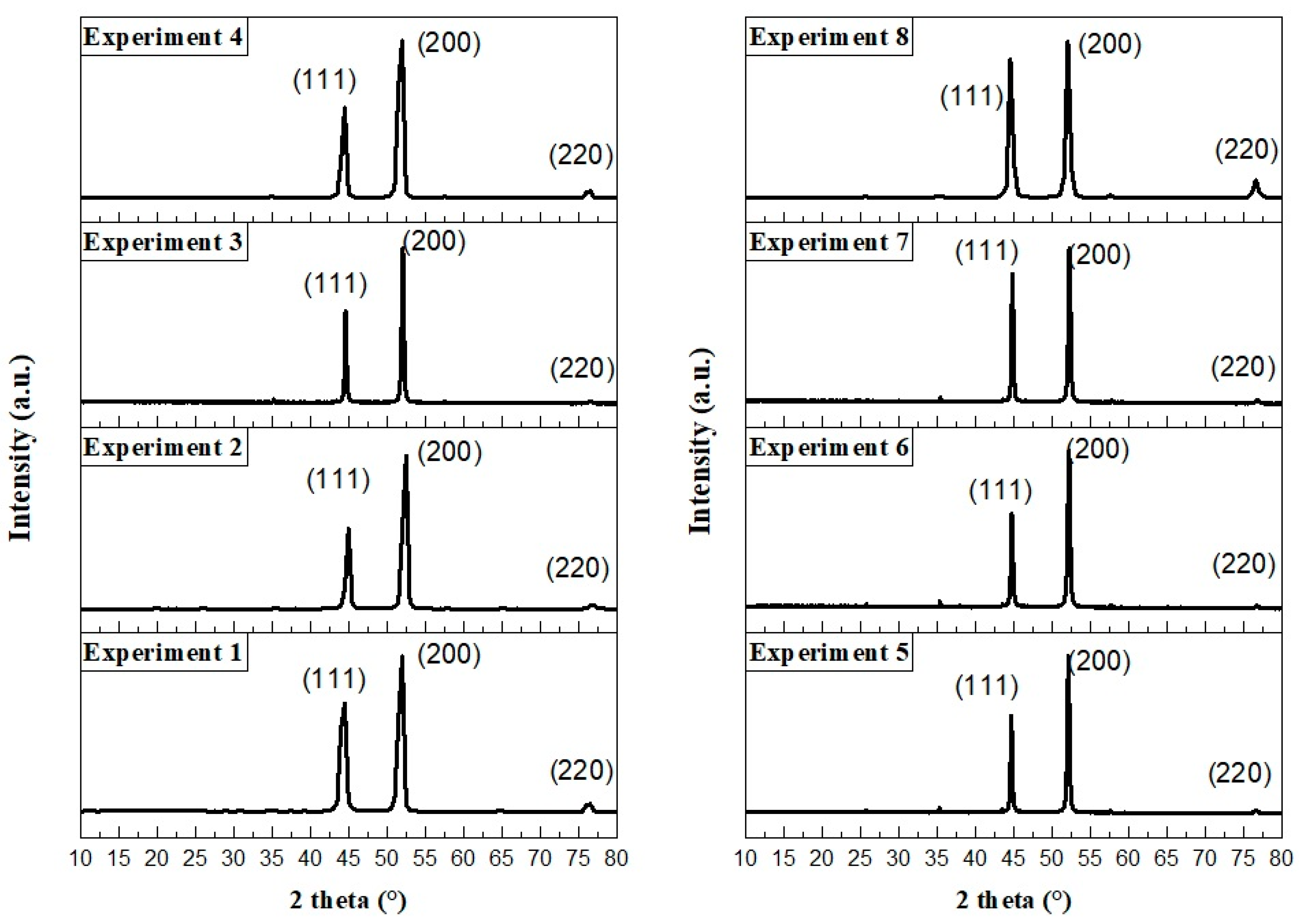

2.3.2. XRD Analysis

2.3.3. Hardness Tests

3. Results

3.1. XRD Analysis

3.2. SEM Examination

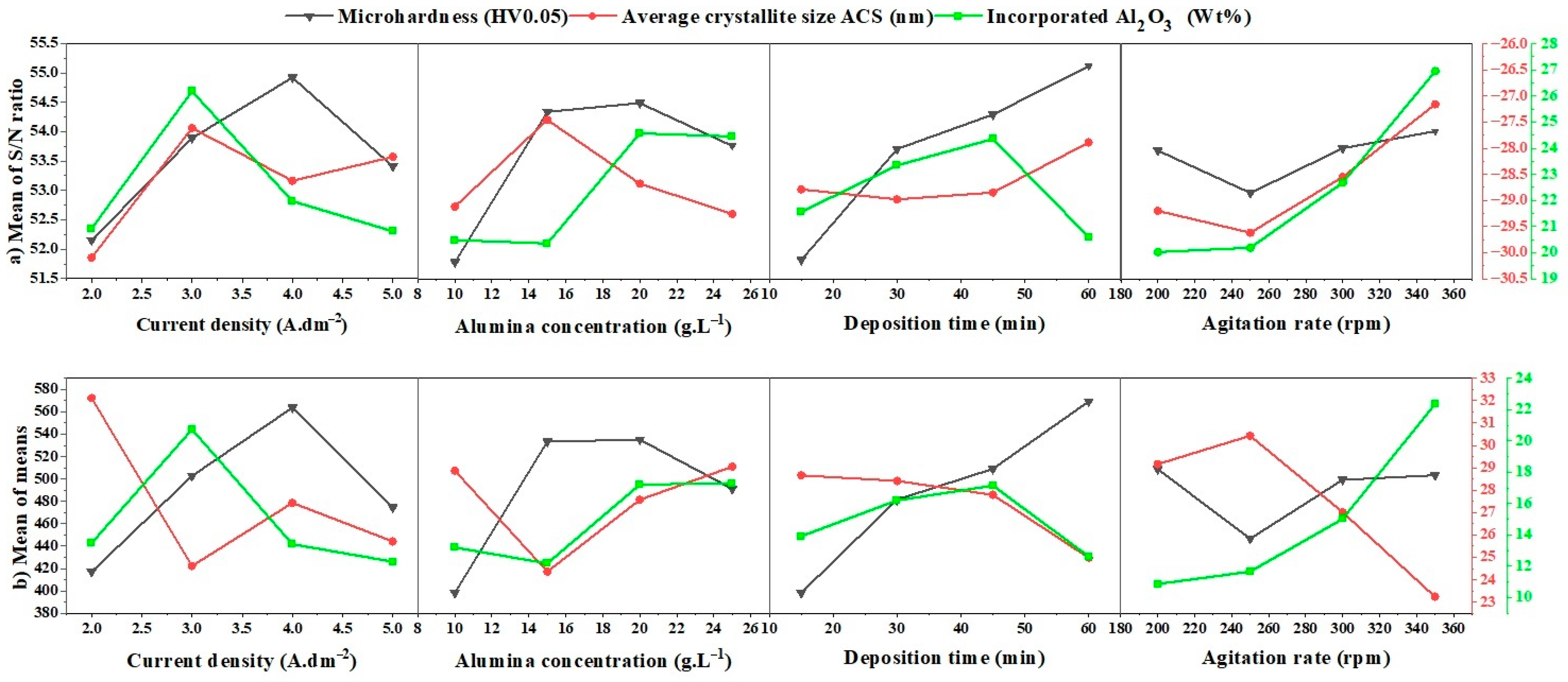

3.3. Analysis of Variance

3.4. Linear Regression

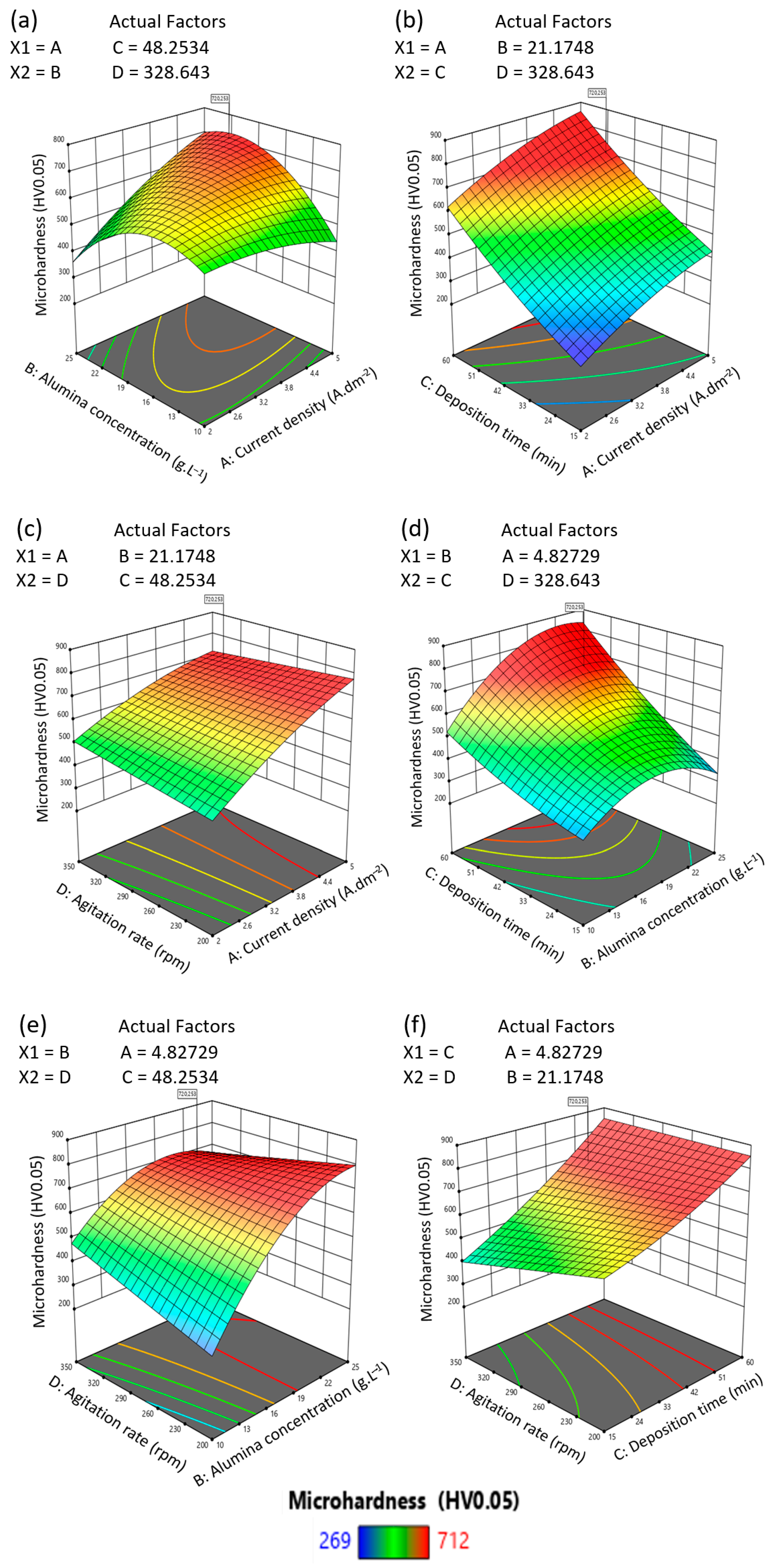

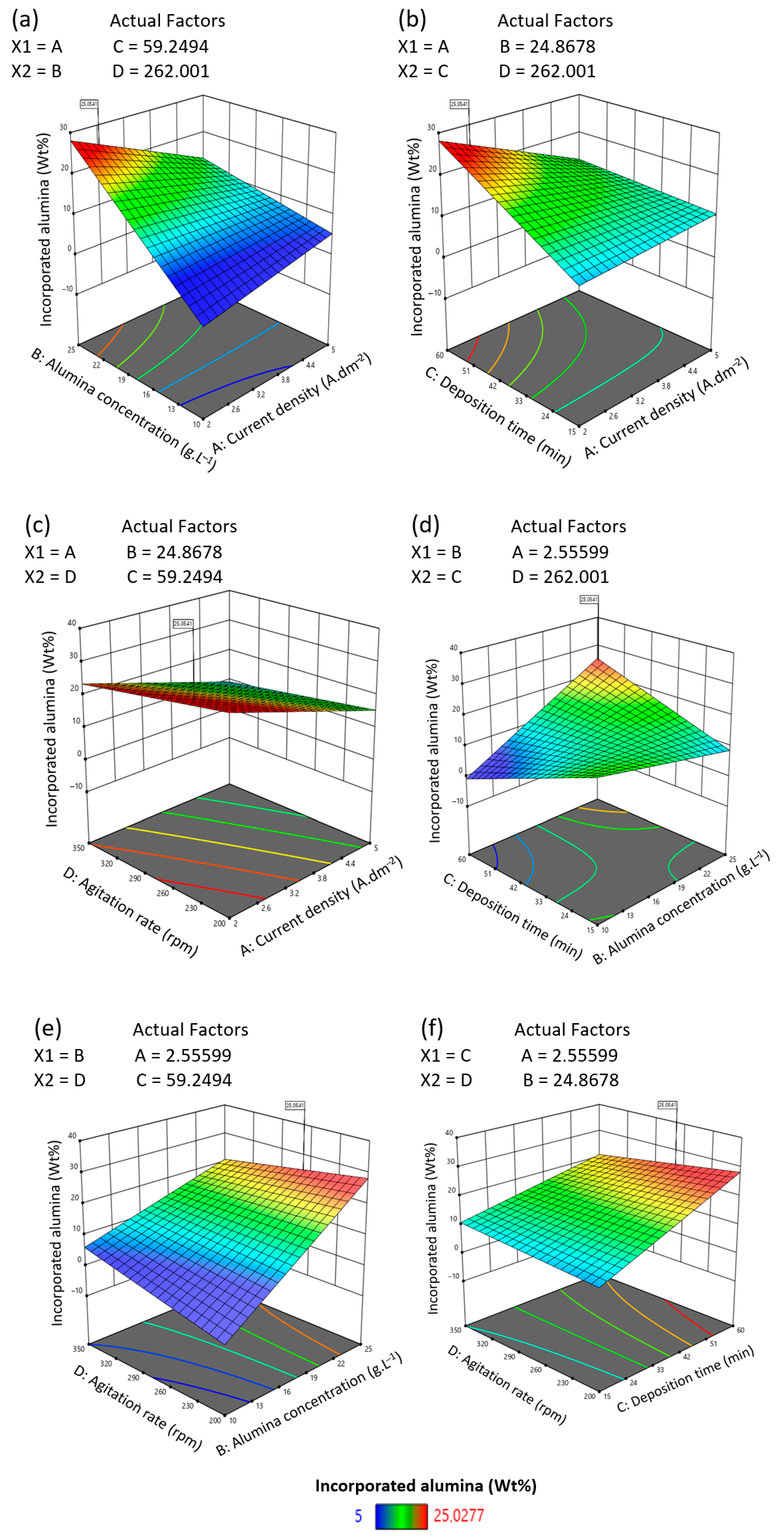

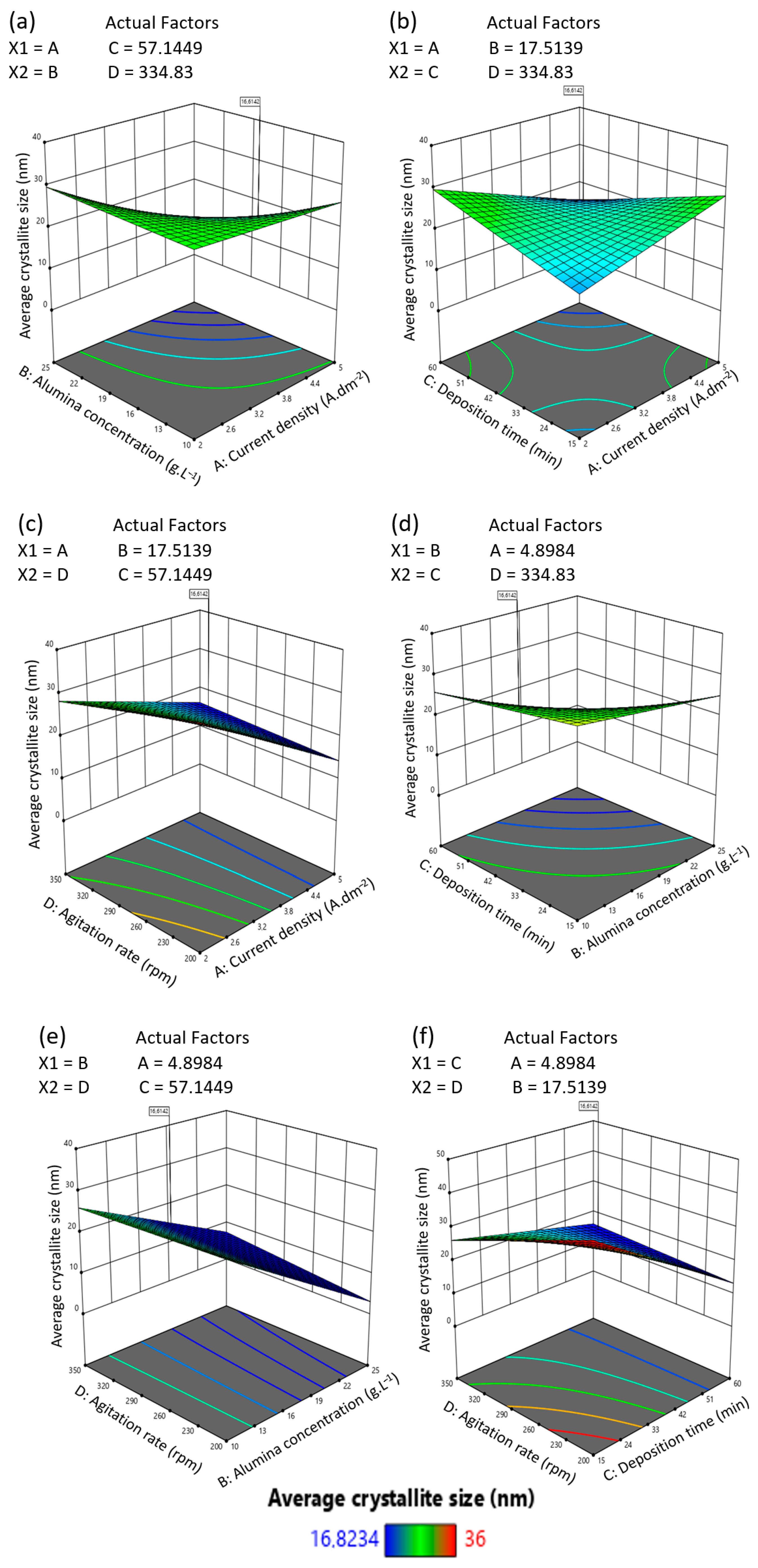

3.5. Three-Dimensional Response Surface Approach Analysis

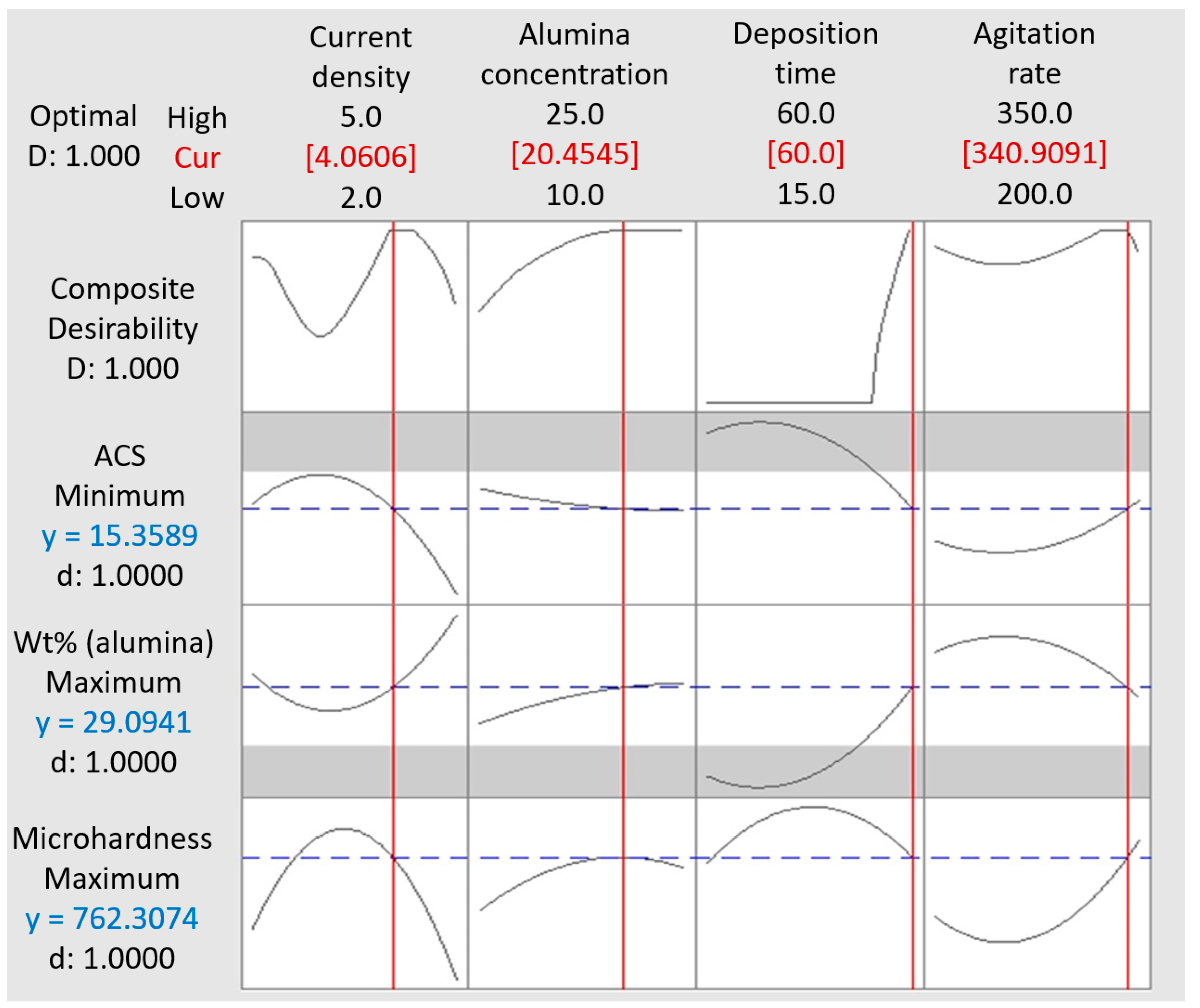

3.6. Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sajjadnejad, M.; Haghshenas, S.M.S.; Badr, P.; Setoudeh, N.; Hosseinpour, S. Wear and Tribological Characterization of Nickel Matrix Electrodeposited Composites: A Review. Wear 2021, 486–487, 204098. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, S.; Khanna, V. A Review on Surface Modification Techniques. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Holden, K.E.K.; Qi, Y.; Conley, J.F. Precision Defect Engineering of Metal/Insulator/Metal Diodes Using Atomic Layer Deposition to Localize Ni Impurities in Al2O3 Tunnel Barriers. J. Appl. Phys. 2021, 129, 144502. [Google Scholar] [CrossRef]

- Kim, M.; Kang, K.-M.; Wang, Y.; Park, H.-H. N-Doped Al2O3 Thin Films Deposited by Atomic Layer Deposition. Thin Solid Films 2018, 660, 657–662. [Google Scholar] [CrossRef]

- Aruna, S.T.; Srikanth, P.V.K.; Ahamad, M.J.; Latha, S.; Rajam, K.S. Optimization of the Properties of Electrodeposited Ni-YSZ Composites Using Taguchi Method and Regression Analysis. Port. Electrochim. Acta 2011, 29, 23–37. [Google Scholar] [CrossRef]

- Abdesselam, Y.; Rezgui, I.; Naoun, M.; Belloufi, A.; Mezoudj, M.; Zerrouki, D. Experimental Investigation and Optimization of Manufacturing Processes of Ni–P–Y2O3 Composite Coatings by Multiple Linear Regression Method Based on Genetic Algorithm. Int. J. Adv. Manuf. Technol. 2023, 126, 3995–4019. [Google Scholar] [CrossRef]

- Wasekar, N.P.; Haridoss, P.; Seshadri, S.K.; Sundararajan, G. Influence of Mode of Electrodeposition, Current Density and Saccharin on the Microstructure and Hardness of Electrodeposited Nanocrystalline Nickel Coatings. Surf. Coat. Technol. 2016, 291, 130–140. [Google Scholar] [CrossRef]

- Mohanty, U.S.; Tripathy, B.C.; Singh, P.; Keshavarz, A.; Iglauer, S. Roles of Organic and Inorganic Additives on the Surface Quality, Morphology, and Polarization Behavior during Nickel Electrodeposition from Various Baths: A Review. J. Appl. Electrochem. 2019, 49, 847–870. [Google Scholar] [CrossRef]

- Saied, S.; Mekkaoui, A.; Belahssen, O.; Chala, A. Effect of TiO2 nanoparticles in Ni matrix on mechanical and corrosion resistance properties. Acta Metall. Slovaca 2017, 23, 37–44. [Google Scholar] [CrossRef]

- Wu, W.; Huang, J.; Näther, J.; Omar, N.A.B.; Köster, F.; Lampke, T.; Liu, Y.; Pan, H.; Zhang, Y. Texture Orientation, Morphology and Performance of Nanocrystalline Nickel Coatings Electrodeposited from a Watts-Type Bath: Effects of H3BO3 Concentration and Plating Time. Surf. Coatings Technol. 2021, 424, 127648. [Google Scholar] [CrossRef]

- Raghavendra, C.R.; Basavarajappa, S.; Sogalad, I. Sliding Wear Behaviour of Ni-α-Al2O3 Nano Composite Coating at Elevated Temperatures. Colloid Interface Sci. Commun. 2018, 27, 18–25. [Google Scholar] [CrossRef]

- Karthik, R.; Mani, R.; Manikandan, P. Tribological Studies of Ni-SiC and Ni-Al2O3 Composite Coatings by Pulsed Electrodeposition. Mater. Today Proc. 2021, 37, 701–706. [Google Scholar] [CrossRef]

- Benamrane, R.; Bennouna, M.S.; Fellah, M.; Sadek, K. The Improvement of the Tensile Properties of Alfa Fibers Using the Taguchi Method. Ind. Crops Prod. 2024, 221, 119398. [Google Scholar] [CrossRef]

- Kumar, S.; Prasad, L.; Kumar, S.; Patel, V.K. Physico-Mechanical and Taguchi-Designed Sliding Wear Properties of Himalayan Agave Fiber Reinforced Polyester Composite. J. Mater. Res. Technol. 2019, 8, 3662–3671. [Google Scholar] [CrossRef]

- Nguyen, P.H.; Banh, T.L.; Mashood, K.A.; Tran, D.Q.; Dong Pham, V.; Muthuramalingam, T.; Duc Nguyen, V.; Nguyen, D.T. Application of TGRA-Based Optimisation for Machinability of High-Chromium Tool Steel in the EDM Process. Arab. J. Sci. Eng. 2020, 45, 5555–5562. [Google Scholar] [CrossRef]

- Asif, M.; Tariq, A.; Singh, K.M. Estimation of Thermal Contact Conductance Using Transient Approach with Inverse Heat Conduction Problem. Heat Mass Transf. 2019, 55, 3243–3264. [Google Scholar] [CrossRef]

- Badkar, D.S.; Pandey, K.S.; Buvanashekaran, G. Parameter Optimization of Laser Transformation Hardening by Using Taguchi Method and Utility Concept. Int. J. Adv. Manuf. Technol. 2011, 52, 1067–1077. [Google Scholar] [CrossRef]

- Touati, S.; Ghelani, L.; Zemmouri, A.; Boumediri, H. Optimization of Gas Carburizing Treatment Parameters of Low Carbon Steel Using Taguchi and Grey Relational Analysis (TA-GRA). Int. J. Adv. Manuf. Technol. 2022, 120, 7937–7949. [Google Scholar] [CrossRef]

- Doumi, A.; Rezgui, I.; Belloufi, A.; Abdelkrim, M. Improvement of the manufacturing of Ni-P-Al2O3 composite coatings by optimizing the parameters of electroplating process. Acad. J. Manuf. Eng. 2022, 20, 51–65. [Google Scholar]

- Abdulkadir, L.N.; Abou-El-Hossein, K.; Abioye, A.M.; Liman, M.M.; Cheng, Y.-C.; Abbas, A.A.S. Process Parameter Selection for Optical Silicon Considering Both Experimental and AE Results Using Taguchi L9 Orthogonal Design. Int. J. Adv. Manuf. Technol. 2019, 103, 4355–4367. [Google Scholar] [CrossRef]

- Laouissi, A.; Nouioua, M.; Yallese, M.A.; Abderazek, H.; Maouche, H.; Bouhalais, M.L. Machinability Study and ANN-MOALO-Based Multi-Response Optimization during Eco-Friendly Machining of EN-GJL-250 Cast Iron. Int. J. Adv. Manuf. Technol. 2021, 117, 1179–1192. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, Y.; Zhao, M.; Liu, P.; Qi, H.; Yang, Y. Impact of Al Nanoparticles upon the Microstructure and Wear Properties of Ni-Cr-Al Nanocomposite Coatings. J. Indian Chem. Soc. 2023, 100, 100822. [Google Scholar] [CrossRef]

- Ma, C.; Li, H.; Xia, F.; Xiao, Z. Effect of Ultrasonic Power on Microstructure and Properties of Ultrasonic-Assisted Electrodeposited Ni–Al2O3 Thin Nanocoatings. Trans. Indian Inst. Met. 2022, 75, 1669–1679. [Google Scholar] [CrossRef]

- Benea, L.; Danaila, E.; Celis, J.-P. Influence of Electro-Co-Deposition Parameters on Nano-TiO2 Inclusion into Nickel Matrix and Properties Characterization of Nanocomposite Coatings Obtained. Mater. Sci. Eng. A 2014, 610, 106–115. [Google Scholar] [CrossRef]

- Li, B.; Li, X.; Huan, Y.; Xia, W.; Zhang, W. Influence of Alumina Nanoparticles on Microstructure and Properties of Ni-B Composite Coating. J. Alloy. Compd. 2018, 762, 133–142. [Google Scholar] [CrossRef]

- Wagih, A. Synthesis of Nanocrystalline Al2O3 Reinforced Al Nanocomposites by High-Energy Mechanical Alloying: Microstructural Evolution and Mechanical Properties. Trans. Indian Inst. Met. 2016, 69, 851–857. [Google Scholar] [CrossRef]

- Okonkwo, B.O.; Jeong, C.; Jang, C. Advances on Cr and Ni Electrodeposition for Industrial Applications—A Review. Coatings 2022, 12, 1555. [Google Scholar] [CrossRef]

- Estrella-Gutiérrez, M.A.; Lizama-Tzec, F.I.; Arés-Muzio, O.; Oskam, G. Influence of a Metallic Nickel Interlayer on the Performance of Solar Absorber Coatings Based on Black Nickel Electrodeposited onto Copper. Electrochim. Acta 2016, 213, 460–468. [Google Scholar] [CrossRef]

- Graff, A.; Barrez, E.; Baranek, P.; Bachet, M.; Bénézeth, P. Complexation of Nickel Ions by Boric Acid or (Poly)Borates. J. Solut. Chem. 2017, 46, 25–43. [Google Scholar] [CrossRef]

- Devesa, S.; Benzarti, Z.; Santos, G.; Cavaleiro, D.; Cunha, A.; Santos, J.; Carvalho, S. Enhancing Solar Absorption with Double-Layered Nickel Coatings and WS2 Nanoparticles on Copper Substrates. Energies 2024, 17, 3869. [Google Scholar] [CrossRef]

- Santos, G.; Benzarti, Z.; Cavaleiro, D.; Figueiredo, L.; Carvalho, S.; Devesa, S. Optimization of Black Nickel Coatings’ Electrodeposit onto Steel. Coatings 2024, 14, 1125. [Google Scholar] [CrossRef]

- Wu, G.; Li, N.; Zhou, D.; Mitsuo, K. Electrodeposited Co–Ni–Al2O3 Composite Coatings. Surf. Coat. Technol. 2004, 176, 157–164. [Google Scholar] [CrossRef]

- Jiang, Q.; Lu, H.M. Size Dependent Interface Energy and Its Applications. Surf. Sci. Rep. 2008, 63, 427–464. [Google Scholar] [CrossRef]

- Mersagh Dezfuli, S.; Sabzi, M. Deposition of Ceramic Nanocomposite Coatings by Electroplating Process: A Review of Layer-Deposition Mechanisms and Effective Parameters on the Formation of the Coating. Ceram. Int. 2019, 45, 21835–21842. [Google Scholar] [CrossRef]

- Mamaghani, K.R.; Naghib, S.M. The Effect of Stirring Rate on Electrodeposition of Nanocrystalline Nickel Coatings and Their Corrosion Behaviors and Mechanical Characteristics. Int. J. Electrochem. Sci. 2017, 12, 5023–5035. [Google Scholar] [CrossRef]

- Lv, J. Effect of Grain Size on Mechanical Property and Corrosion Resistance of the Ni-Based Alloy 690. J. Mater. Sci. Technol. 2018, 34, 1685–1691. [Google Scholar] [CrossRef]

- Badarulzaman, N.A.; Purwadaria, S.; Mohamad, A.A.; Ahmad, Z.A. The Production of Nickel–Alumina Composite Coating via Electroplating. Ionics 2009, 15, 603–607. [Google Scholar] [CrossRef]

- Gül, H.; Uysal, M.; Akbulut, H.; Alp, A. Effect of PC Electrodeposition on the Structure and Tribological Behavior of Ni–Al2O3 Nanocomposite Coatings. Surf. Coat. Technol. 2014, 258, 1202–1211. [Google Scholar] [CrossRef]

- Borkar, T.; Harimkar, S.P. Effect of Electrodeposition Conditions and Reinforcement Content on Microstructure and Tribological Properties of Nickel Composite Coatings. Surf. Coat. Technol. 2011, 205, 4124–4134. [Google Scholar] [CrossRef]

- Noroozi, Z.; Rajabi, M.; Bostani, B. Characterization of Co-Electrodeposited Functionally Gradient Ni-Al2O3 Composite Coating. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2019, 13, 771–776. [Google Scholar] [CrossRef]

- Pouladi, S.; Shariat, M.H.; Bahrololoom, M.E. Electrodeposition and Characterization of Ni–Zn–P and Ni–Zn–P/Nano-SiC Coatings. Surf. Coat. Technol. 2012, 213, 33–40. [Google Scholar] [CrossRef]

- García-Lecina, E.; García-Urrutia, I.; Díez, J.A.; Morgiel, J.; Indyka, P. A Comparative Study of the Effect of Mechanical and Ultrasound Agitation on the Properties of Electrodeposited Ni/Al2O3 Nanocomposite Coatings. Surf. Coat. Technol. 2012, 206, 2998–3005. [Google Scholar] [CrossRef]

- Sajjadnejad, M.; Mozafari, A.; Omidvar, H.; Javanbakht, M. Preparation and Corrosion Resistance of Pulse Electrodeposited Zn and Zn–SiC Nanocomposite Coatings. Appl. Surf. Sci. 2014, 300, 1–7. [Google Scholar] [CrossRef]

- Bezazi, A.; Boumediri, H.; Garcia del Pino, G.; Bezzazi, B.; Scarpa, F.; Reis, P.N.B.; Dufresne, A. Alkali Treatment Effect on Physicochemical and Tensile Properties of Date Palm Rachis Fibers. J. Nat. Fibers 2022, 19, 3770–3787. [Google Scholar] [CrossRef]

- Bouhemame, N.; Aiadi, K.E.; Bezazi, A.; Boumediri, H.; Reis, P.N.B.; Imad, A.; Scarpa, F. Tensile Properties Optimization of Date Palm Leaflets Using Taguchi Method. J. Nat. Fibers 2022, 19, 6348–6364. [Google Scholar] [CrossRef]

- Dehestani, M.; Khayati, G.R.; Sharafi, S. An Improved Optimization Model to Predict the Microhardness of Ni/Al2O3 Nanocomposite Coatings Prepared by Electrodeposition: A Hybrid Artificial Neural Network-Modified Particle Swarm Optimization Approach. Measurement 2021, 179, 109423. [Google Scholar] [CrossRef]

- Rezgui, I.; Mihi, A.; Belloufi, A.; Abdelkrim, M.; Brabie, G. Fuzzy Logic Approach for Predicting the Effect of Manufacturing Parameters of Ni-Al2O3 Composite Coatings by Electrodeposition. Int. J. Mod. Manuf. Technol. 2017, 9, 65–72. [Google Scholar]

| Chemical Reagents | Concentration (g.L−1) |

|---|---|

| NiCl2·6H2O | 23.77 |

| NH4Cl | 21.4 |

| H3BO3 | 18.54 |

| Factor | Representation | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|

| Current density | A | 2 | 3 | 4 | 5 |

| Alumina concentration | B | 10 | 15 | 20 | 25 |

| Deposition time | C | 15 | 30 | 45 | 60 |

| Agitation rate | D | 200 | 250 | 300 | 350 |

| Column Numbers, Deposition Parameters, and Factor Allocation | ||||||||

|---|---|---|---|---|---|---|---|---|

| Experiment | Current Density (A.dm−2) | Coded Values | Alumina Concentration (g.L−1) | Coded Values | Deposition Time (min) | Coded Values | Agitation Rate (rpm) | Coded Values |

| 1 | 2 | 1 | 10 | 1 | 15 | 1 | 200 | 1 |

| 2 | 2 | 1 | 15 | 2 | 30 | 2 | 250 | 2 |

| 3 | 2 | 1 | 20 | 3 | 45 | 3 | 300 | 3 |

| 4 | 2 | 1 | 25 | 4 | 60 | 4 | 350 | 4 |

| 5 | 3 | 2 | 10 | 1 | 30 | 2 | 300 | 3 |

| 6 | 3 | 2 | 15 | 2 | 15 | 1 | 350 | 4 |

| 7 | 3 | 2 | 20 | 3 | 60 | 4 | 200 | 1 |

| 8 | 3 | 2 | 25 | 4 | 45 | 3 | 250 | 2 |

| 9 | 4 | 3 | 10 | 1 | 45 | 3 | 350 | 4 |

| 10 | 4 | 3 | 15 | 2 | 60 | 4 | 300 | 3 |

| 11 | 4 | 3 | 20 | 3 | 15 | 1 | 250 | 2 |

| 12 | 4 | 3 | 25 | 4 | 30 | 2 | 200 | 1 |

| 13 | 5 | 4 | 10 | 1 | 60 | 4 | 250 | 2 |

| 14 | 5 | 4 | 15 | 2 | 45 | 3 | 200 | 1 |

| 15 | 5 | 4 | 20 | 3 | 30 | 2 | 350 | 4 |

| 16 | 5 | 4 | 25 | 4 | 15 | 1 | 300 | 3 |

| Run | Coded Matrix | Current Density (A.dm−2) | Alumina Concentration (g.L−1) | Deposition Time (min) | Agitation Rate (rpm) | |||

|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | |||||

| 1 | 1 | 1 | 1 | 1 | 2 | 10 | 15 | 200 |

| 2 | 1 | 2 | 2 | 2 | 2 | 15 | 30 | 250 |

| 3 | 1 | 3 | 3 | 3 | 2 | 20 | 45 | 300 |

| 4 | 1 | 4 | 4 | 4 | 2 | 25 | 60 | 350 |

| 5 | 2 | 1 | 2 | 3 | 3 | 10 | 30 | 300 |

| 6 | 2 | 2 | 1 | 4 | 3 | 15 | 15 | 350 |

| 7 | 2 | 3 | 4 | 1 | 3 | 20 | 60 | 200 |

| 8 | 2 | 4 | 3 | 2 | 3 | 25 | 45 | 250 |

| 9 | 3 | 1 | 3 | 4 | 4 | 10 | 45 | 350 |

| 10 | 3 | 2 | 4 | 3 | 4 | 15 | 60 | 300 |

| 11 | 3 | 3 | 1 | 2 | 4 | 20 | 15 | 250 |

| 12 | 3 | 4 | 2 | 1 | 4 | 25 | 30 | 200 |

| 13 | 4 | 1 | 4 | 2 | 5 | 10 | 60 | 250 |

| 14 | 4 | 2 | 3 | 1 | 5 | 15 | 45 | 200 |

| 15 | 4 | 3 | 2 | 4 | 5 | 20 | 30 | 350 |

| 16 | 4 | 4 | 1 | 3 | 5 | 25 | 15 | 300 |

| Run | Coded Matrix | Microhardness (HV0.05) | S/N Ratio (dB) | Average Crystallite Size (nm) | S/N Ratio (dB) | Incorporated Alumina (wt%) | S/N Ratio (dB) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | |||||||

| 1 | 1 | 1 | 1 | 1 | 269.00 | 48.5950 | 36.0 | −31.1261 | 5.0 | 13.9794 |

| 2 | 1 | 2 | 2 | 2 | 415.38 | 52.3689 | 33.0 | −30.3703 | 7.0 | 16.9020 |

| 3 | 1 | 3 | 3 | 3 | 468.75 | 53.4188 | 30.4 | −29.6653 | 18.7 | 25.4368 |

| 4 | 1 | 4 | 4 | 4 | 515.00 | 54.2361 | 29.0 | −29.2480 | 23.2 | 27.3135 |

| 5 | 2 | 1 | 2 | 3 | 416.00 | 52.3819 | 28.5 | −29.1017 | 22.6 | 27.0816 |

| 6 | 2 | 2 | 1 | 4 | 446.10 | 52.9886 | 16.8 | −24.5183 | 25.0 | 27.9684 |

| 7 | 2 | 3 | 4 | 1 | 652.71 | 56.2944 | 24.0 | −27.6056 | 14.9 | 23.4675 |

| 8 | 2 | 4 | 3 | 2 | 496.00 | 53.9096 | 29.1 | −29.2714 | 20.4 | 26.1790 |

| 9 | 3 | 1 | 3 | 4 | 511.10 | 54.1701 | 25.0 | −27.9638 | 19.6 | 25.8441 |

| 10 | 3 | 2 | 4 | 3 | 712.00 | 57.0496 | 21.0 | −26.4400 | 6.8 | 16.5874 |

| 11 | 3 | 3 | 1 | 2 | 478.00 | 53.5886 | 33.7 | −30.5576 | 12.3 | 22.6978 |

| 12 | 3 | 4 | 2 | 1 | 553.57 | 54.8635 | 30.0 | −29.5424 | 13.6 | 22.6978 |

| 13 | 4 | 1 | 4 | 2 | 397.00 | 51.9758 | 25.9 | −28.2795 | 5.6 | 14.9974 |

| 14 | 4 | 2 | 3 | 1 | 560.00 | 54.9638 | 26.6 | −28.5096 | 9.9 | 19.9510 |

| 15 | 4 | 3 | 2 | 4 | 541.00 | 54.6639 | 22.1 | −26.9038 | 21.6 | 26.6792 |

| 16 | 4 | 4 | 1 | 3 | 400.00 | 52.0412 | 28.1 | −28.9778 | 12.0 | 21.5962 |

| Response Variable | Mean S/N Ratio | ||||

|---|---|---|---|---|---|

| Microhardness | Level | Current Density (A.dm−2) | Alumina Concentration (g.L−1) | Deposition Time (min) | Agitation Rate (rpm) |

| 1 | 52.15 | 51.78 | 51.80 | 53.68 | |

| 2 | 53.89 | 54.34 | 53.57 | 52.96 | |

| 3 | 54.92 | 54.49 | 54.12 | 53.72 | |

| 4 | 53.41 | 53.76 | 54.89 | 54.01 | |

| Δ | 2.76 | 2.71 | 3.09 | 1.05 | |

| Rank | 2 | 3 | 1 | 4 | |

| Response Variable | Mean S/N Ratio | ||||

|---|---|---|---|---|---|

| Incorporated Alumina | Level | Current Density (A.dm−2) | Alumina Concentration (g.L−1) | Deposition Time (min) | Agitation Rate (rpm) |

| 1 | 20.91 | 20.48 | 21.56 | 20.02 | |

| 2 | 26.17 | 20.35 | 23.34 | 20.19 | |

| 3 | 21.96 | 24.57 | 24.35 | 22.68 | |

| 4 | 20.81 | 24.45 | 20.59 | 26.95 | |

| Δ | 5.37 | 4.22 | 3.76 | 6.93 | |

| Rank | 2 | 3 | 4 | 1 | |

| Response Variable | Mean S/N Ratio | ||||

|---|---|---|---|---|---|

| Average Crystallite Size—ACS | Level | Current Density (A.dm−2) | Alumina Concentration (g.L−1) | Deposition Time (min) | Agitation Rate (rpm) |

| 1 | −30.10 | −29.12 | −28.79 | −29.20 | |

| 2 | −27.62 | −27.46 | −28.98 | −29.62 | |

| 3 | −28.63 | −28.68 | −28.85 | −28.55 | |

| 4 | −28.17 | −29.26 | −27.89 | −27.16 | |

| Δ | 2.48 | 1.80 | 1.09 | 2.6 | |

| Rank | 1 | 3 | 4 | 2 | |

| Source | R2 | DF | Adj SS | Adj MS | F-Value | p-Value | |

|---|---|---|---|---|---|---|---|

| Microhardness | Model | 99.7 | 13 | 1.672 × 105 | 12,860.80 | 69.70 | 0.0142 |

| A | 1 | 14,956.40 | 14,956.40 | 81.06 | 0.0121 | ||

| B | 1 | 3881.85 | 3881.85 | 21.04 | 0.0444 | ||

| C | 1 | 41,722.50 | 41,722.50 | 226.12 | 0.0044 | ||

| D | 1 | 1999.95 | 1999.95 | 10.84 | 0.0812 | ||

| AB | 1 | 8637.51 | 8637.51 | 46.81 | 0.0207 | ||

| AC | 1 | 62.32 | 62.32 | 0.3378 | 0.6199 | ||

| AD | 1 | 2299.25 | 2299.25 | 12.46 | 0.0717 | ||

| BC | 1 | 4400.66 | 4400.66 | 23.85 | 0.0395 | ||

| BD | 1 | 2153.30 | 2153.30 | 11.67 | 0.0760 | ||

| CD | 1 | 5657.31 | 5657.31 | 30.66 | 0.0311 | ||

| A2 | 1 | 309.71 | 309.71 | 1.68 | 0.3245 | ||

| B2 | 1 | 37,464.64 | 37,464.64 | 203.04 | 0.0049 | ||

| C2 | 1 | 673.52 | 673.52 | 3.65 | 0.1962 | ||

| D2 | 0 | 0.0000 | |||||

| Residual | 2 | 369.03 | 184.52 | ||||

| Total | 15 | 1.676 × 105 | |||||

| Incorporated alumina (Wt %) | Model | 92.8 | 10 | 641.11 | 64.11 | 6.46 | 0.0263 |

| A | 1 | 16.08 | 16.08 | 1.62 | 0.2590 | ||

| B | 1 | 0.0001 | 0.0001 | 9.874 × 10−6 | 0.9976 | ||

| C | 1 | 30.16 | 30.16 | 3.04 | 0.1417 | ||

| D | 1 | 58.77 | 58.77 | 5.92 | 0.0591 | ||

| AB | 1 | 22.67 | 22.67 | 2.28 | 0.1910 | ||

| AC | 1 | 18.54 | 18.54 | 1.87 | 0.2300 | ||

| AD | 1 | 0.1855 | 0.1855 | 0.0187 | 0.8966 | ||

| BC | 1 | 123.68 | 123.68 | 12.46 | 0.0167 | ||

| BD | 1 | 84.35 | 84.35 | 8.50 | 0.0332 | ||

| CD | 1 | 28.93 | 28.93 | 2.92 | 0.1485 | ||

| Residual | 5 | 9.92 | |||||

| Total | 15 | ||||||

| Average crystallite size | Model | 92.5 | 10 | 341.30 | 34.13 | 6.20 | 0.0287 |

| A | 1 | 29.56 | 29.56 | 5.37 | 0.0682 | ||

| B | 1 | 14.87 | 14.87 | 2.70 | 0.1610 | ||

| C | 1 | 41.23 | 41.23 | 7.50 | 0.0409 | ||

| D | 1 | 122.72 | 122.72 | 22.31 | 0.0052 | ||

| AB | 1 | 20.73 | 20.73 | 3.77 | 0.1099 | ||

| AC | 1 | 32.70 | 32,70 | 5.94 | 0.0588 | ||

| AD | 1 | 11.12 | 11.12 | 2.02 | 0.2143 | ||

| BC | 1 | 20.43 | 20.43 | 3.71 | 0.1119 | ||

| BD | 1 | 8.00 | 8.00 | 1.45 | 0.2819 | ||

| CD | 1 | 86.32 | 86.32 | 15.69 | 0.0107 | ||

| Residual | 5 | 27.50 | 5.50 | ||||

| Total | 15 | 368.81 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reddah, I.; Ghelani, L.; Touati, S.; Lekmine, F.; Hvizdoš, P.; Devesa, S.; Boumediri, H. Experimental Investigation and Optimization of the Electrodeposition Parameters of Ni-Al2O3 Composite Coating Using the Taguchi Method. Coatings 2025, 15, 482. https://doi.org/10.3390/coatings15040482

Reddah I, Ghelani L, Touati S, Lekmine F, Hvizdoš P, Devesa S, Boumediri H. Experimental Investigation and Optimization of the Electrodeposition Parameters of Ni-Al2O3 Composite Coating Using the Taguchi Method. Coatings. 2025; 15(4):482. https://doi.org/10.3390/coatings15040482

Chicago/Turabian StyleReddah, Ilias, Laala Ghelani, Sofiane Touati, Farid Lekmine, Pavol Hvizdoš, Susana Devesa, and Haithem Boumediri. 2025. "Experimental Investigation and Optimization of the Electrodeposition Parameters of Ni-Al2O3 Composite Coating Using the Taguchi Method" Coatings 15, no. 4: 482. https://doi.org/10.3390/coatings15040482

APA StyleReddah, I., Ghelani, L., Touati, S., Lekmine, F., Hvizdoš, P., Devesa, S., & Boumediri, H. (2025). Experimental Investigation and Optimization of the Electrodeposition Parameters of Ni-Al2O3 Composite Coating Using the Taguchi Method. Coatings, 15(4), 482. https://doi.org/10.3390/coatings15040482