High-Throughput Phase Screening and Laser-Directed Energy Deposition of Ti-Ni-Nb Gradient Alloys

Abstract

1. Introduction

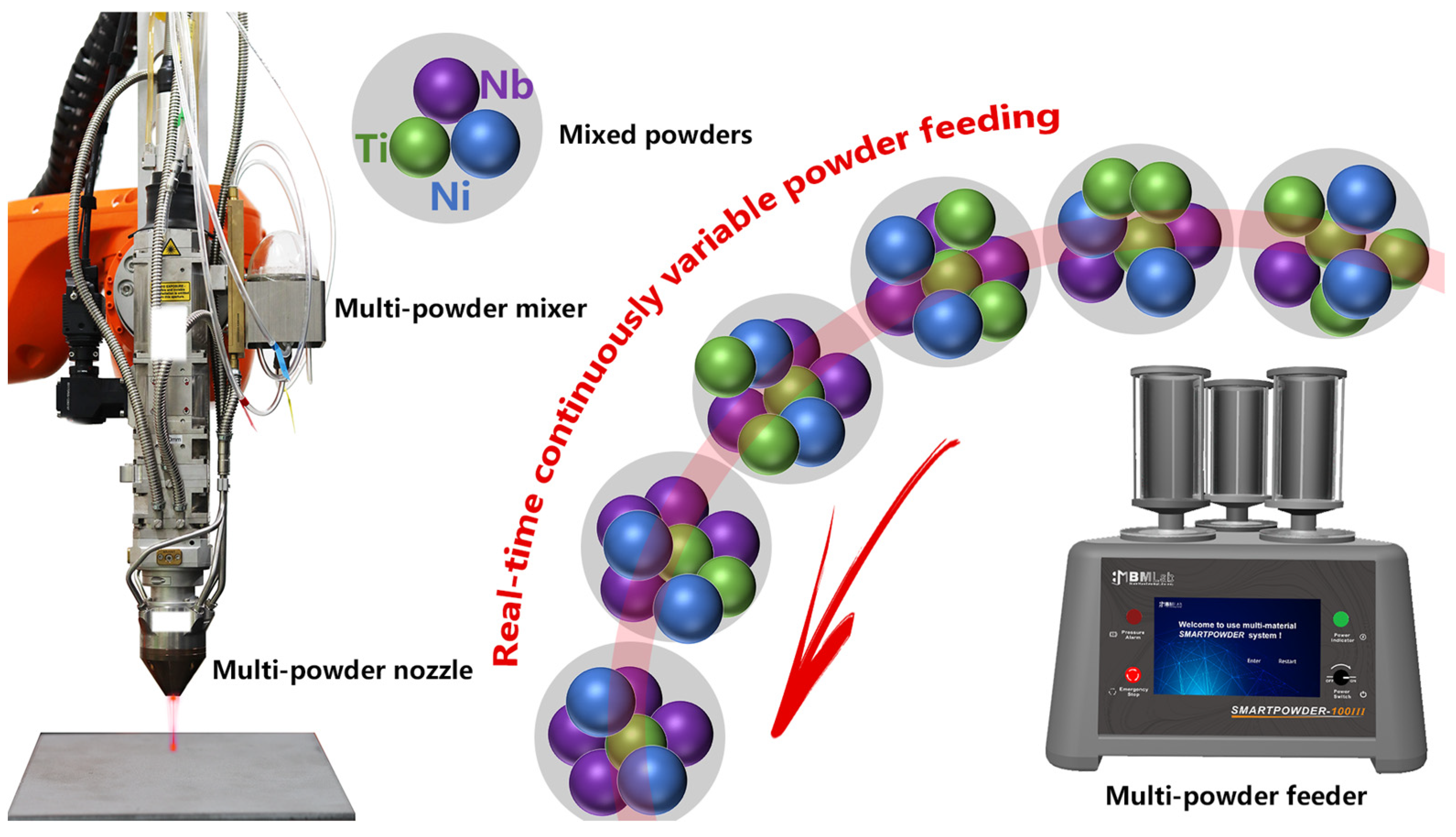

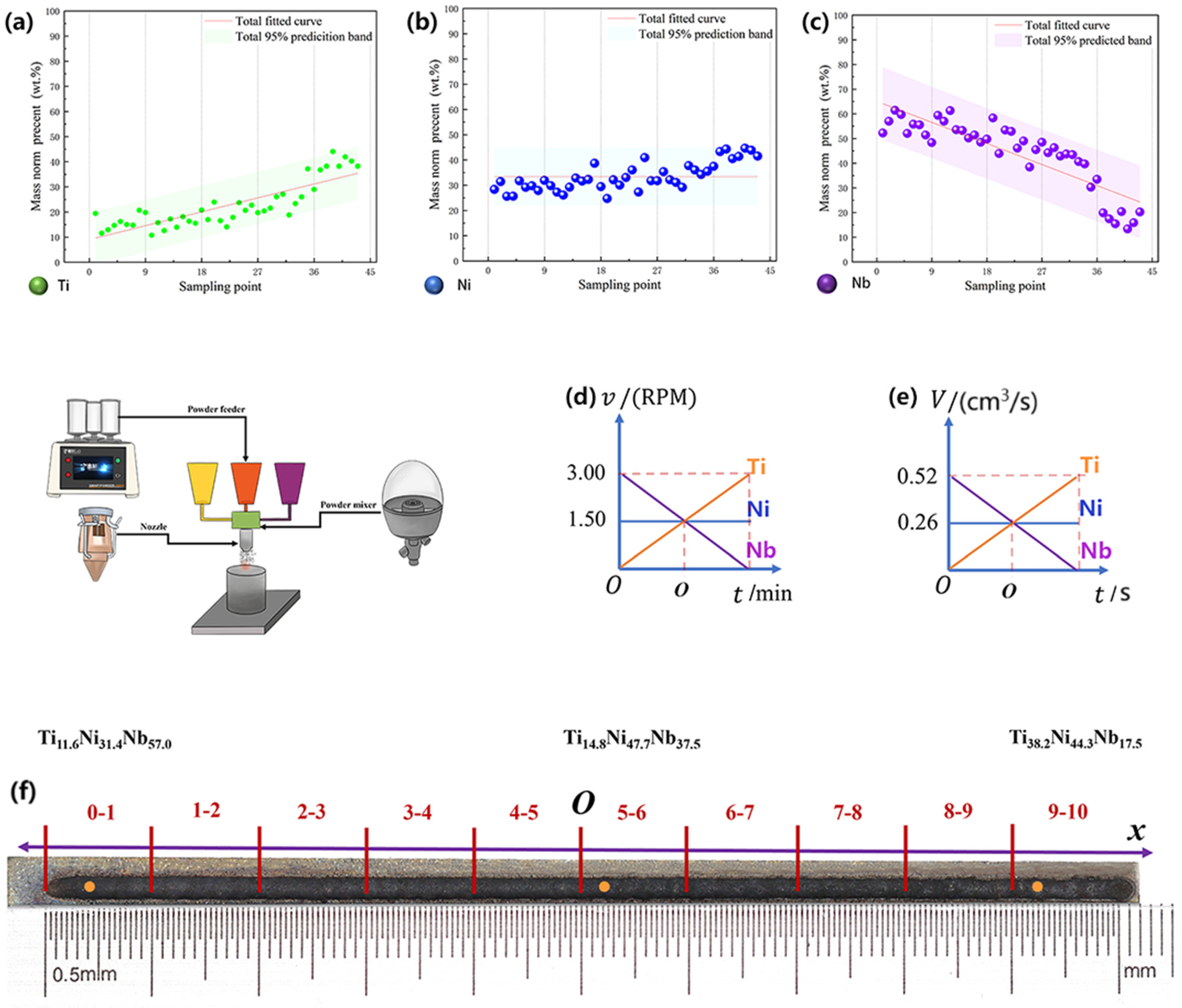

2. Materials and Methods

2.1. Materials

2.2. Manufacturing

2.3. Characterization

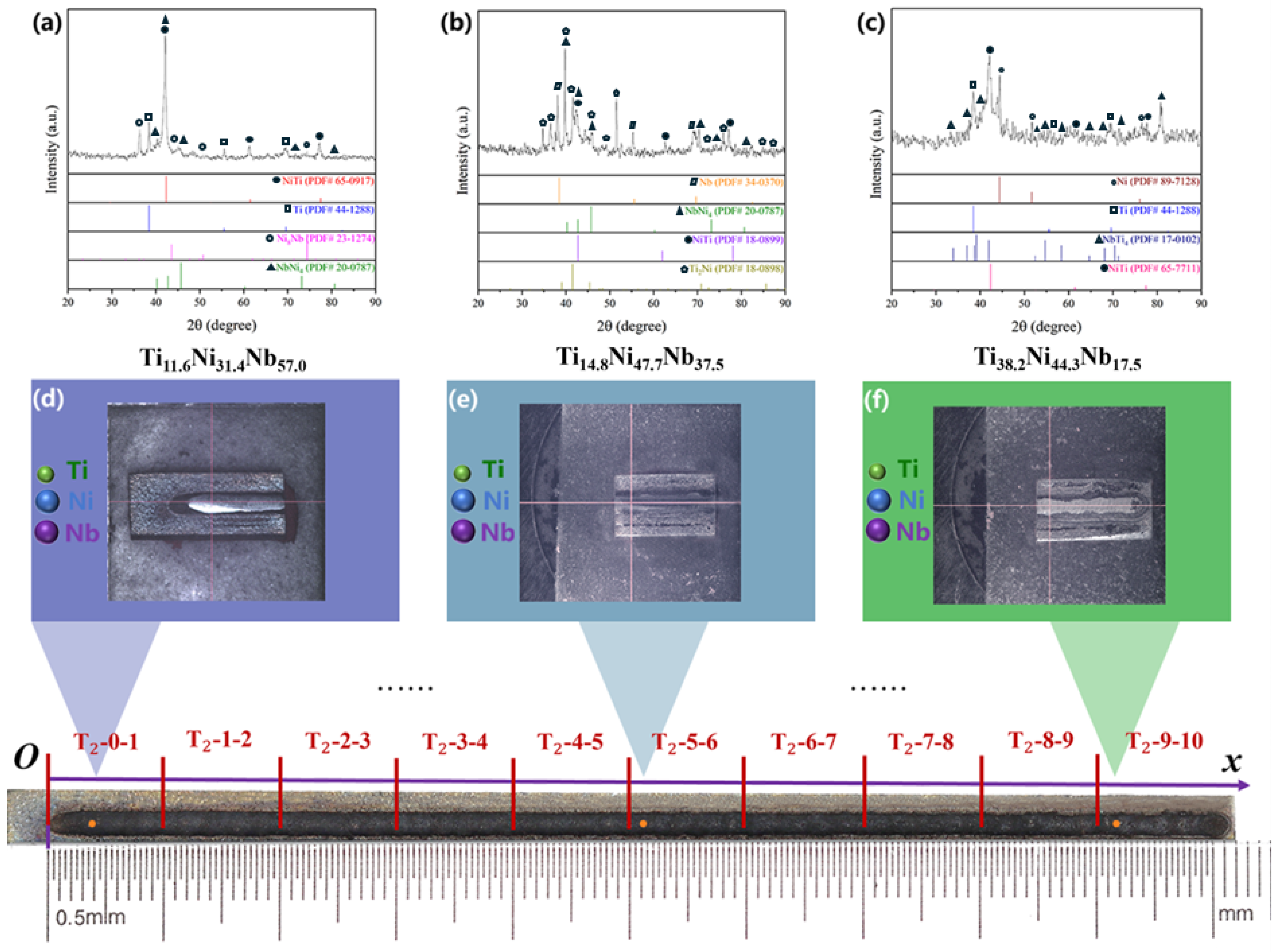

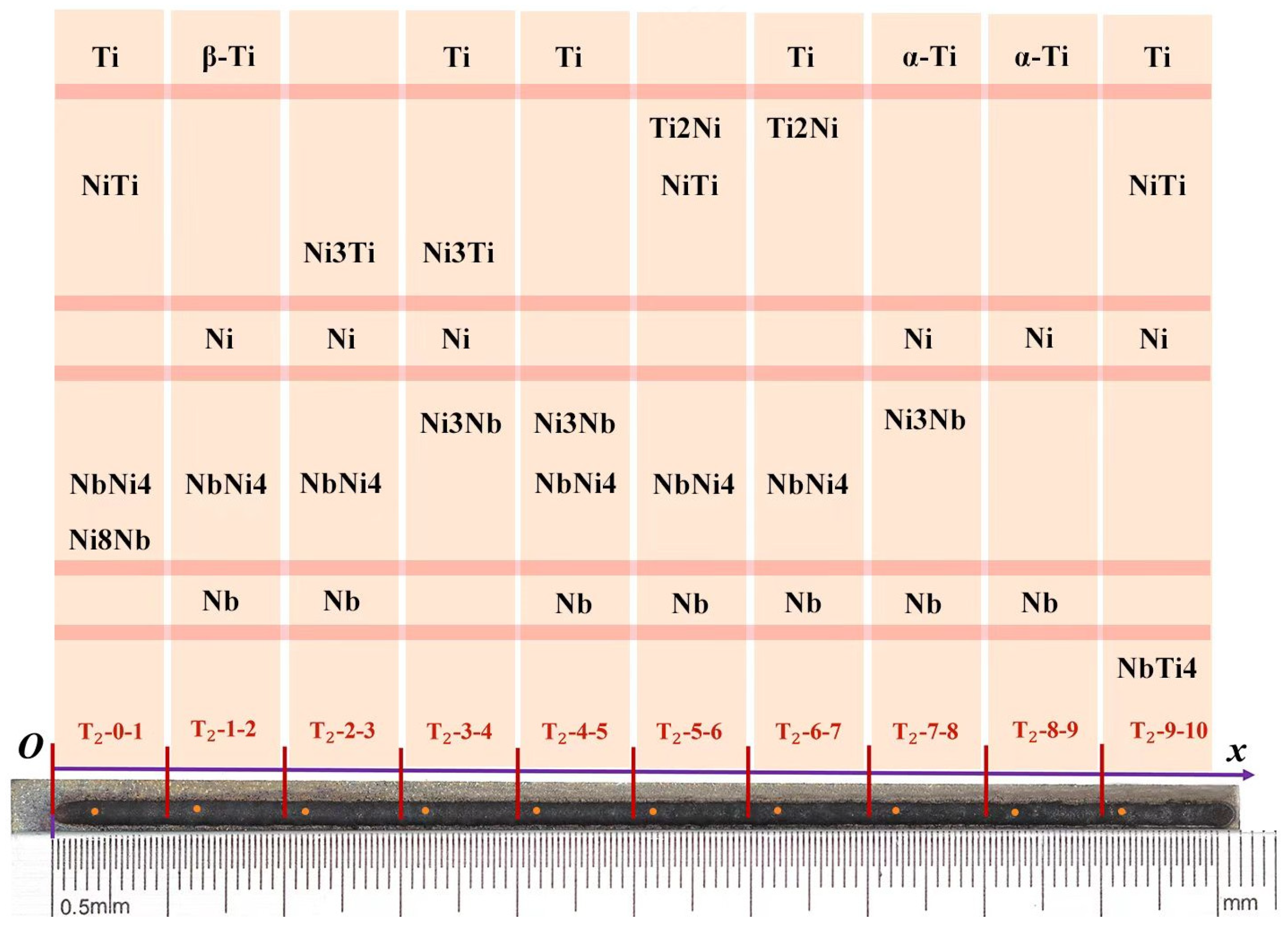

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tomar, B.; Shiva, S.; Nath, T. A Review on Wire Arc Additive Manufacturing: Processing Parameters, Defects, Quality Improvement and Recent Advances. Mater. Today Commun. 2022, 31, 103739. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, H.; Liu, Z.-K.; Beese, A.M. Design Methodology for Functionally Graded Materials: Framework for Considering Cracking. Addit. Manuf. 2023, 73, 103672. [Google Scholar] [CrossRef]

- Kim, E.S.; Park, J.M.; Karthik, G.M.; Kim, K.T.; Yu, J.-H.; Lee, B.-J.; Kim, H.S. Local Composition Detouring for Defect-Free Compositionally Graded Materials in Additive Manufacturing. Mater. Res. Lett. 2023, 11, 586–594. [Google Scholar] [CrossRef]

- Hu, Z.; Ma, Z.; Yu, L.; Liu, Y. Functionally Graded Materials with Grain-Size Gradients and Heterogeneous Microstructures Achieved by Additive Manufacturing. Scr. Mater. 2023, 226, 115197. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, S.; Cao, Y.; Yu, J.; Zhou, S.; Zhu, D.; Yang, H. Corrosion Behavior of Laser Directed Energy Deposited SS316L/Inconel718 Functionally Graded Materials. Mater. Today Commun. 2024, 40, 110038. [Google Scholar] [CrossRef]

- Ouyang, L.; Xie, X.; Wang, X.; Li, H.; Wang, J.; Wang, Z.; Feng, L.; Gui, Y.; Pan, F. Heterogeneous Structure Formation of Mg Alloy during Direct Laser Deposition with Dissimilar Alloy. Mater. Today Commun. 2024, 41, 111071. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Kolodziejska, J.; Roberts, S.; Otis, R.; Dillon, R.P.; Suh, J.-O.; Liu, Z.-K.; Borgonia, J.-P. Compositionally Graded Metals: A New Frontier of Additive Manufacturing. J. Mater. Res. 2014, 29, 1899–1910. [Google Scholar] [CrossRef]

- Wei, C.; Liu, L.; Gu, Y.; Huang, Y.; Chen, Q.; Li, Z.; Li, L. Multi-Material Additive-Manufacturing of Tungsten—Copper Alloy Bimetallic Structure with a Stainless-Steel Interlayer and Associated Bonding Mechanisms. Addit. Manuf. 2022, 50, 102574. [Google Scholar] [CrossRef]

- Feenstra, D.R. Critical Review of the State of the Art in Multi-Material Fabrication via Directed Energy Deposition. Mater. Sci. 2021, 25, 100924. [Google Scholar] [CrossRef]

- Li, W.; Liou, F.; Newkirk, J.; Taminger, K.M.B.; Seufzer, W.J. Investigation on Ti6Al4V-V-Cr-Fe-SS316 Multi-Layers Metallic Structure Fabricated by Laser 3D Printing. Sci. Rep. 2017, 7, 7977. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Wang, X.; Luo, S.; Wang, L.; Rong, Y. Multicomponent Multiphase Modeling of Dissimilar Laser Cladding Process with High-Speed Steel on Medium Carbon Steel. Int. J. Heat Mass Transf. 2020, 48, 118990. [Google Scholar] [CrossRef]

- Eliseeva, O.V. Functionally Graded Materials through Robotics-Inspired Path Planning. Mater. Des. 2019, 182, 107975. [Google Scholar] [CrossRef]

- Jacquier, V.; Zollinger, J.; Zeller, P.; Schuster, F.; Maskrot, H.; Pacquentin, W. Directed Energy Deposition with a Graded Multi-Material Compatibility Interface Enables Deposition of W on Cu. Mater. Des. 2024, 244, 113114. [Google Scholar] [CrossRef]

- Konrad, G.; Lillian, A.; Mohammed, F.; Irina, S. Diffuse reflectance spectroscopy for the qualification of powder blends for additive manufacturing. Powder Technol. 2025, 453, 120652. [Google Scholar] [CrossRef]

- Wang, R.; Zhou, R.; Zhou, J.; Chen, J.; Li, H.; He, W.; Zhang, W.; Wang, L.; Lu, Y.; Liu, Y. Additive manufacturing of high-quality NiCu/diamond composites through powder bed fusion. Addit. Manuf. 2024, 89, 104288. [Google Scholar] [CrossRef]

- Marta, O.; Jon, I.A.; Aitzol, L. CFD modelling of the powder segregation in multi-material laser directed energy deposition. Int. J. Therm. Sci. 2024, 198, 108885. [Google Scholar]

- Wang, K.; Tong, Y.; Chen, Y.; Kong, L.; Lu, K.; Wang, J.; Liang, X. Powder stream performance of a novel annular laser direct metal deposition with inside-laser coaxial powder feeding nozzle: Simulation and experimental perspectives. Opt. Laser Technol. 2024, 175, 110723. [Google Scholar] [CrossRef]

- Han, Y. Structural Design, Numerical Examination and Experimental Approach of the Multi-Powder Mixer for Directed Energy Deposition. Powder Technol. 2022, 398, 117144. [Google Scholar] [CrossRef]

- Zhang, X.; Rao, J.H.; Wang, M.; Cai, B.; Liu, H. Structural Design of a Novel Fume Hood for Vapor and Spatter Removal in Direct Energy Deposition via Numerical Investigation. Addit. Manuf. 2021, 37, 101704. [Google Scholar] [CrossRef]

- Gao, G.; Zhang, X.; Han, Y.; Xu, M.; Liu, H.; Ao, J.; Cai, Y.; Wang, J.; Wang, M. Structural Design of a Coaxial-Jet Vortex Powder Mixer for Multi-Material Directed Energy Deposition. Powder Technol. 2023, 425, 118586. [Google Scholar] [CrossRef]

- Xi, R.; Jiang, H.; Li, G.; Kustov, S.; Zhang, Z.; Wei, H.; Liu, Z.; Zhao, G.; Humbeeck, J.V.; Wang, X. In-situ alloying of NiTiNb ternary shape memory alloys via laser powder bed fusion using pre-alloyed NiTi and elemental Nb powders: Microstructure, phase transformation behavior and functional properties. Addit. Manuf. 2024, 79, 103933. [Google Scholar] [CrossRef]

- Nie, M.; Jiang, P.; Li, X.; Zhu, D.; Yue, T.; Zhang, Z. Microstructure and wear resistance of NiTiNb ternary alloy coatings fabricated in situ by laser cladding. Surf. Coat. Technol. 2024, 487, 131020. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhang, X.; An, Z.; Li, B.; Wang, Y.; Yang, Y.; Tong, K.; Zhu, Y. High-Throughput Phase Screening and Laser-Directed Energy Deposition of Ti-Ni-Nb Gradient Alloys. Coatings 2025, 15, 401. https://doi.org/10.3390/coatings15040401

Li J, Zhang X, An Z, Li B, Wang Y, Yang Y, Tong K, Zhu Y. High-Throughput Phase Screening and Laser-Directed Energy Deposition of Ti-Ni-Nb Gradient Alloys. Coatings. 2025; 15(4):401. https://doi.org/10.3390/coatings15040401

Chicago/Turabian StyleLi, Jinlong, Xiaowei Zhang, Zhe An, Biqiang Li, Yizheng Wang, Yaoyuan Yang, Kexin Tong, and Yingze Zhu. 2025. "High-Throughput Phase Screening and Laser-Directed Energy Deposition of Ti-Ni-Nb Gradient Alloys" Coatings 15, no. 4: 401. https://doi.org/10.3390/coatings15040401

APA StyleLi, J., Zhang, X., An, Z., Li, B., Wang, Y., Yang, Y., Tong, K., & Zhu, Y. (2025). High-Throughput Phase Screening and Laser-Directed Energy Deposition of Ti-Ni-Nb Gradient Alloys. Coatings, 15(4), 401. https://doi.org/10.3390/coatings15040401