Abstract

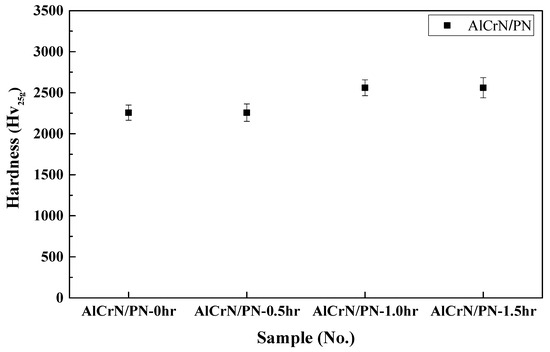

Plasma nitriding (PN) is often used to enhance the mechanical properties (surface hardness, wear and corrosion resistance) of bulk alloys. High-quality AlCrN hard coatings were obtained using high-power pulsed magnetron sputtering (HiPIMS) technology. This study proposes a combination of two surface treatment methods (plasma nitriding and hard coating deposition) in a continuous plasma process to optimize the application and service life of cutting tools. The main feature of this study is to verify the mechanical properties and adhesion strength of nitride tungsten carbide (WC-Co) bulk at a lower temperature (∼300 °C) and shorter time (0.5 to 1.5 h) of PN treatment. After 1.5 h of PN treatment on the WC-Co substrate without subsequent coating, the ultra-thin WNx diffusion interlayer (thickness ∼11.5 nm) on the subsurface was directly observed via TEM analysis, and the types of chemical bonding were confirmed by XPS analysis. Vickers analysis indicated that the surface hardness of the nitrided WC-Co substrate was enhanced by PN treatment from 1534 to 2034 Hv. The AlCrN coating deposited on the nitrided WC-Co substrate significantly enhances the surface mechanical properties, including adhesion strength (increasing from 70 to 150 N), hardness (rising from 2257 to 2568 HV), and wear resistance (with the wear rate decreasing from 14.5 to 3.4 × 10−8 mm3/Nm). Composite surface technology has a high commercial application value because it enhances the value of products under the existing equipment of manufacturers.

1. Introduction

Due to the rapid development of 5G technology, AI technology, and related autopilot applications, it is necessary to develop new printed circuit boards (PCBs) with high stability, multilayer, and high temperature resistance [1,2,3,4]. Mechanical microdrills are mostly used for drilling and cutting PCBs. However, existing microdrill products are inadequate for modern PCB applications. Although microdrills are composed of high-strength tungsten carbide (WC-Co), they fail to meet the demands of modern PCB drilling and cutting, leading to a significant reduction in their service life [5]. Therefore, researchers have applied surface treatment to microdrills to enhance their service life. In surface treatment processes, nitriding is a widely used metal heat treatment technique.

The nitriding treatment involves high temperature and pressure to dissociate nitrogen atoms, allowing them to diffuse onto the metal surface, thereby enhancing surface hardness and improving the mechanical properties of the alloy, including its hardness and wear resistance. Nitriding techniques include gas nitriding [6,7], salt bath nitriding [8,9], and plasma nitriding. Among these methods, plasma nitriding shows significant potential for further development. Plasma nitriding (PN) lowers processing temperature, gas consumption, energy consumption, and environmental impact [10,11,12]. Plasma nitriding primarily applies a high voltage to the substrate, ionizing the surrounding nitrogen gas to generate nitrogen atoms and ions. Through ion bombardment diffusion or injection into the alloy matrix, a nitride layer [13] is formed on the surface, enhancing the alloy’s mechanical properties and wear resistance [14]. A.F. Yetim et al. [15] investigated the effects of plasma nitriding on Ti6Al4V alloy and reported a significant increase in hardness. Their analysis revealed that nitrogen diffusion induced lattice distortion in the α-Ti phase, leading to solid solution strengthening and precipitation hardening within the diffusion layer. Similarly, Junji Miyamoto et al. [16] demonstrated that extending plasma nitriding duration further enhances hardness. These findings reinforce the potential of plasma nitriding as a promising surface modification technique for improving the mechanical performance of various materials. Nitriding treatments are predominantly applied to iron-based metals or alloys, with limited studies on tungsten carbide materials. Therefore, this study investigates the performance of plasma nitriding on tungsten carbide (WC) materials.

Recently, duplex surface treatment technology for continuous processing has been developed. This approach integrates two independent surface treatment technologies that can complement, combine, or enhance each other. The most widely used duplex surface continuous treatment involves nitriding the alloy substrate followed by the deposition of a hard thin film on the surface [17,18,19,20,21]. This process enhances hardness, shear stress, fracture toughness, and load-bearing capacity. Chang-Zi Chen et al. [22] reported a duplex treatment combining a Ti/TiN multilayer coating with plasma nitriding. Their results showed that the hardness of the continuously deposited Ti/TiN multilayer coating on an iron-based alloy substrate after plasma nitriding treatment was five times higher than that of the Ti/TiN multilayer coating without plasma nitriding. Similarly, Yang Deng et al. [23] investigated the dual treatment of plasma nitriding and AlTiN coating, demonstrating that the hardness of the AlTiN coating on an alloy steel substrate was significantly higher than that of the single-layer AlTiN coating. Additionally, Xin Zhang et al. [24] examined a dual treatment approach for CrAlN coatings, integrating plasma nitriding and cathodic arc deposition techniques. Their findings indicated that the hardness of the CrAlN coating continuously deposited after plasma nitriding high-speed steel increased from 2765 to 3156 HV compared to the CrAlN coating without plasma nitriding treatment. These studies on Fe-based alloy substrates subjected to duplex plasma nitriding and surface coating treatments align with the findings of this study, confirming that the dual treatment approach effectively enhances hardness and mechanical properties. Therefore, in this study, after plasma nitriding, instead of transferring the samples to a separate furnace for surface coating, AlCrN coatings were deposited using high-power impulse magnetron sputtering (HiPIMS) within the same furnace. The continuous duplex surface treatment further reduces processing time and costs while offering significant commercial application potential.

The integration of high-density plasma technology with magnetron sputtering has been under development for the past two decades. This technique is known as high-power impulse magnetron sputtering (HiPIMS). HiPIMS operates with a low duty cycle (<5%) and a low repetition frequency (<1 kHz), characterized by short pulse-on and long pulse-off durations. This process generates high gas ionization, instantaneous current, peak power density, and high-density plasma, thereby enhancing film compactness, mechanical properties, thin-film adhesion, and surface roughness [25,26,27,28]. AlCrN coatings are widely applied as hard coatings for cutting tools, milling cutters, molds, and mechanical components due to their high hardness, wear resistance, and high-temperature oxidation resistance [29,30,31,32]. In this study, plasma nitriding was applied to the WC-Co substrate, followed by the deposition of an AlCrN coating using high-power impulse magnetron sputtering.

2. Experimental Details

2.1. Deposition Techniques and Methods

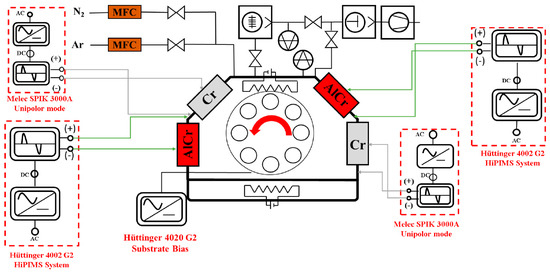

The configuration of the commercial composite coating system utilized in this study is presented in Figure 1. This system is employed for the plasma nitriding of WC-Co substrates, followed by the sequential deposition of AlCrN coatings. The tungsten carbide substrate is initially subjected to an ultrasonic cleaning pre-treatment. The initial step involves subjecting the substrate to ultrasonic cleaning using a degreasing liquid for 1 min. The second step involves conducting ultrasonic cleaning with deionized water for 1 min. The third step involves conducting ultrasonic cleaning using an alkaline solution for 10 min. The fourth step involves conducting ultrasonic cleaning with deionized water for 1 min. In the final step, the substrate is blow-dried with nitrogen and then dried in a hot air circulation oven at 70 °C for 10 min. Subsequently, it was transferred to a vacuum chamber and evacuated to achieve a base pressure of 5 × 10−6 Torr. Second, plasma nitriding was performed on the WC-Co substrate, and nitrogen was introduced to maintain a partial pressure of 8 mtorr. Under heating conditions of 300 °C, the DC power supply (Hüttinger 4020, Ditzingen, Germany) was used to apply a voltage of −1000 V to the WC-Co substrate for nitrogen ionization and bombardment treatment. The WC-Co substrates subjected to plasma nitriding treatment for 0 h (PN-0 h), 0.5 h (PN-0.5 h), 1 h (PN-1.0 h), and 1.5 h (PN-1.5 h) were subsequently coated with AlCrN using HiPIMS technology. At a temperature of 300 °C, the chamber pressure was maintained at 3 mtorr, the bias voltage of the WC-Co substrate was maintained at −60 V, and two HiPIMS power supplies (Melec SPILK 3000A, Baden-Baden, Germany), each connected to a separate Cr target (99.99%), were used to deposit a Cr layer. A CrN layer was deposited through the reaction between introduced nitrogen gas and Cr plasma to enhance adhesion to the WC-Co substrate. Subsequently, two HiPIMS power supplies (Melec SPILK 3000A), each connected to a separate AlCr target (70:30 at.%), were activated to deposit an AlCrN layer. The deposition parameters in HiPIMS mode included a fixed duty cycle of 3%, a repetition frequency of 200 Hz, a pulse turn-on time of 150 μs, a pulse turn-off time of 4850 μs, and a constant output power of 5 kW, which were applied to both the Cr target and the AlCr target. The process parameters are listed in Table 1.

Figure 1.

Schematic of the commercial hybrid coating system.

Table 1.

Experimental parameters of plasma nitriding of tungsten carbide substrate and continuous deposition of AlCrN coatings.

2.2. Characterization

Samples were prepared for transmission electron microscopy (TEM) analysis using a focused ion beam system (FIB, FEI Versa 3D, Hillsboro, OR, USA). The cross-sectional morphology, thickness, crystal structure, and element distribution of AlCrN coated on the nitride WC-Co substrate were observed by field-emission transmission electron microscopy (FE-TEM, JEM-ARM200FTH, JEOL, Tokyo, Japan), including selected area electron diffraction (SAED) and energy-dispersive X-ray spectrometry (EDS). Compositional analysis was quantified by wavelength dispersive spectroscopy (WDS) on a field-emission electron probe microanalyzer (FE-EPMA, JEOL, JXA-8500F, Japan), and this study used standard bulk samples provided by the EPMA manufacturer for more precise quantitative analysis. An X-ray diffractometer (XRD, PANalytical Empyrean, Almelo, The Netherlands) with a Cu Kα radiation was used to analyze the crystallization of the AlCrN coatings using the grazing incidence technique with an incident angle of 0.5°. After 1.5 h of PN treatment on the WC-Co substrate without subsequent coating, the chemical bonding of the nitride WC-Co substrate was analyzed using X-ray photoelectron spectroscopy (XPS, PHI 5000 VersaProbe III, Kanagawa, Japan) with a monochromatic Al Kα radiation source at RT. The samples were pre-sputtered before XPS analysis (pre-sputter settings: 1 kV, 1 × 1 mm2, sputter time 20 s).

The surface hardness value was measured using a Vickers microhardness tester (HMV-G21S, SHIMADZU, Kyoto, Japan) at a load of 25 g and a dwelling time of 15 s. The quoted hardness values are the average of at least 8 readings. Adhesion measurements were analyzed using milli-scratch and Rockwell indentation to study the adhesion of AlCrN coatings on nitride WC-Co substrates with different plasma nitriding treatment times. The milli-scratch (Scratch Tester, RST3, Anton Paar, Graz, Austria) was loaded with a Rock C diamond indenter (200 μm radius), loaded from a loading range of 0 to 150 N, at a loading speed of 20 N/min, and the scratch length was 5 mm. Additionally, using a Rockwell indentation and loading a diamond tip (C type tip, 200 μm radius), a weight of 150 kg was applied to the AlCrN coatings deposited on the WC-Co substrates for 10 s. The image of the indentation was observed by optical microscopy, and the adhesion grade was evaluated in accordance with the HF1 to HF6 grades according to the DIN 4856 test specification [33]. To investigate the coefficient of friction of AlCrN coatings deposited on WC-Co nitride substrates, a ball-on-disc tribometer (TRB3, Anton Paar) was employed, with a stationary tungsten carbide ball measuring 9 mm in diameter and subjected to a normal load of 12 N. The pin-on-disk wear test was performed at a distance of 500 m with a sliding speed of 15 cm/s at RT and a relative humidity of 60%. The wear volume loss after the wear test was determined by white light interferometry (Profilm3D, 3D optical profiler, Filmetrics, San Diego, CA, USA) to calculate the wear rate (mm3/Nm), which is the result of the wear volume loss divided by the product of the normal load and total wear length.

3. Results and Discussion

3.1. Plasma Nitriding Treatment

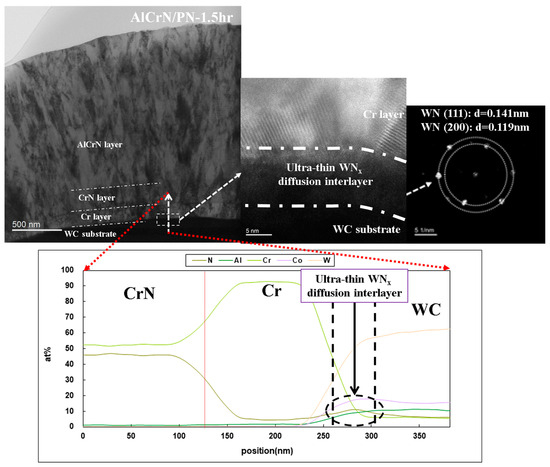

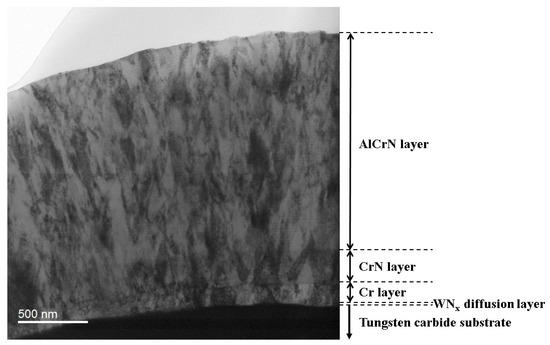

In this study, the plasma-nitriding treatment temperature was 300 °C. According to conventional nitriding methods, within this temperature range, nitrogen gas dissociates into nitrogen atoms and ions; therefore, a high bias voltage is applied to ionize the nitrogen gas, generating nitrogen atoms and ions. Therefore, to confirm that the plasma nitriding process in this study resulted from nitrogen diffusion or interstitial solid solution in the tungsten carbide substrate, a tungsten nitride hardened layer was formed. Figure 2 presents the cross-sectional TEM morphology and EDS composition analysis of the WC-Co substrate after 1.5 h of plasma nitriding, followed by the deposition of the AlCrN coating (AlCrN/PN-1.5 h). An approximately 11.5 nm hardened tungsten nitride layer was observed at the interface between the WC-Co substrate and the AlCrN coating. The selected area electron diffraction (SAED) results were consistent with the crystal structures of the WN (111) and WN (200) phases [34]. Based on the above analysis, it was confirmed that the WC-Co substrate formed a hardened tungsten nitride layer after plasma nitriding in this study.

Figure 2.

TEM and SAED images and EDS analysis of the treated AlCrN/PN-1.5 sample.

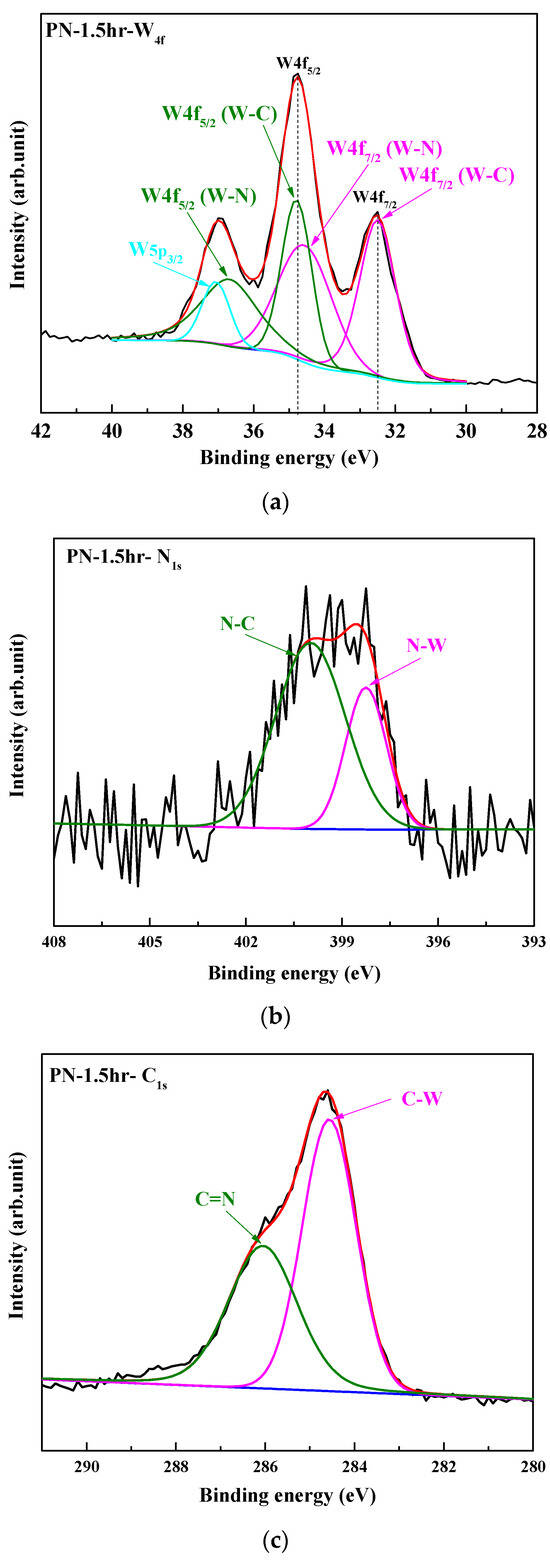

To confirm that the plasma nitriding treatment in this study resulted from nitrogen diffusion or interstitial solid solution in the WC-Co substrate, leading to the formation of a tungsten nitride-hardened layer, XPS bonding analysis was conducted. In this study, plasma nitriding treatment was conducted on the WC-Co substrate for 1.5 h without subsequent coating, and the sample was then analyzed using XPS. The longer the plasma nitriding treatment time, the thicker the nitriding diffusion layer, which facilitates XPS analysis and discussion. Figure 3 shows the XPS analysis results of the plasma nitriding treatment of the WC-Co substrate for 1.5 h (PN-1.5 h). The W 4f orbital is split into W 4f7/2 and W 4f5/2, with an energy separation of 2.18 eV and an area ratio of 0.75. Through peak fitting, the bonding energies of W 4f7/2 (W-N) and W 4f7/2 (W-C) [35,36,37,38] were identified at 34.6 eV and 32.5 eV, respectively, while the bonding energies of W 4f5/2 (W-N) and W 4f5/2 (W-C) were determined to be 36.78 eV and 34.68 eV, respectively. In addition, a broad peak observed at 37.1 eV corresponds to the bonding energy of the W 5p3/2 level. The N1s orbitals were split into peaks to obtain N-W and N-C bonds [35,36,38,39,40,41,42], and the bonding energies were 398.3 eV and 399.9 eV, respectively. The C1s orbitals were split into peaks to obtain C-N and C-W bonds [35,37,39,40,41,43], and the bonding energies were 286.1 eV and 284.6 eV, respectively. This indicates that in this study, the WC-Co substrate underwent plasma nitriding treatment for 1.5 h (PN-1.5 h), demonstrating that nitrogen diffusion or interstitial formation led to the solid-solution strengthening of the WC-Co substrate. This effect resulted in the formation of a hardened tungsten nitride layer after the 1.5 h plasma nitriding treatment.

Figure 3.

XPS analysis of the WC-Co substrate after 1.5 h of plasma nitriding treatment: (a) W4f, (b) N1s, and (c) C1s.

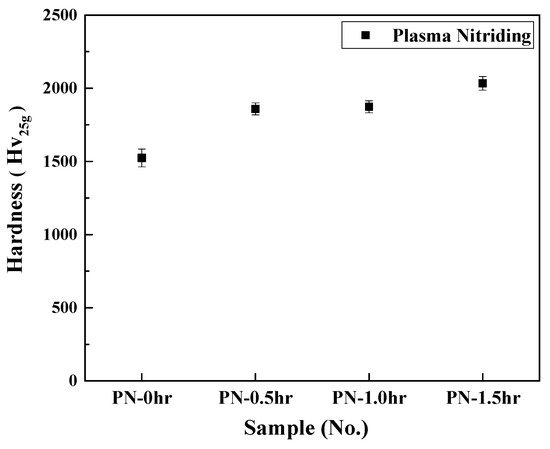

Figure 4 shows the hardness analysis of the plasma-nitriding-treated WC-Co substrates after different treatment times. The results show that the hardness of the WC-Co matrix without plasma nitriding treatment was 2257.8 ± 92.9 HV, as determined by the micro-Vickers hardness test under a 25 g load. The hardness increased from 2258.2 ± 106.2 Hv to 2568.2 ± 122.6 Hv as the plasma nitriding duration was extended from 0.5 h (PN-0.5 h) to 1.5 h (PN-1.5 h). With a longer plasma nitriding duration, the WC-Co substrate underwent nitrogen diffusion or interstitial solid solution, leading to increased compressive stress and a greater depth of the tungsten nitride hardened layer, thereby enhancing hardness (hardening effect).

Figure 4.

Hardness values of WC-Co substrates subjected to different plasma nitriding treatment durations.

3.2. Duplex Surface Treatment (Plasma Nitriding and COATING)

The duplex surface treatment method enables plasma nitriding and coating processes to be conducted in the same chamber, improving surface treatment efficiency, reducing energy loss, and preventing contamination during intermediate processing. The sample designations were as follows: 0 h (untreated) (AlCrN/PN-0 h), 0.5 h (AlCrN/PN-0.5 h), 1 h (AlCrN/PN-1.0 h), and 1.5 h (AlCrN/PN-1.5 h). Figure 5 presents the TEM cross-sectional morphology of the AlCrN coating deposited on the plasma-nitrided WC-Co substrate, which is the same as the TEM cross-sectional morphology shown in Figure 2. The thicknesses of the various layers are as follows: Cr metal layer (155.8 nm), CrN layer (231.5 nm), AlCrN layer (1535.6 nm), and total layer (2 μm). After the plasma nitriding treatment of the WC-Co substrate, the primary purpose of depositing the Cr metal layer and the CrN layer was to enhance the adhesion between the WC-Co substrate and the AlCrN coating, thereby improving the mechanical properties.

Figure 5.

TEM cross-sectional morphology of the AlCrN coating deposited on nitride WC-Co substrate.

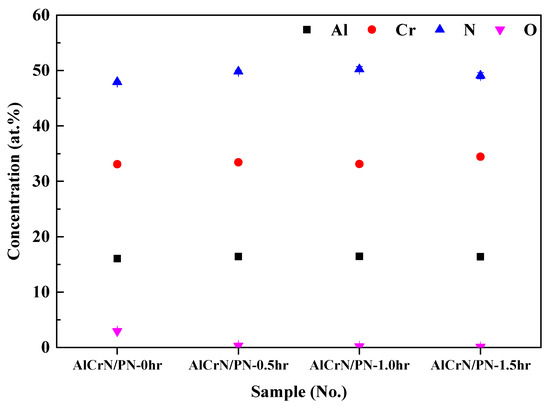

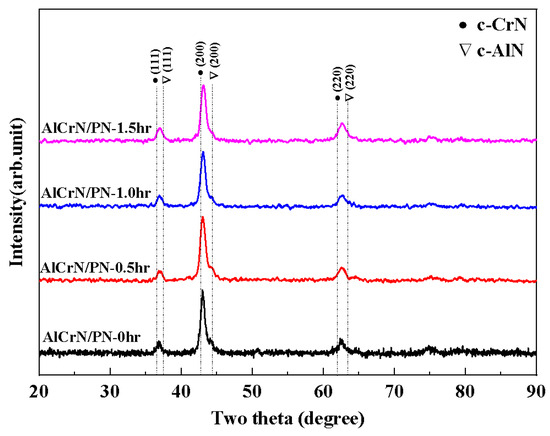

EPMA and XRD analyses were conducted to examine the composition and crystal phase structure of continuous AlCrN coatings on WC-Co substrates following different plasma nitriding durations. Figure 6 presents the EPMA composition analysis of AlCrN coatings continuously deposited on WC-Co substrates after various plasma nitriding durations. The results indicate that the compositional ratios of elements in the continuously deposited AlCrN coatings remained largely unchanged between the WC-Co substrate without plasma nitriding and those subjected to different plasma nitriding durations. Plasma nitriding of the WC-Co substrate had no impact on the composition of the subsequently deposited AlCrN coatings. The elemental composition range was as follows: Al, 16.05–16.46 at.%; Cr, 33.07–33.44 at.%; N, 47.83–50.23 at.%; and O, 0.1–2.95 at.%. Figure 7 shows the XRD analysis results for the continuous deposition of the AlCrN coating on the WC-Co substrate following plasma nitriding treatment with different durations. The analysis results indicate that the AlCrN coatings primarily consisted of fcc-CrN (111), (200), and (220) crystal phases (JCPDS No. 00-011-0065), with diffraction peak angles at 37.5°, 43.7°, and 63.5°, respectively. Additionally, fcc-AlN (JCPDS No. 00-025-1495) exhibits (111), (200), and (220) crystal phases, with diffraction peak angles at 37.8°, 43.9°, and 63.8°, respectively. This study confirms that variations in plasma nitriding duration and the continuous deposition of AlCrN coatings on WC-Co substrates, with or without prior plasma nitriding, do not influence the crystal phase, preferred orientation, or intensity of the AlCrN coatings.

Figure 6.

EPMA analysis results for the continuous deposition of the AlCrN coatings on the WC-Co substrates following plasma nitriding treatment with different durations.

Figure 7.

XRD analysis and EPMA composition of continuously deposited AlCrN coatings on WC-Co substrates following different plasma nitriding durations.

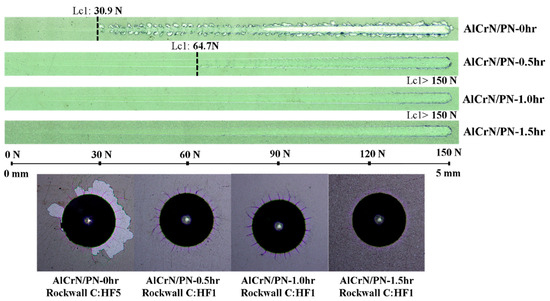

Rockwell indentation analysis was conducted to assess adhesion, determining the adhesion grade based on DIN 4856 specifications and various criteria. The critical loads (LC1, LC2) were used to evaluate scratch resistance; LC1 represented the onset of cracking, while LC2 indicated coating delamination, exposing the substrate. Figure 8 presents the Rockwell indentation and scratch test results for the continuously deposited AlCrN coatings on WC-Co substrates following different plasma nitriding durations. The results indicate that for the AlCrN coating continuously deposited on a WC-Co substrate without plasma nitriding, the critical load LC1 was 30.9 N, and the Rockwell indentation was classified as HF5. Through the film layer design in this study, incorporating a Cr metal layer and a CrN layer enhances the adhesion between the AlCrN coating and the WC-Co substrate. H. Caliskan et al. [44] reported that double-layer, progressive-layer, and multilayer designs enhance thin-film adhesion and mechanical properties. However, the ability to improve adhesion through film design is limited. Therefore, this study examines the adhesion of continuously deposited AlCrN coatings following plasma nitriding treatment. As the plasma nitriding duration increased from 0 h (AlCrN/PN-0 h) to 1.5 h (AlCrN/PN-1.5 h), the critical load LC1 rose from 30.9 N to over 150 N, while the Rockwell indentation rating improved from HF5 to HF1. As mentioned above, a Cr interlayer and a CrN layer were incorporated between the WC-Co substrate and the AlCrN coating, resulting in a critical scratch load of up to 30.9 N. The critical load of the duplex surface-treated AlCrN coating, following plasma nitriding and surface deposition, exceeds 150 N. Radial cracks were observed in the Rockwell indentation morphology analysis. With an increase in the plasma nitriding duration of the tungsten carbide substrate to 1.5 h, radial cracks gradually diminished, became more refined, or disappeared. The literature has indicated that combining plasma nitriding with surface coating can form a nitride diffusion layer between the coating and the substrate, create a hardness gradient, reduce mismatch, and enhance adhesion between the coating and the substrate [20,22,45].

Figure 8.

Rockwell indentation and scratch analysis of continuously deposited AlCrN coatings on WC-Co substrates following different plasma nitriding durations.

Figure 9 presents the micro-Vickers hardness analysis of continuously deposited AlCrN coatings on WC-Co substrates following different plasma nitriding durations. The continuously deposited AlCrN coatings on untreated WC-Co substrates exhibited a micro-Vickers hardness of 2258 ± 93 Hv. As the plasma nitriding duration increased, the micro-Vickers hardness of the continuously deposited AlCrN coating rose to 2568 ± 123 Hv. This improvement resulted from the formation of a solid solution-strengthened tungsten nitride diffusion layer at the interface after plasma nitriding of the WC-Co substrate, leading to increased compressive stress. The strengthened tungsten carbide matrix provided sufficient support, allowing the continuously deposited AlCrN coating to undergo duplex treatment, significantly enhancing its hardness. The results of this study align with previously reported findings on the hardness enhancement of iron-based alloy substrates subjected to duplex treatment with plasma nitriding and surface coating, as outlined in the literature review. This study further confirmed that the dual treatment of plasma nitriding and surface coating on the WC-Co substrate enhanced hardness and mechanical properties.

Figure 9.

Hardness analysis results for the continuous deposition of the AlCrN coatings on the WC-Co substrates following plasma nitriding treatment with different durations.

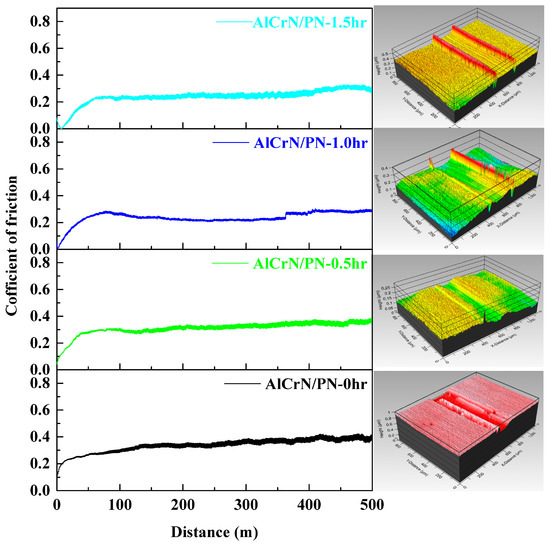

Figure 10 presents the wear analysis of continuously deposited AlCrN coatings on WC-Co substrates following different plasma nitriding durations. Wear tests were conducted using tungsten carbide grinding balls under a load of 12 N over a distance of 500 m. The results indicate that the average coefficient of friction of the AlCrN coating without plasma nitriding was 0.34. However, as the plasma nitriding duration increased and AlCrN was continuously deposited, the coefficient of friction progressively decreased, ranging from approximately 0.32 to 0.25. The duplex treatment, involving continuous deposition of the AlCrN coating following plasma nitriding, contributed to a lower coefficient of friction. To assess the wear resistance of continuously deposited AlCrN coatings on WC-Co substrates, both with and without plasma nitriding, the wear rate was calculated and analyzed. Table 2 presents the wear rate of continuously deposited AlCrN coatings following plasma nitriding of WC-Co substrates. The wear rate of the AlCrN coating on the WC-Co substrate without plasma nitriding reached 14.504 (10−8 mm3/Nm). However, as the plasma nitriding duration increased and duplex treatment was applied during continuous AlCrN deposition, the wear rate decreased. The wear rate of the AlCrN coating without plasma nitriding decreased from 14.5 × 10−8 mm3/Nm to 3.367 × 10−8 mm3/Nm. The duplex treatment, involving the continuous deposition of an AlCrN coating on a WC-Co substrate following plasma nitriding, offers superior wear resistance compared to the direct deposition of an AlCrN coating on a WC-Co substrate. Xin Zhang et al. [45] reported that the duplex treatment combining plasma nitriding and CrAlN coating deposition improved surface hardness, adhesion, and load-carrying capacity due to the effects of nitrogen ion implantation and coating formation. Furthermore, M. Naeem et al. [46] reported on the plasma nitriding and deposition of Hastelloy coatings on AISI-1045 steel substrates. Wear analysis results indicate that the wear rate of the duplex treatment was significantly lower than that of the single-deposited Hastelloy coating or AISI-1045 steel. Improved wear resistance resulted from enhanced adhesion and increased hardness due to the hardness gradient formed by the nitride diffusion layer in the substrate.

Figure 10.

Wear analysis and the profile of the AlCrN coatings deposited on nitrided WC-Co substrates.

Table 2.

Hardness, coefficient of friction, and wear rate of continuously deposited AlCrN coatings following plasma nitriding treatment on tungsten carbide substrates.

4. Conclusions

This study demonstrates that plasma nitriding treatment significantly enhances the hardness and mechanical properties of WC-Co substrates through a low-temperature nitriding process driven by plasma ion bombardment. With increasing plasma nitriding duration, the hardness reaches 2134 ± 47 HV, representing a 24% improvement compared to untreated samples. This enhancement is primarily attributed to nitrogen diffusion and the formation of an interstitial solid solution, leading to the development of an ultrathin tungsten nitride (WNx) diffusion interlayer. TEM and XPS analyses confirm the formation of this WNx-hardened layer, which contributes to the improved mechanical performance of the substrate.

Following 1.5 h of plasma nitriding treatment and subsequent deposition of an AlCrN coating, the highest recorded hardness reached 2568 ± 123 HV, with an adhesive critical load (LC1) exceeding 150 N, a minimum coefficient of friction of 0.25, and the lowest wear rate of 3.367 × 10−8 mm3/Nm. Comparative analysis of AlCrN coatings deposited with and without plasma nitriding treatment confirms that the presence of the ultrathin WNx diffusion interlayer (~11.5 nm) leads to a 12% increase in hardness, an improvement in adhesion of more than 10%, and a 77% reduction in wear rate. This improvement is primarily attributed to the formation of the ultrathin WNx diffusion interlayer during plasma nitriding treatment, which enhances lattice matching and consequently improves hardness, adhesion, and wear resistance.

Therefore, the duplex treatment proposed in this study effectively enhances the mechanical properties of WC-Co substrates while reducing capital investment, processing time, and energy consumption. These findings highlight the significant potential of this treatment method for commercial applications in cutting tools and wear-resistant coatings.

Author Contributions

Methodology, T.-W.L. and C.-L.C.; Investigation, T.-W.L.; Resources, Y.-L.K. and C.-L.C.; Writing—original draft, F.-S.Y.; Writing—review & editing, F.-S.Y., J.-F.T. and C.-L.C.; Visualization, F.-S.Y.; Supervision, Y.-L.K. and C.-L.C. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to thank the Ministry of Science and Technology, Taiwan, for financially supporting this research project under grant No. MOST (NSTC)-110-2221-E-131-006.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors gratefully acknowledge the use of the FE-EPMA (JXA-iHP200F) apparatus at the Instrument Center of National Tsing Hua University.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

References

- Shi, H.; Liu, X.; Lou, Y. Materials and micro drilling of high frequency and high speed printed circuit board: A review. Int. J. Adv. Manuf. Technol. 2019, 100, 827–841. [Google Scholar] [CrossRef]

- Huang, G.; Wan, Z.; Yang, S.; Li, Q.; Zhong, G.; Wang, B.; Liu, Z. Mechanism investigation of micro-drill fracture in PCB large aspect ratio micro-hole drilling. J. Mech. Work. Technol. 2023, 316, 117962. [Google Scholar] [CrossRef]

- Geier, N.; Patra, K.; Anand, R.S.; Ashworth, S.; Balázs, B.Z.; Lukács, T.; Magyar, G.; Tamás-Bényei, P.; Xu, J.; Davim, J.P. A critical review on mechanical micro-drilling of glass and carbon fibre reinforced polymer (GFRP and CFRP) composites. Compos. Part B 2023, 254, 110589. [Google Scholar] [CrossRef]

- Hasan, M.; Zhao, J.; Jiang, Z. A review of modern advancements in micro drilling techniques. J. Manuf. Process. 2017, 29, 343–375. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, S.; Aravindan, S. Investigation of oxidation behaviour of AlCrN and AlTiN coatings deposited by arc enhanced HIPIMS technique. Appl. Surf. Sci. 2020, 508, 144812. [Google Scholar] [CrossRef]

- Ge, L.; Tian, N.; Lu, Z.; You, C. Influence of the surface nanocrystallization on the gas nitriding of Ti–6Al–4V alloy. Appl. Surf. Sci. 2013, 286, 412–416. [Google Scholar] [CrossRef]

- Wang, B.; Sun, S.; Guo, M.; Jin, G.; Zhou, Z.; Fu, W. Study on pressurized gas nitriding characteristics for steel 38CrMoAlA. Surf. Coat. Technol. 2015, 279, 60–64. [Google Scholar] [CrossRef]

- Kumar, B.C.; Charan, P.S.; Jayakumar, K.; Alankrutha, D.; Sindhu, G.; Subbiah, R. Assessment of wear properties on low temperature molten salt bath nitriding on austenitic stainless steel. Mater. Today Proc. 2020, 27, 1541–1544. [Google Scholar] [CrossRef]

- Wang, J.; Lin, Y.; Yan, J.; Zen, D.; Zhang, Q.; Huang, R.; Fan, H. Influence of time on the microstructure of AISI 321 austenitic stainless steel in salt bath nitriding. Surf. Coat. Technol. 2012, 206, 3399–3404. [Google Scholar] [CrossRef]

- Zhao, C.; Li, C.; Dong, H.; Bell, T. Study on the active screen plasma nitriding and its nitriding mechanism. Surf. Coat. Technol. 2006, 201, 2320–2325. [Google Scholar] [CrossRef]

- Li, Y.; He, Y.; Xiu, J.; Wang, W.; Zhu, Y.; Hu, B. Wear and corrosion properties of AISI 420 martensitic stainless steel treated by active screen plasma nitriding. Surf. Coat. Technol. 2017, 329, 184–192. [Google Scholar] [CrossRef]

- Kovacı, H.; Hacısalihoğlu, İ.; Yetim, A.; Çelik, A. Effects of shot peening pre-treatment and plasma nitriding parameters on the structural, mechanical and tribological properties of AISI 4140 low-alloy steel. Surf. Coat. Technol. 2019, 358, 256–265. [Google Scholar] [CrossRef]

- Lampe, T.; Eisenberg, S.; Laudien, G. Compound Layer Formation during Plasma Nitriding and Plasma Nitrocarburising. Surf. Eng. 1993, 9, 69–76. [Google Scholar] [CrossRef]

- Esfandiari, M.; Dong, H. Improving the surface properties of A286 precipitation-hardening stainless steel by low-temperature plasma nitriding. Surf. Coat. Technol. 2007, 201, 6189–6196. [Google Scholar] [CrossRef]

- Yetim, A.; Kovacı, H.; Uzun, Y.; Tekdir, H.; Çelik, A. A comprehensive study on the fatigue properties of duplex surface treated Ti6Al4V by plasma nitriding and DLC coating. Surf. Coat. Technol. 2023, 458, 129367. [Google Scholar] [CrossRef]

- Miyamoto, J.; Abraha, P. The effect of plasma nitriding treatment time on the tribological properties of the AISI H13 tool steel. Surf. Coat. Technol. 2019, 375, 15–21. [Google Scholar] [CrossRef]

- Kovacı, H.; Bozkurt, Y.B.; Yetim, A.F.; Baran, O.; Çelik, A. Corrosion and tribocorrosion properties of duplex surface treatments consisting of plasma nitriding and DLC coating. Tribol. Int. 2021, 156, 106823. [Google Scholar] [CrossRef]

- Nishimoto, A.; Amano, R.; Tamiya, T. Duplex treatment of active screen plasma nitriding and amorphous hydrogenated carbon coating. Appl. Surf. Sci. Adv. 2021, 6, 100129. [Google Scholar] [CrossRef]

- Alvarez-Vera, M.; Hdz-García, H.M.; Díaz-Guill, J.C.; Mu, R.; Acevedo-Davila, J.L.; Mtz-Enriquez, A.I.; Badillo, C.K.F. Tribological performance of Ti nanolayer coating post plasma nitriding treatment on Co based alloy. Wear 2021, 477, 203798. [Google Scholar] [CrossRef]

- Sun, F.; Liu, X.-L.; Luo, S.-Q.; Xiang, D.-D.; Ba, D.-C.; Lin, Z.; Song, G.-Q. Duplex treatment of arc plasma nitriding and PVD TiN coating applied to dental implant screws. Surf. Coat. Technol. 2022, 439, 128449. [Google Scholar] [CrossRef]

- Tang, J.-F.; Huang, C.-H.; Lin, C.-Y.; Tsai, Y.-J.; Chang, C.-L. Effect of plasma nitriding and modulation structure on the adhesion and corrosion resistance of CrN/Cr2O3 coatings. Surf. Coat. Technol. 2019, 379, 125051. [Google Scholar] [CrossRef]

- Chen, C.-Z.; Li, Q.; Leng, Y.-X.; Chen, J.; Zhang, P.-C.; Bai, B.; Huang, N. Improved hardness and corrosion resistance of iron by Ti/TiN multilayer coating and plasma nitriding duplex treatment. Surf. Coat. Technol. 2010, 204, 3082–3086. [Google Scholar] [CrossRef]

- Deng, Y.; Tan, C.; Wang, Y.; Chen, L.; Cai, P.; Kuang, T.; Lei, S.; Zhou, K. Effects of tailored nitriding layers on comprehensive properties of duplex plasma-treated AlTiN coatings. Ceram. Int. 2017, 43, 8721–8729. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, X.; Gong, C.; Liu, X.; Li, J.; Zhu, J.; Lin, H. Effect of plasma nitriding ion current density on tribological properties of composite CrAlN coatings. Ceram. Int. 2022, 48, 3954–3962. [Google Scholar] [CrossRef]

- Anders, A. Deposition rates of high power impulse magnetron sputtering: Physics and economics. J. Vac. Sci. Technol. A 2010, 28, 783–790. [Google Scholar] [CrossRef]

- Meng, L.; Yu, H.; Szott, M.M.; McLain, J.T.; Ruzic, D.N. Downstream plasma transport and metal ionization in a high-powered pulsed-plasma magnetron. J. Vac. Sci. Technol. A 2011, 29, 011024. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.D. Structure and properties of Cr2O3 coatings deposited using DCMS, PDCMS, and DOMS. Surf. Coat. Technol. 2015, 276, 70–76. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, T.-G.; Yan, B.; Qi, H.-J.; Guo, Y.-Y.; Xu, S.-S. Study on the microstructure and mechanical properties of Zr-B-(N) tool coatings prepared by hybrid coating system. Procedia Manuf. 2018, 26, 806–817. [Google Scholar] [CrossRef]

- Le Bourhis, E.; Goudeau, P.; Staia, M.; Carrasquero, E.; Puchi-Cabrera, E. Mechanical properties of hard AlCrN-based coated substrates. Surf. Coat. Technol. 2009, 203, 2961–2968. [Google Scholar] [CrossRef]

- Sanjinés, R.; Banakh, O.; Rojas, C.; Schmid, P.; Lévy, F. Electronic properties of Cr1−xAlxN thin films deposited by reactive magnetron sputtering. Thin Solid Films 2002, 420–421, 312–317. [Google Scholar] [CrossRef]

- Tang, J.-F.; Lin, C.-Y.; Yang, F.-C.; Tsai, Y.-J.; Chang, C.-L. Effects of nitrogen-argon flow ratio on the microstructural and mechanical properties of AlCrN coatings prepared using high power impulse magnetron sputtering. Surf. Coat. Technol. 2020, 386, 125484. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, J.C.; Zhang, B.R.; Chen, J.J.; Tang, C.R.; Zhu, R.Y.; Zheng, J. Effect of duty cycle on microstructure and mechanical properties of AlCrN coatings deposited by HiPIMS. Vacuum 2022, 205, 111409. [Google Scholar] [CrossRef]

- DIN 4856:2018-02; Carbon-Based Films and Other Hard Coatings—Rockwell Penetration Test to Evaluate the Adhesion. DIN Media GmbH: Berlin, Germany, 2018.

- Shen, L.; Wang, N. Effect of Nitrogen Pressure on the Structure of Cr-N, Ta-N, Mo-N, and W-N Nanocrystals Synthesized by Arc Discharge. J. Nanomater. 2011, 2011, 781935. [Google Scholar] [CrossRef]

- Wicher, B.; Chodun, R.; Nowakowska-Langier, K.; Trzcinski, M.; Skowroński, L.; Okrasa, S.; Minikayev, R.; Naparty, M.K.; Zdunek, K. Chemical and structural characterization of tungsten nitride (WNx) thin films synthesized via Gas Injection Magnetron Sputtering technique. Vacuum 2019, 165, 266–273. [Google Scholar] [CrossRef]

- Wang, C.; Tao, Q.; Li, Y.; Ma, S.; Dong, S.; Cui, T.; Wang, X.; Zhu, P. Excellent mechanical properties of metastable c-WN fabricated at high pressure and high temperature. Int. J. Refract. Met. Hard Mater. 2017, 66, 63–67. [Google Scholar] [CrossRef]

- Bozzini, B.; Dalmiglio, M.; De Gaudenzi, G.P.; D’Urzo, L.; Gregoratti, L. An investigation of the corrosion of WC–Co cermets in CN–-containing aqueous solutions. Part II: Synchrotron-based high lateral-resolution XPS study. Corros. Sci. 2009, 51, 1675–1678. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Yamamoto, K.; Veldhuis, S.; Kovalev, A.; Shuster, L.; Ning, L. Self-adaptive wear behavior of nano-multilayered TiAlCrN/WN coatings under severe machining conditions. Surf. Coat. Technol. 2006, 201, 1852–1860. [Google Scholar] [CrossRef]

- Tillmann, W.; Stangier, D.; Roese, P.; Shamout, K.; Berges, U.; Westphal, C.; Debus, J. Structural and mechanical properties of carbon incorporation in DC/HiPIMS CrAlN coatings. Surf. Coat. Technol. 2019, 374, 774–783. [Google Scholar] [CrossRef]

- Pengfei, H.; Bailing, J. Study on tribological property of CrCN coating based on magnetron sputtering plating technique. Vacuum 2011, 85, 994–998. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Zhou, Z.; Li, L.K.-Y.; Yan, J. Influence of carbon concentration on the electrochemical behavior of CrCN coatings in simulated body fluid. Surf. Coat. Technol. 2015, 265, 16–23. [Google Scholar] [CrossRef]

- Yu, L.; Zhao, H.; Xu, J. Influence of silver content on structure, mechanical and tribological properties of WCN–Ag films. Mater. Charact. 2016, 114, 136–145. [Google Scholar] [CrossRef]

- Zellner, M.B.; Chen, J.G. Surface science and electrochemical studies of WC and W2C PVD films as potential electrocatalysts. Catal. Today 2005, 99, 299–307. [Google Scholar] [CrossRef]

- Caliskan, H.; Panjan, P.; Kurbanoglu, C. 3.16 Hard Coatings on Cutting Tools and Surface Finish. Compr. Mater. Finish. 2017, 3, 230–242. [Google Scholar]

- Paschke, H.; Weber, M.; Kaestner, P.; Braeuer, G. Influence of different plasma nitriding treatments on the wear and crack behavior of forging tools evaluated by Rockwell indentation and scratch tests. Surf. Coat. Technol. 2010, 205, 1465–1469. [Google Scholar] [CrossRef]

- Naeem, M.; Torres, A.; Serra, P.; Monção, R.; Junior, C.A.; Rossino, L.; Costa, T.; Costa, C.; Iqbal, J.; Sousa, R. Combined plasma treatment of AISI-1045 steel by hastelloy deposition and plasma nitriding. J. Build. Eng. 2022, 47, 103882. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).