Recent Research Progress of Polysaccharide Polymer Coatings for Improving Properties of Paper-Based Packaging Materials

Abstract

1. Introduction

2. Mechanism of Coating Barrier Technology

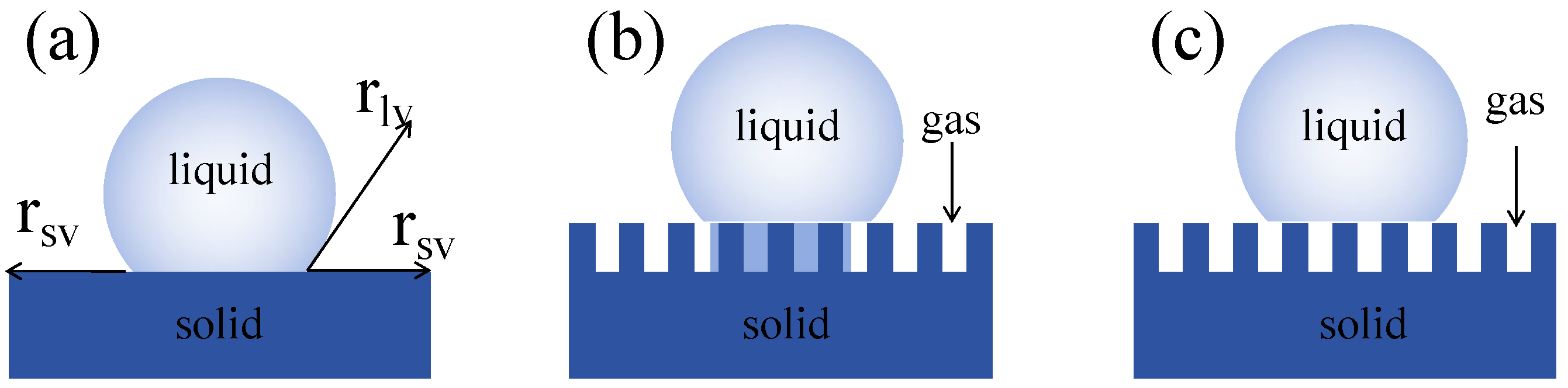

2.1. Hydrophobic Mechanism

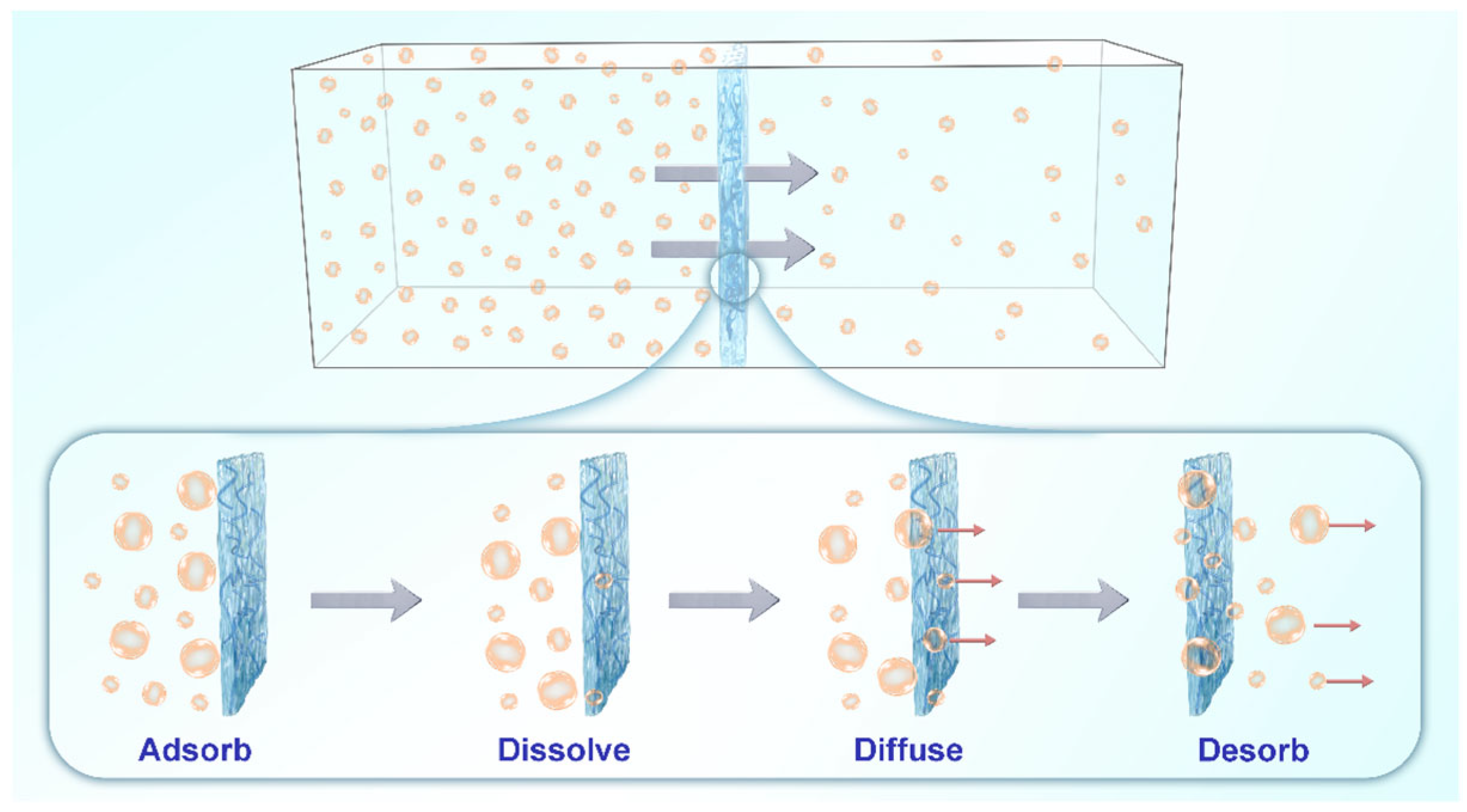

2.2. Gas Barrier Mechanism

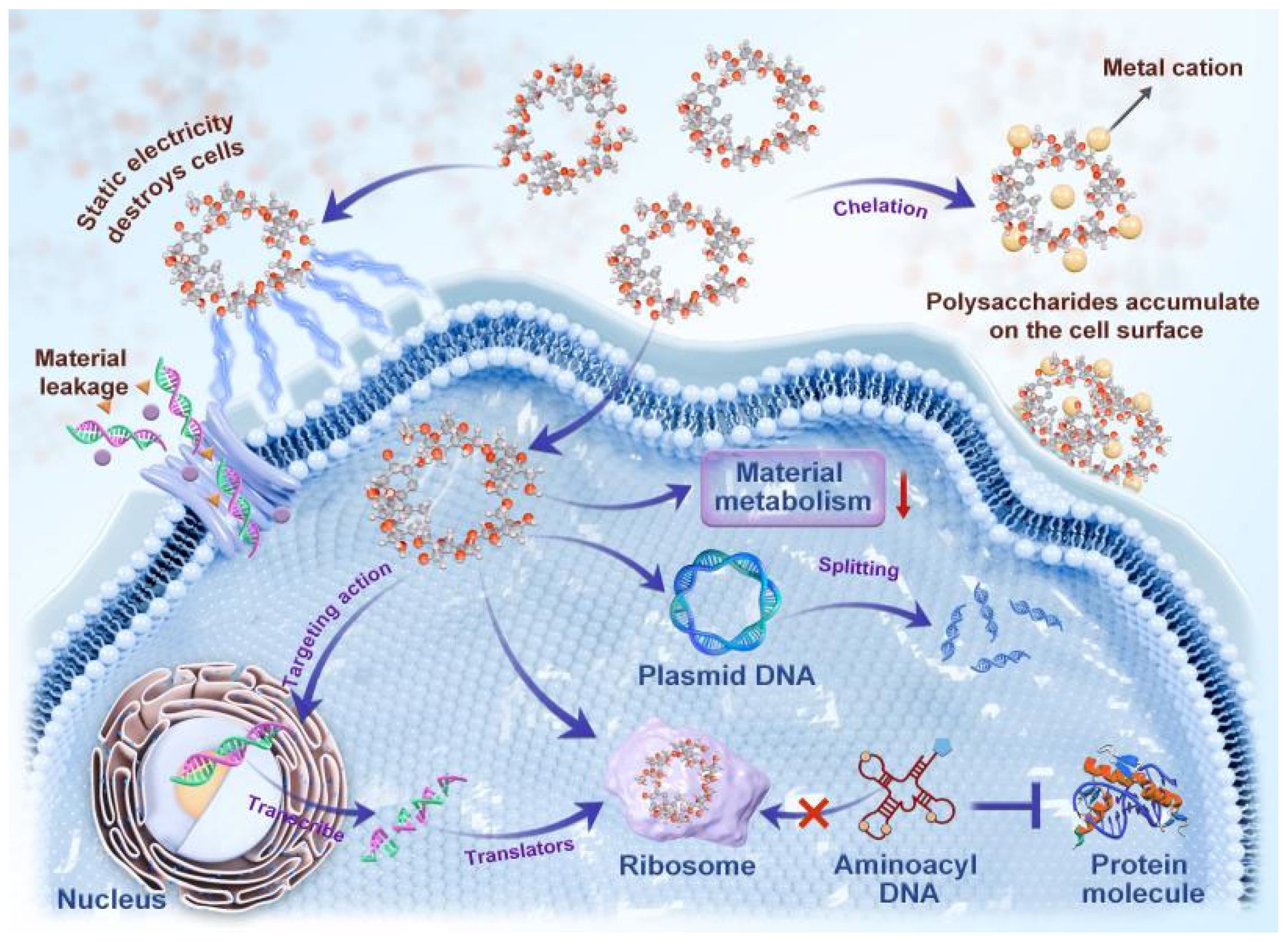

2.3. Antimicrobial Mechanism

2.3.1. Prevent Bacteria Cells from Sticking

2.3.2. Damage the Bacteria Cell Membrane or Cell Wall

2.3.3. Inhibition of Bacteria Nucleic Acid and Protein Synthesis

2.3.4. Interferes with Bacteria Metabolism

2.3.5. Inhibiting or Destroying the Biofilm

2.3.6. Hinder the Absorption of Nutrients

2.4. Oil Resistance Mechanism

3. Classification of Common Polysaccharide Polymer Coatings

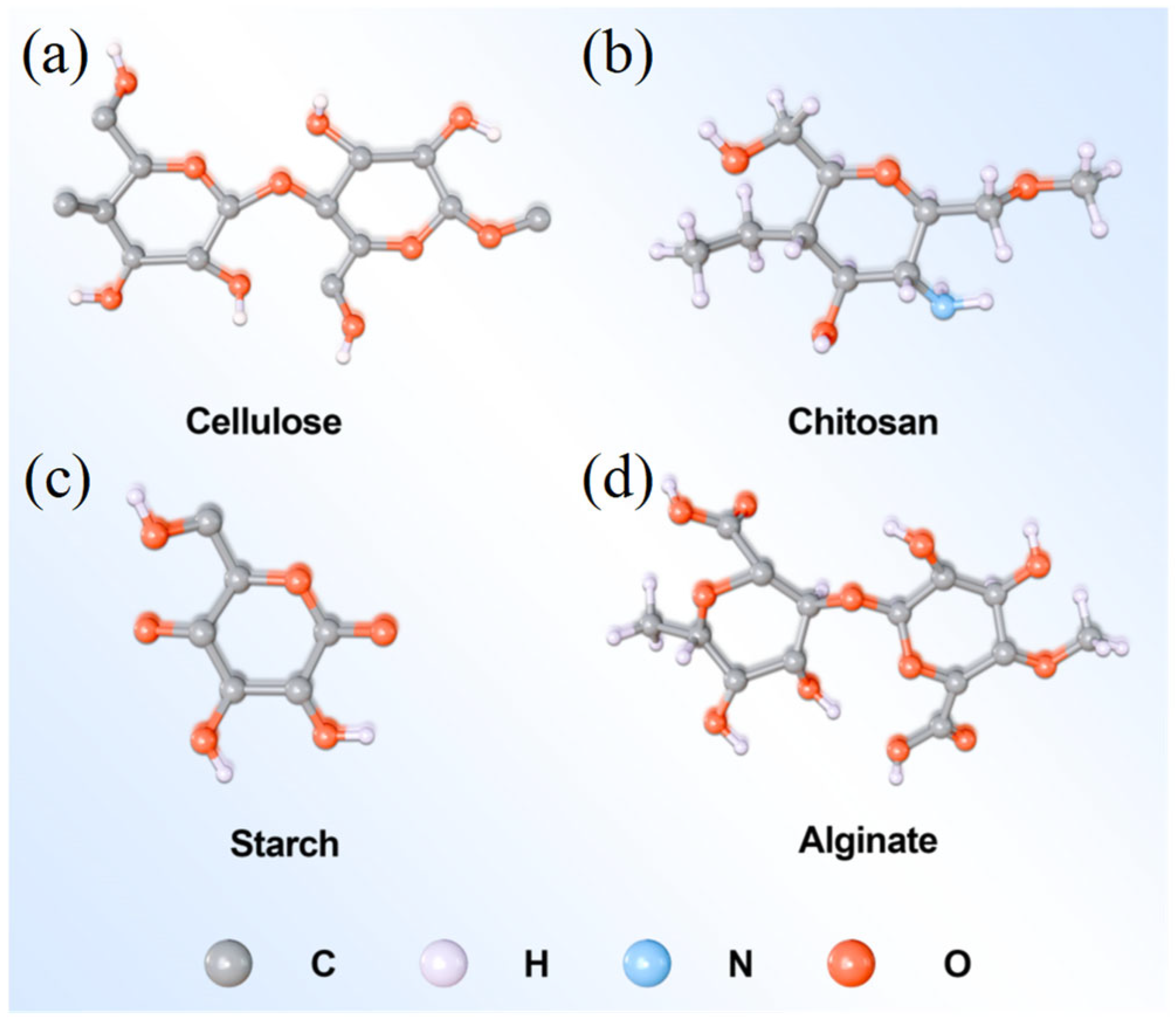

3.1. Natural Cellulose

3.2. Chitosan

3.3. Starch

3.4. Seaweed Derivatives

4. Application Classification of Polysaccharide Polymer Coating for Improving the Performance of Paper-Based Packaging

4.1. Hydrophobic Properties

| Materials | Method | Features | Ref. |

|---|---|---|---|

| Cellulose nanofibers | Treat the bamboo fiber with biological enzymes, reduced fiber size and increased crystallinity. | The increase of cellulose nanofibers can effectively increase the hydrophobicity, hydrophobicity and tensile properties of paper-based materials. | [90] |

| Chitosan, glutinous rice starch | Chitosan and glutinous rice starch are aqueous phase, polylactic acid is oil phase and hydrophobic polylactic acid is embedded in the form of microspheres, mimicking the lotus leaf effect. | Coated paper has a high hydrophobicity and water barrier. The water contact angle is greater than 130, and the water vapor penetration rate is 3.57 × 1010 g m−1 s−1 Pa−1. | [91] |

| Chitosan derivatives and micro-fibrotic cellulose | Three water-soluble chitosan derivatives with specific functions were tested separately (alkyl chitosan-ach, season chitosan-qch and carboxymethyl chitosan-ch). | Alkyl chitosan alone or in combination with microfiber cellulose improves the barrier of water and water vapor; carboxymethyl chitosan improves the tensile strength; and seasonal chitosan has a general effect on the water barrier and strength performance. | [94] |

| Chitosan | Hydrophobic compounds grafted to chitosan. | The gas-phase barrier performance of chitosan-palm emulsion-coated paper remained unchanged, while chitosan-O, O′-double palmitoyl-chitosan-coated paper decreased significantly. | [95] |

| Hemicellulose | Hemicellulose-grafted lauric acid micelles were used as a nano-stabilizer. | The coating density was 8.4 g/m2, the water contact angle was about 130 and the waterproof time was 6 h. | [96] |

| Chitosan | The chitosan-grafted sunflower seed oil paper coating was prepared by chitosan open-ring method. | A good thermal stability at 250 °C. | [97] |

4.2. Gas Barrier Property

| Materials | Method | Features | Ref. |

|---|---|---|---|

| Polylactic acid | Cellulose paper as paper-based material, polylactic acid and cassia bark aldehyde as barrier layer, and nano-silica modified stearic acid as superhydrophobic layer. | With thermal stability, can block oil and natural gas, with hydrophobic, pollution prevention and antimicrobial functions. | [100] |

| Long chain stearic acid | Long-chain stearic acid modified the microcrystalline cellulose to form hydrophobic microcrystalline cellulose esters, and it was mixed with stearic acid. | The coated paper forms a continuous hydrophobic film, which completely covers the pores of the original bagasse fiber paper, and shows good water resistance and oxygen resistance activity. The water also showed good dimensional stability and good wet tensile strength. | [101] |

| Bacterial cellulose | Cellulose was used as a scaffold, and the ethylene-propylene fibers were coated on the cellulose surface. | Plant-bacterial cellulose fibers were fully filled, and hot-coated ES fibers increased the water contact angle of the cellulose scaffold from 25° to 153°, while increasing the wet tensile strength of the composite by about 6.7 times compared to pure cellulose paper. | [53] |

| Cellulose nanofibers | Foam coating was prepared from a mixture of anionic surfactants and cellulose nanofibers. | Low coating weight and high air barrier efficiency. | [102] |

| Cellulose | Carboxythyl-pretreated bleached bamboo pulp. | After carboxyethyl pretreatment, the cellulose coating of bleached bamboo pulp had the highest efficiency. | [103] |

4.3. Antimicrobial Performance

| Materials | Method | Features | Ref. |

|---|---|---|---|

| Carbamate starch, and cellulose nanofibers | The three polysaccharide derivatives enhance the compatibility between the polysaccharide derivatives and the nanoparticles through electrostatic interactions and hydrogen bonding interactions, thus improving the interfacial binding force between the paper and the bio-composite coating. | Hydrophobicity and excellent mechanical, air barrier and UV light blocking properties; inhibition of E. coli and Staphylococcus aureus. | [107] |

| Cellulase | Using cellulase-activated kraft paper and dipping kraft paper with clove essential oil and cold-pressed grape seed oil. | The hydrophobicity of the modified kraft paper was improved, and the water contact angle increased from 97° to above 110° and showed different antioxidant and antimicrobial properties. | [108] |

| Chitosan | Chitosan/Brazilian palm wax emulsion was prepared by using the one-step method as an oil-resistant and waterproof coating for cellulose-based food packaging paper. | When the concentration of chitosan is 3% and the amount of CW is 90% of the total solid content, the comprehensive performance of coated paper is the best in water resistance and oil resistance and has an excellent thermal stability and high antimicrobial rate of 99.1%. | [109] |

| Starch | The guanidine-modified starch was prepared by two-step reaction with guanidine hydrochloride as a modified agent. | Growth hormone was successfully grafted onto starch by Schiff base reaction, and the film was antimicrobial against both E. coli and Staphylococcus aureus. | [75] |

| Nanocellulose, sodium alginate | Nanocellulose was prepared by acid hydrolysis-fractionation. | Sodium alginate–nanocellulose composite coating improves the barrier and strength of paper, and the incorporation of AgN Ps into the coating mixture also introduces the antimicrobial activity of paper. | [82] |

4.4. Oil Resistance

| Materials | Method | Features | Ref. |

|---|---|---|---|

| Chitosan | Apply different breathable oil-proof papers with chitosan. | When the coating amount exceeds 5 g/m2, the paper fracture strain is the highest, and the paper obtains high oil prevention performance. | [66] |

| Chitosan | Food oil-resistant packaging materials were prepared with a chitosan/starch compound oil agent. | Adding cationic starch to the oil repellent can improve the oil repellent ability of the paper. | [110,111] |

| Chitosan and sodium alginate | Chitosan solution and sodium alginate solution as raw material, by ferulic acid crosslinking, coated on food packaging base paper. | When the quality ratio of chitosan and sodium alginate is 8:2 and the coating amount is 4 g/m2, the oil control paper can reach the highest oil control grade (grade 12). | [113] |

| Chitosan/cationic starch | The oil-proof properties of chitosan and chitosan/cationic starch-coated paper were compared. | Chitosan coating paper and chitosan/cationic starch coating paper both have good oil resistance, and their oil resistance increases with the increase of coating weight. The thermal stability and water resistance of the chitosan/cationic starch composites are better than the chitosan-coated paper. | [114] |

| Oxidized acetate starch | Organic chromium was crosslinked with oxidized acetate starch | The highest oil protection grade of the coated paper is grade 7. | [115] |

| Cationic starch, oxidized starch and cassava starch | Cationic starch, oxidized Starch and cassava starch with a certain amount of polyvinyl alcohol and oil prevention agent compound. | The adhesive agent made of cationic starch is better than the other two kinds of starch. | [116] |

5. Challenges and Future Perspectives

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rhim, J.-W.; Park, H.-M.; Ha, C.-S. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Jeevahan, J.; Chandrasekaran, M. Nanoedible films for food packaging: A review. JMatS 2019, 54, 12290–12318. [Google Scholar] [CrossRef]

- Abbas, M.; Buntinx, M.; Deferme, W.; Peeters, R. (Bio) polymer/ZnO nanocomposites for packaging applications: A review of gas barrier and mechanical properties. Nanomaterials 2019, 9, 1494. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.-Y. Technological innovation hotspots and prospects of paper-based functional materials. China Pulp Pap. Ind. 2021, 42, 7. [Google Scholar]

- Xu, G.-Y. Preparation and Modification of Biodegradable Polylactic Acid/Polyvinyl Alcohol Food Packaging Materials. Master’s Thesis, North Central University, Taiyuan, China, 2020. [Google Scholar]

- Mahardika, I.H.; Kin, S.; Kwon, O.-S.; Shin, K. Extended functionalities of paper-based analytical devices using hydrogels for biomedical applications. Flex. Print. Electron. 2023, 8, 033001. [Google Scholar] [CrossRef]

- An, S.; Xie, J.-L.; Wang, X.; Chen, Y.; Zhang, H.-J. Research on the Wettability of Fiber Surface and Its Response Relationship with Fiber Bonding Performance. China Pulp Pap. 2018, 37, 7. [Google Scholar]

- Wang, C.; Gao, H.-L.; Chen, X.-Q.; Ni, S.-Z.; Liu, N.; Dai, H.-Q. Research Progress on Surface Hydrophobic Modification of Cellulose Based Paper. J. Cellul. Sci. Technol. 2020, 28, 11. [Google Scholar]

- Li, J.-W.; Cheng, Z.-B.; Liu, L.-Q.; Liu, X.; Cao, H.-B.; Zhang, X.-H.; Liu, H.-B.; An, X.-Y. Research Progress in the Application of Paper-based Superhydrophobic Functional Materials. China Pulp Pap. 2023, 42, 162–172. [Google Scholar]

- Li, Y.; Tang, Z.; Wang, W.; Huang, X.; Lv, Y.; Qian, F.; Cheng, Y.; Wang, H. Improving air barrier, water vapor permeability properties of cellulose paper by layer-by-layer assembly of graphene oxide. Carbohydr. Polym. 2021, 253, 117227. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Ana, F.; Preeti, T.; Yin, Y.; Carlos, S.; Lokendra, P.; Rojas, O.J. Nanocellulose in Thin Films, Coatings, and Plies for Packaging Applications: A Review. Bioresources 2017, 12, 2143–2233. [Google Scholar] [CrossRef]

- Farris, S.; Piergiovanni, L. Emerging coating technologies for food and beverage packaging materials. In Emerging Food Packaging Technologies; Elsevier: Amsterdam, The Netherlands, 2012; pp. 274–302. [Google Scholar]

- Das, S.; Kumar, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. A review on superhydrophobic polymer nanocoatings: Recent development and applications. Ind. Eng. Chem. Res. 2018, 57, 2727–2745. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Wenzel, R.N. Surface roughness and contact angle. J. Phys. Chem. 1949, 53, 1466–1467. [Google Scholar] [CrossRef]

- Wang, X.-D.; Peng, X.-F.; Min, J.-C.; Liu, T. Theoretical analysis of contact Angle hysteresis. Chin. J. Eng. Thermophys. 2001, 9, 11. [Google Scholar]

- Robbins, M.O.; Joanny, J.-F. Contact angle hysteresis on random surfaces. Europhys. Lett. 1987, 3, 729. [Google Scholar] [CrossRef]

- Liu, X.-F.; Zhang, X.; Cheng, Y.; Zhang, H.-J. Research progress of polysaccharide polymer coating on water vapor barrier properties of paper-based packaging materials. Chin. J. Pap. Mak. 2021, 36, 76–84. [Google Scholar]

- Yang, Z.; Zhang, J.; Qi, Y.; Shen, Y.; Li, H. Application of hydrophobically modified hydroxyethyl cellulose-methyl methacrylate copolymer emulsion in paper protection. Nord. Pulp Pap. Res. J. 2022, 37, 282–289. [Google Scholar] [CrossRef]

- Padhi, S.; Singh, A.; Routray, W. Nanocellulose from agro-waste: A comprehensive review of extraction methods and applications. Rev. Environ. Sci. Bio/Technol. 2023, 22, 1–27. [Google Scholar] [CrossRef]

- Dufresne, A. Preparation and Properties of Cellulose Nanomaterials. Pap. Biomater. 2020, 5, 1–13. [Google Scholar]

- Pacaphol, K.; Seraypheap, K.; Aht-Ong, D. Extraction and Silylation of Cellulose Nanofibers from Agricultural Bamboo Leaf Waste for Hydrophobic Coating on Paper. J. Nat. Fibers 2023, 20, 2178581. [Google Scholar] [CrossRef]

- Xiang, H.; Wang, B.; Zhong, M.; Liu, W.; Yu, D.; Wang, Y.; Tam, K.C.; Zhou, G.; Zhang, Z. Sustainable and versatile superhydrophobic cellulose nanocrystals. ACS Sustain. Chem. Eng. 2022, 10, 5939–5948. [Google Scholar] [CrossRef]

- Gatto, M.; Ochi, D.; Yoshida, C.M.P.; da Silva, C.F. Study of chitosan with different degrees of acetylation as cardboard paper coating. Carbohydr. Polym. 2019, 210, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Zhu, R.; Fu, X.; Jin, S.; Ma, R.; He, Z.; Zhang, D.; Long, Z. Water and oil-resistant paper materials based on sodium alginate/hydroxypropyl methylcellulose/polyvinyl butyral/nano-silica with biodegradable and high barrier properties. Int. J. Biol. Macromol. 2023, 225, 162–171. [Google Scholar] [CrossRef]

- Wang, J.; Gardner, D.J.; Stark, N.M.; Bousfield, D.W.; Tajvidi, M.; Cai, Z. Moisture and oxygen barrier properties of cellulose nanomaterial-based films. ACS Sustain. Chem. Eng. 2018, 6, 49–70. [Google Scholar] [CrossRef]

- Tan, W.-Z. Preparation and Barrier Properties of Regenerated Cellulose Matrix Composite Films. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2019. [Google Scholar]

- Liu, X.F. Study on Improvement of Gas Barrier Properties of Paper-Based Fiber Materials by Chitosan Composite Coating. Master’s Thesis, China Pulp and Paper Research Institute Co., Ltd., Beijing, China, 2022. [Google Scholar]

- Despond, S.; Espuche, E.; Cartier, N.; Domard, A. Barrier properties of paper–chitosan and paper–chitosan–carnauba wax films. J. Appl. Polym. Sci. 2005, 98, 704–710. [Google Scholar] [CrossRef]

- Afra, E.; Mohammadnejad, S.; Saraeyan, A. Cellulose nanofibils as coating material and its effects on paper properties. Prog. Org. Coat. 2016, 101, 455–460. [Google Scholar] [CrossRef]

- Wittschier, N.; Lengsfeld, C.; Vorthems, S.; Stratmann, U.; Ernst, J.; Verspohl, E.; Hensel, A. Large molecules as anti-adhesive compounds against pathogens. J. Pharm. Pharmacol. 2007, 59, 777–786. [Google Scholar] [CrossRef]

- Wang, L.-L.; Zhang, W.-Q.; Xia, W.; Qian, J.-W. Research progress on antimicrobial of chitosan and its derivatives. Adv. Biomed. Eng. 2006, 27, 111–114. [Google Scholar]

- Chen, H.-X. Study on Antibacterial Activity of Marine Sulfate Polysaccharide and Its Application in Meat Preserving. Master’s Thesis, Jimei University, Xiamen, China, 2016. [Google Scholar]

- Ji, F.; Shen, Y.; Tang, L.; Cai, Z. Determination of intracellular metabolites concentrations in Escherichia coli under nutrition stress using liquid chromatography-tandem mass spectrometry. Talanta 2018, 189, 1–7. [Google Scholar] [CrossRef]

- Chen, X.; Tao, L.; Ru, Y.; Weng, S.; Chen, Z.; Wang, J.; Guo, L.; Lin, Z.; Pan, W.; Qiu, B. Antibacterial mechanism of Tetrastigma hemsleyanum Diels et Gilg’s polysaccharides by metabolomics based on HPLC/MS. Int. J. Biol. Macromol. 2019, 140, 206–215. [Google Scholar] [CrossRef] [PubMed]

- Rabin, N.; Zheng, Y.; Opoku-Temeng, C.; Du, Y.; Bonsu, E.; Sintim, H.O. Biofilm formation mechanisms and targets for developing antibiofilm agents. Future Med. Chem. 2015, 7, 493–512. [Google Scholar] [CrossRef] [PubMed]

- Grishin, A.; Karyagina, A. Polysaccharide galactan inhibits Pseudomonas aeruginosa biofilm formation but protects pre-formed biofilms from antibiotics. Biochemistry 2019, 84, 509–519. [Google Scholar] [CrossRef]

- Li, Y.-T.; Chen, B.-J.; Wu, W.-D.; Ge, K.; Wei, X.-Y.; Kong, L.-M.; Xie, Y.-Y.; Gu, J.-P.; Zhang, J.-C.; Zhou, T. Antioxidant and antimicrobial evaluation of carboxymethylated and hydroxamated degraded polysaccharides from Sargassum fusiforme. Int. J. Biol. Macromol. 2018, 118, 1550–1557. [Google Scholar] [CrossRef]

- Chung, Y.-C.; Wang, H.-L.; Chen, Y.-M.; Li, S.-L. Effect of abiotic factors on the antibacterial activity of chitosan against waterborne pathogens. Bioresour. Technol. 2003, 88, 179–184. [Google Scholar] [CrossRef] [PubMed]

- Ham-Pichavant, F.; Sèbe, G.; Pardon, P.; Coma, V. Fat resistance properties of chitosan-based paper packaging for food applications. Carbohydr. Polym. 2005, 61, 259–265. [Google Scholar] [CrossRef]

- Jin, K.-Y. Carboxymethylation Modification of Cellulose Nanofibers and Its Application in Paper Coating. Master’s Thesis, Zhejiang University of Science and Technology, Hangzhou, China, 2021. [Google Scholar]

- Jing, X.; Li, X.; Jiang, Y.; Zhao, R.; Ding, Q.; Han, W. Excellent coating of collagen fiber/chitosan-based materials that is water-and oil-resistant and fluorine-free. Carbohydr. Polym. 2021, 266, 118173. [Google Scholar] [CrossRef]

- Sheng, J.; Li, J.; Zhao, L. Fabrication of grease resistant paper with non-fluorinated chemicals for food packaging. Cellulose 2019, 26, 6291–6302. [Google Scholar] [CrossRef]

- Kopacic, S.; Walzl, A.; Zankel, A.; Leitner, E.; Bauer, W. Alginate and chitosan as a functional barrier for paper-based packaging materials. Coatings 2018, 8, 235. [Google Scholar] [CrossRef]

- Shankar, S.; Rhim, J.-W. Antimicrobial wrapping paper coated with a ternary blend of carbohydrates (alginate, carboxymethyl cellulose, carrageenan) and grapefruit seed extract. Carbohydr. Polym. 2018, 196, 92–101. [Google Scholar] [CrossRef]

- He, J.Z.; Ru, Q.M.; Dong, D.D.; Sun, P.L. Chemical Characteristics and Antioxidant Properties of Crude Water Soluble Polysaccharides from Four Common Edible Mushrooms. Molecules 2012, 17, 4373–4387. [Google Scholar] [CrossRef] [PubMed]

- Abdul Khalil, H.; Chong, E.; Owolabi, F.; Asniza, M.; Tye, Y.; Rizal, S.; Nurul Fazita, M.; Mohamad Haafiz, M.; Nurmiati, Z.; Paridah, M. Enhancement of basic properties of polysaccharide-based composites with organic and inorganic fillers: A review. J. Appl. Polym. Sci. 2019, 136, 47251. [Google Scholar] [CrossRef]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends Food Sci. Technol. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- Dar, A.A.; Malik, A.H.; Dar, A.H.; Ganayee, M.A.; Rather, A.M. Cellulose-Based Nanomaterials Solving the Food Crisis. In Sustainable Green Nanotechnology; CRC Press: Boca Raton, FL, USA, 2024; pp. 97–109. [Google Scholar]

- Rather, A.M.; Dar, A.H.; Shah, U.H.; Shome, A.; Borbora, A. Cellulose-Based Nanomaterials in Energy Conversion/Storage Devices. In Green Nanomaterials in Energy Conversion and Storage Applications; Apple Academic Press: Palm Bay, FL, USA, 2024; pp. 119–144. [Google Scholar]

- Cazón, P.; Velazquez, G.; Ramírez, J.A.; Vázquez, M. Polysaccharide-based films and coatings for food packaging: A review. Food Hydrocoll. 2017, 68, 136–148. [Google Scholar] [CrossRef]

- Kamierczak, M.; Olejnik, T.P.; Kmiotek, M. Natural Paper-layered Composites with Air Barrier Properties Achieved by Coating with Bacterial Cellulose. Bioresources 2020, 15, 9569–9574. [Google Scholar] [CrossRef]

- Yun, T.; Wang, Y.; Lu, J.; Cheng, Y.; Lyu, Y.; Wang, H. Facile Fabrication of Cellulosic Paper-based Composites with Temperature-controlled Hydrophobicity and Excellent Mechanical Strength. Pap. Biomass 2020, 5, 20. [Google Scholar]

- Takeshita, S.; Zhao, S.; Malfait, W.J. Transparent, Aldehyde-Free Chitosan Aerogel. Carbohydr. Polym. 2021, 251, 117089. [Google Scholar] [CrossRef]

- Oliveira, G.; Goncalves, I.; Nunes, C.; Ferreira, P.; Coimbra, M.A.; Martin, C.; Bras, J. Feasibility of chitosan crosslinked with genipin as biocoating for cellulose-based materials. Carbohydr. Polym. Sci. Technol. Asp. Ind. Important Polysacch. 2020, 242, 116429. [Google Scholar] [CrossRef]

- Laufer, G.; Kirkland, C.; Cain, A.A.; Grunlan, J.C. Clay−Chitosan Nanobrick Walls: Completely Renewable Gas Barrier and Flame-Retardant Nanocoatings. ACS Appl. Mater. Interfaces 2012, 4, 1643–1649. [Google Scholar] [CrossRef]

- Li, G.-H.; Mo, Q.-Y.; Hu, W.; Hou, G.-Y.; Xie, H.; Zhang, D.-J.; Cui, J.-Y.; Fang, Z.-Q. Study on Preparation and Properties of Chitosan/Cellulose Fiber Composite Paper. China Pulp Pap. 2020, 39, 1–9. [Google Scholar]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, C.; Coelhoso, I.M.; Fernando, A.L. Chitosan Composites in Packaging Industry—Current Trends and Future Challenges. Polymers 2020, 12, 417. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.F.; Guan, Y.L.; Yang, D.Z.; Li, Z.; Yao, K.D. Antibacterial action of chitosan and carboxymethylated chitosan. J. Appl. Polym. Sci. 2001, 79, 1324–1335. [Google Scholar]

- Knorr, D. Functional Properties of Chitin and Chitosan. J. Food Sci. 2010, 47, 593–595. [Google Scholar] [CrossRef]

- Nikmawahda, H.T.; Sugita, P.; Arifin, B. Synthesis and characterization of N-alkylchitosan as well as its potency as a paper coating material. Adv. Appl. Sci. Res. 2015, 6, 141–149. [Google Scholar]

- Zhao, J.; Wang, Y.; Li, J.; Lei, H.; Zhen, X.; Gou, D.; Liu, T. Preparation of chitosan/Enoki mushroom foot polysaccharide composite cling film and its application in blueberry preservation. Int. J. Biol. Macromol. 2023, 246, 125567. [Google Scholar] [CrossRef]

- Abdel-Naeem, H.H.; Sallam, K.I.; Malak, N.M. Improvement of the microbial quality, antioxidant activity, phenolic and flavonoid contents, and shelf life of smoked herring (Clupea harengus) during frozen storage by using chitosan edible coating. Food Control. 2021, 130, 108317. [Google Scholar] [CrossRef]

- Lin, M.; Sun, H.; Chen, C.J. Study on the performance and application of coatings based on chitosan/gelatin/microbeads composite aerogel. Packag. Technol. Sci. 2024, 37, 85–95. [Google Scholar] [CrossRef]

- Kjellgren, H.; Gällstedt, M.; Engström, G.; Järnström, L. Barrier and surface properties of chitosan-coated greaseproof paper. Carbohydr. Polym. 2006, 65, 453–460. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, L.; He, B. Chitosan/Montmorillonite Coatings for the Fabrication of Food-Safe Greaseproof Paper. Polymers 2021, 13, 1607. [Google Scholar] [CrossRef]

- Thakur, M.; Majid, I.; Hussain, S.; Nanda, V. Poly(ε-caprolactone): A potential polymer for biodegradable food packaging applications. Packag. Technol. Sci. 2021, 34, 449–461. [Google Scholar] [CrossRef]

- Le Corre, D.B.; Bras, J.; Dufresne, A. Starch nanoparticles: A review. Biomacromolecules 2010, 11, 1139. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Kim, Y.R. Clean label starch: Production, physicochemical characteristics, and industrial applications. Food Sci. Biotechnol. 2021, 30, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Shah, U.; Naqash, F.; Gani, A.; Masoodi, F. Art and science behind modified starch edible films and coatings: A review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 568–580. [Google Scholar] [CrossRef] [PubMed]

- Ana, F.; Vítor, A.; Isabel, C. Polysaccharide-Based Membranes in Food Packaging Applications. Membranes 2016, 6, 22. [Google Scholar] [CrossRef]

- Yang, S.-X.; Gao, F.-H.; Zhang, X.-M.; Li, X.; Liang, Y.-X.; Zhang, H.-H.; Xiong, J.-Y.; Zhang, L. The study of complex modified starch is advanced. Agric. Prod. Process. 2019, 513, 69–71+76. [Google Scholar]

- Ni, S.; Zhang, H.; Dai, H.; Xiao, H. Starch-Based Flexible Coating for Food Packaging Paper with Exceptional Hydrophobicity and Antimicrobial Activity. Polymers 2018, 10, 1260. [Google Scholar] [CrossRef]

- Liu, K.; Lin, X.; Chen, L.; Huang, L. Preparation of guanidine-modified starch for antimicrobial paper. J. Bioresour. Bioprod. 2016, 1, 3–6. [Google Scholar]

- Ziaee, Z.; Xiao, H.; Guan, Y.; Fatehi, P. Coating PHGH-Modified Starch on Papers to Induce Antimicrobial Properties. BioResources 2014, 9, 3632–3641. [Google Scholar] [CrossRef]

- Quilez-Molina, A.I.; Merino, D.; Dumon, M. Porous starch embedded with anthocyanins-CMC coating as bifunctional packaging with seafood freshness monitoring properties. Food Hydrocoll. 2024, 154, 15. [Google Scholar] [CrossRef]

- Lipatova, I.M.; Yusova, A.A.; Makarova, L.I. Fabrication and characterization of starch films containing chitosan nanoparticles using in situ precipitation and mechanoactivation techniques. J. Food Eng. 2021, 304, 110593. [Google Scholar] [CrossRef]

- Ni, S.; Zhang, H.; Godwin, P.M.; Dai, H.; Xiao, H. ZnO nanoparticles enhanced hydrophobicity for starch film and paper. Mater. Lett. 2018, 230, 207–210. [Google Scholar] [CrossRef]

- Senturk Parreidt, T.; Müller, K.; Schmid, M. Alginate-based edible films and coatings for food packaging applications. Foods 2018, 7, 170. [Google Scholar] [CrossRef] [PubMed]

- Draget, K.I.; Taylor, C. Chemical, physical and biological properties of alginates and their biomedical implications. Food Hydrocoll. 2011, 25, 251–256. [Google Scholar] [CrossRef]

- Hossen, M.N.; Rahman, M.M.; Ferdous, T.; Nayeem, J.; Jahan, M.S. Biobased nanocomposite coating of paper for packaging. Nord. Pulp Pap. Res. J. 2024, 39, 655–665. [Google Scholar] [CrossRef]

- Pereira, R.; Tojeira, A.; Vaz, D.C.; Mendes, A.; Bártolo, P. Preparation and characterization of films based on alginate and aloe vera. Int. J. Polym. Anal. Charact. 2011, 16, 449–464. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, T.; Li, Y.; Huang, L.; Tang, Y. Fluorine-free, highly durable waterproof and breathable fibrous membrane with self-clean performance. Nanomaterials 2023, 13, 516. [Google Scholar] [CrossRef]

- Zhong, L.; Ding, Y.; Zhang, B.; Wang, Z.; Li, C.; Fu, X.; Huang, Q. Effect of Octenylsuccinylation of Oxidized Cassava Starch on Grease Resistance and Waterproofing of Food Wrapping Paper. Starch-Stärke 2019, 71, 1800284. [Google Scholar] [CrossRef]

- Ovaska, S.-S.; Geydt, P.; Österberg, M.; Johansson, L.-S.; Backfolk, K. Heat-Induced changes in oil and grease resistant hydroxypropylated-starch-based barrier coatings. Nord. Pulp Pap. Res. J. 2015, 30, 488–496. [Google Scholar]

- Li, C.; Li, X.; Wang, L.; Xia, Z.A.; Yang, J.; Wang, N.; Li, Y.; Zhang, H. Preparation of high-barrier performance paper-based materials from biomass-based silicone-modified acrylic polymer emulsion. Polym. Eng. Sci. 2024, 64, 3348–3362. [Google Scholar] [CrossRef]

- Jiang, X.; Chen, G.; Fang, Z.Q. The Application of Starch—Sodium Alginate Composite Coating on Transparent Paper for Food Packaging. Adv. Mater. Res. 2014, 893, 472–477. [Google Scholar] [CrossRef]

- Yun, T.; Tao, Y.; Li, Q.; Cheng, Y.; Lu, J.; Lv, Y.; Du, J.; Wang, H. Superhydrophobic modification of cellulosic paper-based materials: Fabrication, properties, and versatile applications. Carbohydr. Polym. 2023, 305, 120570. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Wang, X.; Zhang, Y.; Meng, Y.; Hua, F.; Xia, X. Cellulose nanofibers/polyvinyl alcohol blends as an efficient coating to improve the hydrophobic and oleophobic properties of paper. Sci. Rep. 2022, 12, 16148. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Guo, J.; Gao, Y.; Li, X.; Ni, M.; Shen, X.; Chu, Z.; Yang, Z.; Hu, Y. Facile preparation of Pickering emulsion-based coatings for hydrophobic, oil-resistant, biodegradable green paper-based packaging. Food Hydrocoll. 2024, 149, 109624. [Google Scholar] [CrossRef]

- Yang, T.; Hu, Y.; Wang, C.; Binks, B.P. Fabrication of Hierarchical Macroporous Biocompatible Scaffolds by Combining Pickering High Internal Phase Emulsion Templates with Three-Dimensional Printing. ACS Appl. Mater. Interfaces 2017, 9, 22950–22958. [Google Scholar] [CrossRef]

- Yong, H.; Li, Z.; Huang, X.; Wang, K.; Zhou, Y.-N.; Li, Q.; Shi, J.; Liu, M.; Zhou, D. Superhydrophobic Materials: Versatility and Translational Applications. Adv. Mater. Interfaces 2022, 9, 2200435. [Google Scholar] [CrossRef]

- Balan, T.; Guezennec, C.; Nicu, R.; Ciolacu, F.; Bobu, E. Improving barrier and strength properties of paper by multi-layer coating with bio-based additives. Cellul. Chem. Technol. 2015, 49, 607–615. [Google Scholar]

- Bordenave, N.; Grelier, S.; Coma, V. Hydrophobization and Antimicrobial Activity of Chitosan and Paper-Based Packaging Material. Biomacromolecules 2010, 11, 88–96. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Kan, L.; Shen, F.; Ling, H.; Wang, X. All-biomass-based eco-friendly waterproof coating for paper-based green packaging. Green Chem. 2022, 24, 7039–7048. [Google Scholar] [CrossRef]

- Kansal, D.; Rabnawaz, M. Fabrication of oil and water-resistant paper without creating microplastics on disposal. J. Appl. Polym. Sci. 2021, 138, 49692. [Google Scholar] [CrossRef]

- Giridhar, J.; Kishore; Rao, R. Moisture Absorption Characteristics of Natural Fibre Composites. J. Reinf. Plast. Compos. 1986, 5, 141–150. [Google Scholar] [CrossRef]

- Shi, H.; Wu, L.; Luo, Y.; Yu, F.; Li, H. A facile method to prepare cellulose fiber-based food packaging papers with improved mechanical strength, enhanced barrier, and antibacterial properties. Food Biosci. 2022, 48, 101729. [Google Scholar] [CrossRef]

- Jiang, X.; Li, Q.; Li, X.; Meng, Y.; Ling, Z.; Ji, Z.; Chen, F. Preparation and characterization of degradable cellulose− based paper with superhydrophobic, antibacterial, and barrier properties for food packaging. Int. J. Mol. Sci. 2022, 23, 11158. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Mao, L.; Wang, W.; Li, Z.; Qin, C. A facile strategy to fabricate antibacterial hydrophobic, high-barrier, cellulose papersheets for food packaging. Int. J. Biol. Macromol. 2023, 236, 123630. [Google Scholar] [CrossRef] [PubMed]

- Kinnunen-Raudaskoski, K.; Hjelt, T.; Kenttä, E.; Forsström, U. Thin coatings for paper by foam coating. Tappi J. 2014, 13, 9–19. [Google Scholar] [CrossRef]

- Zhang, R.; Su, Y.; Liu, J. Different Kinds of Microfibrillated Cellulose as Coating Layers Providing Fiber-based Barrier Properties. Pap. Biomater. 2021, 6, 33–40. [Google Scholar]

- Chen, C.; Chen, L.; Mao, C.; Jin, L.; Wu, S.; Zheng, Y.; Cui, Z.; Li, Z.; Zhang, Y.; Zhu, S. Natural Extracts for Antibacterial Applications. Small 2023, 20, 2306553. [Google Scholar] [CrossRef]

- Todorova, D.; Yavorov, N.; Lasheva, V.; Damyanova, S.; Kostova, I. Lavender essential oil as antibacterial treatment for packaging paper. Coatings 2022, 13, 32. [Google Scholar] [CrossRef]

- Lu, D.; Ning, Y.; Liu, X.; Ren, S.; Ni, B.; Song, Y.; Li, J.; Li, Z.; Liu, W. Preparation and properties of antibacterial food-preservative paper incorporating ceramic pigments. Packag. Technol. Sci. 2024, 37, 273–282. [Google Scholar] [CrossRef]

- Xia, Y.; Wang, S.; Meng, F.; Xu, Z.; Fang, Q.; Gu, Z.; Zhang, C.; Li, P.; Kong, F. Eco-friendly food packaging based on paper coated with a bio-based antibacterial coating composed of carbamate starch, calcium lignosulfonate, cellulose nanofibrils, and silver nanoparticles. Int. J. Biol. Macromol. 2024, 254, 127659. [Google Scholar] [CrossRef]

- Irimia, A.; Popescu, C.M. Bioactive Paper Packaging for Extended Food Shelf Life. Coatings 2023, 13, 1658. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, H.; Sha, D.Y.; Yuan, T. One-step fabrication of eco-friendly multi-functional amphiphobic coatings for cellulose-based food packaging. Int. J. Biol. Macromol. Struct. Funct. Interact. 2023, 253 Pt 8, 127578. [Google Scholar] [CrossRef] [PubMed]

- Peng, H.; Long, Z. Preparation and application of oil repellent for Chitosan paper. Packag. Eng. 2013, 34, 6. [Google Scholar]

- Long, Z.; Peng, H. A Preparation Method of Anti-Fat Food Wrapping Paper. CN Patent 102242533A, 16 November 2011. [Google Scholar]

- Jiang, X. Application of Carboxymethyl Chitosan in Paper Barrier Coating. Master’s Thesis, South China University of Technology, Guangzhou, China, 2014. [Google Scholar]

- Zhu, R.-F.; Long, Z.; Qin, C.-R.; Lü, W.-Z.; Zheng, H.; Wang, Z.-Y. Preparation and properties of polysaccharide, plant wax and nano-silica waterproof and oil-proof wrapping paper. Chin. J. Compos. 2023, 40, 2107–2118. [Google Scholar]

- Long, Z.; Wu, M.; Peng, H.; Dai, L.; Zhang, D.; Wang, J. Preparation and oil-resistant mechanism of chitosan/cationic starch oil-proof paper. BioResources 2015, 10, 7907–7920. [Google Scholar] [CrossRef]

- Zhang, B.-J. Preparation of Starch Complex and Its Application in Paper Barrier Coating. Master’s Thesis, South China University of Technology, Guangzhou, China, 2016. [Google Scholar]

- Wu, W.; Liu, Z.-H. Effect of starch on water and oil resistance of greaseproof paper. Tianjin Pap. Mak. 2017, 39, 17–20. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Yuan, Q.-Y.; Lou, C.-W.; Lin, J.-H.; Li, T.-T. Recent Research Progress of Polysaccharide Polymer Coatings for Improving Properties of Paper-Based Packaging Materials. Coatings 2025, 15, 326. https://doi.org/10.3390/coatings15030326

Yang L, Yuan Q-Y, Lou C-W, Lin J-H, Li T-T. Recent Research Progress of Polysaccharide Polymer Coatings for Improving Properties of Paper-Based Packaging Materials. Coatings. 2025; 15(3):326. https://doi.org/10.3390/coatings15030326

Chicago/Turabian StyleYang, Lan, Qian-Yu Yuan, Ching-Wen Lou, Jia-Horng Lin, and Ting-Ting Li. 2025. "Recent Research Progress of Polysaccharide Polymer Coatings for Improving Properties of Paper-Based Packaging Materials" Coatings 15, no. 3: 326. https://doi.org/10.3390/coatings15030326

APA StyleYang, L., Yuan, Q.-Y., Lou, C.-W., Lin, J.-H., & Li, T.-T. (2025). Recent Research Progress of Polysaccharide Polymer Coatings for Improving Properties of Paper-Based Packaging Materials. Coatings, 15(3), 326. https://doi.org/10.3390/coatings15030326