Microstructure and Antioxidative Performance of Y2O3-CeO2 Co-Modified Molybdenum Silicide Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Characterization of Microstructure

2.3. Oxidation Test

3. Results and Discussion

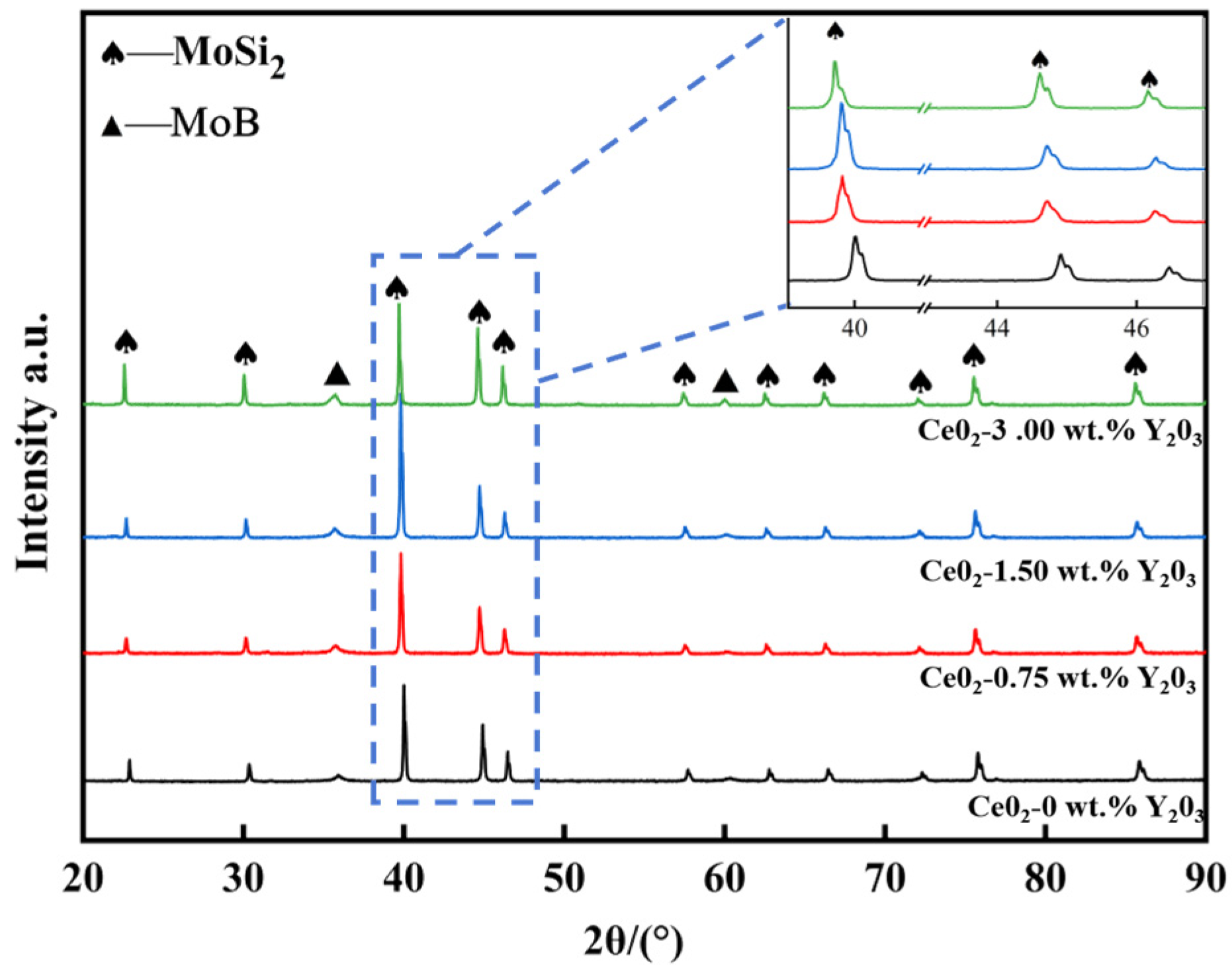

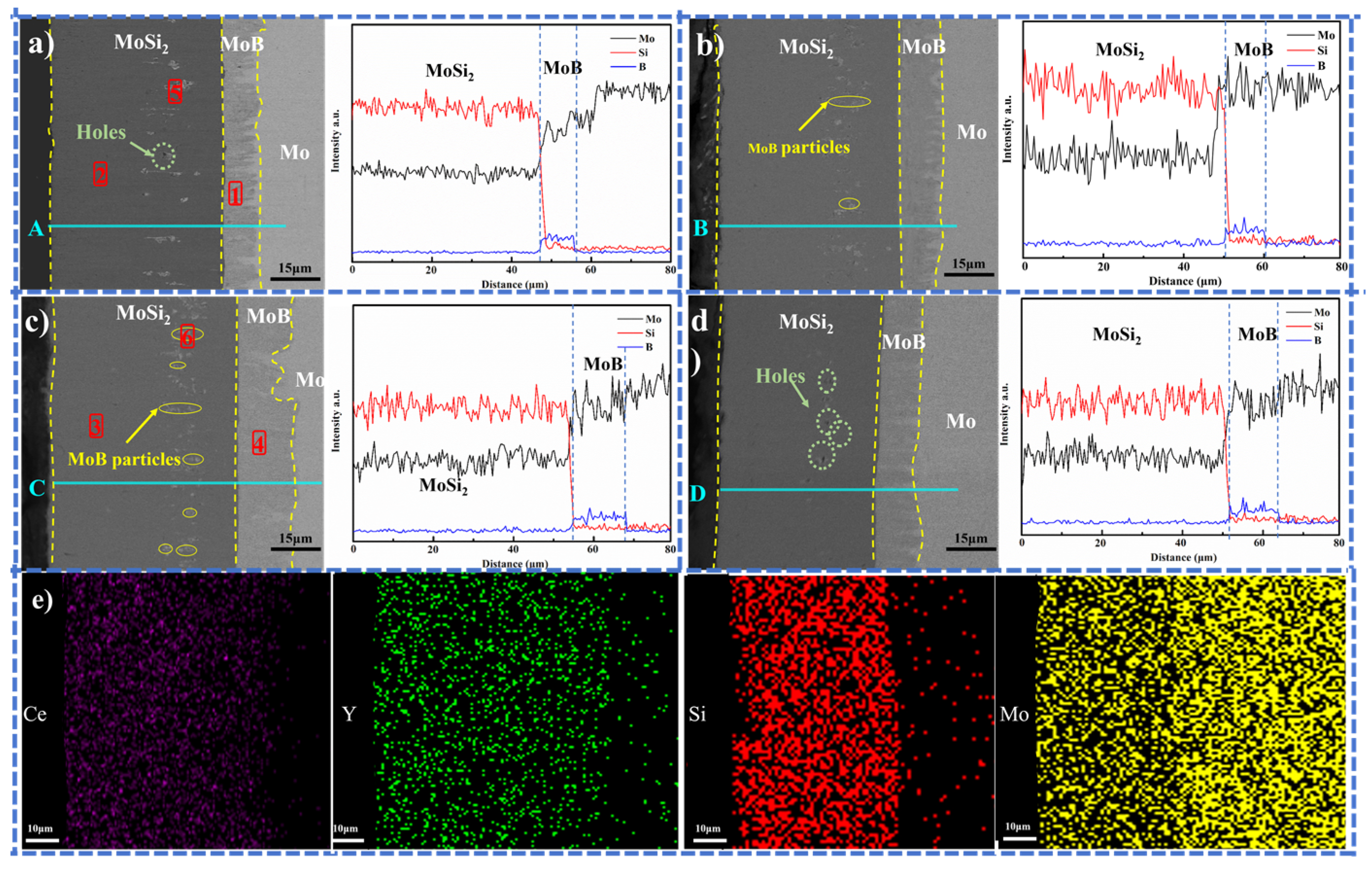

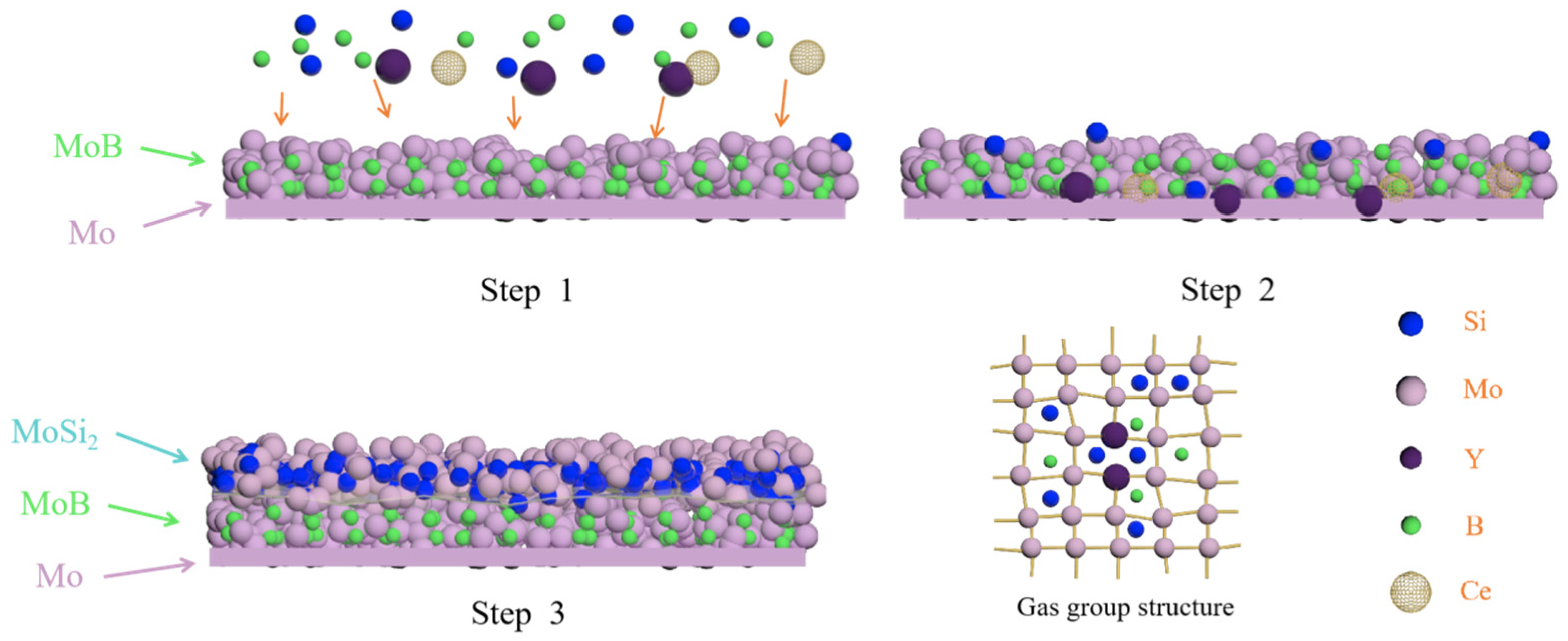

3.1. Microstructure of the Y2O3-CeO2 Co-Modified Silicide Coating

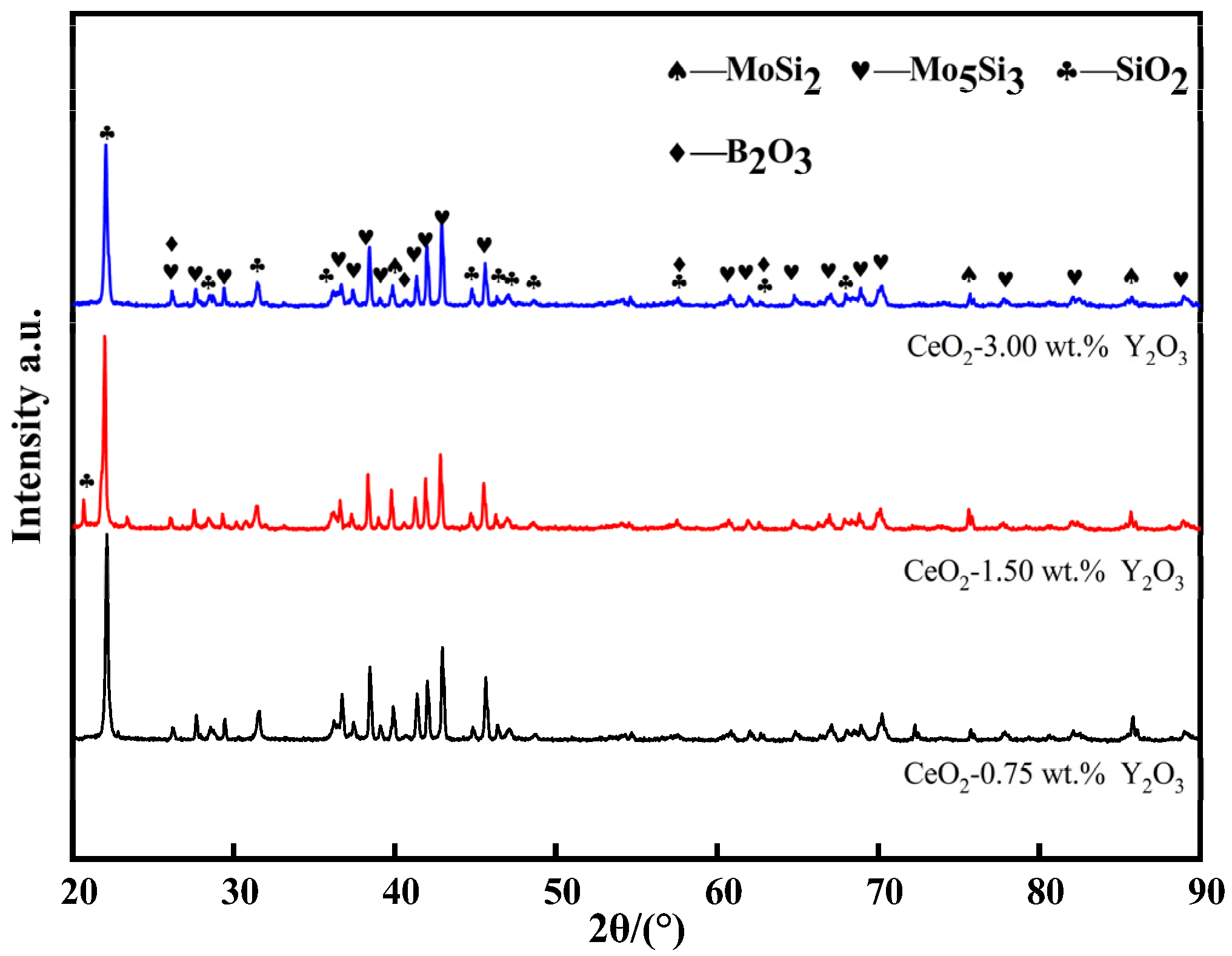

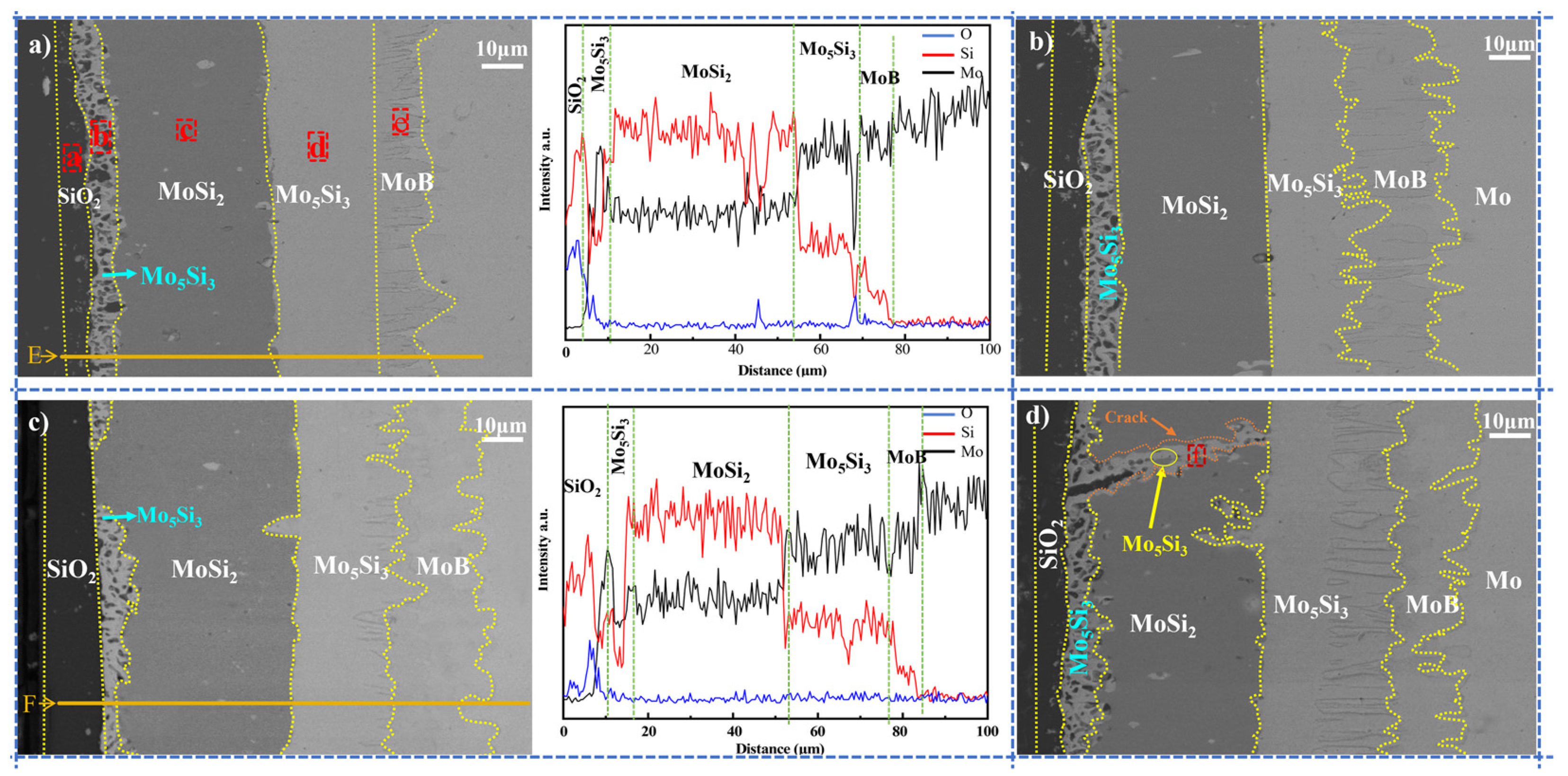

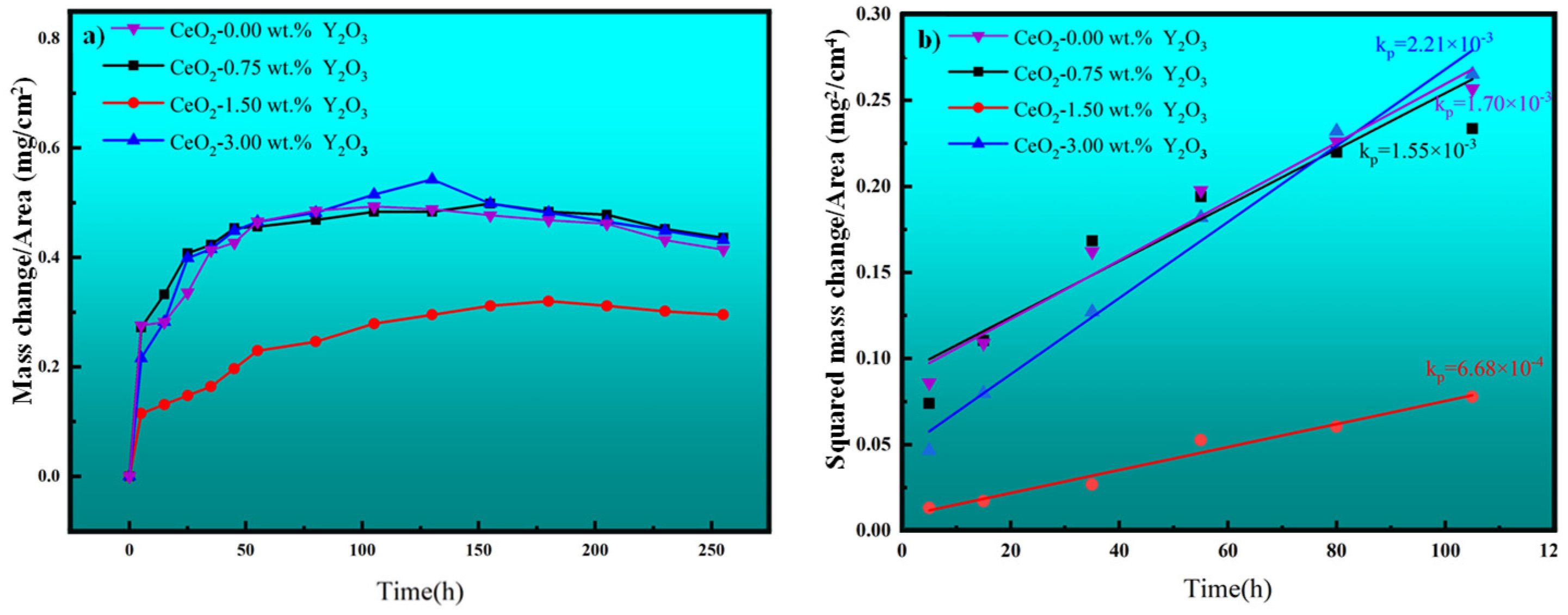

3.2. High-Temperature Oxidation of the Y2O3-CeO2 Co-Modified Coatings

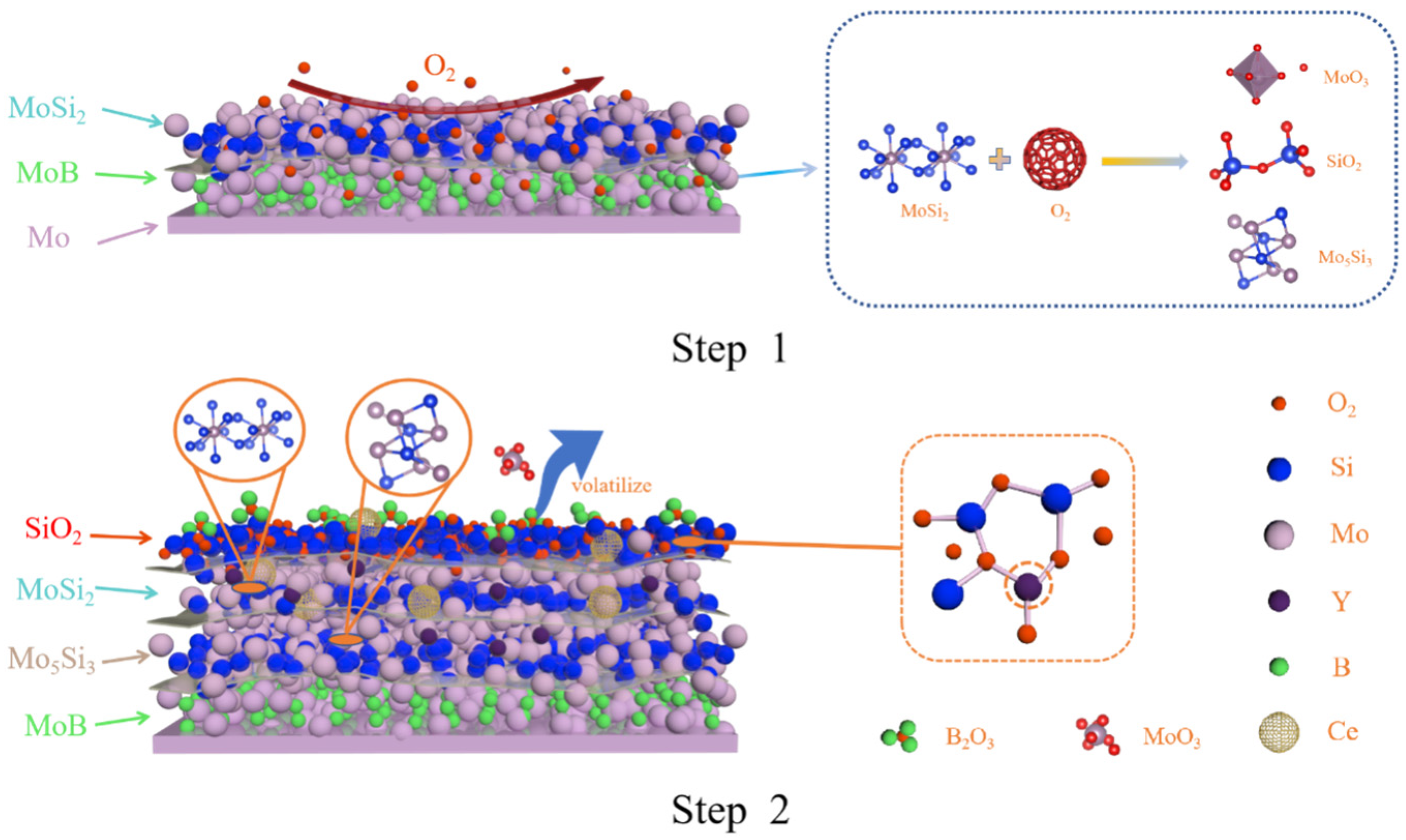

3.3. Modification Mechanism of Ce and Y in the Coatings

4. Conclusions

- (1)

- CeO2 and Y2O3 have a synergistic modification effect, which can promote the diffusion of Si and B atoms to the substrate, refine and promote MoSi2 crystal growth, and make the coating more compact. The thickness of the coating is the largest as the additional amount of CeO2 and Y2O3 are 1 wt.% and 1.5 wt.%, respectively. The coating is composed of MoSi2 and MoB layers, which are both distributed parallel to the substrate, and the thickness is 58.691 μm and 15.834 μm, respectively.

- (2)

- After oxidation, the coating structure from the inside out is the SiO2 layer, Mo5Si3 layer, MoSi2 layer, Mo5Si3, and MoB layer. The thickness of the SiO2 layer increases to 13.42 μm with 1.50 wt.% Y2O3 and the thickness of the transition Mo5Si3 layer was 20.08 μm. The co-modified composite coating with 1.50 wt.% Y2O3 exhibits a mass gain of 0.29 mg/cm2 after 105 h of oxidation at 1150 °C, with an oxidation rate constant of 6.68 × 10−4 mg2/(cm4·h).

- (3)

- The doped Y2O3 can provide a large number of Y3+ to occupy the Si-O bond gap and form a Si-O-Y bond, thus improving the compactness of SiO2. CeO2 and Y2O3 segregated at the grain boundary can also produce a pinning effect, hinder the internal diffusion of Si, and promote the external diffusion of Si atoms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, L.; Huang, C.; Zhao, Y.Y.; Liu, H.; Huang, H.Z.; Lin, M.R.; Duan, H.M.; Zhao, S.H.; Mo, J.Y.; Tu, J.; et al. Microstructure and anti-oxidation behavior of laser clad Ni-Si coating on molybdenum surface. Int. J. Refract. Met. Hard Mater. 2024, 120, 8. [Google Scholar] [CrossRef]

- Zhang, F.J.; Liu, C.H.; Chandrasekar, S.; Li, Y.W.; Xu, F.C. Preparation of sodium molybdate from molybdenum concentrate by microwave roasting and alkali leaching. Int. J. Miner. Metall. Mater. 2024, 31, 91–105. [Google Scholar] [CrossRef]

- Zhao, W.G.; Wang, L.; Hu, P.; Man, C.; Long, J.Y.; Han, J.Y.; Luo, J.; Chu, Q.J.; Gao, L.L.; Yang, J.Z. Enhancing the oxidation resistance of TZM alloy by laser-clading MoSi2-TiVAlZrNb composite coating. Surf. Coat. Technol. 2024, 478, 10. [Google Scholar] [CrossRef]

- Gatzen, C.; Smokovych, I.; Scheffler, M.; Krüger, M. Oxidation-Resistant Environmental Barrier Coatings for Mo-Based Alloys: A Review. Adv. Eng. Mater. 2021, 23, 20. [Google Scholar] [CrossRef]

- Fu, T.; Zhang, Y.Y.; Chen, L.Y.; Shen, F.Q.; Zhu, J.J. Micromorphology evolution, growth mechanism, and oxidation behaviour of the silicon-rich MoSi2 coating at 1200 °C in air. J. Mater. Res. Technol.-JMRT 2024, 29, 491–503. [Google Scholar] [CrossRef]

- Cairang, W.; Ma, S.; Gong, X.; Zeng, Y.; Sun, J. Oxidation mechanism of refractory Molybdenum exposed to oxygen-saturated lead-bismuth eutectic at 600 °C. Corros. Sci. 2020, 179, 109132. [Google Scholar] [CrossRef]

- Guan, H.C.; Lv, C.S.; Ding, Q.M.; Wang, G.D.; Xiong, N.; Zhou, Z.J. The Effect of Cr Addition on the Strength and High Temperature Oxidation Resistance of Y2O3 Dispersion Strengthened Mo Composites. Materials 2024, 17, 2550. [Google Scholar] [CrossRef]

- Perepezko, J.H. High temperature environmental resistant Mo-Si-B based coatings. Int. J. Refract. Met. Hard Mater. 2018, 71, 246–254. [Google Scholar] [CrossRef]

- Filipovic, J.; Beck, K.; Kontermann, C.; Galetz, M.; Oechsner, M. Mechanical Characterization Potentials of Aluminide Diffusion Coatings on Molybdenum Substrates. Adv. Eng. Mater. 2024, 26, 2302027. [Google Scholar] [CrossRef]

- Ren, X.R.; Lv, J.S.; Li, W.; Hu, Y.W.; Sun, K.; Ma, C.; Chu, H.A.; Wang, W.G.; Xu, L.H.; Li, Z.Y.; et al. Influence of MoSi2 on oxidation protective ability of TaB2-SiC coating in oxygen-containing environments within a broad temperature range. J. Adv. Ceram. 2020, 9, 703–715. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, J.; Fu, Q. Effect of mullite on the microstructure and oxidation behavior of thermal-sprayed MoSi2 coating at 1500 °C. Ceram. Int. 2020, 46, 10058–10066. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, S.P.; Ye, F.; Ren, X.R.; Feng, P.Z. Recycling of MoSi2-based industrial solid wastes for the fabrication and high-temperature oxidation behavior of MoSi2-ZrSi2-SiC composite coating. Compos. Part B-Eng. 2024, 274, 18. [Google Scholar] [CrossRef]

- Afzal, W.; Yun, F.F.; Li, Z.; Yue, Z.J.; Zhao, W.Y.; Sang, L.N.; Yang, G.S.; He, Y.H.; Peleckis, G.; Fuhrer, M.; et al. Magneto-transport and electronic structures in MoSi2 bulks and thin films with different orientations. J. Alloys Compd. 2021, 858, 157670. [Google Scholar] [CrossRef]

- Wang, L.; Fu, Q.G.; Zhao, F.L. Improving oxidation resistance of MoSi2 coating by reinforced with Al2O3 whiskers. Intermetallics 2018, 94, 106–113. [Google Scholar] [CrossRef]

- Dai, L.; Yu, Y.; Zhou, H.; Yan, X.; Zhu, J.; Li, Y.; Wang, L. In-situ synthesis of MoSi2 coating on molybdenum substrate by electro-deoxidation of a SiO2 layer in molten salt. Ceram. Int. 2015, 41, 13663–13670. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, Y.H.; Wu, Y.S.; Yang, Z.K.; Wang, N.; Fu, T.R. Temperature dependence mechanism of high-temperature oxidation of transition metal silicide MoSi2. J. Phys.-Condens. Matter 2024, 36, 345002. [Google Scholar] [CrossRef]

- Pang, J.; Wang, W.; Zhou, C.G. Microstructure evolution and oxidation behavior of B modified MoSi2 coating on Nb-Si based alloys. Corros. Sci. 2016, 105, 1–7. [Google Scholar] [CrossRef]

- Yoon, J.-K.; Kim, G.-H.; Byun, J.-Y.; Lee, J.-K.; Yoon, H.-S.; Hong, K.-T. Effect of Cl/H input ratio on the growth rate of MoSi2 coatings formed by chemical vapor deposition of Si on Mo substrates from SiCl4-H2 precursor gases. Surf. Coat. Technol. 2003, 172, 176–183. [Google Scholar] [CrossRef]

- Cai, Z.; Liu, S.; Xiao, L.; Fang, Z.; Zhang, B. Oxidation behavior and microstructural evolution of a slurry sintered Si-Mo coating on Mo alloy at 1650 °C. Surf. Coat. Technol. 2017, 324, 182–189. [Google Scholar] [CrossRef]

- Kermani, M.; Razavi, M.; Rahimipour, M.R.; Zakeri, M. The effect of temperature on the in situ synthesis-sintering and mechanical properties of MoSi2 prepared by spark plasma sintering. J. Alloys Compd. 2014, 585, 229–233. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, H.Y.; Yan, J.H.; Wang, D.Z. Preparation and Characterization of MoB Coating on Mo Substrate. Metals 2018, 8, 93. [Google Scholar] [CrossRef]

- Zhai, R.; Song, P.; Huang, T.; Li, C.; Hua, C.; Huang, W.; Li, Q.; Zheng, B.; Lu, J. Microstructure and oxidation behaviour of MoSi2 coating combined MoB diffusion barrier layer on Mo substrate at 1300 °C. Ceram. Int. 2021, 47, 10137–10146. [Google Scholar] [CrossRef]

- Parthasarathy, T.; Mendiratta, M.; Dimiduk, D. Oxidation mechanisms in Mo-reinforced Mo5SiB2 (T2)–Mo3Si alloys. Acta Mater. 2002, 50, 1857–1868. [Google Scholar] [CrossRef]

- Knittel, S.; Mathieu, S.; Vilasi, M. The oxidation behaviour of uniaxial hot pressed MoSi2 in air from 400 to 1400 °C. Intermetallics 2011, 19, 1207–1215. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, J.; Wang, D. High temperature oxidation and microstructure of MoSi2/MoB composite coating for Mo substrate. Int. J. Refract. Met. Hard Mater. 2017, 68, 60–64. [Google Scholar] [CrossRef]

- Schliephake, D.; Gombola, C.; Kauffmann, A.; Heilmaier, M.; Perepezko, J.H. Enhanced Oxidation Resistance of Mo-Si-B-Ti Alloys by Pack Cementation. Oxid. Met. 2017, 88, 267–277. [Google Scholar] [CrossRef]

- Majumdar, S. Formation of MoSi2 and Al doped MoSi2 coatings on molybdenum base TZM (Mo–0.5Ti–0.1Zr–0.02C) alloy. Surf. Coat. Technol. 2012, 206, 3393–3398. [Google Scholar] [CrossRef]

- Tian, X.D.; Guo, X.P.; Sun, Z.P.; Yin, Z.Q.; Wang, L.J. Formation of B-modified MoSi2 coating on pure Mo prepared through HAPC process. Int. J. Refract. Met. Hard Mater. 2014, 45, 8–14. [Google Scholar] [CrossRef]

- Xiao, L.R.; Zhou, X.J.; Wang, Y.F.; Pu, R.; Zhao, G.; Shen, Z.Q.; Huang, Y.L.; Liu, S.N.; Cai, Z.Y.; Zhao, X.J. Formation and oxidation behavior of Ce-modified MoSi2-NbSi2 coating on niobium alloy. Corros. Sci. 2020, 173, 108751. [Google Scholar] [CrossRef]

- Chen, F.; Xu, J.; Yan, J.; Tang, S. Effects of Y2O3 on SiC/MoSi2 composite by mechanical-assistant combustion synthesis. Int. J. Refract. Met. Hard Mater. 2013, 36, 143–148. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, X. Microstructure and growth kinetics of Ce and Y jointly modified silicide coatings for Nb–Ti–Si based ultrahigh temperature alloyMicrostructure and growth kinetics of Ce and Y jointly modified silicide coatings for Nb–Ti–Si based ultrahigh temperature alloyretain. Prog. Nat. Sci. Mater. Int. 2013, 23, 190–197. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, G.; Zhang, Y.; Ning, F.; Chao, Y.; Feng, P. Preparation and oxidation behaviour of CeO2-doped Si-B composite coatings. Mater. Rep. 2020, 34, 18035–18038. [Google Scholar] [CrossRef]

- Li, J.; Yu, Z.S.; Wang, H.P. Effects of Y2O3 on Microstructure and Mechanical Properties of Laser Clad Coatings Reinforced by In Situ Synthesized TiB and TiC. Mater. Sci. Forum 2011, 675–677, 589–592. [Google Scholar] [CrossRef]

- Wang, K.L.; Zhang, Q.B.; Sun, M.L.; Wei, X.G. Microstructural characteristics of laser clad coatings with rare earth metal elements. J. Mater. Process. Technol. 2003, 139, 448–452. [Google Scholar] [CrossRef]

- Du, W.; Zhu, Z.; Zhang, X.; Wang, D.; Liu, D.; Qian, X.; Du, J. RE/ZrO2 (RE = Sm, Eu) composite Oxide nano-materials: Synthesis and applications in photocatalysis. Mater. Res. Bull. Int. J. Report. Res. Cryst. Growth Mater. Prep. Charact. 2013, 48, 3735–3742. [Google Scholar] [CrossRef]

- Song, X.; Wang, L.; Liu, Y.; Ma, H.-P. Effects of temperature and rare earth content on oxidation resistance of Ni-based superalloy. Prog. Nat. Sci. Mater. Int. 2011, 21, 227–235. [Google Scholar] [CrossRef]

- Wang, C.C.; Li, K.Z.; He, D.Y.; Shi, X.H. Oxidation kinetics of supersonic atmospheric plasma spraying ytterbium oxide doped molybdenum silicide coating. Ceram. Int. 2020, 46, 6723–6732. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, L. Effect of Ce on microstructure and properties of hot dip aluminized tritium permeation barrier. Acta Metall. Sin. 2011, 47, 1527–1534. [Google Scholar] [CrossRef]

- Tian, X.D.; Guo, X.P.; Yin, Z.Q.; Sun, Z.P.; Wang, L.J. Microstructure and low temperature oxidation of pack Si-B co-deposition coating on pure Mo. Trans. Mater. Heat Treat. 2014, 35, 171–175. [Google Scholar]

- Tian, S.D. Microstructure and low-temperature oxidation behaviour of pure molybdenum surface-embedded Si-B co-infiltration coatings. Trans. Mater. Heat Treat. 2014, 5. [Google Scholar] [CrossRef]

- Wang, C.C.; Li, K.Z.; He, D.Y.; Shi, X.H. Oxidation behavior and mechanism of MoSi2-Y2O3 composite coating fabricated by supersonic atmospheric plasma spraying. Appl. Surf. Sci. 2020, 506, 144776. [Google Scholar] [CrossRef]

- Liu, F.; Li, H.; Gu, S.; Yao, X.; Fu, Q. Effect of Y2O3 on the oxidation properties of ZrSi2/SiC coating prepared by SAPS on the carbon-carbon composites. Ceram. Int. 2018, 44, 15065–15071. [Google Scholar] [CrossRef]

- Qiao, Y.Q.; Kong, J.P.; Li, Q.; Guo, X.P. Comparison of two kinds of Si-B-Y co-deposition coatings on an Nb-Ti-Si based alloy by pack cementation method. Surf. Coat. Technol. 2017, 327, 93–100. [Google Scholar] [CrossRef]

- Choi, H.J.; Lee, J.G.; Kim, Y.W. Oxidation behavior of liquid-phase sintered silicon carbide with aluminum nitride and rare-earth oxides (Re2O3, where Re = Y, Er, Yb). J. Am. Ceram. Soc. 2002, 85, 2281–2286. [Google Scholar] [CrossRef]

- Zacate, M.O.; Minervini, L.; Bradfield, D.J.; Grimes, R.W.; Sickafus, K.E. Defect cluster formation in M2O3-doped cubic ZrO2. Solid State Ion. 2000, 128, 243–254. [Google Scholar] [CrossRef]

- Chen, Z.; Cui, X.; Fang, Y.; Yan, C.; Wang, R.; Jing, Y.; Wang, X.; Jin, G.; Wang, X. A comparative study on the hot corrosion behavior of plasma sprayed Sm/Gd doped La2Zr2O7/YSZ and Sm and Gd co-doped La2Zr2O7/YSZ coatings. Surf. Coat. Technol. 2023, 452, 15. [Google Scholar] [CrossRef]

- Li, F.; Zhou, L.; Liu, J.X.; Liang, Y.C.; Zhang, G.J. High-entropy pyrochlores with low thermal conductivity for thermal barrier coating materials. J. Adv. Ceram. 2019, 8, 576–582. [Google Scholar] [CrossRef]

| Mo | Fe | Ni | O | C | Si | N | Ca | Mg |

|---|---|---|---|---|---|---|---|---|

| Balance | 0.0031 | 0.001 | 0.003 | 0.003 | 0.003 | 0.001 | 0.0005 | 0.0003 |

| Process Steps | Sample | Pack Mixtures (wt.%) | ||||||

|---|---|---|---|---|---|---|---|---|

| B | NaF | Al2O3 | Si | SiO2 | CeO2 | Y2O3 | ||

| First boronizing | Boronizing agent | 4 | 5 | 91 | - | - | - | - |

| Second Si-Ce-Y depositing | Siliconizing agent-1 | 0.5 | 5 | - | 20 | 73.5 | 1 | 0 |

| Siliconizing agent-2 | 0.5 | 5 | - | 20 | 72.75 | 1 | 0.75 | |

| Siliconizing agent-3 | 0.5 | 5 | - | 20 | 72 | 1 | 1.5 | |

| Siliconizing agent-4 | 0.5 | 5 | - | 20 | 70.5 | 1 | 3 | |

| Spot | Composition/at.% | Main Phase | ||

|---|---|---|---|---|

| Mo | Si | B | - | |

| 1 | 54.4 | 0.1 | 45.4 | MoB |

| 2 | 34.5 | 65.2 | - | MoSi2 |

| 3 | 32.3 | 67.6 | - | MoSi2 |

| 4 | 53.6 | 0.2 | 46.2 | MoB |

| 5 | 54.4 | 0.1 | 45.4 | MoB |

| 6 | 54.2 | 0.1 | 45.67 | MoB |

| Spot | Composition/at.% | Main Phase | |||

|---|---|---|---|---|---|

| Mo | Si | O | B | - | |

| a | 1.2 | 32.7 | 60.4 | 0.7 | SiO2 |

| b | 62.0 | 36.7 | - | 0.3 | Mo5Si3 |

| c | 34.5 | 65.3 | - | 0.2 | MoSi2 |

| d | 63.4 | 36.5 | - | 0.1 | Mo5Si3 |

| e | 53.4 | 1.3 | - | 44.3 | MoB |

| f | 60.4 | 38.8 | 0.8 | - | Mo5Si3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, M.; Zhang, G.; Liu, Q.; Huang, M.; Lan, Y.; Feng, P. Microstructure and Antioxidative Performance of Y2O3-CeO2 Co-Modified Molybdenum Silicide Coatings. Coatings 2025, 15, 310. https://doi.org/10.3390/coatings15030310

Zhang Y, Zhang M, Zhang G, Liu Q, Huang M, Lan Y, Feng P. Microstructure and Antioxidative Performance of Y2O3-CeO2 Co-Modified Molybdenum Silicide Coatings. Coatings. 2025; 15(3):310. https://doi.org/10.3390/coatings15030310

Chicago/Turabian StyleZhang, Yong, Minglong Zhang, Gengfei Zhang, Qiaoyun Liu, Meilin Huang, Yongqiang Lan, and Pengfa Feng. 2025. "Microstructure and Antioxidative Performance of Y2O3-CeO2 Co-Modified Molybdenum Silicide Coatings" Coatings 15, no. 3: 310. https://doi.org/10.3390/coatings15030310

APA StyleZhang, Y., Zhang, M., Zhang, G., Liu, Q., Huang, M., Lan, Y., & Feng, P. (2025). Microstructure and Antioxidative Performance of Y2O3-CeO2 Co-Modified Molybdenum Silicide Coatings. Coatings, 15(3), 310. https://doi.org/10.3390/coatings15030310