Wear and Corrosion Behavior of Diamond-like Carbon Coatings in Artificial Saliva

Abstract

1. Introduction

2. Materials and Methods

2.1. Diamond-like Carbon (DLC) Coating Preparation

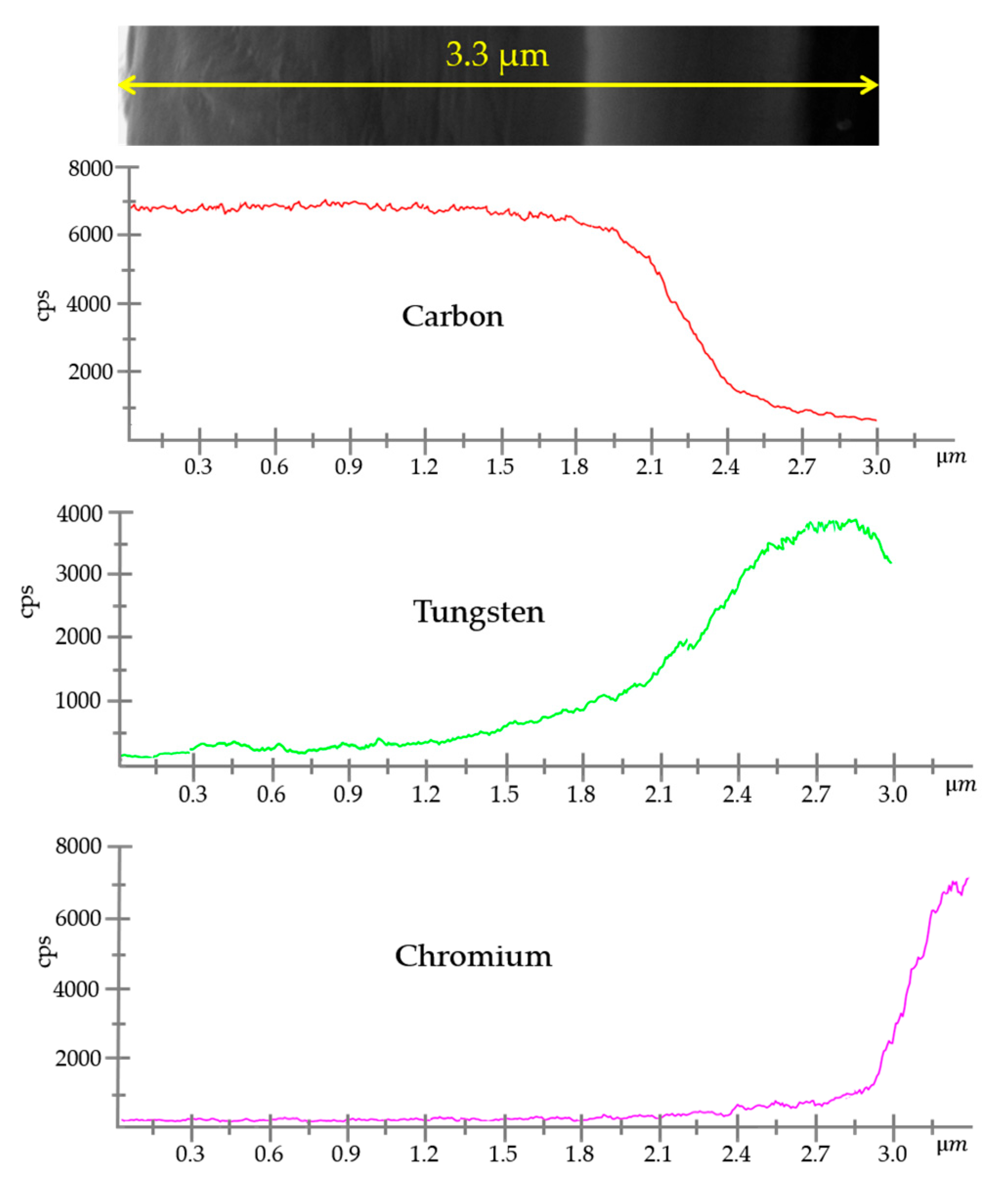

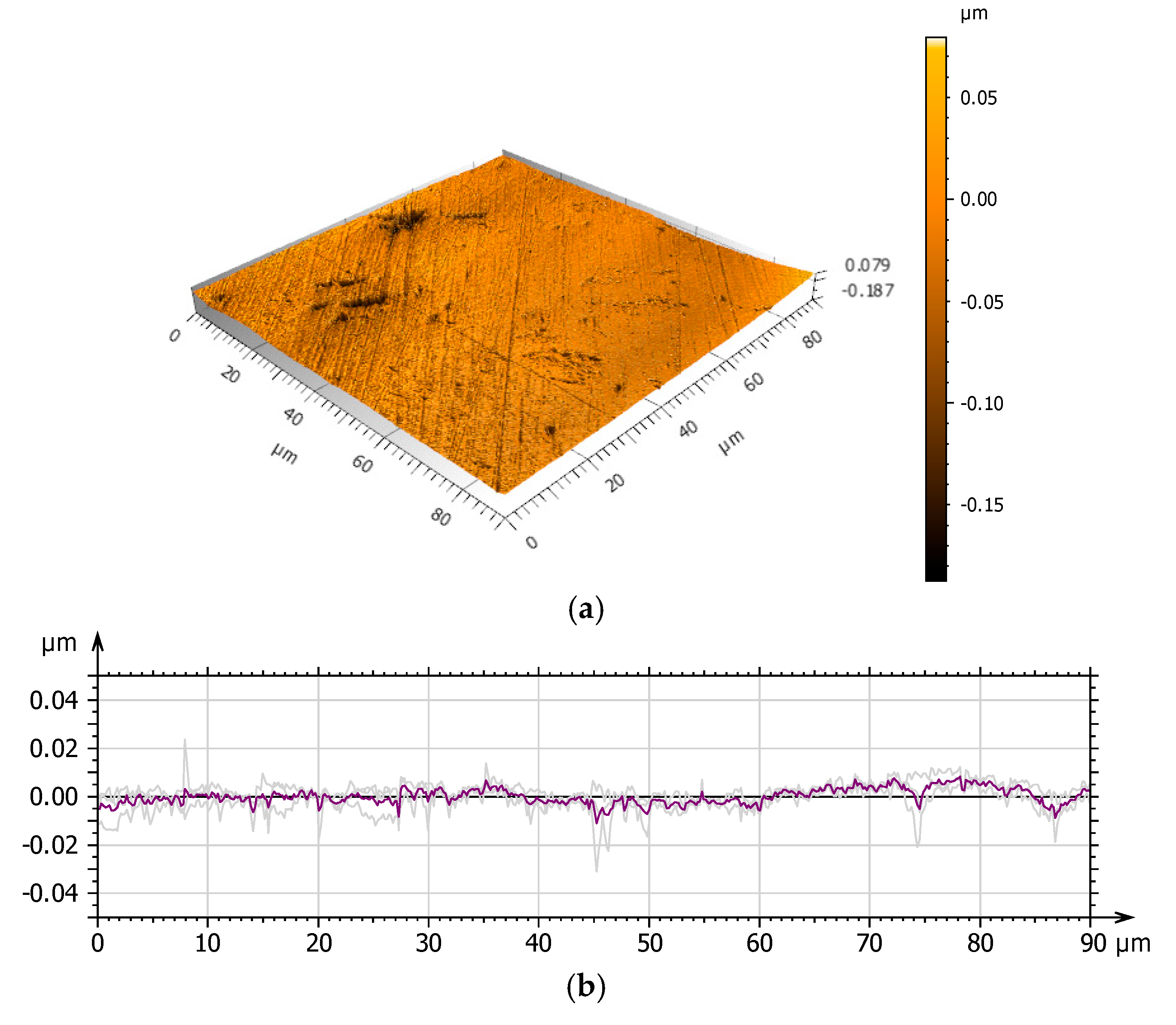

2.2. Microstructure and Surface Texture

2.3. Adhesion and Mechanical Parameters

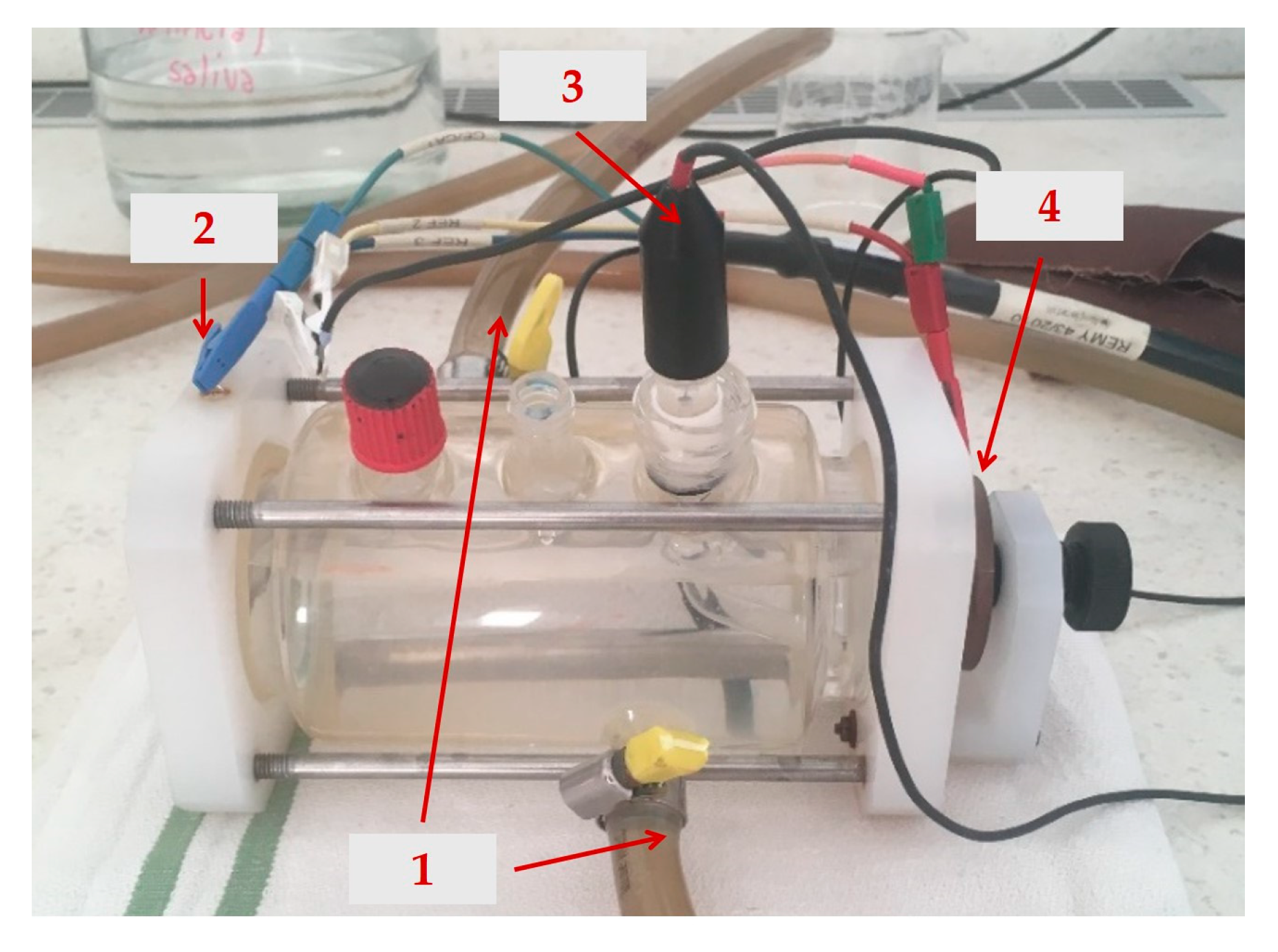

2.4. Corrosion Properties

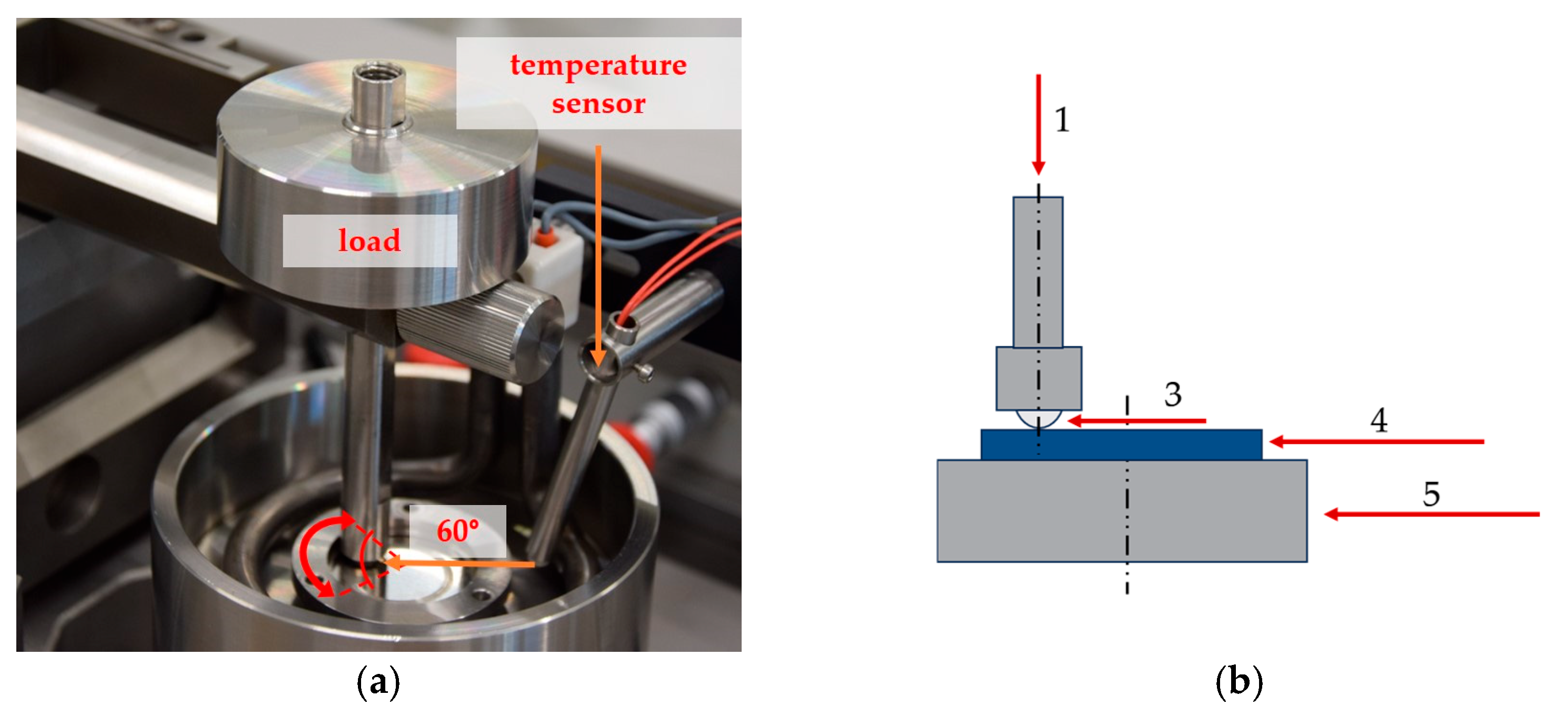

2.5. Tribological Tests and Assessment of Surface Geometric Structure After Tribological Test

3. Results

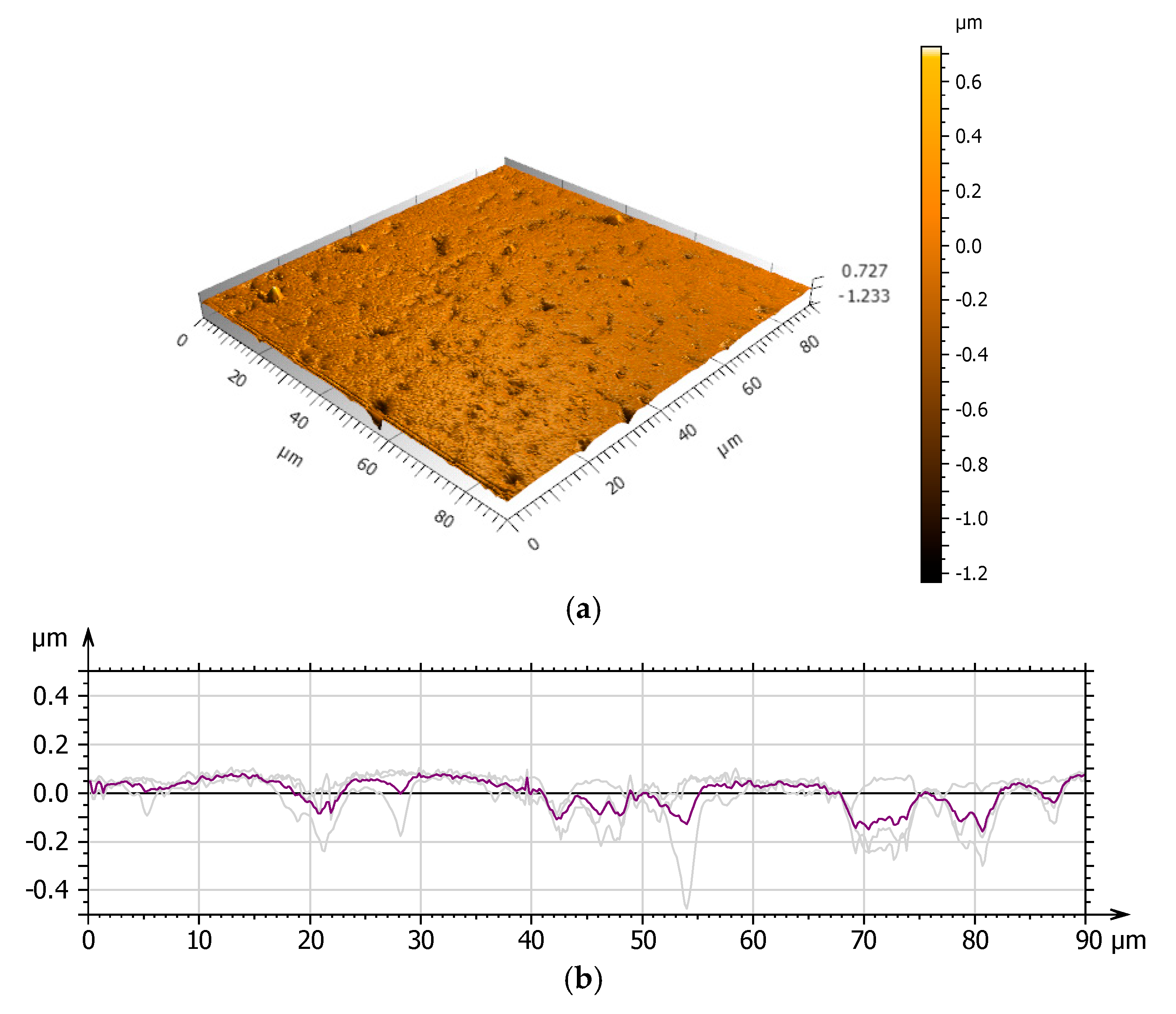

3.1. Scanning Microscopy and Atomic Force Microscopy

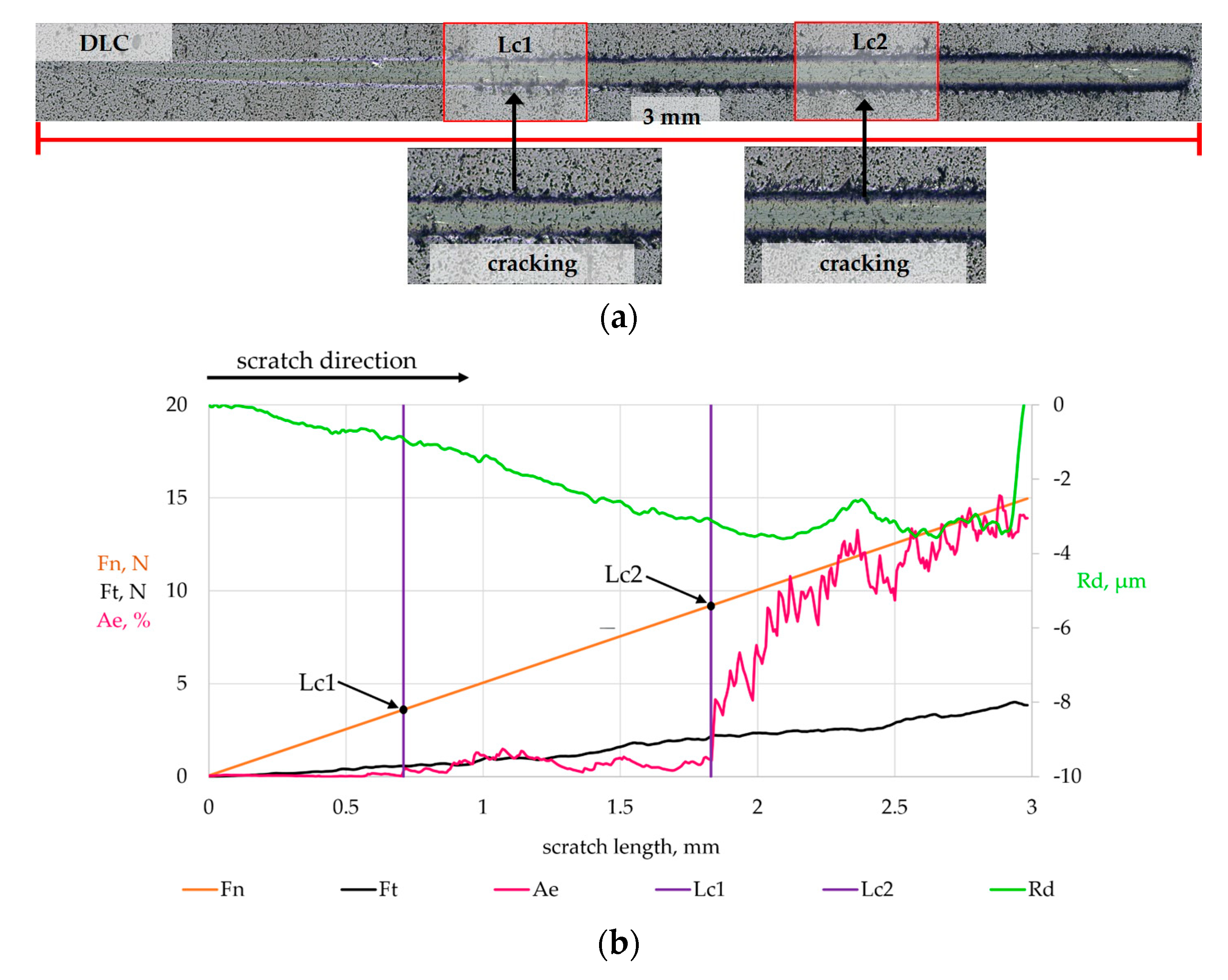

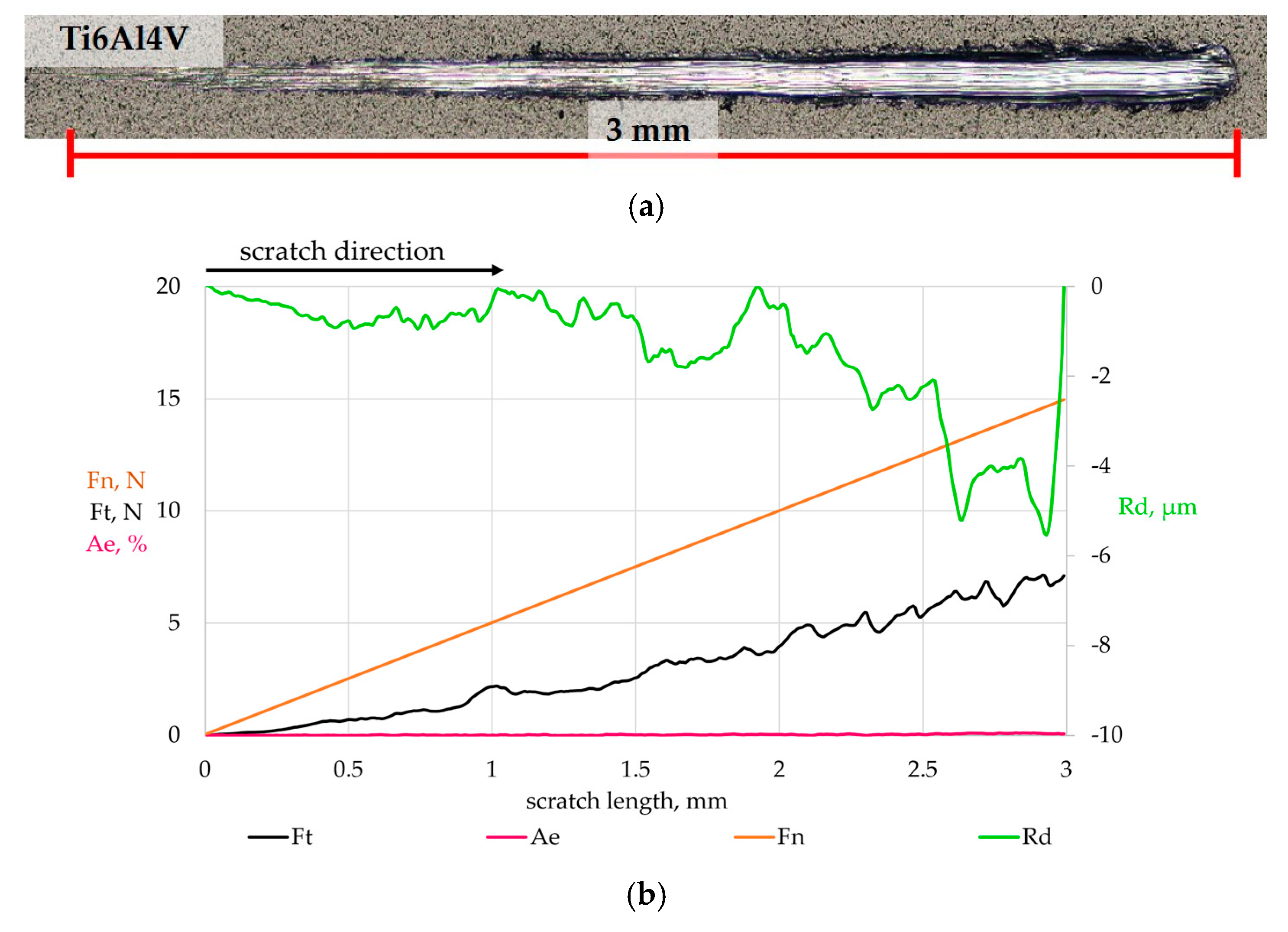

3.2. Adhesion and Hardness

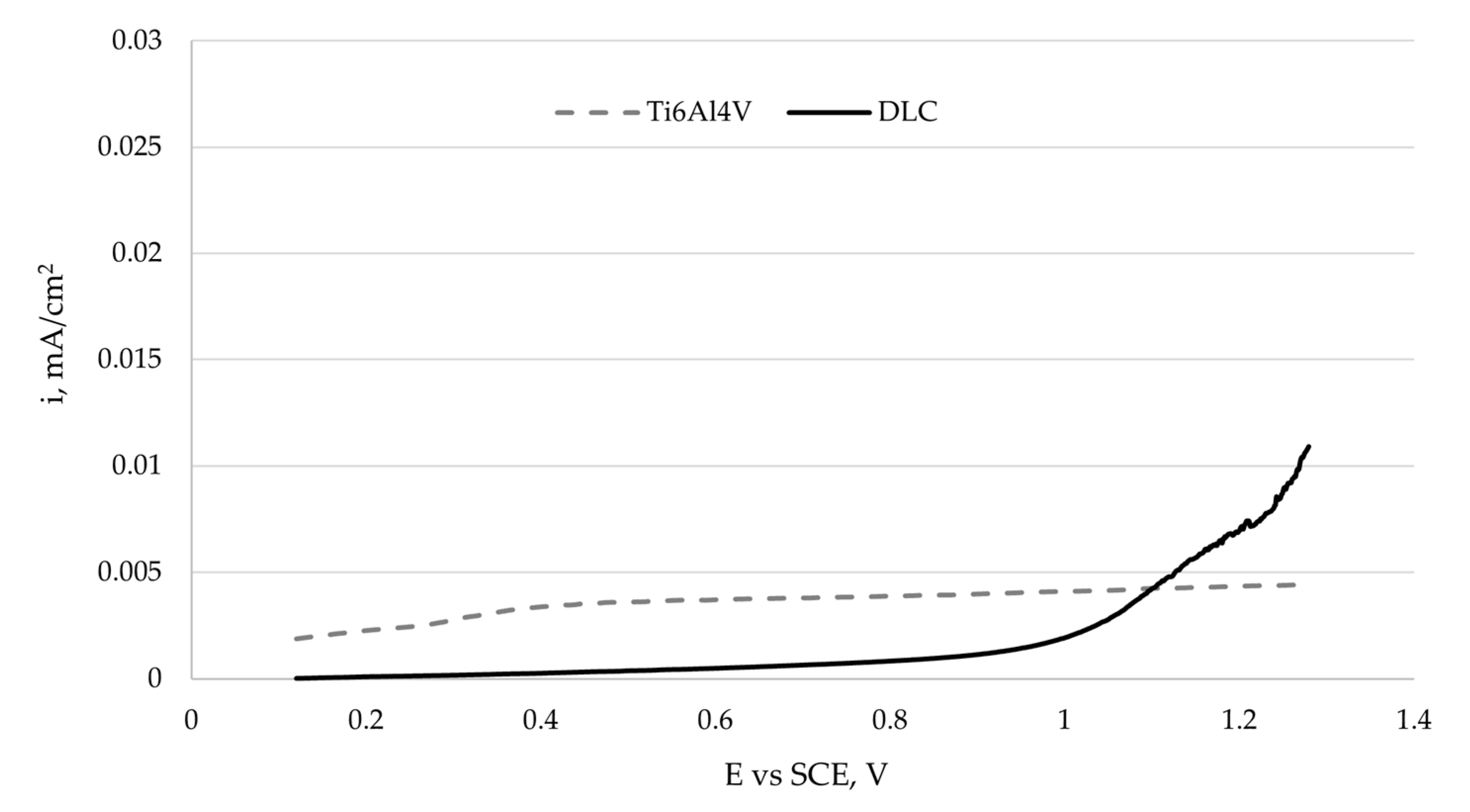

3.3. Corrosion

3.4. Tribological Tests

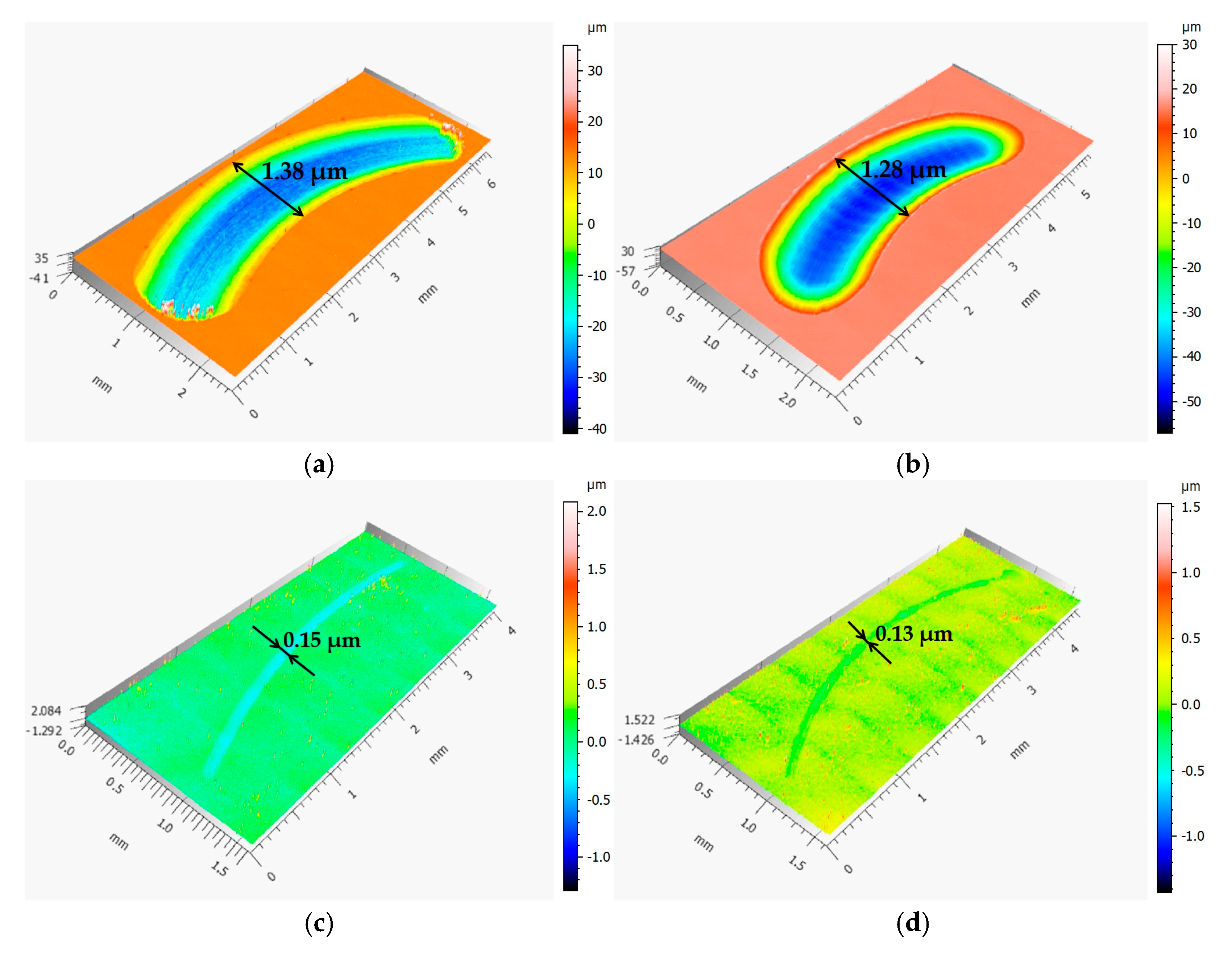

3.5. Assessment of Surface Geometric Structure After Tribological Tests

4. Conclusions

- Applying the chemical vapor deposition (PACVD) technique resulted in coatings with a thickness of approximately 3.2 µm. Microscopic examination indicated that the deposition of the DLC coating resulted in significant changes to the surface morphology of the Ti6Al4V alloy. The DLC-coated surface displayed a characteristic rough texture, characterized by numerous hills and valleys, in contrast to the smoother surface of the uncoated substrate. Analysis of amplitude parameters confirmed the increased roughness of the DLC coating, with values approximately 80% higher than those obtained for the uncoated Ti6Al4V alloy.

- Scratch test results indicated that the titanium alloy exhibited poor scratch resistance, while the DLC coating demonstrated good adhesion to the metallic substrate. The deposition of carbon coatings increased the instrumental hardness and Young’s modulus of the Ti6Al4V titanium alloy by approximately 75% and 11%, respectively.

- A comparison of the polarization curves demonstrated that both the DLC coating and the Ti6Al4V alloy exhibited passive behavior in the artificial saliva environment. However, the values of potentiodynamic parameters indicated superior corrosion resistance of the DLC coating, characterized by higher thermodynamic stability and slower corrosion kinetics compared to the Ti6Al4V alloy.

- The tribological tests and microscopic observations of wear tracks revealed that the DLC coating exhibited lower friction coefficients and volumetric wear than the substrate material. Moreover, the application of artificial saliva as a lubricant intensified this trend. The findings of this study indicate that DLC coatings outperform Ti6Al4V alloy in terms of wear and corrosion resistance when exposed to an artificial saliva solution.

- The application of DLC coatings improved the properties of the titanium alloy Ti6Al4V, particularly in terms of tribological and corrosion resistance in the analyzed artificial saliva environment, making DLC coatings promising candidates for application in the stomatognathic system. The findings of this research suggest that further studies are necessary. Future work could involve tribological testing in distributed contact configurations and with different material combinations, motion types, and lubricants.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geetha, M.; Kamachi, U.; Gogia, A.K.; Asokamani, R.; Baldev, R. Influence of microstructure and alloying elements on corrosion behaviour of Ti13Nb13Zr alloy. Corros. Sci. 2024, 46, 877–892. [Google Scholar] [CrossRef]

- Grupp, T.M.; Meisel, H.-J.; Cotton, J.A.; Schwiesau, J.; Fritz, B.; Blömer, W.; Jansson, V. Alternative bearing materials for intervertebral disc arthroplasty. Biomaterials 2010, 31, 523–531. [Google Scholar] [CrossRef] [PubMed]

- Madej, M.; Piotrowska, K. Characterisation of TiCN Coatings for Biomedical Applications. Coatings 2024, 14, 775. [Google Scholar] [CrossRef]

- Rautray, T.R.; Narayanan, R.; Kim, K.H. Ion implantation of titanium based biomaterials. Prog. Mater. Sci. 2011, 56, 1137–1177. [Google Scholar] [CrossRef]

- Piotrowska, K.; Madej, M.; Ozimina, D. Assessment of the Functional Properties of 316L Steel Alloy Subjected to Ion Implantation Used in Biotribological Systems. Materials 2021, 14, 1–21. [Google Scholar] [CrossRef]

- Aniołek, K.; Barylski, A.; Rak, J. Effect of Temperature on Thermal Oxidation Behavior of Ti-6Al-4V ELI Alloy. Materials 2024, 17, 4129. [Google Scholar] [CrossRef]

- Kowalski, S.; Gonciarz, W.; Belka, R.; Góral, A.; Chmiela, M.; Lechowicz, Ł.; Kaca, W.; Żórawski, W. Plasma-Sprayed Hydroxyapatite Coatings and Their Biological Properties. Coatings 2022, 12, 1317. [Google Scholar] [CrossRef]

- Piotrowska, K.; Madej, M.; Granek, A. Assessment of Mechanical and Tribological Properties of Diamond-Like Carbon Coatings on the Ti13Nb13Zr Alloy. Open Eng. 2020, 10, 536–545. [Google Scholar] [CrossRef]

- Yi, X.W.; Zhang, Z.; Liao, Z.W.; Dong, X.J.; You, J.Y.; Su, G. T-carbon: Experiments, properties, potential applications and derivatives. Nanotoday 2022, 42, 101346. [Google Scholar] [CrossRef]

- Tian, J.; Qi, X.; Chenggao, L.; Xian, G. Friction behaviors and wear mechanisms of multi-filler reinforced epoxy composites under dry and wet conditions: Effects of loads, sliding speeds, temperatures, water lubrication. Tribol. Int. 2023, 179, 108148. [Google Scholar] [CrossRef]

- Roy, R.K.; Lee, K.R. Biomedical applications of diamond-like carbon coatings: A review. J. Biomed. Mater. Res. B Appl. Biomater. 2007, 83, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Wang, Y.; Gong, C.; Liu, B.; Wei, G. Production, structural design, functional control, and broad applications of carbon nanofiber-based nanomaterials: A comprehensive review. Chem. Eng. J. 2020, 402, 125189. [Google Scholar] [CrossRef]

- Xian, G.; Bai, Y.; Qi, X.; Wang, J.; Tian, J.; Xiao, H. Hygrothermal aging on the mechanical property and degradation mechanism of carbon fiber reinforced epoxy composites modified by nylon 6. J. Mater. Res. Technol. 2024, 33, 6297–6306. [Google Scholar] [CrossRef]

- Mostofizadeh, A.; Li, Y.; Song, B.; Huang, Y. Synthesis, properties, and applications of low-dimensional carbon-related nanomaterials. J. Nanomater. 2010, 2011, 1–21. [Google Scholar] [CrossRef]

- Novoselov, K.S. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Shcherbytska, O.V.; Garbuz, V.V.; Klipov, V.D.; Sergeev, V.P.; Kononko, I.V.; Klevtsov, V.M.; Lobunets, T.F.; Uvarova, I.V. Studying the formation of carbon nanostructures in thermal destruction and carbonization of hydrated cellulose fibers. Nanostrukt. Mater. 2010, 2, 24–31. [Google Scholar] [CrossRef]

- Mahajan, S.S.; Barshilia, H.C.; Mehta, B.R.; Vankar, V.D. On the determination of the sp3 to sp2 ratio in diamond-like carbon thin films. Thin Solid. Film. 1997, 302, 250–255. [Google Scholar] [CrossRef]

- Radoń-Kobus, K.; Madej, M.; Kowalczyk, J.; Piotrowska, K. Properties of Diamond-like Tungsten-Doped Carbon Coatings Lubricated with Cutting Fluid. Coatings 2024, 14, 342. [Google Scholar] [CrossRef]

- Hauert, R. A review of modified DLC coatings for biological application. Diam. Relat. Mater. 2003, 12, 583–589. [Google Scholar] [CrossRef]

- Ma, W.J.; Ruys, A.J.; Mason, R.S.; Martin, P.J.; Bendavid, A.; Liu, Z.; Ionescu, M.; Zreiqat, H. DLC coatings: Effects of physical and chemical properties on biological response. Biomaterials 2007, 28, 1620–1628. [Google Scholar] [CrossRef]

- Gałuszka, R.; Madej, M.; Ozimina, D.; Krzyszkowski, A.; Gałuszka, G. The Characterisation of the microstructure and mechanical properties of diamond—Like carbon (DLC) for endoprothesis. Metalurgija 2017, 56, 195–198. [Google Scholar]

- Love, C.A.; Cook, R.B.; Harvey, T.J.; Dearnley, P.A.; Wood, R.J.K. Diamond like carbon coatings for potential application in biological implants—A review. Tribol. Int. 2013, 63, 141–150. [Google Scholar] [CrossRef]

- Thorwarth, G.; Falub, C.V.; Müller, U.; Weisse, B.; Voisard, C.; Tobler, M.; Hauert, R. Tribological behavior of DLC-coated articulating joint implants. Acta Biomater. 2010, 6, 2335–2341. [Google Scholar] [CrossRef] [PubMed]

- Ruiz Santiago, F.; Santiago Chinchilla, A.; Ansari, A.; Guzmán Álvarez, L.; Castellano García Mdel, M.; Martínez Martínez, A.; Tercedor Sánchez, J. Imaging of Hip Pain: From Radiography to Cross-Sectional Imaging Techniques. Radiol. Res. Pract. 2016, 2016, 6369237. [Google Scholar] [CrossRef]

- Zhang, T.F.; Deng, Q.Y.; Liu, B.; Wu, B.J.; Jing, F.J.; Leng, Y.X.; Huang, N. Wear and corrosion properties of diamond like carbon (DLC) coating on stainless steel, CoCrMo and Ti6Al4V substrates. Surf. Coat. Technol. 2015, 273, 12–19. [Google Scholar] [CrossRef]

- Falub, C.V.; Müller, U.; Thorwarth, G.; Parlinska-Wojtan, M.; Voisard, C.; Hauert, R. In vitro studies of the adhesion of diam ond-like carbon thin films on CoCrMo biomedical implant alloy. Acta Mater. 2011, 59, 4678–4689. [Google Scholar] [CrossRef]

- Rodriguez, B.; Romero, A.; Soto, O.; Varorna, O. Biomaterials for orthopedics. In Appl. Eng. Mech. Med.; University of Puerto Rico: Mayagüez, PR, USA, 2004; pp. 1–26. [Google Scholar]

- Joska, L.; Fojt, J.; Mestek, O.; Cvrcek, L.; Březina, V. The effect of a DLC coating adhesion layer on the corrosion behavior of titanium and the Ti6Al4V alloy for dental implants. Surf. Coat. Technol. 2012, 206, 4899–4906. [Google Scholar] [CrossRef]

- Wang, S.; Liao, Z.; Liu, W.; Liu, Q. Recent development on surface modification of artificial disc material for wear resistance. J. Funct. Mater. 2013, 44, 609–613. [Google Scholar] [CrossRef]

- Wang, S.; Liao, Z.; Liu, Y.; Liu, W. Different tribological behaviors of titanium alloys modified by thermal oxidation and spraying diamond like carbon. Surf. Coat. Technol. 2014, 252, 64–73. [Google Scholar] [CrossRef]

- Luo, Y.; Ge, S.; Jin, Z.; Fisher, J. Effect of surface modification on surface properties and tribological behaviours of titanium alloys. Proc. IME. J. J. Eng. Tribol. 2009, 223, 311–316. [Google Scholar] [CrossRef]

- Zaid, M.B.; O’Donnell, R.J.; Potter, B.K.; Forsberg, J.A. Orthopaedic Osseointegration: State of the Art. J. Am. Acad. Orthop. Surg. 2019, 27, 977–985. [Google Scholar] [CrossRef] [PubMed]

- Shah, R.; Pai, N.; Khandekar, R.; Aslam, R.; Wang, Q.; Yan, Z.; Rosenkranz, A. DLC coatings in biomedical applications—Review on current advantages, existing challenges, and future directions. Surf. Coat. Technol. 2024, 487, 131006. [Google Scholar] [CrossRef]

- Navaneethakrishnan, P.; Ganesh Sundara Raman, S.; Pathak, S.D.; Gnanamoorthy, R.; Ravi, N. Fretting wear studies on diamond;like carbon coated Ti-6Al-4V. Surf. Coat. Technol. 2009, 203, 1205–1212. [Google Scholar] [CrossRef]

- Huang, T.H.; Guo, J.U.; Kao, C.T. A comparasion of the friction associated with diamond-like carbon (DLC) or titanium nitride (TiN) plating metal brackets. Surf. Coat. Technol. 2010, 205, 1917–1921. [Google Scholar] [CrossRef]

- Metel, A.; Sotova, C.; Fyodorov, S.; Zhylinski, V.; Chayeuski, V.; Milovich, F.; Seleznev, A.; Bublikov, Y.; Makarevich, K.; Vereschaka, A. Improving the Wear and Corrosion Resistance of Titanium Alloy Parts via the Deposition of DLC Coatings. J. Carbon. Res. 2024, 10, 106. [Google Scholar] [CrossRef]

- Marin, E.; Fedrizzi, L.; Zagra, L. Porous Metallic Structures for Orthopaedic Applications: A Short Review of Materials and Technologies. Eur. Orthop. Traumatol. 2010, 2, 103–109. [Google Scholar] [CrossRef]

- Rack, H.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- ISO 7206-2:2011; Implants for Surgery Partial and Total Hip Joint Prostheses—Part 2: Articulating Surfaces Made of Metallic, Ceramic and Plastics Materials. International Organization for Standardization: Geneva, Switzerland, 2024.

- Piotrowska, K.; Madej, M.; Kowalczyk, J.; Radoń-Kobus, K. Surface Roughness Effects on the Properties of Silicon-Doped Diamond-like Carbon Coatings. Coatings 2023, 13, 1629. [Google Scholar] [CrossRef]

- „Corundum, Aluminum Oxide, Alumina”, MatWeb—Material Property Data. Available online: https://www.matweb.com/search/datasheet_print.aspx?matguid=c8c56ad547ae4cfabad15977bfb537f1&n=1 (accessed on 5 February 2025).

- ISO 10993-15:2019; Biological Evaluation of Medical Devices—Part 15: Identification and Quantification of Degradation Products of Metals and Alloys. International Organization for Standardization: Geneva, Switzerland, 2019.

- Kot, M.; Rakowski, W.; Major, Ł.; Lackner, J. Examination of the fracture toughness and wear resistance of multilayer coatings. Tribologia 2014, 2, 89–99. [Google Scholar]

- Niemczewska-Wójcik, M. Surface geometric structure created by the electrical discharge machining process. Tribologia 2010, 41, 233. [Google Scholar]

- Angst, U.; Büchler, M. On the applicability of the Stern–Geary relationship todetermine instantaneous corrosion rates in macro-cell corrosion. Mater. Corros. 2015, 66, 1017–1028. [Google Scholar] [CrossRef]

- Danişman, S.; Demirel, T. Corrosion Resistance Of Diamond Like Carbon (DLC) Coatings In The Biomedical Field. Gaziosmanpasa J. Sci. Res. 2023, 12, 57–72. [Google Scholar]

- Szklarska–Smialowska, Z. Pitting and Crevice Corrosion, 1st ed.; NACE International: Houston, TX, USA, 2005; pp. 15–138. [Google Scholar]

- Manhabosco, T.M.; Muller, I.L. Tribocorrosion of dlc deposited on Ti6Al4V. Tribol. Lett. 2009, 34, 22. [Google Scholar] [CrossRef]

- Rodríguez-Rojas, F.; Kovylina, M.; Pinilla-Cienfuegos, E.; Borrero-López, O.; Bendavid, A.; Martin, P.J.; Hoffman, M. Effect of a DLC film on the sliding-wear behaviour of Ti6Al4V: Implications for dental implants. Surf. Coat. Technol. 2023, 460, 129409. [Google Scholar] [CrossRef]

- Mohan, L.; Anandan, C. Wear and corrosion behavior of oxygen implanted biomedical titanium alloy Ti-13Nb-13Zr. Appl. Surf. Sci. 2013, 282, 281–290. [Google Scholar] [CrossRef]

- Cvijović-Alagić, I.; Cvijović, Z.; Mitrovic, S.; Panić, V. Wear and corrosion behavior of Ti-13Nb-13Zr and Ti-6Al-4V alloys in simulated physiological solution. Corros. Sci. 2011, 53, 796–808. [Google Scholar] [CrossRef]

| Ti6Al4V, % Content | |||||||

|---|---|---|---|---|---|---|---|

| Ti | V | Al | Fe | C | N | O | H |

| Balance | 3.5–4.5 | 5.5–6.75 | max 0.4 | max 0.08 | max 0.05 | max 0.2 | max 0.0125 |

| Parameter | Value and Unit |

|---|---|

| Type of movement | oscillatory |

| Load | 1 N |

| Frequency | 1 Hz |

| Radius and angle | 9 mm, 60° |

| Number of cycles, distance | 25,000, 460 m |

| Humidity | 50 ± 1% |

| Ambient temperature | 23 ± 1 °C |

| Lubricant | without (TDF), artificial saliva (AS) |

| Lubricant temperature | 23 ± 1 °C and 37 ± 1 °C |

| Counter sample | Al2O3 (Ø 6 mm) |

| Hardness, GPa | Compressive Strength, MPa | Resistance to Chemical Exposure | Density g/dm3 | Thermal Conductivity, W/(m × K) |

|---|---|---|---|---|

| 1365 | 300–630 | good | 3.9 | 28–35 |

| Artifical Saliva, g/dm3 | |||||

|---|---|---|---|---|---|

| NaCl | KCl | CaCl2 × 2H2O | NaH2PO4 × 2H2O | Na2S × 9H2O | Urea |

| 0.4 | 0.4 | 0.795 | 0.780 | 0.005 | 1.0 |

| Parameter | Ti6Al4V | DLC | ||

|---|---|---|---|---|

| Mean | Stand. Dev. | Mean | Stand. Dev. | |

| Sq, μm | 0.01 | 0.002 | 0.06 | 0.005 |

| Sv, μm | 0.09 | 0.015 | 0.53 | 0.017 |

| Sp, μm | 0.05 | 0.002 | 0.36 | 0.128 |

| Ssk | −0.95 | 0.629 | −1.82 | 0.575 |

| Sku | 7.42 | 2.43 | 12.97 | 0.825 |

| Parameter | Unit | Ti6Al4V | DLC | ||

|---|---|---|---|---|---|

| Mean | Std. Dev. | Mean | Std. Dev. | ||

| Instrumental Hardness, HIT | MPa | 4930 | 137.6 | 20,103 | 501.3 |

| Young’s Modulus, EIT | GPa | 127 | 2.6 | 144 | 1.6 |

| Maximum Penetration Depth, hm | nm | 697 | 6.3 | 429 | 3.6 |

| Elastic Work, Welast | % | 23 | 3.7 | 71 | 7.5 |

| Plastic Work, Wplast | % | 77 | 4.9 | 29 | 5.8 |

| Parameter | Unit | Sample | |

|---|---|---|---|

| Ti6Al4V | DLC | ||

| Corrosion Potential, Ecorr | V vs. SCE | −0.299 | 0.114 |

| Corrosion current density, icorr | µA/cm2 | 0.081 | 0.012 |

| Corrosion rate, vcorr | mm/year | 0.41 × 10−3 | 0.061 × 10−3 |

| Polarization resistance, Rp | kΩ·cm2 | 552.318 | 608.125 |

| Tribological Test | Scratch Test | |||||

|---|---|---|---|---|---|---|

| WD, µm | WD, µm | V, mm3 | ||||

| TDF | AS | TDF | AS | |||

| Ti6Al4V | 42.7 | 64.5 | 3.9 × 10−4 | 4.30 × 10−4 | 5.54 | 6.06 × 10−4 |

| DLC | 0.29 | 0.23 | 7.39 × 10−8 | 2.97 × 10−8 | 3.56 | 3.36 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madej, M.; Piotrowska, K.; Vicen, M.; Zatkaliková, V. Wear and Corrosion Behavior of Diamond-like Carbon Coatings in Artificial Saliva. Coatings 2025, 15, 305. https://doi.org/10.3390/coatings15030305

Madej M, Piotrowska K, Vicen M, Zatkaliková V. Wear and Corrosion Behavior of Diamond-like Carbon Coatings in Artificial Saliva. Coatings. 2025; 15(3):305. https://doi.org/10.3390/coatings15030305

Chicago/Turabian StyleMadej, Monika, Katarzyna Piotrowska, Martin Vicen, and Viera Zatkaliková. 2025. "Wear and Corrosion Behavior of Diamond-like Carbon Coatings in Artificial Saliva" Coatings 15, no. 3: 305. https://doi.org/10.3390/coatings15030305

APA StyleMadej, M., Piotrowska, K., Vicen, M., & Zatkaliková, V. (2025). Wear and Corrosion Behavior of Diamond-like Carbon Coatings in Artificial Saliva. Coatings, 15(3), 305. https://doi.org/10.3390/coatings15030305